Siemens QVM62.1 Installation Instructions Manual

Installation Instructions

QVM62.1 Air Velocity Sensor

Personal injury/loss of life may

procedures as specified.

Equipment damage or loss of

specified.

Product Description

This sensor is used to measure the air ve loc ity in a

duct and provide a 0 to 10V signal to a controller

that is proportional to the velocity. This allows the

controller to maintain a constant airflow in the duct,

balance out pressure fluctuations (supply or exhaust

air control), or just monitor the flow in a duct. The Air

Velocity Sensor is generally used for modulating fan

control in primary applications to set the basic

volume flow.

Product Number

QVM62.1

Warning/Caution Notations

WARNING:

CAUTION:

occur if you do not follow the

data may occur if you do not

follow the procedures as

Document No. 129-095

September 24, 2009

Installation

Probe Mounting Flange and Sensor

1. Determine the depth of insertion required for

the probe and assemble the extension tube

and/or probe end cap onto the primary sensor

head tube.

NOTE: If the insertion depth required is less

than or equal to 5.7 inches (145 mm)

the extension tube may be removed by

disconnecting the probe cable at the

transducer head, and sliding the

extension tube off the cable. (With the

extension tube installed, the probe’s

depth of insertion is 11.8 inches

[300mm].) If the extension tube is

removed, be sure to reinstall the

probe’s end cap on the cable before

rewiring it to the transducer head.

2. Position the probe mounting flange on the duct

where will be installed. Lightly tap the screw

heads to create drill marks for the mounting

screw holes.

Required Tools

• Pencil

• Hammer

• Center hole punch

• Screwdrivers

• Four - #8 × 1/2-inch sheet metal screws

• Electric drill with 1/8-inch and 7/8-inch

drill bits

Expected Installation Time

45 minutes

Prerequisites

Field wiring must be pulled to installation location.

