Page 1

058

3

RDF210, RDF210.2, RDF210/IR, RDF210.2/IR

Room Temperature

Controllers with LCD

with 7-day time program

for 2-pipe fan coil units

for use with compressors in DX type equipment

RDF210…

N3058en

10.01.2006

Output for on / off valve actuator or 1-stage compressor

Operating modes: Normal operation, Auto Timer (energy saving) and Standby

3-speed fan control: Automatic or manual

8 programmable timers

Adjustable commissioning and control parameters

Optional display of room temperature or setpoint

Minimum and maximum setpoint limitation

Operating voltage AC 230 V

Additional features of RDF210

Automatic heating / cooling changeover

Input for heating / cooling changeover or return air temperature sensor

Additional features of RDF210.2

Manual heating / cooling changeover

Optional

Infrared remote control (RDF210/IR, RDF210.2/IR)

Building Technologies

HVAC Products

Page 2

Use

Functions

For controlling the room temperature in individual rooms and zones that are

• heated or cooled with 2-pipe fan coil units

• cooled with a single compressor in DX type equipment

The controller controls

• a 3-speed fan

• either a valve actuator in a 2-pipe system, or

• a 1-stage compressor in DX type equipment

Suitable for use in systems with

• automatic heating / cooling changeover (RDF210)

• continuous heating or cooling mode (RDF210)

• manual heating / cooling changeover (RDF2110.2)

• Changeover between heating and cooling mode is either automatic by a QAH11.1

changeover cable temperature sensor or manually

• Maintenance of room temperature either with integrated temperature sensor or external room / return air temperature sensor (only with RDF210)

• Selection of operating mode with the operating mode button

AUTO

or on the

controller

• 8 programmable timers for changing over between Normal operation and Energy

Saving mode

• 3-speed fan control (automatic or manual)

• Output for 2-position (on / off) valve actuator or 1-stage compressor

• Optional with infrared remote control (only with RDF210…/IR)

Controller

Temperature control

Display

The controller acquires the room temperature via its built-in sensor and maintains the

setpoint by delivering 2-position valve control commands or compressor output commands. With the RDF210, an external room temperature sensor (QAA32) or external

return air temperature sensor (QAH11.1) can be used instead.

The switching differential is 2 K in heating mode and 1 K in cooling mode (adjustable

via parameters P08 and P09).

The display shows the acquired room / return air temperature or the setpoint of the

current operating mode. This can be selected via parameter P18. Factory setting is

display of the current room temperature.

The heating

and cooling symbols on the display show the status of the fan coil.

This means that the symbols are also shown while the controller operates in the neutral

zone.

If required, room temperature and setpoint can also be displayed in °F in place of °C by

changing parameter P17.

2/15

Building Technologies Room Temperature Controllers N3058en

HVAC Products 10.01.2006

Page 3

Operating modes

Y

Y

The following operating modes are available:

Normal operation

Tip!

Auto Timer mode

Energy Saving mode

Standby

Avoiding damage

due to moisture

In Normal operation, the controller maintains the setpoint, which can be adjusted via

the

buttons. The fan can be set to automatic or manual fan speed: Low, medium

or high.

The setpoint setting range can be limited to a minimum (P05) and maximum (P06). This

helps prevent the waste of energy, thus saving costs.

In Auto Timer mode

AUTO

, the controller will automatically change over between Normal

operation and Energy Saving mode according to the 8 preprogrammed timers. The

AUTO

display shows the Auto Timer mode symbol

currently maintained, either Normal operation

and the symbol of the operating mode

or Energy Saving mode

.

The setpoints of Energy Saving mode can be adjusted via control parameters

P01 and P02.

The default fan speed in Auto Timer mode is automatic fan.

When the controller is in Standby mode

, the relevant setpoints of heating or cooling

are maintained. These setpoints can be adjusted via control parameters P03 and P04.

Factory setting of both setpoints is OFF, which means that the controller is not activated when in Standby mode.

To avoid damage due to moisture in very warm and humid climatic zones resulting from

lack of air circulation in Energy Saving mode, the fan can be kept running all the time

(e.g. in apartments or shops during unoccupied periods), when setting parameter P20

“ON in dead zone”. In this case, the fan keeps running at minimum fan speed 1.

