Page 1

725

2

Temperature controller

for ducted systems

Multifunctional controller used for central control of ducted HVAC systems in

connection with a QAX850 master room unit.

Standard model without zoning functions.

Use

RRV851

Applications

Comfort control of ducted HVAC systems via fan, heating and cooling output:

• Apartments

• Single-family houses

• Autonomous light commercial applications

The RRV851 controller is designed for central ducted HVAC systems that require easy

operation by the building occupant. The MMI to be connected to the controller is the

QAX850 master room unit. Fan, heating and / or cooling outputs control the

temperature in the building. The RRV851 controller can be configured for various types

of HVAC equipment. These include:

• Heating only ducted systems

• Cooling only ducted systems

• DX cooling and heating (1-speed fan on heating)

• DX cooling and heating (3-speed fan)

• Air-to-air heat pumps

• Water-to-air heat pumps

• 4-pipe FCU

• 2-pipe FCU

• 1- or 3-speed fans

CE1N2725en

27.08.2007

Building Technologies

HVAC Products

Page 2

Functions

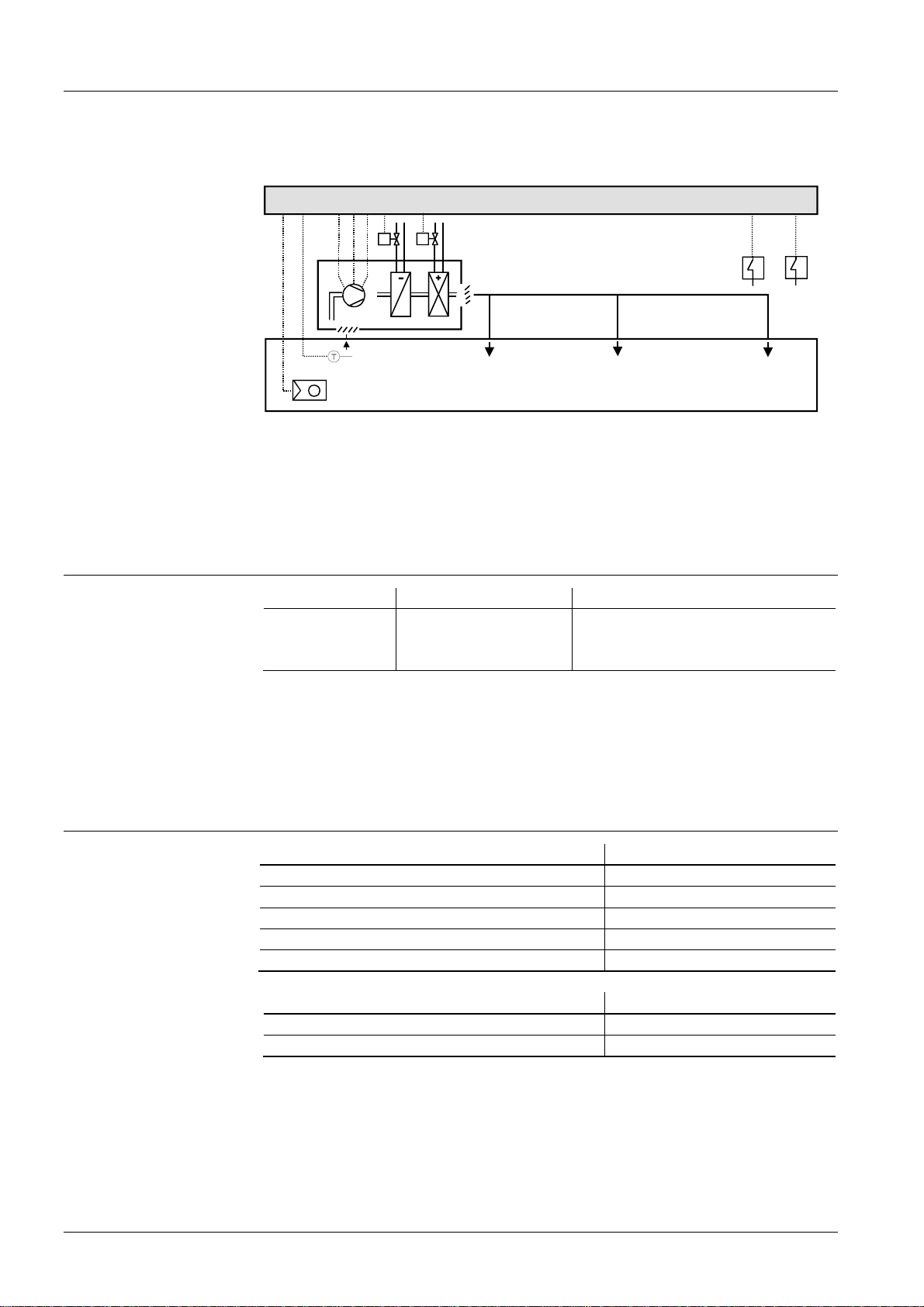

Application example:

4-pipe FCU system

The controller’s functionality is determined by the application selected with the DIP

switches, parameter settings and operating mode selection via the QAX850 master

room unit.

HB B1

Y1

Y2Y1Y3Q7Q8Q9

Y2

FCU

D1

D2

D2

N1

D1

Type summary

Note

SAF

B1

T

N2

B1 Optional remote temp. sensor N1 RRV851 controller

C1 Cooling coil N2 QAX850 master room unit

D1 Remote comfort mode input SAF Supply air fan

D2 Fault or emergency heat input Y1 Cooling control valve

FCU Fan coil unit Y2 Heating control valve

H1 Heating coil

C1

H1

Type reference Description Compatible with

RRV851

Temperature controller • QAX850 Master room unit

• QAA32 Room temperature sensor

• QAH11.1 Cable temperature sensor

The QAX850 is the master MMI for the RRV851 and must be ordered as a separate

item. Any additional remote temperature sensors must also be ordered separately.

Terminal covers are included in the RRV851 box.

2725A01

Not suitable for use with the Desigo RX range of wall-mounted units.

