Siemens QVE1901U Technical Instructions

QVE1901U

Flow Switch

Description

Technical Instructions

Document No. 155-711

September 20, 2012

Flow switch for liquids in piping 3/4-inch to 8-inch (20 mm to 200 mm) diameter

Features

Application

Product Number

• Contact load/switching capacity:

Maximum 24 Vac, 1 A, 26 VA

Maximum 24 Vdc, 1 A, 20 W

• Nominal pressure maximum 365 psi

• Manual setting of contact type (NO/NC)

• Housing IP 65 (excluding conduit adapter)

• Maintenance-free

The QVE1901U Flow Switch is used in HVAC installations to monitor the flow of fluids

in hydraulic systems, especially in refrigeration, heat pump and heating installations (for

example: for use with condensers, boilers, heat exchangers, and so on).

QVE1901U

Warning/Caution Notations

WARNING:

CAUTION:

Personal injury/loss of life may occur if you do not perform a

procedure as specified.

Equipment damage may occur if you do not perform a

procedure as specified.

Siemens Industry, Inc.

Technical Instructions QVE1901U Flow Switch

Document Number 155-711

September 20, 2012

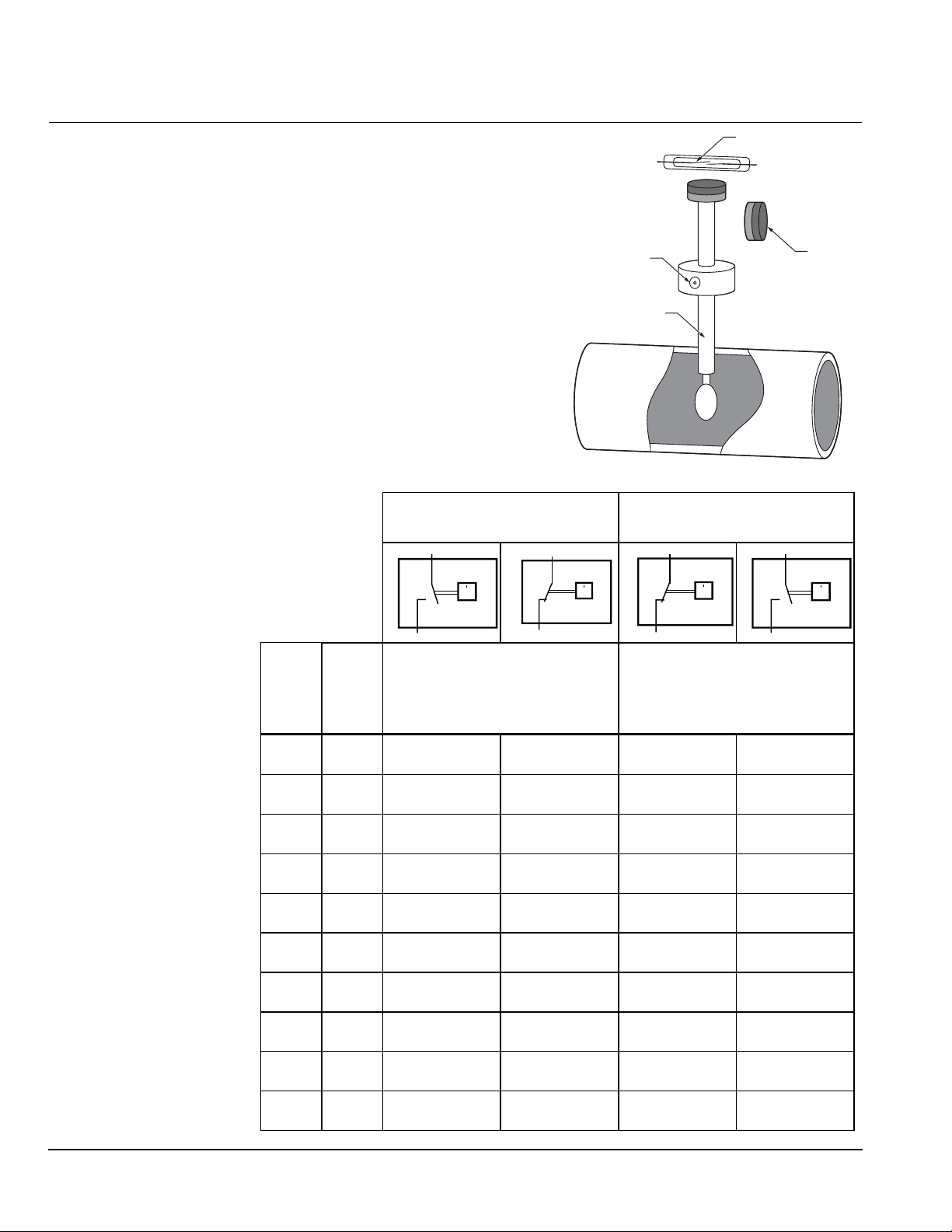

Mechanical Design

The device records the flow of monitored

Reed Contact (3)