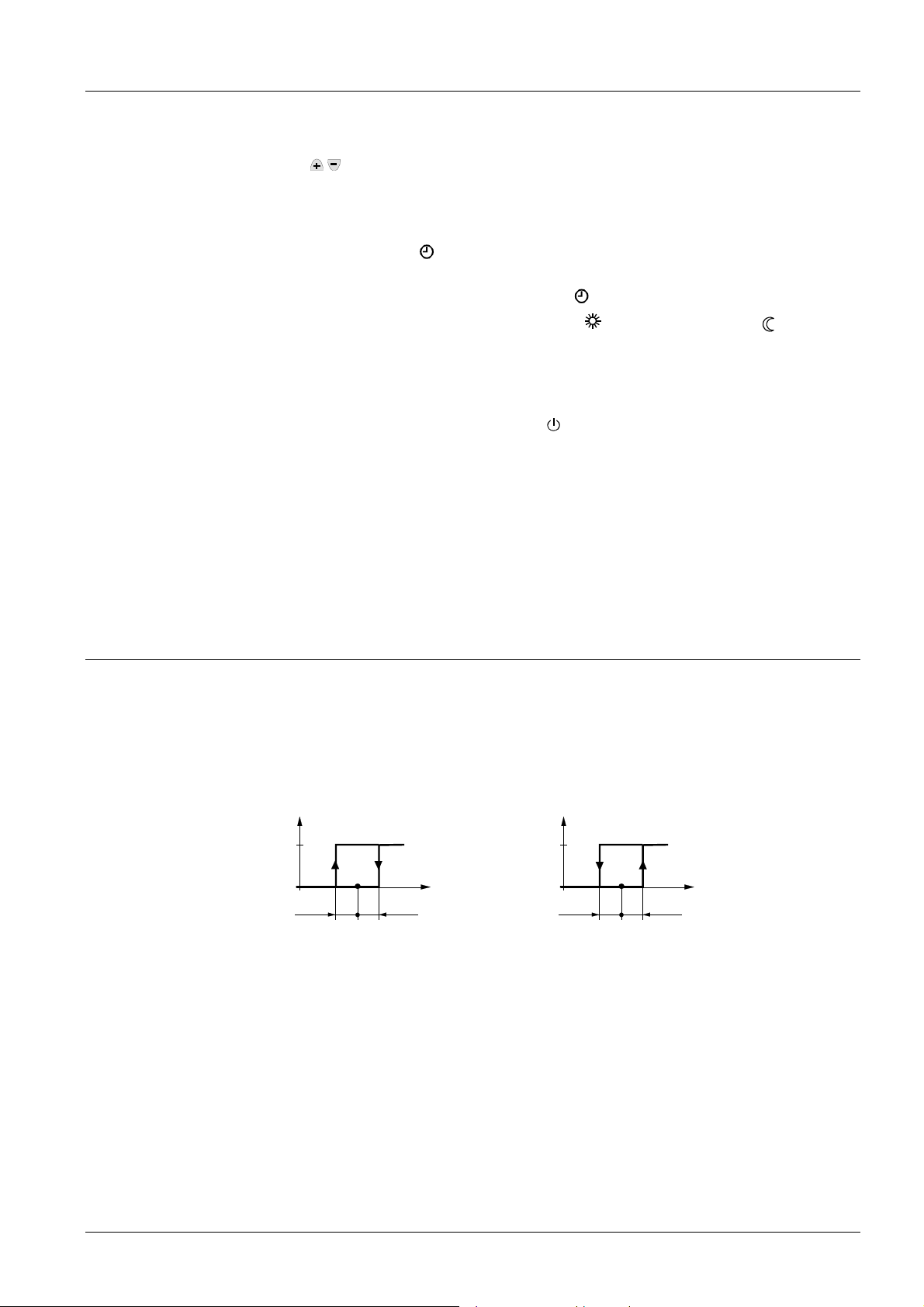

Control sequences

Water-based fan coil

application

Compressor based

application

ON

OFF

Used in conjunction with a valve, either for heating / cooling with changeover, heating

only or cooling only.

Used in conjunction with a 1-stage compressor for cooling only or heating only.

Heating mode Cooling mode

11

3058D01

1

0

½ SDH

T[°C] Room temperature SDH Switching differential “Heating”

W Room temperature setpoint SDC Switching differential “Cooling”

Y11 Control output “Valve” or “Compressor”

w

T[°C]

½ SDH

11

1

0

½ SDC

3058D02

w

T[°C]

½ SDC

The valve or compressor receives the OPEN command via control output Y11 when

1. the acquired room temperature lies by half the switching differential below the set-

point (heating mode) or above the setpoint (cooling mode), and

2. control output Y11 was not energized for more than the “Minimum output off time”

(factory setting 1 minute, adjustable via parameter P16)

The valve or compressor receives the CLOSE command via control output Y11 when

1. the acquired room temperature lies by half the switching differential above the set-

point (heating mode) or below the setpoint (cooling mode), and

3/15

Building Technologies Room Temperature Controllers N3058en

HVAC Products 10.01.2006

Page 4

2. control output Y11 was energized for more than the “Minimum output on time”;

(factory setting 1 minute, adjustable by parameter P15)

Note: Control output Y12 delivers a control command which is inverted to the control

command at output Y11 and which can be used for normally open valves.

Heating / cooling

mode

Minimum output

on time / off time Y11

Fan operation

With the RDF210, the changeover between cooling and heating takes place either

automatically via a heating / cooling changeover sensor or a remote changeover

switch. If the controller was set to ”Cooling only” or ”Heating only”, changeover will not

be possible (parameter P22, factory setting ”Cooling only”).

