Page 1

s

5

2

.

RCU50U and RCU50.2U

Room Temperature Controllers for

CAV Systems

Technical Instruction

Document No. 155-327P2

Rev. 1, March, 200

Description

Features

Application

RCU50U

The RCU microprocessor controlled CAV room controller is designed for air only, or air

and water heating and/or cooling systems. Controllers have proportional response.

• Modulating P-control

• 0 to 10 Vdc output for heating or cooling

• Automatic heating/cooling changeover (RCU50U)

• Manual heating/cooling changeover (RCU50.2U)

• Operating modes: Normal, Energy Saving, Frost Protection and Standby (RCU50U)

• Operating modes: Normal and OFF (RCU50.2U)

• Active 0 to 10 Vdc input for set point shifting (RCU50U)

• Operating mode changeover input for remote control (RCU50U)

• Adjustable minimum limitation for cooling output (RCU50U)

• Operating voltage 24 Vac

Controlling individual room temperature in HVAC installations that are heated or cooled

Controlling these types of equipment:

• Valve actuators

RCU50.2U

• Air damper actuators

Product Numbers

Product Numbers Features

NOTE:

Table 1.

RCU50U Without operating mode selector

RCU50.2U With manual heating/cooling changeover switch

To order without logo, change suffix to "/U/NL".

Example:

Siemens Building Technologies, Inc.

RCU50/U/NL.

Page 2

Technical Instructions RCU50U and RCU50.2U Room Temperature Controllers

r

l

0

Document Number 155-327P25 for CAV Systems

Rev. 1, March, 2002

Ordering

The temperature sensor, changeover mounting kit, and valve and damper actuators

must be ordered separately.

Table 2. Equipment Combinations.