Item Number 129-095, Rev. AA Page 1 of 3

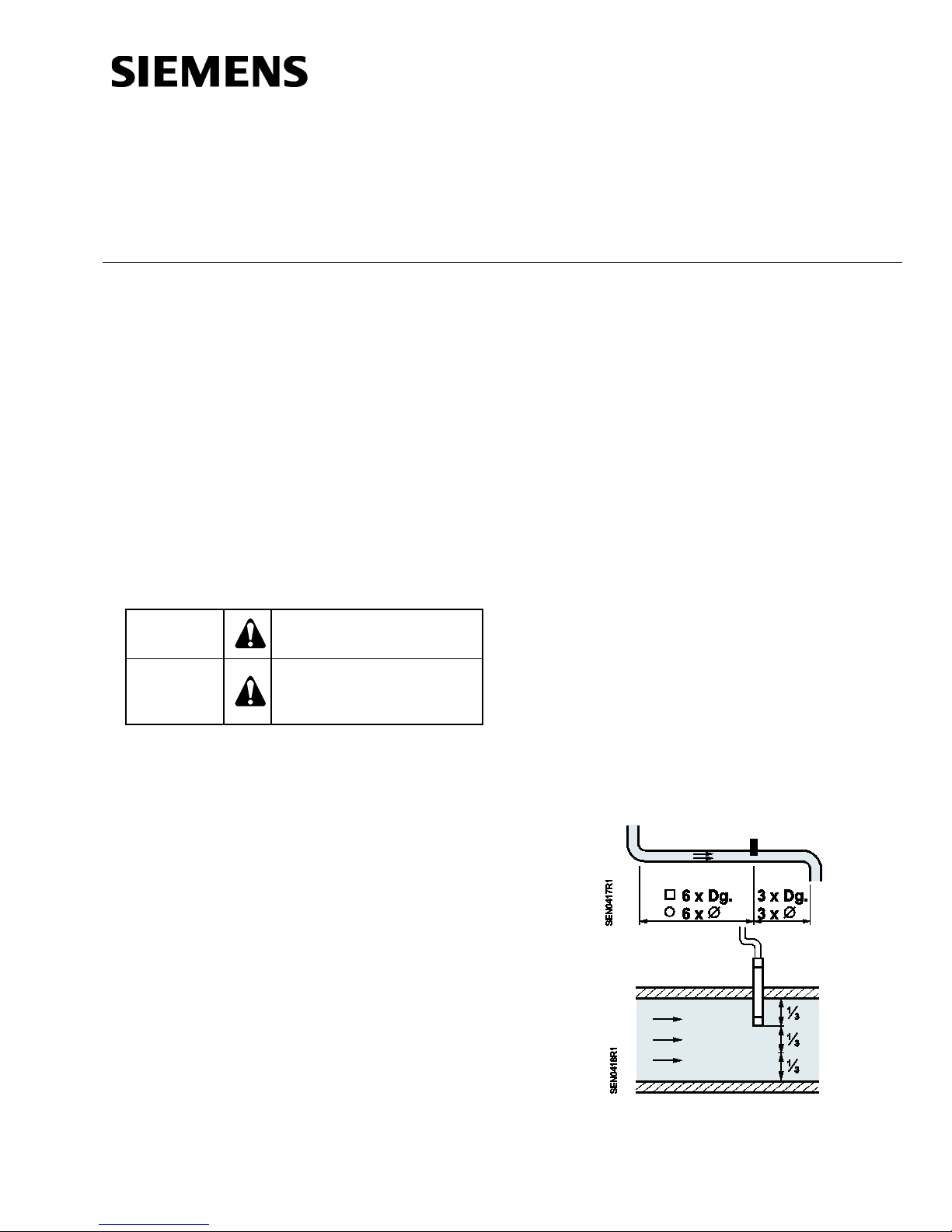

NOTE: Install the sensor in the ductwork in a

location where the airflow is not

turbulent. Do not place it close to

dampers, registers, or bends in

ductwork.

Figure 1. Mounting Locations.

Document No. 129-095

CAUTION:

can irreparably damage the unit.

.

