Siemens QAA2280.xWNC,QAA2280.xWSC,QAA3280.xWNC,QAA2281.xWSC,QAA3280.xWSC Installation Instructions Manual

Installation Instructions

Series 2200 Temperature and Series

TEC

CAUTION

Equipment damage or loss of

specified.

Document No. 129-484

April 17, 2014

3200 Combination RH&T Room Units,

Product Description

These room units allow users to view and adjust

points in the controller using the room unit buttons

and digital display.

They work with various Terminal Equipment

Controllers (TECs) and Actuator Terminal

Controllers (ATECs) offered by Siemens Industry,

Inc. These devices incorporate a solid state or 10K

NTC sensing element to detect temperature (and

humidity for QFA models). The effective sensing and

setpoint range is 55°F to 95°F (13°C to 35°C).

These room units can be mounted on electrical

boxes, stud-type mounting brackets, or drywall.

Obtain the necessary mounting hardware and follow

the appropriate mounting procedures for the type of

installation required.

Product Numbers

QAA2280.xWNC QFA3280.xWNC

QAA2280.xWSC QFA3280.xWSC

QAA2281.xWSC

Expected Installation Time

20 minutes

Required Tools

If using non-terminated or damaged cables, you also

need:

• Phillips sizes 1 and 2 screwdrivers

• Small and medium, flat-blade screwdrivers

• 1/16-inch hex key or 544-643A Passke y

(includes hex bit)

• Medium-duty electric drill

• 3/16-inch (4.8 mm) drill bit

• One-inch (25 mm) hole saw

• Small level

• Tape measure

• Marker or pencil

• Room unit connector tool (RJ-11 crimping

tool – SBT P/N 540-140 or third-party tool)

• Room unit connector kit (SBT P/N 540-141)

Accessories

AQA2200-INTL Room Unit Back Plate (10-pack)

AQA2200-2X4 Room Unit Back Plate (Single)

563-102 GSKT Kit Room Sensor Insulating

Gasket (10-pack)

(For hollow wall in s ta llations)

TEC to Room Sensor Cable

Yellow, 6-pin m ale with RJ -11 jacks on both ends

(Choose 1, a cable may already be installed):

588-100A 25-foot

588-100B 50-foot

588-100C 100-foot

Caution Notations

data may occur if you do not

Item Number 129-484, Rev. JA Page 1 of 3

follow a procedure as

Prerequisites

• Review these instructions before beginning.

• Installed: appropriate field wiring (standard

six-conductor room unit cables, plenum or

non-plenum as required) within the

maximum wiring run length for the individual

equipment controller. The maximum

recommended length is 100 feet (30 m).

• All wiring must comply with Nationa l Electric

Code (NEC) and local regulations.

Figure 1. Temperature Room Unit.

Document No. 129-484

Installation Instructions

April 17, 2014

Mounting Information

Always mount the room unit vertically, on a flat wall.

Locate the room unit:

• according to design specif i c ations and loc a l

regulations.

• where the air circulates around it freely (not

in recessed areas or behind doors).

• allowing a minimum of 4 inches (10 cm) free

space above and below for proper airflow,

the hex bit or passkey tool, and the

computer communication cable.

• away from drafts caused by doors, windows,

outside walls, air registers, pipes , return air

plenums, etc.

• away from heat sources such as strong

lights, fireplaces, direct sunlight, etc.

• on an inside wall (preferably), about 5 feet

(1.5 m) above the finished floor, or per code

(ANSI, ADA, or local regulation).