With the RDF210.2, when pressing the heating / cooling changeover button

, the

controller will change from heating to cooling, or vice versa.

The minimum output on time and off time of Y11 can be adjusted from 1…10 minutes

via parameters P15 and P16. Factory setting is 1 minute. In this case, any readjustment

of the setpoint or of heating / cooling mode changeover will be used immediately for

computing the output status and output Y11 may not hold the minimum on / off time of

1 minute.

If parameter P15 or P16 is set to a level above 1 minute, the minimum on / off time of

Y11 will be maintained as set, even if the setpoint or changeover mode has been readjusted.

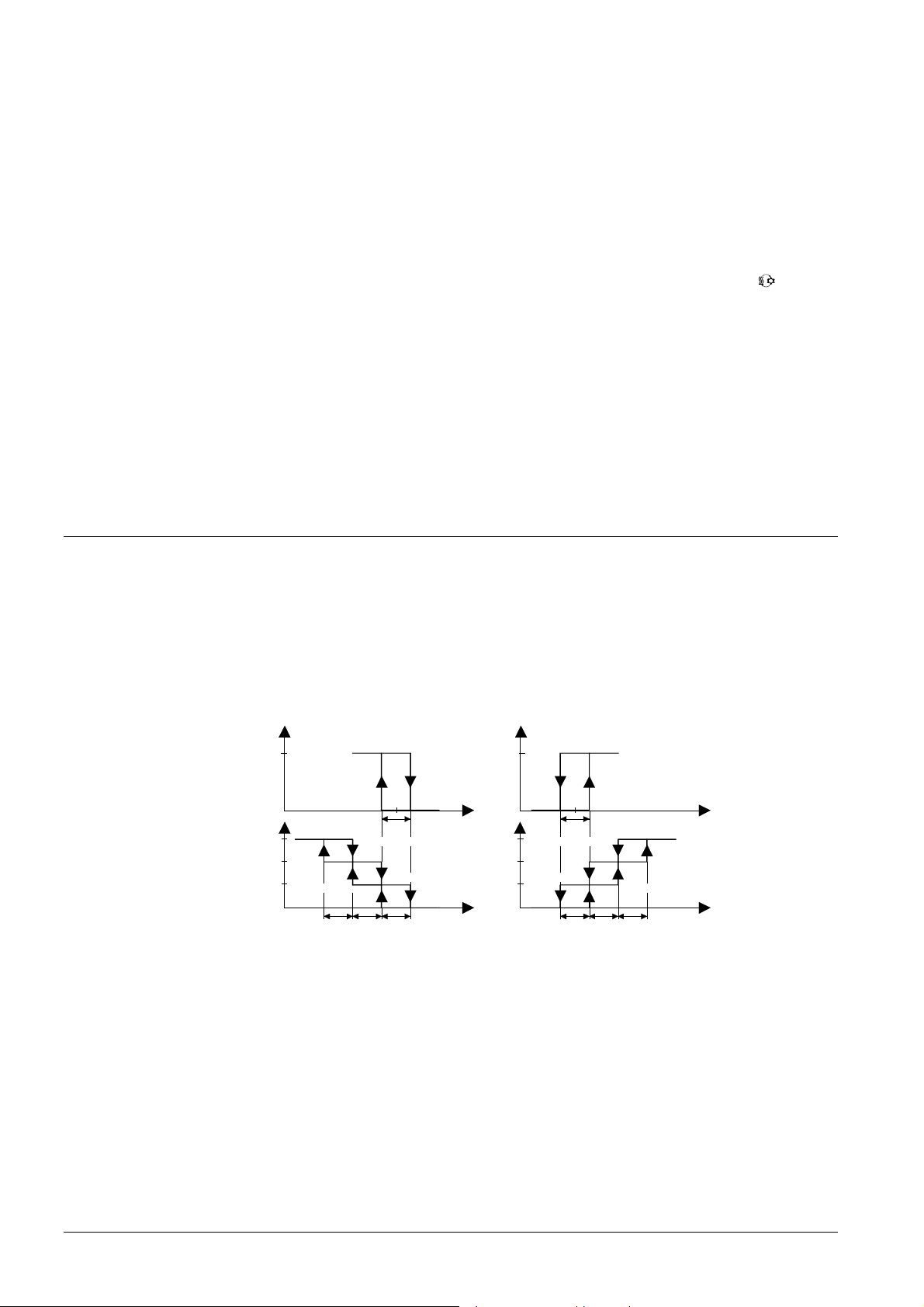

The fan operates either in automatic mode or at the selected speed when using manual

mode. In automatic mode, the fan speed depends on the setpoint and the current room

temperature. When the room temperature reaches the setpoint, the control valve will

close and the fan switch off: Temperature-dependent fan control (see diagram below).

