Page 1

Installation Instructions

Model RCC-3/-3R/-3C/-3F/-3FC/-3FR

Remote Command Center

INTRODUCTION

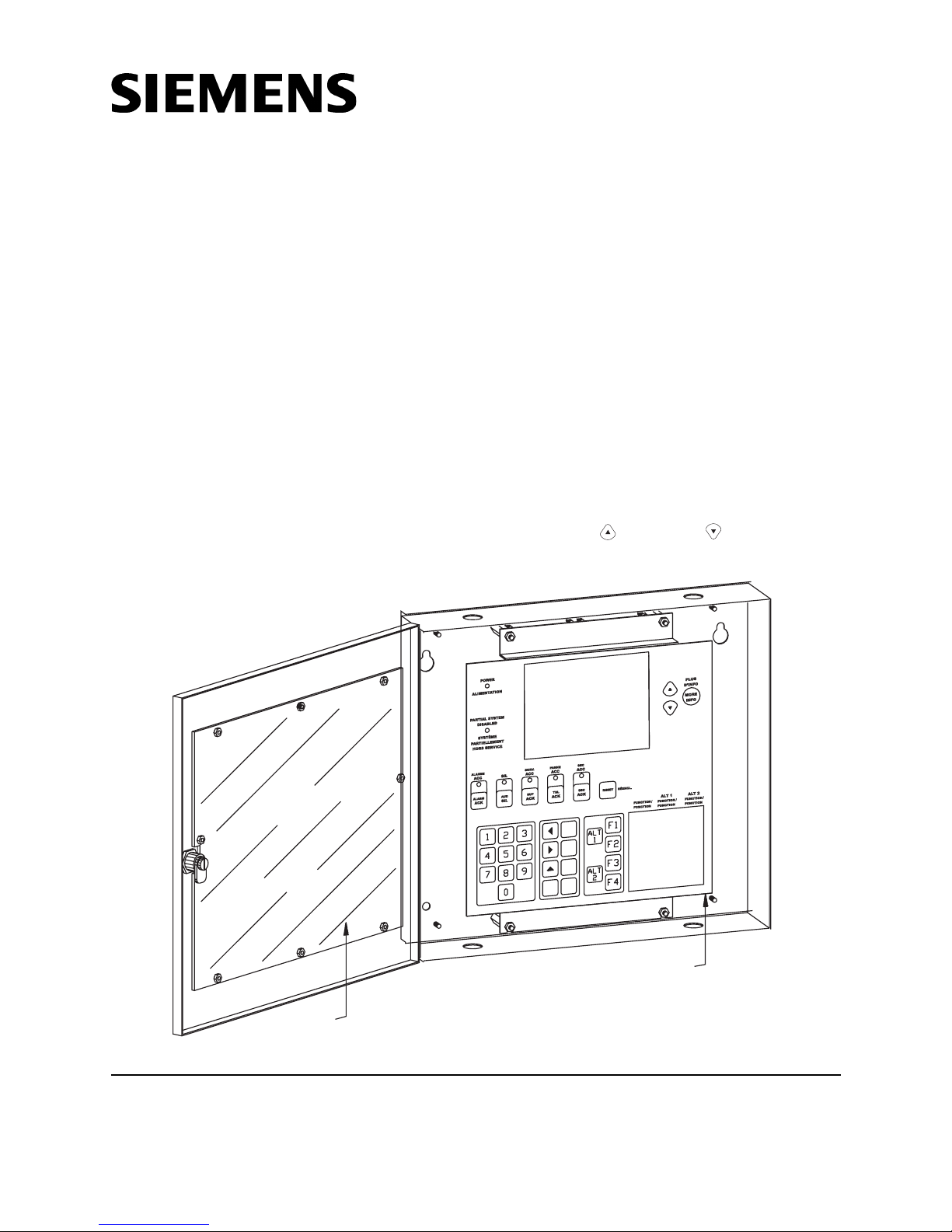

The Model RCC-3/-3R/-3C Remote Command

Center from Siemens Industry, Inc. is an optional

MXL/MXLV System remote keyboard panel (See

Figure 1). The RCC-3R is red and will be referred to in the remainder of this document as

the RCC-3. The RCC-3F/-3FC/-3FR Remote

Command Center, which is used for flush

mounting applications, has a 3/4 inch flange on

all four sides of the enclosure. The RCC-3FR is

red and will be referred to in the remainder of

this document as the RCC-3F.

