Page 1

s

A6V

11282546

Touch Screen Flush-mount Room

with an additional HMI for

Thermostats with KNX

Communications

Under Floor Heating (UFH) control application

Variable Refrigerant Flow (VRF) commands via KNX S-mode

· Large display, touch screen with backlight

· VRF HMI: adjust setpo int, fan mode, fan speed and operating modes

· 2-position (ON/OFF) temperature control with potential free output for UFH

via build-in / external temperature sensor

· Display room temperature value (°C) and relative humidity value (% r.h.)

via a build-in temperature and humidity sensor

· One setpoint adjustment for both VRF HMI and UFH controls

· Fan auto and manual speed setting from 1 up to 7 speed

· Operating mode selection for VRF: AUTO, COOL, HEAT, FAN and DRY

· Operating mode selection for UFH: Comfort and Protection

· Economy operating mode for both VRF and UFH to save energy

· 2 mult ifunctional inputs (see details in functional descriptions)

· Adjustable contro l parameters for alternative settings

· KNX bus communications via S-mode and LTE-mode

· Integration to VRF system via S-mode and third party gateways

· Commissioning via ETS download

· Wizard function for fast commissioning via HMI

· Alarm / Error information

· AC 230 V operating voltage

· RDF880KN/NF: Mounting on recessed square 86 mm box with 60.3 mm

fixing centers and min 40 mm depth, requires additional mounting frame

to complete installation

RDF880KN/NF

A6V11282546_en--_a

2018-04-19

Building Technologies

Page 2

Use

More than just room temperature control via a connected VRF system or a UFH

system or both:

Typical applications:

· Residential apartments

· Small office or commercial buildings

· Schools / Universities

For the VRF HMI, the unit interfaces to VRF systems via a third party gateway for:

· User application selection: - UFH only or VRF only or both

· Setpoint adjustment: - maximum / minimum limitations

· Fan speed adjustment: - auto / manual speeds (up to 7 speeds)

· Operating mode selection: - AUTO, HEAT, COOL, FAN and DRY

· Economy mode: - energy saving

· Fan swing adjustment (optional): - auto swing or fix at any position (10)

· Delay off timer (optional): - allow up to 23 hours operations before off

For the control of the following pieces of heating equipment:

· Floor Heating

· Thermal valves or zone valves

· Gas or oil boilers

· Fans

· Pumps

Functions

The configuration can be done locally or remotely via one of the following:

· Local HMI & DIP switches

· Synco ACS (UFH only)

· ETS4/5 (binding S-mode objects for VRF & UFH)

· Room temperature control via a built-in or external room temperature sensor

· Calibrations for both internal temperature and relative humidity sensors

· Display of current room temperature or setpoint in °C

· Minimum and maximum limitation of room temperature setpoint

· Fan speed adjustment, auto, manual (up to 7 speeds)

· Selection of VRF operating mode:

à AUTO, HEAT, COOL, FAN and DRY

· Selection of UFH operating mode:

à Comfort and Protection

· Energy saving (Economy mode) for both VRF and UFH

· Key lock function: unlock, total lock and setpoint lock

· 2 multifunctional inputs, freely selectable for:

- External room temperature or return air temperature sensor

- Window contact

- Fault input

- Monitor input for temperature sensor or switch state

· Floor heating temperature limitation

· Display of outdoor temperature and time scheduling via KNX bus

· Reload factory settings for commissioning and control parameters

Optional: enable / disable via parameters

· Relative humidity display via a built-in humidity sensor

· Fan swing selection: auto swing or fix at any position (up to 10)

