Siemens PXC-16 Compact, PXC Compact Series, PXC-24 Compact, PXC-36 Compact, PXC Modular Series Technical Reference Manual

Page 1

PXC Compact Series

Technical Reference Manual

145-172

Building Technologies

2018

-09-25 Restricted

Page 2

Copyright Notice

2

| 100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

Copyright Notice

Notice

Document information is subject to change without notice by Siemens Industry, Inc.

Companies, names, and various data used in examples are fictitious unless otherwise

noted. No part of this document may be reproduced or transmitted in any form or by

any means, electronic or mechanical, for any purpose, without the express written

permission of Siemens Industry, Inc.

Warning

This equipment generates, uses, and can radiate radio frequency energy. If equipment

is not installed and used in accordance with the instructions manual, it may cause

interference to radio communications. Equipment has been tested and found to comply

within the limits for a Class B digital device pursuant to Part 15 of the FCC rules. These

limits are designed to provide reasonable protection against such interference when

operated in a commercial environment. Operation of this equipment in a residential

area is likely to cause interference. Residential area equipment users are required to

take whatever measures necessary to correct the interference at their own expense.

Service Statement

Control devices are combined to make a system. Each control device is mechanical in

nature and all mechanical components must be regularly serviced to optimize their

operation. Siemens Industry, Inc. branch offices and authorized distributors offer

Technical Support Programs that will ensure continuous, trouble-free system

performance.

For further information, contact your nearest Siemens Industry representative.

Copyright 2018 Siemens Industry, Inc.

FCC Regulations

The manual for an intentional or unintentional radiator shall caution the user that

changes or modifications not expressly approved by the party responsible could void

the user’s authority to operate the equipment.

For a Class B digital device or peripheral, the instructions furnished the user shall

include the following or similar statement, placed in a prominent location in the text of

the manual:

NOTE: This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur

in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

●

Reorient or relocate the receiving antenna.

●

Increase the separation between the equipment and receiver.

●

Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

●

Consult the dealer or an experienced radio/TV technician for help.

Page 3

Copyright Notice

3 |

100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

To the Reader

Your feedback is important to us. If you have comments about this manual, please

submit them to: SBT_technical.editor.us.sbt@siemens.com

Credits

APOGEE, APOGEE GO, InfoCenter Administrator, InfoCenter Report Manager,

InfoCenter Server, InfoCenter Suite, and Insight are registered trademarks of Siemens

Industry, Inc.

Desigo® and Desigo® CC™ are registered trademarks of Siemens Schweiz AG.

Other product or company names mentioned herein may be the trademarks of their

respective owners.

Printed in the USA.

Cyber security disclaimer

Siemens provides a portfolio of products, solutions, systems and services that includes

security functions that support the secure operation of plants, systems, machines and

networks. In the field of Building Technologies, this includes building automation and

control, fire safety, security management as well as physical security systems.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art

security concept. Siemens’ portfolio only forms one element of such a concept.

You are responsible for preventing unauthorized access to your plants, systems,

machines and networks which should only be connected to an enterprise network or

the internet if and to the extent such a connection is necessary and only when

appropriate security measures (e.g. firewalls and/or network segmentation) are in

place. Additionally, Siemens’ guidance on appropriate security measures should be

taken into account. For additional information, please contact your Siemens sales

representative or visit

https://www.siemens.com/global/en/home/company/topic-

areas/future-of-manufacturing/industrial-security.html.

Siemens’ portfolio undergoes continuous development to make it more secure.

Siemens strongly recommends that updates are applied as soon as they are available

and that the latest versions are used. Use of versions that are no longer supported,

and failure to apply the latest updates may increase your exposure to cyber threats.

Siemens strongly recommends to comply with security advisories on the latest security

threats, patches and other related measures, published, among others, under

https://www.siemens.com/cert/en/cert-security-advisories.htm

.

Page 4

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

4

| 100

Table of Contents

Cyber security disclaimer ................................................................................................ 3

Compact Series Product Overview ............................................................................. 7

Compatibility with the APOGEE Automation System ...................................................... 7

BACnet Protocol Compatibility .............................................................................. 8

TCP/IP Protocol Compatibility ............................................................................... 8

Required IP Addresses .......................................................................... 8

Device Registration ................................................................................ 8

Address Assignment .............................................................................. 8

System Program .............................................................................................................. 9

Minimum Firmware Revision Required ............................................................... 10

License Manager ................................................................................................. 10

Purpose of Licenses ............................................................................ 11

Supported Point Types .................................................................................................. 12

PXC Compact Series, Rev 1 Hardware, Point Types ......................................... 14

16- and 24-Point Compact Series Diagram ................................................................... 15

36-Point Compact Series Product Diagram .................................................................. 17

Hardware Features ................................................................................................... 19

24 Vdc External Sensor Power Source ......................................................................... 20

Shield Termination .............................................................................................. 20

Custom Sensor Support ...................................................................................... 21

Memory .......................................................................................................................... 21

Flash Read-Only Memory (Flash ROM) .............................................................. 22

Compressed ROM ............................................................................... 22

Auto-Restore and Database Backup to Flash ..................................... 22

Auto Save ............................................................................................ 23

File System Operations........................................................................ 23

Random Access Memory (RAM) ......................................................................... 23

Compact Series Backup Batteries ................................................................................. 23

AA Battery ........................................................................................................... 24

AA Battery ........................................................................................................... 25

Coin Cell Battery ................................................................................................. 26

Coin Cell Battery ................................................................................................. 27

Memory Size and Typical Battery Backup Time ................................................. 28

Compact Series Specifications ...................................................................................... 28

Sensor Limits ....................................................................................................... 33

Communication Connections ......................................................................................... 33

HMI and Tool Ports ............................................................................................. 34

Pin-Out Diagrams for HMI Connectors ................................................ 35

10B/100B Ethernet Port ...................................................................................... 36

Page 5

5 |

100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

RS-485 Port ......................................................................................................... 36

FLN Support ......................................................................................... 37

PXC Compact on P1 ............................................................................ 38

PXC Compact on P1 ............................................................................ 38

Virtual AEM .......................................................................................... 38

Virtual AEM .......................................................................................... 38

USB Host Port ..................................................................................................... 39

TX-I/O Island Bus ................................................................................................ 39

HOA (Hand-Off-Auto) Upgrade Kits .............................................................................. 39

HOA Specifications ............................................................................................. 40

Hardware Features.............................................................................................. 40

Default Mapping .................................................................................................. 40

Communication ................................................................................................... 41

Using the HOA Switches ..................................................................................... 42

PXC Compact on P1 ..................................................................................................... 44

What is a PXC Compact on P1? ......................................................................... 44

P1 Mode Application ........................................................................................... 45

P1 Mode Operation ............................................................................................. 46

P1 Mode Enhanced Field Panel Point Team ...................................................... 47

Tips for P1 Mode ................................................................................................. 48

Backing up and Restoring the PXC Compact Database ..................... 48

Loading Applications with WCIS .......................................................... 48

Merging Multiple Applications into One .ISB File ................................. 48

Using the P1 COMM Panel Team Point .............................................. 48

Miscellaneous ...................................................................................... 49

Referencing Points on the PXC Compact on P1 ................................. 49

Procedures for Advanced Features .................................................................... 49

Adding Unused I/O for PXC Compact on P1 (Optional) ...................... 49

Changing the Point Team Descriptor After Database Conversion ...... 50

Defining an L2SL from a PXC Compact on P1 into the Host Field

Panel 50

Identifying the Hardware Model Used in an Application Design .......... 51

Making Changes to the Original PXC Compact on P1 Database ....... 52

Program to Allow LPACI Points to Count Over the LAO Maximum

Value 53

Real Time Applications in a PXC Compact on P1 ............................... 54

Synchronizing System Time in a PXC Compact on P1 ....................... 58

Default Applications ............................................................................................ 59

Point Database for Application 3916 ................................................................... 60

Point Database for Application 3924 ................................................................... 61

PXM10S/T Product Overview and Description ............................................................. 62

Product Features ................................................................................................. 63

Communication Connections ............................................................... 63

Requirements ...................................................................................................... 63

Page 6

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

6

| 100

Application Menus ............................................................................................... 64

Operator Display Specifications .......................................................................... 64

Operator Display Layout...................................................................................... 65

Operator Display Menu Tree ............................................................................... 68

Login and Logoff .................................................................................................. 68

Logging In ............................................................................................ 69

Logging Off .......................................................................................... 73

Navigation Menu ................................................................................................. 74

Alarms Application Menu..................................................................................... 75

Points (Command and Release) Application Menu ............................................ 77

Point Monitor Application Menu .......................................................................... 78

Login Application Menu ....................................................................................... 79

Settings Application Menu ................................................................................... 80

Unitary Equipment Controller ........................................................................................ 81

Unitary Equipment Controller Specifications ....................................................... 83

Compact Series Smoke Control Application Requirements ....................................... 86

Example ALN Configuration for Smoke Control Applications ....................................... 87

Service Information .................................................................................................. 88

Electrostatic Discharge .................................................................................................. 88

Ordering Replacement Parts ......................................................................................... 88

Replacing the Batteries ................................................................................................. 88

Reinstalling the Mounting Tabs ..................................................................................... 89

Troubleshooting Compact Field Panels ........................................................................ 90

Analog Input and Analog Output Points .............................................................. 90

BATT LOW LED .................................................................................................. 91

RUN LED ............................................................................................................. 92

TX and RX LEDs ................................................................................................. 92

Communication ................................................................................................... 93

Display ............................................................................................................. 93

Errors ............................................................................................................. 94

Troubleshooting the TX-I/O Island Bus ......................................................................... 94

Troubleshooting the LCD Panel Indications ........................................................ 95

Resetting an I/O Module to Factory Settings ...................................................... 97

Replacing a TX-I/O Plug-in Module ..................................................................... 98

Replacing a TX-I/O Module Assembly ................................................................ 98

Page 7

Compact Series Product Overview

Compatibility with the APOGEE Automation System

7 |

100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

Compact Series Product Overview

The PXC Compact Series operates on the Automation Level Network (ALN) or the

Field Level Network (FLN).

● When connected to the ALN, the PXC Compact uses a logical point firmware

database to communicate directly with PXC Modulars, MBCs, RBCs, MECs, SCUs,

and other nodes on the network.

● When connected to the MS/TP FLN, the PXC Compact operates as a third-party

BACnet device.

● When the PXC-16 or PXC-24 is connected to the P1 FLN, it operates as a P1

device.

– No license is required when using the PXC Compact as an FLN device.

– PXC Compact on P1 displays as a TEC with application range 3000-3899.

● The PXC Compact is available with 16, 24, or 36 point terminations.

– Selected PXC-24 and PXC-16 models provide an extended temperature range

for the control of rooftop devices.

– Optional hot-swappable HOA (Hand/Off/Auto) Modules for the PXC Compact

Series enable output points to be manually placed into HAND, ON/OFF, or

AUTO control.

Support for FLN Devices

● Selected models in the PXC Compact Series can support P1 or MS/TP FLN

devices. Those which support FLN devices may require an additional license.

Selected models can be purchased with the license already installed.

NOTE:

No license is required when the PXC Compact is being polled as an FLN device on

the P1 or MS/TP FLN.

TX-I/O Island Bus Support

● The PXC-36 supports the TX-I/O Island Bus, which uses TX-I/O modules to

expand the number of point terminations.

– Selected PXC-36 models require a license to support the TX-I/O Island Bus.

– For more information on connecting the PXC-36 to the Island Bus, see the TX-

I/O Island Bus Technical Reference Manual (140-0914).

Compatibility with the APOGEE Automation System

The PXC Compact Series in P2 Mode is fully compatible with and will communicate

with all the APOGEE or pre-APOGEE products in your facility. However, PXC Compact

Series in P1 Mode is not designed for use on the FLN of a pre-APOGEE field panel.

CAUTION

When working on a network with multiple firmware revisions, always connect to the

operator interface at the field panel with the newest firmware revision. Otherwise, you

cannot view features in newer firmware revisions, or the field panel may coldstart.

Page 8

Compact Series Product Overview

Compatibility with the APOGEE Automation System

8

| 100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

BACnet Protocol Compatibility

APOGEE BACnet is compatible with the BACnet/IP protocol.