CAUTION: When preparing the opening for the

RCC-3F/-3FC make sure it does not exceed the

dimensions of the enclosure as shown in Figure 2,

plus the dimensions of the flange.

The panel in the RCC-3/-3C/-3F/-3FC has a multiline display that continuously updates information

about the system event status. If there are

multiple events (alarms, security conditions,

supervisories and/or troubles), the highest

priority event that occurred displays on the

screen. The user can view up to 8 events at a

time and can scroll through the complete list

using the Up ( ) and Down ( ) keys located

next to the More Info key. For further information

Clear lens

RCC-3C/3FC Remote Command Center

Siemens Industry, Inc.

Building Technologies Division

Florham Park, NJ

P/N 315-048665-7

Figure 1

/

P

L

E

H

E

D

I

A

/

T

N

I

R

P

.

P

M

I

/

E

C

A

P

S

E

C

A

P

S

E

/

R

A

E

L

C

/

R

E

T

N

E

R

E

C

A

F

F

E

R

E

R

T

N

E

Keyboard/Display panel

Siemens Building Technologies, Ltd.

Fire Safety & Security Products

2 Kenview Boulevard

Brampton, Ontario

L6T 5E4 Canada

Page 2

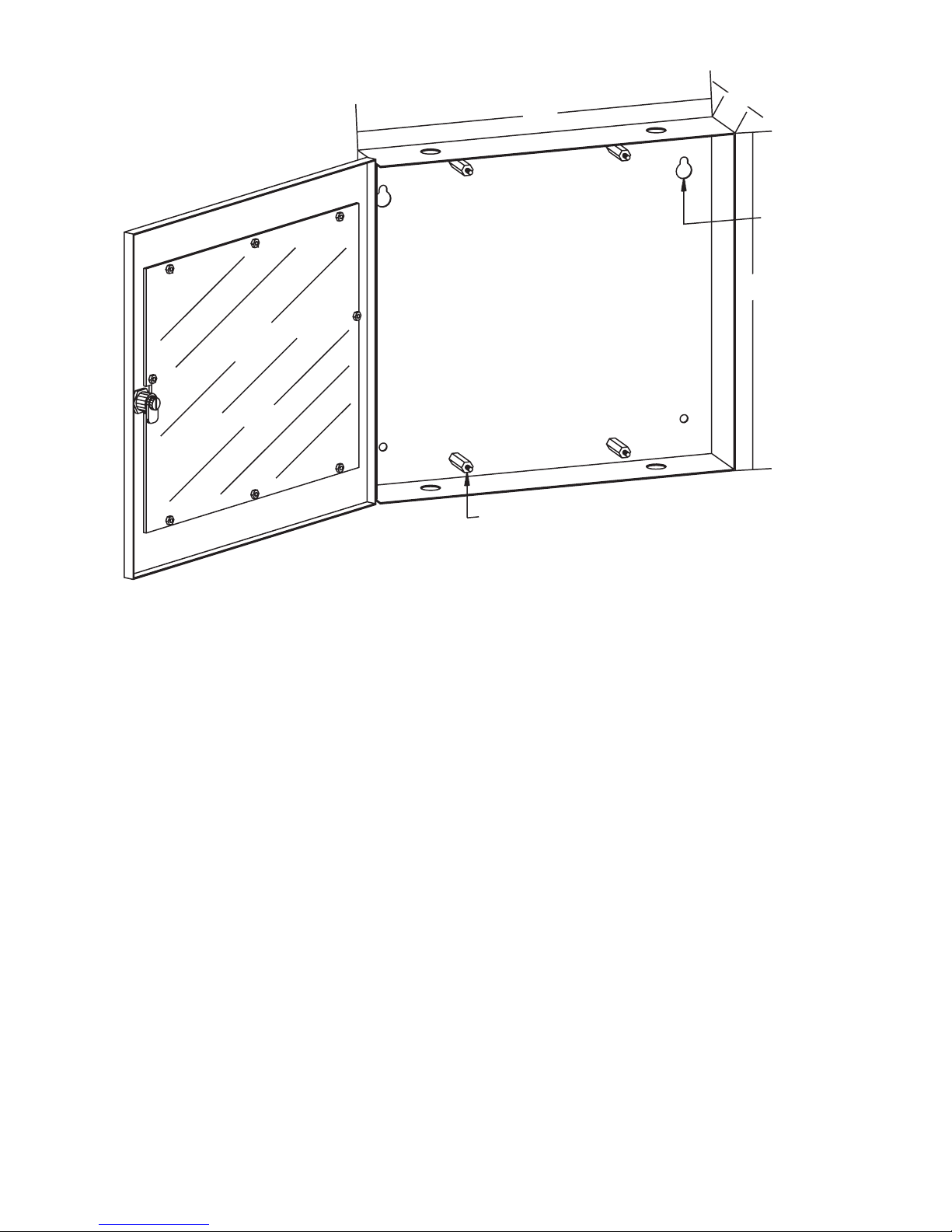

14"

Standoffs for

keyboard panel

2½"

13"

Mounting holes

(4 places)

Mounting the RCC-3/3F

on the operation of the MXL Multi-Line Keyboard/

Display Panel, refer to the MXL Keyboard/

Display Panel Operating Instructions, P/N 315048692, and Section 3, OPERATION, in the