Product documentation

Document Document number

Data sheet N2725

Installation instructions G2725

Operating instructions, with QAX850 room unit B2725en01

Application manual A2725

Declaration of conformity T2725

Supporting

documentation

Document and unit type Document number

Data sheet QAX850 N2722

Mounting instructions QAX850 M2721

2/11

Siemens Temperature Controller RRV851 CE1N2725en

Building Technologies 27.08.2007

Page 3

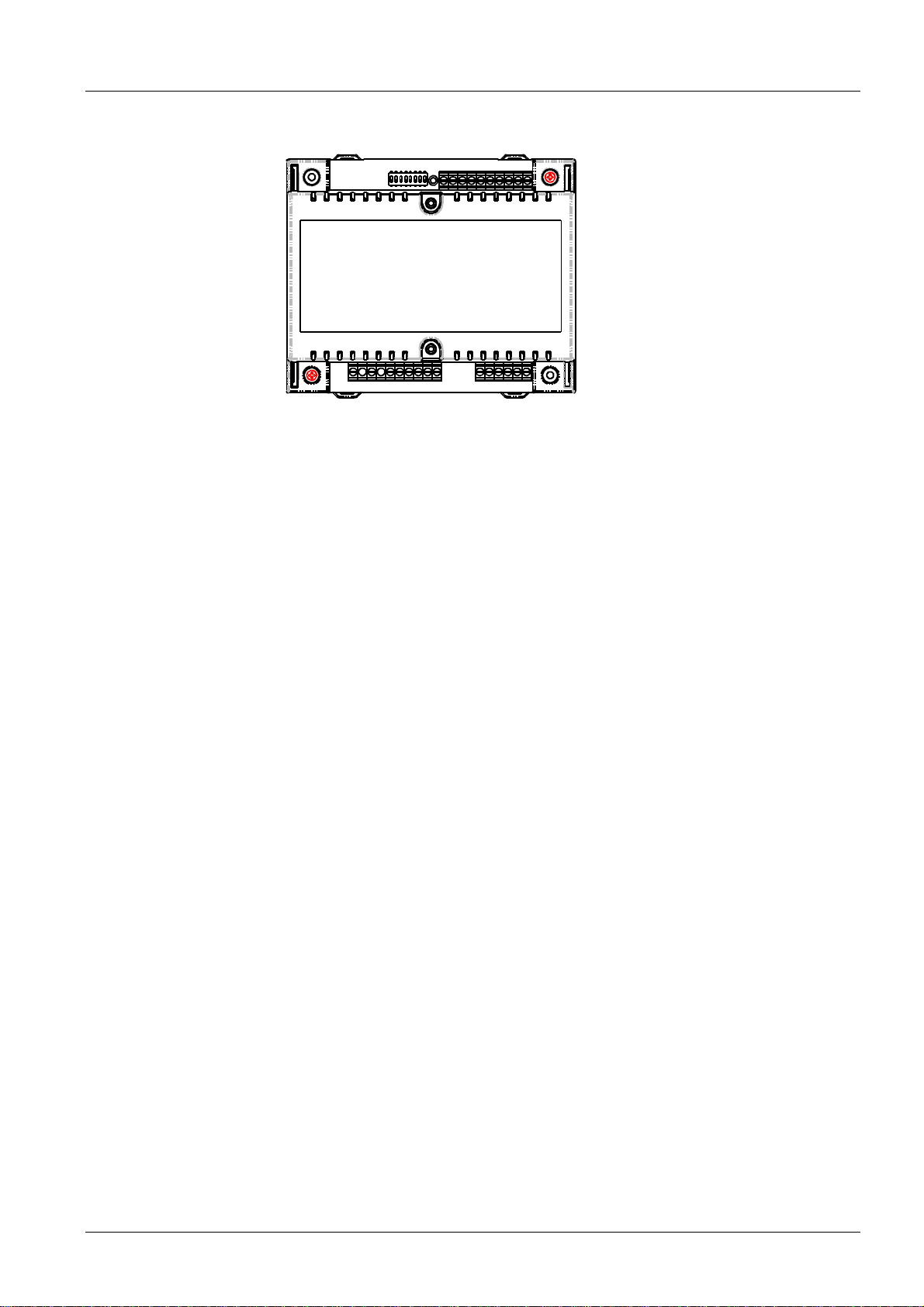

Mechanical design

The RRV851 is a temperature controller providing connection of power supply,

inputs/outputs and QAX850 master room unit.

2725Z01

The unit consists of the following components:

• Base for DIN rail or screwed surface-mounting

• Cable strain reliefs

• IP30 covers (when mounted directly to the wall or FCU without DIN rail)

• PCB and built-in transformer

• PCB cover

• Input / output terminals

• RS-485 terminals

• MMI bus terminals

• LED for power supply indication

• Configuration DIP switches

Connection terminals

Bus interface

(HB+ HB–)

RS-485

(TX+, TX–)

Digital inputs

(D1, D2)

Temperature sensor

input (B1, M)

Low-voltage power supply (DC 12 V) and communication transfer is supplied via two

wires to the QAX850 from terminals HB+ and HB–. The LED on the QAX850 will flash if

a communication error exists between RRV851 and QAX850 for longer than 5 seconds.

The RS-485 connections are only suitable for downloading manufacturer specific

parameter sets. This is for factory use only.

Two digital inputs are provided. A potential-free contact closed across the D1 and

D_GND terminals will override to Comfort mode only when the mode selector is set to

Auto Timer mode. D2 can be configured for an emergency heating enable signal or an

external fault lockout signal. Either of these functions can be selected via the

configuration DIP switches.

