Page 1

RDF20U

Technical Instructions

Document No. 155-334

September 27, 2007

Room Temperature Controller

with LCD for Two-Pipe Fan Coil

Units with Electric Heat

Siemens Industry, Inc.

Description

Room temperature controller with LCD for two-pipe fan coil units with electric heat.

Features

• Output for an on/off valve actuator

• Output for electric heat.

• Outputs for a three-speed fan.

• Control depending on the room or the return air temperature.

• Automatic heating/cooling changeover.

• Operating modes: Normal, Economy and Standby.

• Operating mode changeover input for remote control (Day/Night).

• Air movement control function for avoiding damage resulting from moisture.

• Selectable installation and control parameters.

• Display of room temperature or setpoint (selectable).

• Electronic minimum and maximum setpoint limits.

• Operating voltage 24 Vac.

Application

Typical use:

• Control of the room temperature in individual rooms that are heated or cooled with

two-pipe fan coil units equipped with electric heat.

• Opening or closing a valve.

• Switching electric heat.

• Switching a three-speed fan.

Suitable for two-pipe fan coil unit systems with:

• Automatic heating/cooling changeover.

• Continuous heating or cooling mode.

Product Number

RDF20U

Page 2

Technical Instructions RDF20U Room Temperature Controller with LCD

Document Number 155-334 for Two-Pipe Fan Coil Units with Electric Heat

September 27, 2007

Page 2 Siemens Industry, Inc.

Accessories

ARG70 Adapter plate for 4-inch × 4-inch or 2-inch × 4-inch conduit boxes

141-570 Lockable thermostat guard

QAH11.1 Changeover/remote temperature sensor

Warning/Caution

Notations

WARNING:

Personal injury or loss of life may occur if you do not perform

a procedure as specified.

CAUTION:

Equipment damage may occur if you do not follow a

procedure as specified.

Operation

The controller acquires the room temperature via its integrated sensor or optional

external return air temperature sensor (QAH11.1) and maintains the setpoint by

delivering two-position valve control and electric heat output commands.

The switching differential is 2 K (3.6F) in Heating mode and 1 K (1.8F) in Cooling

mode (adjustable).

Fan Operation

The fan is switched to the selected speed via control output 12, 11 or 10.

When the “Temperature-dependent fan control“ function is activated (can be selected

with DIP Switch No. 1), the fan is switched on/off depending on the temperature,

together with the valve.

It is switched off when any of the following occurs:

• leaving the heating or cooling sequence, provided the “Temperature-dependent fan

control“ function is activated.

• manually changing to Standby “ ” provided no setpoints (example, for freeze

protection) are set and active.

• activating an external operating mode changeover switch, provided application

conditions do not call for Economy mode.

• turning off the controller’s power supply.

NOTE: To avoid overheating the electric heat or to prevent the thermal cut-out from

responding, the fan will overrun for 60 seconds (default Parameter 21) when

the electric heat is switched off.

CAUTION:

In the event of failure, the RDF20U cannot protect the electric heat against

overheating. Therefore, the electric heat must be equipped with a separate

safety device (high temperature detection thermostat).

Display

If DIP Switch No. 2 is set to ON (factory setting), the controller displays the measured

room or return air temperature (unless parameters or setpoints are temporarily

changed). If the DIP switch is set to OFF, the controller displays the Normal operating

mode setpoint. In this case, the value of the current temperature reading can only be

visualized temporarily by selecting Parameter P14.

Page 3

RDF20U Room Temperature Controller with LCD Technical Instructions

For Two-Pipe Fan Coil Units with Electric Heat Document Number 155-334

September 27, 2007

Siemens Industry, Inc. Page 3

Water-based Fan Coil

Application

Use in conjunction with one valve, either for heating and/or cooling with changeover,

heating only or cooling only operation.

Heating Mode

Output terminals 4 and 2 (neutral) or 5 and 2 command the control valve.

