Page 1

NOTIFICATION OF MANUAL STATUS

RB-6 L-801A (Airport) Rotating Beacon (Export) is now sold by Halibrite. Use manual 96A0221 only

for old equipment in the field. Discard this notification page before sending manual.

Page 2

RB-6 L-801A (Airport)

Rotating Beacon (Export)

Document No. 96A0221

Issued: February 6, 1998

Rev. B: May 16, 2001

Manufactured to FAA Specification

AC 150/5345-12C

Copyright 2001 by Siemens Airfield Solutions, Incorporated. All rights reserved.

Page 3

RB-6 L-801A (Airport) Rotating Beacon (Export) Record of Changes

Record of Changes

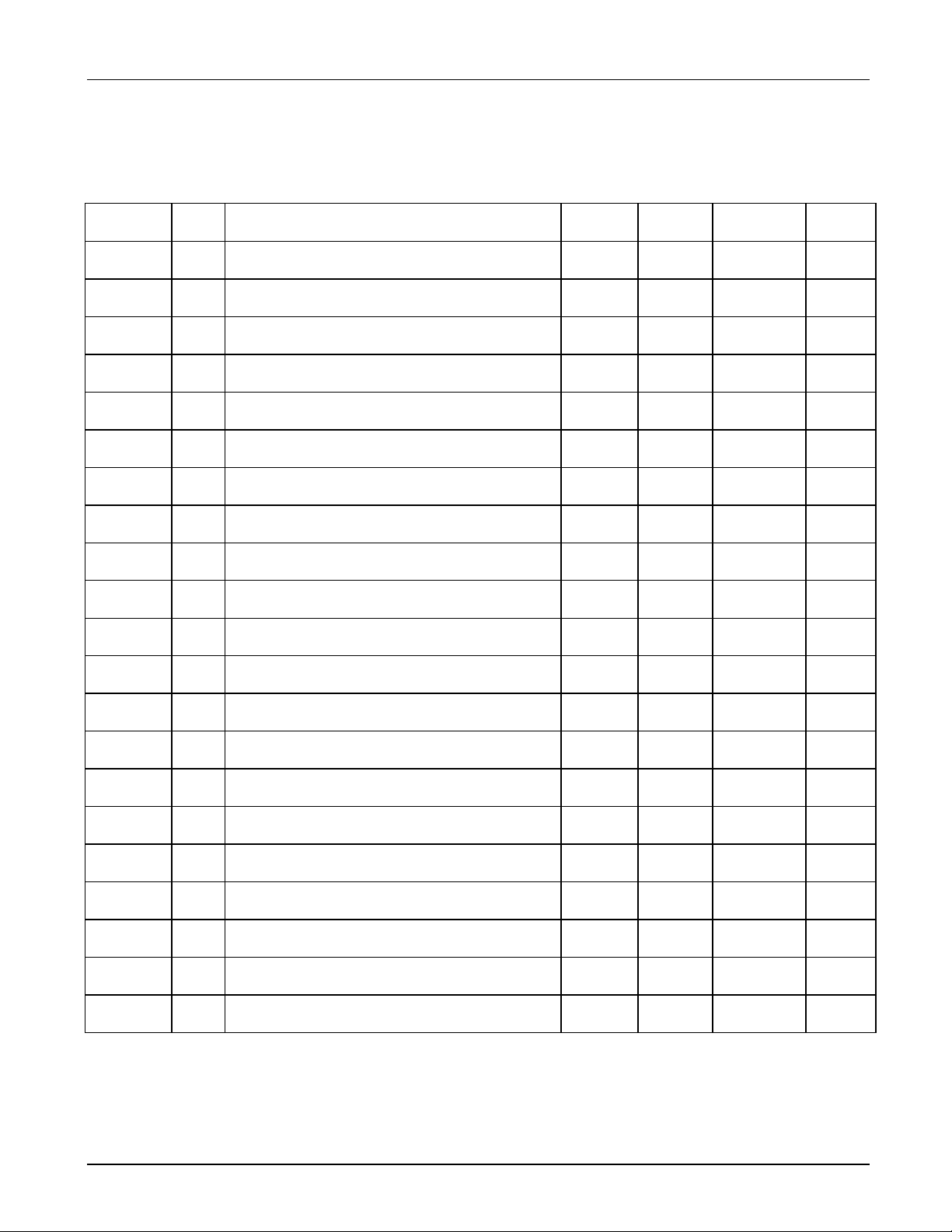

Page Rev Description EC No. Checked Approved Date

A Released manual.

All B Changed to new title page. Changed ADB to

Siemens Airfield Solutions.

3250 KJ VP 2/6/98

00696 KJ WT 5/16/01

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page ii

Page 4

RB-6 L-801A (Airport) Rotating Beacon (Export) Table of Contents

Table of Contents

Record of Changes.......................................................................................................................................................................ii

Table of Contents........................................................................................................................................................................iii

Warranties...................................................................................................................................................................................vi

Safety

Description

1. Introduction...........................................................................................1-1

2. Safety Symbols .....................................................................................1-1

3. Qualified Personnel...............................................................................1-2

4. Intended Use .........................................................................................1-2

5. Installation.............................................................................................1-3

6. Operation...............................................................................................1-3

7. Action in the Event of a System

or Component Malfunction...................................................................1-4

8. Maintenance and Repair........................................................................1-4

1. Introduction...........................................................................................2-1

2. RB-6 Beacon Assemblies......................................................................2-3

Head Assembly .................................................................................2-3

Hub and Shaft Assembly...................................................................2-3

Box Assembly...................................................................................2-3

Motor and Drive Assembly...............................................................2-3

3. Options..................................................................................................2-3

Optional Obstruction Light...............................................................2-3

Optional Heater Assembly................................................................2-5

Optional Mounting Bases..................................................................2-6

Optional Photocell Assembly............................................................2-8

4. Theory of Operation..............................................................................2-8

RB-6 Rotating Beacon Operations ................................................2-8

Optional Heater Assembly Operations..........................................2-8

Optional Photocell Assembly Operations......................................2-9

Optional Obstruction Light Operations.........................................2-9

5. RB-6 Rotating Beacon: Required Equipment.......................................2-9

6. Specifications......................................................................................2-10

Input................................................................................................2-10

Beacon Wattage ..............................................................................2-10

Lenses..............................................................................................2-10

Rated Lamp Life .............................................................................2-10

Lamp Wattage.................................................................................2-10

Beam Intensity ................................................................................2-11

Rotation Speed................................................................................2-11

Heater..............................................................................................2-11

Environmental Operating Conditions..............................................2-11

Weight.............................................................................................2-11

Dimensions......................................................................................2-12

Clearance for Rotation ....................................................................2-12

Mounting Dimensions.....................................................................2-12

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page iii

Page 5

RB-6 L-801A (Airport) Rotating Beacon (Export) Table of Contents

Installation

Maintenance

Troubleshooting

Parts

Wiring Schematics

1. Introduction...........................................................................................3-1

2. Unpacking.............................................................................................3-1

3. RB-6 Beacon Installation......................................................................3-1

Mounting ..........................................................................................3-1

Wiring ...............................................................................................3-2

Optional Heater Wiring.....................................................................3-2

Angle Adjustment.............................................................................3-2

Export Beacon Installation Requirement ..........................................3-4

1. Introduction...........................................................................................4-1

2. Maintenance Schedule ..........................................................................4-1

3. Maintenance Procedures .......................................................................4-2

Replacing Lamp................................................................................4-2

Adjusting Lamp Beam ......................................................................4-2

Replacing Brushes and Brush Brackets ............................................4-3

Cleaning Lenses................................................................................4-6

Cleaning Head Assembly..................................................................4-6

Cleaning Slip Rings and Brushes......................................................4-6

Lubricating Parts...............................................................................4-7

1. Introduction...........................................................................................5-1

2. Troubleshooting Procedures .................................................................5-1

1. Introduction.........................................................................................6-1

2. Using the Illustrated Parts List............................................................6-1

3. RB-6 Rotating Beacon Final Assembly Parts List..............................6-2

4. Head Assembly (Single Head) Parts List............................................6-4

5. Box Assembly Parts List.....................................................................6-6

6. Motor Assembly Parts List..................................................................6-8

7. Brush Block Assembly Parts List........................................................6-9

8. Photocell Contractor Parts List .........................................................6-11

9. Heater Assembly Parts List...............................................................6-13

10. Reflector Assembly Parts List...........................................................6-15

11. Obstruction Light and Relay Parts List.............................................6-17

12. Optional Assemblies Parts List.........................................................6-19

1. Introduction...........................................................................................7-1

2. Wiring Schematics................................................................................7-1

RB-6 with Optional Heater Wiring...................................................7-1

Optional Photocell Assembly Wiring ...............................................7-3