CAUTION

When sharing data values from APOGEE P2 (proprietary) field panels to BACnet

devices, the Cross-Trunk Service does not support requests originating from BACnet

devices to access points (objects) that reside in APOGEE P2 field panels.

If you plan to share data values from APOGEE P2 field panels with BACnet devices

(field panels), you must do one of the following:

● Install and enable the Insight BACnet Server Option.

● Use PPCL in the APOGEE P2 field panels to command values in the BACnet

devices through the Insight Cross-Trunk service.

APOGEE P2 and BACnet Product Features Order of Implementation

The APOGEE field panel firmware supports the BACnet protocol as follows:

● If both the BACnet and APOGEE protocols have a function, the BACnet function is

implemented.

● If APOGEE provides a function that the BACnet protocol does not support, the

APOGEE function is retained.

This approach to BACnet implementation retains the APOGEE feature set while

providing compatibility with standard BACnet/IP protocol.

TCP/IP Protocol Compatibility

PXC Compact Series controllers with BACnet/IP or Ethernet TCP/IP (P2) ALN provide

the following:

● 100% compatibility with the TCP/IP protocol suite.

● Support of Dynamic Host Configuration Protocol (DHCP) and Domain Name

Servers (DNS).

● Support and auto detection of 10Base-T and 100Base-TX Ethernet.

Required IP Addresses

APOGEE BACnet/IP or Ethernet TCP/IP (P2) ALN uses:

● One IP address per device (field panel or workstation).

● One additional shared IP address per ALN for the multicast group (when using

multicast optimization).

Device Registration

Devices register with the DHCP server and Domain Name Server, if either is present.

Address Assignment

IP addresses are dynamically assigned by the DHCP server.

Page 9

Compact Series Product Overview

System Program

9 |

100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

If an address changes or is not recognized, the field panel firmware lets you release

the dynamically assigned IP address and then reconnect the field panel to the DHCP

server, accepting a new IP address assignment in the process.

If there is no DHCP server at the site, you must manually assign static IP addresses as

part of the startup system configuration.

Physical Addressing

Each device on the BACnet/IP or Ethernet TCP/IP (P2) ALN has a hard-wired MAC

address, which is printed on the product label.

Port Numbers

The default TCP/IP port number for APOGEE BACnet/IP or Ethernet TCP/IP (P2) ALN

communications is

5033. You can change the TCP/IP port number if necessary.

NOTE:

All devices on the network must use the same TCP/IP port number.

The default TCP/IP port number for Virtual AEM communications is 3001.

You must specify a UDP port number when using multicast optimization. The default

UDP port number is

8.

Network Bandwidth

BACnet/IP or Ethernet TCP/IP (P2) ALN does not add significantly to your network

overhead. Burst conditions for this product occur during:

● Database downloading after coldstart.

● Database uploading.

● Trend data uploading.

● Burst of alarms or COVs.

Data Exchange

BACnet/IP or Ethernet TCP/IP (P2) ALN sends and receives APOGEE data in TCP/IP

packets.

BACnet/IP or Ethernet TCP/IP (P2) ALN synchronizes global data between all devices.

Each device runs a global data replication engine that communicates with peer devices

to:

● Exchange new and changed global data.

● Resolve conflicts when data does not match.

Device Naming Conventions

Field panel DNS node names are limited to 30 characters and cannot contain spaces.

Network Security

BACnet/IP or Ethernet TCP/IP (P2) ALN uses your intranet security within the firewall

and a username/password combination to restrict access outside the firewall. You can

use VLAN to improve internal security.

System Program

The PXC Compact contains a non-volatile system program called

firmware

, which can

be upgraded in the field. The firmware is stored in Flash ROM memory, which keeps it

Page 10

Compact Series Product Overview

System Program

10

| 100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

virtually immune to all forms of power fluctuations or failure, including battery failure.

For more information on Flash ROM memory, see Memory [➙ 21].

General functionality of the firmware includes:

● Executing control programs.

● Communicating between other field panels and the workstation.

● Monitoring points.

● Managing point-related information.

● Keeping track of real time (both clock and calendar time).

● Executing self-test and error detection in the PXC Compact.

Minimum Firmware Revision Required

The APOGEE Field Panels Configuration and Sizing Guidelines (145-214) outlines the

minimum firmware revision required for support of a specific feature with the PXC

Compact Series.

License Manager

The licenses used to activate features are associated with a specific field panel

through the ID_STRING. The ID_STRING uniquely identifies a piece of hardware; it is

burned into the field panel’s EEPROM and read by software and firmware.

The ID_STRING is composed of the panel's part number, revision, year and week of

manufacture, and serial number. Therefore, a license for one field panel will not work

on another field panel. Information for the ID_STRING can be found:

● Printed on a label adhered to the outside of the field panel,

● Printed on a label adhered to the outside of the field panel shipping box, or

● Burned into the field panel’s non-volatile memory and read through Commissioning

Tool (CT), Insight software, or the field panel HMI.

For PXC-36 field panels that include FLN support, a default license named

FLNNode36_254 displays in the field panel configuration.

CAUTION

Licensed FLN support only works if the correct license is loaded on the field panel.

An FLN license for PXC-16 and PXC-24 field panels supports 32 FLN devices.

For field panels that include island bus support, a default license named TXIOExp_8

displays in the field panel configuration.

NOTICE

PXC Compact Series models with Island Bus support allow four TX-I/O modules.

See the APOGEE Field Panels Configuration and Sizing Guidelines (145-214) for more

information on applications and functionality that can be activated through License

Manager.

See the License to enable SNMP Agent on Siemens Modular or Compact hardware

with BACnet Firmware Revision 3.2.3

(LSM-SNMP) for information on adding licensed

applications or functionality.

Page 11

Compact Series Product Overview

System Program

11 |

100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

Purpose of Licenses

The use of licenses and features allows added flexibility for customers. Because many

features add functionality to a field panel’s firmware, a single part number can be

ordered and installed. Additional functionality can be added at a later date without the

need to replace the hardware or perform a firmware flash.

Example

A PXC-16 or PXC-24 field panel with an FLN Expansion Module is installed on the

ALN to serve as a director for FLN devices; it only passes information about FLN

devices to other ALN devices. The customer orders product number PXC36-E.A, which

does not provide FLN support or TX-I/O island bus support.

Two years later, the customer decides to add physical points. By adding the TX-I/O

island bus license, the PXC-16 or PXC-24 is converted to product number PXC16.2EF.A or PXC24.2-EF.A which provides FLN and TX-I/O island bus support. Without

replacing the PXC-16 or PXC-24 hardware or firmware, the customer can now install

TX-I/O modules and expand the number of physical points.