Output terminals 4 and 2 are closed (24 Vac) when:

1. the measured room temperature is half the switching differential below the setpoint (W,

Heating mode), and

2. the valve has been closed for more than one minute (Parameter P20).

Output terminals 4 and 2 are open (0 Vac) when:

1. the measured room temperature is half the switching differential above the setpoint (W,

Heating mode), and

2. the valve has been closed for more than one minute (Parameter 19).

Cooling Mode

Output terminals 4 and 2 are open (0 Vac) when:

1. The measured room temperature is half the switching differential below the Cooling

mode setpoint (W), and

2. the valve has been closed for more than one minute (Parameter 20).

Output terminals 4 and 2 are closed (24 Vac) when:

1. the measured room temperature is half the switching differential above the Cooling

Mode setpoint (W), and

2. the valve has been open for more than one minute (Parameter 19).

NOTE: Terminal output 5 (NC) delivers a control command which is inverted to the

control command at output 4 (NO) and can be used for Normally Open

valves.

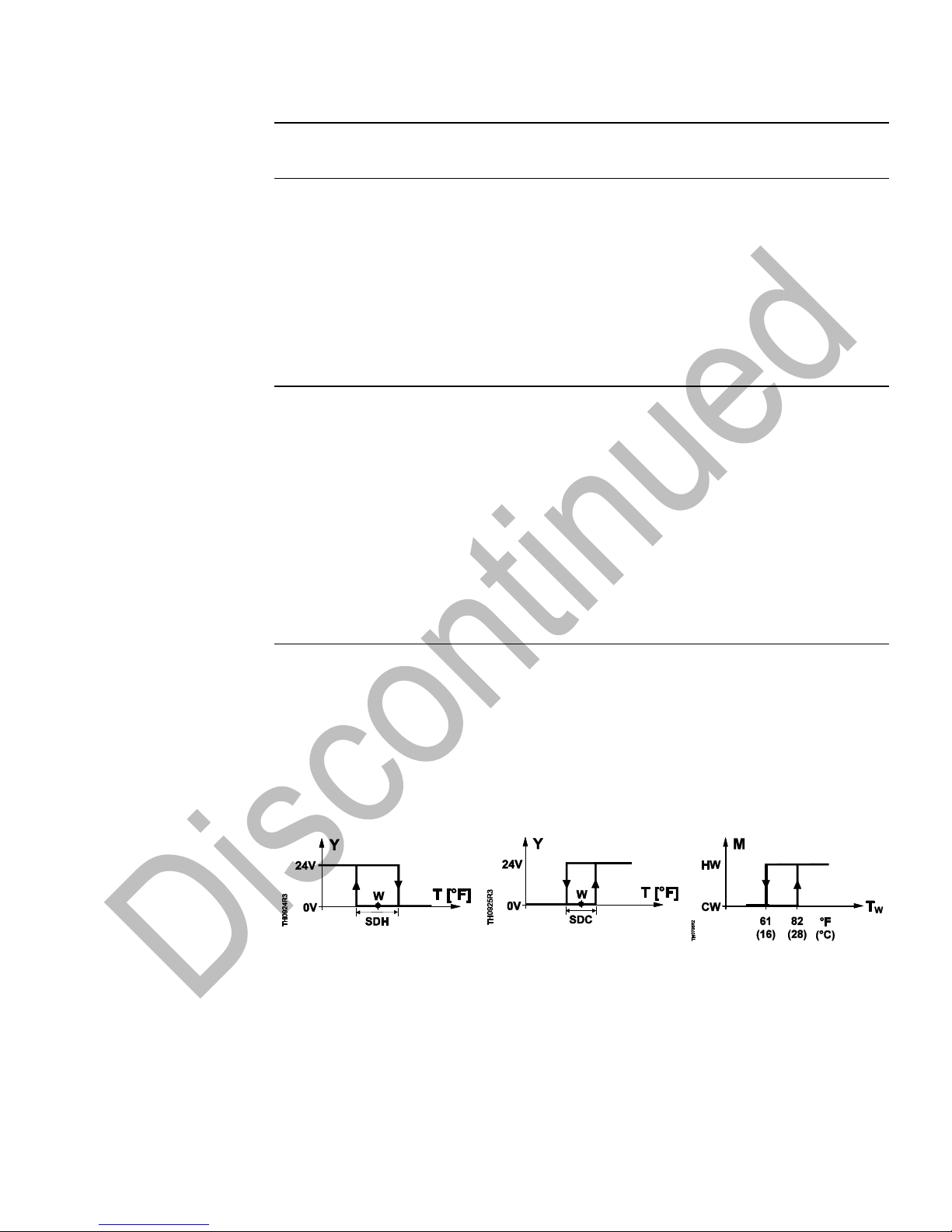

Automatic Changeover

The water temperature measured by the changeover sensor (QAH11.1) is used by the

controller to switch from Heating to Cooling mode, or vice versa. When the water

temperature rises above 82°F (28°C) (adjustable in Parameter P08), the controller

switches to Heating mode; below 61°F (16°C) (adjustable in Parameter P07) it switches

to Cooling mode. If, immediately after switching on, the water temperature is between

the two changeover points, the controller will start in Heating mode. The water

temperature is measured at 30-second intervals and the operating state is updated.

The value of the current temperature reading and the mode can be temporarily

displayed by selecting Parameter P15.

Figure 1. Heating Mode.

Figure 2. Cooling Mode.

Figure 3. Automatic

Changeover.

NOTE: Figures 1 and 2 show Output Terminal 4.

CW

HW

M

Cooling mode

Heating mode

Operating mode

SDH

SDC

Tw

Switching differential, Heating

Switching differential, Cooling

Water temperature

W

Y

T

Room temperature setpoint

Heating/cooling valve output