· Delay off timer: up to 23 hour operations

· Chinese text display for 4 navigation icons

2 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 3

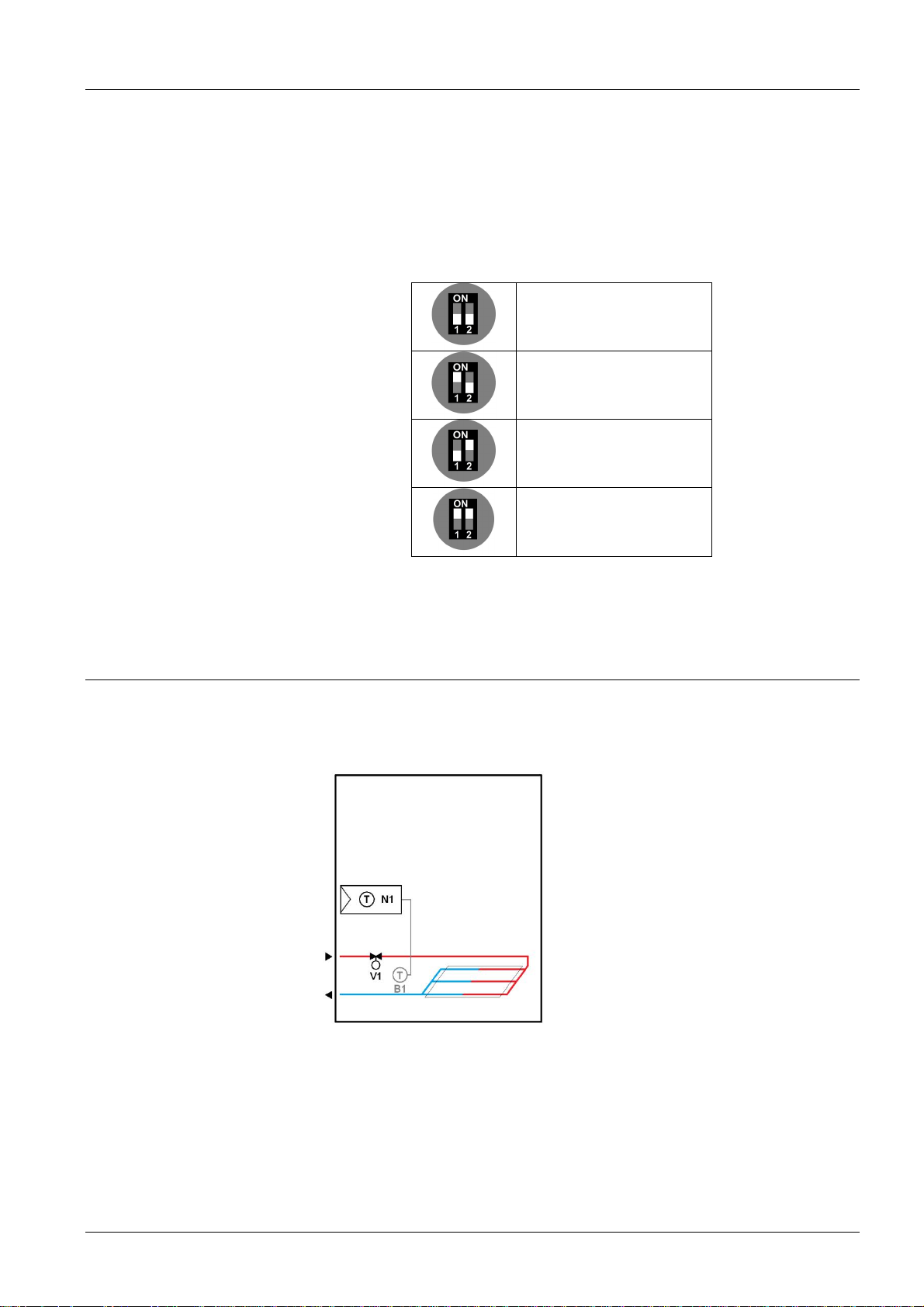

Applications

RDF880KN/NF is designed to provide easy-to-understand HMI for any existing

VRF system installed in residential homes and apartments where Under Floor

Heating (UFH) room thermostat may be required at the same time.

RDF880KN/NF has three kinds of applications including VRF HMI or UFH or both.

Applications are selectable via DIP switches.

Download via ETS

(All in OFF positions)

UFH only

VRF HMI only

VRF HMI and UFH

UFH Application

For selection under application mode via HMI, refer to user manual A6V11272225

for selecting applications.

For the UFH application, RDF880KN/NF provides an ON/OFF output to control

water valve to maintain a comfort level of room temperature.

Room thermostat to control the valve

for the floor heating application

3 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 4

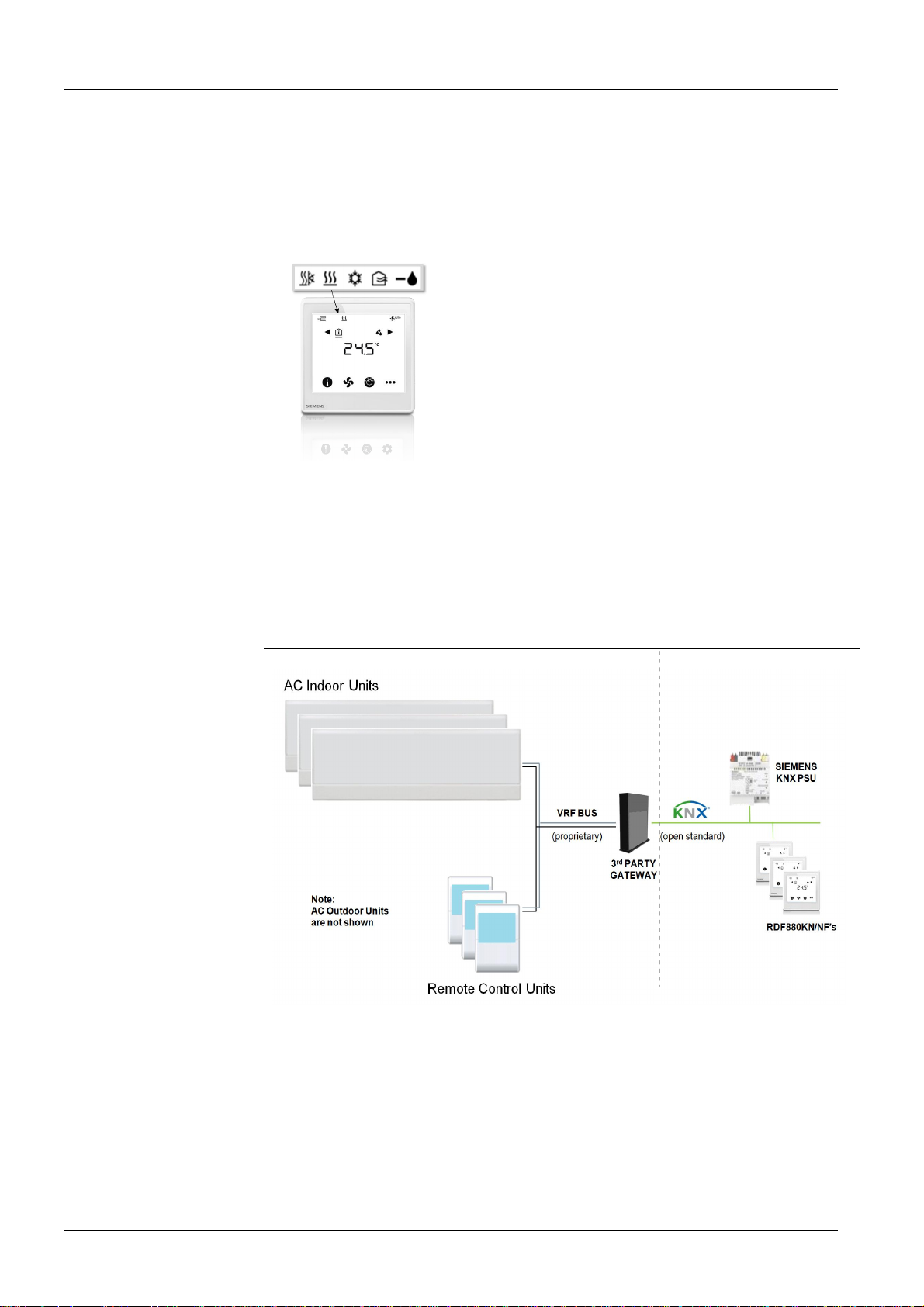

VRF Application (HMI only)

For the VRF application, RDF880KN/NF provides an easy-to-understand HMI for

adjusting frequent used operations of the VRF systems such as adjustments of

temperature setpoint, fan speed, VRF operating mode, etc.

Since all VRF brands have their own communication protocols

between the remote control unit and VRF equipments (e. g. indoor

or outdoor units), RDF880KN/NF can send all standard KNX

commands (S-mode KNX objects) via the KNX bus to a third party

KNX/VRF gateway (as a protocol converter) and then communicate

indirectly with the VRF indoor or outdoor units. Effectively, it works

similarly like a remote control unit of a VRF system.

Note that RDF880KN/NF cannot replace all functions of the remote

control unit of the VRF system but the following typical VRF

functions:

· Temperature - provide current room temperature value

- adjust temperature setpoint

· Fan - select auto or manual speed up to 7 levels

- select auto swing or fixed swing positions

· Operation - set to AUTO, HEAT, COOL, FAN and DRY

Typical VRF Systems

(Provided by 3rd Party, non-Siemens products)

Integration

via KNX Bus S-mode

4 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 5

Other Heating Applications

RDF880KN/NF is not limited to UFH applications but also for the following heating

applications such as radiators, wall hung boilers, etc.

