Siemens QAA2212.*W*N, QAA2220.*W*N, QAA2232.*W*N, QAA2221.*W*N, QAA2235.*W*N Installation Instructions Manual

...Page 1

Installation Instructions

Docume nt No. 129-477

Series 2200 Room

Units

CAUT

ION

Novemb er 15, 2017

Product Description

These room units measure t emperature in the

occupied space in which they are installed. Models

with display allow users to view the measured

temperature value. A version with temperature

setpoint adjustment is also offered.

The effective sensing and setpoint range is 55°F to

95°F (13°C to 35°C).

These room units can be mounted on electrical

boxes, stud-type mounting brackets, or drywall.

Hardware is included for installation on drywall or on

a 2” × 4” electrical box.

Product Numbers

QAA2212.xWxN QAA2232.xWxN

QAA2220.xWxN QAA2235.xWxN

QAA2221.xWxN QAA22SS.xWxN

QAA2230.EWxN

Accessories

AQA2200-INTL Room Unit Back Plate (10-pack)

Required Tools

• Sizes 1 and 2 Phillips screwdrivers

• Small and medium flat-blade screwdrivers

• 1/16-inch hex key

• Medium-duty electric drill

• 3/16-inch (4.8 mm) drill bit

• One-inch (25 mm) hole saw

• Small level

• Tape measure

• Marker or pencil

Prerequisites

• Review these instructions before beginning.

• Installed: appropriate field wiring within the

maximum wiring run length for the individual

equipment controller. The maximum

recommended length is 100 feet (30 m).

• All wiring must comply with National Electric

Code (NEC) and local regulations.

563-102 GSKT KIT Room Sensor Insulating

Gasket (10-pack)

(For hollow wall installations)

Caution Notations

Equipm ent damage or l oss of

data may occur if you do not

follow a procedure as

specified.

Expected Installation Time

20 minutes

Item Number 129-477, Rev. JA

Figure 1. Typical Temperature Room Unit.

Page 1 of 4

Page 2

Document No. 129-477

Installation Instructions

November 15, 2017

Mounting Information

Always mount the room unit vertically.

Locate the room unit:

• according to design specifications and local

regulations.

• where the air circulates around it freely (not in

recessed areas or behind doors).

• allowing a minimum of 4 inches (10 cm) free

space above and below for proper airflow, the

front cover removal tool, and the computer

communicati on cabl e.

• away from drafts caused by doors, windows,

outside walls, air registers, pipes, return air

plenums, and so on.

• away from heat sources such as strong lights,

fireplaces, direct sunlight, and so on.

• on an inside wall (preferably), about 5 feet

(1.5 m) above the finished floor, or per code

(ANSI, ADA, or local regulation).