Page 12

Compact Series Product Overview

Supported Point Types

12

| 100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

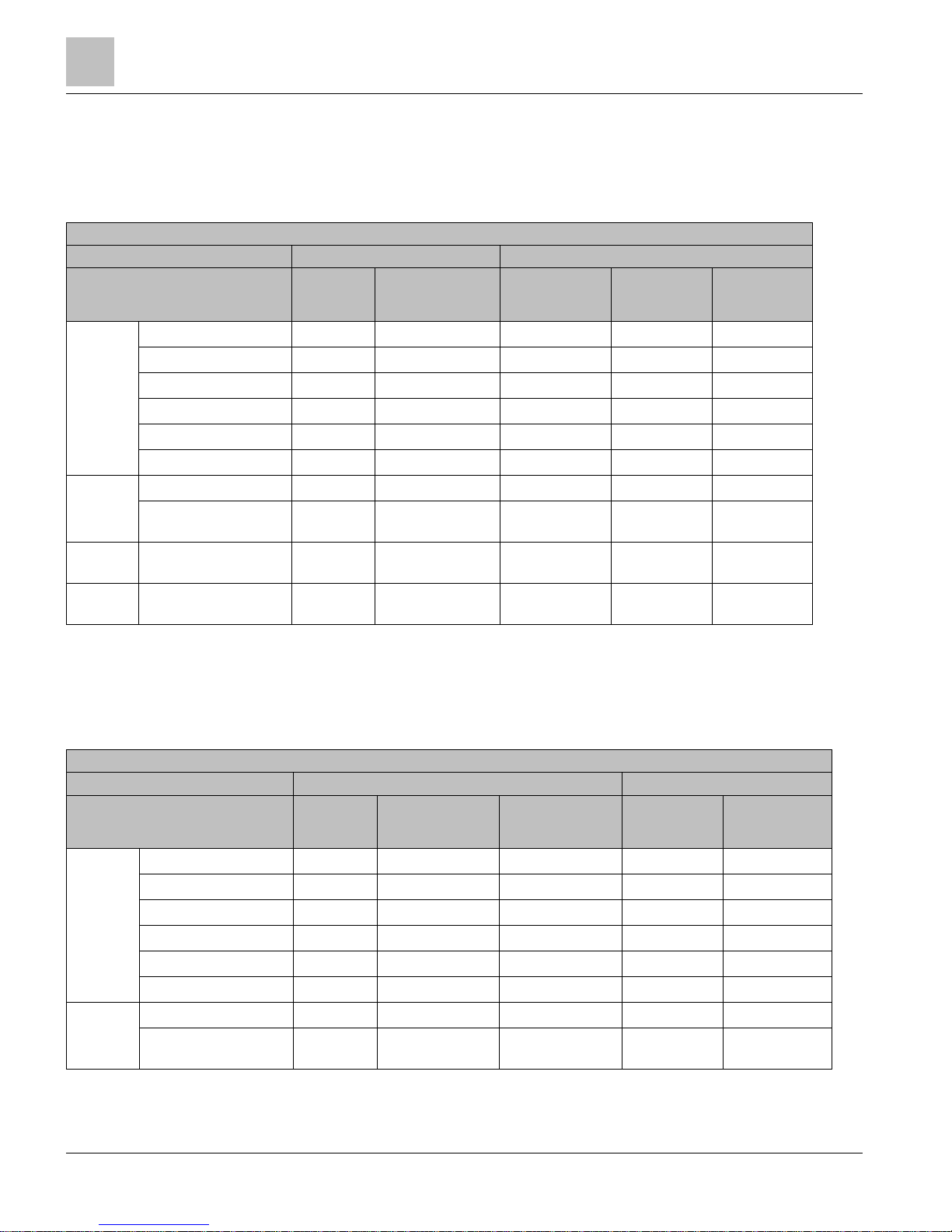

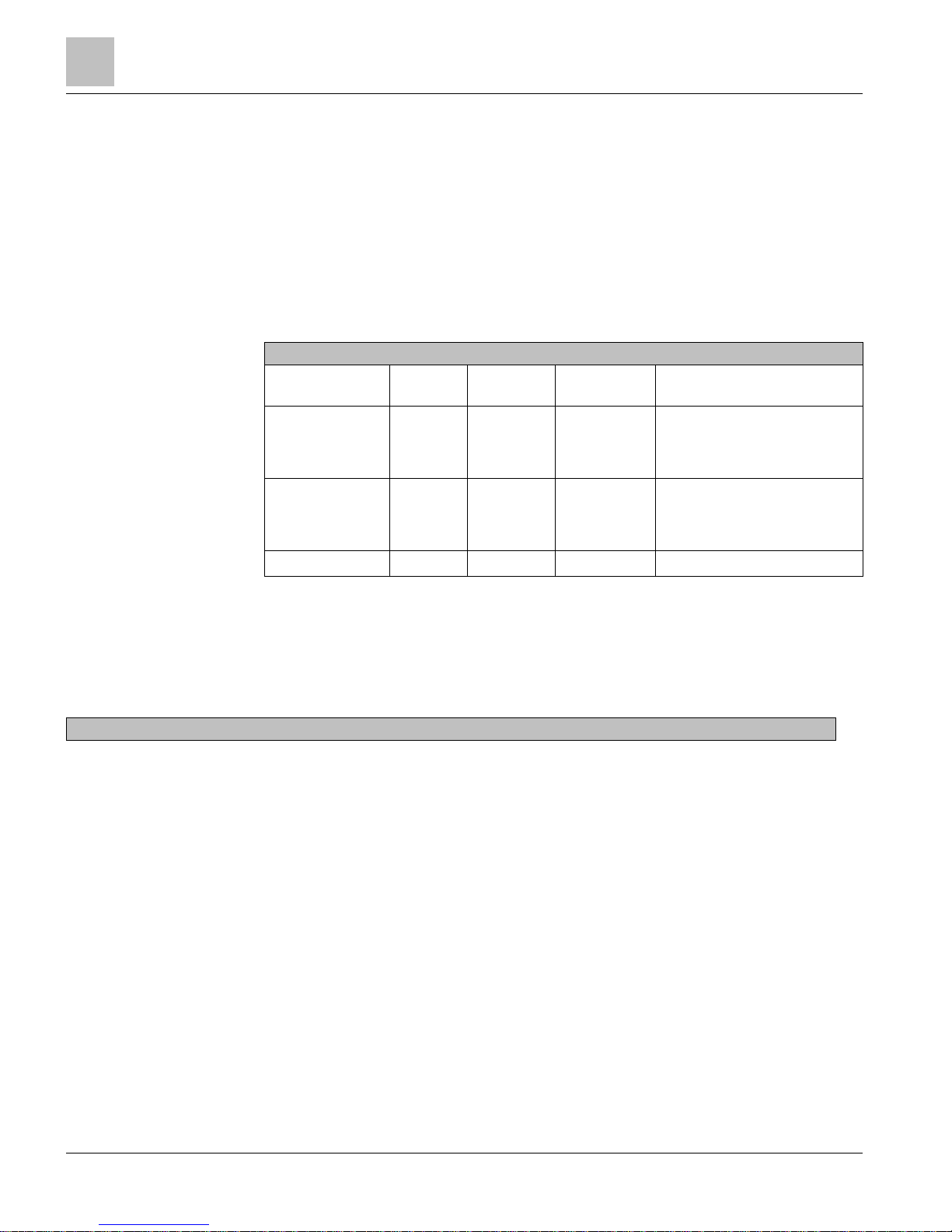

Supported Point Types

The PXC Compact Series provides software-configurable and dedicated points. The

point types and their possible configurations are shown in the following tables.

PXC-16 Supported Point Types.

Configurable Points

Dedicated Points

Point Type

Universal

Input (UI)

Points 1-3

Universal

Input/Output (U)

Points 4-8

Analog Output

(AO)

Points 9-11

Digital Input (DI)

Points 12-13

Digital Output

(DO)

Points 14-16

Analog

Input

4

Voltage 0 to 10 Vdc

• •

Current 4 to 20 mA

• •

RTD Pt 1K1

• •

RTD Ni 1K2

• •

Thermistor 10K NTC3

• •

Thermistor 100K NTC3

• •

Digital

Input

Status (Binary Input)

• • •

Pulse Accumulator

(Counter)

• •

Analog

Output

Voltage 0 to 10 Vdc

• •

Digital

Output

Binary/Digital Output

•

1)

Platinum 1K 375 or 385 alpha.

2)

Siemens, Johnson Controls, and DIN Standard Nickel.

3)

10K and 100K Type 2 and 10K Type 3.

4)

Sensor supply 24 Vdc, 4.8W

PXC-24 Supported Point Types.

Configurable Points

Dedicated Points

Point Type

Universal

Input (UI)

Points 1-3

Universal

Input/Output (U)

Points 4-12

Super Universal (X)

Points 13-16

Analog Output

(AO)

Points 17-19

Digital Output

(DO)

Points 20-24

Analog

Input

5

Voltage 0 to 10 Vdc

• • •

Current 4 to 20 mA

• • •

RTD Pt 1K1

• • •

RTD Ni 1K2

• • •

Thermistor 10K NTC3

• • •

Thermistor 100K NTC3

• • •

Digital

Input

Status (Binary Input)

• • •

Pulse Accumulator

(Counter)

• • •

Page 13

Compact Series Product Overview

Supported Point Types

13 |

100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

PXC-24 Supported Point Types.

Configurable Points

Dedicated Points

Point Type

Universal

Input (UI)

Points 1-3

Universal

Input/Output (U)

Points 4-12

Super Universal (X)

Points 13-16

Analog Output

(AO)

Points 17-19

Digital Output

(DO)

Points 20-24

Analog

Output

Voltage 0 to 10 Vdc

• • •

Current 0 to 20 mA

•

Digital

Output

Binary/Digital Output

•

4

•

1)

Platinum 1K 375 or 385 alpha.

2)

Siemens, Johnson Controls, and DIN Standard Nickel.

3)

10K and 100K Type 2 and 10K Type 3.

4)

Requires an external relay.

5)

Sensor supply 24 Vdc, 4.8W

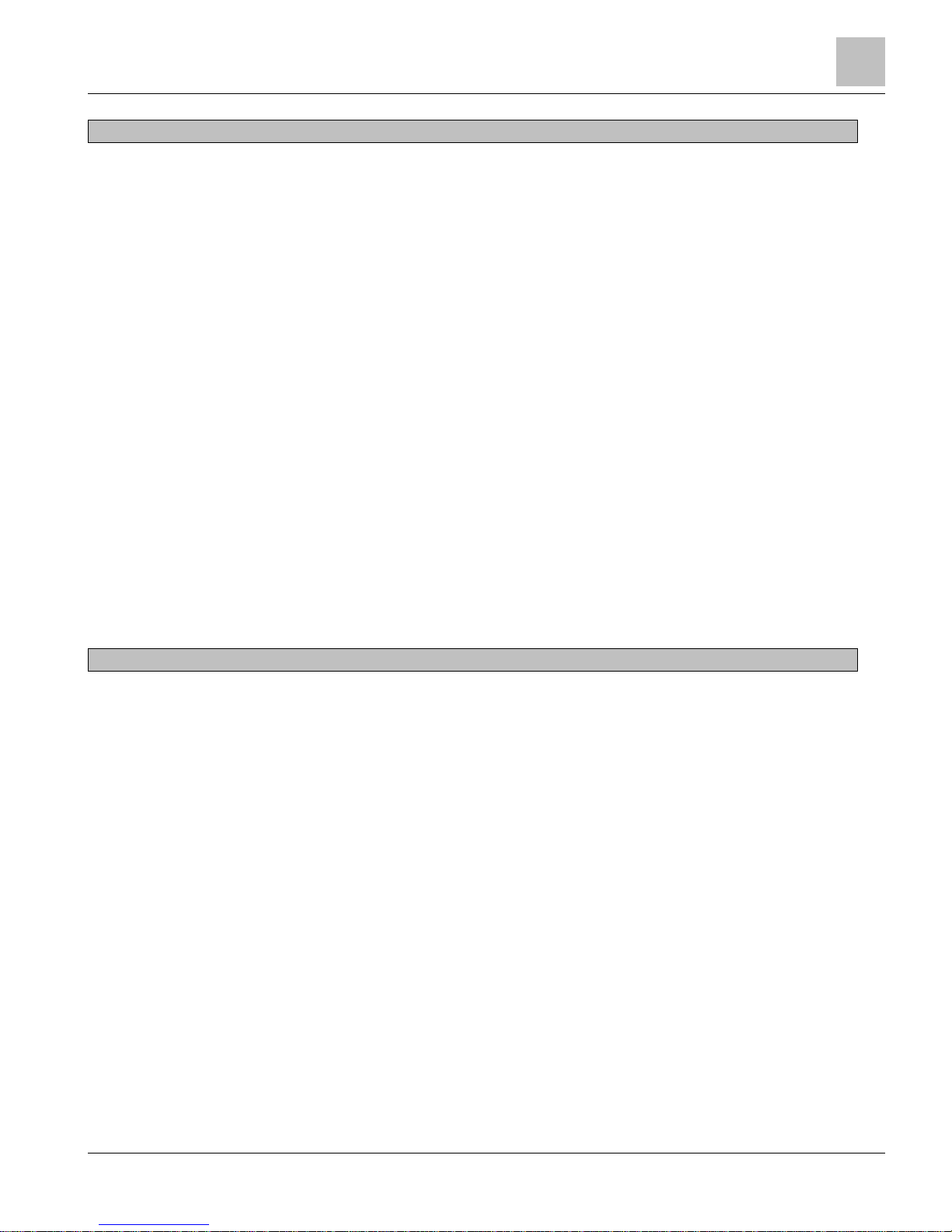

PXC-36 Supported Point Types.

Configurable Points

Dedicated Points

Point Type

Super Universal

(X)

Points 1-6

Universal

Input/Output (U)

Points 7-24

Digital Input (DI)

Points 25-28

Digital Output (DO)

Points 29-36

Analog Input5 Voltage 0 to 10 Vdc

• •

Current 4 to 20 mA

• •

RTD Pt 1K1

• •

RTD Ni 1K2

• •

Thermistor 10K NTC3

• •

Thermistor 100K NTC3

• •

Digital Input Status (Binary Input)

• • •

Pulse Accumulator (Counter)

• •

Analog

Output

Voltage 0 to 10 Vdc

• •

Current 0 to 20 mA

•

Digital

Output

Binary/Digital Output

•

4

•

1)

Platinum 1K 375 or 385 alpha.

2)

Siemens, Johnson Controls, and DIN Standard Nickel.

3)

10K and 100K Type 2 and 10K Type 3.

4)

Requires an external relay.

5)