The individual switching differentials of the fan speeds can be adjusted via control parameters P08 – P13.

Heating mode Cooling mode

Valve

Valve

Y11Y11

3058D03

Q3

Q2

Q1

Fan

SDH

SDHSDH2SDH3

W

Temp

Q3

Q2

Q1

Temp

Fan

W

SDC

Temp

Temp

SDC3SDC2SDC

Ventilation

always on

If desired, fan control can be set to ”Temperature-independent”, which means that ventilation is always on, even within the dead zone, using at least fan speed 1. This can be

selected individually for Normal operation using parameter P21 and for Energy Saving

mode using parameter P20 (also refer to “Avoiding damage due to moisture”).

Dwelling time

In automatic mode, a dwelling time of 2 minutes (factory setting) is active. The fan

maintains that speed for at least 2 minutes before it switches to the next speed. This

dwelling time can be adjusted from 1…5 minutes using parameter P14.

4/15

Building Technologies Room Temperature Controllers N3058en

HVAC Products 10.01.2006

Page 5

Fan start

Fan in Auto Timer

mode

Auto Timer

Whenever the fan starts from standstill, it starts with speed 3 for 1 second in order to

guarantee a safe fan motor start (to overcome inertia and friction)

In Auto Timer mode, the default fan mode is automatic. The fan mode can be changed

to manual fan speed. With each changeover from Normal operation to Energy Saving

mode, or vice versa, the fan will return to default mode automatic.

The controller provides an Auto Timer mode with 8 programmable timers. In this mode,

the controller will automatically change over between Normal operation and Energy

Saving mode according to the preprogrammed timers.

Setting the timers

Auto Timer during Normal operation Auto Timer during Energy Saving mode

1

AUTO

o

C

1

AUTO

o

C

Each timer has a Normal operation start time and a Normal operation end time which

can be applied to several weekdays.

To adjust the time schedule, keep the

button depressed for 3 seconds to go to

the programmable timer setting mode.

This mode is indicated by displaying Ax (x= auto timer 1...8) and the time xx:xx flashing.

For each auto timer, proceed as follows:

1. The

and symbols are displayed. Press or to adjust the Normal opera-

tion start time and confirm by pressing

.

2. The

and symbols are displayed. Press or to adjust the Normal operation

end time or Energy Saving start time respectively and confirm by pressing

.

3. Symbol

the next day. Confirm setting for actual timer by pressing

1

will flash. Press or to select or deselect each day and advance to

and advance to t

he

next timer.

5/15

Building Technologies Room Temperature Controllers N3058en

HVAC Products 10.01.2006

Page 6

View the timers

Default timer setting

The controller will leave the programmable timer setting mode if no button is pressed

within 20 seconds. All changes made after the last press of

button will not be

saved.

Press the

button to sequentially review the 8 timers.

Timers A1…A4 have the following default setting:

Reload default timer

setting

Overlapping of timer

sequences

Day/s

Time when controller is in Normal operation

Mo (1) – Fr (5) 06:30 – 08:30 (A1) 17:30 – 22:30 (A2)

Sa (6) 08:00 – 23:00 (A3)

Su (7) 08:00 – 22:30 (A4)

- During the remaining time, controller is in Energy Saving mode

- Timers A5…A8 are free, no default setting

The setting of these timers can be changed to suit individual needs. The default setting

can be reloaded any time:

1. Set the controller to Standby .

2. Press and simultaneously for 3 seconds. Release them and, within 2 seconds,

press 2 times

.

Then, the display will show “8888“ during the reloading process.

In case 2, or when several timer sequences overlap, the resulting output is the OR

combination of the normal operating mode time of all timers.

22:00

20:00

A1=09:00-22:00

12:00

09:00

7day-time clock

Setting the time clock

Power failure

A2=12:00-20:00

Resul t in g output = 09 : 0 022:00

3058D04

The 7day-time clock supports the 12-hour and 24-hour format. The format is chosen

during setting of the time clock as follows:

1. Keep the

button depressed until the time digits start to flash and then press or

to set the time of day. If the current time is the 24-hour format and you wish to

change to the 12-hour format, press

passing 23:59 or press passing 00:00.

Vice versa back to the 24-hour format.

2. Confirm the time of day by pressing

3. Press

or to set the current weekday.

4. Confirm the current weekday by pressing

and the weekday indicator starts to flash.

.

In case of a power failure, the clock will stop, but its last running time will be stored.

This time information will be reloaded and start running after a power up. The clock will

flash to indicate that there was a power failure until the time will be confirmed by pressing

or readjusted by folowing the above procedure.

6/15

Building Technologies Room Temperature Controllers N3058en

HVAC Products 10.01.2006

Page 7

External sensor input B1-M

Automatic heating /

cooling changeover

Remote heating /

cooling changeover

With the RDF210, a return air / external room temperature sensor or heating / cooling

changeover sensor can be connected to terminal B1-M. The function of this sensor

input is determined by parameter P22.

