Siemens QFM3100, QFM2100, QFM2101, QFM3101, QFM4101 Installation Instructions Manual

...

Installation Instructions

Q-Series Relative Humidity (RH) and

QFM2100

±5%

QFM3100

±2%

QFM2101

±5%

QFM3101

±2%

QFM4101

±2% Certified

QFM2160

±5%

QFM3160

QFM3160D

QFM4160

±2% Cert.

QFM2171

±5%

QFM3171

QFM3171D

QFM4171

±2% Cert.

QFM2110

Pt 1KΩ

QFM2120

Ni 1K

QFM3110

Pt 1K

±2%

QFM21…

155-748

QFM3160

155-749

QFM4160

155-750

Document No. 129-413

October 5, 2009

Relative Humidity & Temperature (RH/T) Duct Sensors

Product Descript ion

Relative Humidity (RH) and Relative Humidity &

Temperature (RH/T) duct sensors monitor the

relative humidity or the relative humidity and

temperature in a duct, depending on the model.

Sensors are directly wired to the controller via

twisted pair and/or three conductor cables

(18 to 22 AWG). The number and type of cables

required depends on the model selected. All field

wiring is terminated in a terminal block on the sensor

body.

Product Numbers

Table 1. Relative Humidity Only.

Product

Number

Humidity

Signal

0 to 10 Vdc

4 to 20 mA

Accuracy

♦

Additional Reference Document s

Product Number Technical Instructions

Required Tools

• Phillips screwdrivers, No. 1 and No. 2

• Wire cutters/strippers

• Medium flat-blade screwdriver

• Tape measure

• Medium-duty electric drill

• Marker or pencil

• No. 26 (0.147-inch) drill bit

• Small level

• 7/8-inch drill bit or hole saw

• Two No. 8 × 1-inch sheet metal screws

Expected Installation Time

One hour

Table 2. Relative Humidity and Temperature.

Product

Number

♦

Applies to humidity only

Temperature

Signal

0 to 10 Vdc 0 to 10 Vdc

4 to 20 mA 4 to 20 mA

Ω

Ω

Humidity

Signal

0 to 10 Vdc

Accuracy

±2%

±2%

±5%

NOTE: Sensor tips on QFM31… and QFM41…

models are field replaceable.

Item Number 129-413, Rev. CA Page 1 of 3

Prerequisites

♦

• Ensure that the appropriate field wiring is

installed.

Appropriate wiring is one or more twisted

pairs, or three conductor cables (plenum or

non-plenum as required), within the maximum

wiring run length for the individual equipment

controller. The maximum recommended

length is 750 feet (229 m).

• Ensure that all wiring complies with National

Electric Code (NEC) and local regulations.

Mounting Infor m a t ion

Locate the sensor:

• In the center of a duct.

• Away from fans, corners, heating and cooling

coils, and so on.

• Where it receives adequate airflow for proper

operation.