Function

Heating-Cooling with

Minimum Limitation

Cooling

Product Numbe

Description Technical Instructions

QAH11.1 Temperature sensor 155-329P25

GDE16… 44 lb-in NSR Air damper actuator

155-187P25

GLB16… 88 lb-in NSR Air damper actuator

SSB61U Valve actuator 155-192P25

SSC61U

Valve actuator 155-313P25

SSC61.5U

SQS65U

Valve actuator 155-190P25

SQS65.5U

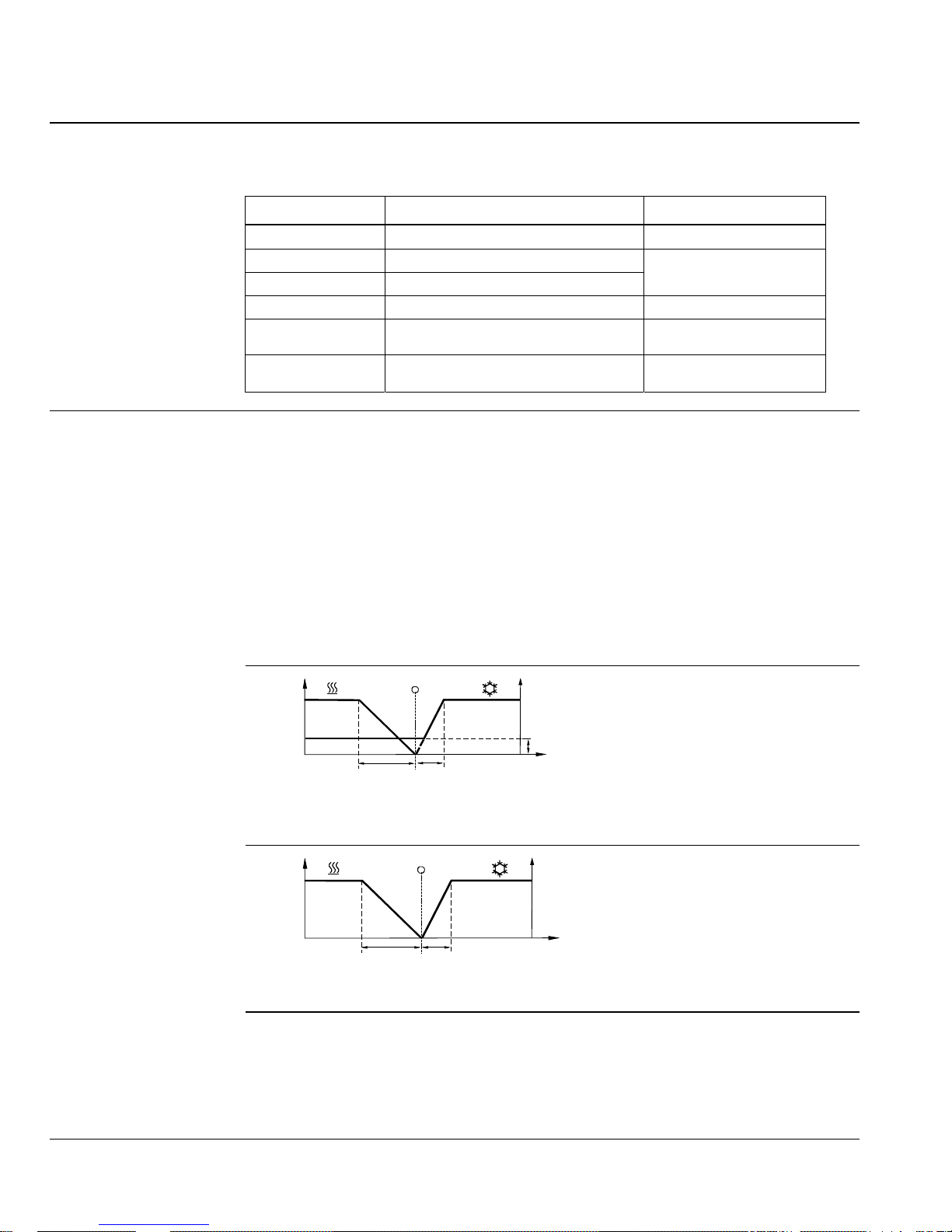

The controller measures the room temperature with its integrated sensor and maintains

the set point by delivering 0 to10 Vdc control commands. The RCU50U and RCU50.2U

provide P-control. With the RCU50U, the proportional band can be 2°F or 7°F (1°C or

4°C) in heating mode and 1°F or 3.5°F (0.5°C or 2°C) in cooling mode (selectable with

DIP Switch No. 4). With the RCU50.2U, the proportional band is fixed, 7°F (4°C) in

heating mode and 3.5°F (2°C) in cooling mode.

• RCU50U – When in the heating mode, on increase in temperature, the output signa

goes down (Reverse Acting - R.A.) from 10 to 0 volts. When in cooling mode, on

increase in temperature, the output signal goes up (Direct Acting - D.A.) from 0 to 1

volts.

• RCU50.2U – The output signal can be reversed 0 to 10 or 10 to 0 volts via the DIP

switch.

Y10 [%] Y10 [%]

100

c/o

100

T Room temperature

Y10 Output percentage

W Room temperature set point

XpH Proportional band heating

TH0577R1

0

XpKXpH

W

VR

T [˚F]

XpK Proportional band cooling

VR 0 to 100% minimum limitation of

cooling output

c/o Changeover

Figure 1. RCU50U Function Diagram.

Heating-Cooling

Y10 [%]

100

0

TH0578R1

Figure 2. RCU50.2U Function Diagram.