Sensor input B1-M is not galvanically separated from the AC 230 V mains supply.

Therefore, only a cable temperature sensor and wiring with sufficient insulation must be

used.

When P22 is set to “Automatic H/C changeover”, the sensor input acts to ensure automatic heating / cooling changeover. The water temperature acquired by the changeover

sensor (QAH11.1 + ARG86.3) is used to switch from heating to cooling mode, or vice

versa. When the water temperature lies above 28 °C (parameter P24), the controller

switches to heating mode; below 16 °C (parameter P23), it switches to cooling mode. If,

immediately after switching on, the water temperature lies between the 2 changeover

points, the controller will start in heating mode. The water temperature is acquired at

30-second intervals and the operating state is updated.

Automatic H/C changeover

M

CM

HM

M Operating mode CM Cooling mode

T

16 28

Water temperature HM Heating mode

w

3021D03

TW [°C]

The QAH11.1 cable temperature sensor for automatic heating / cooling changeover can

be replaced by an external switch (suited for mains voltage) for manual remote changeover:

External room or

return air temperature

sensor

Summary

B1-M and P22

Contact open Æ heating mode

Contact closed Æ cooling mode

T °C

B1

M

T

QAH11.1

B1

M

3058Z03

With parameter P99 (diagnostic value), automatic heating / cooling changeover can be

checked.

When parameter P22 is set to “Cooling only” or “Heating only”, sensor input B1-M can

be used to connect an external room temperature (QAA32) or a return air temperature

sensor (QAH11.1). Changeover is automatic if a sensor is detected at the sensor input.

With parameter P98 (diagnostic value), the sensor status can be checked.

The following table summarizes the relation between parameter P22, external sensor

B1-M and variables which the controller uses for maintaining the temperature:

Parameter

P22

Heating only

Cooling only

Automatic

H/C changeover

Variables:

The controller….

No sensor at

B1-M

is in H/C mode Heating

controls according Internal sensor

is in H/C mode Cooling

controls according to Internal sensor

is in H/C mode Heating

controls according to

Internal sensor Internal sensor

QAH11.1/QAA32 at

B1-M

Heating

Sensor at B1

Cooling

Sensor at B1

depending on the tempera-

ture from sensor B1-M

7/15

Building Technologies Room Temperature Controllers N3058en

HVAC Products 10.01.2006

Page 8

Error handling

Temperature out

of range

External sensor

failure

Infrared remote control

When the room temperature is out of the measuring range, which means above 49 °C

or below 0 °°C, the display shows the limiting temperature in flashing figures, e.g. “0 °C”

or “49 °C”.

If the current setpoint is not OFF (see parameters 1-4) and the controller is in heating

mode, and the temperature is below 0 °C, output Y11 will be energized. In all other

cases, output Y11 will be deenergized. When the temperature returns to the measuring

range, the controller will resume Normal operation.

In case of an external sensor failure (short-circuit or open-circuit), the controller will

immediately switch back to the internal sensor to ensure control.

Should both the external and internal sensor fail, the display will flash “Err” to call the

user‘s attention.

The RDF210/IR and RDF210.2/IR have an infrared receiver built in. Together with the

IRA210 infrared remote control, the following operations can be performed from a remote location:

• Selection of operating mode: Standby, Normal operation or Auto Timer

• Adjustment of setpoint in Normal operation

• Selection of fan mode: Automatic or manual fan speed

Using parameter P25, infrared remote control can be disabled.

Control parameters

Parameter settings

With the RDF210 and RDF210.2, a number of control parameters can be readjusted to

optimize the control performance. These parameters can also be set during operation

without opening the unit. In the event of a power failure, all control parameter settings

will be maintained.

The parameters can be changed as follows:

1. Set the controller to Standby

2. Press buttons

and simultaneously for 3 seconds. Release them and,

within 2 seconds, press button

.

again for 3 seconds. Then, the display will

show “P01“.

3. Select the required parameter by repeatedly pressing buttons

P25

+-

+

4. By pressing buttons

+-+

P01 P02 P22 P98

--

3057z03

-

and simultaneously, the current value of the selected

+

P99

and :

-

parameter appears, which can be changed by repeatedly pressing buttons

or

.

5. By pressing buttons

and simultaneously again or 5 seconds after the last

press of a button, the last parameter will be displayed again.

6. If you wish to display and change additional parameters, repeat steps 3

through 5.

7. 10 seconds after the last display or setting, all changes will be stored and the

controller returns to Standby.

Note:

8/15

Building Technologies Room Temperature Controllers N3058en

HVAC Products 10.01.2006

Parameters not used by the RDF210.2 are not available and cannot be displayed.