MXL/MXLV Manual, P/N 315-092036.

The keyboard/display panel has keys for the

following functions:

• Acknowledging fire alarms (ALARM ACK)

• Silencing audibles (AUD SIL)

• Acknowledging supervisories (SUPV ACK)

• Acknowledging troubles (TRBL ACK)

• Acknowledging security conditions (SEC ACK)

There is also a separate key for resetting the

Control Panel (RESET)

The 10-digit phone style keypad allows entry of

the three levels of user passwords. It is also

used to perform specific menu-driven operations,

as well as programming and maintenance

functions.

Separate UP and DOWN keys located next to the

MORE INFO key allow the user to scroll forward

and backwards through the entire list of events.

Figure 2

The SPACE key allows the user to input addresses faster by enabling them to reduce

redundant key presses of the “0” key.

The MORE INFO key allows the user to instantly

view all relevant information about the highlighted

event, which is displayed in the last three lines of

the screen.

The user can access the MXL Control menu by

pressing the ENTER key.

The panel has System status indicator LEDs.

The ALARM and TROUBLE LEDs function even

if the main processor fails. (See Figure 1).

INSTALLATION

Always remove all power before installation,

first the battery and then the AC.

The RCC-3/-3C/3F/-3FC comes with the keyboard/display panel installed in the enclosure and

a clear lens installed in the door, as shown in

Figure 1.