Room thermostat to control the valve of

the radiator application

Room thermostat with direct control of a

gas-fired wall-hung boiler

Room thermostat with direct control of a

heat pump (pre-controlled by manual

mixing valve)

F1 Thermal reset limit thermostat

F2 Safety limit thermostat

M1 Circulating pump

Room thermostat with direct control of a

gas-fired floor-standing boiler

Room thermostat with direct control of

hydronic floor heating system

N1 Room thermostat

V1 2-port valve

V2 Mixing 3-port valve with

manual adjustm ent

V3 Magnetic valve

5 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 6

Type summary

2)

Product no. Stock no .

Operati ng

voltage

RDF880KN/NF2) S55770-T398 AC 230 V --

1)

ON/OFF output with potential free input from AC 24…230 V

2)

Mounting frames are not included and must be ordered separately. (See

“Accessories”)

Ordering

· When ordering, indicate product number, SSN and name.

e.g. RDF880KN/NF (S55770-T398) heating thermostat with VRF HMI

· A mounting frame or multi-frame must be ordered for RDF880KN/NF installation.

(See “Accessories”)

· Order valve actuators separately.

Equipment combinations

Type of unit Product no. Data sheet

Cable temperature sensor or

changeover sensor

cable length 2.5 m

NTC (3 kW at 25 °C)

Room temperature sensor

NTC (3 kW at 25 °C)

Cable temperature sensor,

cable length 4 m

NTC (3 kW at 25 °C)

Control outputs

3-pos ON/OFF DC 0..10 V

1)

1

-- Square conduit box

QAH11.1

QAA32

QAP1030/UFH

Suitable for

d)

1840

1747

1854

ON/OFF actuators

Electromotoric ON/OFF actuator

Electromotoric ON/OFF valve and

actuator

Zone valve actuators

Thermal actuator

Thermal actuator

a)

a)

b)

c)

Damper actuator

Damper actuator

Damper actuator

Rotary damper actuator

a)

only available in AP, UAE, SA and IN

b)

for radiator valve

c)

for small valves 2.5 mm

SFA21...

MVI…/MXI…

SUA…

STA23...

STP23...

GDB..

GSD..

GQD..

GXD..

4863

A6V11251892

4832

4884

4884

4634

4603

4604

4622

6 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 7

d)

both QAH11.1 and QAP1030/UFH are for floor heating applications, such as

temperature limitation controls. QAP1030/UFH has a special head and 4 m long

that is more suitable for such application.

Accessories

Note:

Refer to data sheets of the actuators for the maximum number of parallel

operation.

Designation Product no. / SSN Data sheet

Single mounting frame*), Ivory White

KNX Power supply 160 mA (Siemens BT LV)

KNX Power supply 320 mA (Siemens BT LV)

KNX Power supply 640 mA (Siemens BT LV)

*)

See the dimensions of mounting frame on page 24.

ARG800.1 /

S55770-T370

5WG1 125-1AB02

5WG1 125-1AB12

5WG1 125-1AB22

--

--

--

--

7 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 8

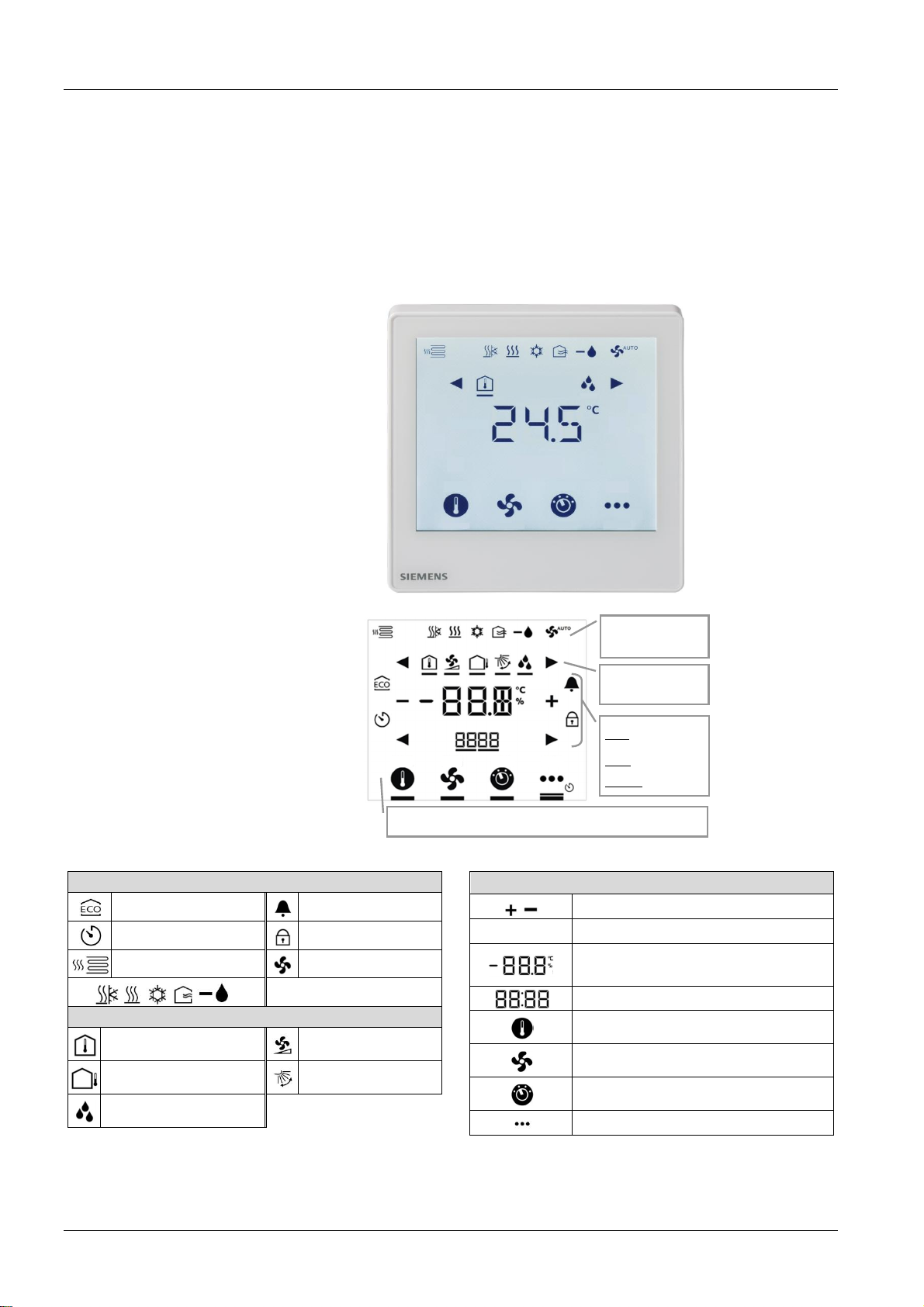

Mechanical design

INFORMATION

Operation and

settings

The thermostats consist of the following parts:

· Front panel with electronics, operating elements and built-in room temperature

and relative humidity sensors.