When emergency heating is selected, a potential-free contact closed across the D2 and

D_GND terminals will disable the primary heating output and enable the emergency

heating output. The emergency heating output will only be activated when there is

demand for heating. Not available on applications A2, A3, A4, and A5.

When external fault (default) is selected, a potential-free contact closed across the D2

and D_GND terminals will deactivate all outputs and the standby icon on the QAX850

LCD will flash to indicate the fault. The fault will disappear after the contact is opened.

An NTC temperature sensor can be connected to the B1 and M terminals for the

following functions:

3/11

Siemens Temperature Controller RRV851 CE1N2725en

Building Technologies 27.08.2007

Page 4

Fan speed outputs

Heat/cool outputs

• Remote room temperature sensing: The QAX850 can be used as a master control

unit without using the built-in temperature sensor. A separate room sensor (QAA32)

can be mounted in a location more convenient for accurate temperature acquisition

• Return air temperature sensing: A temperature sensor (QAH11.1) can be mounted in

the return air path of the FCU if accurate temperature acquisition in the room is not

possible

• 2-pipe application heating/cooling changeover: For application A8 (2-pipe FCU) a

temperature sensor (QAH11.1/ARG86.3) is clamped to the water pipe in order to

activate heating/cooling mode changeover

The RRV851 controller can be configured for a 1- or 3-speed fan. Voltage-free (SPST)

relay outputs Q74, Q84 and Q94 can switch loads up to AC 250 V, 6 (4) A. Power is

supplied via terminal Q71. The low-speed terminal is used when a 1-speed fan is

configured. On fan startup, high-speed will be activated first for approximately

3 seconds and then resume the selected speed. In Auto Fan mode, the fan speeds will

be activated automatically depending on demand.

For further details on auto fan speed control, refer to the Application Manual.

• Output Y1: Cooling or compressor output

• Output Y2: Heating or reversing valve output

• Output Y3: Auxiliary output that can be configured for auxiliary heating, emergency

nd

heating, 2

step cooling or dual compressor

Output control is 2-position. 3-position modulating can be selected via parameter P17

for applications A1, A2 and A8 only.