Minimum Limitation of

Cooling Signal

RCU50U

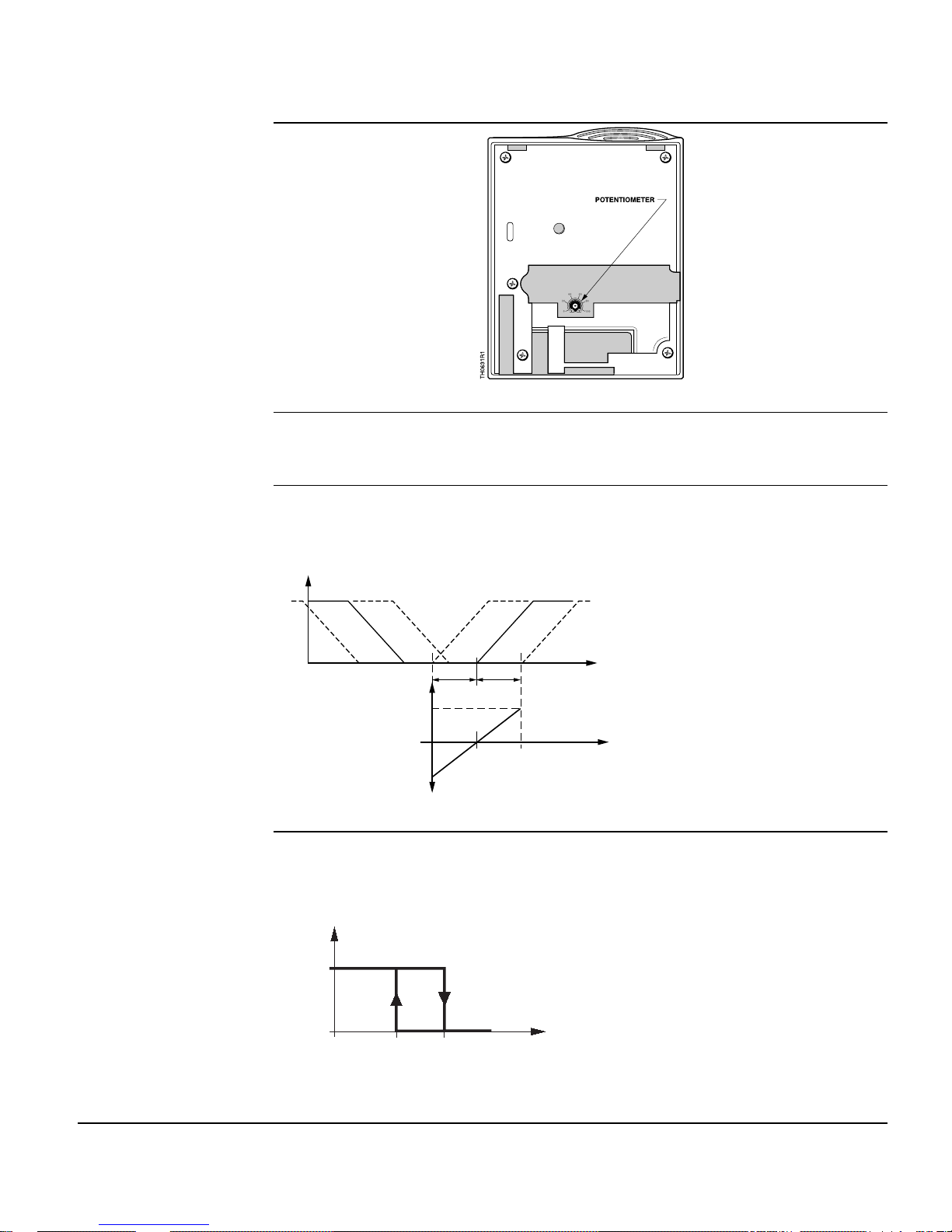

Using the potentiometer located on the circuit board, the cooling signal output can be

limited to a minimum value of between 0 and 100%. This can be used to ensure a

minimum supply air volume. When used in connection with a VAV controller, this

setting must be taken into account. To set minimum limitation, use a screwdriver to

adjust the potentiometer (see Figure 3). Values on the scale are percentage of full

operation.

Page 2

Siemens Building Technologies, Inc.

c/o

Y10 [%]

100

T Room temperature

Y10 Output percentage

W Room temperature set point

XpH Proportional band heating

XpK Proportional band cooling

c/o Changeover

XpH

0

XpK

W

T [˚F]

Page 3

RCU50U and RCU50.2U Room Temperature Controllers Technical Instructions

c

For VAV Systems Document Number 155-327P25

Rev. 1, March, 2002

Minimum Limitation of

Cooling Signal,

Continued

Figure 3. Potentiometer Location (RCU50U).