Page 9

Parameter reset

The factory setting of the control parameters can be reloaded as follows:

1. Set the controller to Standby

2. Press buttons

and simultaneously for 3 seconds. Release them and,

within 2 seconds, press operating mode selector button

.

2 times.

Then, the display will show “888“ during the reloading process.

Control parameters of the RDF210 and RDF210.2

Para-

Meaning Setting range Factory

meter

P01 Setpoint of heating in Energy Saving mode (Wheat

P02 Setpoint of cooling in Energy Saving mode (Wcool

P03

P04

Setpoint of heating in Standby

Setpoint of cooling in Standby

(Wheat

(Wcool

P05 Minimum setpoint limitation in Normal operation (Wmin

P06 Maximum setpoint limitation in Normal operation (Wmax

) OFF, 5 °C…Wcool

Eco

) OFF, Wheat

Eco

OFF, 5 °C…Wcool

)

Stb

OFF, Wheat

)

Stb

) 5 °C…Wmax

Comf

) Wmin

Comf

…40 °C 35 °C

Comf

Eco

…40 °C

Eco

Stb

…40 °C OFF

Stb

Comf

P07 Sensor calibration -3…+3 K 0 K

P08 Switching differential heating mode SDH 0.5…+4K 2 K

P09 Switching differential cooling mode SDC 0.5…+4K 1 K

P10 Switching differential fan speed 2 in heating mode SDH2 0.5…+4K 1 K

P11 Switching differential fan speed 2 in cooling mode SDC2 0.5…+4K 1 K

P12 Switching differential fan speed 3 in heating mode SDH3 0.5…+4K 1 K

P13 Switching differential fan speed 3 in cooling mode SDC3 0.5…+4K 1 K

P14 Dwelling time of auto fan speeds 1…5 minutes 2 min

P15 Minimum output on time (Y11) 1…10 minutes 1 min

P16 Minimum output off time (Y11) 1…10 minutes 1 min

P17 Selection of °C or °F °C or °F °C

OFF: Setpoint

P18

Display of temperature or setpoint

ON: Room (or return air)

temperature

P20 Fan control in Energy Saving mode

P21 Fan control in Normal operation

OFF in dead zone

ON in dead zone

OFF in dead zone

ON in dead zone

0: Heating only

P22 Heating / cooling mode

1: Cooling only

2: Automatic H/C

changeover

P23 Heating / cooling changeover switching point cooling 10…25 °C 16 °C

P24 Heating / cooling changeover switching point heating 27…40 °C 28 °C

P25 Infrared receiver (only with RDF.../IR)

P98 Active temperature sensor

0: Disabled

1: Enabled

0: Internal sensor

1: External sensor

100 = input open Æ

mode

0…49 °C = cur. temp. value

P99

Value of current heating / cooling changeover temperature

reading and indication of current mode

00 = input bridged Æ

mode

OFF= not commissioned as

automatic H/C changeover

1) Not available with RDF210.2

setting

16 °C

28 °C

OFF

5 °C

ON

OFF

OFF

1: Cooling

1)

only

1)

1)

1

Diagnostic

value

Diagnostic

1)

value

9/15

Building Technologies Room Temperature Controllers N3058en

HVAC Products 10.01.2006

Page 10

Type summary

Type reference Features

Equipment combinations

RDF210

With input for automatic heating / cooling changeover or return air

temperature sensor

RDF210.2

With manual heating / cooling changeover

Without input for sensor

(only available in AP)

RDF210/IR

RDF210.2/IR

Same as RDF210 plus infrared remote control

Same as RDF210.2 plus infrared remote control

(only available in AP)

Type of unit Type reference Data Sheet

Infrared remote control

Cable temperature sensor

Room sensor

Changeover mounting kit

Electromotoric on / off valve and actuator

Electromotoric on / off actuator

Thermal actuator (for radiator valve)

Thermal actuator (for small valves 2.5 mm)

Zone valve actuators

(only available in AP, UAE, SA and IN)

IRA210

QAH11.1

QAA32

ARG86.3

MVI…/MXI…

SFA21...

STA21...

STP21...

SUA…

1840

1747

1840

4867

4863

4893

4878

4830

Accessories

Ordering

Description Type reference

Adapter plate 120 x 120 mm for 4“ x 4“ conduit boxes ARG70

Adapter plate 96 x 120 mm for 2“ x 4“ conduit boxes ARG70.1

Adapter plate for surface wiring 112 x 130 mm ARG70.2

When ordering, please give name and type reference:

e.g. room temperature controller RDF210

The IRA210 infrared remote control is to be ordered as separate item

The QAH11.1 can be used as a return air temperature or heating / cooling changeover

sensor. In case it is used as a changeover sensor, the ARG86.3 changeover sensor

mounting kit is to be ordered as a separate item.

Valve actuators are to be ordered as separate items.