· Mounting base with power electronics.

· Mounting frame is an additional part to complete the installation for

RDF880KN/NF, e.g. single or multi-frames.

The rear of the mounting base contains the screw terminals.

Slide the front panel in the mounting base and snap on.

Display

Status sy mbols:

Economy active Alarm / Service active

Delay timer active Key lock active

Floor heat active Fan active

VRF operating modes

Selection symbols:

Indoor temperatur e VRF fan speed

Outdoor temperature VRF fan swing

Relative humidity

STATUS &

OPERATION of the

room thermostat

SELECTIONof

available information and

VRF fan modes

1st line: temperature or

humidity, values of

parameters

2nd line: parameters and

alarms

Both sides: STATUS

ADJUSTMENTfor temperature setpoint, fan speed, operating modes of VRF and

Floor Heating, more INFO and settings (for example, Alarm, Delay Off Timer, etc.)

Operational icons:

Increment, decrement OR selection

ƒ „

Selection OR move to next items

Temperature, relative humidity OR

parameter values, etc.

Parameters OR password, etc.

Setpoint mode (temperature only)

Fan mode OR fan speed mode

VRF & floor heat operating modes

More info & settings

8 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 9

Engineering notes

Mounting and installation

See the "Reference documentation", page 21, for information on how to engineer

the KNX bus (topology, bus repeaters, etc.) and how to select and dimension

connecting cables for supply voltage and field devices.

Mount the room thermostat on a conduit box. Do not mount on a wall in niches or

between bookshelves, behind curtains, above or near heat sources, or exposed to

direct solar radiation. Mount about 1.5 m above the floor.

Mounting / Dismounting

Wiring

· Do not apply excessive force on screws! The deformation of the mounting

frame may lead to improper connections and operation of the unit.

· Mount the room thermostat on a clean, dry indoor place without direct airflow

from a heating / cooling device, and not exposed to drips or water.

· Before removing the front cover, disconnect the power supply.

See the User Manual for the installation instructions enclosed with the thermostat.

· Comply with local regulations to wire, protection and earth the thermostat.

· The device has no internal fuse for supply lines to fan and actuators. To avoid

risk of fire and injury due to short-circuits, the AC 230 V mains supply line must

have a circuit breaker with a rated current of no more than 10 A.

· The wiring cross section used for power supply (L, N) and 230 V outputs

(Qxx - N) must be adapted to the preceding overload protection elements (max

10 A) under all circumstances. Comply under all circumstances with local

regulations.

· Properly size the cables to the thermostat and valve actuators for

AC 230 V mains voltage.

· Cables of SELV inputs X1-M / X2-M: Use cables with min 230 V insulation, as

the conduit box carries AC 230 V mains voltage.

· Inputs X1-M or X2-M of different units (e.g. window contact) may be connected

in parallel with an external switch. Consider overall maximum contact sensing

current for switch rating.

· KNX communication cables (input CE+ / CE-): Use cables with min 230 V

insulation, as the conduit box carries AC 230 V mains voltage.

· When a KNX bus power supply is connected on the line with communicating

thermostats and Synco controllers, the internal KNX power supply of the

Synco controllers must be switched off.

· No cables provided with a metal shield.

· Disconnect from supply before opening the cover.

9 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 10

Commiss ioning notes

Before power up

Select DIP switch setting is required for RDF880KN... thermostats.

COMMISSIONING: Download via ETS

1. DIP switch setting

All in OFF positions

3. Touch & hold this

icon > 5 s to enter

2. First power up

Press to turn ON

4. Ready for downloading

address & application

Programming mode

Touch “ON“ to exit

Wizard function

COMMISSIONING: Local via DIP Switches

1. Set application via

DIP switches

DIP switch

positions

1 2

ON ON VRF+FLOOR HEAT

OFF ON VRF ONLY

ON OFF FLOOR HEAT ONLY

APPLIC ATION

2. Configure basic

control parameters

via Wizard

See Configure Parameters

via Wizard in Wizard function.

After power up, the wizard function guides users to configure the basic parameters

for normal operation according to the table below.

Touch ƒ / „ to advance / return to any parameter;

Touch + / - to select any desired available values.

10 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 11

LCD display Parameter Range Factory setting

Operation Selector

1: COMF > PROT

2: COMF > ECON > PROT

1

Reset

Internal Relative

Humidity Sensor

Maximum Fan

Speed

Maximum Fan

Swing

Chinese Text

Display

End of wizard

setup

OFF: Disable

ON: Enable

1 to 7

0: no swing function

1 to 10 positions

0: Disable

1: Enable

- -

ON

3

0

0

If more details are required about parameters, refer to basic documentation

CE1P3174.

To reload factory setting for all parameters, set parameter P71 to ON. Restart the

thermostat after reset, all LCD segments flash, indicating that the reset is correct.

3 seconds later, the thermostat is ready for commissioning by qualified HVAC staff.

11 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 12

A6V11282546A0

0

Siemens

Applications

RDF880KN… thermostats are for VRF HMI and heating applications.

Configure or changing parameter settings during commissioning using one of the

following tools:

- Local HMI

- Synco ACS

- ETS4/5

Connect tool

Note:

Connect the Synco ACS or ETS tools to the KNX bus cable at any point for

commissioning:

KNX

Siemens

L

X1 M X2

N Q12

Q11 Q14

RDF880KN...

CE+ CE-

ETS

RS232

N148 /

UP146 /

UP152

ETS / ACS

OCI700

or

OCI702

ACS and ETS4/5 require an interface:

- RS232 KNX interface (such as Siemens N148 / UP146 / UP152)

- OCI700 or OCI702 USB-KNX interface

An external KNX bus power supply is required if an RDF880KN/NF is connected

directly to a tool (ACS or ETS4/5) via KNX interface.

