Siemens QUADLOG Installation And Service Instructions Manual

Siemens

Energy & Automation, Inc.

SDQLCAI-1

Rev: 4

September 2005

Installation and Service Instruction

QUADLOG

Critical Analog Input Module (CAI)

Trademarks

ProcessSuite, QUADLOG, 4-mation, and APACS+ are trademarks of Siemens Energy & Automation, Inc.

Other names in this publication might be trademarks, the use of which by third parties for their own purposes may

violate the rights of the registered holder.

Copyright Siemens Energy & Automation, Inc. 2005

All rights reserved

The reproduction, transmission or use of this document or

its contents is not permitted without express written

authority. Offenders will be liable for damages. All rights,

including rights created by patent or registration of a utility

model or design, are reserved.

Siemens Energy & Automation, Inc.

1201 Sumneytown Pike

P.O. Box 900

Spring House, PA 19477-0900

Disclaimer of Liability

We have checked the contents of this manual for

agreement with the hardware and software described.

Since deviations cannot be precluded entirely, we cannot

guarantee full agreement. However, the data in this

manual is reviewed regularly and any necessary

corrections included in subsequent editions. Suggestions

for improvement are welcomed.

©Siemens Energy & Automation, Inc. 2005

Technical data subject to change.

SDQLCAI-1 Contents

Table of Contents

Section Title Page

1 Introduction....................................................................................................................1-1

1.1 Product Description......................................................................................................1-1

1.2 Product Support............................................................................................................1-3

1.3 Related Literature.........................................................................................................1-5

2 Installation......................................................................................................................2-1

2.1 Hardware Identification................................................................................................2-1

2.1.1 Module Identification.............................................................................................2-1

2.1.2 Marshalled Termination Assembly Identification..................................................2-2

2.2 Preparations..................................................................................................................2-2

2.3 Environmental Considerations .....................................................................................2-2

2.4 Equipment Delivery and Handling...............................................................................2-3

2.4.1 Predelivery Test .....................................................................................................2-3

2.4.2 Factory Shipment...................................................................................................2-3

2.4.3 Receipt of Shipment...............................................................................................2-3

2.4.4 Return of Equipment within North America..........................................................2-3

2.4.5 Return of Equipment outside North America ........................................................2-4

2.4.6 Equipment Handling and Storage ..........................................................................2-4

2.5 Marshalled Termination Assembly and Cable Installation...........................................2-4

2.5.1 Marshalled Termination Assembly Installation.....................................................2-4

2.5.2 Optional (Flat Surface) Marshalled Termination Assembly Installation...............2-9

2.5.3 Interconnect I/O Cable Installation......................................................................2-10

2.6 CAI Installation ..........................................................................................................2-12

2.6.1 Module Rack Mechanical Keying........................................................................2-14

2.6.2 Module Installation..............................................................................................2-14

2.7 Electrical Installation..................................................................................................2-15

2.7.1 Field Wire Selection.............................................................................................2-16

2.7.2 Marshalled Termination Assembly – I/O Wiring Connections ...........................2-16

2.7.3 Unterminated I/O Cable Assembly Connections.................................................2-19

2.8 Configuration..............................................................................................................2-20

3 Maintenance...................................................................................................................3-1

3.1 Requirements................................................................................................................3-1

3.2 Visual Inspection..........................................................................................................3-1

3.3 Cleaning........................................................................................................................3-1

3.4 Troubleshooting............................................................................................................3-2

3.5 CAI Removal/Replacement..........................................................................................3-3

3.5.1 Removal.................................................................................................................3-3

3.5.2 Replacement...........................................................................................................3-3

3.6 Marshalled Termination Assembly Removal/Replacement.........................................3-4

3.6.1 Removal.................................................................................................................3-4

3.6.2 Replacement...........................................................................................................3-4

3.7 Interconnect I/O Cable Removal/Replacement............................................................3-4

3.7.1 Removal.................................................................................................................3-4

September 2005 i

Contents SDQLCAI-1

3.7.2 Replacement...........................................................................................................3-5