Sensor supply 24 Vdc, 4.8W

Page 14

Compact Series Product Overview

Supported Point Types

14

| 100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

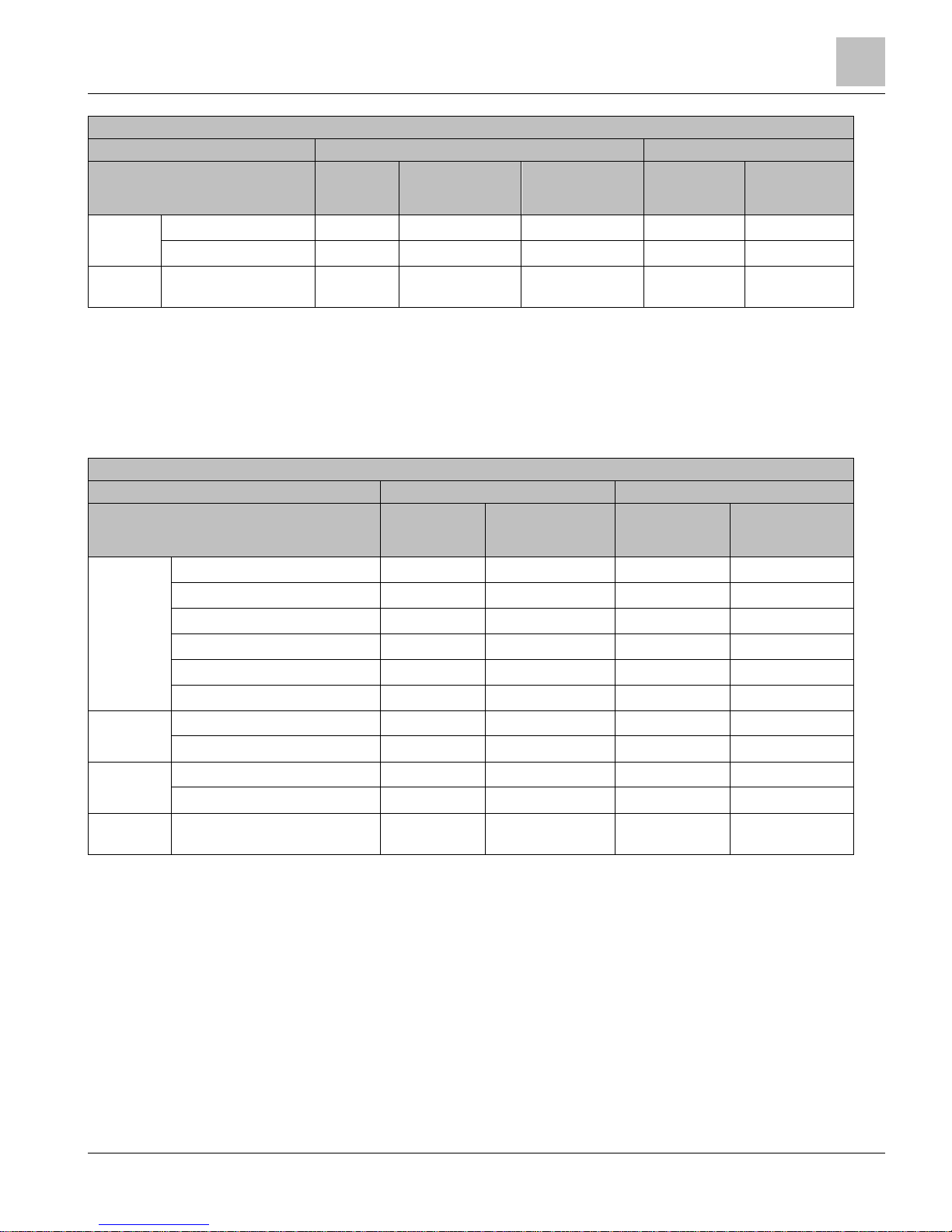

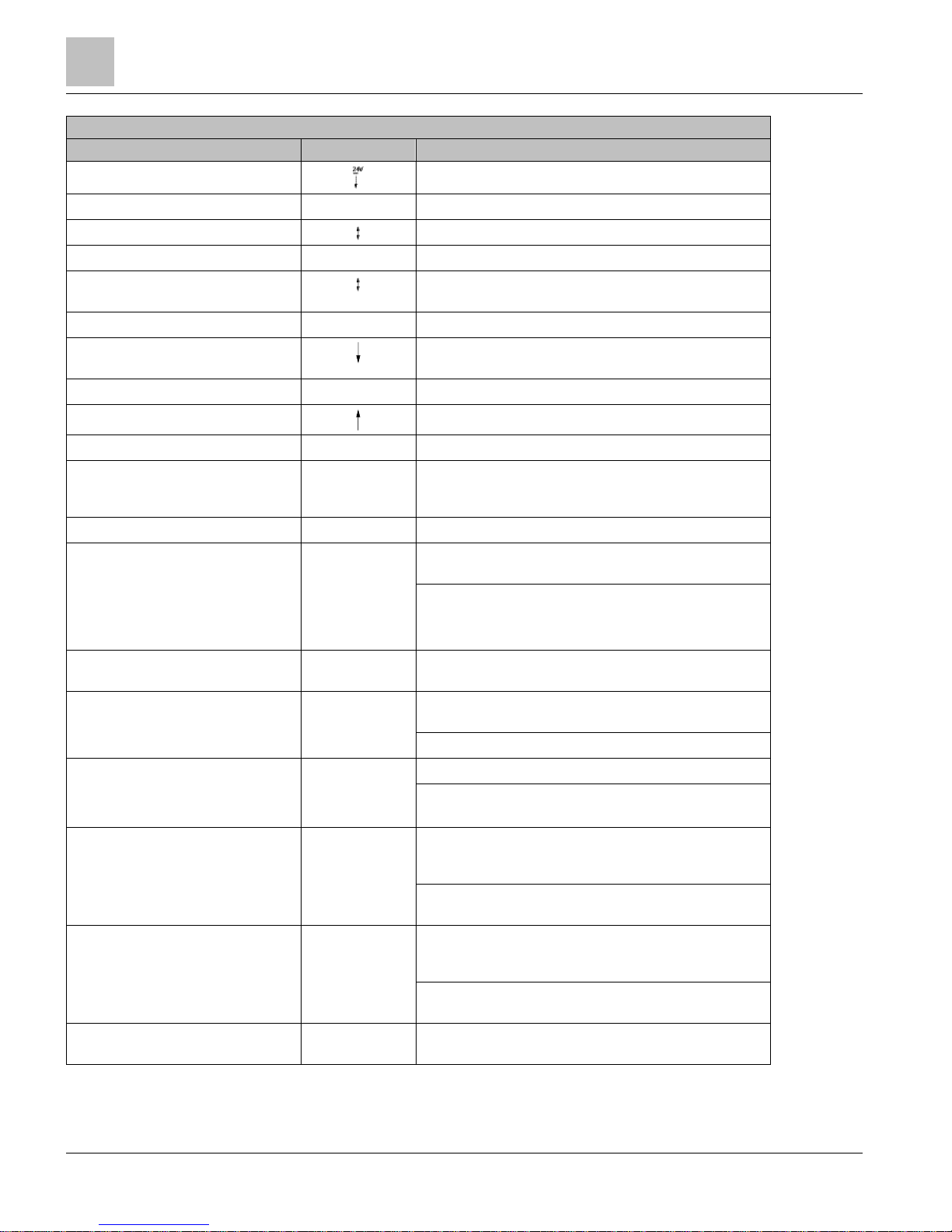

PXC Compact Series, Rev 1 Hardware, Point Types

NOTE:

The following tables are for Revision 1 PXC Compact Series hardware.

16-Point PXC Compact Controller Connector Range and Supported Point Types—Revision 1 Hardware.

Physical

Point

Address

Point Type

Analog Inputs

Digital Inputs

Analog

Outputs

Digital

Inputs

Voltage

Current

RTD

NTC

Thermistor

Status

(Binary

Supply)

Pulse

Accumulator

(Counter)

Voltage

Binary/

Digital

Output

0 to 10

Vdc

4 to 20

mA

PT 1K

(375)

PT 1K

(385)

Ni

1Ka

10Kb

100Kb

0 to 10

Vdc

UI 1 - 3

Universal Input

(configurable)

● ● ● ● ● ● ● ● ●

U 4 – 8

Universal

Input/Output

(configurable)

● ● ● ● ● ● ● ● ● ●

AO 1 – 3

Voltage Analog

Output (AOV),

dedicated

●

DI 1 – 2

Digital Input,

dedicated

●

DO 1 – 3

Digital Output,

dedicated

●

a) Landis & GYR Nickel 1000.

b) Type 2.

24-Point PXC Compact Controller Connector Range and Supported Point Types—Revision 1 Hardware.

Physical

Point

Address

Point Type

Analog Inputs

Digital Inputs

Analog

Outputs

Digital

Inputs

Voltage

Current

RTD

NTC

Thermistor

Status

(Binary

Supply)

Pulse

Accumulator

(Counter)

Voltage

Binary/

Digital

Output

0 to 10

Vdc

4 to 20

mA

PT 1K

(375)

PT 1K

(385)

Ni

1Ka

10Kb

100Kb

0 to 10

Vdc

UI 1 - 3

Universal Input

(configurable)

● ● ● ● ● ● ● ● ●

U 4 – 16

Universal

Input/Output

(configurable)

● ● ● ● ● ● ● ● ● ●

AO 1 – 3

Voltage Analog

Output (AOV),

dedicated

●

DO 1 – 5

Digital Output,

dedicated

●

a) Landis & GYR Nickel 1000.

b) Type 2.

Page 15

Compact Series Product Overview

16- and 24-Point Compact Series Diagram

15 |

100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

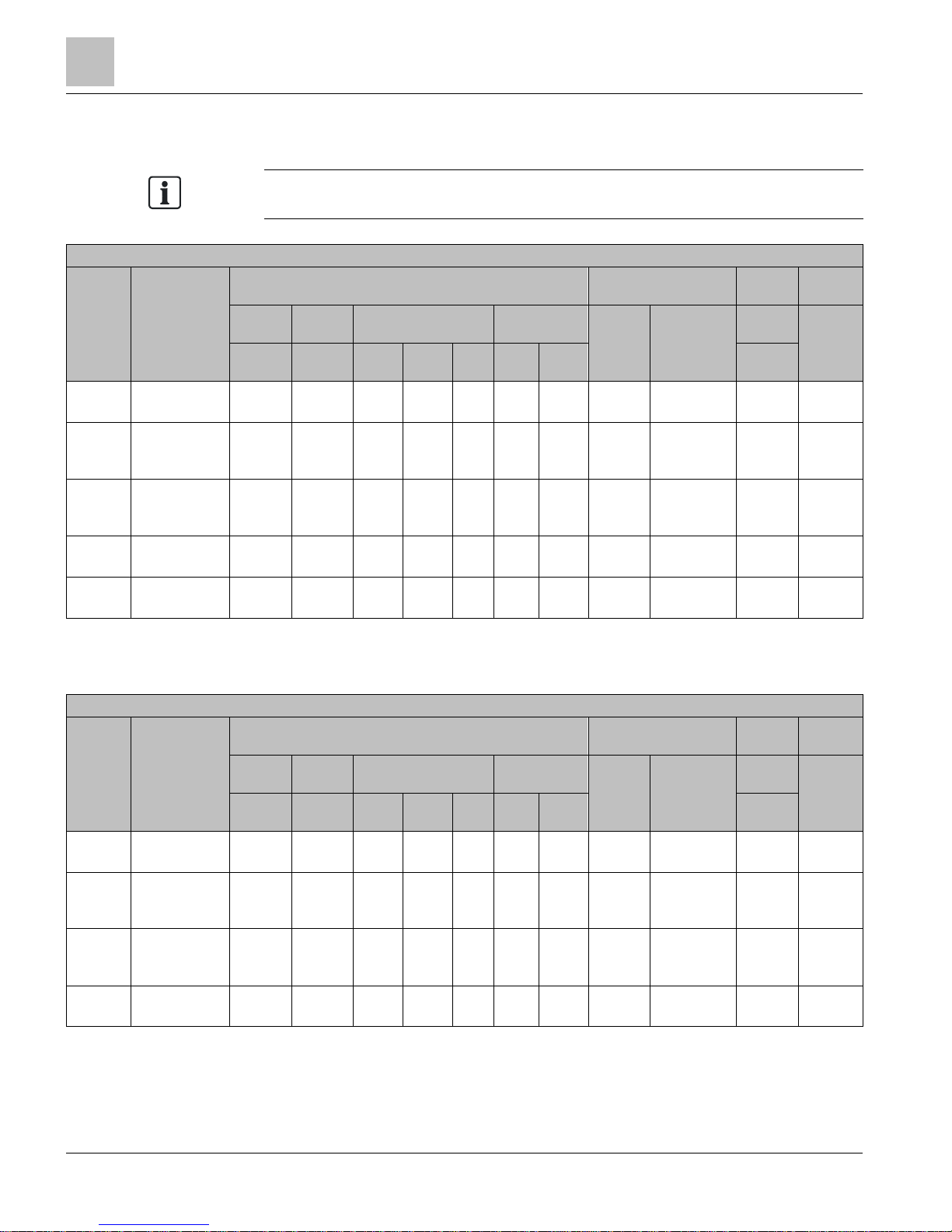

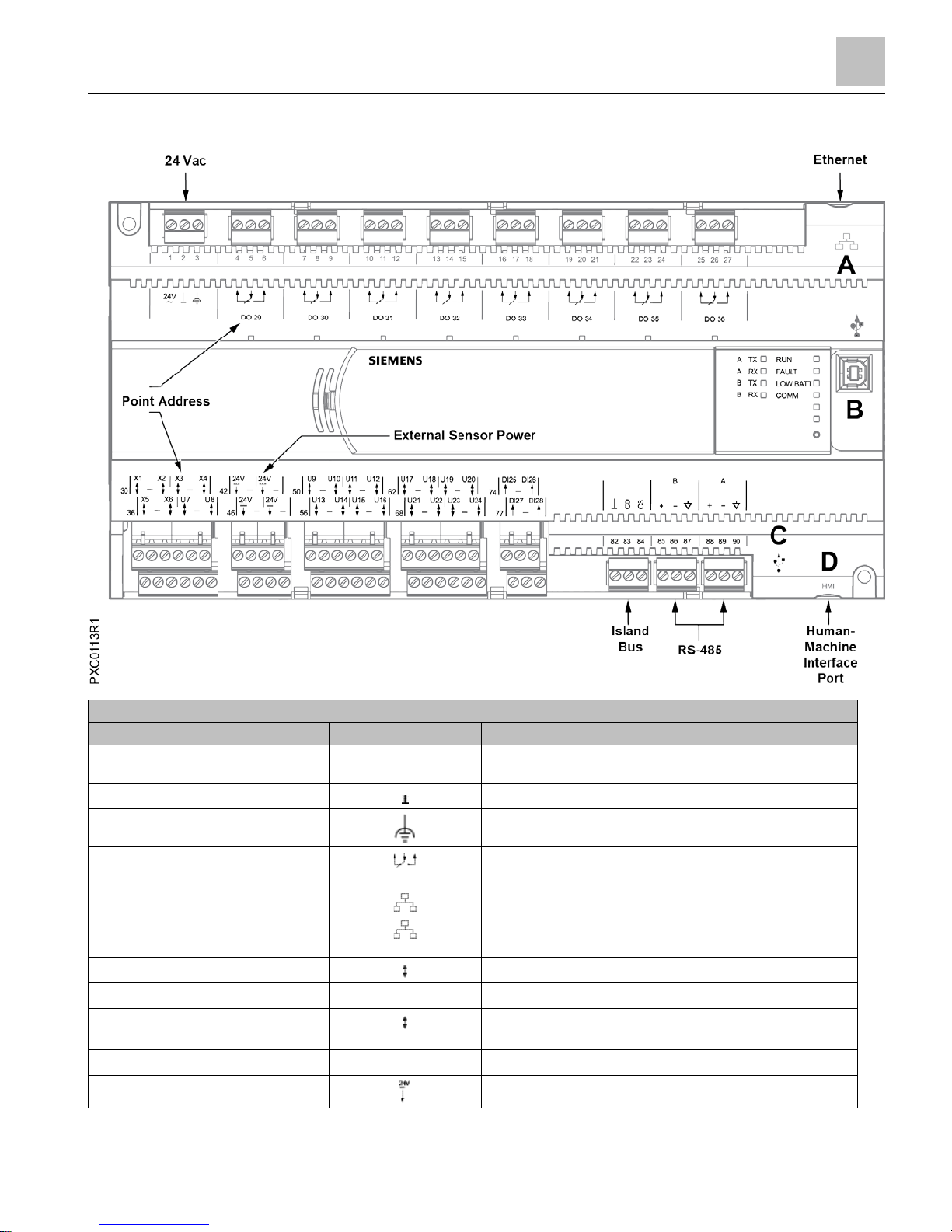

16- and 24-Point Compact Series Diagram

NOTE:

The USB device port is now functional. It requires a computer device driver and

standard computer terminal software, available on Standard Apps).

PXC-16 and PXC-24 Features, Symbols, and Status LEDs.

Terminal Block Connection

Label

Indicates

1

24V

~

Supply voltage, 24 Vac input.

2

System neutral.

3

Functional earth.

4 through 12 (PXC-16)

4 through 18 (PXC-24)

Digital Output relay, Normally Closed (NC), Common (C),

Normally Open (NO).

A (22 through 24)

+ –

RS-485 port.

B

10B/100B Ethernet port.

C

USB Device port. Supports a generic serial interface for an

HMI or Tool connection. Does not support firmware flash

upgrades.

25, 27, 28

Universal Input (+) (UI1 through UI3).

26, 29

–

Signal Common.

30, 31, 33, 34, 36

Universal Input/Output (+) (U4 through U8).

Page 16

Compact Series Product Overview

16- and 24-Point Compact Series Diagram

16

| 100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

PXC-16 and PXC-24 Features, Symbols, and Status LEDs.

Terminal Block Connection

Label

Indicates

37, 39

24 Vdc external sensor power (+) source.

38, 40

–

Signal Common.

41, 43, 44, 46

Universal Input/Output (+) PXC-24 only (U9 through U12).

42, 45

–

Signal Common (PXC-24 only).

47, 49, 50, 52

Super Universal Input/Output (+) PXC-24 only (X13 through

X16).

48, 51

–

Signal Common.

53, 55, 57

Analog Output (+) (PXC-16: AO9 through AO11; PXC-24:

AO17 through AO19).

54, 56

-

Signal Common.

58, 60

Digital Input (+) PXC-16 only (DI12 through DI13).

59

–

Signal Common (PXC-16 only).

D

HMI

Human-Machine Interface port

(RS-232 8-N-1 signal, RJ-45 8 pin connector, service only, will

not dial out.)

Status LEDs

RUN LED

RUN

(green)

ON - Normal steady Green, unit is powered and running. May

briefly flash while processor is booting.

OFF - Error.

● 24 Vac input is not present.

● Power is ON, but the application firmware has not booted.

FAULT LED

FAULT

(red)

(for future use)

Normal Off, not currently implemented. May be Red if

processor does not complete boot.

LOW BATT LED

LOW BATT

(red)

ON -

Error. RAM Battery (AA) is dead, low, missing or shipping

tab is not removed.

OFF - Normal operation.

Ethernet COMM LED

COMM

(yellow)

(BACnet/IP or

Ethernet TCP/IP

(P2) only)

ON - Linked to Ethernet hub.

OFF - No link to Ethernet hub.

RS-485 TX

RS-485 TX

(yellow) (RS-485

only)

Flashing - Transmitting information over the RS-485, RS-485

P2 or BACnet MS/TP ALN or P1 or MS/TP FLN (depending on

how the port is defined).

OFF or ON solid - No device, no connection, or bad

connection.

RS-485 RX

RS-485 RX

(yellow) (RS-485

only)

Flashing - Receiving information over the RS-485, RS-485 P2

or BACnet MS/TP ALN or P1 or MS/TP FLN (depending on

how the port is defined).

OFF or ON solid - No device, no connection, or bad

connection.

PXC-16: DO 14 through DO 16; PXC-24:

DO 20 through DO 24

DO

XX

ON - Relay Energized.

Page 17

Compact Series Product Overview

36-Point Compact Series Product Diagram

17 |

100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

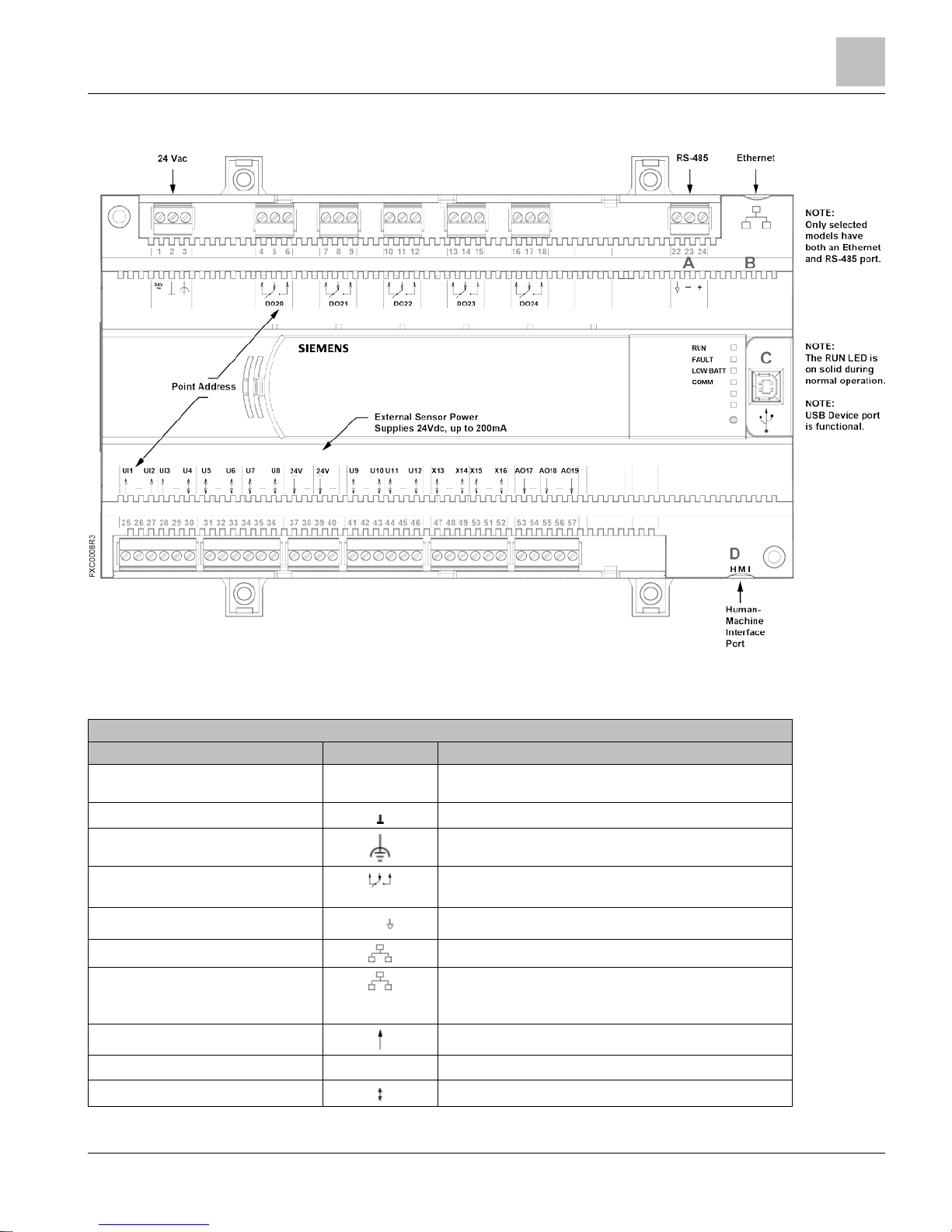

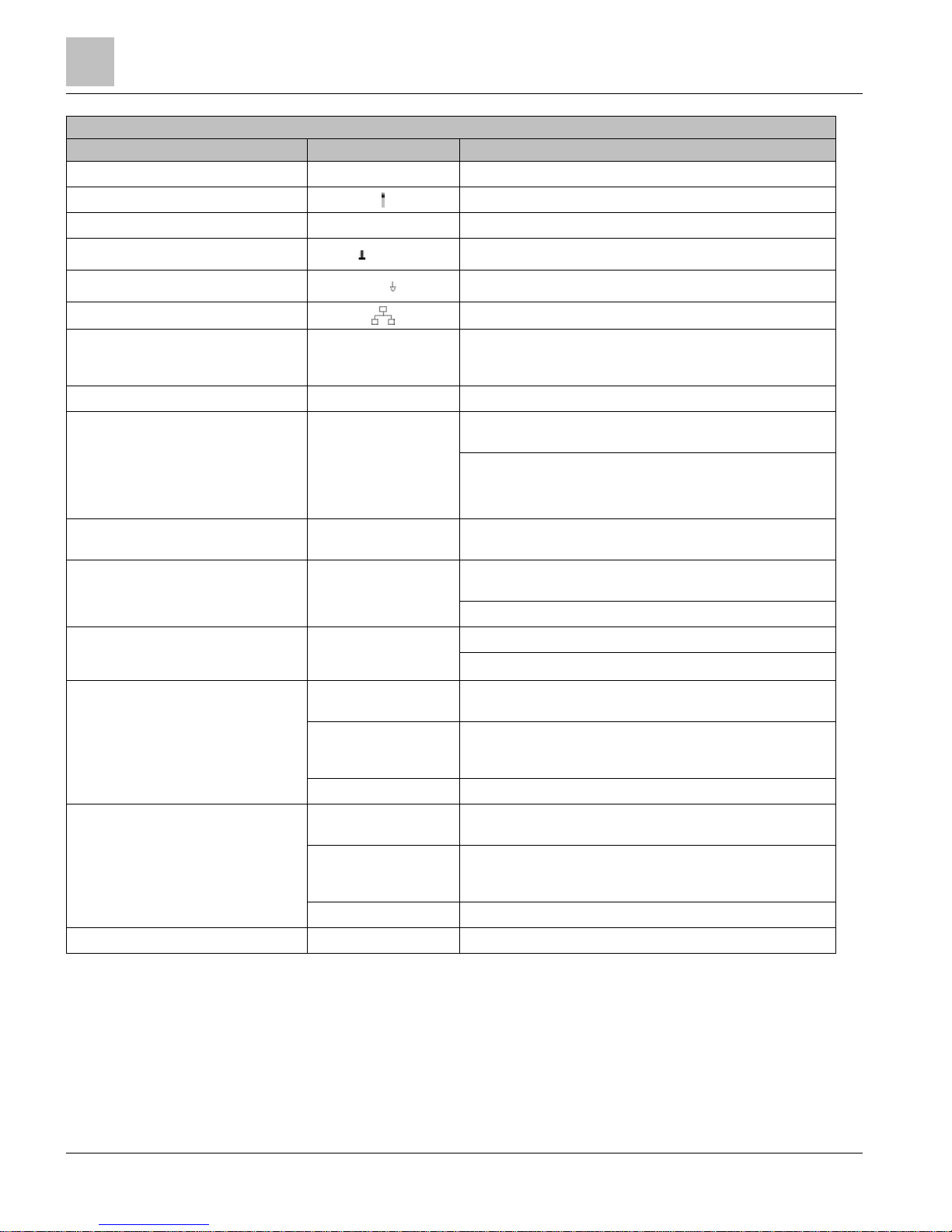

36-Point Compact Series Product Diagram

PXC-36 Features, Symbols, and Status LEDs.

