Siemens QFA3212.FWxN, QFA32SS.FWxN, FA3212.EWxN, QFA32SS.EWxN, FA3232.EWxN Installation Instructions Manual

Installation Instructions

Series

2200 and 3200 Relative

Humidity

and Temperature Room Units

CAUTION

Docume nt No. 129-104

Decemb er 11, 2017

Product Description

These room units measure relative humidity and

temperature in the occupied space in which they are

install ed. Models wit h display allow users to view the

measured temperature value. A version with

temperature setpoint adjustment is also off ered.

The effective sensing range is 32°F to 122°F (0°C to

50°C), and the setpoi nt range is 55°F to 95°F (13°C

to 35°C). The humidity measuring range is 0 to

100% RH.

Hardware is included for installation on drywall or on

a 2” × 4” electrical box.

Product Numbers

QFA3212.FWxN QFA32SS.FWxN

QFA3212.EWxN QFA32SS.EWxN

QFA3232.EWxN

Accessories

AQA2200-INTL Room Unit Back Plate

(10-pack)

563-102 GSKT KIT Room Sensor Insulating

Gasket (10-pack)

(For hollow wall installations)

Expected Installation Time

20 minutes

Required Tools

• Sizes 1 and 2 Phillips screwdrivers

• Small and medium flat-blade screwdrivers

• 1/16-inch hex key

• Medium-duty electric drill

• 3/16-inch (4.8 mm) drill bit

• One-inch (25 mm) hole saw

• Small level

• Tape measure

• Marker or pencil

Prerequisites

• Review these instructions before beginning.

• Installed: appropriate field wiring within the

maximum wiring run length for the individual

equipment controller. The maximum

recommended length is 750 feet (229 m) for

18 AWG; 300 feet (91 m) for 22 AWG.

• All wiring must comply with National Electric

Code (NEC) and local regulations.

Caution Notations

Equipm ent damage or l oss of

data may occur if you do not

follow a procedure as

specified.

Item Number 129-104, Rev. JA

Figure 1. Typical Temperature Room Unit.

Page 1 of 4

Document No. 129-104

Installation Instructions

December 11, 2017

Mounting Information

Always mount the room unit vertically.

Locate the room unit:

• according to design specifications and local

regulations.

• where the air circulates around it freely (not in

recessed areas or behind doors).

• allowing a minimum of 4 inches (10 cm) free

space above and below for proper airflow, the

front cover removal tool, and the computer

communicati on cabl e.

• away from drafts caused by doors, windows,

outside walls, air registers, pipes, return air

plenums, etc.

• away from heat sources such as strong lights,

fireplaces, direct sunlight, etc.

• on an inside wall (preferably), about 5 feet

(1.5 m) above the finished floor, or per code

(ANSI, ADA, or local regulation).

Drywall Mounting (No Rough-in),

Typical

Base Plate Mounting and Wiring

1. Mark the center (cable) hole and the mounting hole

locations, using t he room unit base plate as a

template. See Figure 3.