voltage

Room temperature

Page 4

Technical Instructions RDF20U Room Temperature Controller with LCD

Document Number 155-334 for Two-Pipe Fan Coil Units with Electric Heat

September 27, 2007

Page 4 Siemens Industry, Inc.

Automatic Changeover,

Continued

In systems without automatic changeover, the temperature sensor can be replaced by

an external switch (D1, GND) (must be suited for live voltage) for manual changeover.

In systems with continuous heating mode, no sensor will be connected to the

controller’s input. With continuous cooling mode, the controller (7/8) input must be

bridged.

Purging Function

(Optional)

The changeover sensor initiates the change from Heating to Cooling mode, based on

the measured water temperature. If a two-way valve is used, it is highly recommended

to activate the purging function (adjustable in Parameter P16). This function ensures

the correct acquisition of the medium temperature even if the two-way valve is closed

for a longer period of time. To achieve this, the valve is opened for one to five minutes

(adjustable in Parameter P16) at two-hour intervals during off hours.

When the purging function is activated, the first purging action is performed after

changing Parameter P16 and exiting the parameter setting mode.

Return Air Temperature

(Optional)

The RDF20U provides control based on the measured room temperature or the fan coil

unit’s return air temperature. It detects if a QAH11.1 cable temperature sensor is

connected to input 8-9 and then operates automatically according to that temperature.

Electric Heat, Active in

Heating Mode

NOTE: This function is not active when using thermal actuators.

In addition to hot water heating, the electric heat receives an ON command via output 6

when:

▪ the measured room temperature is x w − wD − 1/2 SDH, and

▪ the electric heat has been switched off for more than one minute.

The OFF command for the electric heat is given when:

1. the measured room temperature is x w − wD + 1/2 SDH, and

2. the electric heat has been switched on for more than one minute.

Electric Heat, Active in

Cooling Mode

For this operation, DIP Switch No. 4 must be set to ON (factory setting).