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page iv

Page 6

RB-6 L-801A (Airport) Rotating Beacon (Export) Table of Contents

List of Figures

List of Tables

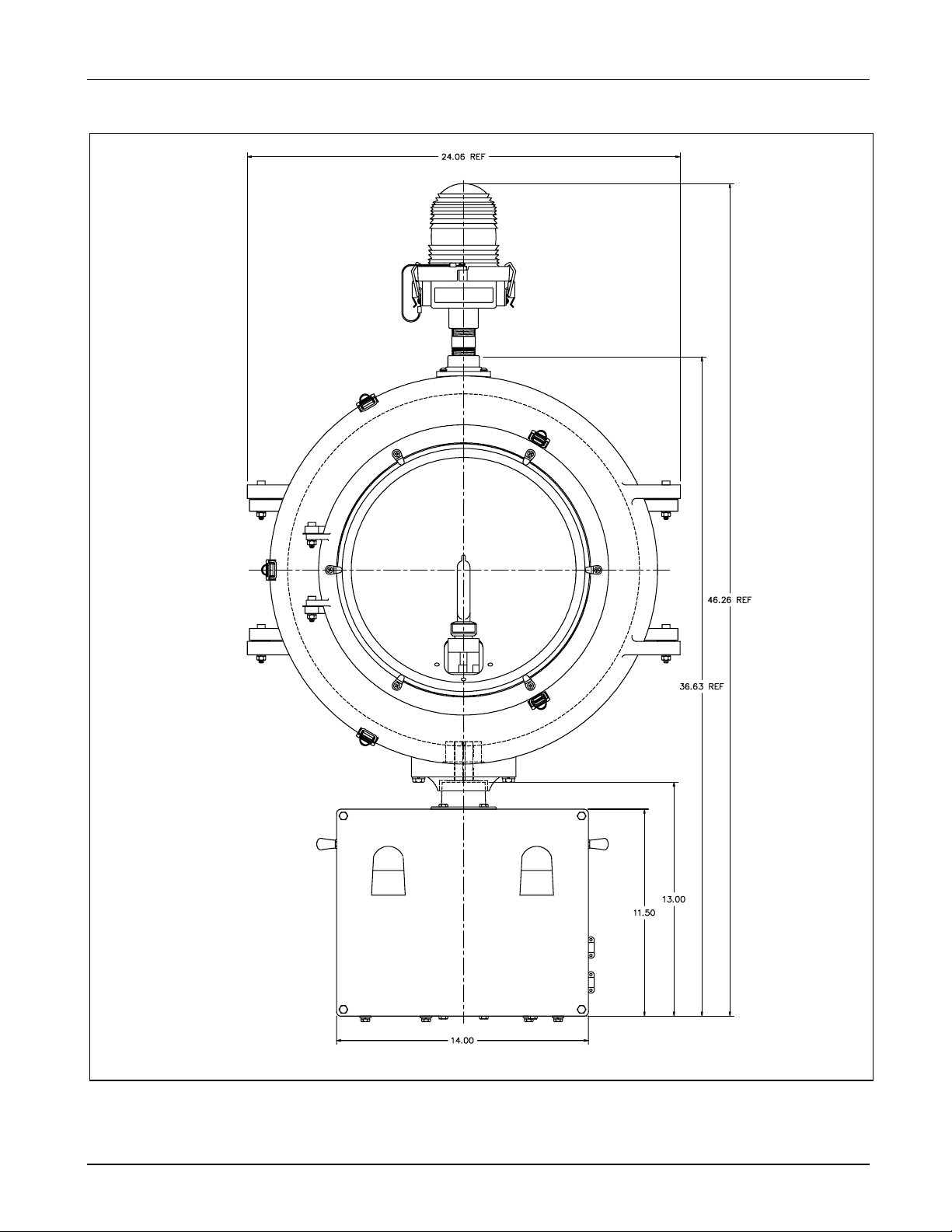

Figure 2-1. RB-6 Rotating Beacon............................................................2-2

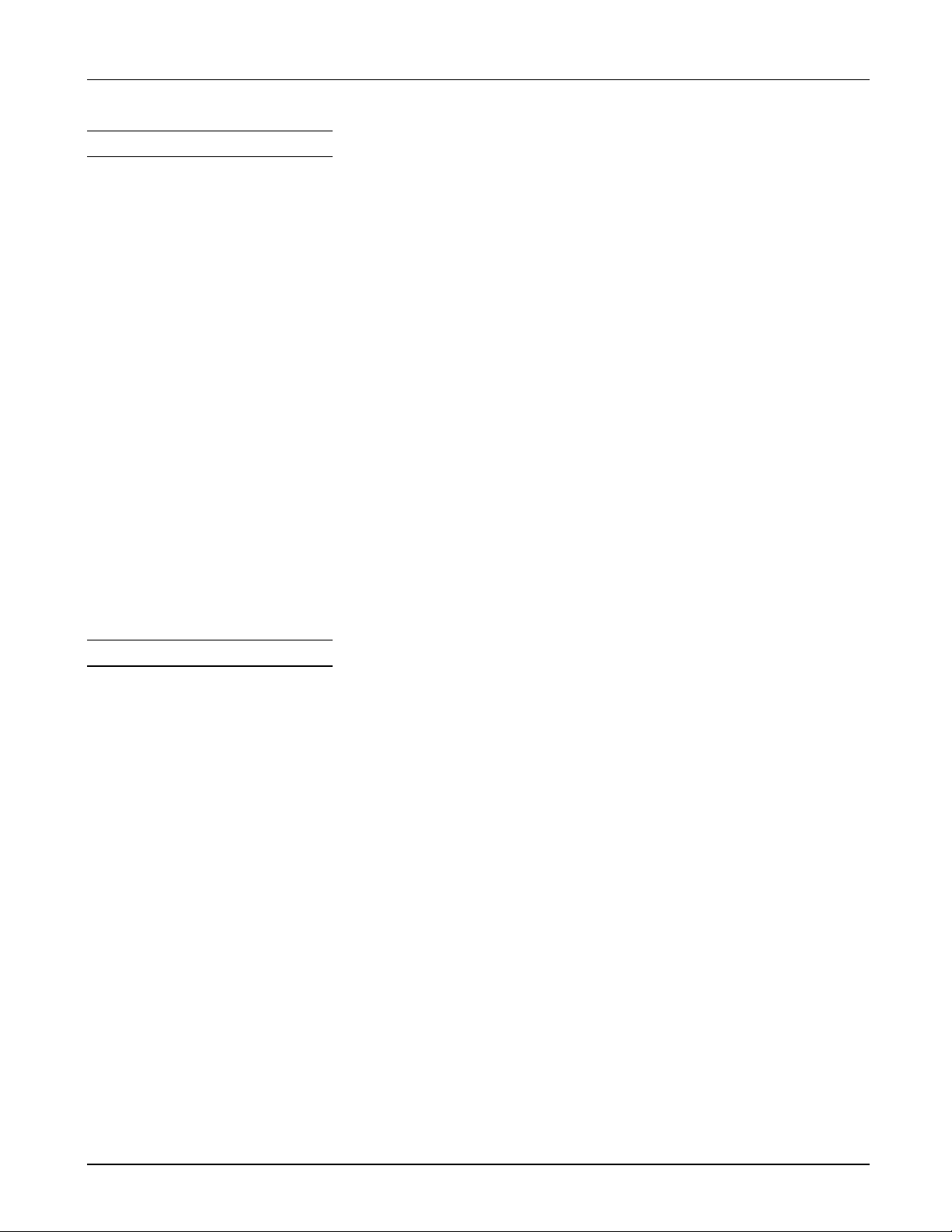

Figure 2-2. RB-6 Final Assembly with Optional

Obstruction Light Wiring.......................................................2-4