2

Page 3

1 2 3 4 5

TO OPTION

MODULES

SERIAL

PRINTER

PARALLEL

PRINTER

1

J3

BACKLIGHT

VR2

BRIGHTNESS

J2 J1 J5

J10

SERIAL

PRINTER

1

PARALLEL

PRINTER

1

J11

LCD KEYBOARD LEDS

J13

J7

+

1

J12

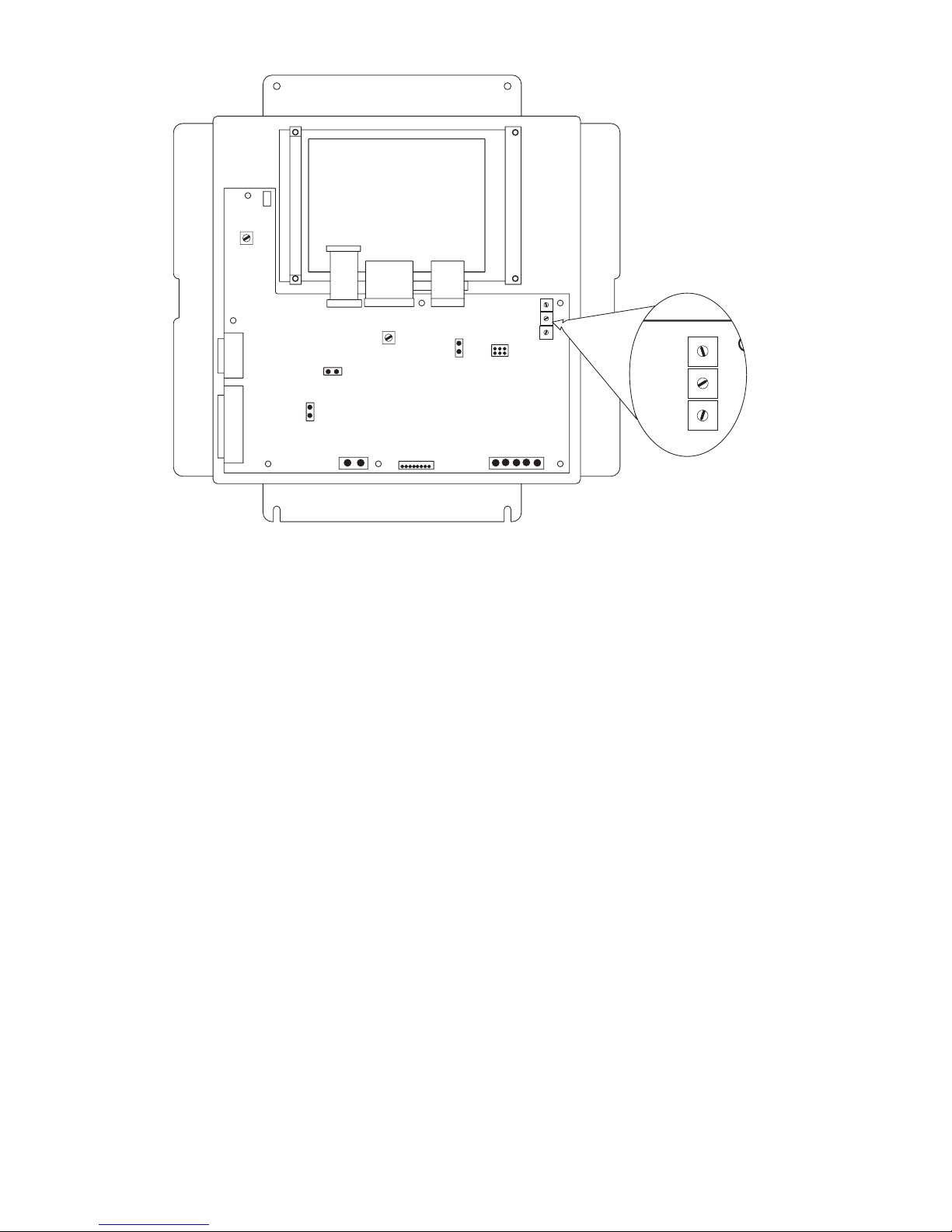

Rear View of Keyboard/Display Panel in RCC-3/3F

Before mounting the RCC-3/-3C/3F/-3FC,

remove the four nuts from the keyboard panel

and place them to one side. Carefully lift the

panel up and off the standoffs. Set the panel to

one side.

Consider the following when mounting the

backbox:

• Mounting height for visual and manual

access to the keyboard/display panel

• Weight and size of the enclosure

• Local mounting codes

1. Fasten the backbox securely to a clean, dry,

shock-free, and vibration-free surface using

the four mounting holes provided. Position

the backbox clear of obstructions so that the

door opens freely and the indicators and

controls are easily accessible.