The electric heat receives the ON command via control output 6 when:

1. the measured room temperature is half the switching differential below the adjusted

setpoint, and

2. the electric heat has been switched off for more than one minute.

The OFF command for the electric heat is given when:

1. the measured room temperature is half the switching differential above the adjusted

setpoint, and

2. the electric heat has been switched on for more than one minute.

Page 5

RDF20U Room Temperature Controller with LCD Technical Instructions

For Two-Pipe Fan Coil Units with Electric Heat Document Number 155-334

September 27, 2007

Siemens Industry, Inc. Page 5

Application Diagrams

Figure 4. Heating Mode (Hot Water Plus

Electric Heat).

Figure 5. Cooling Mode with Optional

Electric Heat

(DIP Switch 4: ON, Electric Heat

Enabled)).

Figure 6. Cooling Mode (Chilled Water)

(DIP Switch 4: OFF, Electric Heat

Disabled).

T[°F] Room temperature

w Room temperature setpoint

wD Setpoint differential

Y Heating/cooling valve output

voltage

E Electric heat

SDH Switching differential, Heating

SDC Switching differential, Cooling

Xdz Dead zone

Page 6

Technical Instructions RDF20U Room Temperature Controller with LCD

Document Number 155-334 for Two-Pipe Fan Coil Units with Electric Heat

September 27, 2007

Page 6 Siemens Industry, Inc.

Operating Modes

Normal Mode

Heating or Cooling mode with automatic changeover and manually selected fan speed

(III, II or I). In Normal mode, the controller maintains the adjusted setpoint.

Economy Mode

A potential-free operating mode changeover switch can be connected to status input

D1-GND. When the switch closes its contact (due to an open window, for instance), the

operating mode will change from Normal to Economy. In this operating mode, the

relevant setpoints of heating or cooling are maintained (adjustable in Parameters P01

[setback temperature for heating] and P02 [setback temperature for cooling]). The

operating action of the switch (NC or NO) can be selected.

Standby

The relevant setpoints of heating and cooling are maintained when in Standby mode,

provided those setpoints have been adjusted. The standby temperature setting for

Heating mode in Parameter P03 is adjustable from 41°F to 68°F (5°C to 20°C) or “OFF”

and the setting for Cooling mode in Parameter P04 is adjustable from 70°F to 95°F

(21°C to 35°C) or OFF.

Avoiding Damage Due to

Moisture (continuous

fan)

To avoid damage due to moisture in very warm and humid climates resulting from lack

of air circulation in Economy mode (for example, in hotel rooms during unoccupied

periods), the fan can be kept running in Economy mode when activating Parameter

P17. In this case, the fan keeps running at the selected speed or at speed I if the

operating mode selector is in Standby “ ”.

Setting the Control

Parameters

A number of control parameters can be set to optimize control performance. These

parameters can also be set during operation without opening the unit. In the event of a

power failure, all set control parameters will be maintained.

Settings

The parameters can be changed as follows:

1. Set the operating mode selector to Standby “ ”.

2. Press buttons "+" and "–" simultaneously for a minimum of three seconds. Release

them and, within two seconds, press the "+" button again for three seconds. The

display will show P01.

3. Select the required parameter by repeatedly pressing the "+" and "–" buttons:

4. Press buttons "+" and "–" simultaneously; the current value of the selected

parameter appears, and can be changed by repeatedly pressing the "+" and "–"

buttons.

5. Press buttons "+" and "–" simultaneously again or five seconds after the last press

of a button. The last parameter will be displayed again.

6. To display and change additional parameters, repeat steps 3 through 5.

7. All changes will be stored and the controller returns to Normal operation 10

seconds after the last display or setting.

Page 7

RDF20U Room Temperature Controller with LCD Technical Instructions

For Two-Pipe Fan Coil Units with Electric Heat Document Number 155-334

September 27, 2007

Siemens Industry, Inc. Page 7

Table 1. Control Parameters.

