Page 1

RUGGEDCOM

Industrial Remote Communication

Remote Networks

Operating Instructions

Preface

Description of the device

1

Installation

2

Connecting up

3

Dimension drawing

4

Technical specifications

5

Approvals

A

RUGGEDCOM RM1224

10/2016

RC1260-EN-02

Page 2

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens Canada Ltd.. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens Canada Ltd.

Division Process Industries and Drives

300 Applewood Drive

Concord, ON, L4K 5C7

CANADA

Document order number: RC1260-EN-02

© 10/2016 Subject to change

Copyright © Siemens Canada Ltd.

2016.

All rights reserved

Page 3

Preface

Purpose of the Operating Instructions

These compact operating instructions contain information with which you will be able to

install and connect up the RUGGEDCOM RM1224. The configuration and the integration of

the device in a network are not described in these instructions.

RUGGEDCOM manuals

You will find RUGGEDCOM manuals on the Internet pages of Siemens Industry Online

Support:

Link to Siemens Industry Online Support (http://support.automation.siemens.com/)

Trademarks

The following and possibly other names not identified by the registered trademark sign®are

registered trademarks of Siemens Canada Ltd.:

RUGGEDCOM, ROS

Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, solutions, machines, equipment and/or networks. They are

important components in a holistic industrial security concept. With this in mind, Siemens’

products and solutions undergo continuous development. Siemens recommends strongly

that you regularly check for product updates.

For the secure operation of Siemens products and solutions, it is necessary to take suitable

preventive action (e.g. cell protection concept) and integrate each component into a holistic,

state-of-the-art industrial security concept. Third-party products that may be in use should

also be considered. For more information about industrial security, visit

http://www.siemens.com/industrialsecurity.

To stay informed about product updates as they occur, sign up for a product-specific

newsletter. For more information, visit http://support.automation.siemens.com.

License conditions

Note

Open source software

Read the license conditions for open source software carefully before using the product.

You will find license conditions in the following documents on the supplied data medium:

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 3

Page 4

Preface

● DOC_OSS-RUGGEDCOM-RM1224_74.pdf

● DC_LicenseSummaryRUGGEDCOMRM1224_76.htm

● DC_LicenseSummaryRUGGEDCOMRM1224_76.htm

SIMATIC NET glossary

Explanations of many of the specialist terms used in this documentation can be found in the

SIMATIC NET glossary.

You will find the SIMATIC NET glossary here:

● SIMATIC NET Manual Collection or product DVD

The DVD ships with certain SIMATIC NET products.

● On the Internet under the following entry ID:

50305045 (http://support.automation.siemens.com/WW/view/en/50305045)

RUGGEDCOM RM1224

4 Operating Instructions, 10/2016, RC1260-EN-02

Page 5

Table of contents

Preface............................................................................................................................................................. 3

1 Description of the device......................................................................................................................... 7

1.1 Product characteristics..............................................................................................................7

1.2 Accessories...............................................................................................................................8

1.3 LED display...............................................................................................................................9

1.4 SET button..............................................................................................................................12

1.5 C-PLUG and KEY-PLUG........................................................................................................14

2 Installation ............................................................................................................................................ 17

2.1 Securing the housing..............................................................................................................18

2.2 Wall mounting .........................................................................................................................18

2.3 Installation on the DIN rail.......................................................................................................19

2.4 Installing on the S7-300 standard rail .....................................................................................21

2.5 Installing on the S7-1500 standard rail ...................................................................................22

3 Connecting up....................................................................................................................................... 25

3.1 Safety when connecting up.....................................................................................................25

3.2 SIM card..................................................................................................................................27

3.3 Power supply ..........................................................................................................................28

3.4 Grounding ...............................................................................................................................29

3.5 Digital input/output ..................................................................................................................30

3.6 Antennas.................................................................................................................................32

3.7 Ethernet port ...........................................................................................................................35

3.8 Inserting and removing the PLUG ..........................................................................................36

4 Dimension drawing ............................................................................................................................... 39

4.1 RUGGEDCOM RM1224 .........................................................................................................39

5 Technical specifications ........................................................................................................................ 41

A Approvals.............................................................................................................................................. 45

A.1 EU declaration of conformity...................................................................................................47

A.1.1 R&TTE ....................................................................................................................................47

A.1.1.1 Protection of health and safety...............................................................................................47

A.1.1.2 EMC........................................................................................................................................48

A.1.1.3 Efficient use of the radio spectrum .........................................................................................49

A.1.2 RoHS.......................................................................................................................................49

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 5

Page 6

Table of contents

A.1.3 Products................................................................................................................................. 50

A.2 RCM / C-TICK........................................................................................................................ 50

A.3 IECEx..................................................................................................................................... 51

A.4 FM certification.......................................................................................................................51

A.5 UL certification (product safety) ............................................................................................. 51

A.6 EAC........................................................................................................................................ 52

Index 53

RUGGEDCOM RM1224

6 Operating Instructions, 10/2016, RC1260-EN-02

Page 7

Description of the device

1

Use the SIM card from the chosen mobile wireless provider

1.1 Product characteristics

Interfaces

Functionality RM1224

Connectors for external antennas 2 x SMA antenna connectors

Ethernet interface 4 x RJ-45 10 / 100 Mbps

Digital input/output 1/1

Scope of delivery

The following components ship with the product:

● One device

● A 5-pin terminal block for the power supply

● A 2-pin terminal block for the digital output

Article numbers

● A 2-pin terminal block for the digital input

● Product CD

Note

Not included with the product

The following components do not ship with the product:

KEY-PLUG / C-PLUG

You will find more detailed information in "C-PLUG and KEY-PLUG (Page 14)".

Antennas

You will find more detailed information in "Accessories (Page 8)".

SIM card

Type Article number Description

RUGGEDCOM

RM1224

6GK6 108-4AM00-2BA2 Mobile wireless router for 4G (LTE) with antenna

diversity

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 7

Page 8

Description of the device

1.2 Accessories

Unpacking and checking

WARNING

Do not use any parts that show evidence of damage

If you use damaged parts, there is no guarantee that the device will function according to

the specification.

If you use damaged parts, this can lead to the following problems:

Injury to persons

Loss of the approvals

Violation of the EMC regulations

Use only undamaged parts.

1. Make sure that the package is complete.

2. Check all the parts for transport damage.

1.2 Accessories

You will find further information on the accessories program for the M-800 in the Industry

Mall

(https://eb.automation.siemens.com/goos/WelcomePage.aspx?regionUrl=/en&language=en)

.

Antennas

Type Properties Article number

ANT794-3M Flat antenna for GSM networks, for tri-band

ANT794-4MR Omnidirectional antenna for GSM (2G), UMTS

6NH9870-1AA00

with 900 / 1800 / 1900 MHz; weatherproof for

indoor and outdoor areas; 1.2 m connecting

cable connected permanently to the antenna;