Inversion of Output

Signal

RCU50.2U

Set Point Shifting

RCU50U

With the RCU50.2U, the output signal can be inverted with the help of DIP Switch

No. 1. If set to ON, 0V corresponds to 0% travel and 10V to 100% travel. In position

OFF, 0V corresponds to 100% travel and 10V to 0% travel.

Signal Input 1 and 2 is used for outside temperature compensation. Using a 0 to 10 Vd

signal, the set point can be shifted by ±22.5°F at 72°F set point. The neutral position is

at 5 Vdc and means no set point shift.

Q(%)

heating cooling

100

W Original set point

W1 Highest set point at 10V input

W2 Lowest set point at 0V input

set point shift

72ºF

0

Set Point Shift (K)

TH0621R1

Figure 4. Set Point Shifting (RCU50U).

Automatic Changeover

RCU50U

The water temperature measured by the changeover sensor (QAH11.1) is used by the

controller to switch from heating to cooling mode, or vice versa. When the water

W2 W1

22.5ºF

0

22.5ºF

1

W

22.5ºF 22.5ºF

5

(72ºF)

10

T [ºF]

Input Voltage (V)

(V) Input voltage

temperature is above 82°F (28°C), the controller switches to heating mode; below

61°F (16°C) it switches to cooling mode.

CM

HM

TH0579R1

Siemens Building Technologies, Inc.

M

61

(16)82(28)

Figure 5. Automatic Changeover Mode.

˚

(˚C)