12 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 13

Setting parameters

Service level p arameters

Name Factory setting Range Resolution

Service level

Parameter

P02 User operating mode

profile (mode button)

P05 Sensor calibration (intern,

extern)

P06 Standard temperature

display

P08 Comfort setpoint 21 °C P9 to P10 0.5 K

P09 Minimum setpoint in

Comfort mode

P10 Maximum setpoint in

Comfort mode

P11 Economy heating setpoint 15 °C OFF, 5…40 °C 0.5 K

P14 Keylock function 0 0 = Unlock

P16 Buzzer function ON = Enable OFF = Disable

P22 Internal r.h. sensor ON = Enable OFF = Disable

P23 Calibration internal r.h

sensor

P27 Operating mode settings

after power failure or reset

P28 Timer with delay Off OFF = Disable OFF = Disable (do not display Delay

P29 User level password 0000 0000 - 9999

1 = Auto - Comfort Protection

0 K -5 K…+5 K 0.5 K

0 = Room Temperature or

Relative Humidity

5 °C 5…P10

35 °C P09…40 °C

0% ±20% 1%

0 = Return to Previous

Operating Mode / User

Settings

1 = Auto - Comfort - Protection

2 = Auto - Comfort - Economy Protection

0 = Room Temperature or Relative

Humidity

1 = Setpoint for Room Temperature

0.5 K

(P10 = 40 °C max)

0.5 K

(P09 = 5 °C min)

1 = Locked

2 = Setpoint

ON = Enable

ON = Enable

0 = Return to Previous Operating

Mode / User Settings

1 = Protection Mode

1 hour

Timer Mode symbol)

ON = Enable (display Delay Timer

Mode symbol)

Note: Parameter display depends on the selected application and function.

Expert level parameters with diagnostics and test

Name Factory setting Range Resolution

Expert level

Parameter

P30 P-band / Switching

diff erential in heati ng mode

P38 Functionality of X1 0 = --- no function 0 = --- (no function)

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

1 K 0.5…6 K 0.5 K

1 = Room temp ext / Return temp

(AI)

3 = Window open detection (DI)

6 = Fault input (DI)

7 = Monitor input [Digital]

8 = Monitor input [Temp]

13 / 24

Page 14

Name Factory setting Range Resolution

Expert level

Parameter

P39 Operating action of X1 if

digital input

0 = Normally open / Open 0 = Normally open / Open

1 = Normally closed / Close

P40 Functionality of X2 0 = --- no function 0 = --- (no function)

1 = Room temp ext / Return temp

(AI)

3 = Window open detection (DI)

6 = Fault input (DI)

7 = Monitor input [Digital]

8 = Monitor input [Temp]

P41 Operating action of X2 if

digital input

P48 Minimum output on time 2-

0 = Normally open / Open 0 = Normally open / Open

1 = Normally closed / Close

1 min. 1…20 minutes 1 min.

position control output

P49 Minimum output off time 2-

1 min. 1…20 minutes 1 min.

position control output

P51 Floor heat limit

OFF OFF, 10…50 °C 1 K

temperature

P53 Fan speed 3 = 3-speed 1 = maximum 1-speed

2 = maximum 2-speed

3 = maximum 3-speed

4 = maximum 4-speed

5 = maximum 5-speed

6 = maximum 6-speed

7 = maximum 7-speed

P54 Fan Swing Position 0 = Swing function is not

available

0 = Swing function is not available

1 = Maximum 1 Position

2 = Maximum 2 Positions

3 = Maximum 3 Positions

4 = Maximum 4 Positions

5 = Maximum 5 Positions

6 = Maximum 6 Positions

7 = Maximum 7 Positions

8 = Maximum 8 Positions

9 = Maximum 9 Positions

10 = Maximum 10 Positions

P65 Protection heating setpoint 8 °C OFF, 5…40 °C 0.5 K

P68 Prolong Comfort period 0: OFF 0: OFF

1 min

1…360 min

P69 Temporary setpoint

comfort (see also comfort

OFF = Disable OFF = Disable

ON = Enable

basic setpoint)

P71 Reload factory setting OFF = Disable OFF = Disable

ON = Reload factory setting

Reload starts only after exits

parameter mode.

P81 Device address 255 1…255 1

P82 Geographical zone

(apartment)

--(out of service)

---, 1…126 1

P83 Geographical zone (room) 1 ---, 1…63 1

14 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 15

Name Factory setting Range Resolution

Diagnostics and

Expert level

Parameter

P84 Heat distr. zone heating

coil

P88 Substitution for PreComfort

(from BUS)

P98 Chinese text display

enable

---

---, 1…31 1

(out of service)

0 = Economy 0 = Economy

1 = Comfort

0: Disable 0: Disable

1: Enable

P99 Installer Level Password 9999 5000 - 9999

Name Factory setting Range Resolution

Parameter

test

d01 Application no Diagnose 0 = --- (No application)

1 = Floor Heating only

2 = VRF only

3 = VRF and Floor Heating

d02 X1 status Diagnose

(display values according

to the selected function of

X1:

DI, AI, HC changeover,

0 = Not activated (for DI)

1 = Activated (DI)

0…49 °C = cur. temp. value (for AI)

00 = HC input short

100 = HC input open

etc)

d03 X2 status Diagnose

(display values according

to the selected function of

X2:

DI, AI, HC changeover,

0 = Not activated (for DI)

1 = Activated (DI)

0…49 °C = cur. temp. value (for AI)

00 = HC input short

100 = HC input open

etc)

d07 Software version

Show Ux.xx

d11 Floor Heating NC Output

Status (Q12)

d12 Floor Heating NO Output

Status (Q14)

Diagnose OPE = OPEN

CLO = CLOSE

Diagnose OPE = OPEN

CLO = CLOSE

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

15 / 24

Page 16

Control parameters

KNX communications

The thermostat's control parameters can be set to ensure optimum performance of

the entire system (refer to basic documentation CE1P3174).

The parameters can be adjusted using

- Local HMI

- Synco ACS

- ETS4/5

For commissioning via local HMI, refer to user manual A6V11272225 for setting the

passwords.

Control sequence

Calibrate sensor

Setpoint and range

limitation

Programming mode

Assign KNX device

address

· Only heating sequence is available.

· Recalibrate the temperature sensor if the room temperature displayed on the

thermostat does not match the room temperature measured (after min. 1 hour of

operation). To do this, change parameter P05.

LCD display Parameter Range Factory setting

Sensor Calibration

-5…5 K

0 K

· We recommend to review heating setpoint and their range limitation via

parameters P08…P11. If necessary, adjust them to achieve maximum comfort

and save energy.

The programming mode helps identify the thermostat in the KNX network during

commissioning.

Touch and hold for more than 5 seconds to activate programming mode, which

is indicated on the display with Pr09. Programming mode remains active until

thermostat identification is complete.

Assign device address (P81) via HMI, ACS or ETS4/5.

With device address set to 255, the communication is deactivated (no exchange of

process data).

Assign KNX group

addresses

KNX serial number

S-mode

LTE mode

16 / 24

Use ETS4/5 to assign the KNX group addresses of the RDF communication

objects.

Each device has a unique KNX serial number inside the front panel. An additional

sticker with the same KNX serial number is enclosed in the packaging box. This

sticker is intended for installers for documentation purposes.