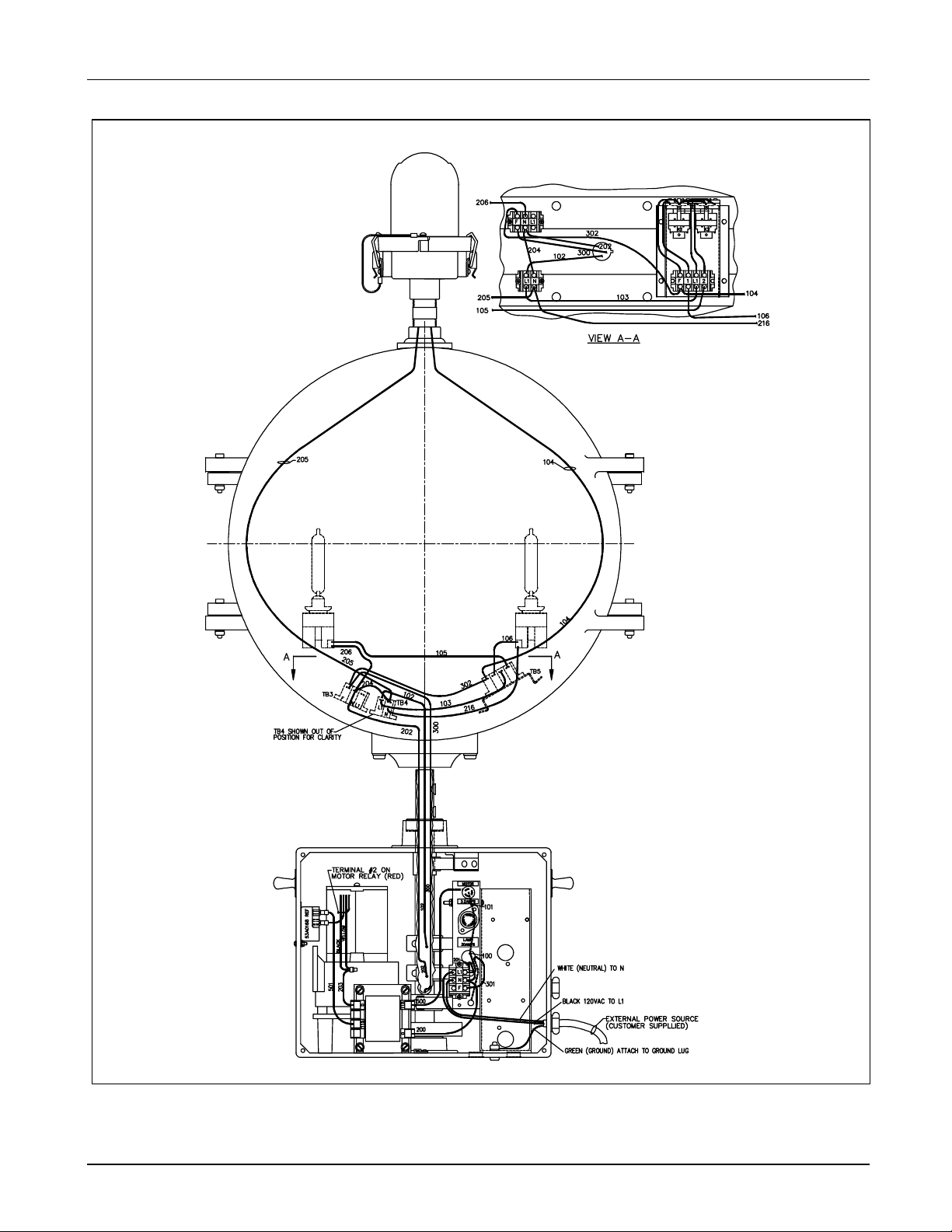

Figure 2-3. Optional Heater Assembly Wiring.........................................2-5

Figure 2-4. Optional Pole Mounting Adapter ...........................................2-6

Figure 2-5. Optional Roof Mounting Assembly .......................................2-7

Figure 2-6. Mounting Holes....................................................................2-12

Figure 3-1. Adjusting Beacon Angle ........................................................3-3

Figure 4-1. Brush Block Assembly...........................................................4-3

Figure 4-2. Pre-Bending New Brush Brackets..........................................4-5

Figure 6-1. RB-6 Rotating Beacon Final Assembly (Export Version) ....6-3

Figure 6-2. Head Assembly (Single Head)...............................................6-5

Figure 6-3. Box Assembly........................................................................6-7

Figure 6-4. Motor Assembly.....................................................................6-8

Figure 6-5. Brush Block Assembly.........................................................6-10

Figure 6-6. Photocell Contactor Assembly.............................................6-12

Figure 6-7. Heater Assembly ..................................................................6-14

Figure 6-8. Reflector Assembly..............................................................6-16

Figure 6-9. Obstruction Light .................................................................6-18

Figure 7-1. RB-6 Beacon with Optional Heater Wiring Schematic..........7-2

Figure 7-2. Optional Photocell Assembly Wiring Schematic...................7-3

Table 2-1. Required Equipment Supplied.................................................2-9

Table 2-2. Required Equipment Not Supplied........................................2-10

Table 4-1. RB-6 Rotating Beacon (Export Version) Maintenance...........4-1

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page v

Page 7

RB-6 L-801A (Airport) Rotating Beacon (Export) Warranties

Products of Siemens Airfield Solutions manufacture are guaranteed against

Warranties

Disclaimers

mechanical, electrical, and physical defects (excluding lamps) for a period

of one year from the date of installation or a maximum of two years from

the date of shipment and are guaranteed to be merchantable and fit for the

ordinary purposes for which such products are made.

Siemens Airfield Solutions will correct by repair or replacement, at its

option, equipment or parts which fail because of mechanical, electrical or

physical defects, provided that the goods have been properly handled and

stored prior to installation, properly installed and properly operated after

installation, and provided further that Buyer gives Siemens Airfield

Solutions written notice of such defects after delivery of the goods to

Buyer.

Siemens Airfield Solutions reserves the right to examine goods upon which

a claim is made. Said goods must be presented in the same condition as

when the defect therein was discovered. Siemens Airfield Solutions furthers

reserves the right to require the return of such goods to establish any claim.

Siemens Airfield Solutions’s obligation under this guarantee is limited to

making repair or replacement within a reasonable time after receipt of such

written notice and does not include any other costs such as the cost of

removal of defective part, installation of repaired product, labor or

consequential damages of any kind, the exclusive remedy being to require

such new parts to be furnished.

Siemens Airfield Solutions’s liability under no circumstances will exceed

the contract price of goods claimed to be defective. Any returns under this

guarantee are to be on a transportation charges prepaid basis. For products

not manufactured by, but sold by Siemens Airfield Solutions, warranty is

limited to that extended by the original manufacturer.

This is Siemens Airfield Solutions’s sole guarantee and warranty with

respect to the goods; there are no express warranties or warranties of fitness

for any particular purpose or any implied warranties of fitness for any

particular purpose or any implied warranties other than those made

expressly herein. All such warranties being expressly disclaimed.

This manual could contain technical inaccuracies or typographical errors.

Siemens Airfield Solutions reserves the right to revise this manual from

time to time in the contents thereof without obligation of Siemens Airfield

Solutions to notify any person of such revision or change.

Details and values given in this manual are average values and have been

compiled with care. They are not binding, however, and Siemens Airfield

Solutions disclaims any liability for damages or detriments suffered as a

result of reliance on the information given herein or the use of products,

processes or equipment to which this manual refers. No warranty is made

that the use of the information or of the products, processes or equipment to

which this manual refers will not infringe any third party’s patents or rights.

The information given does not release the buyer from making their own

experiments and tests.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page vi

Page 8

RB-6 L-801A (Airport) Rotating Beacon (Export) Safety

Section 1

Safety

1. Introduction

2. Safety Symbols

This section contains general safety instructions for using your Siemens

Airfield Solutions equipment. Some safety instructions may not apply to

the equipment in this manual. Task- and equipment-specific warnings are

included in other sections of this manual where appropriate. Note all

warnings and follow all instructions carefully. Failure to do so may result

in personal injury, death, or property damage.

To use this equipment safely,

• refer to the FAA Advisory Circular AC 150/5340-26, Maintenance of

Airport Visual Aids Facilities, for instructions on safety precautions.

• observe all safety regulations. To avoid injuries, always remove power

prior to making any wire connections and touching any parts. Refer to

FAA Advisory Circular AC 150/5340-26.

• read and become familiar with the general safety instructions provided

in this section of the manual before installing, operating, maintainin g,

or repairing this equipment.

• read and carefully follow the instructions given throughout this manual

for performing specific tasks and working with specific equipment.

• store this manual within easy reach of personnel installing, operating,

maintaining, or repairing this equipment.

• follow all applicable safety procedures required by your company,

industry standards, and government or other regulatory agencies.

• obtain and read Material Safety Data Sheets (MSDS) for all materials

used.

Become familiar with the safety symbols presented in this section. These

symbols will alert you to safety hazards and conditions that may result in

personal injury, death, or property and equipment damage.

WARNING: Failure to observe this warning may result in

personal injury, death, or equipment damage.

WARNING: Risk of electrical shock. Failure to observe this

warning may result in personal injury, death, or equipment

damage.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 1-1

Page 9

RB-6 L-801A (Airport) Rotating Beacon (Export) Safety

2. Safety Symbols (contd.)

3. Qualified Personnel

4. Intended Use

The term qualified personnel is defined here as individuals who thoroughly

understand the equipment and its safe operation, maintenance, and repair.

Qualified personnel are physically capable of performing the required tasks,

familiar with all relevant safety rules and regulations and have been trained

to safely install, operate, maintain, and repair the equipment. It is the

responsibility of the company operating this equipment to see that its

personnel meet these requirements.

Siemens Airfield Solutions cannot be responsible for injuries or damages

resulting from nonstandard, unintended applications of its equipment. This

equipment is designed and intended only for the purpose described in this

manual. Uses not described in this manual are considered unintended uses

and may result in serious personal injury, death, or property damage.

Unintended uses may result from taking the following actions:

• making changes to equipment that have not been recommended or

• failing to make sure that auxiliary equipment complies with approval

• usin g materials or auxiliary equipment that are inappropriate or

• allowing unqualified personnel to perform any task

WARNING: Disconnect equipment from line voltage. Failure

to observe this warning may result in personal injury, death, or

equipment damage.

WARNING: Wear safety goggles. Failure to observe may

result in serious injury.

CAUTION: Failure to observe may result in equipment

damage.

