Siemens QBM Series, QBM3100U025U, QBM3100U1, QBM3100U2.5, QBM3100U5 Installation Instructions Manual

...

Air Differential Pressure Sensors

Product Description

The Siemens QBM Series Air Differential Pressure

Sensors use a well-proven ceramic technology.

They deliver temperature-compensated sensor

signals for registering airflow in HVAC systems and

for the measurement of differential pressures in

environmental, laboratory and cleanroom

applications.

Installation Instructions

Document No. 129-903

October 4, 2013

Expected Installation Time

30 minutes

Prerequisites

Even though the device is protected against electromagnetic interference, installation and cabling must

be carried out correctly to ensure interference

immunity.

Product Numbers

Product Number Percent

Accuracy

QBM3100U025U +/- 0.25

QBM3100U1 1

QBM3100U2.5 2.5

QBM3100U5 5

QBM3100U10

+/-1% FS

Pressure

Range

Inches WC

(Water

Column)

10

Contents

• Sensor

• Conduit Adapter

• Use shielded cables for the signal and control

lines with the connecting lead of the shield

being kept as short as possible. The connection

point of the shielding depends on the existing

connection conditions.

• Never route signal and control cables together

with the trunk line or feeder cables of motors,

cylinder coils, rectifiers, and so on. The cables

must be routed in conductive and grounded

cable conduits. This applies especially to longdistance cables, or environments where the

cables are exposed to strong radio waves from

broad casting stations.

CAUTION:

• Prior to mounting or removing the

• Do not mount sensors in locations

Warning/Caution Notations

WARNING:

CAUTION:

Personal injury/loss of life may

occur if you do not follow the

procedures as specified.

Equipment damage/loss of

data may occur if you do not

follow the procedures as

specified.

• Significant thermal changes in the

sensor, verify that the system is

depressurized.

subject to high pressure pulses.

sensor environment can lead to a zero

shift. As a result, the measuring value

displayed in a depressurized state will

read zero. This kind of drift can be

corrected by zero point reset.

Required Tools

• Small, Phillips screwdriver

• Small, flat-blade screwdriver

• Adjustable wrench

Item Number 129-903, Rev. BA Page 1 of 2

Document No. 129-903

SSEN0024R2

Installation Instructions

October 4, 2013

Installation

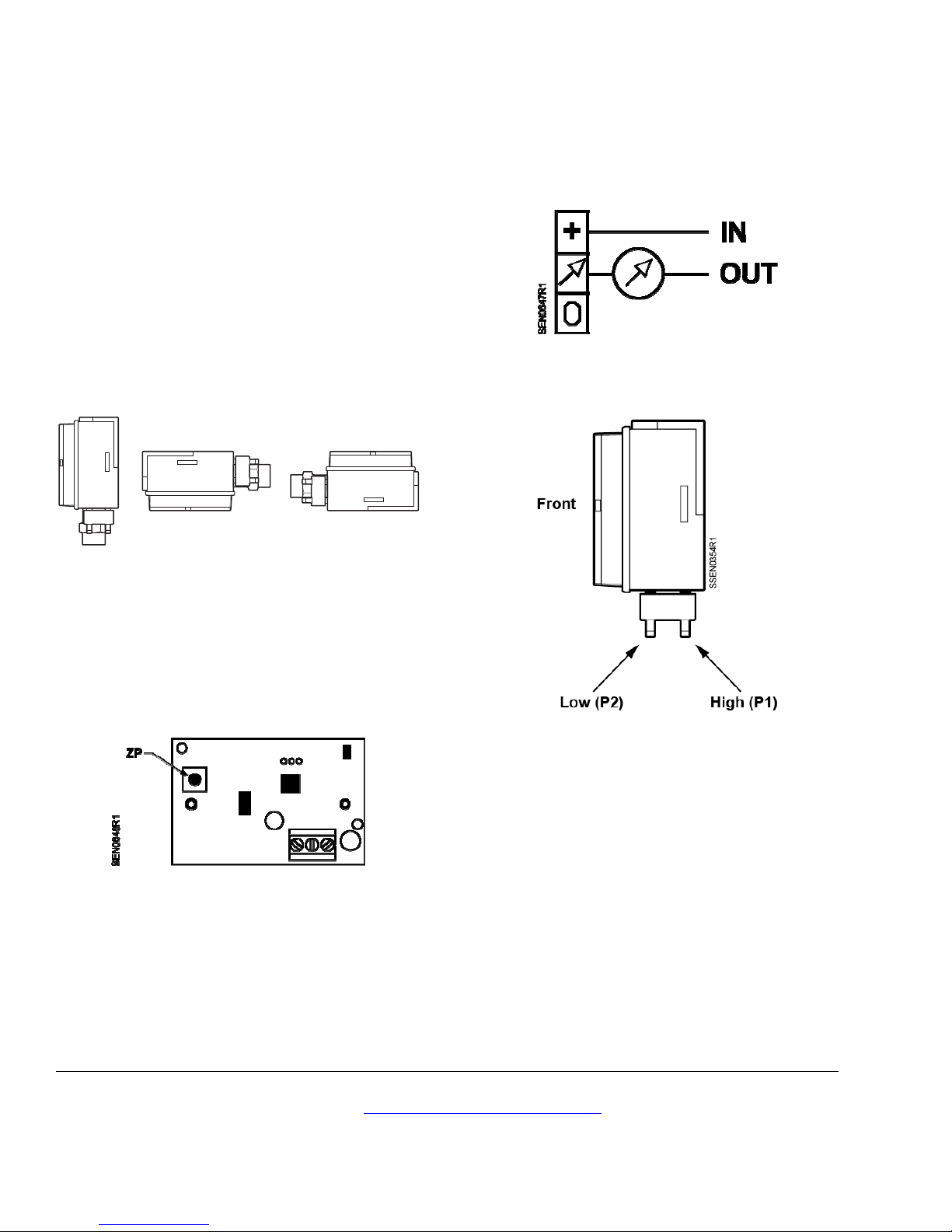

Recommended mounting positions:

• Vertical, with the pressure connections

facing downward, drain off possible

condensed water (factory calibration).