10/15

Building Technologies Room Temperature Controllers N3058en

HVAC Products 10.01.2006

Page 11

Mechanical design

The controller consists of 2 parts:

• Plastic housing which accommodates the electronics, the operating elements and the

built-in room temperature sensor

• Mounting base

The housing engages in the mounting base and snaps on.

The base carries the screw terminals.

Setting and operating

elements

Legend

3

1

AM

2

4

PM

AUTO

$

5

6

8

7

9

10

11

15

12

14

1 Display of the room temperature, setpoints and control parameters

2

Symbol used when displaying the current room temperature

3 Weekday 1..7 (1 = Monday / 7 = Sunday)

4 Current time of day

5 Standby / fan mode status

Standby mode

AUTO Auto fan active

fan speed low, medium, high

13

6

in cooling mode

in heating mode

AUTO

Auto Timer mode

7

Normal operation

Energy Saving mode

8 Buttons for adjusting the setpoints, control parameters and time of day

9 Button for changing fan operation and Standby (

)

AUTO

10 Button operating mode (

11 Button for setting time of day and weekday (

12 Manual heating / cooling changeover (

13 Auto timer program (

14 Confirmation (

)

): Normal operation / Auto Timer mode

)

) (only with RDF210.2)

AUTO

)

15 Infrared receiver (only with RDF210…/IR)

11/15

Building Technologies Room Temperature Controllers N3058en

HVAC Products 10.01.2006

Page 12

Mounting and installation

Wiring

The room controller can be mounted on a wall or inside the fan coil unit. The mounting

location on a wall should not be in niches or bookshelves, not behind curtains, above or

near heat sources and not exposed to direct solar radiation. Mounting height is about

1.5 m above the floor.

The controller can be fitted on a recessed conduit box.

When using a heating / cooling changeover sensor, then, before fitting the sensor,

thermal conductive paste must be applied to the location on the pipe where the sensor

is placed.

Also refer to the Mounting Instructions B3058 enclosed with the controller.

Commissioning

Heating / cooling mode

Compressor-based

application

Calibrating the sensor

Setpoint and range

limitation

Diagnostic values

• Wiring, fuse and earthing must be installed in compliance with local regulations. It

must be made certain that safety extra low-voltage lines (SELV circuit) are clearly

separated from AC 230 V mains voltage cable

• The cables to the controller, external sensor, fan and valves carry AC 230 V mains

voltage and must be appropriate sized

• Only sensors and valves rated for AC 230 V may be used

• The AC 230 V mains supply line must have an external fuse or circuit breaker with a

rated current of no more than 10 A

• Maximum 10 changeover contact inputs B1-M can be connected in parallel if an

external switch is used in place of a changeover sensor. The switch must be suited

for AC 230 V. The cable length must not exceed 80 m overall

After applying power, the controller makes a reset during which all LCD segments flash,

indicating that the reset has been correctly made. This takes about 3 seconds. Then,

the controller is ready for commissioning by qualified HVAC staff. The control parameters of the controller can be set to ensure optimum performance of the whole system

(also refer to “Setting the control parameters”).

• Only with RDF210: Depending on the application, the heating / cooling mode must

be set via parameter P22. Factory setting is “Cooling only”. When using the ”Automatic heating / cooling changeover” function, P22 must be set to “Automatic H/C

changeover”.

Note: When P22 is set to “Automatic H/C changeover”, the integrated sensor is

used for acquiring the room temperature

• If the controller is used in conjunction with a compressor, the minimum output on

time (parameter P15) and off time (parameter P16) of Y11 must be adjusted in order

not to harm the life time of the compressor

• If the room temperature displayed by the controller dos not accord with the room

temperature effectively measured, the temperature sensor can be recalibrated. In

that case, parameter P07 must be changed

• For comfort and energy saving reasons, it is suggested to review the setpoints and

setpoint ranges (parameters P01…P06) and, if necessary, to change them accordingly

• Only with RDF210: Parameters P98 and P99 are diagnostic values and help check

the system. With P98, the status of the active temperature sensor is shown and,

with P99, the status of the heating / cooling changeover sensor

12/15

Building Technologies Room Temperature Controllers N3058en

HVAC Products 10.01.2006

Page 13

Technical data

Power supply

Outputs

Inputs

Operational data

Environmental

conditions

Norms and standards

Operating voltage AC 230 V +10/-15 %

Frequency 50/60 Hz

Power consumption max. 8 VA

Fan control Q1, Q2, Q3- N

Rating

Control output Y11-N (N.O.) / Y12-N (N.C.)