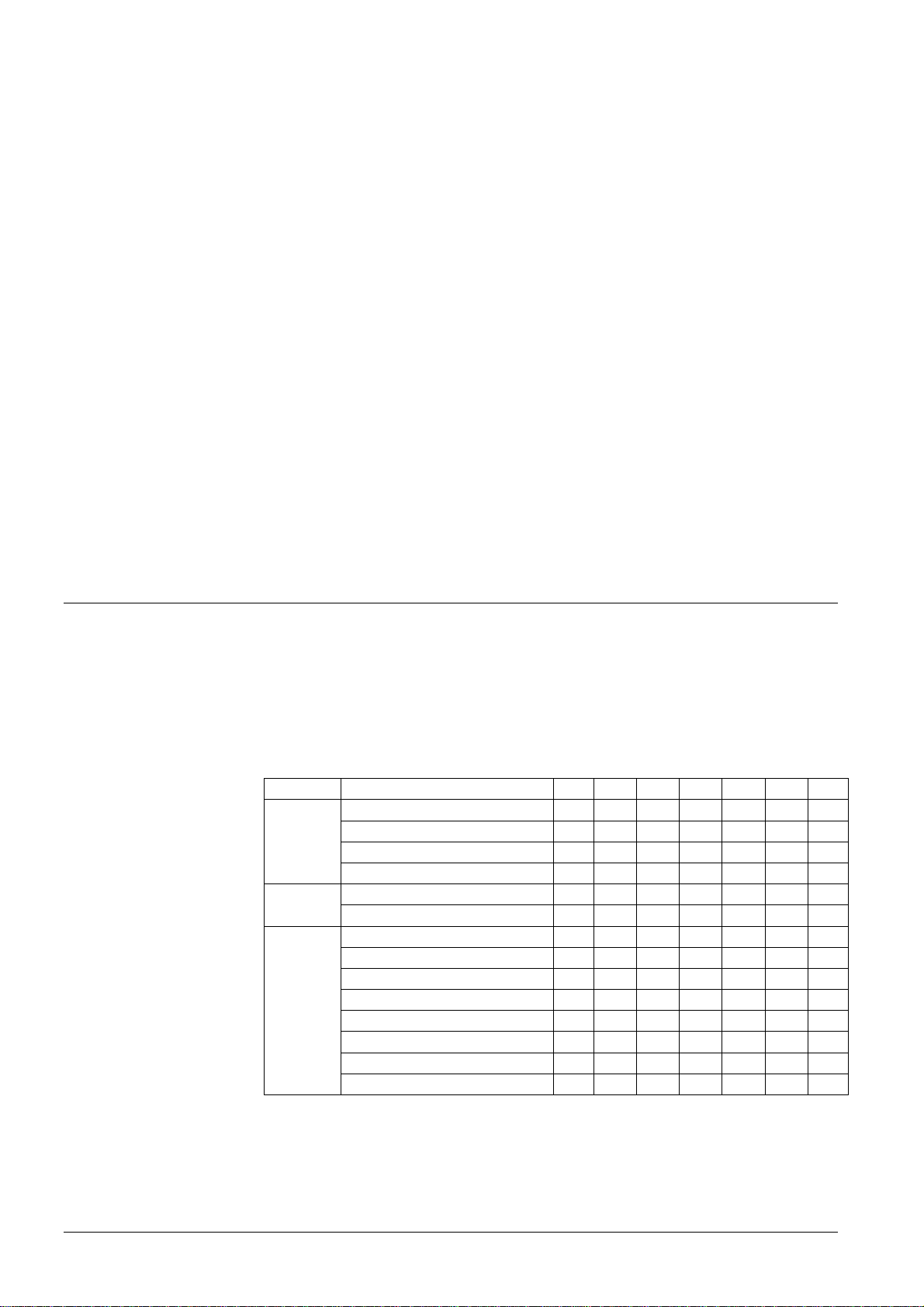

Configuration

DIP switches

DIP switch settings

Initial application setup of the RRV851 controller to match the connected HVAC

equipment is made by the selection of DIP switch positions. DIP switches are located

on the top of the controller. An adhesive label is included in the RRV851 packaging box

for the final recording of the DIP switch positions. This can be placed on the DIP switch

block to avoid unauthorized changes. Further parameter settings can be made via the

QAX850 if required.

Function Selections 1 2 3 4 5 6 7

Y3

Auxiliary

output

Auxiliary heating 20 min delay

Auxiliary heating 10 min delay on off - - - - Emergency heating via D2 off on - - - - -

nd

stage cool or compressor on on - - - - -

2

off off

- - - - -

Single speed - - off - - - - Fan

speed

Application

Three speed - -

A1 – Heating only

A2 – Cooling only

A3 – Cool./(heat. 3 speed fan)

A4 – Cool./(heat. 1 speed fan)

A5 – Heat pump (comp + RV)

A6 – Heat pump (heat/cool)

A7 – 4-pipe FCU

A8 – 2-pipe FCU

- - -

- - - on off off off

- - - off on off off

- - - on on off off

- - - off off on off

- - - on off on off

- - - off on on off

- - - on on on off

on

- - - -

off off off off

Default (as delivered) positions are in bold text.

4/11

Siemens Temperature Controller RRV851 CE1N2725en

Building Technologies 27.08.2007

Page 5

Commissioning notes

Response on startup

User operation

Sensor calibration

Commissioning

Setup parameters

When powering up, the QAX850 will display all LCD icons for approximately 3 seconds,

and then the software version number for another 3 seconds. It will then revert to the

normal display. The time segments will be blinking if the time needs to be set. Set the

time of day as per Operating Instructions. There will be a delay before operation

commences due to polling of all values.