SMA connector, including adhesive mounting

tape

6NH9860-1AA00

(3G) and LTE(4G); weatherproof for indoor and

outdoor areas; 5 m connecting cable connected

permanently to the antenna; SMA connector,

including installation bracket, screws, wall plugs

RUGGEDCOM RM1224

8 Operating Instructions, 10/2016, RC1260-EN-02

Page 9

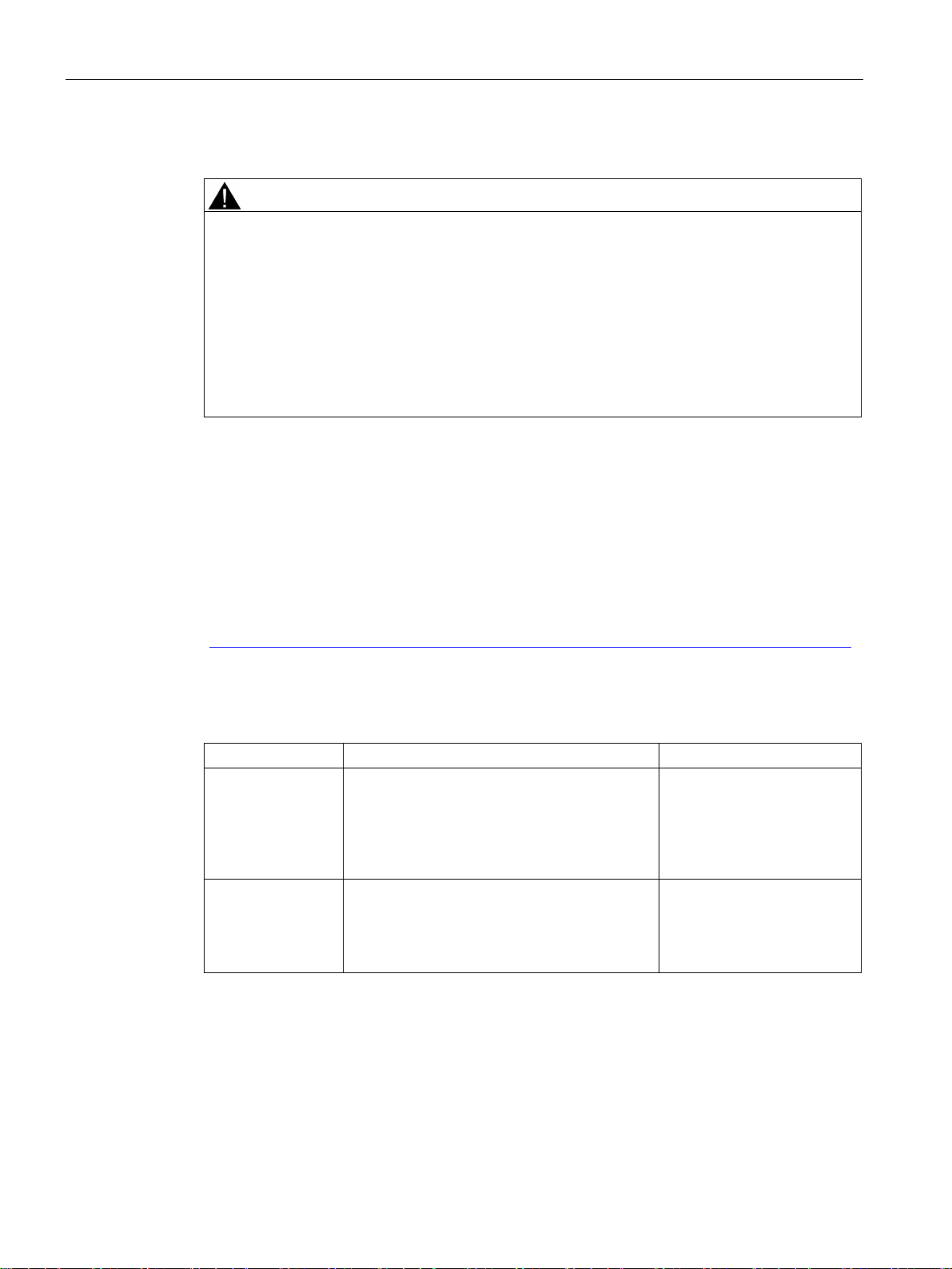

1.3 LED display

Description of the device

1.3 LED display

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 9

Page 10

Description of the device

1.3 LED display

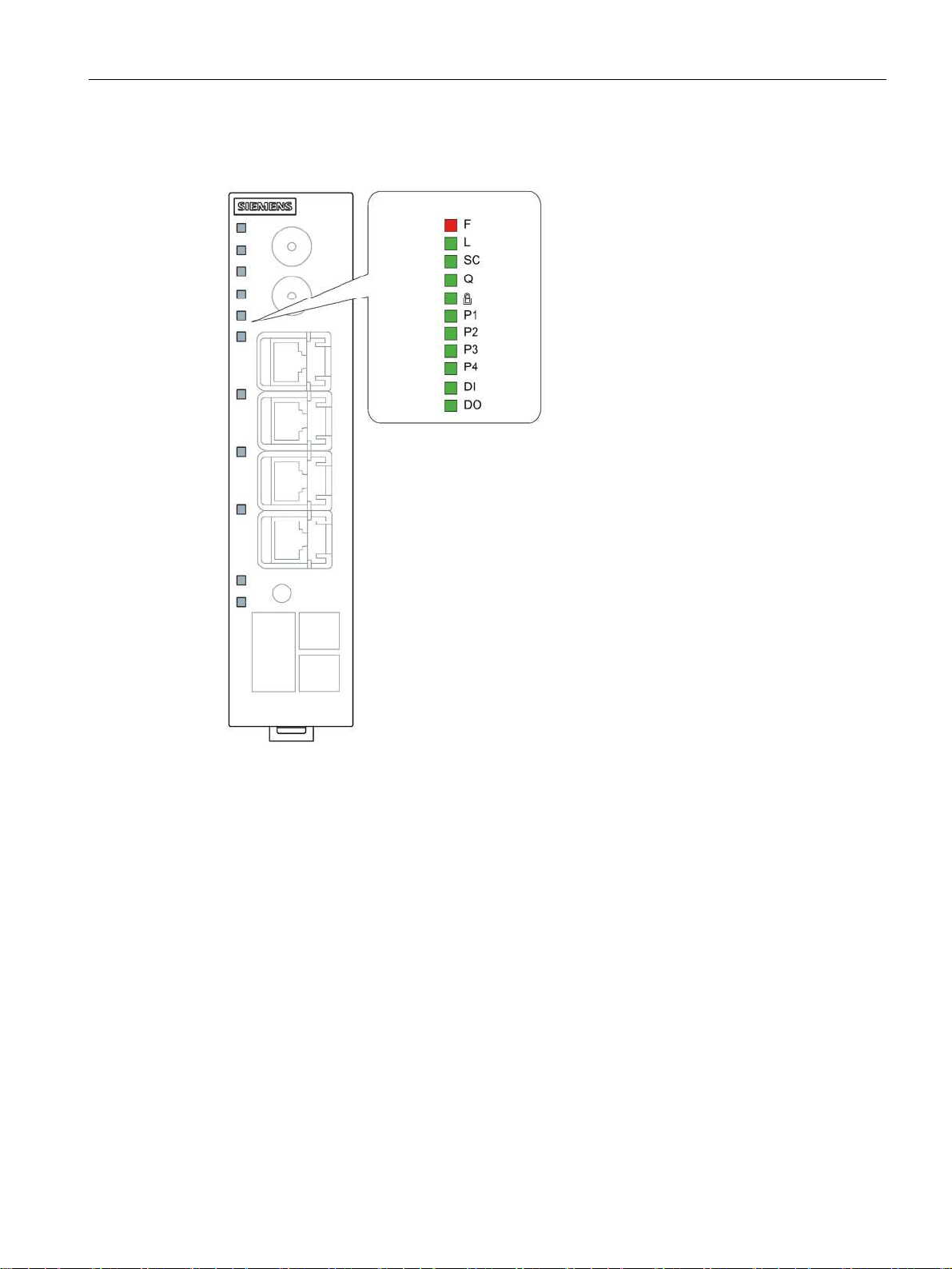

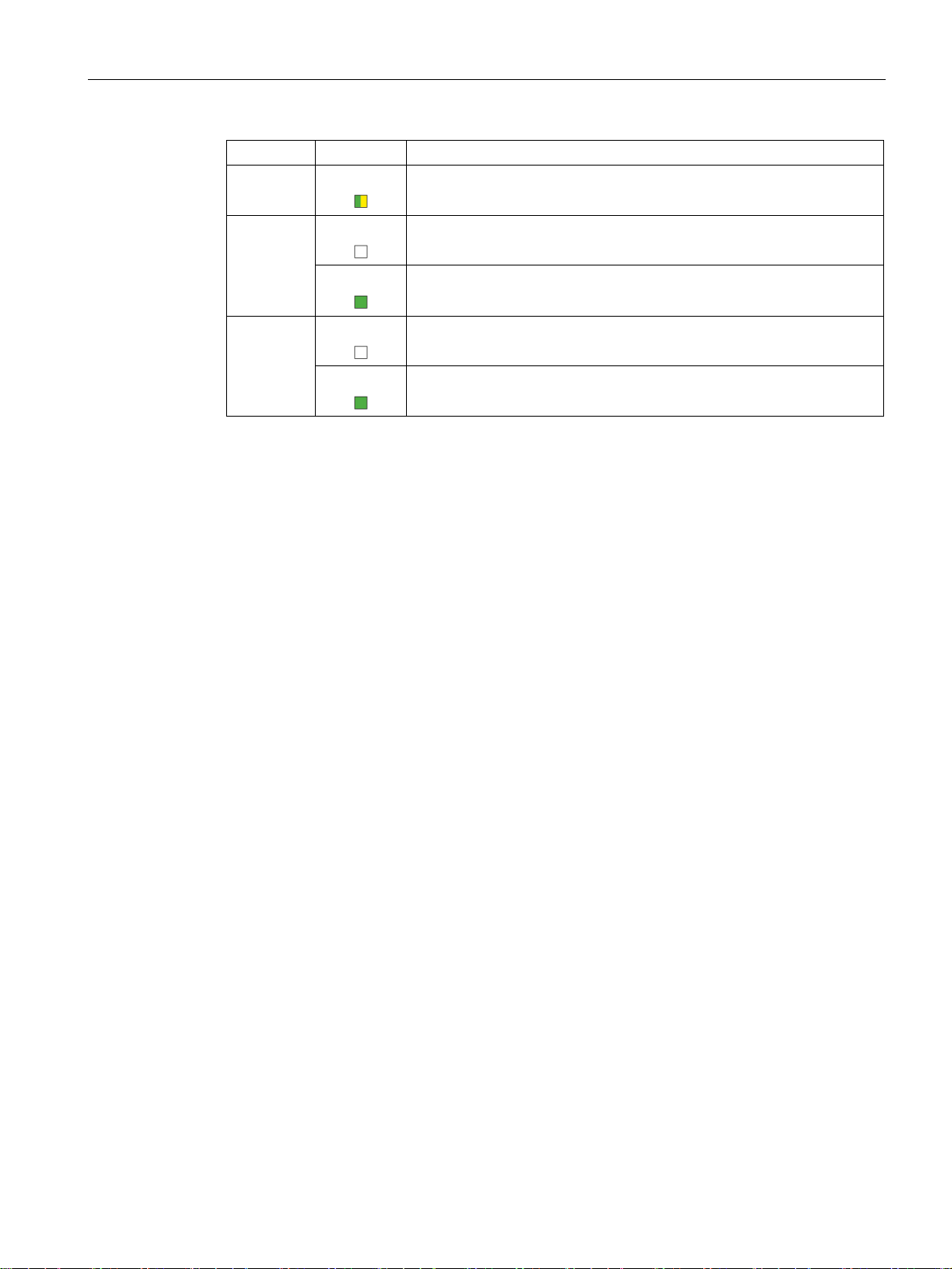

LED Status Meaning

F OFF No fault/error.

L OFF Device turned off, no power supply.

SC OFF SIM card OK, no connection.

ON The device is starting up or an error has occurred.

Possible errors/faults:

Wrong PIN number

Flashing The bootloader waits in this state for a new firmware file that you can

download using TFTP.

ON Device turned on, power supply present.

ON Wrong PIN number / SIM card error

ON Connection established

Q OFF No reception

Signal strength: < -109 dBm

Flashing Signal strength bad: -89 dBm to -109 dBm

On Signal strength medium: -73 dBm to -89 dBm

ON Signal strength good: > -73 dBm

OFF No VPN connection is established.

ON All configured VPN connections are established.

Flashing Only some of the configured VPN connections are established.

P1

P2

P3

P4

OFF Ethernet connection to local computer or LAN not established

ON Ethernet connection to local computer or LAN established

RUGGEDCOM RM1224

10 Operating Instructions, 10/2016, RC1260-EN-02

Page 11

LED Status Meaning

ON Device receiving / sending data

DI OFF Digital input inactive

ON Digital input active.

DO OFF Digital output inactive

ON Digital output active.

Description of the device

1.4 SET button

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 11

Page 12

Description of the device

1.4 SET button

1.4 SET button

With a M-800RUGGEDCOM RM1224, the SET button is on the front of the housing beside

the LED display.

RUGGEDCOM RM1224

12 Operating Instructions, 10/2016, RC1260-EN-02

Page 13

Description of the device

1.4 SET button

The SET button has the following functions:

● Restart

Hold down the button for longer than 3 seconds to run a restart.

● Loading new firmware

If the normal procedure with the "Load & Save" menu of Web Based Management does

not work, the reset button can be used to load new firmware. This situation can occur if

there is a power outage during the normal firmware update.

– Hold down the button until the red fault LED (F) starts to flash after approximately 3

seconds.

– Now release the button. The bootloader waits in this state for a new firmware file that