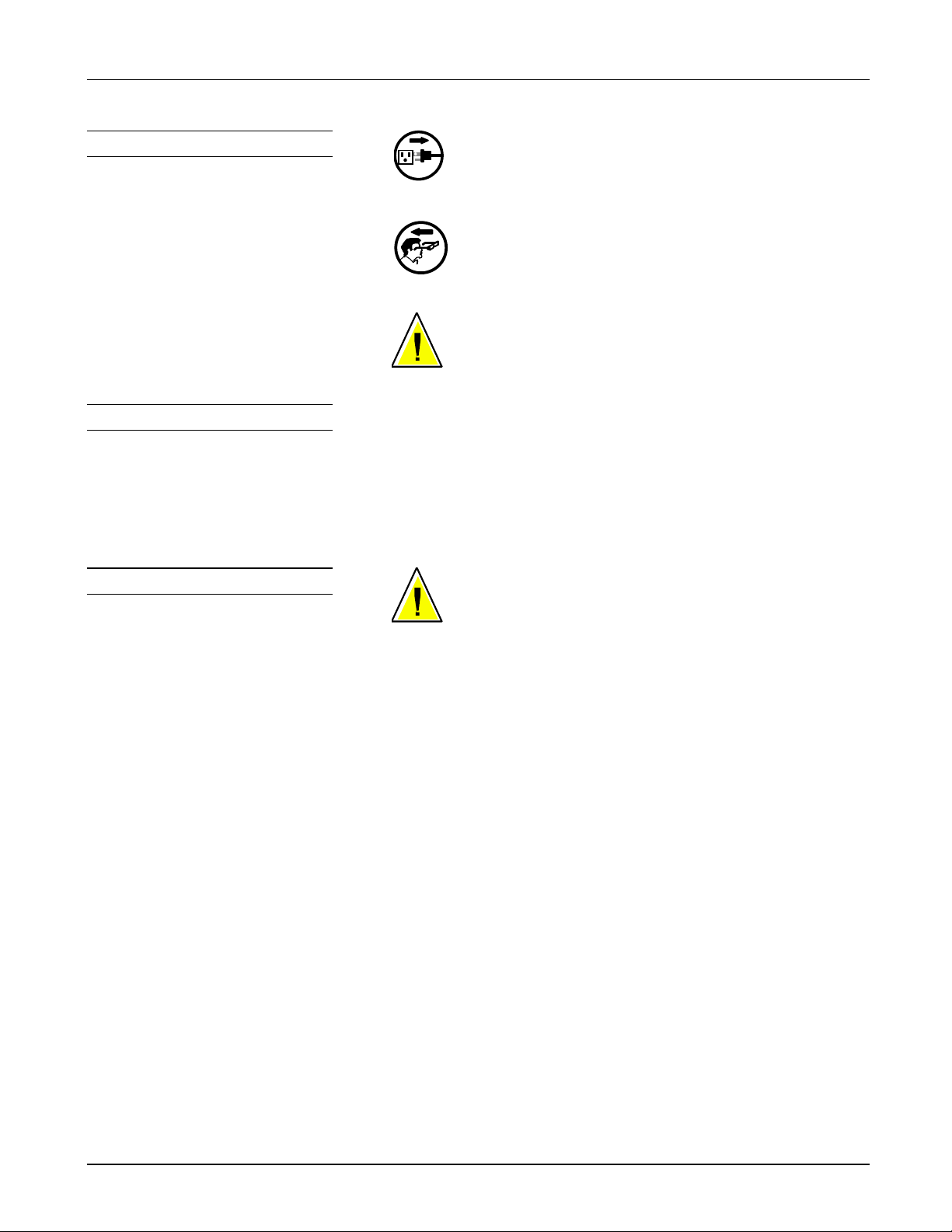

WARNING: Use of this equipment in ways other than

described in this manual may result in personal injury, death, or

property and equipment damage. Use this equipment only as

described in this manual.

described in this manual or using parts that are not genuine Siemens

Airfield Solutions replacement parts

agency requirements, local codes, and all applicable safety standards

incompatible with your Siemens Airfield Solutions equipment

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 1-2

Page 10

RB-6 L-801A (Airport) Rotating Beacon (Export) Safety

5. Installation

6. Operation

Read the installation section of all system component manuals before

installing your equipment. A thorough understanding of system

components and their requirements will help you install the system safely

and efficiently.

WARNING: Failure to follow these safety procedures can

result in personal injury or death.

• Allow only qualified personnel to install Siemens Airfield Solutions

and auxiliary equipment. Use only approved equipment. Using

unapproved equipment in an approved system may void agency

approvals.

• Make sure all equipment is rated and approved for the environment in

which you are using it.

• Follow all instructions for installing components and accessories.

• Install all electrical connections to local code.

• Use only electrical wire of sufficient gauge and insulation to handle the

rated current demand. All wiring must meet local codes.

• Route electrical wiring along a protected path. Make sure they will not

be damaged by moving equipment.

• Protect components from damage, wear, and harsh environment

conditions.

• Allow ample room for maintenance, panel accessibility, and cover

removal.

• Protect equipment with safety devices as specified by applicable safety

regulations.

• If safety devices must be removed for installation, install them

immediately after the work is completed and check them for proper

functioning.

Only qualified personnel, physically capable of operating the equipment

and with no impairments in their judgment or reaction times, should operate

this equipment.

Read all system component manuals before operating this equipment. A

thorough understanding of system components and their operation will help

you operate the system safely and efficiently.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 1-3

Page 11

RB-6 L-801A (Airport) Rotating Beacon (Export) Safety

6. Operation (contd.)

7. Action in the Event of a

System or Component

Malfunction

8. Maintenance and Repair

• Before starting this equipment, check all safety interlocks, fire-

detection systems, and protective devices such as panels and covers.

Make sure all devices are fully functional. Do not operate the system if

these devices are not working properly. Do not deactivate or bypass

automatic safety interlocks or locked-out electrical disconnects or

pneumatic valves.

• Never operate equipment with a known malfunction.

• Do not attempt to operate or service electrical equipment if standing

water is present.

• Use this equipment only in the environments for which it is rated. Do

not operate this equipment in humid, flammable, or explosive

environments unless it has been rated for safe operation in these

environments.

• Never touch exposed electrical connections on equipment while the

power is ON.

Do not operate a system that contains malfunctioning components. If a

component malfunctions, turn the system OFF immediately.

• Disconnect and lock out electrical power.

• Allow only qualified personnel to make repairs. Repair or replace the

malfunctioning component according to instructions provided in its

manual.

Allow only qualified personnel to perform maintenance, troubleshooting,

and repair tasks. Only persons who are properly trained and familiar with

Siemens Airfield Solutions equipment are permitted to service this

equipment.

• Always use safety devices when working on this equipment.

• Follow the recommended maintenance procedures in your equipment

manuals.

• Do not service or adjust any equipment unless another person trained in

first aid and CPR is present.

• Connect all disconnected equipment ground cables and wires after

servicing equipment. Ground all conductive equipment.

• Use only approved Siemens Airfield Solutions replacement parts.

Using unapproved parts or making unapproved modifications to

equipment may void agency approvals and create safety hazards.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 1-4

Page 12

RB-6 L-801A (Airport) Rotating Beacon (Export) Safety

8. Maintenance and Repair

(contd.)

• Check interlock systems periodically to ensure their effectiveness.

• Do not attempt to service electrical equipment if standing water is

present. Use caution when servicing electrical equipment in a highhumidity environment.

• Use tools with insulated handles when working with electrical

equipment.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 1-5

Page 13

RB-6 L-801A (Airport) Rotating Beacon (Export) Description

Section 2

Description

1. Introduction

See Figure 2-1. This section describes the Siemens Airfield Solutions RB-6

rotating beacon (Export Version). The RB-6 is manufactured to

specification AC 150/5345-12C.

The RB-6 all-weather rotating beacon (Export Version) consists of a

rotating unit on which are mounted a cast-aluminum housing containing

1000-W PAR64 spot quartz lamps, and a motor box.

An electrical connection is provided on the terminal block, located in the

motor box, for a light or alarm to indicate a lamp failure. The rotating unit

is mounted on a vertical shaft that turns at 12.5 revolutions per minute,

resulting in an output of 24-30 flashes per minute, alternately white and

green.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 2-1

Page 14

RB-6 L-801A (Airport) Rotating Beacon (Export) Description

Figure 2-1. RB-6 Rotating Beacon

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 2-2

Page 15

RB-6 L-801A (Airport) Rotating Beacon (Export) Description

2. RB-6 Beacon Assemblies

Head Assembly

Hub and Shaft Assembly

Box Assembly

Motor and Drive Assembly

3. Options

Optional Obstruction Light

The RB-6 beacon consists of the following assemblies: a head assembly,

hub and shaft assembly, box assembly, and motor assembly. These

assemblies are described below.

The head is made of aluminum castings. The forward and aft sections of

the housings are hinged to allow access to the lamp for replacement, or to

the lens for cleaning, or replacement.

Clear and green lenses are mounted 180 degrees apart, and each head is

factory preset to an elevation of 5 degrees above the horizontal.

The rotating hub is mounted on a shaft which passes through the top of the

motor box, and is supported by bearings at the top and bottom of the box.