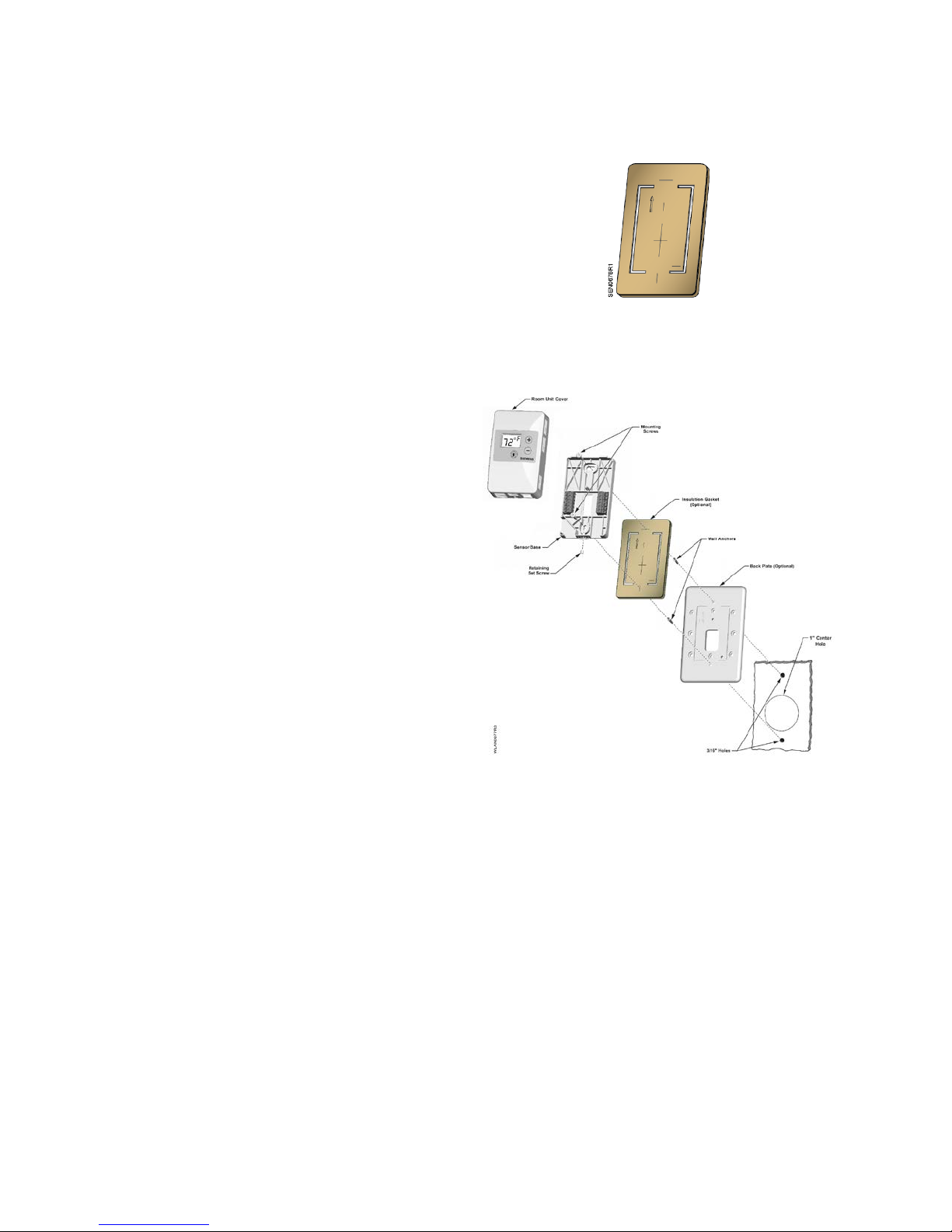

Figure 2. Insulating Gasket.

4. Pull about three inches (75 mm) of the cable

through the hole in the base plate.

Drywall Mounting (No Rough-in),

Typical

1. Mark the center (cable) hole and the mounting

hole locations, using the room unit base pl ate as

a template. See Figure 2.

2. Drill two 3/16-inch (4.8 mm) mounting holes and

mount the two plastic wall anchors flush to

below the wall surface for stable mounting of the

device.

3. Cut a 1-inch (25 mm) center hole with a hole

saw.

NOTE: It is recommended that you use the

optional Insulating Gasket on the back

of the Sensor Base for hollow wall

installations.

When applying the adhesive-backed

gasket to the back of the Sensor Base,

orient the gasket so that the cut-out

arrow portion of the gasket is in the

upper lefthand quadrant of the Sensor

Base. The Sensor Base has an UP

arrow molded into the surface in the

same quadrant location.

NOTE: See Figure 2 for details on optional

Gasket application.

Figure 2. Drywall Mounting (No Rough-in), Typical.

5. Mount the room unit base plate on the wall,

noting the "UP" arrow:

NOTE: If required, position the Back Plate

behind the Room Unit Base, aligning

the top and bottom mounting holes,

prior to mounting to the wall:

a. Install the two mounting screws provided,

but do not tighten.

b. Level the room unit base plate for

appearance.

c. Tighten the two mounting screws to the

room unit base plate.

Page 2 of 3 Siemens Industry, Inc.

Loading...

Loading...