you can download using TFTP.

You will find more information in the section "Service and Maintenance" in the

RUGGEDCOM RM1224 Web Based Management configuration manual.

● Reset to factory defaults

– Hold down the button until the red fault LED (F) stops flashing after approximately 10

seconds and is permanently lit.

– Now release the button and wait until the fault LED (F) goes off again. The device then

starts automatically with the factory settings and can be reached via the IP address

192.168.1.1.

You will find more information in the section "Service and Maintenance" in the

RUGGEDCOM RM1224 Web Based Management configuration manual.

WARNING

EXPLOSION HAZARD

Do not press the SET button when there is an explosive atmosphere.

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 13

Page 14

Description of the device

1.5 C-PLUG and KEY-PLUG

1.5 C-PLUG and KEY-PLUG

How it works

The C-PLUG or KEY-PLUG is used to transfer the configuration of the old device to the new

device when a device is replaced.

NOTICE

Do not remove or insert a C-PLUG / KEY-PLUG during operation!

A PLUG may only be removed or inserted when the device is turned off.

The device checks whether or not a PLUG is present at one second intervals. If it is

detected that the PLUG was removed, there is a restart.

If a valid KEY-PLUG was inserted in the device, the device changes to a defined error state

following the restart.

When the new device starts up with the PLUG, it then continues automatically with exactly

the same configuration as the old device. One exception to this can be the IP configuration if

it is set over DHCP and the DHCP server has not been reconfigured accordingly.

A reconfiguration is necessary if you use functions based on MAC addresses.

If an incorrect PLUG, for example from another product or a damaged PLUG is inserted, the

device signals an error with the "F" LED.

You can either remove the PLUG again or select the option to reformat the PLUG.

In terms of the PLUG, devices work in two modes:

● Without PLUG

The device stores the configuration in internal memory. This mode is active when no

PLUG is inserted.

● With PLUG

The configuration stored on the PLUG is displayed in WBM in "Information > PLUG". If

changes are made to the configuration, the device stores the configuration directly on the

PLUG and in the internal memory. This mode is active as soon as a PLUG is inserted. As

soon as the device is started with a PLUG inserted, the device starts up with the

configuration data on the PLUG.

License information on the KEY-PLUG

In addition to the configuration, the KEY-PLUG also contains a license that allows the use of

Siemens Remote Services.