Installation Instructions

September 24, 2009

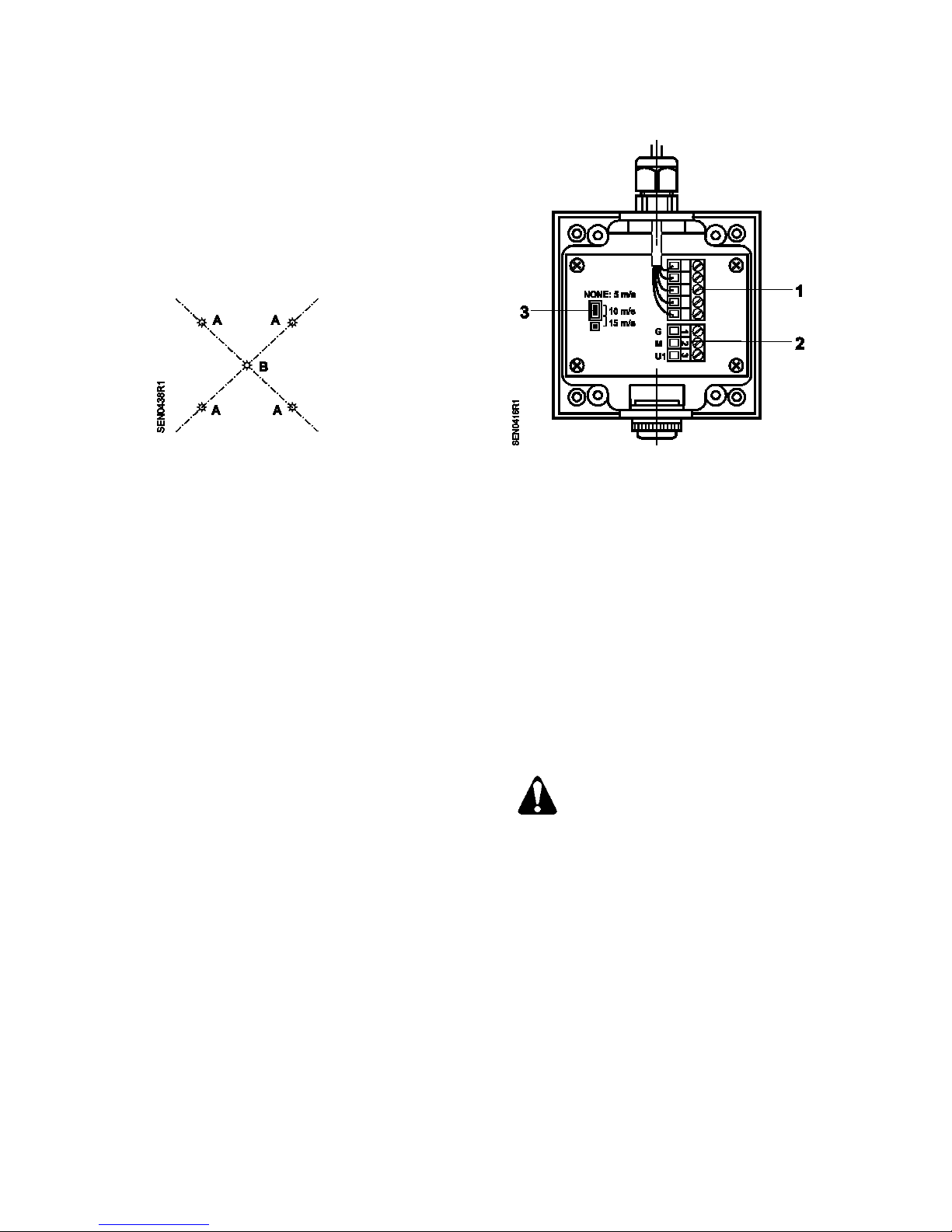

3. Draw a line between opposite drill marks,

farthest from each other, and make a drill mark

with the punch, at the intersection of the two

lines.

4. Drill four 1/8-inch holes for the mounting screws

at the points labeled “A”, and a 7/8-inch

diameter hole at the point labeled “B” (see

Figure 2).

Figure 2. Mounting Screw Locations.

5. Secure the flange to the duct using the screws

included with the flange and insert the probe into

the duct. Do not tighten the mounting screw at

this time.

Transducer

1. Remove the cover from the transducer head

unit.

2. Hold the base on the duct or structure to which it

is to be mounted and mark the center positions

of the four mounting holes.

NOTE: Make sure there is enough slack in the

probe’s cable so that, if necessary, the

probe can be removed for servicing or

replacement.

3. Make drill hole marks with the punch at the

mounting hole points, and drill four 1/8-inch

holes.

4. Secure the transducer head to its mounting

location with four #8 × 1/2-inch sheet metal

screws.

5. Set jumper for desired airflow range (see

Figure 3).

6. Connect the Field wiring to the transducer head

connector (see Figure 3.)

1 Terminal block for connection to the

immersion stem

2 Terminal block for connection to controller

3 Plug-in unit for setting the three velocity

ranges. The following applies:

No plug-in jumper = 0 to 5 m/s

Plug-in jumper on 1 and 2 = 0 to 10 m/s

(factory setting)

Plug-in jumper on 2 and 3 = 0 to 15 m/s

Figure 3. Wiring and Setting Elements.

.

7. Reinstall the cover

The sensor head connections are not

protected against 24 Vac operating

voltage.

If the unit power supply lead being

connected to terminal G is live during

the installation of the sensor, contact

with any of the sensor head terminals

8. Set the probe’s depth of insertion and position

the arrow on the probe cap so that it points in

the direction of the airflow.

9. Tighten the mounting screw located on the side

of the mounting flange (see Figure 4).

Page 2 of 3 Siemens Industry, Inc.

The installation is now complete.

Loading...

Loading...