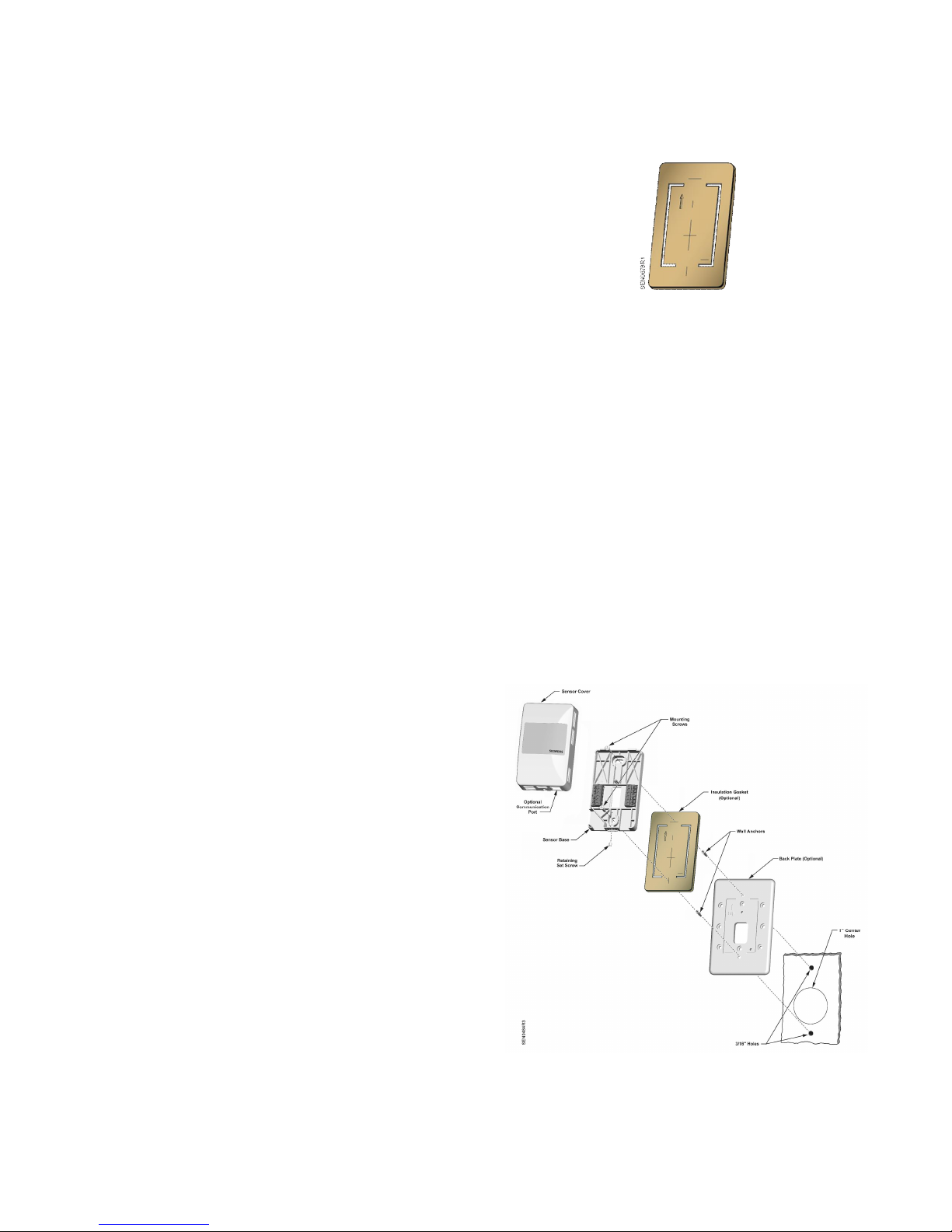

Drywall Mounting (No Rough-in),

Typical

Base Plate Mounting and Wiring

1. Mark the center (cable) hole and the mounting

hole locations, using the temperature sensor base

plate as a template. See Figure 3.

Figure 2. Insulating Gasket.

4. Pull about three inches (75 mm) of the cable through

the hole in the base plate.

5. Mount the room unit base plate on the wall, noting the

UP arrow:

NOTE: If required, position the back plate behind the

room unit base, aligning the top and bottom

mounting holes, prior to mounting to the wall:

a. Install the two mounting screws provi ded, but do

not tighten.

b. Level the room unit base plate for appearance.

c. T ighten the two m ounting screws to the room unit

base plate.

6. Cut the cable, leaving about three inches (75 mm) on

the room unit side of the drywall. Ensure that pin

Number 1 connects to the same wire at each end of

the cable.

2. Drill two 3/16-inch (4.8 mm) mounting holes and

mount the two plastic wall anchors flush to below

the wall surface for stable mounting of the dev ice.

3. Cut a 1-inch (25 mm) center hole with a hole saw.

NOTE: It is recommended that you use the

optional insulating gasket on the back of

the Sensor Base for hollow wall

install ati ons.

When applying the adhesive-backed

gasket to the back of the Sensor Base,

orient the gasket so that the cut-out

arrow portion of the gasket is in the

upper left-hand quadrant of the Sensor

Base. The Sensor Base has an UP

arrow molded into the surface in the

same quadrant location (see Figure 6).

NOTE:See Figure 2 for details on optional Gasket

application.

Figure 3. Drywall Mounting (No Rough-in), Typical.

Page 2 of 4 Siemens Industry, Inc.

Page 3

7. Terminate the wires to the termination blocks on the

CAUTION:

room unit's base plate. (See Figure 6.)

8. Feed the extra cable back through the hole.

Sensor Set-up

Document No. 129-477

Installation Instructions

November 15, 2017

Figure 5. Changing Display to °C.

3. Snap the room unit cover to the base plate by first

hooking the room unit’s front to the top latches, and

then rotating the cover downward until it latches.

Figure 4. Circuit Board

(Located inside Room Unit Cover.