RUGGEDCOM RM1224

14 Operating Instructions, 10/2016, RC1260-EN-02

Page 15

Article numbers

See also

Description of the device

1.5 C-PLUG and KEY-PLUG

Type Article number Description

C-PLUG 6GK1900-0AB00 Exchangeable storage medium (32 MB) for

the configuration data

KEY-PLUG SINEMA

RC

6GK5908-0PB00 Exchangeable storage medium (256 MB) to

enable the connection functionality to

SINEMA Remote Connect and for accepting

configuration data.

Inserting and removing the PLUG (Page 36)

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 15

Page 16

Page 17

Installation

2

Safety notices

When installing the device, keep to the safety notices listed below.

WARNING

If a device is operated in an ambient temperature of more than 50 °C, the temperature of

the device housing may be higher than 75 °C. The device must therefore be installed so

that it is only accessible to service personnel or users that are aware of the reason for

restricted access and the required safety measures at an ambient temperature higher than

50 °C.

Safety notices on use in hazardous areas

General safety notices relating to protection against explosion

WARNING

The device may only be operated in an environment with pollution degree 1 or 2 (see IEC

60664-1).

WARNING

When used in hazardous environments corresponding to Class I, Division 2 or Class I,

Zone 2, the device must be installed in a cabinet or a suitable enclosure.

General notes on use according to ATEX and IECEx

WARNING

To comply with EC Directive 94/9 (ATEX95) or the conditions of IECEx, this enclosure or

cabinet must meet the requirements of at least IP54 in compliance with EN 60529.

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 17

Page 18

Installation

2.1 Securing the housing

2.1 Securing the housing

Types of installation

For the device, you have the following options:

● Wall mounting (no ceiling mounting)

● Installation on a DIN rail

● Installing on the S7-300 standard rail

● Installing on the S7-1500 standard rail

Strain relief for the cables

Regardless of the type of installation, make sure that there is suitable strain relief for the

connecting cable.

Shielding of cables

If cables are installed permanently, it is advisable to remove the insulation of the shielded

cable and to establish contact on the shield/PE conductor bar.

Permitted installation direction

● Vertical installation (ventilation openings at the top and bottom)

Clearances

Keep to the minimum clearances to other components or to walls of a housing so that the

convection ventilation of the device is not blocked.

● Below at least 10 cm

● Above at least 10 cm

● With an RM1224, a clearance of 5 cm must be maintained between the sides and

adjacent devices.

2.2 Wall mounting

Note

The wall mounting must be capable of supporting four times the weight of the device, but at

least 50 N. For information on the weight, refer to the section "Technical specifications

(Page 41)".

Requirement

There is a SIM card for the device.

RUGGEDCOM RM1224

18 Operating Instructions, 10/2016, RC1260-EN-02

Page 19

Installation

Installation

2.3 Installation on the DIN rail

1. Insert the SIM card, see section "SIM card (Page 27)".

2. Prepare the drill holes for wall mounting. For the precise dimensions, refer to the section "

Dimension drawing (Page 39)".

3. Secure the device to the wall with two screws. When mounting on a wall, use mounting

fittings suitable for the type of wall.

4. Connect the power supply, refer to the section "Power supply (Page 28)".

5. Fit the connectors for the digital input and digital output, refer to the section "Digital

input/output (Page 30)".

6. Connect the antenna, refer to the section "Antennas (Page 32)".

7. Connect the device to the local network, refer to the section "Ethernet port (Page 35)".

8. Connect the terminal with as short a cable as possible ≤ 150 mm and a large cross-

sectional area ≥ 2.5 mm² to the ground of the system, see section "Grounding (Page 29)"

2.3 Installation on the DIN rail

Requirement

There is a SIM card for the device.

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 19

Page 20

Installation

2.3 Installation on the DIN rail

Installation

1. Insert the SIM card, see section "SIM card (Page 27)".

2. Place the third housing guide of the device on the top edge of the DIN rail ①.

Dismantling

3. Press the device down against the DIN rail until the spring catch locks in place ②.

4. Connect the power supply, refer to the section "Power supply (Page 28)".

5. Fit the connectors for the digital input and digital output, refer to the section "Digital

input/output (Page 30)".

6. Connect the antenna, refer to the section "Antennas (Page 32)".

7. Connect the device to the local network, refer to the section "Ethernet port (Page 35)".

8. Connect the terminal with as short a cable as possible ≤ 150 mm and a large cross-

sectional area ≥ 2.5 mm² to the ground of the system, see section "Grounding (Page 29)"

1. Disconnect all connected cables.

2. Using a screwdriver, pull down the catch on the rear of the device.

3. Pull lower part of the device away from the DIN rail.

RUGGEDCOM RM1224

20 Operating Instructions, 10/2016, RC1260-EN-02

Page 21

2.4 Installing on the S7-300 standard rail

Requirement

There is a SIM card for the device.

Installation

1. Insert the SIM card, see section "SIM card (Page 27)".

2. Place the second housing guide of the device on the top edge of the standard rail ①.

Installation

2.4 Installing on the S7-300 standard rail

3. Press the device down against the standard rail until the spring catch locks in place ②.

4. Connect the power supply, refer to the section "Power supply (Page 28)".

5. Fit the connectors for the digital input and digital output, refer to the section "Digital

input/output (Page 30)".

6. Connect the antenna, refer to the section "Antennas (Page 32)".

7. Connect the device to the local network, refer to the section "Ethernet port (Page 35)".

8. Connect the terminal with as short a cable as possible ≤ 150 mm and a large cross-

sectional area ≥ 2.5 mm² to the ground of the system, see section "Grounding (Page 29)"

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 21

Page 22

Installation

2.5 Installing on the S7-1500 standard rail

Dismantling

1. Disconnect all connected cables.

2. Using a screwdriver, pull down the catch on the rear of the device.

3. Remove the device from the standard rail.

2.5 Installing on the S7-1500 standard rail

Requirement

There is a SIM card for the device.

Installation

1. Insert the SIM card, see section "SIM card (Page 27)".

2. Place the first housing guide of the device on the top edge of the standard rail ①.

3. Using a screwdriver, pull down the catch ② on the rear of the device.

4. Swing the device down while pulling down the catch ③. After it is released, the spring

catch locks in place.

5. Connect the power supply, refer to the section "Power supply (Page 28)".

6. Fit the connectors for the digital input and digital output, refer to the section "Digital

input/output (Page 30)".

RUGGEDCOM RM1224

22 Operating Instructions, 10/2016, RC1260-EN-02

Page 23

Dismantling

Installation

2.5 Installing on the S7-1500 standard rail

7. Connect the antenna, refer to the section "Antennas (Page 32)".

8. Connect the device to the local network, refer to the section "Ethernet port (Page 35)".

9. Connect the terminal with as short a cable as possible ≤ 150 mm and a large cross-

sectional area ≥ 2.5 mm² to the ground of the system, see section "Grounding (Page 29)"

1. Disconnect all connected cables.

2. Using a screwdriver, pull down the catch on the rear of the device.

3. Remove the device from the standard rail.

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 23

Page 24

Page 25

Connecting up

3

WARNING

EXPLOSION HAZARD

SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION

2 OR ZONE 2.

WARNING

EXPLOSION HAZARD

DO NOT OPEN WHEN ENERGIZED.

3.1 Safety when connecting up

Safety notices

When connecting up the device, keep to the safety notices listed below.

WARNING

The equipment is designed for operation with Safety Extra-Low Voltage (SELV) by a

Limited Power Source (LPS).

This means that only SELV / LPS complying with IEC 60950-1 / EN 60950-1 / VDE 0805-1

must be connected to the power supply terminals. The power supply unit for the equipment

power supply must comply with NEC Class 2, as described by the National Electrical Code

(r) (ANSI / NFPA 70).

If the equipment is connected to a redundant power supply (two separate power supplies),

both must meet these requirements.