Para-

meter

Description

Setting Range

Factory

Setting

P01

Heating setpoint in Economy mode

(operating mode changeover contact activated )

OFF,

41F to 68F (5C to 20C) (in increments of 0.5 K)

61F

(16C)

P02

Cooling setpoint in Economy mode

(operating mode changeover contact activated )

OFF,

70F to 95F (21C to 35C) (in increments of 0.5 K)

82F

(28C)

P03

Heating setpoint in Standby

OFF,

41F to 68F (5C to 20C) (in increments of 0.5 K)

46F (8C)

P04

Cooling setpoint in Standby

OFF,

70F to 95F (21C to 35C) (in increments of 0.5 K)

OFF

P05

Minimum setpoint limit stops in Normal mode

41F to 68F (5C to 20C) (in increments of 0.5 K)

41F (5°C)

P06

Maximum setpoint limit stops in Normal mode

70F to 95F (21C to 35C) (in increments of 0.5 K)

95F

(35°C)

P07

Heating/cooling changeover cooling switching

point

50F to 77F (10°C to 25°C) (in increments of 0.5 K)

61F

(16C)

P08

Heating/cooling changeover heating switching

point

8°F to 104°F (27°C to 40° C) (in increments of

0.5 K)

82F

(28C)

P09

Sensor calibration

-3K to 3 K (-5.4°F to 5.4°F) (in increments of 0.5 K)

0 K (0F)

P10

P-band in Heating mode or switching differential

heating. NOTE: This parameter is in degrees

Kelvin, 1 K = 1.8F.

0.5 K to 4 K (1°F to 7°F) (in increments of 0.5 K)

2 K

(3.6°F)

P11

P-band in Cooling mode or switching differential

cooling. NOTE: This parameter is in degrees

Kelvin, 1 K = 1.8F.

0.5 K to 4 K (1°F to 7°F) (in increments of 0.5 K)

1 K

(1.8°F)

P12

Dead zone in Normal mode

0.5 K to 10 K (1°F to 18°F) (in increments of 0.5 K)

2 K

(3.6°F)

P13

Active temperature sensor (no setting, display

only)

1: Room temperature sensor active

2: Return air temperature sensor active

--

P14

Value of current room temperature reading

(no setting, display only)

32°F to 120°F (0°C to 49°C) = current temperature

value

--

P15

Value of current heating/cooling changeover

temperature reading including indication of

current mode ( , ) (no setting, display only)

100 = input open (no sensor connected, heating

mode ( )

32°F to 120°F (0°C to 49°C) = current temperature

value

00 = input bridged, Cooling mode ( )

--

P16

Purging function

0 min.: Not active

1 to 5 min.: Active with selected duration

0 min.

P17

Fan control in Economy mode

OFF: Fan is off in the dead zone

ON: Fan is on in the dead zone,

ON: Running at the selected speed or at speed 1 if

in Standby

OFF

P18

Setpoint differential

0.5 K to 5 K (1°F to 9°F)

2 K

(3.6°F)

P19

Minimum output on time (4, 6)

1 to 20 minutes (in increments of 1 min.)

1 min.

P20

Minimum output off time (4, 6)

1 to 20 minutes (in increments of 1 min.)

1 min.

P21

Fan overrun

0 to 300 seconds (in increments of 10 seconds)

60 s

P22

Point of reference for setpoint in Normal mode

HA: Heating sequence; CL: Cooling sequence

HA

P23

Display unit of measure

°F, °C

°F

Page 8

Technical Instructions RDF20U Room Temperature Controller with LCD

Document Number 155-334 for Two-Pipe Fan Coil Units with Electric Heat

September 27, 2007

Page 8 Siemens Industry, Inc.

Ordering

The QAH11.1 temperature sensor can be used as a return air temperature or

changeover sensor. The changeover sensor and the valves must be ordered

separately.

Equipment

Combinations

Table 2.