3.8 Spare and Replacement Parts........................................................................................3-5

3.9 Maintenance Records ...................................................................................................3-6

4 Circuit Description ........................................................................................................4-1

4.1 Isolated Power Supply..................................................................................................4-1

4.2 IOBUS Modem.............................................................................................................4-1

4.3 Multiplexers/Converters...............................................................................................4-1

4.4 CPU ..............................................................................................................................4-2

5 Model Designation .........................................................................................................5-1

5.1 Options .........................................................................................................................5-1

5.2 Accessories...................................................................................................................5-2

6 Specifications..................................................................................................................6-1

6.1 Module Specifications..................................................................................................6-1

6.2 Environmental Specifications.......................................................................................6-1

6.3 Electrical Classification................................................................................................6-3

6.3.1 Approvals...............................................................................................................6-3

6.3.2 CSA Hazardous Locations Precautions .................................................................6-3

Index 5

List of Tables

Table Title Page

2–1 Field Wire Selection ......................................................................................................2-16

2–2 Unterminated I/O Cable Assembly................................................................................2-21

3–1 LED Indications...............................................................................................................3-2

5–1 CAI Options.....................................................................................................................5-1

5–2 CAI Accessories ..............................................................................................................5-2

6–1 CAI Specifications...........................................................................................................6-1

6–2 CAI Environmental Specifications..................................................................................6-1

6–3 Agency Approvals For CAI.............................................................................................6-3

List of Illustrations

Figure Title Page

1–1 Critical Analog Input Module (CAI) and Associated Hardware .....................................1-2

2–1 CAI Identification Label..................................................................................................2-1

2–2 Marshalling Utility Panel Dimensions.............................................................................2-6

ii September 2005

SDQLCAI-1 Contents

2–3 Standard CAI/SAI Marshalled Termination Assembly...................................................2-7

2–4 Installing or Removing a Marshalled Termination Assembly.........................................2-8

2–5 Marshalled Termination Assembly Mounting Ear Installation...................................2-9

2–6 Keying an Interconnect I/O Cable Assembly for CAI Use............................................2-11

2–7 Module and Rack Keying ..............................................................................................2-13

2–8 CAI I/O Wiring Connections on Marshalled Resistor Termination Assembly ............2-18

2–9 I/O Supply Monitor Line Connections ..........................................................................2-19

4–1 CAI Block Diagram.........................................................................................................4-2

4–2 CAI Channel Circuit........................................................................................................4-3

Significant Changes for Revision 4

Section Description

Preface (Conventions and Symbols)— new section

1.2 Product Support—contact information updated.

2.7 Electrical Installation—DANGER alert added

3 Maintenance—DANGER alert added

6.3.2 CSA Hazardous Locations Precautions—DANGER alert added

September 2005 iii

Contents SDQLCAI-1

PREFACE

Conventions and Symbols

The following symbols may appear in this manual and may be applied to the equipment. The reader

should become familiar with the symbols and their meaning. Symbols are provided to quickly alert the

user to safety related situations, issues, and text.

Symbol Meaning

Indicates an immediate hazardous situation which, if not avoided, will result in

DANGER

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result

WARNING

in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in

CAUTION

minor or moderate injury.

CAUTION

NOTICE

Important

Note

Indicates a potentially hazardous situation which, if not avoided, may result in

property damage.

Indicates a potential situation which, if not avoided, may result in an

undesirable result or state.

Identifies an action that should be taken to avoid an undesirable result or state.

Identifies additional information that should be read.

Electrical shock hazard. The included Warning text states that the danger of

electrical shock is present.

Electrical shock hazard. Indicated that the danger of electrical shock is

present.

Explosion hazard. Indicates that the danger of an explosion hazard exists.

Electrostatic discharge. The presence of this symbol indicates that

electrostatic discharge can damage the electronic assembly.

iv September 2005

SDQLCAI-1 Contents

Qualified Persons

The described equipment should be installed, configured, operated, and serviced only by qualified persons

thoroughly familiar with this publication. The current version, in Portable Document Format (PDF), is

available at http://sitescape.sea.siemens.com/

.