2. Set the Network Address for the RCC-3

using the three ten-position rotary switches

(S1, S2 and S3) located on the back of the

keyboard/display panel, as shown in Figure 3.

For example, to set the switches to address

248: set S1 to 2, set S2 to 4, and set S3 to 8.

The possible addresses for this module are

248, 259, 250, and 251.

1

VR1

CONTRAST

_

2

J4

1

MODULES

1

1

J6

J9

NETWORKTO OPTION

12345

J8

Figure 3

3

2

4

1

5

0

6

9

S1

7

8

3

2

4

1

5

0

6

9

S2

7

8

3

2

4

1

5

0

6

9

S3

7

8

S1

S2

S3

3

2

4

1

5

0

6

9

7

8

3

2

4

1

5

0

6

9

7

8

3

2

4

1

5

0

6

9

7

8

NOTE:

There is no need to set supervision on the

RCC-3/-3C/3F/-3FC because it is, by default,

always supervised. No unsupervised

annunciators (MKB-1/-2/-3/-4) are allowed

at the same address as an RCC-3/-3C/3F/3FC. Unsupervised applications require the

use of the MKB-1/-2/-3/-4 and they must all

be set to the same address.

3. Pull all field wiring into the backbox and

dress the wiring to the approximate location

to which it will go.

4. Remove the connector plugs from J8. Attach

the wiring to the connector plugs in positions

1 and 2 for Style 4 (refer to Figure 4) and

positions 1, 2, 3 and 4 for Style 7 (refer to

Figures 5 and 6). Always connect position 5

to Chassis GND (Earth GND).

5. Remove the connector plugs from J12.

Attach the field wiring to the connector plugs,

making sure that position 1 on J12 is for

+24VDC and position 2 on J12 is for -24VDC

return.

6. To adjust the contrast and brightness of the

display, use pots VR1 and VR2 respectively,

located on the back of the keyboard /display

panel. (Refer to Figure 3.)

3

Page 4

POWER

MMB-1/-2:

120 OHMS, 1/4W, 5%

*

P/N 140-820150

MMB-3:

RES EOL ASSEMBLY

120 OHMS, 1/4W, 5%

P/N 140-049099

*

SERIAL PRINTER

PARALLEL PRINTER

TB1

4

3

2

1

SUPERVISION

NOTE:

INSTALL EITHERA SERIAL OR

PARALLEL PRINTER. ONLY ONE

PRINTER CAN BE CONNECTED

TO THE SYSTEM.

SUPERVISED BY DEFAULT

MMB

BACKLIGHT

OPTIONAL

SERIAL PRINTER

PARALLELPRINTER

For RCC-3/3 F Installation Only

1

J3

J10

J11

CHASSIS

GND

1

13

14

2

LCD

KEYBOARD

12 1

J2 J1

J12

12

+-

+24VDC

-24VDC

For 24 VDC connections, refer to the following terminations:

MMB

PSR-1

PLM-35 (Used with PS-35)

ALARMSAF (Model BN4-002-UL)

PAD-3

81

J4

TO OPTIONAL

MODULES

18

P/N 140-820150

120 OHMS, 1/4W, 5%

LEDS

J5

J8

NETWORK

12345

TB5, 9-12

TB3, 3-6

TB1, 1-2

DC1

TB2, 18-19

Notes:

1. Use a minimum wire gauge of 22 AWG.

2. Use a maximum of 80 ohms per pair of wires for

the network connections.

3. Use shielded twisted pair for network connections.

4. Terminate the shield ONLY at the MMB

enclosure.

5. For MMB-1/-2 Style 4, use a 120 Ohm, 1/4W,

5% EOLR, P/N 140-820150, in positions 1 and

2 on plug J8.

For MMB-3 Style 4, use Res EOL Assembly, 120

Ohm, 1/4W, 5%, P/N 140-049099.

6. This configuration is power limited to NFPA

70 according to NEC 760.