Terminal Block Connection

Label

Indicates

1

24V

~

Supply voltage, 24 Vac input.

2

System neutral.

3

Functional earth.

4 through 27

Digital Output relay, Normally Closed (NC), Common (C), Normally

Open (NO).

A

10B/100B Ethernet port.

B

USB Device port. Supports a generic serial interface for an HMI or

Tool connection. Does not support firmware flash upgrades.

30, 32, 33, 35, 36, 38

Super Universal (+). (X1 through X6)

31, 34, 37

–

Signal Common.

39, 41, 50, 52, 53, 55, 56, 58, 59, 61, 62,

64, 65, 67, 68, 70, 71, 73

Universal Input/Output (+). (U7 through U24)

40, 51, 54, 57, 60, 63, 66, 69, 72

–

Signal Common.

42, 44, 46, 48

24 Vdc external sensor power (+) source.

Page 18

Compact Series Product Overview

36-Point Compact Series Product Diagram

18

| 100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

PXC-36 Features, Symbols, and Status LEDs.

Terminal Block Connection

Label

Indicates

43, 45, 47, 49

–

Signal Common.

74, 76, 77, 79

Digital Input (+) (DI25 through DI28)

75, 78

–

Signal Common

82 through 84

CD CS

Island Bus Communication

85 through 87 and 88 through 90

+ –

RS-485 port.

C

USB Host port

D

HMI

Human-Machine Interface port

(RS-232 8-N-1 signal, RJ-45 8 pin connector, service only, will not

dial out.)

Status LEDs

RUN LED

RUN

(green)

ON - Normal steady Green, unit is powered and running. May

briefly flash while processor is booting.

OFF - Error.

● 24 Vac input is not present.

● Power is ON, but the application firmware has not booted.

FAULT LED

FAULT

(red) (for future

use)

Normal Off, not currently implemented. May be Red if processor

does not complete boot.

LOW BATT LED

LOW BATT

(red)

ON - Error. RAM Battery (AA) is dead, low, missing or shipping tab

is not removed.

OFF - Normal operation.

COMM LED

COMM

(yellow)

(BACnet/IP or Ethernet

TCP/IP (P2) only)

ON - Linked to Ethernet hub.

OFF - No link to Ethernet hub.

RS-485 TX

A TX

(yellow)

Flashing - Transmitting information over RS-485 P1 (FLN 1) or

MS/TP FLN.

B TX

(yellow)

Flashing - Transmitting information over , RS-485 P2 or BACnet

MS/TP ALN or P1 or MS/TP FLN (depending on how the port is

defined)..

A TX or B TX

OFF or ON solid - No device, no connection, or bad connection.

RS-485 RX

A RX

(yellow)

Flashing - Receiving information over RS-485 P1 (FLN 1) or

MS/TP FLN.

B RX

(yellow)

Flashing - Receiving information over , RS-485 P2 or BACnet

MS/TP ALN or P1 or MS/TP FLN (depending on how the port is

defined).

A RX

or

B RX

OFF or ON solid - No device, no connection, or bad connection.

DO 29 through DO 36

DO

XX

ON - Relay Energized.

Page 19

Hardware Features

36-Point Compact Series Product Diagram

19 |

100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

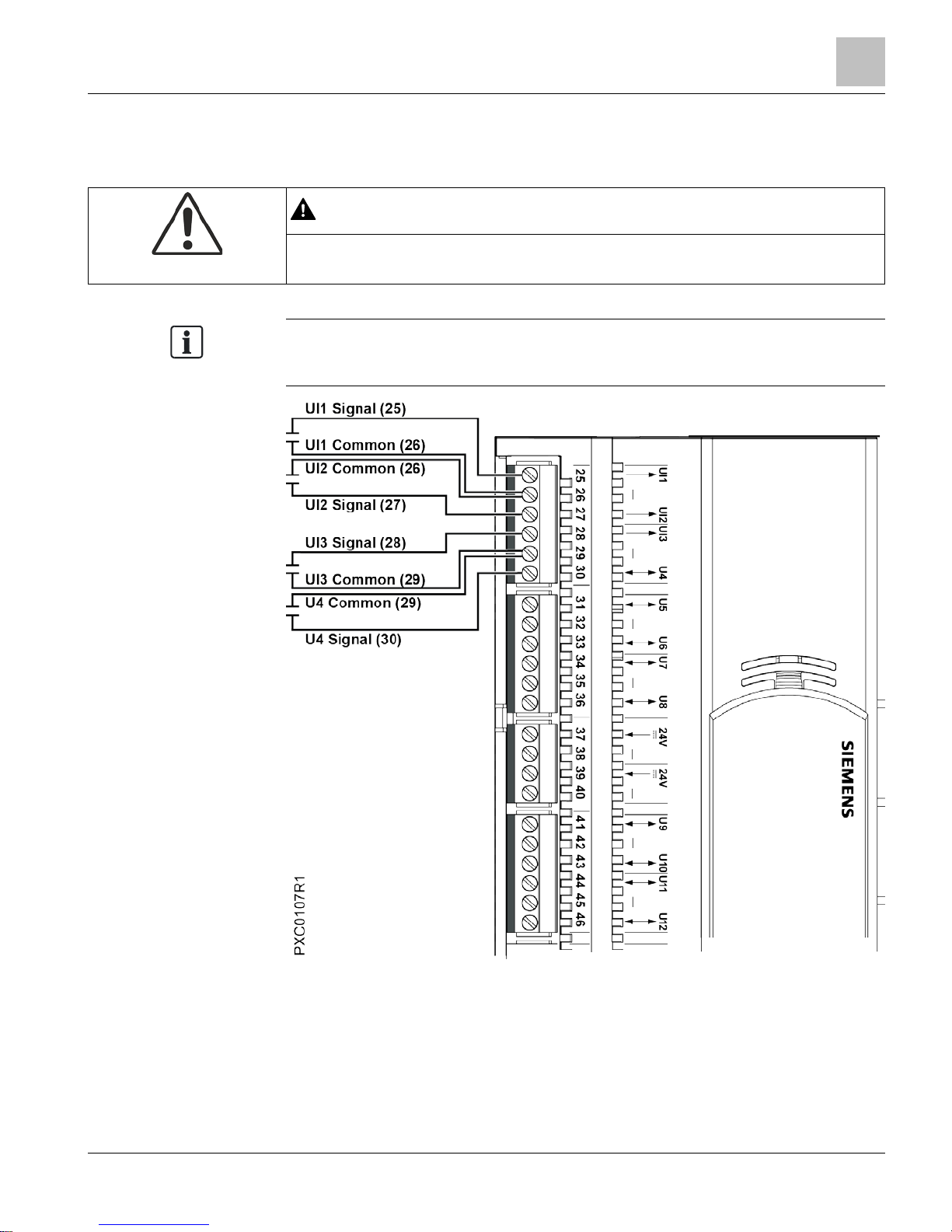

Hardware Features

CAUTION

Adjacent point connections on the PXC Compact Series share a Common

connection. See the Figure,

Common and Sensor Power Connections

.

NOTE:

The common for input and output analog points is floating and is not connected to the

common of the 24 Vac input.

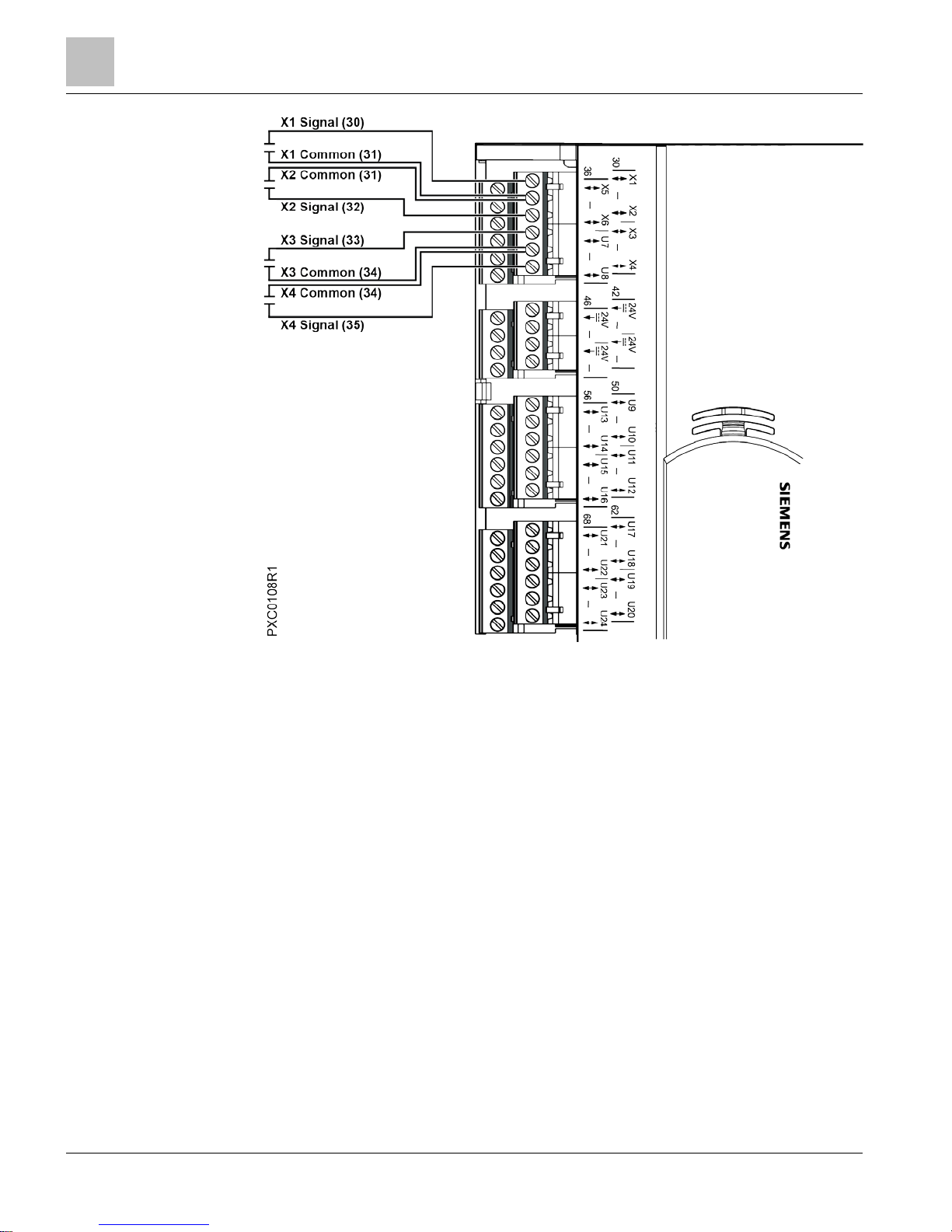

Figure 1: Compact 16/24 Shared Ground Connections.

Page 20

Hardware Features

24 Vdc External Sensor Power Source

20

| 100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

Figure 2: Compact 36 Shared Ground Connections.

24 Vdc External Sensor Power Source

The 24 Vdc Sensor Power source on the PXC Compact should only be used to supply

power to sensors. No accessories of any kind can be powered by this connector.

For powering actuators, use either the 24V ACTUATORS connector on the Service

Box or an external power supply.

Shield Termination

Terminating shield on the enclosure is the preferred method. The "-" termination next

to the 24 Vdc sensor power termination may be used as either a ground for the power

or as a cable shield connection. "-" is not connected to earth ground.

Page 21

Hardware Features

Memory

21 |

100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

Custom Sensor Support

In both P2 Mode (ALN device) and P1 Mode (FLN device), the PXC Compact supports

three custom sensor inputs for the AI points: Johnson Controls Nickel 1000, DIN

Standard Nickel 1000, and Thermistor 10K Type 3. These sensors display as an option

under the Sensor type HMI prompt when entering an AI point at the HMI.