For the purpose of this publication and product labels, a qualified person is one who is familiar with the

installation, construction, and operation of the equipment, and the involved hazards. In addition, he or she

has the following qualifications:

Is trained and authorized to energize, de-energize, clear, ground and tag circuits and equipment in

accordance with established safety practices.

Is trained in the proper care and use of protective equipment such as rubber gloves, hard hat, safety

glasses or face shields, flash clothing, etc., in accordance with established safety practices.

Is trained in rendering first aid.

Scope

This publication does not purport to cover all details or variations in equipment, nor to provide for every

possible contingency to be met in connection with installation, operation, or maintenance. Should further

information be desired or should particular problems arise which are not covered sufficiently for the

purchaser’s purposes, the matter should be referred to one of the support groups listed in the Product

Support section of this manual.

The contents of this manual shall not become part of or modify any prior or existing agreement,

commitment or relationship. The sales contract contains the entire obligation of Siemens. The warranty

contained in the contract between the parties is the sole warranty of Siemens. Any statements continued

herein do not create new warranties or modify the existing warranty.

General Warnings and Cautions

WARNING

This equipment contains hazardous voltages, and it has been certified for use in the hazardous locations

specified on the product nameplate and in the Model Designation and Specifications section. Death,

serious personal injury, or property damage can result if safety instructions are not followed. Only

qualified personnel should work on or around this equipment after becoming thoroughly familiar with all

warning, safety notices, and maintenance procedures contained herein. The successful and safe operation

of this equipment is dependent upon proper handling, installation, operation, and maintenance.

The perfect and safe operation of the equipment is conditional upon proper transport, proper storage,

installation and assembly, as well as, on careful operation and commissioning.

The equipment may be used only for the purposes specified in this publication.

September 2005 v

Contents SDQLCAI-1

CAUTION

Electrostatic discharge can damage or cause the failure of semiconductor devices such as

integrated circuits and transistors. The symbol at right may appear on a circuit board or other

electronic assembly to indicate that special handling precautions are needed.

A properly grounded conductive wrist strap must be worn whenever an electronics

module or circuit board is handled or touched. A service kit with a wrist strap and static dissipative

mat is available from Siemens (PN15545-110). Equivalent kits are available from both mail order and

local electronic supply companies.

Electronic assemblies must be stored in anti-static protective bags when not installed in equipment.

DANGER

Explosion hazard

Will cause death, serious injury or property damage

In potentially hazardous atmosphere, remove power from equipment before

connecting or disconnecting power, signal, or other circuit, or extracting/inserting

module.

Observe all pertinent regulations regarding installation in hazardous area.

Ensure all devices are rated for hazardous (classified) locations.

DANGER

Electrical shock hazard

Explosion hazard

Will cause death, serious injury or property damage

Remove power from all wires and terminals and verify that there

are no hazardous voltages before working on equipment.

In potentially hazardous atmosphere, remove power from

equipment before connecting or disconnecting power, signal, or

other circuit, or extracting/inserting module.

Observe all pertinent regulations regarding installation in

hazardous area.

Ensure all devices are rated for hazardous (classified) locations.

vi September 2005

SDQLCAI-1 Contents

September 2005 vii

SDQLCAI-1 Introduction

1 Introduction

This Instruction provides installation and service information for the QUADLOG Critical Analog Input

Module (CAI) model QLCAIAAN.

It is divided into six major sections as follows:

Section 1, Introduction - Summarizes the information presented in this document. In addition, it

presents a description of the product, provides information about obtaining product support, furnishes

the definitions and usage of international symbols, and supplies a list of related literature.

Section 2, Installation - Describes the mechanical and electrical installation of the product and its

associated signal wire termination hardware. This includes procedures for proper preparation,

identification, and handling of the product. It also lists environmental considerations and provides

overview information about software-based product configuration.