The RDF880KN… room thermostats support communications as per KNX

specification.

- S-mode: Standard mode; engineering using group addresses.

- LTE mode: Logical Tag Extended mode, for easy engineering, used in

conjunction with Synco.

· This mode corresponds to KNX communications. Connections are established

via ETS by assigning communication objects to group addresses.

· LTE mode is specifically designed to simplify engineering. In contrast to S-mode,

there is no need to create individual connections (group addresses) in the tool.

The devices establish connections autonomously.

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 17

KNX S-mode communication object

Obj. Obje ct N am e Function Type Length CRWTU

4 Fault informati on alarm info 219.001 6 bytes CT

5 Fault state faulty/normal 1.005 1 bit CT

6 Fault transmission enable/disable 1.003 1 bit CWU

Room op eratin g mode:

7

Preselection

Room op eratin g mode:

8

Preselection Auto

Room op eratin g mode:

9

Presele ction Comfort

Room op eratin g mode:

10

Preselection Economy

Room op eratin g mode:

11

Preselection Protection

Room op eratin g mode:

12

Time switch

Room op eratin g mode:

13

Time sw itch Com fort

Room op eratin g mode:

14

Time switch Economy

Room op eratin g mode:

15

Time switch Protection

Room op eratin g mode:

16

State

Room op eratin g mode:

17

State Comfort

Room op eratin g mode:

18

State Economy

Room op eratin g mode:

19

State Prote ction

Room op eratin g mode:

20

Window state

21 Room temp erature

Room temp: Comfort

22

basic setpoint

Room temp: Comfort

23

setpoint

Room temp: Current

24

setpoint

Heating output

25

primary

VRF Operating Mode:

31

State

33*)Fan operation

HVAC mode

switch 1.001 1 bit CW

switch 1.001 1 bit CW

switch 1.001 1 bit CW

switch 1.001 1 bit CW

HVAC mode

switch 1.001 1 bit CW

switch 1.001 1 bit CW

switch 1.001 1 bit CW

Comfort

Economy

Protection

switch 1.001 1 bit CT

switch 1.001 1 bit CT

switch 1.001 1 bit CT

open/c lose 1.019 1 bit CWU

temp erature

value (°C)

temp erature

value (°C)

temp erature

value (°C)

temp erature

value (°C)

percentage

(0..100% )

HVAC

control mode

switch

20.102 1 byte CWTU

20.102 1 byte CWU

20.102 1 byte CRT

9.001 2 byt es CRT

9.001 2 byt es CWU

9.001 2 byt es CWTU

9.001 2 byt es CRT

5.001 1 byte CRT

20.105 1 byte CWU

1.001 1 bit CRWTU

Descriptions / Selections:

visibility depends on DIP switch setting

CONTROL: all D IP switch Settings

It is a command to send out common ala rm output in alarm numbers/codes.

CONTROL : all DIP switch S ettings

It is a command to set the alarm flag if an alarm occ urs.

STATU S: all DIP sw itch Settings

A value (enable o r disable) is received f rom a supervisory alarm system to enable

or disable the b roadcasting of alarms by the devices. This has no impac t on the

local display of alarms. The sending of faults/alarms will be enabled automatically

after time out (48 hours).

CONTROL/STATU S: use for DIP switch Setting à 1: UFH, 3: BOTH

To change or to receive the room operating mode select ion via the bus.

Note: The thermostat will switch from Precomfort to Economy or Comfort mode

(selectable via P88).

STATUS: use fo r DIP switch Setti ng à 1: UFH, 3: BOTH

The value is received to switch the room operating mode to Auto, Comfort,

Economy or Protection.

STATUS: use fo r DIP switch Setti ng à 1: UFH, 2: VRF

A time schedule defining the required operating modes is provided by a cent ral

time switch or a supervisor.

Protection mode ha s the highest priorit y and cannot be overridden. (also refe r to

P88 - P recomfo rt à Economy or Comfort)

STATUS: use fo r DIP switch Setti ng à 1: UFH, 2: VRF

The value is received to switch the room operating mode to Auto, Comfort,

Economy or Protect ion according to a time schedule provided by a central time

switch or a sup ervisor.

CONTROL: use f or DIP switch Setting à 1: UFH, 3: BOTH

It is a command to set the operating mode to Comfort, Economy or Protection

depending on user selection, windo w contact, etc.

CONTROL: use f or DIP switch Setting à 1: UFH, 3: BOTH

it is a command to s witch the room operating mode to Comfort, Economy or

Protection.

STATUS: all DIP switch Settings

A value “1” (ope n) is received to set ope rating mode t o Protection (UFH) or Off

(VRF) i.e. UFH to Protection, VRF to Off.

A value “0” (close) is received to switch bac k to the previous operating mode

"Window state" is recei ved from a KNX control device or via the local window

contac t X1, X2 (P38, P 40).

Note: Only one input source must be used, eit her local input X 1/X2 or KNX bus.

CONTROL: all D IP switch Settings

It is a command to send out the current room temperat ure measured using builtin or external sensor (via X1 or X2).

STATUS: all DIP switch Settings

If temporary setpoint function is enabled (P69=ON), after any operating mode

changes, the setpoint will be reset to the C omfort ba sic setpoint.

Note: User setpoint via the local HMI may be overwritten du ring a system startup

from a central cont rol unit, e.g. RMB795B.

CONTROL/STATUS: all DIP switch Settings

Communication object is used to shift the setpoint for the thermostat. Same

priority as local setpoint shift on the thermostat.

Note: The Comf ort basic setpoint (objec t 22) is not changed.

CONTROL: all D IP switch Settings

It is the command to send out f or the current setpoint under c urrent operating

mode, including shift, compensation, etc., used by the thermostat for room

temp erature co ntrol.

CONTROL: use f or DIP switch Setting à 1: UFH, 3: BOTH

It is a command to send out to i ndicate the current position of the heating

actuator when UFH is act ive.

STATUS: all DIP switch Settings

The value of the V RF operating mode is set by a KNX control device.

0 - Auto; 1 - Heat ; 3 - Cool; 9 - Fan; 1 4 - Dry

CONTROL/STATU S: use for DIP switch Setting à 2: VRF

It is a command to set the current f an mode to the VRF: Auto ( 0); Manual (1).