>Sensor type : > 1) I ( Current )

> 2) V ( Voltage )

> 3) P ( Pneumatic )

> 4) T ( Thermistor 100K )

> 5) O ( Thermistor 10K )

> 6) S ( Thermistor 10K Type 3 )

> 7) M ( RTD 1K Platinum 375 )

> 8) R ( RTD 1K Platinum 385 )

> 9) N ( RTD 1K Nickel )

> 10) J ( RTD 1K Nickel JCI )

> 11) D ( RTD 1K Nickel DIN )

> 12) L ( L-Type )

> 13) C ( Custom )

Enter option # or <C> for Cancel> 1-

For the two RTD sensors, use the following updated

Intercept Adjustments

table to

create the value entered at the > Wire resistance adjustment : prompt.

Intercept Adjustments.

RTD Type and temperature

coefficient1

Intercept Formula for

Fahrenheit

2 3

Intercept Formula for Celsius

2 4

(M) RTD 1K Platinum 375 I - (R × ft)/2.117 I - (R × m)/3.8102

(R) RTD 1K Platinum 375 I - (R × ft)/2.171 I - (R × m)/3.9080

(N) RTD 1K Nickel I - (R × ft)/2.459 I - (R × m)/4.427

(J) RTD 1K Nickel JCI I - (R × ft)/2.9667 I - (R × m)5.3400

(D) RTD 1K Nickel DIN I - (R × ft)/3.0589 I - (R × m)5.5060

1)

Intercept Formula uses average temperature coefficient for the sensor connected.

2)

Resistance (R) is from the wire specification or the typical wire resistance table.

3)

I is for the intercept from the field panel Slope/Intercept table and ft is the wire length in feet.

4)

I is for the intercept from the field panel Slope/Intercept table and m is the wire length in meters.

Memory

The APOGEE firmware (program), its point database, PPCL program, trend data, and

other information reside in the field panel memory. Memory consists of two areas:

Flash Read-Only Memory (Flash ROM) and Random Access Memory (RAM).

Page 22

Hardware Features

Memory

22

| 100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

Flash Read-Only Memory (Flash ROM)

Flash Read-Only Memory (Flash ROM) is the non-volatile, permanent memory of the

PXC Compact, which stores the operating system, the APOGEE firmware, and the

language files. A limited amount of secondary storage is provided in Electrically

Erasable Programmable Read-Only Memory (EEPROM) for the field panel address or

name, communication speeds, and other set-up parameters. In the event of a power

surge, a power loss, or failure of the battery backup, the Flash ROM and EEPROM

contents stay intact.

PXC Compact Flash ROM size cannot be upgraded in the field.

Compressed ROM

The PXC Compact has a large amount of high performance RAM. To allow for future

features and to provide high system performance, the APOGEE firmware is stored in

ROM in a compressed state; it is de-compressed into RAM on system power-up. As a

result, the entire onboard RAM is not available for the point database, the PPCL

program, and trend data.

Auto-Restore and Database Backup to Flash

APOGEE Firmware Revision 2.8.4/3.1 and later supports Auto-Restore and Database

Backup to Flash.

● Database Backup to Flash allows the user to manually save a copy of the

database in flash memory of the controller.

● The field panel may be configured to automatically restore the database from flash

memory after a coldstart.

– When auto-restore is enabled, a coldstart does not result in the same downtime

as with earlier revisions of APOGEE Firmware. Because there is no waiting on

a full download from the backup system, the database is restored from flash so

quickly that there is little to no downtime. However, the accumulated trend data

is deleted from memory.

– Database restoration from flash is disabled by default.

– When FLN Mode is selected for the PXC Compact or UEC, database

restoration from flash is automatically enabled.

– When P1 Mode is selected for the PXC Compact, database restoration from

flash is automatically enabled and 128K of memory is reserved for ISB files.

● The field panel may be configured to automatically restore the database from flash

memory after a coldstart.

– When auto-restore is enabled, a coldstart does not result in the same downtime

as with earlier revisions of APOGEE firmware. Because there is no waiting on a

full download from the backup system, the database is restored from flash so

quickly that there is little to no downtime. However, the accumulated trend data

is deleted from memory.

– Database restoration from flash is disabled by default.

For procedures on using Auto-Restore and Database Backup to Flash, see the

APOGEE P2 ALN Field Panel User's Manual (125-3019) or the APOGEE BACnet ALN

Field Panel User's Manual (125-3020).

Page 23

Hardware Features

Compact Series Backup Batteries

23 |

100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

Auto Save

This feature allows the database to be backed up automatically whenever database is

changed, instead of being an operator selected function. It does not provide any

safeguard and or protection against power loss while the process is underway.

However, this feature sends messages to HMI that the auto save operation is in

progress or finished.

The feature may be turned on or off using a prompt similar to the existing Autorestore

prompt. See the APOGEE BACnet ALN Field Panel User's Manual (125-3020) for

more information.

File System Operations

File System Operations provide many features and works on three drives of a field

panel.

The following is a list of supported features:

● List Drives — list the drives on the field panel where A: is the RAM drive, B: is the

USB drive if attached, and

IFD: is the internal Flash Drive.

● Set_drive — identifies the drive that you want to perform other functions on.

● listDirectory — lists the files and folders contained on the selected drive.

● Change_dir — changes the current directory to allow you to view the contents of

subfolders on the drive.

● File_ops — opens up the file control menu which allows you to copy, rename,

delete and move files in the panel. These functions work on the drive that was

selected by the Set_drive function.

● File_ops/Copy_file — allows you to copy files within a drive or to another drive.

● File_ops/Rename_file — allows you to rename a file.

● File_ops/Move_file — allows you to move a file within a drive or to another drive.

● File_ops/Delete_file — allows you to delete a file.

USB Media Support

● Support for USB mass storage devices (Memory sticks or USB hard drives).

● Backup of database, storage for graphics, Web Server upgrades

Random Access Memory (RAM)

Synchronous Dynamic Random Access Memory (SDRAM) is the working memory of

the PXC Compact. When the PXC Compact has booted and is operating normally, the

APOGEE firmware, the PPCL control program, the point database, and trend data

have been transferred from Flash ROM. Information stored in RAM, such as the point

database or PPCL, may be viewed, modified, deleted, activated, or deactivated from

an operator terminal by any high-level authorized user. In the event of a power loss,

the contents of RAM are kept intact by a backup battery.

PXC Compact RAM size cannot be upgraded in the field.

The program length, number of database points, and number of trend entries is limited

only by available memory.

Compact Series Backup Batteries

The PXC Compact Series contains one non-rechargeable AA (LR6) battery and one

non-rechargeable coin cell (BR2032) battery that serve as a power backup in the event

Page 24

Hardware Features

Compact Series Backup Batteries

24

| 100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

of a power failure. The batteries only discharge during a power loss. They do not

recharge.

CAUTION

Only use a 3.6 Volt lithium battery in PXC Compact models with extended

temperature range operation.

Only use a 1.5 Volt alkaline battery in standard PXC Compact models.

• The 3.6 Volt lithium battery is designed to operate at both high and low temperature

extremes, and it provides a long service life in an extended temperature environment.

• The 1.5 Volt alkaline battery is not guaranteed to provide backup protection in

models with extended temperature range operation, even if the controller is operating

in a room-temperature environment.

• If a 3.6 Volt lithium battery is used in standard PXC Compact models, the battery

quickly discharges and provides much less backup protection than a 1.5 Volt alkaline

battery.

AA Battery

CAUTION

Batteries

Failure to change DEAD alkaline battery will eventually result in battery leakage,

causing permanent damage and loss of building control.

Failure to change a DEAD lithium battery will result in loss of trend and database if

not backed up, causing loss of data or building control.

Establish a preventative maintenance schedule based on expected battery usage and

life cycle.

● The AA battery maintains databases and volatile data, such as Trend, in RAM

when power to the controller is off.

● If reserve power in the AA battery is low, the battery status is reported as LOW or

DEAD and the red LOW BATT LED on the field panel is lit. When this occurs,

replace the battery; do not wait until it goes dead.

● Using PPCL and the $BATT point, the PXC Compact can be programmed to signal

an alarm printer and an operator terminal with a battery replacement message.

For more information, see the APOGEE Powers Process Control Language (PPCL)

User's Manual (125-1896).

Using Auto Restore and Database Backup to Flash

● RAM is cleared if the AA battery is dead, disabled, or missing when power to the

field panel is off. In this case, if Auto Restore and Database Backup to Flash have

been enabled, the database reloads in RAM when power returns; however, Trend

data is lost.

● If a power failure lasts longer than the protection offered by the battery, and Auto

Restore and Database Backup to Flash are not enabled, the information stored in

RAM must be either reloaded from an Insight workstation, Datamate Base or

Datamate Advanced, or entered again by an operator.

Page 25

Hardware Features

Compact Series Backup Batteries

25 |

100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

AA Battery

CAUTION

Batteries

Failure to change DEAD alkaline battery will eventually result in battery leakage,

causing permanent damage and loss of building control.

Failure to change a DEAD lithium battery will result in loss of trend and database if

not backed up, causing loss of data or building control.

Establish a preventative maintenance schedule based on expected battery usage and

life cycle.

● The AA battery maintains databases and volatile data, such as Trend, in RAM

when power to the controller is off.

● If reserve power in the AA battery is low, the battery status is reported as LOW or

DEAD and the red LOW BATT LED on the field panel is lit. When this occurs,

replace the battery; do not wait until it goes dead.

● Using PPCL and the $BATT point, the PXC Compact can be programmed to signal

an alarm printer and an operator terminal with a battery replacement message.

Monitoring the State of the AA Battery

● The resident AI point $BATT monitors the state of the AA battery.

– Status is reported as ALIVE for a value of 100.

– Status is reported as DEAD for a value of 0.

● Access BATT from the HMI or PPCL using one of the following:

– “!Field panel

<node>

:BATT” for RS-485 P2 or BACnet MS/TP ALN

–

“!<Node Name>

:BATT” for BACnet/IP or Ethernet TCP/IP (P2) ALN

– “*:BATT” where wildcard is permitted.

– The short name $BATT in PPCL.

For more information, see the APOGEE Powers Process Control Language (PPCL)

User's Manual (125-1896).

Using Auto Restore and Database Backup to Flash

● RAM is cleared if the AA battery is dead, disabled, or missing when power to the

field panel is off. In this case, if Auto Restore and Database Backup to Flash have

been enabled, the database reloads in RAM when power returns; however, Trend

data is lost.

● If a power failure lasts longer than the protection offered by the battery, and Auto

Restore and Database Backup to Flash are not enabled, the information stored in

RAM must be either reloaded from an Insight workstation, Datamate Base or

Datamate Advanced, or entered again by an operator.

NOTE:

The information stored in RAM may also be reloaded using Commissioning Tool (CT).

● If Auto Restore and Database Backup to Flash have been enabled, the AA battery

may be removed from the PXC Compact if there is not a requirement to maintain

volatile data, such as Trend, over a power cycle.

Page 26

Hardware Features

Compact Series Backup Batteries

26

| 100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

Coin Cell Battery

The coin cell battery is present on all PXC-36 Compact Series and on Version 2 or

later of PXC-16 and PXC-24. The hardware version is indicated in the Product Number

as follows:

● The number after

PXC16

or

PXC-24

indicates the hardware version. For example,

PXC24

.2-PE.A is Version 2.

● No number after

PXC16

or

PXC-24

is Version 1 hardware. For example, PXC24-

PE.A is Version 1.

CAUTION

Batteries

Failure to change a DEAD lithium coin cell battery will result in loss of current timedate, which may cause loss of data or building control.

Establish a preventative maintenance schedule based on expected battery usage and

life cycle.

● The coin cell battery maintains the current time-date in the Real Time Clock (RTC)

when power to the field panel is off.

● There is no physical status on the field panel for a dead coin cell battery.

● If the coin cell battery is dead or missing when power is off, then RTC time-date is

reset as follows:

– If the field panel resides on an ALN with an Insight workstation, the Insight

workstation sets the time-date when the field panel returns to the network.

– If the field panel resides on an ALN without an Insight workstation, the time-

date is synchronized with the network time during the next automatic daily time

update.

● When the PXC Compact is operating in P1 mode, if the coin cell battery is dead or

missing when power is off, RTC time-date is reset to the factory default. RTC timedate and must be set manually or by PPCL to ensure time-date based applications

operate as expected.