Section 3, Maintenance - Provides information about preventive maintenance, troubleshooting

techniques, assembly replacement, and choosing spare and replacement parts.

Section 4, Circuit Description - Contains a brief block diagram level description of the product. It

explains how the CAI processes I/O signals and operates in conjunction with a control module.

Section 5, Model Designation - Provides model designation and tables of accessories, attachments,

and options.

Section 6, Specifications - Lists the product’s mechanical, electrical, and environmental

specifications.

1.1 Product Description

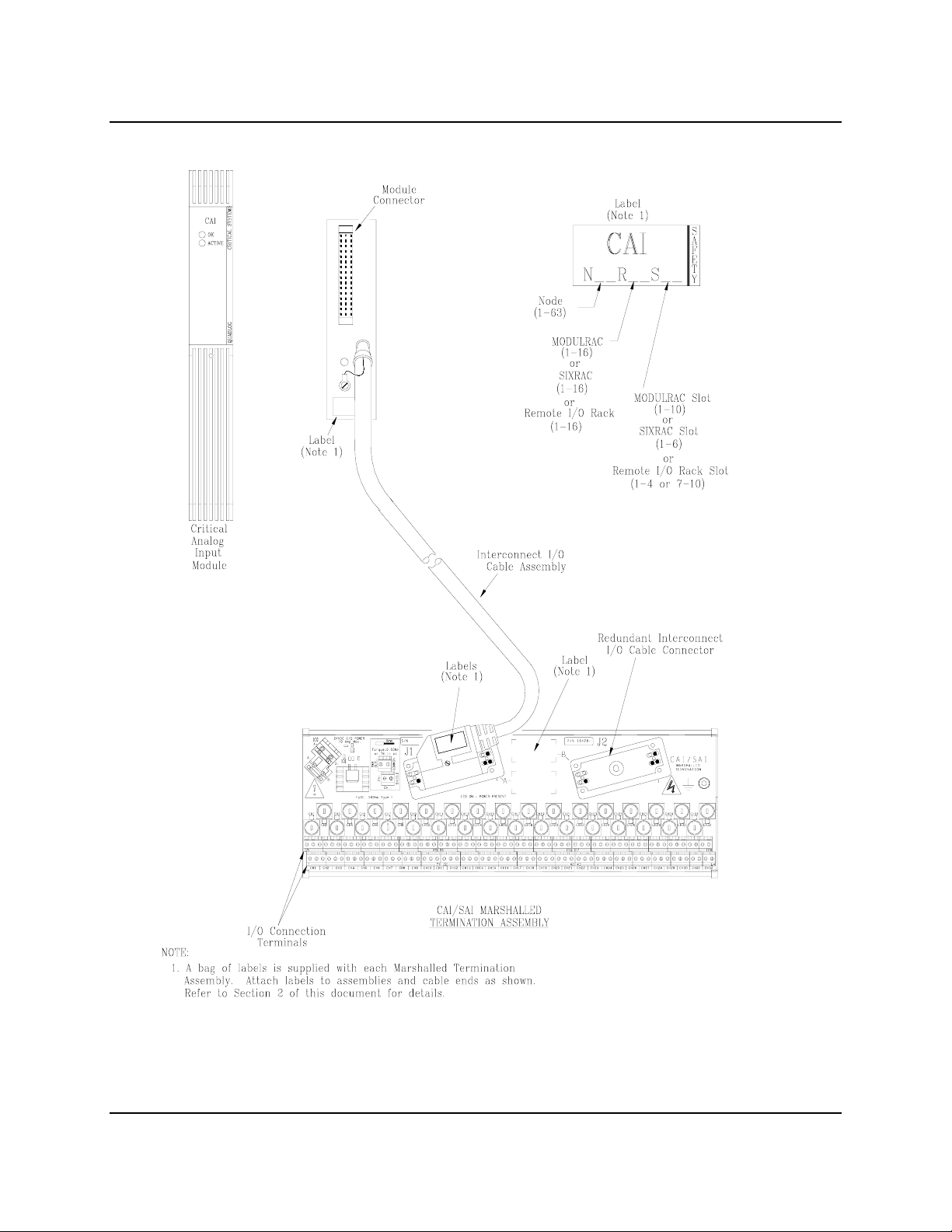

The QUADLOG Critical Analog Input Module (CAI) is part of the QUADLOG family of safety critical

control and I/O modules. It is ideally suited for such applications as emergency shutdown or burner

management. The CAI uses standard QUADLOG module packaging. It plugs into any of the standard

module racks, where it operates in conjunction with a QUADLOG resource module such as a Critical