A heavy duty aluminum casting with a cover plate houses the motor and

electrical equipment, and is vented to prevent an accumulation of excess

heat. Access to the interior of the housing is gained by removal of the four

cover plate screws and the plate.

The 50/60 Hz motor is geared to drive the shaft at 12.5 (Export) RPM when

operating at 50 Hz. This output shaft is connected to the hub assembly that

rotates the lamp heads.

This subsection describes options for the RB-6 rotating beacon (Export

Version).

See Figure 2-2. An L-810 obstruction light is available for mounting on top

of the beacon. The obstruction light lights when one or both of the beacon

lamps fail to operate. A fault circuit is also available. The fault circuit can

be wired to a horn or light to serve as an alarm indicating that one or both

of the beacon lamps have failed.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 2-3

Page 16

RB-6 L-801A (Airport) Rotating Beacon (Export) Description

Figure 2-2. RB-6 Final Assembly with Optional Obstruction Light Wiring

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 2-4

Page 17

RB-6 L-801A (Airport) Rotating Beacon (Export) Description

Optional Heater Assembly

See Figure 2-3. A heater assembly is available for use at temperatures

below -10 °C (+14 °F). The heater turns off at temperatures above +10 °C

(+50 °F).

Figure 2-3. Optional Heater Assembly Wiring

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 2-5

Page 18

RB-6 L-801A (Airport) Rotating Beacon (Export) Description

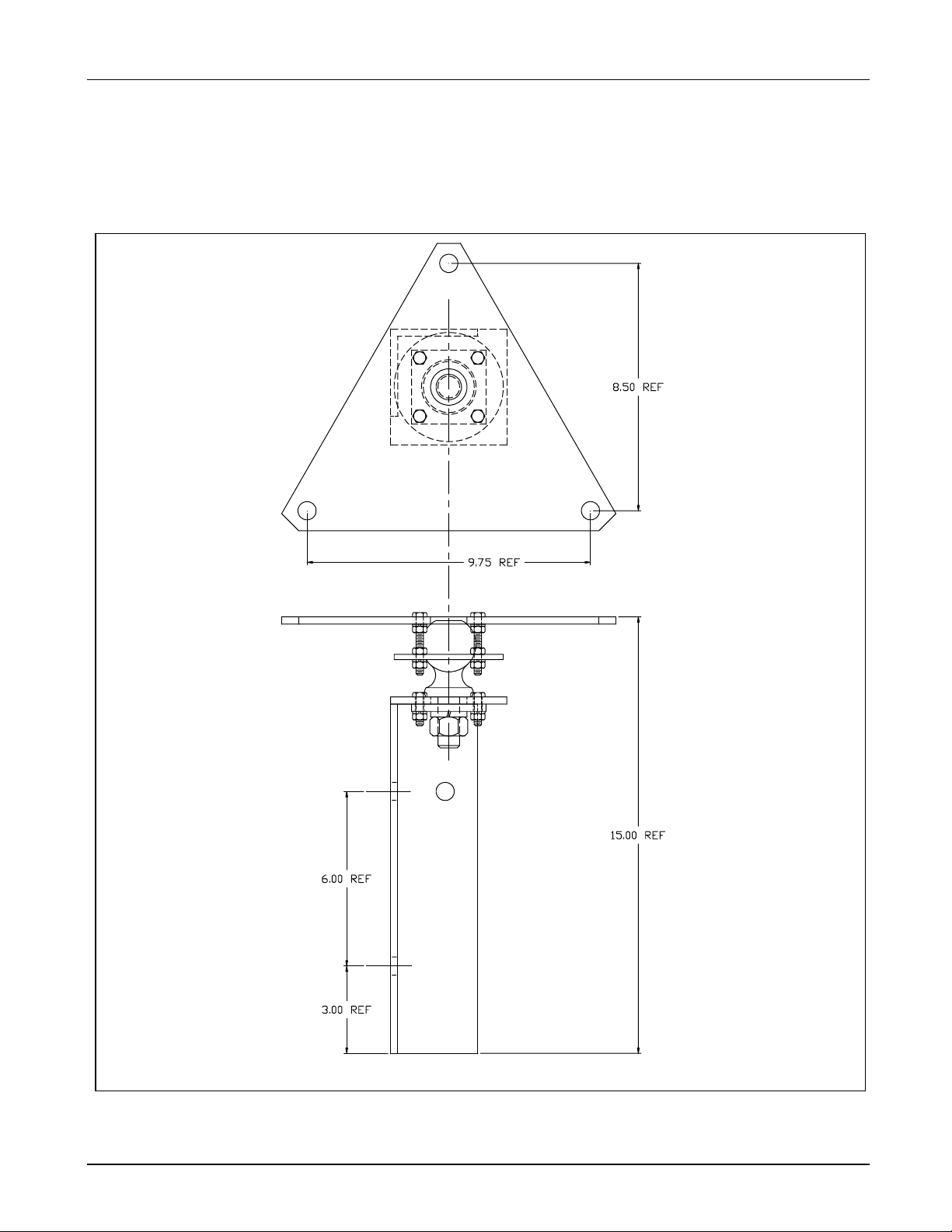

Optional Mounting Bases

Optional bases are available for mounting the beacon on a flat, horizontal

roof or on top of a pole. See Figure 2-4 for optional pole mounting adapter.

An optional roof mounting assembly is shown in Figure 2-5.

Figure 2-4. Optional Pole Mounting Adapter

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 2-6

Page 19

RB-6 L-801A (Airport) Rotating Beacon (Export) Description

Figure 2-5. Optional Roof Mounting Assembly

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 2-7

Page 20

RB-6 L-801A (Airport) Rotating Beacon (Export) Description

Optional Photocell Assembly

4. Theory of Operation

RB-6 Rotating Beacon

Operations

Optional Heater Assembly

Operations

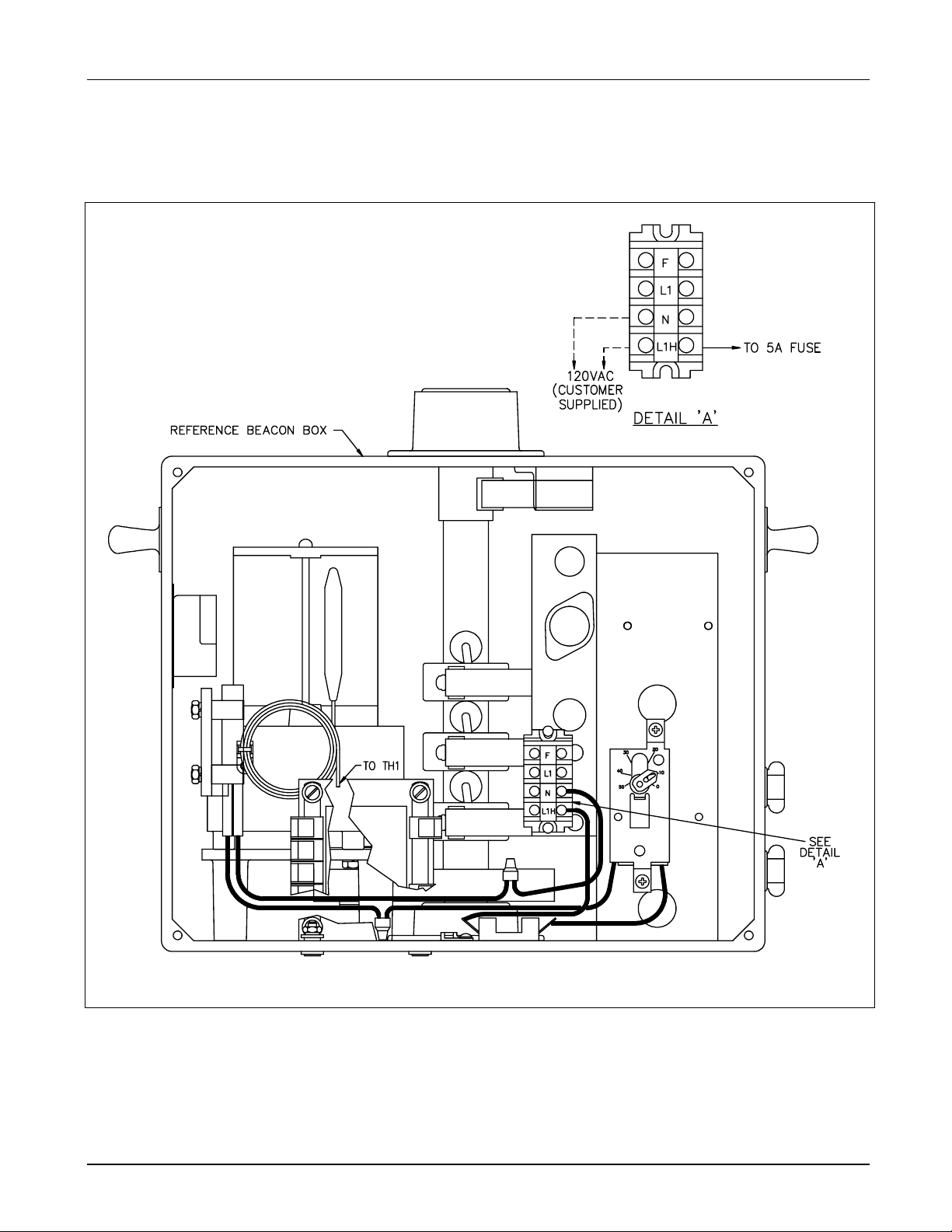

See Figure 7-2 the Wiring Schematics section. An optional photocell

assembly is available to automatically turn the beacon on at dusk and off at

dawn.