The user should not have access to the DIP switches or parameter settings. User

operation is via the QAX850 master room unit. For user operation details, refer to the

Operating Instructions included in the packaging box (document B2725en.01).

Generally, there is no need to recalibrate the sensor. However, the room temperature

displayed on the QAX850 LCD can be recalibrated if there is any discrepancy from the

actual temperature measured with a certified thermometer. The calibration function can

be accessed by pressing simultaneously the

and buttons for 5 seconds. The

displayed value can then be adjusted via the same buttons in increments of 0.1 K. The

range is ±3 K.

The RRV851 controller is operational after the DIP switch settings have been made and

power is connected. Default parameter settings are based on the application selected

and may be modified if required. Refer to the list below. Parameters cannot be

accessed if the system is in Off mode. Refer to the Installation Instructions for setup

details and the Application Manual for default parameter values.

No. Parameter Range

P00 Temperature scale °C / F°

P01 Frost protection limit in Off mode Off / 5…8 °C

P02 Overtemperature limit in Off mode Off / 30…35 °C

P03 Min. off time delay 0…600 s

P04 Min. on time delay 0…600 s

P05 Dead band between cooling and heating off points 0.5…6 K

P06 RV on in heating or cooling mode Heating/Cooling

P07 Fan run on after heating output turns off 0…300 s

P08 Fan run on after cooling output turns off 0…300 s

P09 FCU flush pipe time 120…600 s

P11 Water temperature heating mode changeover 22…32 °C

P12 Water temperature cooling mode changeover 10…21 °C

P13 Fan auto speed high range H: 80…100 %

P14 Fan auto speed medium range M: 30…75 %

P15 Fan auto speed low range L: 1…15 %

P17 2- or 3-position control selection 2-pos / 3-pos

P18 P-band in heating mode / switching differential 0.5…10 K

P19 P-band in cooling mode / switching differential 0.5…10 K

P20 Integration time 0…60.0 min in

0.5 min steps

P21 3-position valve actuator running time 50…300 s

P23 Ventilation in dead zone Off, H/C, C only

5/11

Siemens Temperature Controller RRV851 CE1N2725en

Building Technologies 27.08.2007

Page 6

Mounting and installation notes

The RRV851 controller can be mounted in any orientation using the following fixing

options:

DIN rail mounting

The housing base is designed for snapmounting on DIN rails conforming to

EN 50022-35 × 7.5 (can be released

with a screwdriver).

When mounting, note the following:

• The controller should not be freely accessible after mounting

• Ensure adequate air circulation to dissipate heat generated during operation

• Easy access is required for service personnel

• Local installation regulations must be observed

Surface mounting

There are 2 drill holes for screw-mounting

(refer to “Dimensions”).

Screws: Max. diameter 3.5 mm, min. length

38 mm.

STOP

Note!

Terminal covers

The Mounting Instructions are included in the RRV851 controller packaging.

When not mounting within a panel, cable strain

2725Z02

reliefs must be used for all wiring to (AC 230 V)

terminals. The conductors must be secured with

cable ties (see diagram).

Cable strain reliefs should be used for all wiring

to avoid disconnection.

Terminal covers are provided in the RRV851 packaging box. The covers include

screws for fixing to the controller and knockout holes for cable entry. Covers should

only be used where suitable access is restricted to authorized personnel and there is

protection from ambient conditions. The covers will provide IP30 protection when

surface-mounted on the wall or FCU.