Document No. 129-413

Installation Instructions

October 5, 2009

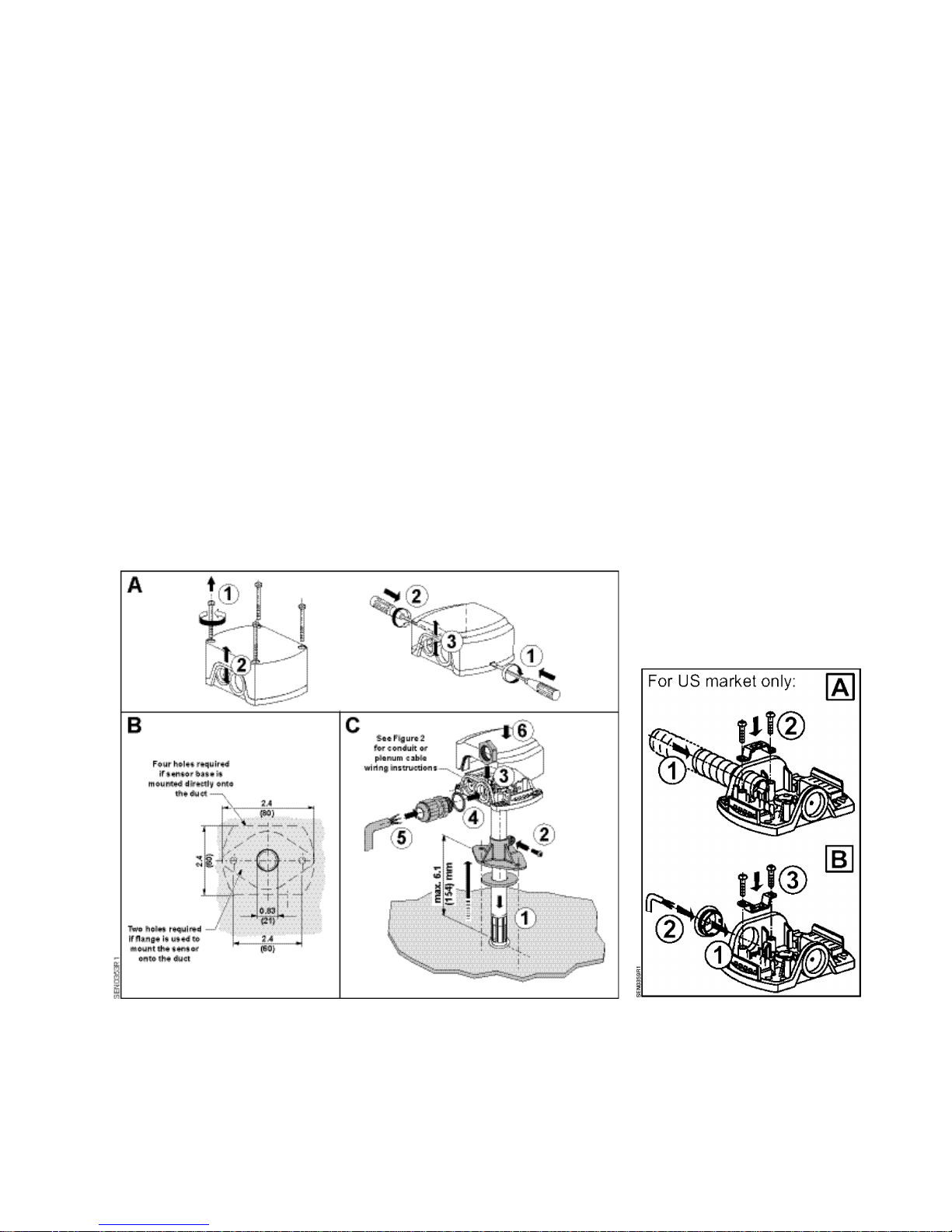

Instructions

1. Drill a 7/8-inch diameter hole into the duct at the

desired location of the sensor.

2. Decide if the sensor will be mounted directly to

the duct or if the mounting flange will be used.

• Sensor Mounting Bracket Installation

a. Use the bracket as a template, and drill

two holes with a No. 26 (0.147-inch) drill

bit. See Figure 1(B).

b. Attach the sensor mounting bracket and

gasket to the duct using two No. 8 × 1inch sheet metal screws. See

Figure 1(C1).

c. Insert the sensor in the duct through the

bracket and tighten the mounting screw

to set the insertion depth. See

Figure 1(C2).

• Direct installation:

a. Remove the sensor cover.

b. Use the base as a template, and drill four

holes with a No. 26 (0.147-inch) drill bit.

See Figure 1(B).

c. Insert the probe through the gasket and

into the hole. Secure the head to the duct

with four No. 8 × 1-inch sheet metal

screws.

3. Attach conduit or plenum wire to the sensor

base. See Figures 1 and 2.

4. If you are using conduit, pull the field wiring

through the conduit and into the sensor base.

5. Connect the field wiring to the sensor terminal

block on the base. See Figures 3 through 7 for

wiring diagrams.

6. Reinstall the sensor cover. See Figure 1(C6).

The installation is now complete.

Figure 1. RH/T Duct Sensor Installation. Figure 2. Conduit or Plenum

Cable Wiring Installation.

NOTE: Figure 2 shows how to connect the conduit or plenum cable to the sensor head.

.

Page 2 of 3 Siemens Industry, Inc.

Loading...

Loading...