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 25

Page 26

Connecting up

3.1 Safety when connecting up

Safety notices on use in hazardous areas

General safety notices relating to protection against explosion

WARNING

EXPLOSION HAZARD

DO NOT CONNECT OR DISCONNECT EQUIPMENT WHEN A FLAMMABLE OR

COMBUSTIBLE ATMOSPHERE IS PRESENT.

Safety notices when using the device according to Hazardous Locations (HazLoc)

If you use the device under HazLoc conditions you must also keep to the following safety

notices in addition to the general safety notices for protection against explosion:

WARNING

EXPLOSION HAZARD

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE UNLESS AREA IS KNOWN TO BE

NON-HAZARDOUS.

This equipment is suitable for use in Class I, Division 2, Groups A, B, C and D or nonhazardous locations only.

This equipment is suitable for use in Class I, Zone 2, Group IIC or non-hazardous locations

only.

Safety notices for use according to ATEX and IECEx

If you use the device under ATEX or IECEx conditions you must also keep to the following

safety notices in addition to the general safety notices for protection against explosion:

WARNING

Take measures to prevent transient voltage surges of more than 40% of the rated voltage.

This is the case if you only operate devices with SELV (safety extra-low voltage).

RUGGEDCOM RM1224

26 Operating Instructions, 10/2016, RC1260-EN-02

Page 27

3.2 SIM card

NOTICE

Turn off the power supply before replacing SIM cards

Before you insert or remove the SIM card, turn off the power supply of the RM1224.

Do not open the compartment for the SIM card during operation. This can damage the SIM

card and the device.

Procedure

1. The compartment for the SIM card is located on the back of the device. Directly beside to

the compartment for the SIM card in the opening in the housing, there is a small button.

To open the drawer, press the button with a sharp object, for example a pencil.

Connecting up

3.2 SIM card

2. Place the SIM card in the tray so that the card audibly locks in place and so that its goldplated contacts remain visible.

3. Then push the tray with the SIM card completely back into the housing.

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 27

Page 28

Connecting up

3.3 Power supply

3.3 Power supply

The power supply is connected using a 5-pin terminal block. The power supply is nonfloating.

PIN Signal Description

1 L1+ 24 VDC

2 M1 Ground

3 M2 Ground

4 L2+ 24 VDC

5 Functional ground, refer to the section Grounding (Page 29)"

RUGGEDCOM RM1224

28 Operating Instructions, 10/2016, RC1260-EN-02

Page 29

External power supply

Note

Permitted external power supplies

The power supply unit to supply the RUGGEDCOM RM1224 must comply with the

requirements for a limited power source according to IEC/EN 60950-1, section 2.5.

The external power supply for the RUGGEDCOM RM1224 must meet the requirements for

NEC class 2 circuits as specified in the National Electrical Code ® (ANSI/NFPA 70).

Refer to the section Connecting up (Page 25) and the installation instructions and

instructions for use of the manufacturer of the power supply, the battery or the accumulator.

Note

External power supply for operation in China

The device may only be used with an external power supply that has a CCC approval.

Connecting up

3.4 Grounding

3.4 Grounding

EMC disturbances are diverted to ground via ground. This increases the immunity of the

data transmission.

It is crucial for the correct operation of ground that the connection to the reference potential

surface always has low impedance. Such a connection of the functional ground of the device

does not go first through the cable channel and then to the mounting plate or DIN rail

terminal, but goes directly to the mounting plate or DIN rail terminal.

The RUGGEDCOM RM1224 has a terminal for grounding, refer to the section "Power supply

(Page 28)".

The terminal is identified by the following symbol for the grounding.

1. Connect the terminal of the device with as short a cable as possible ≤ 150 mm and a

large cross-sectional area ≥ 2.5 mm² to the functional ground of the system. In many

cases, the entire metallic construction of the system serves as ground.

2. Also connect the standard rails of a system with ground.

Protective earth/functional ground

The connection of the reference potential surface with the protective earth system is

normally in the cabinet close to the power feed-in. This earth conducts fault currents to

ground safely and according to DIN/VDE 0100 is a protective earth to protect people,

animals and property from too high contact voltages.

Apart from the protective earth, there is functional grounding in the cabinet. According to

EN60204-1 (DIN/VDE 0113 T1) electrical circuits must be grounded. The chassis (0 V) is

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 29

Page 30

Connecting up

3.5 Digital input/output

grounded at one defined point. Here, once again the grounding is implemented with the

lowest leakage resistance to ground in the vicinity of the power feed-in.

With automation components, functional ground also ensures interference-free operation of

a controller. Via the functional ground, interference currents coupled in via the connecting

cables are discharged to ground.

In terms of the large-area and low impedance implementation, a functional ground set up for

this purpose generally also meets the requirements of protective earth. On the other hand,

protective earth does not always meet the requirements of functional ground. In general

while the connection for protective earth is always low resistance, it is not necessarily low

impedance.

The resistance of a connection for protective earth must always be as small as possible to

divert fault currents safely to ground. The length of a protective earth cable can therefore be

several meters (m) long, without seriously impairing this effect. For a functional ground for

diverting HF disturbances, this cable does however have impedance and is therefore not

suitable.

3.5 Digital input/output

The digital input/output (relay contact) is a floating switch with which error/fault states can be

signaled by breaking the contact.

CAUTION

Damage due to voltage being too high or too low

The voltage at the digital input/output must not exceed 30 VDC and not fall below -30 VDC,

otherwise the digital input/output will be destroyed.

RUGGEDCOM RM1224

30 Operating Instructions, 10/2016, RC1260-EN-02

Page 31

Digital input

Connecting up

3.5 Digital input/output

The 2-pin terminal block has the following assignment:

DI+ 24 VDC

DI- (input ground) -

If there is an adequate switching voltage at the digital input, the digital input is active and the

"DI" LED is lit. This means that, for example a local application connected to the in port can

trigger an alarm message by SMS outside the IP data connection.

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 31

Page 32

Connecting up

3.6 Antennas

Digital output

The 2-pin terminal block has the following assignment:

DO+ Relay 24 VDC / 1 A

DO- Relay 24 VDC / 1 A

3.6 Antennas

Note

Use the antennas from the accessories program for the RM1224 device. You will find more

detailed information in "Accessories(Page 8)". If you use a different antenna, there is no

guarantee the device will function according to the specification.

RUGGEDCOM RM1224

32 Operating Instructions, 10/2016, RC1260-EN-02

Page 33

The antenna socket for connecting the antenna is of the type SMA. The antenna used

should have an impedance of about 50 ohms.

CAUTION

Minimum clearance to the device

The device may only be operated when the distance between the device (or antenna) and

user is at least 20 cm.

Notes on lightning protection

WARNING

Danger due to lightning strikes

Antennas installed outdoors must be within the area covered by a lightning protection

system. Make sure that all conducting systems entering from outdoors are protected by

lightning protection electrical bonding.

Connecting up

3.6 Antennas

When implementing your lightning protection concept, make sure you adhere to the

requirements of the VDE 0182 or IEC 62305 standards.

Suitable lightning protectors are available in the range of accessories of RUGGEDCOM. For

more information, contact Siemens Customer Support.

● Depending on the connector, an adapter cable is required to connect to SMA.

WARNING

Danger due to lightning strikes

Installing this lightning protector between an antenna and a RUGGEDCOM RM1224 is not

adequate protection against a lightning strike. Most lightening protectors only works within

the framework of a comprehensive lightning protection concept. If you have questions, ask

a qualified specialist company.