This subsection describes the operations of the RB-6, the optional heater

assembly, and the optional photocell assembly.

See Figure 7-1 the Wiring Schematics section. Power is connected to TB1

terminals L1 (120 Vac) and N (neutral). Power is supplied through fuse F1

to motor relay K1. Relay K1 is a motor starting relay. When power is first

applied, 120 Vac is present at K1 pins 2 and 3. Relay pin 3 is connected to

the motor main winding and pin 2 is connected to the start winding. When

the motor is first turned on, it draws a current greater than 4.4 A, energizing

the relay and placing 120 Vac on pin 2. After the motor has reached its

operating speed, the current drops to less than 3.2 A and relay K1 deenergizes. This disconnects 120 Vac from the motor start winding. 120

Vac is continuously connected to the motor main winding at relay K1 pin 3.

Power is supplied to the lamps through fuse F2, brush brackets #2 and #3,

and terminal blocks TB3 and TB4.

See Figure 2-3. The optional heater assembly consists of a 400-watt

heating element, thermostat, and safety fuse. The heater assembly should be

connected through a power cord to a separate circuit breaker, so that it may

remain operable when the beacon is turned off. The circuit breaker should

be switched off during the summer months.

When the temperature drops below +14 °F (-10 °C), the thermostat

activates the heater, which is attached to the motor gear box. The gear box

lubricant is warmed and this facilitates rotation of the beacon when it is

energized; the more effective lubrication which results also extends the

service life of the motor.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 2-8

Page 21

RB-6 L-801A (Airport) Rotating Beacon (Export) Description

Optional Photocell Assembly

Operations

Optional Obstruction Light

Operations

5. RB-6 Rotating Beacon:

Required Equipment

See Figure 7-2 the Wiring Schematics section. At dusk the decrease in light

on the photocell causes a current to flow through terminal block TBX, the

photocell and into the coil of relay Kl in the photocell relay assembly. This

closes the normally open contact which connects 120 Vac to terminal block

TBX terminal L0. This is connected to terminal block TB1 in the rotating

beacon and starts it operating. At dawn the increase in light on the

photocell stops current from flowing through relay K1 which opens the

contact and shuts down the beacon.

See Figure 7-1 in the Wiring Schematics section. When power is applied to

the RB-6 beacon, lamp #1 illuminates because current is taken through fuse

F2, brush block #2, terminal block TB4 terminal L1, terminal block TB3

terminal L1. Lamp #2 illuminates because current is taken through fuse F2,

brush block #2, terminal block TB4 terminal L1.

Neutral is connected through brush block #3 and terminal blocks TB3 and

TB4 terminal N.

Refer to Table 2-1 for required equipment that is supplied. Refer to

Table 2-2 for required equipment that is not supplied. Refer to the Parts

section for ordering information.

Table 2-1. Required Equipment Supplied

Description Quantity

RB-6 rotating beacon 1

Instruction manual 1

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 2-9

Page 22

RB-6 L-801A (Airport) Rotating Beacon (Export) Description

Table 2-2. Required Equipment Not Supplied

Description Quantity

Wrenches, 7/16 in. 1

Voltmeter 1

Insulation tester 1

Level 1

Lightening rod 1

SO-3 cable, AWG 10 1

Set of screwdrivers As required

Ground wire for lightening rod As required

Set of pliers As required

Liquid glass cleaner As required

Linear barrel scale, 0-16 oz 1

6. Specifications

Input

Beacon Wattage

Lenses

Rated Lamp Life

Lamp Wattage

This subsection describes the specifications for the RB-6, Type L-801A

rotating beacons. Refer to the Parts section for part numbers.

120 Vac, ±10%, 50/60 Hz

Refer to the table below for beacon wattage.

Standard RB-6 Lamp Wattage

(W)

Without optional heater 2100

With optional heater 2500

One pair: one clear, one green

4000 hours

1000 W

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 2-10

Page 23

RB-6 L-801A (Airport) Rotating Beacon (Export) Description

Beam Intensity

Rotation Speed

Heater

Environmental Operating

Conditions

Weight

Refer to the table below.

Beam Direction Measured Beam Intensity

Candelas (cd)

+1 to +2 degrees above horizontal 25,000 (minimum)

+2 to +8 degrees above horizontal 50,000 (minimum)

+8 to +10 degrees above horizontal 25,000 (minimum)

The RB-6 has a rotation speed of 12.5 rpm when operating at 50 Hz.

400 W heating element (optional)

The RB-6 beacon automatically turns on below -10 °C (+14 °F).

The RB-6 beacon automatically turns off above +10 °C (+50 °F).

The RB-6 rotating beacon is designed to operate under the conditions

presented below for temperature, altitude, and relative humidity.

Temperature

-55 to + 55 °C (-67 to +131 °F)

Altitude

Sea level to 10,000 feet (3000 m)

Relative Humidity

Up to 100 %

Wind

Velocities to 100 mph (161 km/h)

Approximately 135 lb (61 kg)

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 2-11

Page 24

RB-6 L-801A (Airport) Rotating Beacon (Export) Description

Dimensions

Clearance for Rotation

Mounting Dimensions

See Figure 2-1. This subsection describes the dimensions for the RB-6

beacon and the obstruction light. Refer to the table below.

RB-6 Beacon RB-6 Beacon

with Obstruction Light

Height: 35-1/4 in. (895.35 mm) 46-1/4 in. (1174.75 mm)

Width: 24 in. (609.6 mm) 24 in. (609.6 mm)

30 in. (762 mm)

See Figure 2-6. Three holes are tapped 1/2−13 UNC.

Figure 2-6. Mounting Holes

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 2-12

Page 25

RB-6 L-801A (Airport) Rotating Beacon (Export) Installation

Section 3

Installation

1. Introduction

2. Unpacking

3. RB-6 Beacon Installation

Mounting

WARNING: Allow only qualified personnel to perform the

following tasks. Observe and follow the safety instructions in

this document and all other related documentation.

This section describes instructions for installing the RB-6 rotating beacon

(Export Version).

Handle equipment very carefully to prevent component damage. Note any

exterior damage to the carton/crate that might lead to detection of

equipment damage. Open the top of the carton/crate. Remove foam

packing from the top of the box. Carefully lift the unit out of the box by the

handles on the side of the motor box.

Unpack the carton/crate upon receipt and check the contents and their

condition. If you note any damage to any equipment, file a claim with the

carrier immediately. The carrier may need to inspect the equipment.

This subsection provides instructions for the installation of the RB-6

rotating beacon (Export Version). Refer to the project plans and

specifications for the specific installation instructions.

The RB-6 rotating beacon comes completely assembled except for

installation of a customer-supplied AWG 10, S0-3 power cord (not

supplied).

Remove the cover plate from the motor box. Inspect the interior to make

sure all parts are tight and have not been loosened in shipment. Reinstall

the cover plate. Mounting adapters furnished are for mounting on a level

surface with the following mounting dimensions: Three holes are tapped

1/2−13 UNC. If the surface is not level, spacers or shims will be needed.

Place a level on top of the motor box and use shims as necessary under the

four corners to bring the beacon to level. Tighten the mounting bolts, four

each #1/4 - 20 length as required.

CAUTION: Do not lift the unit by the head. Failure to observe

this warning may result in equipment damage.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 3-1

Page 26

RB-6 L-801A (Airport) Rotating Beacon (Export) Installation

Wiring

Optional Heater Wiring

Angle Adjustment

See Figure 7-1 the Wiring Schematics section for final assembly wiring

diagram. An AWG 10, S0-3 power cord (user supplied) must be attached

to the beacon.

To install power cord, perform the following procedure:

1. Remove the motor box cover plate and gasket by removing the four

screws (7/16 wrench required) on the front of the motor box.

2. Route the cable through side hole into box.

3. Connect the power cord at the terminal strip as shown in Figure2-2 in

the Description section.

4. Attach 3-conductor black wire (120 VAC) to terminal marked Ll, white

wire (neutral) to terminal marked N, and green wire (ground) to the

ground lug in the base of the box.

See Figure 2-3 the Description section. The optional heater assembly,

when ordered, is pre-wired at the factory. The power cord for the heater

assembly should be connected from a separate circuit breaker to terminal

block TB1 terminals L1

and N so the heater can be operated when the

H

beacon is off.

All beacons are shipped from the factory preset at an angle of 5 degrees.