Control Module (CCM) as part of a data acquisition and control system. It is an intelligent

(microprocessor-based), configurable I/O module that interfaces 32 channels of analog input signals

between field devices and the IOBUS. The CAI and its associated wiring termination hardware are

shown in Figure 1-1. As shown, field wiring is connected to a remote mounted Marshalled Termination

Assembly. The operating status of the CAI is shown by two bezel-mounted LED indicators.

Using the 4-mation™ Configuration software in conjunction with QUADLOG software configures the

CAI. This software runs on an MS Windows® based personal computer. The configuration is developed

off-line as part of a control module (CCM) configuration. When the configuration is transferred from

4-mation to the control module, the CAI portion is automatically copied from the control module to the

CAI.

May 2002 1-1

Introduction SDQLCAI-1

Figure 1–1 Critical Analog Input Module (CAI) and Associated Hardware

1-2 May 2002

SDQLCAI-1 Introduction

1.2 Product Support

Our Technical Support Centers (TSC) offer a variety of technical support services that are designed to

assist you with Siemens products and systems. Our support engineers have experience with

troubleshooting, development, system startup, and system test. They will help you to solve your issues in

an efficient and professional manner.

Customers in North America can contact Siemens Technical Support Center at 1-800-333-7421, on the

web at: http://support.automation.siemens.com

, or by e-mail: techsupport.sea@siemens.com

Customers outside North America can contact their local Siemens subsidiary; addresses and telephone

numbers are listed on the Internet at the web site: http://support.automation.siemens.com

.

When contacting Siemens, customers will be asked to provide site-contact information (name, address,

and phone number), the product involved and detailed information regarding the nature of the issue.

Product documentation is now located in the Library forum of the Process Automation User Connection

at: http://sitescape.sea.siemens.com/

. The Process Automation User Connection is a secure site.

Registration is open to all verified users of Siemens process automation systems. If you are not already,

and would like to become a member, please visit our Process Automation User Connection web page at:

http://www.sea.siemens.com/process/support/papauc.html

Contained within the Process Automation User Connection is the APACS+/QUADLOG Secure Site at:

http://sitescape.sea.siemens.com/forum/aca-1/dispatch.cgi/f.apacsquadlo

forum. This site is only open to

customers with an active service agreement. It contains all service manuals, service memos, service notes,

configuration manuals, etc. for the APACS+ and QUADLOG family of products. If you are experiencing

technical difficulties with the site, please contact SiteScape technical support at: toll free 1-877-234-1122

(US) or 1-513-336-1474.

May 2002 1-3

Introduction SDQLCAI-1

A&D Technical Support

Worldwide, available 24 hours a day:

Nürnberg

Johnson Cit y

Beijing

United States: Johnson City, TN Worldwide: Nürnberg Asia / Australia: Beijing

Technical Support and Authorization

Local time: Monday to Friday

8:00 AM to 5:00 PM

Telephone:+1 (423) 262 2522

or +1 (800) 333-7421 (USA only)

Fax:+1 (423) 262 2289

Mail to: techsupport.sea@siemens.com

GMT: -5:00

Automation and Drives Service and Support International

http://www.siemens.com/automation/service&support

The languages of the SIMATIC Hotlines and the authorization hotline are generally German and English.