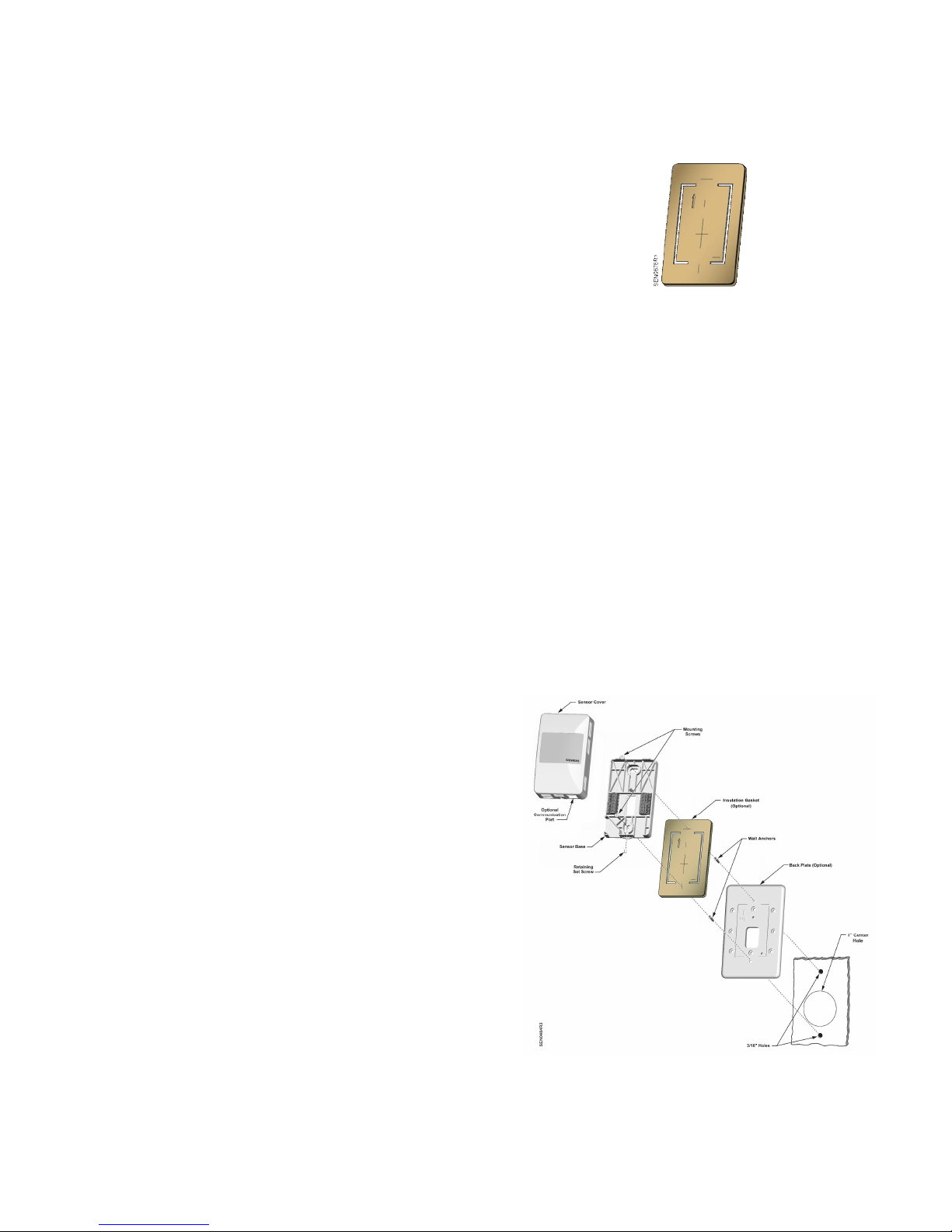

Figure 2. Insulating Gasket.

4. Pull about three inches (75 mm) of the cable through

the hole in the base plate.

5. Mount the room unit base plate on the wall, noting

the UP arrow:

NOTE: If required, position the back plate behind

the room unit base, aligning the top and

bottom mounting holes, prior to mounting

to the wall:

a. Install the two mounting screws prov ided, but

do not tighten.

b. Level the room unit base plate for appearance.

c. Ti ghten the two mounting screws to the room

unit base plate.

6. Cut the cable, leaving about three inches (75 mm)

on the room unit side of the drywall. Ensure that pin

Number 1 connects to the same wire at each end of

the cable.

2. Drill two 3/16-inch (4.8 mm) mounting holes and

mount the two plastic wall anchors flush to below the

wall surface for stable mounting of the device.

3. Cut a 1-inch (25 mm) center hole with a hole saw.

NOTE: It is recommended that you use the

optional Insulating Gasket* on the back

of the Unit Base for hollow wall

install ati ons.

When applying the adhesive-backed

gasket to the back of the unit base, orient

the gasket so that the cut-out arrow

portion of the gasket is in the upper

lefthand quadrant of the unit base. The

sensor base has an UP arrow mol ded

into the surf ace in the same quadrant

location (see Figure 6).

*Insulating gasket s are sold in 10-packs

(Part Number 563-102 GSKT KIT).

Page 2 of 4 Siemens Industry, Inc.

NOTE: See Figure 2 for details on optional Gasket

application.

Figure 3. Drywall Mounting (No Rough-in), Typical.

Loading...

Loading...