Rating

Changeover or external room temperature sensor B1-M

Temperature sensor

Voltage against earth

Cable length

Infrared receiver (only with RDF210…/IR)

Transmission distance

Orientation angle

Switching differential, adjustable from 0.5...4K

Heating mode (factory setting)

Cooling mode (factory setting)

Setpoint setting range

Normal operation

Energy Saving mode (only with RDF110)

Standby

Factory setting of setpoints

Normal operation

Energy Saving in heating / cooling mode

Standby (heating and cooling mode)

Built-in room temperature sensor

Measuring range

Accuracy at 25 °C

Temperature calibration range

Resolution of settings and display

Setpoints

Current temperature value displayed

Operation

Climatic conditions

Temperature

Humidity

Transport

Climatic conditions

Temperature

Humidity

Mechanical conditions

Storage

Climatic conditions

Temperature

Humidity

conformity to

EMC directive

Low voltage directive

N474

C-Tick conformity to

EMC emission standard

AC 230 V

max. 4(2)A

AC 230 V

max. 4(2)A

QAH11.1, safety class II

AC 230 V

max. 80 m (min. 1.5 mm

2

)

≤ 7.5 m

≤ ± 30 °

2 K

1 K

5...40 °C

off, 5...40 °C

off, 5...40 °C

20 °C

16 °C / 28 °C

OFF

0…49 °C

< ± 0.5 K

± 3.0 K

0.5 °C

0.5 °C

to IEC 721-3-3

class 3K5

0...+ 50 °C

<95 % r.h.

to IEC 721-3-2

class 2K3

− 25...+60 °C

<95 % r.h.

class 2M2

to IEC 721-3-1

class 1K3

− 25...+60 °C

<95 % r.h.

89/336/EEC

73/23/EEC and 93/68/EEC

AS/NSZ 4251.1:1994

13/15

Building Technologies Room Temperature Controllers N3058en

HVAC Products 10.01.2006

Page 14

General

Connection terminals

Product standards

Automatic electrical controls for household

and similar use

Special requirements for temperature-

EN 60 730 – 1

EN 60 730 – 2 - 9

dependent controls

Electromagnetic compatibility

Emissions

Immunity

IEC/EN 61 000-6-3

IEC/EN 61 000-6-1

Devices of safety class II to EN 60 730

Pollution class normal

Degree of protection of housing IP 30 to EN 60 529

Connection terminals solid wires or prepared

stranded wires

2 x 0.4-1.5 mm

2

mm

2

or 1 x 2.5

Weight 0.28 kg

Color of housing front white, NCS S 0502-G (RAL

9003)

Connection diagrams

Application:

2-pipe fan coil units

Application:

Compressor

in DX type equipment

AC 230 V

LB1*M

N Q1Q2Q3 Y11N

Y12

L, N Operating voltage AC 230 V

B1* Changeover (QAH11.1+ ARG86.3) or

external room temperature sensor

(QAH11.1 / QAA32)

M Measuring neutral for sensor

L

N

L

N

B1/B2

*

B1

I II III

4(2)A

max.

B1/B2

*

I II III

4(2)A

max.

QAH11.1 +

ARG86.3

/ QAA32

M

QAH11.1 +

(ARG86.3)

/ QAA32

Y12

M1

Y12

M1

10 A

L

N Q1Q2Q3 Y11 N

AC 230 V

10 A

LB1M

N Q1Q2Q3 Y11 N

AC 230 V

4(2)A

max.

4(2)A

max.

RDF210

*

N1

RDF210

*

N1

C1

Y1

Q1 Control output “Fan speed 1 AC 230 V

Q2 Control output “Fan speed 2 AC 230 V

3058G01

Q3 Control output “Fan speed 3 AC 230 V

Y11 Control output “Valve” AC 230 V (N.O.,

for normally closed valves) or output for

compressor

Y12 Control output “Valve” AC 230 V (N.C.,

for normally open valves)

* Only with RDF210 or RDF210/IR

B1* Return air temperature sensor (QAH11.1)

or external room temperature sensor (QAA32)

B2* Changeover sensor (temperature sensor

QAH11.1 + changeover mounting kit

ARG86.3)

M1 3-speed fan

N1 Room temperature controller RDF210..

Y1 Zone valve

1

0

A

8

5

* Only with RDF210 or RDF210/IR

0

3

B1* Return air temperature sensor (QAH11.1)

or external room temperature sensor (QAA32)

B2* Changeover sensor (temperature sensor

QAH11.1 + changeover mounting kit

ARG86.3)

M1 3-speed fan

N1 Room temperature controller RDF210..

C1 Compressor

• Only with RDF210 or RDF210/IR

2

0

A

8

5

0

3

Note: For compressor applications, RDF210 or

RDF210/IR is recommended

14/15

Building Technologies Room Temperature Controllers N3058en

HVAC Products 10.01.2006

Page 15

Dimensions

Controller

Mounting base

128

120.3

4

0

Z

8

5

30

102

0

3

28

28

4

120.3

21.85

34.15

2.5

30

94.85

2828

28.7

4

35

24.35

30

31.65

11.8

10.15

3058Z05

©2006 Siemens Switzerland Ltd. Subject to alteration

Building Technologies Room Temperature Controllers N3058en

HVAC Products 10.01.2006

15/15

Loading...

Loading...