Technical Support

24 hours a day, 365 days a year

Phone:+49 (180) 5050-222

Fax:+49 (180) 5050-223

E-Mail: ad.support@siemens.com

GMT:+1:00

Authorization

Local time: Monday to Friday

8:00 AM to 5:00 PM

Phone: +49 (180) 5050-222

Fax: +49 (180) 5050-223

Mail to: ad.support@siemens.com

GMT: +1:00

Technical Support and Authorization

Local time: Monday to Friday

8:00 AM to 5:00 PM

Phone:+86 10 64 75 75 75

Fax:+86 10 64 74 74 74

Mail to:ad.support.asia@siemens.com

GMT:+8:00

1-4 May 2002

SDQLCAI-1 Introduction

1.3 Related Literature

The following documents are available to complement the installation, configuration, and maintenance of

the CAI. Generally, all needed documentation is supplied with your equipment. It may be supplied in

electronic form in the Adobe portable document format (PDF), printed form, or both. Refer to these

documents as needed or as called for in text. Documents may be located on your workstation’s hard drive

or on a CD supplied with your system.

Using the 4-mation Configuration Software (document number CG39-20)

QUADLOG I/O Module Configuration (document number CGQL-4)

QUADLOG CCM/ACM+ Standard Function Blocks (document number CGQL-3)

MODULPAC 1000 Installation and Service Instruction (document number SD39MODULPAC-1)

May 2002 1-5

Introduction SDQLCAI-1

1-6 May 2002

SDQLCAI-1 Installation

2 Installation

This section describes installation of the Critical Analog Input Module (CAI) and its associated I/O

wiring termination hardware. Review and complete the preparatory steps in section 2.2 before proceeding

with the installation.

IMPORTANT

The CAI installation should be in accordance with the National Electrical

Code (NEC), other applicable construction, and electrical codes.

The CAI is only to be used for the purposes described by Siemens.