Removing the terminal covers

6/11

Siemens Temperature Controller RRV851 CE1N2725en

Building Technologies 27.08.2007

Page 7

Technical data

Power supply (L, N)

Rated voltage AC 230 V, +10 %, –15 %

Requirement for transformers for switch mode

power supplies

Functional data

Analogy input (B1, M)

Digital input (D1, D2)

Frequency 50 / 60 Hz

Power consumption (excl. external modules) 12 VA

Supply line fusing max. 10 A

Reserve of clock max. 20 min

Passive sensor NTC resistor, 3 kΩ at 25 °C

Measuring range 0…49 °C

Contact sensing

Voltage

Current

Requirements for status and impulse contacts

Signal coupling

Type of contact

Insulating strength against main potential

Switching outputs

External supply line fusing

Non-renewable fuse (slow)

Automatic line cutout

Release characteristic

Relay contacts (Y1x, Y2x, Y3x)

Relay output

Switching voltage

AC current

At 250 V

At 19 V

Switch-on current

Contact life

Boiler (Q1x) Relay contacts (Q7x)

Relay output

Switching voltage

AC current

At 250 V

At 19 V

Switch-on current

Contact life

Insulating strength

Between relay contacts and system electronics

(reinforced insulation)

Between neighboring relay contacts

(operational insulation)

Y1x⇔Y2x⇔Y3x⇔Q7x⇔Q8x⇔Q9x

Interfaces (S+, SG)

HCC bus proprietary protocol

Bus power supply voltage DC 12 V, +10, –15% (supply to room

EN 61 558-2-6

max. DC 5 V

typically 8 mA

Potential-free

Maintained or impulse contacts

AC 3750 V to EN 60 730

max. 10 A

max. 13 A

B, C, D to EN 60 898

potential-free

max AC 250 V

min. AC 19 V

max. 3 A res., 1 A ind. (cos φ= 0.6)

min. 5 mA

min. 20 mA

max. 5 A (1 s)

5

1 × 10

cycles

potential-free

max. AC 250 V

min. AC 19 V

max. 6 A res., 4 A ind. (cos φ= 0.6)

min. 5 mA

min. 20 ma

max. 10 A (1 s)

5

1 × 10

cycles

AC 3750 V, to EN 60 730-1

AC 1250 V, to EN 60 730-1

unit QAX850)

7/11

Siemens Temperature Controller RRV851 CE1N2725en

Building Technologies 27.08.2007

Page 8

Permissible cable lengths

Electrical connections

(all terminals)

Degrees of protection

Environmental conditions

Classification to EN 60 730

Materials and colors

Norms and standards

Weight

Baud rate 9.6 kbit/s

For bus communication

A ≥0.5 mm²

A ≥1 mm²

max. 60 m

max. 100 m

Type of cable 2-wire standard installation cable

(unshielded)

Note:

Twisted pair (unshielded) is recommended for enhanced

immunity to external electromagnetic interference, e.g. in the

vicinity of radio transmitters or variable speed drives

Connection terminals

For wires

screw terminals

0.6 mm dia. … 2.5 mm

2

Degree of protection of housing to IEC 60 529 IP 20 without terminal covers

IP 30 with terminal covers

Safety class to EN 60 730 device suited for use with equipment

of safety class II

Operation to

Climate conditions

Temperature (housing and electronics)

Humidity

Mechanical conditions

Transport to

Climate conditions

Temperature

Humidity

Mechanical condition

IEC 721-3-3

class 3K5

0…50 °C

5…95 % r. h. (non-condensing)

class 3M2

IEC 721-3-2

class 2K3

–25…+70 °C

<95 % r. h.

class 2M2

Mode of operation, automatic controls type 1B

Degree of contamination, controls Environment 2

Rated surge voltage

4000 V

Software class A

Controller housing Polycarbonate, RAL 7035 (lightgrey)