medium via a paddle system (1), which

has a permanent magnet (2) attached at its

upper end. A reed contact (3) is positioned

outside the flow above this magnet. A

Magnet (2)

N

S

N

S

second magnet (4) with opposite polarity is

used to create a reset force. The paddle

system moves once it comes into contact

Shaft

Magnet (4)

with the monitored flow. The magnet (2)

changes its position to the reed contact (3).

The contact opens/closes depending on

Paddle System (1)

the contact type. As soon as the flow is

interrupted, the paddle returns to its

original position and the reed contact

opens/closes depending on the contact

type.

Flow

(See Adjusting the Switching Unit.)

Switching Value Table

for Water at 68°F (20°C)

Make Contact (NO)

1

2

SEN0529R1

Max.

Flow

Rate

gpm

3

(m

15

(4)

20

(5)

35

(8)

45

(10)

60

(14)

94

(23)

130

(30)

180

(40)

440

(100)

800

(180)

/h)

4.0 (0.9) 4.8 (1.1) 4.0 (0.9) 4.8 (1.1)

4.8 (1.1) 5.7 (1.3) 4.8 (1.1) 5.7 (1.3)

6.6 (1.5) 7.8 (1.8) 6.6 (1.5) 7.8 (1.8)

7.7 (1.7) 9.1 (2.0) 7.7 (1.7) 9.1 (2.0)

10.3 (2.3) 11.5 (2.6) 10.3 (2.3) 11.5 (2.6)

16.6 (3.8) 17.9 (4.1) 16.6 (3.8) 17.9 (4.1)

18.9 (4.3) 20.4 (4.6) 18.9 (4.3) 20.4 (4.6)

25.5 (5.8) 27.0 (6.1) 25.5 (5.8) 27.0 (6.1)

61.7 (14.0) 68.3 (15.5) 61.7 (14.0) 68.3 (15.5)

126.0(28.6) 130.4 (29.6) 126.0 (28.6) 130.4 (29.6)

Inches

Line

Size

(mm)

0.75

(19)

1.00

(25)

1.25

(32)

1.50

(40)

2.00

(50)

2.50

(65)

3.00

(80)

4.00

(100)

6.00

(150)

8.00

(200)

Red Arrow

1

V

2

SEN0530R1

Setpoints

gpm (m

3

/h)

Factory Setting

SEN0528R1

V

Figure 1.

Break Contact (NC)

White Arrow

1

V

2

SEN0530R1

Setpoints

gpm (m

SEN0529R1

3

/h)

1

V

2

Page 2 Siemens Industry, Inc.

QVE1901U Flow Switch Technical Instructions

Document Number 155-711

September 20, 2012

Engineering Notes

• On site:

– A T-junction with a female-threaded (1/2" NPT) fitting is required for 3/4” to 2”

line sizes.

– A 1-inch, female-threaded (1/2” NPT) welding socket is required for 3" to 8" line

sizes.

• All dimensions and data provided in the table of switching values are based on water

at 68°F (20°C), and the use of T-junctions and horizontal piping.

Flow Switch

Installation

Mechanical installation

General installation

instructions

• When choosing the installation site, ensure that the specified limit values (see

Technical Data) are not exceeded.

• Select suitable measures to prevent the medium from freezing. If the flow switch is to

be used in ambient temperatures of <39°F (4°C), do not carry out any operation

beforehand using pure water. Residual water in the flow switch can result in frost

damage.

• First, clean the pipe system where the flow switch is installed and remove any

magnetic particles, such as welding residue.