To adjust the beacon angle needs, perform the following procedure:

1. See Figure 3-1. Loosen the wing nut (4) holding the head in place.

2. Slide the elevation adjustment device (3) to the desired angle and

tighten nut.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 3-2

Page 27

RB-6 L-801A (Airport) Rotating Beacon (Export) Installation

1

2

3

4

4

Front View

Figure 3-1. Adjusting Beacon Angle

1. Lens Clip

2. Lamp

3. Elevation Adjustment Device

4. Wing Nut

Side View

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 3-3

Page 28

RB-6 L-801A (Airport) Rotating Beacon (Export) Installation

Export Beacon Installation Requirement

Requirement for export beacon installation only: A fence with a padlock

gate shall be installed around the beacon to prevent unauthorized entry.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 3-4

Page 29

RB-6 L-801A (Airport) Rotating Beacon (Export) Maintenance

Section 4

Maintenance

1. Introduction

2. Maintenance Schedule

Interval Maintenance Task Action

Daily Check for lamp failure. Replace lamp. Refer to Replacing Lamps in this

Check for 24-30 flashes per minute to see

if beacon has correct rpm.

Bimonthly (60 days) Check for dirty or pitted slip rings and

brushes.

Check for loose lens retainer. Tighten screws or clamps on the lens retainer.

Check for dirty or pitted photocell relay

contacts.

Check for dirty lamp glassware. Clean lamp glassware.

Semi-annually Check for input voltage out of tolerance. Record reading. If the voltage is out of tolerance,

Verify beam elevation. Adjust beam elevation. Check the angle indicator

Poor contact on the electrical switches and

contacts.

Check for loose lightening rod

connections.

This section provides maintenance information for the RB-6 rotating

beacon (Export Version).

To keep RB-6 rotating beacons operating efficiently, follow a preventive

maintenance schedule. Refer to Table 4-1. Refer to FAA AC 150/5340-26

for more detailed information.

Table 4-1. RB-6 Rotating Beacon (Export Version) Maintenance

section.

Check the motor and shaft bearing.

Clean slip rings and brushes. Replace worn

brushes, deeply pitted slip rings, or shaft. Refer to

Replacing Brushes and Brush Brackets and

Cleaning Slip Rings and Brushes in this section.

Clean photocell relay contacts. Replace if badly

pitted.

contact the power company or install an

autotransformer. The voltage is out of tolerance if it

is not within ±10% rated lamp voltage.

on the beacon head assembly.

If the contacts are corroded, repair or replace.

Tighten loose connections. Check and record

ground resistance.

Continued on next page

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 4-1

Page 30

RB-6 L-801A (Airport) Rotating Beacon (Export) Maintenance

Table 4-1. RB-6 Rotating Beacon (Export Version) Maintenance

Interval Maintenance Task Action

Annually Check to see if the beacon is level. Make the beacon level, if necessary. Check the

level in four directions.

Check for loose or broken wiring, lugs,

and conduit.

Check for cracked or deteriorated gaskets

or deteriorated weatherproofing.

3. Maintenance Procedures

This subsection describes the following maintenance procedures:

• replacing lamp

• adjusting lamp beam

• replacing brushes

• cleaning lenses

• cleaning head

• cleaning vents

• cleaning slip rings and brushes

• lubricating parts

Replacing Lamp

To replace the lamp, perform the following procedure:

1. See Figure 3-1 in the Installation section. Loosen the two lens clips (1)

on the front of the beacon.

2. Grasp the top of the lamp (2), push downward, and turn

counterclockwise approximately 120 degrees. Lift the lamp out of the

socket.

3. Carefully insert the replacement lamp into the socket.

NOTE: Make sure the lamp filament is vertical before closing the lens

cover and tightening the hexagonal screw.

WARNING: The lens temperature can be as high as 373 °F

(189 °C). Allow one-half hour for the lamps to cool before

opening the lens cover. Failure to observe this warning may

result in personal injury or equipment damage.

Repair or renew wiring when needed. Tighten

loose lugs, conduit supports, and connections.

Replace broken brackets.

Replace gaskets or weatherproofing, if necessary.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 4-2

Page 31

RB-6 L-801A (Airport) Rotating Beacon (Export) Maintenance

Replacing Brushes and Brush

Brackets

Replace all three brushes at the same time to provide even wear.

To replace the brushes and brush brackets, perform the following

procedure:

1. See Figure 4-1. Remove the two screws, lockwashers, and hex nuts

holding the brush block assembly (1) to the motor box.

1

6

7

1

8

5

4

3

2

Side Vie w

Side View of Bracket

Figure 4-1. Brush Block Assembly

1. Brush Block Assembly 4. Brush Block Screw 7. Brush

2. Brass Hex Nut 5. Wire 8. Brush Bracket

3. Hex Nut and Lockwasher 6. Brush Screw 9. Drive Pint

Front View

2

9

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 4-3

Page 32

RB-6 L-801A (Airport) Rotating Beacon (Export) Maintenance

2. Lift the brush block assembly away from the shaft. Be careful not to

place any strain on the wires.

3. Remove the screw (6) holding the brush (7) to the brush bracket (8).

4. Install new brushes on the brush block by performing the following

procedure:

a) Use a screwdriver blade to loosen and remove the 2 x 1/4 round

head drive pin (9) on the old bracket.

b) Remove the outer hex nut and lockwasher (3), and wire (5) from

the screw holding the end of the bracket to the brush block.

c) Remove solder from the remaining brass hex nut (2). Remove the

hex nut and brush bracket from the screw on the brush block.

CAUTION: Do not remove the screw (4). Failure to observe

this warning may result in equipment damage.

d) See Figure 4-2. Pre-bend (4) the new brush bracket(s) (2) so that

the bend in the new bracket is similar to the bend in the old

bracket.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 4-4

Page 33

RB-6 L-801A (Airport) Rotating Beacon (Export) Maintenance

1

3

2

4

4

6

5

7

Figure 4-2. Pre-Bending New Brush Brackets

1. Brush 4. Pre-Bend Brush Bracket Here 7. Bend Brush Bracket Here to Release Tension

2. Brush Bracket 5. Attach Spring Scale Here

3. Slip Ring Assembly 6. Direction of Required Tension

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 4-5

Page 34

RB-6 L-801A (Airport) Rotating Beacon (Export) Maintenance

e) Install the brush bracket assembly.

f) Use a customer-supplied spring scale attached to the head of the

screws (5) to check the tension of the brush (1) against the shaft

assembly (3). The brushes must have a tension of 14 + 2 oz

against the shaft. The spring scale is a Linear Barrel Scale (0-16

oz in 1/4 oz increments).

g) If too much tension exists, release tension by bending the brush

bracket (7).

h) Place a new bracket on the screw, install the drive pin on the

bracket, and use a 60/40 solder to secure the brass hex nut to the

screw and bracket. Then reinstall the wire, lockwasher, and outer

hex nut on the screw.

Cleaning Lenses

Cleaning Head Assembly

Cleaning Slip Rings and

Brushes

Lubricating Parts

Clean lenses periodically with alcohol or glass cleaner and soft cloth.

Wipe dry with a clean soft cloth.

Remove dust and dirt from the head assembly using a soft cloth or sponge

with soap and water.

To clean slip rings and brushes, follow the guidelines below.

• Clean the slip rings and brushes with a cloth moistened with an

appropriate solvent that will not leave a film or residue.

• If sparking or pitting occurs, smooth rings with 420 sandpaper. Avoid

sanding, if possible. Sanding produces a raw copper surface that

shortens brush life.

• Replace brushes showing excessive wear.

NOTE: It is recommended that all three brushes be replaced at the same

time to provide even wear.

WARNING: If the brushes are worn down to the brush

bracket, the bracket may damage the slip rings. Replace the

brushes worn to 1/8 inch (3.175 mm) of the bracket edge.

All moving parts are permanently lubricated and will not require further

attention.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 4-6

Page 35

RB-6 L-801A (Airport) Rotating Beacon (Export) Troubleshooting

Section 5

Troubleshooting

1. Introduction

2. Troubleshooting

Procedures

Problem Possible Cause Corrective Action

1. Short lamp life

Loose connections Tighten connections.

Excess vibrations Replace bearing or shaft.

Low brush pressure Adjust brush bracket or replace brush

Bad socket Replace socket.

Voltage or voltage spikes greater than

126 Vac

This section contains troubleshooting information. This information covers

only the most common problems that you may encounter. If you cannot

solve the problem with the information given here, contact your local

Siemens Airfield Solutions representative for help.

Refer to the table below for troubleshooting procedures.

WARNING: Allow only qualified personnel to perform the

following tasks. Observe and follow the safety instructions in

this document and all other related documentation.

WARNING: De-energize the circuit and lock out the circuit or

regulator so that the circuit cannot be energized by remote

means before attempting to service the fixture.

assembly. Refer to Replacing Brushes and

Brush Brackets in the Maintenance section.

Check input voltage. Record reading. If the

voltage is out of tolerance, contact the power

company or install an autotransformer. The

voltage is in tolerance if it is within ±10%

rated lamp voltage.

Continued on next page

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 5-1

Page 36

RB-6 L-801A (Airport) Rotating Beacon (Export) Troubleshooting

Problem Possible Cause Corrective Action

2. Lamp not lighting

3. Photocell not

operating

4. Poor beacon visibility

5. Motor not turning

6. Motor not turning

during cold weather

7. Heater not operating

Lamp defective Replace lamp. Refer to Replacing Lamp in

the Maintenance section.