• Horizontal, with the cover facing downward.

• Horizontal, with the cover facing upward.

NOTE: Mount the transmitter with a minimum 0.39

inches (10 mm) distance to magnetic

material. If this is not possible there may be

an error of up to -.004 inch WC for

transmitters mounted on sheet steel.

Figure 1. Recommended Mounting Positions.

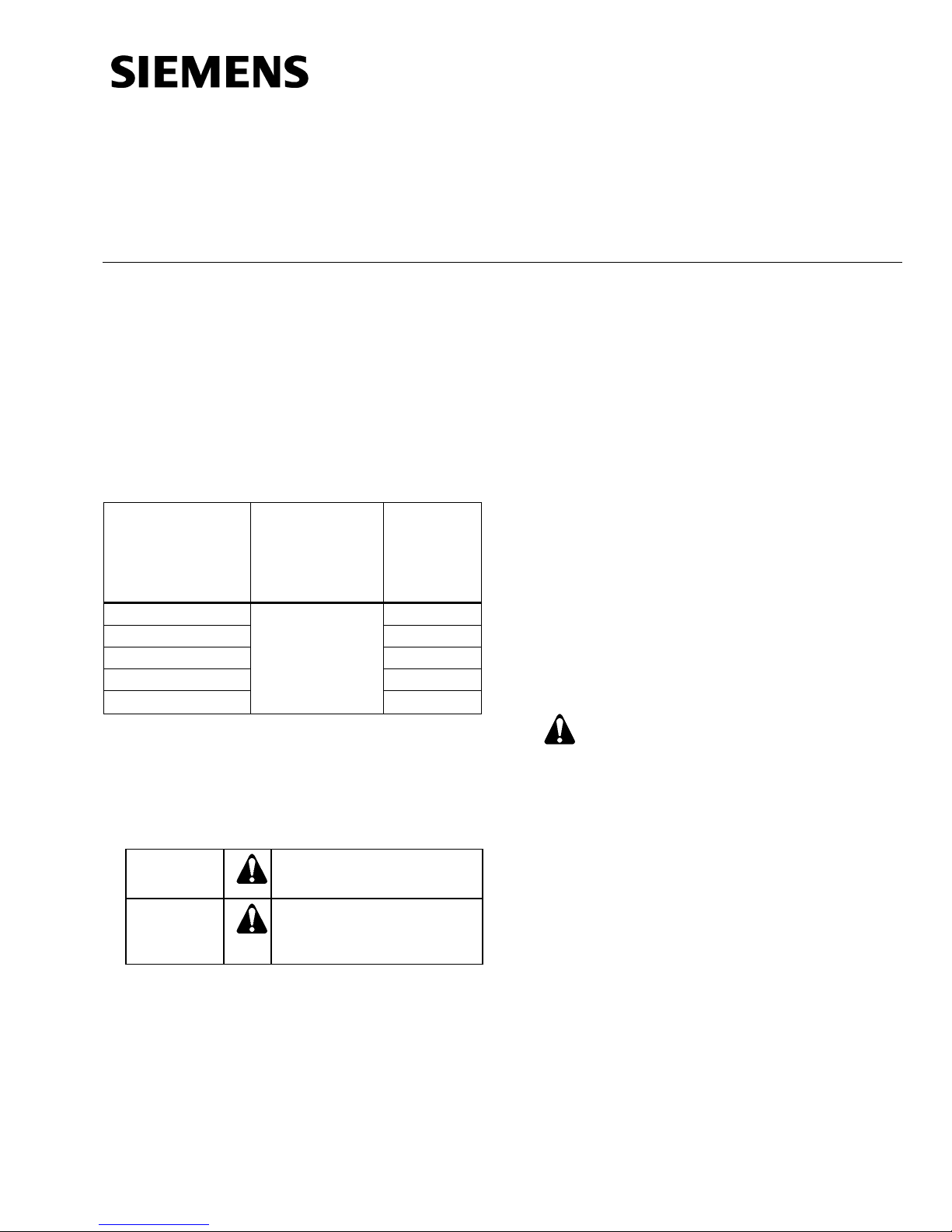

Wiring Diagram

Figure 3. Wiring Diagram, 4 to 20 mA.

Tubing Connections

ZP – Push Zero Point Reset

The installation position is variable by using the Zero

Point Reset button. Pressure variations can be reset

after installation.

Ensure the power supply is not interrupted when

storing customer settings (ZP – reset).

Figure 4. High and Low Pressure Connections.

The installation is now complete.

Figure 2. ZP Push Zero Point Reset.

Information in this publication is based on current specifications. The company reserves the right to make changes in specifications and

models as design improvements are introduced. Product or company names mentioned herein may be the trademarks of their respective

owners. © 2013 Siemens Industry, Inc.

Siemens Industry, Inc.

Building Technologies Division

1000 Deerfield Parkway

Buffalo Grove, IL 60089-4513

USA

+1-847-215-1000

Your feedback is important to us. If you have

comments about this document, please send them

to SBT_technical.editor.us.sbt@siemens.com

Document No. 129-903

Printed in the USA

Page 2 of 2

Loading...

Loading...