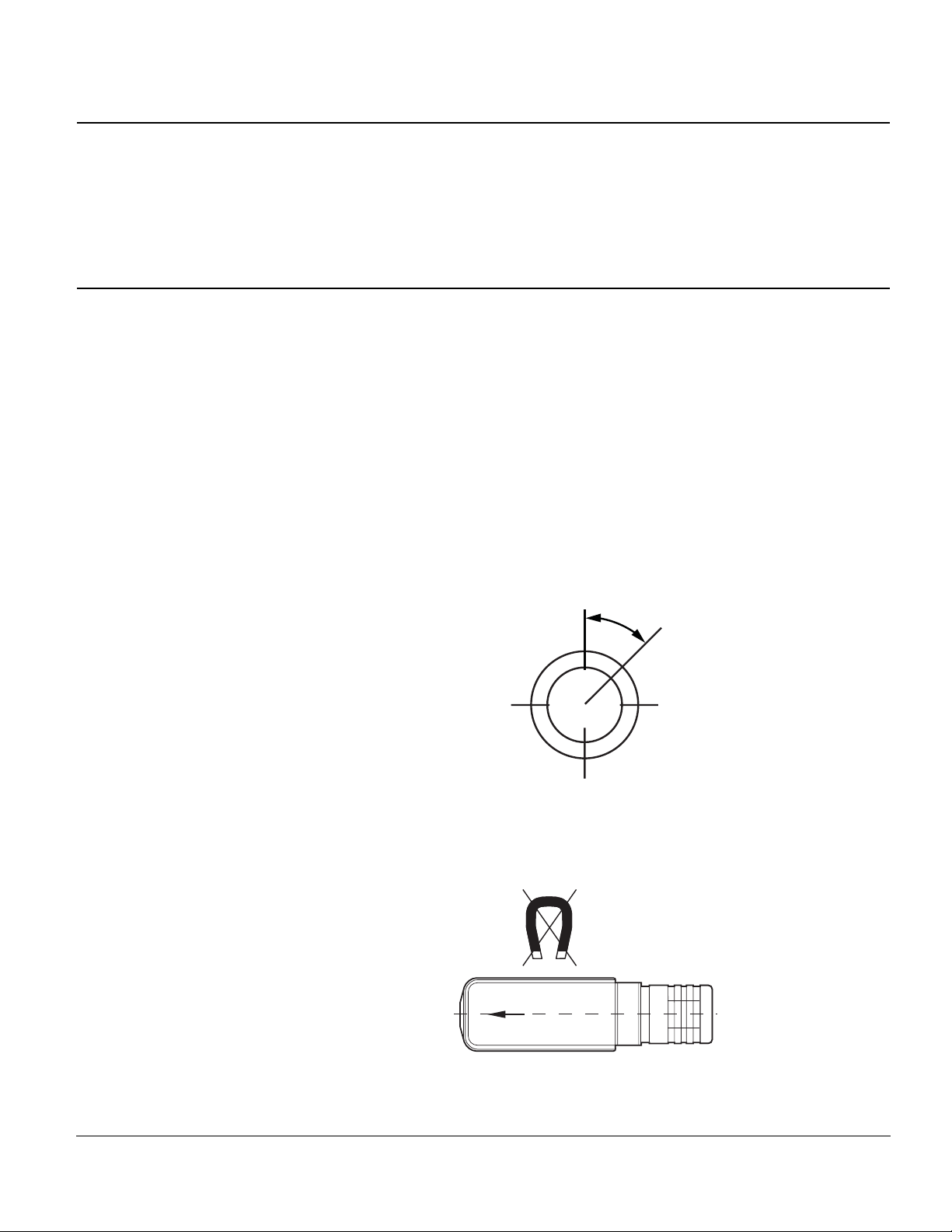

• The laminar path length in front of and behind the flow switch must be at least 10

times and 5 times the pipe diameter, respectively.

• The nominal installation position of the flow switch is an upright standing position in

horizontal pipework.

• The switches should only be installed in a vertical position with a maximum deviation

of 45°.

m

a

x

.

4

5

°

SEN0531R1

Figure 2. Acceptable Switch Mounting Positions.

• Ensure that there are no external magnetic fields in the immediate vicinity of the flow

switch, since these can impair device operation.

• There is an arrow on the flow switch. Install with the arrow parallel with the pipe

shaft, facing in the flow direction.

SEN0522R1

Figure 3. Flow Direction Arrow.

• The brass connecting nut G¾ has a tightening torque of 18 to 22 lb-ft (25-30 Nm)

Siemens Industry, Inc. Page 3

Loading...

Loading...