1. If the device has a switch, determine if voltage or

current output is needed.

• For current, set the switch in t he down positi on

(I).

• For voltage, set t he switch in the up position (V).

NOTE: The output setting applies to all outputs

(temperature, and setpoint).

2. If selecting voltage, set the jumper:

• Use the top and middle pins for 0 to 5V.

• Use the bottom and middl e pi ns f or 0 t o 10V.

NOTE: If the jumper is missing or removed, the

output voltage will default to

0 to 10V.

NOTE: The factory default for displayed temperature

units is °F. To change the display to °C, snip the

wire jumper (0 Ohm resistor R64) on the back of

the PCA.

4. Loosen the safety set screw at the bottom of the

base one or two revoluti ons to lock the cover to the

base. Be careful not to loosen too far as the screw

can be completely removed from the base.

Electrical Box and Rough-in

Mounting, Typical

1. If a locator is attached to the rough-in device,

remove the locator by removing the two screws and

lightly rocking the locator to pull it free.

2. Untie the twist tie and pull about three inches

(75 mm) of the room unit cable through the hole in

the base plate.

3. Mount the room unit base plate on the wall, noting

the UP arrow:

NOTE: If required, position the back plate behind

the room unit base, aligning the top and

bottom mounting holes, prior to mounting

to the wall:

a. Install the two room unit mounting screws

provided, but do not tighten.

b. Level the room unit base plate for appearance

only.

c. Ti ghten the two mounting screws to the room

unit base plate.

Siemens Industry, Inc. Page 3 of 4

Over-tightening may cause the room unit

base plate to crack or bend.

4. Continue with Drywall Mounting (No Rough-in),

Typical, Steps 6 through 8, and Sensor Set-up.

Page 4

Document No. 129-477

CAUTION:

CAUTION:

Sensing Only, Not Sel

ectable

Sensing Only, Selectable

Display, Selectable

Installation Instructions

November 15, 2017

To prevent equipment dam age, do the

following:

If the room unit is powered by AC:

• AC Supply must be type NEC Class 2

and earth grounded at the secondary

neutral.

• Room unit ACN (GND) must be

connected to the controller common.

• If the controller has a float ing common,

that common must be connec ted to the

same earth ground poi nt as the

controller A C supply.

If the room unit is powered by isolated DC:

• Where power is current limited up to

300 mA, it is not required to earth

ground the controller isolated common.

• Room unit DC-(GND) must be

connected to the controller common.

Figure 6. Typical Wiring Base.

(All terminals may not be present.)

Pin No. Function

2 GND

3 TEMP

Follow manufacturer’s Installation

Instructions and Wiring Guidelines for

connecting the controller to the room unit.

For Siemens Controll ers:

1 DC+ or ACH

2 DC- or ACN (GND)

3 Temp Output

5* Passive Temp

6* Passive Temp Common

• APOGEE Controllers with common

already earth grounded are TXIO

used on PXC Modular, PXC Compact

36 Expansion and P1 BI M or PTM

used on MBC and RBC. These do not

require the earth ground wire to be

connected to the controller.

• APOGEE Controllers with floating

common are PXC Compact 16/ 24/36,

1 DC+ or ACH

2 DC- or ACN (GND)

3 Temp Output

5* Passive Temp

6* Passive Temp Common

7 Setpoint Out put

8 Override

9 Override Common

MEC, PXM, LON TEC and PPM.

These require the earth ground wire

to be connected to the controller.

NOTE: If active temperature (0 to 5V/0 to 10V/4 to

20 mA) (Pin 3) rather than passive/resistive

temperature is used, Passive Temp Common

(Pin 6) does not need to be termi nated.

The install ation is now complete.

Information in this publication is based on curr ent specifications. The company reserves the rig ht to make changes in specifications and models as

design i mprovements are introduced. APOGEE is a r egistered trademark or Siemens Industry, Inc. Other pr oduct or company names mentioned herein

may be th e t rademarks of their respective owners. © 2015 Siemens Industry, Inc.

Siemens Industry, Inc.

Building Technologies Division

1000 Deerfield Parkway

Buffalo Grove, IL 60089

USA

+ 1 847-215-1000

Your feedback is i mportant to us . If you have

comments about this document, please send them

toSBT_technical.editor.us.sbt@siemens.com

Document No. 129-477

Printed in the USA

Page 4 of 4

Loading...

Loading...