17 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 18

Obj. Object N am e Function Type Length CRWTU

Fan speed:

35

preselection

36 Fan speed

37 Fan speed status

38 VRF Operating Mode

39 X1: Temperatu re

41 X2: Tem perature

40 X1: Digital switch 1.001 1 bit C RT

42 X2: Digital switch 1.001 1 bit C RT

43 Contr ol on/of f switch 1.001 1 bit C RT

Contr ol vane up /dow n

44

positi on

Contr ol vane up /dow n

45

swing

46 Contr ol eco mode start/stop 1.01 1 bit CRT

47 Status on/off Switch 1.00 1 1 bit CWU

Status vane up/d own

48

positi on

Status vane up/d own

49

swing

50 Sta tus ec o mode Switch 1.001 1 bit CWU

51 Room relative humidity Humidity % 9.007 2 bytes CRT

Room temp: Economy

53

heating setpoint

Application selection:

55

State

Sub application:

56

Preselection

Sub application:

57

State

C: Communication; R: Read; W: Write; T: Transmission; U: Update

Notes: The current RDF880KN/NF is based on a Floor Heating Controller with additional VRF HMI. Therefore, to turn on the controller, effectively, it is to turn on the UFH application.

1. In a UFH application selected via DIP switch setting or remote configuration, the operations are identical to RDD810KN/NF while all VRF relevant S-mode objects are invisible.

2. In a VRF application selected via DIP switch setting or remote configuration, UFH application will not be turned ON remotely via any KNX control devices or locally via HMI.

3. In a combined application (both UFH and VRF) selected via DIP switch setting or remote configuration, the object Sub Application (56, 57) can be used by any KNX control devices

to do remote selection of applications (UFH only, VRF only or UFH & VRF) required. But the objects: Time Switch/Schedule (12, 13, 14, and 15) or ECO mode (10, 18) via any KNX

control devices remotely will turn on/off both VRF and UFH. Therefore, it is not recommended to use objects: Time Switch/Schedule (12, 13, 14, and 15) or ECO mode (10, 18).

*) If object Fan operation (33) is used together with object Fan speed (36), the value “0 – Auto” of object Fan speed (36) cannot be used. If these two objects are not used together, the

value “0 – Auto“ can be used.

percentage

(0..100% )

counter pulses

(0..255)

counter pulses

(0..255)

HVAC

control mode

temp erature

value (°C)

temp erature

value (°C)

counter pulses

(0..255)

boolean 1.002 1 bit CRT

counter pulses

(0..255)

boolean 1.002 1 bit CWU

temp erature

value (°C)

counter pulses

(0..255)

counter pulses

(0..255)

counter pulses

(0..255)

5.001 1 byte CRWTU

5.010 1 byte CRT

5.010 1 byte C WU

20.105 1 byte CRT

9.001 2 byt es CRT

9.001 2 byt es CRT

5.010 1 byte CRT

5.010 1 byte C WU

9.001 2 byt es CWU

5.010 2 byt es CR

5.010 1 byte CRT

5.010 1 byte C WU

Descriptions / Selections:

visibility depends on DIP switch setting

CONTROL/STATU S: use for DIP switch Setting à 2: VRF

It is a command to set the fan speed (ECM) – d epends on value of P53.

e.g. if P53 = 3, indicates the curre nt fan speed as a value 0...100%

Speed Fan output (physical KNX value)

OFF 0% (0)

1 33% (84 )

2 66% (186)

3 100% (255)

CONTROL: use f or DIP switch Setting à 2: VRF

It is a command to set the fan speed – depe nds on value of P53.

0 – Auto; 1 - Speed 1; 2 - Speed 2; 3 - Speed 3;4 - Speed 4; 5 - Speed 5; 6 - Speed

6; 7 - Speed 7

STATUS: use fo r DIP switch Setti ng à 2: VRF

The value of fan speed received will be set and displayed on HMI.

Speed depends on va lue of P53:

0 – Auto; 1 - Speed 1; 2 - Speed 2; 3 - Speed 3;4 - Speed 4; 5 - Speed 5;

6 - Speed 6; 7 - Speed 7

CONTROL: use f or DIP switch Setting à 2: VRF

It is a command to set the VRF ope rating mode fo r VRF equipme nt.

0 - Auto; 1 - Heat ; 3 - Cool; 9 - Fan; 1 4 - Dry

CONTROL: all D IP switch Settings

Indicate the va lues of the temperature sensors connected t o the local inputs

X1/X2 ( P38/P40).

CONTROL: all D IP switch Settings

Indicates the logic state of the digital i nputs (P39 for X1, P41 for X2).

CONTROL: use f or DIP switch Setting à 2: VRF

It is a command t o turn on and off the VR F equipment.

0 - Of f; 1-On

CONTROL: use f or DIP switch Setting à 2: VRF

It is a command to set the vane position of the VRF equipment.

0 – Auto; 1 - Pos 1; 2 - Pos2; 3 - Pos3; 4 - Pos4; 5 - Pos5; 6 - Pos6; 7 - Pos7; 8 - Pos8;

9 - Pos9; 10 - P os10

CONTROL: use f or DIP switch Setting à 2: VRF

It is a command to set the vane to a stop po sition or auto swi ng.

The vane position depends on the object, Control vane up/down position ( 44).

0 - Stop; 1 – Swing

CONTROL: use f or DIP switch Setting à 2: VRF

It is a command t o enable or disable the EC O mode of the VRF equipm ent.

0 - Stop; 1 – Sta rt

STATUS: use fo r DIP switch Setti ng à 2: VRF

A value is received from a KNX control device to turn on and off t he VRF

equipment. 0 - Off; 1-On

STATUS: use fo r DIP switch Setti ng à 2: VRF

A value is received from a KNX control device to set the vane po sition of the VRF

equipment.

0 – Auto; 1 - Pos 1; 2 - Pos2; 3 - Pos3; 4 - Pos4; 5 - Pos5; 6 - Pos6; 7 - Pos7; 8 - Pos8;

9 - Pos9; 10 - P os10

STATUS: use fo r DIP switch Setti ng à 2: VRF

A value is received from a KNX control devic e to set the vane of t he VRF

equipment to stop or a uto swing. 0 - Stop; 1 – Swing

STATUS: use fo r DIP switch Setti ng à 2: VRF

A value is received from a KNX control device to set the VRF equipme nt in ECO

mode. 0 - Off; 1-On

CONTROL: all D IP switch Settings

It is the command to send out f or the current value of relative humidity.

STATUS: all DIP switch Settings

A value is received from a KNX control device to upda te parameter P11.

CONTROL : all DIP switch Settings

A value is required to be read out from RDF880KN/NF for the current DIP SW

setting. Refer to d ip switch position select ion.

1 - UFH only; 2 - VRF only; 3 - both VR F & UFH

CONTROL: use f or DIP switch Setting à 3: BOTH

It is a command to send out for the current sub selection below within a combined

UFH and VRF/VRF unit.