Note

The requirements of EN61000-4-5, "Surge Immunity Test" on power supply lines with 24

VDC are met only when a Blitzductor is used:

24 VDC: BVT AVD 24 type no. 918 422

Vendor: DEHN+SÖHNE GmbH+Co.KG, Hans Dehn Str. 1, Postfach 1640, D -

92306 Neumarkt, Germany

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 33

Page 34

Connecting up

3.6 Antennas

Frequency bands in Europe, China, the USA and other regions

Depending on the frequency bands used by your mobile wireless provider, antennas must be

tuned to the following frequencies:

● In Europe, America, Africa, Asia and Australia:

– GSM 900 MHz

– DCS 1800 MHz

– UMTS 2100 MHz

– LTE 800 MHz, 900 MHz, 1800 MHz, 2100 MHz, 2600 MHz depending on the provider

● In the USA:

– LTE 700 MHz, 1900 MHz

– PCS 1900 MHz (also for UMTS)

● In Korea:

– UMTS 2100 MHz

Check with your mobile wireless provider for the suitable frequencies.

Signal quality

During installation make sure that there is a good signal strength of > -73 dBm.

If the "Q" LED is lit permanently, the signal quality is good. For more detailed information,

refer to the section "LED display (Page Error! Bookmark not defined.)".

Avoid large metal objects in the immediate vicinity.

RUGGEDCOM RM1224

34 Operating Instructions, 10/2016, RC1260-EN-02

Page 35

Antenna connectors

Connecting up

3.7 Ethernet port

3.7 Ethernet port

Connect the local network with the local applications to the Ethernet port, for example a

programmable logic controller, a machine with an Ethernet interface for remote monitoring or

a PC.

To set up the device, connect a PC with a Web browser to one of the Ethernet ports.

For the connection, use a path cable with an RJ-45 plug. You will find the properties of the

Ethernet interface in the technical specifications.

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 35

Page 36

Connecting up

3.8 Inserting and removing the PLUG

3.8 Inserting and removing the PLUG

NOTICE

Do not remove or insert a C-PLUG / KEY-PLUG during operation!

A PLUG may only be removed or inserted when the device is turned off.

The device checks whether or not a PLUG is present at one second intervals. If it is

detected that the PLUG was removed, there is a restart. If a valid KEY-PLUG was inserted

in the device, the device changes to a defined error state following the restart. With

RUGGEDCOM RM1224, the wireless interface is deactivated in this case.

Inserting the PLUG

1. Turn off the power to the device.

2. The housing of the PLUG has a protruding ridge on the long side. The slot has a groove

at this position.

Insert the PLUG correctly oriented into the slot.

RUGGEDCOM RM1224

36 Operating Instructions, 10/2016, RC1260-EN-02

Page 37

Removing the PLUG

1. Turn off the power to the device.

2. Insert a screwdriver between the front edge of the PLUG and the slot and release the

3. Remove the PLUG.

Connecting up

3.8 Inserting and removing the PLUG

PLUG.

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 37

Page 38

Page 39

Dimension drawing

4

4.1 RUGGEDCOM RM1224

Dimensions are specified in mm.

Image 4-1 RM1224 side view

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 39

Page 40

Dimension drawing

4.1 RUGGEDCOM RM1224

Image 4-2 RM1224 front view

RUGGEDCOM RM1224

40 Operating Instructions, 10/2016, RC1260-EN-02

Page 41

Technical specifications

5

Ethernet interface

Attachment to Industrial

Ethernet

Wireless interface

Antenna connector Quantity 2

Frequency bands LTE 2100 MHz = band I

LTE Transmission speed

Quantity 4

Design RJ-45 jack

Characteristics:

10/100BASE-T

Ethernet IEEE 802.3

10/100 Mbps

A1: Main antenna

A2: UMTS: RX diversity

LTE: RX MIMO

Design SMA socket (straight)

Impedance 50 Ω nominal

Antenna cable Cable length < 30 m

1800 MHz = band 3

2600 MHz = band 7

900 MHz = band 8

800 MHz = band 20

UMTS with HSPA+ 900 MHz = band VIII

1800 MHz = band III

2100 MHz = band I

GSM 850 MHz = GSM 850

1900 MHz = GSM 1900

Downlink: up to 100 Mbps

Uplink: up to 50 Mbps

UMTS with HSPA+ Transmission speed

EGPRS Properties Multislot class 12, end device class B

Transmission speed

GPRS Properties Multislot class 12, end device class B, coding

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 41

HSDPA (downlink): up to 14.4 Mbps

HSUPA (uplink): up to 5.76 Mbps

Coding scheme downlink: CS 1 ... 4, MCS 1

... 9

Coding scheme uplink: CS 1 ... 4, MCS 1 ... 9

Downlink: up to 237 kbps:

Uplink: up to 237 kbps:

scheme 1 … 4

Page 42

Technical specifications

Transmission speed

Downlink: up to 85.6 kbps.

Uplink: up to 85.6 kbps.

GSM (CSD dial-in) Properties Radio Link Protocol (RLP) V.110, non-

transparent

Transmission speed up to 14.4 kbps

SMS (TX) Properties Text mode, SMSoverIP

Electrical data

Power supply Quantity 1

Design Terminal block, 5 terminals

Properties Input voltage:

12 to 24 VDC

min. 10.8 VDC, max. 28.8 VDC

Maximum power consumption 8 W

Maximum cable length < 3 m

Digital input Quantity 1

Design Terminal block, 2 terminals

Properties Rated voltage 24 VDC Safety Extra Low Voltage

(SELV)

For state "1": 10 to 30 VDC

For state "0": -30 to 3 VDC

Maximum input current 8 mA

Maximum cable length < 3 m

Inputs isolated from electronics.

Digital output Quantity 1

Design Terminal block, 2 terminals

Properties Rated voltage 24 VDC Safety Extra Low Voltage

(SELV)

Relay, internally not current limited

Maximum current carrying capacity 1 A

Maximum cable length < 3 m

Output isolated from electronics

Permitted ambient conditions

Ambient temperature

1 2

During operation -20 ℃ to +75 ℃

During storage -40 ℃ to +85 ℃

During transporta-

-40 ℃ to +85 ℃

tion

Relative humidity During operation ≤ 95% at 25 °C, no condensation

Design, dimensions and weight

Module format Compact module S7-1500

1

UL certified operational temperature range -20 °C to +70 °C

2

IEC environmentally type tested (16 hours) from -40 °C to +75 °C

RUGGEDCOM RM1224

42 Operating Instructions, 10/2016, RC1260-EN-02

Page 43

Degree of protection IP20

Weight 290 g

Dimensions (W x H x D) 34.8 x 147 x 134.7 mm

Installation options

Wall mounting

Mounting on a DIN rail

Mounting on an S7-300 standard rail

Mounting on an S7-1500 standard rail

Installation direction Vertical

(ventilation openings at the top and bottom)

Clearance between sides and adjacent device: 5

cm

Product functions

Firewall and security

Stateful inspection

Packet filter

IPsec VPN for up to 20 connections

SINEMA RC client

Password protection

Technical specifications

Router functions

NAPT (port forwarding)

NAT (IP masquerading)

NAT traversal

NETMAP

Dynamic DNS client

DNS cache

NTP

Remote logging

Connection monitoring

Alarm SMS

Sending SMS messages from the local area

network

Configuration / management

Web-based administration user interface

(WBM)

Command Line Interface (CLI)

Remote access with HTTPS

SNMP and SNMP traps

Type tests

IEC 60068-2-1 Cold Temperature

-40 ℃ for 16 hours

(Test Ad)

IEC 60068-2-2 Dry Heat (Test Bd) +75 ℃ for 16 hours

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 43

Page 44

Page 45

Approvals

A

Approvals issued

Note

Issued approvals on the type plate of the device

The specified approvals apply only when the corresponding mark is printed on the product.

You can check which of the following approvals have been granted for your product by the

markings on the type plate.

Approvals for shipbuilding are not printed on the device type plate.