Packaging corrugated cardboard

Product safety

Automatic electrical controls for household and

similar use

Special requirements for temperature sensing

controls

Electromagnetic compatibility

Immunity domestic section, light industry

Emissions domestic section, light industry

-conformity

EMC directive

Low-voltage directive

N474

conformity to

Australian EMC framework

Radio interference emission Standard

EN 60 730-1

EN 60 730-2-9

EN 61 000-6-1

EN 61 000-6-3

89/336/EEC

73/23/EEC

Radio Communication Act 1992

AS/NZS 4251.1

Excluding packaging approx. 0.735 kg

8/11

Siemens Temperature Controller RRV851 CE1N2725en

Building Technologies 27.08.2007

Page 9

Connection terminals

Connection diagrams

Typical connection

B1 Signal input (external sensor NTC)

M Signal ground

D1, D2 Digital inputs

D_GND Digital ground

HB+ HB– Communication bus

L, N AC 230 V supply

Q… Digital outputs, AC 24…230 V, 6(4) A

Y… Digital outputs, AC 24…230 V, 3(1) A

D1

B1

1

B

M

D2

D

N

G

1

2

_

D

D

D

RS485

-

+

X

X

T

T

N1 N2

5

d

8

n

4

g

4

4

N

Q

1

7

L

4

1

7

8

9

Q

Q

Q

4

3

3

Y

Y

4

2

1

1

1

1

Y

Y

Y

4

2

1

2

2

2

Y

Y

Y

-

+

B

B

H

H

L

N

AC 230V

2

1

3

F1

1

Y1

Y3

Y2

F2

B1 External temperature sensor (optional) or pipe changeover sensor (application A8)

CR1 Compressor relay stage 1

CR2 Compressor relay stage 2

D1 Remote activation of Comfort mode

D2 Fault or emergency heating

F1 3-speed fan

F1 External supply line fusing, max. 10 A

F2 1-speed fan

N1 RRV851 controller

N2 QAX850 master room unit

RV Reversing valve

Y1 Cooling output

Y2 Heating output

Y3 Auxiliary heating, emergency heating or 2

Y4 Valve actuator, AC 24…230 V

nd

stage cooling

-

+

B

B

H

H

9/11

Siemens Temperature Controller RRV851 CE1N2725en

Building Technologies 27.08.2007

Page 10

Output connections

N1

N1

Output connections

STOP

Note

4

1

2

1

1

1

Y

Y

Y

1

2

Y

Y

4

1

2

2

2

2

Y

Y

Y

AC 24

/230V

4

1

2

1

1

1

Y

Y

Y

1

2

Y

Y

Y4

Y4

4

1

2

2

2

2

Y

Y

Y

AC 24

/230V

2-pipe FCU, 2-position control

(application A8)

Optional 3-position control (applications

A1, A2 and A8)

N1

4

1

4

1

3

3

Y

Y

CR2

2

1

1

1

Y

Y

Y

CR1

4

1

2

2

2

2

Y

Y

Y

AC 24

RV

/230V

Heat pumps (application A5)

(For single compressor heat pumps, CR2 is

not connected)

Note: Contact your local Siemens representative for application-specific wiring

diagrams and information.

• External supply line fusing must be used.

• All input and bus terminals are not protected against connection to AC 230 V.

• Observe the technical data for fan relay outputs: Max. AC 250 V, 6(4) A.

• All output cables used must satisfy insulation requirements with regard to

mains potential.

• AC 24 V outputs must be segregated from AC 250 V outputs.

• Care should be taken when cables pass through sharp metal openings,

conduits or ducts.

• Double insulation on output cables is recommended.

• Local installation regulations must be observed.

Product liability

The products may only be used in building services plant and applications as described

above. When using the products, all requirements specified under ”Technical data”

must be observed.

10/11

Siemens Temperature Controller RRV851 CE1N2725en

Building Technologies 27.08.2007

Page 11

Dimensions

Without terminal covers

With terminal covers

Dimensions in mm

©2005-2007 Siemens Switzerland Ltd

Subject to alteration

Siemens Temperature Controller RRV851 CE1N2725en

Building Technologies 27.08.2007

11/11

Loading...

Loading...