1 - UFH only; 2 - VRF only; 3 - both VR F & UFH

STATUS: use fo r DIP switch Setti ng à 3: BOTH

A value is received from a KNX control device f or the current sub selection below

within a combined UFH and VRF/VRF unit.

1 - UFH only; 2 - VRF only; 3 - both VR F & UFH

18 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 19

Disposal

The device is considered electrical and electronic equipment for disposal in terms of

the applicable European Directive and may not be disposed of as domestic garbage.

· Dispose of the device through channels provided for this purpose.

· Comply with all local and currently applicable laws and regulations.

19 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 20

Technical data

Power supply

Rated voltage AC 230 V

Overvoltage category III

Frequency 50/60 Hz

Power consumption Max. 6.0 VA / 2.1 W

Caution

No internal fuse.

External preliminary protection with max C 10 A circuit breaker required in all cases.

Outputs Control output Q11, Q12, Q14 (SPDT)

Rating Min, Max resistive (inductive)

Caution

No internal fuse.

External preliminary protection with max C 10 A circuit breakers in the supply line

(Q11) required in all cases.

Inputs Multifunctional input X1-M/X2-M

Temperature sensor input:

Type

Temperature range

Cable length

Digital input:

Operating action

Contact sensing

Parallel connection of several thermostats

for one switch

Insulation against mains voltage (SELV)

AC 24…230 V

Min. 10 mA, Max. 5(2) A

See “Equipment combinations”

0...49 °C

Max. 80 m

Selectable (NO / NC)

SELV DC 0...5 V / Max. 5 mA

Max. 20 thermostats per

switch

4 kV, reinforced insulation

Function of inputs:

External temperature sensor, window contact, fault

contact, monitoring input

Selectable

X1: P38

X2: P40

KNX bus Interface type KNX, TP1-64

(electrically isolated)

Bus current 5 mA

Bus topology: See KNX manual (Reference documentation, see below)

Operational data Switching differential, adjustable

Heating mode (P30) 1 K (0.5...6 K)

Setpoint setting and range

Comfort (P08)

Economy (P11)

Protection (P65)

Multifunctional input X1/X2

Input X1 default value (P38)

Input X2 default value (P40)

21 °C (5...40 °C)

15 °C (OFF, 5...40 °C)

8 °C (OFF, 5...40 °C)

Selectable 0, 1, 3, 6, 7, 8

0 (no function)

0 (no function)

Built-in room temperature sensor

Measuring range

Accuracy at 25 °C

Temperature calibration range

0…49 °C

< ± 0.5 K

± 5.0 K

Settings and display resolution

Setpoints

Current temperature value displayed

0.5 °C

0.5 °C

Built-in room humidity sensor

Measuring range

Accuracy at 25 °C

Humidity calibration range

0…100%

± 5% r.h.

± 20%

Settings and display resolution

Display resolution

1% r.h.

20 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 21

Environmental

2

conditions

Operation

Climatic conditions

Temperature

Humidity

Transport

Climatic conditions

Temperature

Humidity

Mechanical conditions

Storage

Climatic conditions

Temperature

Humidity

As per IEC 60721-3-3

Class 3K5

0...50 °C

<95 % r.h.

As per IEC 60721-3-2

Class 2K3

-25... 65 °C

<95 % r.h.

Class 2M2

As per IEC 60721-3-1

Class 1K3

-25...65 °C

<95 % r.h.

Standards and

directives

EU Conformity (CE) A6V11350285

Electronic control type 2.B (micro-disconnection on

*)

operation)

RCM conformity to EMC emission standard

A6V11350287

Safety class II as per EN 60730

Pollution class Normal

Degree of protection of housing IP 30 as per EN 60529

Environmental

compatibility

The product environmental declaration E3174en contains data on environmentally

compatible product design and assessments (RoHS compliance, materials

composition, packaging, environmental benefit, disposal).

Eco design and

labelling directives

Based on EU Regulation 813/2013 (Eco design directive) and 811/2013 (Labelling

directive) concerning space heaters, combination heaters, the following class apply:

- Application with On/Off operation of a heater

Class I value 1%

General Connection terminals Solid wires or prepared

stranded wires

1 x 0.4…1.5 mm2 or

2 x for KNX cables/sensor

Minimal wiring cross section on L, N, Qxx Min 1.5 mm

Housing front color Ivory White

Weight without / with packaging 0.145 kg / 0.245 kg

*)

The documents can be downloaded from http://siemens.com/bt/download.

Reference

documentation

Handbook for Home and Building Control - Basic Principles

(http://www.knx.org/knx-en/training/books-documentation/knx-association-books/index.php)

Synco CE1P3127 Communication via the KNX bus for Synco 700, 900 and RXB/RXL

Basic documentation

Desigo CM1Y9775 Desigo RXB integration – S-mode

CM1Y9776 Desigo RXB / RXL integration – individual addressing

CM1Y9777 Third-party integration

CM1Y9778 Synco integration

CM1Y9779 Working with ETS

21 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 22

Connection terminals

3171A01

-

3171A12

L X1M

N

SELV

Q11 Q14 Q12

X2

Connec tion diagr a m s

CE+ CE

L, N Operating voltage AC 230 V

Q11, Q12 NC contact (for NO valves)

Q11, Q14 NO contact (for NC valves)

X1, X2 Multifunctional input for temperature sensor or potential-

free switch

Factory setting:

– X1 = Window contact

– X2 = External sensor

(function can be selected via parameter P38 / P40)

M Measuring neutral for sensor and switch

CE+ KNX data +

CE- KNX data -

L

10 A

S1

B1

S2

B2

KNX

N1 Room thermostat

V1 Valve actuator

Lx AC 24...230 V

S1, S2 Switch (keycard, window contact, presence detector,

etc.)

L

X1

X2

M

CE+ CE-

B1, B2 Temperature sensor (return air temperature,

external room temperature, changeover sensor, etc.)

Q11 Q 14 Q12

N

AC 230 V

10 A

5(2)A

V1

Lx

N

Max.

N1

CE+ KNX data +

CE- KNX data –

22 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 23

Dimensions (mm)

RDF880KN/NF

for square conduit

boxes on ly

23 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Page 24

www.siemens.com/buildingtechnologies

ARG800.1 single

mounting frame for

RDF880KN/NF

Issued by

Siemens Switzerland Ltd.

Building Technologies Division

International Headquarters

Theilerstrasse 1a

CH-6300 Zug

Tel. +41 58 724 2424

24 / 24

Siemens RDF880KN … A6V11282546_en--_a

Building Technologies Touch Screen Flush- mount Room Thermostats with KNX Communications 2018-04-19

Technical speci fic ati ons and availabi lit y su bjec t to chan ge with out n otice.

© Siemens Switzerland Ltd., 2018

Loading...

Loading...