CM Cooling mode

HM Heating mode

M Operating mode

T

Water temperature

W

T

W

F

Page 3

Page 4

Technical Instructions RCU50U and RCU50.2U Room Temperature Controllers

o

Document Number 155-327P25 for CAV Systems

Rev. 1, March, 2002

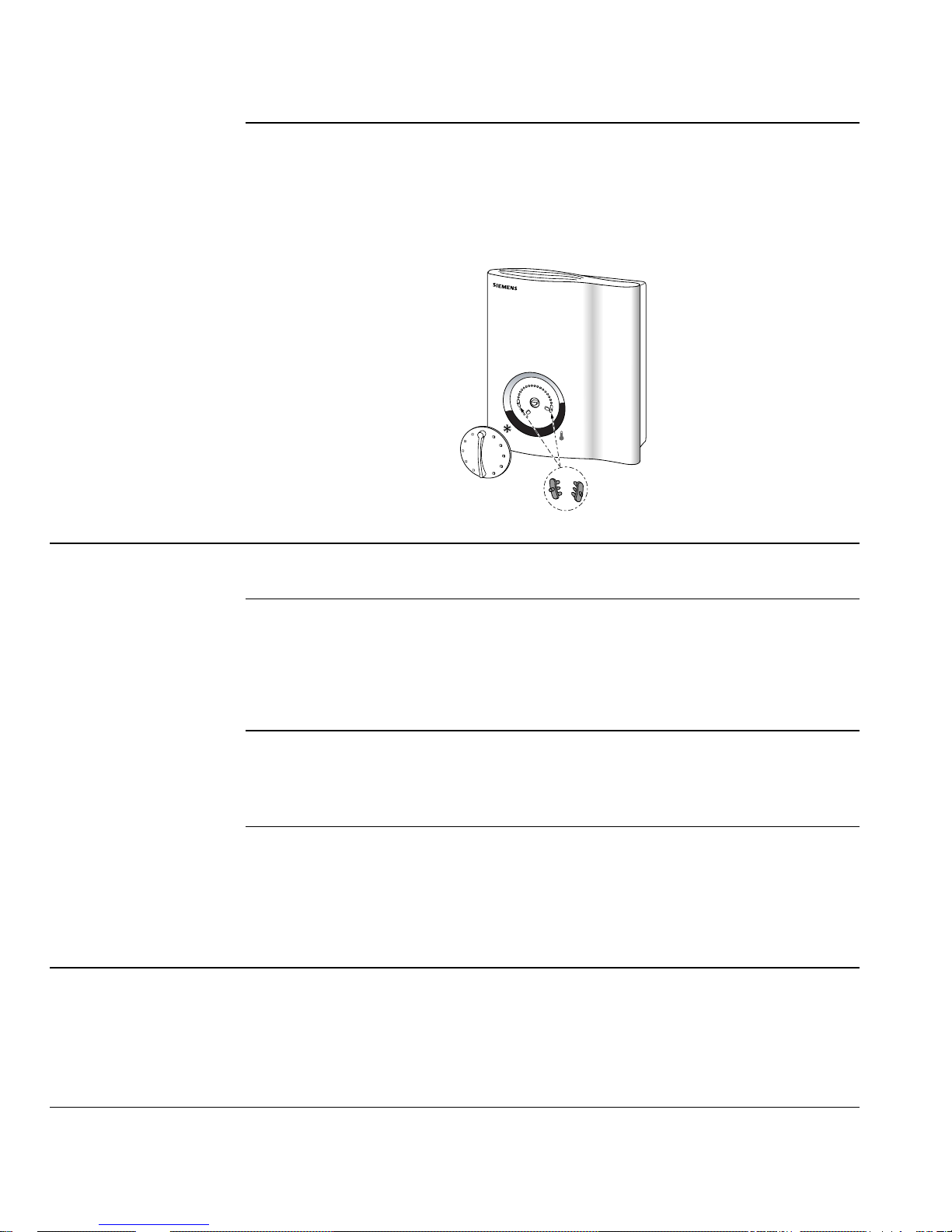

Set Point Limit Stops

The room temperature set point can be limited in increments of 2°F (1°C) by using the

minimum and maximum set point limit stops. This prevents arbitrary set point

readjustments.

To set limit stops, remove the set point knob by pulling it straight off the shaft.

Reposition gray tabs for high and low stops in the holes around the perimeter of knob

as required. See Figure 6.

65

7

0

2

0

60

15

55

10

50

L

a

n

d

i

s

&

75

20

18

22

6

2

5

1

24

14

26

12

1

0

8

S

t

a

e

80

28

30

85ºF

30

Cº

f

a

Operating Modes

Normal Mode

Frost Protection Mode

(RCU50U)

Energy Saving Mode

Operating Mode

Changeover Switch

(RCU50U)

TH0625R1

Figure 6. Set Point Limit Stops.

When dry contact (D1 and Ground) is open, the set point knob setting takes over

control and normal mode is initiated.

Frost protection mode can be initiated by activating the external operating mode

changeover switch, if DIP Switch No. 1 is set to OFF.

If the room temperature falls below 46°F (8°C), the controller will automatically switch t

frost protection mode. In that case, the heating valve opens and the room temperature

is maintained at a set point of 46°F (8°C). The set point adjusted by the user will be

ignored.

Energy saving mode can be initiated by activating the external operating mode

changeover switch, if DIP Switch No. 1 is set to ON.

In energy saving mode, the heating set point is 61°F (16°C) and the cooling set point is

82°F (28°C), independent of the position of the set point knob.

A changeover switch can be connected to status input D1–GND. When the switch

closes its contact (caused by an open window, for instance), the operating mode

changes from normal operation or standby to energy saving mode (if DIP Switch No. 1

is set to ON), or from normal operation or energy saving mode to standby (if DIP Switch

No. 1 is set to OFF).

The operating action of the switch (N.C. or N.O.) can be selected.

Mechanical Design

The unit consists of two parts:

• Plastic housing which accommodates the electronics, the operating elements and

the built-in room temperature sensor.

• Controller base.

The housing snaps into the top and bottom of the mounting base.

Page 4

Siemens Building Technologies, Inc.