7. The RCC-3/-3C/-3F/-3FC MUST have an

earth ground connected to the chassis. Wire

shield or conduit is not an acceptable ground.

Use any available unused, unpainted stud on

the MMB for chassis grounding.

8. Refer to Wiring Specification for MXL, MXL-IQ

and MXLV Systems, P/N 315-092772 revision

6 or higher, for additional wiring information.

9. Maximum voltage: 8V peak to peak

Maximum current: 150mA

Figure 4

RCC-3/3F Style 4 Wiring

4

Page 5

POWER

P/N 140-820150

120 OHMS, 1/4W, 5%

TB1

SERIAL PRINTER

PARALLEL PRINTER

P/N 140-820150

120 OHMS, 1/4W, 5%

1

2

34

5678910111213141516

NET-7

NOTE:

INSTALL EITHER A SERIAL OR

PARALLEL PRINTER. ONLY ONE

PRINTER CAN BE CONNECTED

TO THE SYSTEM.

SUPERVISED BY DEFAULT

MOM-4

SUPERVISION

OPTIONAL

1

2

34

5678910111213141516

1

BACKLIGHT

SERIAL PRINTER

PARALLELPRINTER

J3

J10

J11

1

13

14

2

LCD

KEYBOARD

12 1

81

J2 J1

J12

12

+-

+24VDC

-24VDC

TB3

For 24 VDC connections, refer to the following terminations:

MMB

PSR-1

PLM-35 (Used with PS-35)

ALARMSAF (Model BN4-002-UL)

PAD-3

J4

TO OPTIONAL

MODULES

18

P/N 140-820150

*

120 OHMS, 1/4W, 5%

TO CHASSIS GND ON MMB-1/-2

LEDS

J5

J8

NETWORK

12345

**

TB5, 9-12

TB3, 3-6

TB1, 1-2

DC1

TB2, 18-19

1

2

34

5678910111213141516

TB2

1

2

34

Notes:

1. Use a minimum wire gauge of 22 AWG.

2. Use a maximum of 80 ohms per pair of

wires for the network connections.

3. Use shielded twisted pair for network

connections.

4. Terminate the shield ONLY at the MMB

enclosure.

5. For Style 7, use a 120 Ohm, 1/4W, 5%

EOLR, P/N 140-820150, in positions 1 and 2

and positions 3 and 4 on plug J8.

6. For Style 7, use a NET-7 card and refer to the

NET-7 Installation Instructions, P/N 315-090914.

7. The NET-7 is not compatible with the PS-5N.

RCC-3/3F Style 7 Wiring (MMB-1 or MMB-2)

5678910111213141516

TB4

8. This configuration is power limited to NFPA

70 according to NEC 760.

9. The RCC-3/-3C/-3F/-3FC MUST have an earth

ground connected to the chassis. Wire shield or

conduit is not an acceptable ground. Use any

available unused, unpainted stud on the MMB

for chassis grounding.

10. Refer to Wiring Specification for MXL, MXL-IQ

and MXLV Systems, P/N 315-092772 revision

6 or higher, for additional wiring information.

11. Maximum voltage: 8V peak to peak

Maximum current: 150mA

Figure 5

5

Page 6

POWER

SERIAL PRINTER

PARALLEL PRINTER

TB1

SUPERVISION

NOTE:

INSTALL EITHER A SERIAL OR

PARALLEL PRINTER. ONLY ONE

PRINTER CAN BE CONNECTED

TO THE SYSTEM.

SUPERVISED BY DEFAULT

OPTIONAL

1

BACKLIGHT

SERIAL PRINTER

PARALLELPRINTER

CHASSIS

J3

J10

J11

GND

13

14

LCD

J2 J1

+-

+24VDC

-24VDC

1

2

KEYBOARD

12 1

J12

12

120 OHMS, 1/4W, 5%

81

LEDS

J5

J4

TO OPTIONAL

MODULES

18

P/N 140-820150

*

TO CHASSIS GND ON MMB-3

J8

NETWORK

12345

**

RES EOL ASSEMBLY

120 OHMS, 1/4W, 5%

P/N 140-049099

RES EOL ASSEMBLY

120 OHMS, 1/4W, 5%

P/N 140-049099

4

3

2

1

Notes:

1. Use a minimum wire gauge of 22 AWG.

2. Use a maximum of 80 ohms per pair of

wires for the network connections.