WARNING

Personal injury and property damage can occur

The installation of expansions that are not approved for RUGGEDCOM products or their

target systems may violate the requirements and regulations for safety and electromagnetic

compatibility.

Only use expansions that are approved for the system.

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 45

Page 46

Approvals

● Keep to the installation guidelines

The devices meet the requirements if you adhere to the installation and safety

instructions contained in this documentation and in the following documentation

when installing and operating the devices.

● You can always find the latest documentation on the Internet

The current descriptions of the currently available products can always be found on

the Internet under the specified entry IDs/Internet pages:

– "Industrial Ethernet / PROFINET Industrial Ethernet" System Manual

– "Industrial Ethernet / PROFINET - Passive network components" System Manual

You will find information on the system manuals in the section "ID = 27069465

(http://support.automation.siemens.com/WW/view/en/27069465)", in "Further

documentation".

– "EMC Installation Guidelines" configuration manual

ID = 60612658 (http://support.automation.siemens.com/WW/view/en/60612658)

● Working on the device

To protect the device from electrostatic discharge, personnel must first discharge

any electrostatic charge from their body before touching the device.

Note

The test was performed with a device and a connected communications partner that also

meets the requirements of the standards listed above.

When operating the device with a communications partner that does not comply with

these standards, adherence to the corresponding values cannot be guaranteed.

Current approvals on the Internet

RUGGEDCOM products are regularly submitted to the relevant authorities and approval

centers for approvals relating to specific markets and applications.

You will also find the current approvals for the product on the Internet pages of Siemens

Automation Customer Support under the following entry ID:

80046561 (http://support.automation.siemens.com/WW/view/en/80046561/134200)

→ "Entry list" tab, entry type "Certificates"

National approvals

You will find an overview of the country-specific wireless approvals of RUGGEDCOM

devices with GSM or UMTS services on the Internet pages of Siemens Automation

Customer Support. You will find the link to the document on the following page:

ik-Info (www.siemens.com/simatic-net/ik-info)

RUGGEDCOM RM1224

46 Operating Instructions, 10/2016, RC1260-EN-02

Page 47

A.1 EU declaration of conformity

The EC Declaration of Conformity is available for all responsible authorities at:

Siemens Aktiengesellschaft

Process Industries and Drives,

Process Automation

DE-76181 Karlsruhe

Germany

You will find the EC declaration of conformity for these products on the Internet pages of

Siemens Industry Online Support

(https://support.industry.siemens.com/cs/ww/en/ps/15914/cert).

The RUGGEDCOM products described in these Operating Instructions meet the

requirements of the following EC directives:

● 94/9/EC (ATEX)

Approvals

A.1 EU declaration of conformity

ATEX - Directive of the European Parliament and the Council of 23 March 1994 on the

approximation of the laws of the Member States concerning equipment and protective

systems intended for use in potentially explosive atmospheres.

● 1999/5/EC (R&TTE)

R&TTE directive of the European Parliament and of the Council of 9 March 1999 on

Radio Equipment and Telecommunications Terminal Equipment and the mutual

recognition of their conformity.

● 2011/65/EU (RoHS)

RoHS directive of the European Parliament and of the Council of 8 June 2011 on the

restriction of the use of certain hazardous substances in electrical and electronic

equipment.

Which of the described standards apply to the product can be found in Products (Page 50).

A.1.1 R&TTE

A.1.1.1 Protection of health and safety

Article 3 (1) a) of the R&TTE directive

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 47

Page 48

Approvals

A.1 EU declaration of conformity

Harmonized standards:

3 EN 60950-1+A1+A2+A11+A12

Information technology equipment - Safety - Part 1: General requirements

4 EN 62479

Assessment of the compliance of low power electronic and electrical equipment

with the basic restrictions related to human exposure to electromagnetic fields (10

MHz to 300 GHz)

5 EN 62311

Assessment of electronic and electrical equipment related to human exposure restrictions for electromagnetic fields (0 Hz – 300 GHz)

A.1.1.2 EMC

Article 3 (1) b) of the R&TTE directive

Harmonized standards:

6 ETSI EN 301 489-1

Electromagnetic compatibility and radio spectrum matters (ERM) - Electromagnetic

compatibility for radio equipment and services - Part 1 : Common technical requirements

7 ETSI EN 301 489-7

Electromagnetic compatibility and radio spectrum matters (ERM) - Electromagnetic

compatibility for radio equipment and services - Part 7 : Specific conditions for

mobile and portable radio and ancillary equipment of digital cellular radio telecommunications systems (GSM and DCS).

8 ETSI EN 301 489-24

Electromagnetic compatibility and radio spectrum matters (ERM) - Electromagnetic

compatibility for radio equipment and services - Part 24 : Specific conditions for

mobile and portable IMT-2000 CDMA Direct Spread (UTRA) radio and ancillary

equipment.

9 EN 61000-6-1

Electromagnetic compatibility (EMC) - Part 6-1: Generic standards - Immunity for

residential, commercial and light-industrial environments

10 EN 61000-6-2+AC

Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for

industrial environments

11 EN 61000-6-3+A1+AC

Electromagnetic compatibility (EMC) - Part 6-3: Generic standards - Emission

standard for residential, commercial and light-industrial environments

12 EN 61000-6-4+A1

Electromagnetic compatibility (EMC) - Part 6-4: Generic standards - Emission

standard for industrial environments

RUGGEDCOM RM1224

48 Operating Instructions, 10/2016, RC1260-EN-02

Page 49

13 EN 55022 +AC:Class A / B

cts with

Information technology equipment - Radio disturbance characteristics - Limits and

methods of measurement

14 EN 55024

Information technology equipment - Immunity characteristics -Limits and characteristics - Limits and methods of measurement

15 EN 50121-4

Railway applications - Electromagnetic Compatibility - Emission and Immunity of

the Signaling and Telecommunications Apparatus

A.1.1.3 Efficient use of the radio spectrum

Article 3 (2) of the R&TTE directive

16 ETSI EN 301 511

Global System for Mobile communications (GSM); Harmonized EN for mobile stations in the GSM 900 and GSM 1800 bands covering essential requirements of

article 3.2 of the R&TTE directive

17 ETSI EN 301 908-1

IMT cellular networks - Harmonized EN covering the essential requirements of article 3.2 of the R&TTE directive - Part 1: Introduction and common requirements

18 ETSI EN 301 908-2

IMT cellular networks - Harmonized EN covering the essential requirements of article 3.2 of the R&TTE directive - Part 2: CDMA Direct Spread (UTRA FDD) User

Equipment (UE)

19 ETSI EN 301 908-13

IMT cellular networks - Harmonized EN covering the essential requirements of article 3.2 of the R&TTE directive - Part 13: Further developed universal terrestrial

wireless access (E-UTRA) end devices (UE)

Approvals

A.1 EU declaration of conformity

A.1.2 RoHS

RoHS directive (restriction of the use of certain hazardous substances)

The RUGGEDCOM products described in these operating instructions meet the

requirements of the EC directive 2011/65/EC for the restriction of the use of certain

hazardous substances in electrical and electronic equipment:

Applied standard:

20 EN 50581

Technical documentation for the assessment electrical and electronic produ

respect to restriction of hazardous substances

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 49

Page 50

Approvals

A.2 RCM / C-TICK

A.1.3 Railway

Applied standard:

21 EN 50155

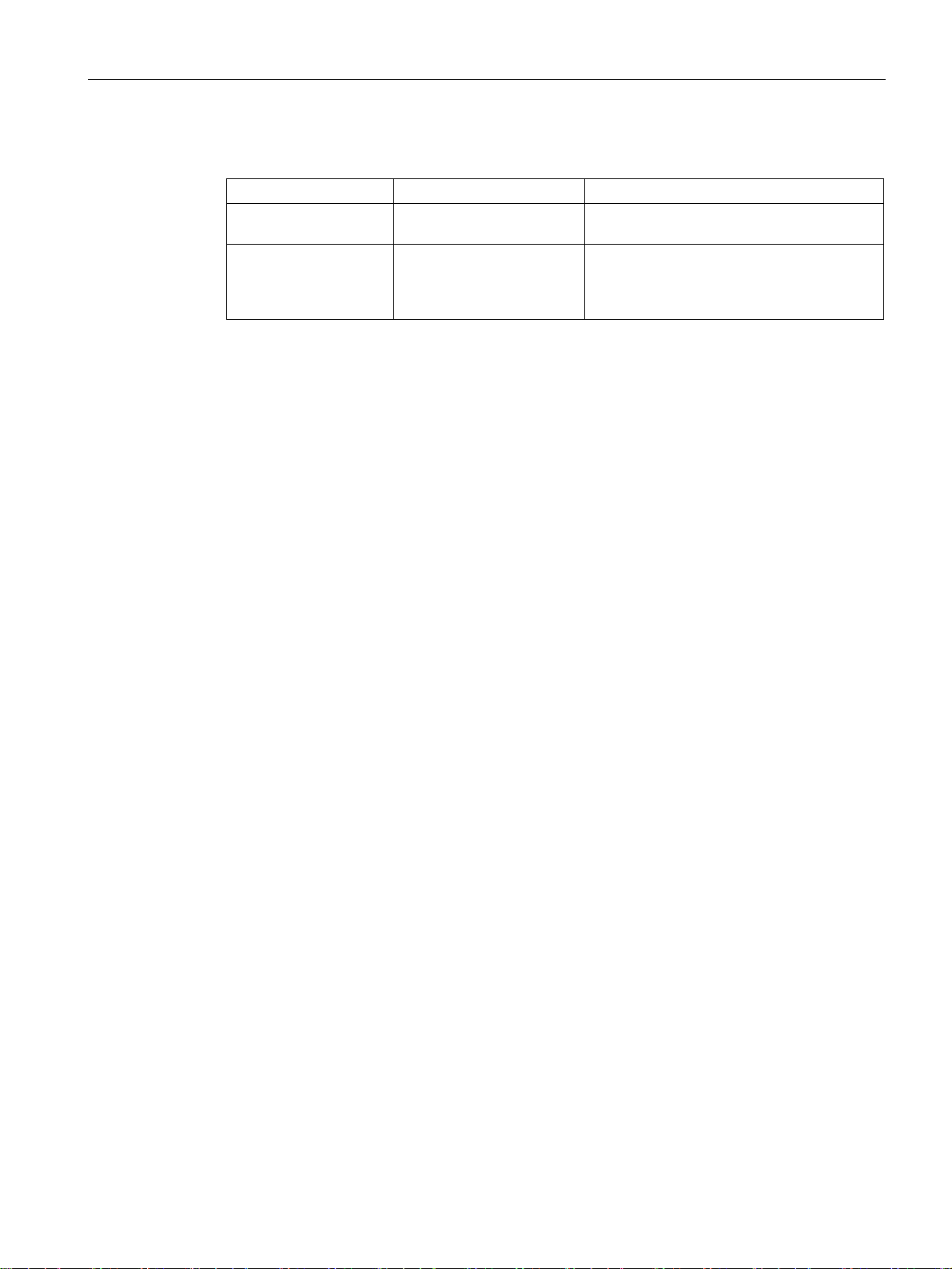

A.1.4 Products

Product designation and standards

The standards that apply to the product are described in R&TTE (Page 47) and RoHS

(Page 49).

● 3, 5, 6, 7, 8, 15, 16, 17, 18, 19

Antenna gain

Note

Railway Applications - Electronic Equipment Used on Rolling Stock

Depending on the selected wireless standard and the wireless frequency used, antennas

with different antenna gains can be used. If you change the frequency band during

operation, it is possible that the maximum permitted antenna again also changes. Check

whether the antenna you are using is approved for the changed frequency range. If

necessary, change the antenna so as not to violate the operational requirements. Or use an

antenna with a gain less than 3.58 dBi to cover all bands.

Frequency band Maximum antenna gain in dBi

GSM /GPRS 900 3.58

E-GPRS 900 9.88

GSM /GPRS 1800 9.84

E-GPRS 1800 13.85

UMTS FDD1 13.35

UMTS FDD III 13.45

UMTS VIII 10.27

LTE FDD 3 12.66

LTE FDD 7 13.86

LTE FDD 8 10.58

LTE FDD 20 8.76

A.2 RCM / C-TICK

The products meet the requirements of the AS/NZS CISPR11 : 2011 standard (Industrial,

scientific and medical equipment - Radio- frequency disturbance characteristics - Limits and

methods of measurement).

RUGGEDCOM RM1224

50 Operating Instructions, 10/2016, RC1260-EN-02

Page 51

A.3 IECEx

IECEx

The RUGGEDCOM products meet the requirements of explosion protection according to

IECEx.

IECEx classification:

Ex nA IIC T4 Gc

DEK 14.0025X

The products meet the requirements of the following standards:

The current versions of the standards can be seen in the current version of the IECEx

certificate DEK 14.0025X.

Approvals

A.3 IECEx

● IEC 60079-0 : Explosive atmospheres - Part 0: Equipment - General requirements

● IEC 60079-15 : Explosive atmospheres - Part 15: Equipment protection by type of

protection "n"

A.4 FM certification

Approved for use in

Cl. 1, Div. 2, GP. A, B, C, D, T4

Cl. 1, Zone 2, GP. IIC T4

Ta: -20 °C to + 60 C

For the use of the product in hazardous areas, the following requirements are met:

● Factory Mutual Approval Standard Class Number 3611

● FM Hazardous (Classified) Location Electrical Equipment:

Non Incendive / Class I / Division 2 / Groups A,B,C,D / T4 and

Non Incendive / Class I / Zone 2 / Group IIC / T4

A.5 UL certification (product safety)

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 51

Page 52

Approvals

A.6 EAC

Applied standards

● UL 60950-1 (Information Technology Equipment)

● UL 508 (Industrial Control Equipment)

● CSA C22.2 No.60950-1 (Information Technology Equipment)

UL certified operational temperature range -20 °C to +70 °C.

IEC environmentally type tested (16 hours) from -40 °C to +75 °C.

A.6 EAC

Marking for the customs union

EAC (Eurasian Conformity)

Customs union of Russia, Belarus and Kazakhstan

Declaration of the conformity according to the technical regulations of the customs union

(TR CU)

RUGGEDCOM RM1224

52 Operating Instructions, 10/2016, RC1260-EN-02

Page 53

Index

A

Accessories, 8

C

Connecting up

Digital input, 31

Digital output, 32

Ethernet interface, 35

Grounding, 29

Power supply, 28

SIM card, 27

C-PLUG, 14

D

Digital input, 31

Digital output, 32

Dimension drawing

DIN rail, 20

E

Ethernet interface, 35

External power supply

China, 29

L

LED display

P

Power supply, 28

Product property, 7

S

S7-1500 standard rail, 22

S7-300 standard rail, 21

Safety notices

for installation, 17

Use in hazardous areas, 17, 25

when connecting up, 25

Scope of delivery, 7

SET button, 12

Signal quality, 34

SIM card, 27

System manual, 46

W

Wall mounting, 19

G

Glossary, 4

Grounding, 29

I

Installation

DIN rail, 20

S7-1500 standard rail, 22, 22

S7-300 standard rail, 21

Wall, 19

K

KEY-PLUG, 14

RUGGEDCOM RM1224

Operating Instructions, 10/2016, RC1260-EN-02 53

Page 54

Index

RUGGEDCOM RM1224

54 Operating Instructions, 10/2016, RC1260-EN-02

Loading...

Loading...