Page 5

RCU50U and RCU50.2U Room Temperature Controllers Technical Instructions

r

.

r

For VAV Systems Document Number 155-327P25

Rev. 1, March, 2002

Mechanical Design,

Continued

The screw terminals are mounted on the base. The DIP switches and the potentiomete

are located at the rear of the unit. To access the DIP switches, remove the controller

from the controller base. See Figure 7.

Figure 7. Dip Switch Setting.

Table 3. RCU50U DIP Switches.

DIP Switch No

1 Operating mode changeove

2 Operating action of switch

for external operating mode

Meaning Position ON Position OFF

Changeover between normal

operation, energy saving and

standby

Changeover activated whe n

contact of switch is open

via external switch

changeover

Changeover between

normal operation and energy

saving mode

Changeover activated whe n

contact of switch is closed

(N.O.) 1

(N.C.)

3 Standby OFF Frost protection mode (heating

output ON at a set point of 46°F

4 P-band 2°F (1°C) in heating mode

1°F (0.5 C) in cooling mode

5 Cooling signal output in

Active Inactive1

7°F (4°C) in heating mode1

3.5°F (2°C) in cooling mode

(8°C)1

energy saving mode

Table 4. RCU50.2U DIP Switches.

DIP Switch

No.

Meaning Position ON Position OFF

1 Signal inversion 0 to 10 Vdc Output signal 0 to 10 Vdc1 Output signal 10 to 0 Vdc

1. Factory setting

Accessories

ARG70 Adapter Plate for 2 × 4-inch or 4 × 4-inch conduit boxes

QAH11.1 Changeover/remote sensor

1

1

Notes

• In systems without automatic changeover, the temperature sensor can be replaced

by an external switch for manual changeover.

• In systems with cooling only operation, the controller changeover input (terminals 2

and 3) must be bridged.

• In systems with heating only operation, do not connect sensor to, or bridge

controller changeover input (terminals 2 and 3).

Siemens Building Technologies, Inc.

Page 5

Page 6

Technical Instructions RCU50U and RCU50.2U Room Temperature Controllers

Document Number 155-327P25 for CAV Systems

Rev. 1, March, 2002

Notes, Continued

• Check the settings of DIP Switches No. 1 through No. 5 and of the potentiometer of

the RCU50U, and of DIP Switch No. 1 of the RCU50.2U and change them, if

required

• After applying power, the controller makes a reset, which takes about three

seconds; it is then ready to operate.

• The unit can be located on a wall of the room to be conditioned. Do not mount in

direct sunlight or near other heat or refrigeration sources.

• Mounting height is approximately 60 inches (150 cm) above the floor. (See

Figure 8.)

• The connecting wires can be run to the controller from a recessed conduit box.

• The controller should be opened by authorized personnel only.

Drywall Mounting

Figure 8. Acceptable Mounting Height.

• When mounting the unit, attach the controller base first. Then, make the electrical

connections and fit and secure the cover.

• The controller must be mounted on a flat wall and in compliance with local

regulations.

• Any radiator valves in the room must be set to their fully open positions upon startup.

• User input via set point knob or operating mode/fan speed selector (RCU50.2U

only) results in instantaneous response. There is a one-minute delay before

changes made to temperature sensing and changeover are implemented.

1. Insert a small screwdriver into the bottom of the controller and press in the tab

located in center of the controller.

2. Lift the bottom of the controller from the controller base and push up to remove

cover from two tabs located at the top of the controller base.

3. Separate the controller base from the controller.

Figure 9. Thermostat Cover Separation.

Page 6

Siemens Building Technologies, Inc.

Page 7

RCU50U and RCU50.2U Room Temperature Controllers Technical Instructions

For VAV Systems Document Number 155-327P25

Rev. 1, March, 2002

Drywall Mounting,

4. Using the controller base as a template, mark the hole locations with a pencil.

Continued

5. Drill two 1/4-inch diameter holes for plastic wall anchors.

6. Using a mallet, tap in the pl as tic wa ll anchor s flush wit h wa ll.

7. Pull the wiring through the opening in the upper portion of the controller base.

8. Level mounting plate.

9. Using the two wood screws provided, fasten controller base to wall. Thermostat is

not position sensitive.