Blown fuse Replace fuse F2 (30 A, Slo-Blo).

Photocell inoperable See Photocell not operating in this table.

Brush assembly not working Replace brush assembly. Refer to Replacing

Brushes and Brush Brackets in the

Maintenance section.

Loose or broken wire Replace cordset or socket.

Photocell defective Replace photocell.

Relay defective Replace relay.

Loose or broken wire Repair or replace wire.

Lamp filament not at focal point of

reflector

Move socket up or down so the lamp filament

is at the focal point of the reflector.

Dirty lenses Clean lenses after they cool off.

Blown fuse Replace fuse F1 (3.2 A, Slo-Blo).

Motor relay defective Replace relay.

Motor defective Replace motor.

Shaft bearing seized Replace defective bearing.

Loose or broken wire Repair or replace wire.

Heater inoperable Refer to Heater not operating in this table.

Blown fuse Replace fuse F3 (5 A, Slo-Blo).

Thermostat defective Replace thermostat.

Heater defective Replace heater.

Loose or broken wire Repair or replace wire.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 5-2

Page 37

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

Section 6

Parts

1. Introduction

2. Using the Illustrated Parts

List

Item Description Part Number Note

NS Assembly

T1 Assembly

Part xxxxxxxx

Part

To order parts, call Siemens Airfield Solutions Customer Service or your

local representative. Use this four-column parts list, and the accompanying

illustration, to describe and locate parts correctly.

The Item column numbers correspond to the numbers that identify parts in

illustrations following each parts list. NS (not shown) indicates that a listed

part is not illustrated.

The Description column gives the part name, as well as its dimensions and

other characteristics when appropriate. Parts are indented under an

assembly to show the part that applies to your particular sign module.

The Part Number column gives the Siemens Airfield Solutions part number.

xxxxxxxx A

xxxxxxxx

The Note column contains letters that refer to notes at the end of each parts

list. Notes contain special ordering information.

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 6-1

Page 38

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

3. RB-6 Rotating Beacon

Final Assembly Parts List

Item Description Part Number Note

A2 Head assembly

A1 Box assembly (Export)

A3 Optional heater assembly

S1 Silicone rubber sealant 67A0006-3

See Figure 6-1.

The RB-6 Beacon Export Version final assembly part number is

44D0221-X.

44D0751

44D4740-3

44B0789

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 6-2

Page 39

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

S1

A2

A3

Figure 6-1. RB-6 Rotating Beacon Final Assembly (Export Version)

A1

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 6-3

Page 40

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

4. Head Assembly

(Single Head) Parts List

Item Description Part Number Note

M6 Lens ring

M9

M11

M10

H5

H6

M8

TB1

M1

H3

H2

NS

NS Adhesive 67A0005

NS: Not Shown

Gasket, lens, RB-6, 14−1-1/16 in. (357.1875 mm) O.D.

Gasket, lens, RB-6, 15−7/8 in. (403.225 mm) O.D.

Gasket, conical ring, RB-6, 21−1/4 in. (539.75 mm) O.D.

Lens, green, 14 in. (355.6 mm) 63A0168

Lens, clear, 14 in. (355.6 mm) 63A0169

Reflector assembly 62D0455

Terminal block, 22−10 AWG, 300 V, 50 A

Lens clip 61A0074

Strike 61A0051-3

Catch 61A0051-1

Silicone sealant 67A0009

See Figure 6-2.

Head assembly (single head) part number is 44C0238-X.

62D0303

63A0167

63A0172

63A0170

72A0016

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 6-4

Page 41

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

M1

Figure 6-2. Head Assembly (Single Head)

H5

M6

M10

M11

M8

H3

M9

H6

H2

2001 Siemens Airfield Solutions, Incorporated

All rights reserved Issued 5/01

96A0221B Page 6-5

Page 42

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

M

5. Box Assembly Parts List

Item Description Part Number Note

H24 Bearing

A3 Shaft assembly

H20 Fiber gear, 48 teeth

A2

A5 Lid assembly 44B0285

otor assembly, export, 115 V, 50/60 Hz, 26-teeth gear

See Figure 6-3.

The box assembly part number is 44C0750-X.

75A0004

44C0393

68A0002

44B0998-2

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 6-6

All rights reserved Issued 5/01

Page 43

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

A3

A2

A5

Figure 6-3. Box Assembly

H20

H24

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 6-7

All rights reserved Issued 5/01

Page 44

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

6. Motor Assembly Parts List

Item Description Part Number Note

MT1 Gear motor, 50/60 Hz, 115 V, 26-28 rpm, Von Weise Gear Co.,

#V0378AA88, Series K83

M1 Motor mount, Export

H3 Gear, 26 teeth, Export 68A0007

See Figure 6-4.

Motor assembly part number is 44B0998-X.

69C0006

62C0179-2

Figure 6-4. Motor Assembly

H3

M1

MT1

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 6-8

All rights reserved Issued 5/01

Page 45

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

7. Brush Block Assembly

Parts List

Item Description Part Number Note

H10 Brush

F3 Fuse, 3.2 A, Slo-Blo

F2 Fuse, 30 A, Slo-Blo 47A0024

See Figure 6-5.

Brush block assembly part number is 44A0222.

76A0001

47A0003

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 6-9

All rights reserved Issued 5/01

Page 46

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

F3

F2

Side View Front View

H10

Side View of Bracket

Figure 6-5. Brush Block Assembly

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 6-10

All rights reserved Issued 5/01

Page 47

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

8. Photocell Contactor

Assembly Parts List

Item Description Part Number Note

1 Photocell

2 Socket

3 Terminal block

4 Relay

See Figure 6-6.

Photocell contactor assembly part number is 44B0812.

48A0089

49A0095

72A0016

53A0126-1

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 6-11

All rights reserved Issued 5/01

Page 48

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

1

2

3

4

Figure 6-6. Photocell Contactor Assembly

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 6-12

All rights reserved Issued 5/01

Page 49

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

9. Heater Assembly Parts

List

Item Description Part Number Note

HT1 Heater element, 400 W

F1 Fuse, 5 A, Slo-Blo

F1 Fuse holder

TH1 Thermostat, Dayton #2E998

TB1 Terminal block 72A0016

See Figure 6-7.

Heater assembly part number is 44B0789.

85A0050

47A0107

47A0061

54A0010

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 6-13

All rights reserved Issued 5/01

Page 50

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

HT1

Figure 6-7. Heater Assembly

TB1

F1

TH1

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 6-14

All rights reserved Issued 5/01

Page 51

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

10. Reflector Assembly Parts

List

Item Description Part Number Note

1 Reflector

2 Lamp support

3 Socket, phenolic

4 Lamp, 1000 w 48A0032

See Figure 6-8.

The reflector assembly part number is 44D0981.

62D0455

62B0323

49A0002

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 6-15

All rights reserved Issued 5/01

Page 52

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

1

2

1

3

4

2

Front View

Figure 6-8. Reflector Assembly

3

Side View

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 6-16

All rights reserved Issued 5/01

Page 53

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

11. Obstruction Light and

Relay Parts List

Item Description Part Number Note

1 Obstruction light assembly

2 Silicone rubber sealant

3 Relay assembly 44B0435

See Figure 6-9.

The optional obstruction light part number is 44B0805.

44B0804

67A0006-1

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 6-17

All rights reserved Issued 5/01

Page 54

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

1

2

3

Figure 6-9. Obstruction Light

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 6-18

All rights reserved Issued 5/01

Page 55

RB-6 L-801A (Airport) Rotating Beacon (Export) Parts

12. Optional Assemblies

Parts List

Item Description Part Number Note

NS Photocell contractor assembly

NS Roof mounting assembly

NS Pole mounting assembly

NS Heater assembly

NS Obstruction light assembly 44D0805

Refer to the table below for optional assemblies part numbers.

44B0812

44D0351-1

44C0259

44B0789

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 6-19

All rights reserved Issued 5/01

Page 56

RB-6 L-801A (Airport) Rotating Beacon (Export) Wiring Schematics

Section 7

Wiring Schematics

1. Introduction

Wiring Schematics

RB-6 Beacon with Optional

Heater Wiring

This section provides wiring schematics for the RB-6 beacon (Export

Version).

Wiring schematics and diagrams for Export Version RB-6 beacons include

the following:

• RB-6 beacon with optional heater wiring schematic

• photocell assembly wiring schematic

See Figure 7-1.

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 7-1

All rights reserved Issued 5/01

Page 57

RB-6 L-801A (Airport) Rotating Beacon (Export) Wiring Schematics

Figure 7-1. RB-6 Beacon with Optional Heater Wiring Schematic

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 7-2

All rights reserved Issued 5/01

Page 58

RB-6 L-801A (Airport) Rotating Beacon (Export) Wiring Schematics

Optional Photocell Assembly

Wiring

See Figure 7-2.

Figure 7-2. Optional Photocell Assembly Wiring Schematic

2001 Siemens Airfield Solutions, Incorporated 96A0221B Page 7-3

All rights reserved Issued 5/01

Loading...

Loading...