3. Use shielded twisted pair for network

connections.

4. Terminate the shield ONLY at the MMB

enclosure.

5. For Style 7, use Res EOL Assembly 120 Ohm,

1/4W, 5%, P/N 140-049099, in positions 1

and 2 and positions 3 and 4 on plug J8.

6. This configuration is power limited to NFPA

70 according to NEC 760.

For 24 VDC connections, refer to the following terminations:

MMB

PSR-1

PLM-35 (Used with PS-35)

ALARMSAF (Model BN4-002-UL)

PAD-3

MMB-3

7. The RCC-3/-3C/-3F/-3FC MUST have an earth

ground connected to the chassis. Wire shield or

conduit is not an acceptable ground. Use any

available unused, unpainted stud on the MMB

for chassis grounding.

8. Refer to Wiring Specification for MXL, MXL-IQ

and MXLV Systems, P/N 315-092772 revision

6 or higher, for additional wiring information.

9. MNET:

Maximum Voltage: 8V Peak To Peak

Maximum Current: 150mA

TB5, 9-12

TB3, 3-6

TB1, 1-2

DC1

TB2, 18-19

Figure 6

RCC-3/3F Style 7 Wiring (MMB-3)

6

Page 7

7. If needed, J11 is the connector for a parallel

printer and J10 is the connector for a serial

printer. The serial connection can be

supervised; the parallel connection is

supervised by default. Note that only one

printer, either parallel or serial, may be

connected to the system.

Supervision for the printer is set in CSG-M. In

the Network Module Map, select the MKB and

press Enter. Scroll down to Printer Option and

press Enter to toggle to the correct printer. The

fields Supervised Operation and Serial Port

must both be set to YES.

8. Make certain the connector plugs are in place

on J13 for normal operation and network

programming.

9. Mount the keyboard panel in the enclosure by

placing it on the standoffs and securing it in

place with the four nuts provided.

10. Refer to the MXL Multi-Line Display/Panel

Operating Instructions, P/N 315-048692, for

additional information on the operation of the

keyboard panel.

11. Refer to MMB-3 Installation Instructions,

P/N 315-048860, Configuration and MNET

sections to configure the MMB-3 and CSGM

for Style 4/7 wiring.

CCU/M and RDM-1 Wiring

to MKB-5/-6 or RCC-3

CCU/M OR RDM-1

RXD

TXD

GND

DSR

CTS

RCC-3

J10

2

3

5

6

8

MXL-VDT Wiring

to MKB-5/-6 or RCC-3

RCC-3

J10

RXD

2

TXD

3

GND

5

DSR

6

CTS

8

DB9

PORT C

RXD

2

TXD

3

DTR

4

GND

5

RTS

7

MXL-VDT

MAIN PORT

RXD

3

TXD

2

DTR

20

GND

7

RTS

4

DB24

ELECTRICAL RATINGS

tnerruCeludoMCDV5evitcAAm0

tnerruCeludoMCDV42evitcAAm003

tnerruCeludoMCDV42ybdnatSAm003

Refer to the following Installation Instructions

as needed:

MMB-2 P/N 315-095097

MMB-3 P/N 315-048860

NET-7 P/N 315-090914

MXL/MXLV Manual P/N 315-092036

7

Page 8

Siemens Industry, Inc.

Building Technologies Division

Florham Park, NJ

P/N 315-048665-7

Siemens Building Technologies, Ltd.

Fire Safety & Security Products

2 Kenview Boulevard

Brampton, Ontario

L6T 5E4 Canada

Loading...

Loading...