10. Pull the wiring through the controller base.

11. Position controller housing over the two mounting lugs located at the top of the

controller base, and press down on cover until bottom lugs snap in place.

12. Terminate wires per wiring instructions located above the terminal block.

Figure 10. Wiring Termination.

13. Reattach the controller to the controller base.

Figure 11. Controller Reattachment.

14. Return selector switches to the normal position (RCU50.2U only). Adjust set point

dial to desired setting.

The installation is now complete.

Siemens Building Technologies, Inc.

Page 7

Page 8

Technical Instructions RCU50U and RCU50.2U Room Temperature Controllers

l

Document Number 155-327P25 for CAV Systems

Rev. 1, March, 2002

4 × 4-inch Electrical Wal

Box Mounting

An ARG70 wall plate adapter is required to mount an RCU50U or RCU50.2U controller

to a 4 × 4-inch electrical wall box. The ARG70 wall plate adapter is included with

electrical wall box mount models.

1. Insert a small screwdriver into the bottom of the controller and press in the tab

located in center of the controller.

2. Lift the bottom of the controller from the controller base and push up to remove

cover from two tabs located at the top of the controller base.

3. Separate the controller base from the controller.

4. Using the four screws provided, fasten wall box adapter (3) to plaster ring (2).

(Plaster ring supplied by others.)

5. Flex adapter mask (4) and snap in place inside wall box adapter (3).

6. Fasten the controller base (5), included with controller, to wall box adapter

assembly (3) and (4) with the two screws provided.

7. Pull wires through plaster ring (2).

TH0567R1

8. Follow Drywall Mounting Steps 6 through 15.

The installation is now complete.

1

2

3

4

5

6

Figure 12. 4 × 4-inch Electrical Wall Box Installation.

1 Electrical wall box

2 Plaster ring

3 Wall box adapter *

* Included with ARG70

Page 8

Siemens Building Technologies, Inc.

4 Adapter mask *

5 Controller base

6 Controller

Page 9

RCU50U and RCU50.2U Room Temperature Controllers Technical Instructions

l

For VAV Systems Document Number 155-327P25

Rev. 1, March, 2002

2 × 4-inch Electrical Wal

Box Mounting

An ARG70 wall plate adapter is required to mount an RCU50U or RCU50.2U controller

to a 2 × 4-inch electrical wall box. The ARG70 wall plate adapter is included with

electrical wall box mount models.

1. Insert a small screwdriver into the bottom of the controller and press in the tab

located in center of the controller.

2. Lift the bottom of the controller from the controller base and push up to remove

cover from two tabs located at the top of the controller base.

3. Separate the controller base (5) from the controller (6).

4. Using the two screws provided, fasten wall box adapter (3) to plaster ring (2).

(Plaster ring supplied by others.)

5. Flex adapter mask (4) and snap in place inside wall box adapter (3).

6. Pull wires through plaster ring (2).

7. Fasten the controller base (5) to wall box adapter assembly (3) and (4) with the two

screws provided.

8. Follow Drywall Mounting Steps 6 through 15.

TH0568R1

The installation is now complete.

1

3

4

5

6

Figure 13. 2 × 4-inch Electrical Wall Box Installation.

1 Electrical wall box

3 Wall box adapter *

4 Adapter mask *

* Included with ARG70

Siemens Building Technologies, Inc.