Product Number

Description

Technical Instructions

QAH11.1

Temperature Sensor

155-329P25

599 Series

Two-way and Three-way

Zone Valves

155-320P25

SF Series

Zone Valve Actuator

155-321P25

Mechanical Design

The controller consists of two parts:

▪ Plastic housing which accommodates the electronics, the operating elements and

the built-in room temperature sensor

▪ Base

The housing engages in the base and is secured with two screws. The base carries the

screw terminals. The DIP switches are located at the rear of the housing.

Setting and Operating

Elements

Figure 7. RDF20U Components.

1

Display of the room temperature, setpoints or control parameters

2

Symbol used when displaying the current room temperature

3

Normal mode

Economy mode

4

Cooling valve open

Fan on

Heating valve open

5

Buttons for adjusting the setpoints and the control parameters

6

Operating mode selector

(Standby “ ”, Heating or Cooling mode with manual selection of fan speed)

Page 9

RDF20U Room Temperature Controller with LCD Technical Instructions

For Two-Pipe Fan Coil Units with Electric Heat Document Number 155-334

September 27, 2007

Siemens Industry, Inc. Page 9

Table 3. DIP Switches.

DIP Switch

No.

Description

Position ON (Factory Setting)

Position OFF

1

Fan control

Fan control is temperatureindependent

Fan control is temperaturedependent

2

Display of temperature or setpoint

Room (or return air) temperature

display

Setpoint display

3

Operating action of switch for external

operating mode changeover

Changeover activated when switch is

closed (NO)

Changeover activated when

switch is open (NC)

4

Electric heat

Active in Cooling mode

Inactive in Cooling mode

Engineering Notes

With the RDF20U, the controller input for automatic heating/cooling changeover can

also be used without the QAH11.1 cable temperature sensor:

▪ In systems without automatic changeover, the temperature sensor can be replaced

by an external switch (suited for live voltage) for manual changeover.

▪ In systems with continuous heating mode, no sensor is connected to the

controller’s input.

▪ In systems with continuous cooling mode, the controller input (7-8) must be

bridged.

Mounting,

Installation and

Commissioning

Notes

▪ Mounting location: On a wall or inside the fan coil unit.

▪ Do not mount in niches or bookshelves, behind curtains, above or near heat

sources.

▪ Do not mount in direct sunlight.

▪ Mounting height is approximately 60 inches (1.5 m) above the floor.

▪ The connecting wires can be run to the controller from a recessed conduit box.

Figure 8. Acceptable Mounting Height in Inches.

▪ Check the positions of the DIP switches and change them, if required.

▪ After applying power, the controller makes a reset during which all LCD segments

flash, indicating that the reset has been correctly made. This takes about three

seconds. Then, the controller is ready to operate.

▪ Prior to installing the changeover sensor, thermal conductive paste must be applied

to the location on the pipe where the sensor is placed.

Page 10

Technical Instructions RDF20U Room Temperature Controller with LCD

Document Number 155-334 for Two-Pipe Fan Coil Units with Electric Heat

September 27, 2007

Page 10 Siemens Industry, Inc.

Mounting,

Installation and

Commissioning

Notes, Continued

▪ Installation Instructions are included with the controller.

WARNING:

• Sensor inputs 7, 8, and 9 carry live voltage potential. If the sensor’s

cables must be extended, the cables used must be suited for live

voltage.

• The cables used must meet the insulation requirements for live

voltage.

Calibrating the Sensor

If the room temperature displayed by the controller is inconsistent with the room

temperature being measured, the temperature sensor of the RDF20U can be

recalibrated. To recalibrate, change Parameter P09.