2.1 Hardware Identification

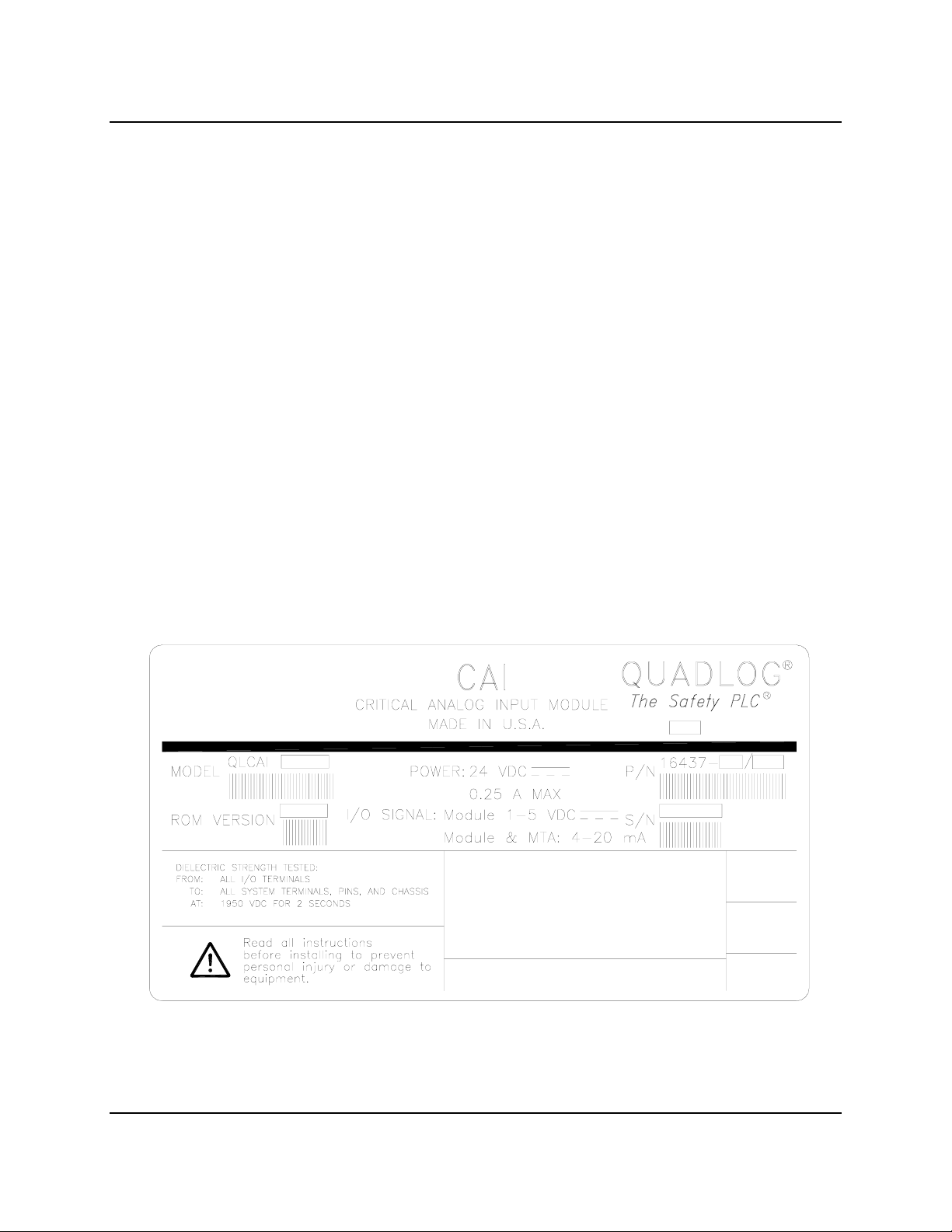

2.1.1 Module Identification

The CAI is identified by the three-letter “CAI” designation on the bezel and by two nameplate labels.

One nameplate label is large, similar to that shown in Figure 2-1, and located on the left side of the

module. A smaller label is located inside the bezel compartment. Both labels contain the CAI’s model

designation, part number/issue level, ROM version number, and serial number (S/N). The larger label

also lists the power requirements, and space is provided for information such as agency certifications.

SIEMENS

Siemens Energy & Automation, Inc.

Figure 2–1 CAI Identification Label

May 2002 2-1

Installation SDQLCAI-1

2.1.2 Marshalled Termination Assembly Identification

The CAI can be used with the CAI/SAI Marshalled Termination Assembly. This assembly is identified

by the following information printed on its surface.

CAI/SAI

MARSHALLED

TERMINATION

P/N 16428-1

2.2 Preparations

1. Install the MODULRAC (SIXRAC, or Remote I/O Rack) in the cabinet where the CAI is to be

installed. The CAI should not be installed in the rack at this time; however, its designated slot

number should be known.

2. If remote I/O termination is employed, complete the following tasks:

If Marshalling Utility Panels are being used, install them in their respective marshalling cabinets.

Tag all I/O cables and route them into the marshalling cabinet. They should be ready for cable

end preparation and connection to the CAI/SAI Marshalled Termination Assemblies. Cable wire

sizes: 24 to 12 AWG.

Route the Interconnect I/O Cable (or Unterminated I/O Cable) between the rack in which the CAI

is to be installed and the marshalling cabinet. Refer to Figure 1-1; the J1 end of the cable is to be

installed in the rack and P2 end is to be connected to the appropriate Marshalled Termination

Assembly in the marshalling cabinet.

If an Unterminated I/O Cable is installed, you must supply and install the appropriate termination

hardware (terminal blocks) for field signal I/O wiring and the I/O Cable.

3. If channel diagnostics are to be used for automatically detecting wiring faults such as short or open

circuits, each channel must be wired with the appropriate resistors (and configured accordingly).

High-power EMI-producing equipment should not be connected to any power lines dedicated to CAI

input signals.

2.3 Environmental Considerations

Many industrial environments create severe operating conditions. The conditions at each CAI

location must be within the specifications stated in section 6.2.

To ensure operator safety, Marshalled Termination Assemblies shall be installed in enclosures, which

require a key or special tool to gain access to the equipment.

2-2 May 2002

Loading...

Loading...