5 Controller base

6 Controller

Page 9

Page 10

Technical Instructions RCU50U and RCU50.2U Room Temperature Controllers

Document Number 155-327P25 for CAV Systems

Rev. 1, March, 2002

Specifications

Power Supply

Functional Data

Environmental

Conditions

Agency Approvals

General

Operating voltage 24 Vac ±20%

Control action (P) Proportional

Frequency 50/60 Hz

Set point setting range 50°F to 85°F (10°C to 30°C)

P-band in heating mode

RCU50U 2°F or 7°F (1°C or 4°C)

RCU50.2U (fixed) 7°F (4°C)

P-band in cooling mode

RCU50 1°F or 3.5°F (0.5°C or 2°C)

RCU50.2 (fixed) 3.5°F (2°C)

Set point (Energy Saving Mode

Set point (Energy Saving Mode

), heating 61°F (16°C)

), cooling 82°F (28°C)

Set point Frost Protection 46°F (8°C)

Set point shift temperature @ 72°F (22°C) ±22.5°F (±40°C)

Control outputs, terminals 4 and 5

Vol tag e 0 to 10 Vdc

Current ±1 mA

Status input D1 (RCU50U)

Contact sensing 6 to 15 Vdc/3 to 6 mA

Insulation against live voltage 4 kV

Maximum number of contacts connected 50

in a panel

Status inputs 1 and 2 (RCU50U)

Set point shift of ± 22.5°F @ 72°F (22°C) 0 to 10 Vdc

Neutral position (no set point shift) 5 Vdc

Signal input terminals 2 and 3 for changeover QAH11.1 safety class 2

sensor

NTC resistor 3K Ω @ 77°F (25°C)

Maximum copper cable length 16 AWG

For Input Signal terminals 1 & 2 (RCU50U) 262 feet (80m)

For Input Signal D1 (RCU50U) 262 feet (80m)

Operation

Temperature 32°F to 122°F (0°C to 50°C)

Humidity <95% rh

Shipping and storage

Temperature –13°F to 158°F (–25°C to 70°C)

Humidity <95% rh

UL listed UL 873

Conforms to CE requirements

cUL certified to Canadian Standard

C22.2 No. 24-93

Connection terminals Use solid wires or prepared stranded

wires. 2 × 16 AWG or 1 × 14 AWG

Maximum 20 AWG

Weight

RCU50U 0.5 lb (0.23 kg)

RCU50.2U 0.5 lb (0.23 kg)

Housing color

Cover White

Base Gray

Page 10

Siemens Building Technologies, Inc.

Page 11

RCU50U and RCU50.2U Room Temperature Controllers Technical Instructions

.

t

For VAV Systems Document Number 155-327P25

Rev. 1, March, 2002

Wiring Diagrams

G

G

Dimensions

G0

TH0637R1

AC

24 V

7

6

54

1mA

max.

7 D1 GND

123

24 VAC

645

G0

TH0638R1

1mA

max.

Figure 14. RCU50U Wiring Diagram. Figure 15. RCU50.2U Wiring Diagram.

1 Signal input set point shift

2 Measuring neutral

3 Heat/cool "changeover sensor" inpu

4 0 to 10 Vdc control signal

5 Ground for control signal

6 Operating voltage, 24 Vac negati ve

7 Operating voltage, 24 Vac positive

D1 Signal input for potential-free

operating mode changeover switch

G 24 Vac, digital input

G0 24 Vac

GND Ground

0.16 (4)

4.49

(114.15)

1.38

(35)

1.10

(28)

1.10

(28)

1.10

(28)

0.16

(4)

1.10

1.18

(28)

(30)

TH0575R1

Figure 16. Controller and Baseplate Dimensions in Inches (Millimeters).

3.80

(96.6)

1.69

(42.8)

0.46

(11.8)

TH0576R1

1.02

(26)

3.34

(90)

0.16 (4)

1.18

(30)

4.09

(104)

Information in this publication is based on current specifications. The company reserves the right to make c hanges i n specifications and models as

design improvements are introduced. Other product or company names mentioned herein may be the trademarks of their respecti ve owners.

© 2002 Siemens Building Technologies, Inc.

Siemens Building Technologies, Inc.

1000 Deerfield Parkway

Buffalo Grove, IL 60089-4513

U.S.A.

Your feedback is important to us. If you have

comments about this document, please send

them to technical.editor@sbt.siemens.com

Document No. 155-327P25

Printed in the U.S.A

Page 11

Loading...

Loading...