Specifications

Power Supply

Operating voltage 24 Vac, +20/-25%

Frequency 50/60 Hz

Power consumption 6 VA maximum

Fan control outputs 12, 11, 10-N 24 Vac

Rating 5 (3) A maximum

Valve control output 4-2 (NO) 24 Vac

Rating 5 (3) A maximum

Valve control output 5-2 (NC 24 Vac

Rating 5 (3) A maximum

Electric heat control output 6-2 (NO) 24 Vac

Rating 5 (3) A maximum

Return air temperature sensor QAH11.1 safety class II

status input 9-8 NTC resistor 3K at 77°F (25°C)

Changeover—status input 7-8 QAH11.1, safety class II

NTC resistor 3K at 77°F (25°C)

Status input D1 and GND

Contact sensing SELV 6 to 15 Vdc/ 3 to 6 mA

Insulation against live voltage 4 kV, reinforced insulation

Operating action Selectable (NO/NC)

Permissible cable length with copper 262 ft (80 m)

cable 14 AWG for connection to terminals

7, 8, and 9 and D1, GND.

Operational Data

Setpoint setting range 41°F to 95°F (5°C to 35°C)

Control deviation at 77°F (25°C) + 1°F (0.5K) maximum

Switching differential in Heating mode, 2 K (3.6°F)

adjustable

Switching differential in Cooling mode, 1 K (1.8°F)

adjustable

Dead zone Xdz in Normal operation, 2 K (3.6°F)

adjustable

Setpoint differential WD, adjustable 2 K (3.6°F)

Setpoint, Economy mode , heating, 61°F (16°C)

adjustable

Setpoint, Economy mode , cooling, 82°F (28°C)

adjustable

Setpoint, Standby , heating, adjustable 46°F (8°C)

Setpoint, Standby , cooling, adjustable OFF

Page 11

RDF20U Room Temperature Controller with LCD Technical Instructions

For Two-Pipe Fan Coil Units with Electric Heat Document Number 155-334

September 27, 2007

Siemens Industry, Inc. Page 11

Specifications,

Continued

Environmental Conditions

Operation

Temperature 32°F to 122°F (0°C to 50°C)

Humidity <95% rh

Transport and storage

Temperature -13°F to 158°F (-25°C to 70°C)

Humidity <95% rh

Agency Approvals

UL Listing UL 873

General

Connection terminals Solid wires or prepared stranded

wires 2 × 16 AWG or 1 × 14 AWG

Weight 0.55 lb (0.25 kg)

Housing front color White (RAL 9003)

Wiring Terminals

Figure 9. Wiring Terminals.

1, 2 24 Vac, negative

3 24 Vac, positive

9 Return air temperature

sensor

8 Measuring neutral

7 Changeover sensor

D1,GND Potential-free operating mode

changeover switch (operating action

can be selected)

12 Control output, Fan speed I, 24 Vac

11 Control output, Fan speed II, 24 Vac

10 Control output, Fan speed III, 24 Vac

4 Control output, Valve 24 Vac

5 Control output, Valve 24 Vac

6 Control output, Electric heat 24 Vac

Wiring Diagrams

Figure 10. Two-Pipe Fan Coil Units with

Electric Heat.

B1 Return air temperature sensor

(QAH11.1)

B2 Changeover sensor (temperature

sensor QAH11.1)

E1 Electric heat

M1 3-speed fan

N1 Room temperature controller

RDF20U

S1 External operating mode

changeover switch

SN 24 Vac, negative

SP 24 Vac, positive

Y1 Zone valve

Page 12

Information in this publication is based on current specifications. The company reserves the right to make changes in specifications and models as

design improvements are introduced. Product or company names mentioned herein may be the trademarks of their respective owners.

© 2007 Siemens Industry, Inc.

Siemens Industry, Inc.

Building Technologies Division

1000 Deerfield Parkway

Buffalo Grove, IL 60089

+ 1 847-215-1000

Your feedback is important to us. If you have comments

about this document, please send them to

SBT_technical.editor.us.sbt@siemens.com

Document No. 155-334

Printed in the USA

Page 12

Dimensions

In Inches

(Millimeters)

Figure 11. RDF20U Controller.

Figure 12. Base Plate.

Loading...

Loading...