For more information on time synchronization, see the APOGEE P2 ALN Field Panel

User's Manual (125-3019) or the APOGEE BACnet ALN Field Panel User's Manual

(125-3020) (125-3019 or 125-3020).

Page 27

Hardware Features

Compact Series Backup Batteries

27 |

100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

Coin Cell Battery

The coin cell battery is present on all PXC-36 Compact Series and on Version 2 or

later of PXC-16 and PXC-24. The hardware version is indicated in the Product Number

as follows:

● The number after

PXC16

or

PXC-24

indicates the hardware version. For example,

PXC24

.2-PE.A is Version 2.

● No number after

PXC16

or

PXC-24

is Version 1 hardware. For example, PXC24-

PE.A is Version 1.

CAUTION

Batteries

Failure to change a DEAD lithium coin cell battery will result in loss of current timedate, which may cause loss of data or building control.

Establish a preventative maintenance schedule based on expected battery usage and

life cycle.

● The coin cell battery maintains the current time-date in the Real Time Clock (RTC)

when power to the field panel is off.

● There is no physical status on the field panel for a dead coin cell battery.

● If the coin cell battery is dead or missing when power is off, then RTC time-date is

reset as follows:

– If the field panel resides on an ALN with an Insight workstation, the Insight

workstation sets the time-date when the field panel returns to the network.

– If the field panel resides on an ALN without an Insight workstation, the time-

date is synchronized with the network time during the next automatic daily time

update.

● When the PXC Compact is operating in P1 mode, if the coin cell battery is dead or

missing when power is off, RTC time-date is reset to the factory default. RTC timedate and must be set manually or by PPCL to ensure time-date based applications

operate as expected.

For more information on time synchronization, see the APOGEE P2 ALN Field Panel

User's Manual (125-3019) or the APOGEE BACnet ALN Field Panel User's Manual

(125-3020) (125-3019 or 125-3020).

Monitoring the State of the Coin Cell Battery

● Resident AI point BATT2 monitors the state of the RTC oscillator when power is

applied to the field panel either during a coldstart or a warmstart.

– If the oscillator is stopped, BATT2 is set to value 0.

– If the RTC oscillator is valid, BATT2 is set to value 100.

– Status is reported as DEAD for a value of 0.

– Status is reported as OK for a value of 100.

NOTE:

The value of

BATT2

is also set to

100

by a coldstart command. Since the controller is

powered and the RTC oscillator does not stop, the value of BATT2 is valid and a

time-date reset will not occur.

Page 28

Hardware Features

Compact Series Specifications

28

| 100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

● Access BATT2 from the HMI or PPCL using one of the following:

– “!Field panel

<node>

:BATT2” for RS-485 P2 or BACnet MS/TP ALN

–

“!<Node Name>

:BATT2” for BACnet/IP or Ethernet TCP/IP (P2) ALN

– “*:BATT2” where wildcard is permitted.

● In PPCL, BATT2 cannot be automatically accessed using the short name $BATT2;

instead, use the full name. That is,

“!Field panel

<node>

:BATT2” for RS-485 P2 or

BACnet MS/TP ALN or

“!<Node Name>

:BATT2” for BACnet/IP or Ethernet TCP/IP

(P2) ALN.

Memory Size and Typical Battery Backup Time

Memory Size and Typical Battery Backup Time.

Compact Model

RAM Flash ROM

Total Memory

Typical Battery Backup

RAM and Real Time Clock Data

1

PXC-16 and PXC-24 16 MB 8 MB 24 MB

Non-rooftop models: 180 days

(accumulated)

Rooftop models: 330 days

(accumulated)

PXC-16 and PXC-24

“F” and “F32”

32 MB 8 MB 40 MB

Non-rooftop models (accumulated):

110 days (accumulated)

Rooftop models: (accumulated):

200 days (accumulated)

PXC-36 64 MB 16 MB 80 MB 60 days (accumulated)

1)

Installing a coin cell battery provides up to 10 years backup power of the Real Time Clock for nonrooftop applications, and 18 months backup power for rooftop applications. These are typical

accumulated times while power is off.

Compact Series Specifications

Dimensions (L × W × D)

PXC-16 and PXC-24

10.7" × 5.9" × 2.45"

(272 mm × 150 mm × 62 mm)

PXC-36

11.5" × 5.9" × 3.0"

(293 mm × 150 mm × 77 mm)

DIN rail (EN 60715 TH 35-7.5, steel)

1.38" × 0.30" × 0.04"

(35 mm × 7.5 mm × 1 mm)

Page 29

Hardware Features

Compact Series Specifications

29 |

100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

Processor, Battery, and Memory

Processor and Clock Speed PXC-16 and PXC-24: Freescale MPC852T, 100 MHz

PXC-36: Freescale MPC885, 133 MHz

Memory PXC-16 and PXC-24: 24 MB (16 MB SDRAM, 8 MB Flash ROM)

PXC-16/24 “F” and “F32”: 40 MB (32 MB SDRAM, 8 MB Flash ROM)

PXC-36: 80 MB (64 MB SDRAM, 16 MB Flash ROM)

NOTE:

See the Configuration and Sizing Guidelines document for supported memory size.

New PXC models will now support high speed 480 Mbps communication (PXC-36 only).

Serial EEPROM 4 KB

Battery backup of Synchronous Dynamic

(SD) RAM (field replaceable)

Non-

rooftop Models

AA (LR6) 1.5 Volt Alkaline (non-rechargeable)

PXC-16 and PXC-24: 180 days (accumulated)

PXC-16 and PXC-24 F and F32: 110 days (accumulated)

PXC-36: 60 days (accumulated)

Rooftop (Extended

Temperature) Models

AA (LR6) 3.6 Volt Lithium (non-rechargeable): 90 days (accumulated)

32MB SDRAM Rooftop (lithium): 200 days

16MB SDRAM Rooftop (lithium): 330 days

Battery backup of Real Time Clock

Non-

rooftop Models

10 years (32°F to 122°F (0°C to 50°C))

Coin cell (BR2032) 3 Volt lithium

Rooftop (Extended Temperature) Models

18 months (-40°F to 158°F (-40°C to 70°C))

Coin cell (BR2032) 3 Volt lithium

These are typical accumulated times while power is off.

Communication

BACnet/IP or Ethernet TCP/IP (P2)

Automation Level Network (ALN) or

BACnet/IP or Ethernet TCP/IP (P2) Floor

Level Network (FLN)

10Base-T or 100Base-TX compliant

10 Mbps or 100 Mbps (autoswitching) over Ethernet cable, RJ-45 jack, shielded, 328 ft (100

m) max. from the field panel to the nearest active hub, router, or signal repeater. Up to 100

nodes per BACnet/IP or Ethernet TCP/IP (P2) ALN or FLN.

10Base-

T Connection Requirements

UTP/STP Category 3 or 5 or better cable

100Base-TX Connection Require

ments

UTP/STP Category 5 or better cable

Supports CSMA/CD protocol, compatible with IEEE 802.xx compliant devices.

PXC-36 supports Auto-MDIX

BACnet MS/TP Automation Level Network

(ALN)

9600 bps to 115.2 Kbps, up to 10 nodes per MS/TP ALN

RS-485 Automation Level Network (ALN)

1200 bps to 115.2 Kbps over 24-gauge, low capacitance shielded twisted pair cable, 4000 ft

(1220 m) max. @ 57.6 Kbps or less, 3280 ft (1 km) max. @ 115.2 Kbps. Up to 100 nodes per

RS-485 ALN.

Human-Machine Interface (HMI)

Three wire, full-duplex, asynchronous serial RS-232 compliant, 1200 bps to 115.2 Kbps, 8-N-

1, no hardware flow control (Xon/Xoff supported). RJ-45 jack, 50 ft (16 m) max. cable length.

Supports dial-in modem.

Factory-

set HMI Communication Speed

PXC-16 and PXC-24: 9600 bps

PXC-36: 115.2 Kbps

Page 30

Hardware Features

Compact Series Specifications

30

| 100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

Communication

USB Device port (for non-smoke control

applications only)

Prior to June 2013

USB 1.1 (12 Mbps) and 2.0 (480 Mbps), Type B female connector.

Self-powered, does not use or supply USB power.

USB 1.0 (1.5 Mbps) and 1.1 (12 Mbps).

NOTE:

See the

Configuration and Sizing Guidelines

documentation for supported speeds per

controller model.

USB Host port (for ancillary smoke control

applications only).

Prior to June 2013

USB 1.0 (1.5 Mbps), 1.1 (12 Mbps), and 2.0 (480 Mbps), Type A female connector.

USB unit loads (5V, 500 mA).

USB 1.0 (1.5 Mbps) and 1.1 (12 Mbps), Type A female connector.

NOTE:

See the

Configuration and Sizing Guidelines

documentation for supported speeds per

controller model..

FLN Support available on selected models, license may be required

RS-485 P1 Field Level Network (FLN)

4800 bps to 38.4 Kbps over 24-gauge, low capacitance shielded twisted pair cable, 4000 ft

(1220 m) max. @ 38.4 Kbps.

PXC-16 and PXC-24: Up to 32 FLN devices supported.

PXC-36: For full-load FLN devices, up to 32 devices per FLN port.

For 1/8-load FLN devices, up to 96 devices per field panel.

BACnet MS/TP Field Level Network (FLN) 9600 bps to 115.2 Kbps

PXC-16 and PXC-24: Up to 32 FLN devices supported.

PXC-36: For full-load FLN devices, up to 32 devices per FLN port.

For 1/8-load FLN devices, up to 96 devices per field panel.

Electrical

Power Requirements 24 Vac ±20% input @ 50/60 Hz

Power Consumption (Maximum) PXC-16: 18 VA @ 24 Vac

PXC-24: 20 VA @ 24 Vac

PXC-36: 35 VA @ 24 Vac

A/D Resolution (analog in) 16 bits

D/A Resolution (analog out) 10 bits

AC Power and Digital Outputs NEC Class 1 Power Limited

Communication and all other I/O NEC Class 2

Digital Input

Dedicated Points

PXC-16:

Points 12-

13

PXC-36:

Points 25-

28

Contact Closure Sensing

Dry Contact/Potential Free inputs only

Does not support counter inputs

Open Circuit Voltage: 24 Vdc

Short Circuit Current: 10 mA

Configurable Points

PXC-16:

Points 1-

8

PXC

-

24:

Points 1-

16

PXC

-

36:

Points 1-

24

Contact Closure Sensing

Dry Contact/Potential Free inputs only

Digital Input (10 ms settling time)

Supports counter inputs up to 20 Hz, minimum

pulse duration 20 ms (open or closed)

Page 31

Hardware Features

Compact Series Specifications

31 |

100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

Electrical

Digital Output

Dedicated Points

PXC

-

16:

Points 14-

16

PXC

-

24:

Points 20-

24

PXC

-

36:

Points 29-

36

Class 1 Relay

Form-C (NO and NC contacts)

125 Vac, 4A

250 Vac, 2A

Configurable Points

using an external relay

PXC-24:

Points 13-

16

PXC-36:

Points 1-

6

0 to 24 Vdc, 22 mA max.

Analog Output

Dedicated Points

PXC-16:

Points 9-

11

PXC-24:

Points 17-

19

0 to 10 Vdc @ 1 mA max.

Resolution: 11 mV

Initial Accuracy: ±2% of full range (32°F to 122°F

(0°C to 50°C) ambient)

Analog Output

Configurable Points, 0 to 10 Vdc

PXC-16:

Points 4-

8

PXC

-

24:

Points 4-

16

PXC-36:

Points 1-

24

0 to 10 Vdc @ 1 mA max.

Resolution: 11 mV

Initial Accuracy: ±2% of full range (32°F to 122°F

(0°C to 50°C) ambient)

Configurable Points, 0 to 20 mA

PXC-24:

Points 13-

16

PXC-36:

Points 1-

6

0 to 20 mA @ 650 Ω max.

Resolution: 22 µA

Initial Accuracy: ±2% of full range (32°F to 122°F

(0°C to 50°C) ambient)

Analog Input

Configurable Points

PXC-16:

Points 1-

8

PXC

-

24:

Points 1-

16

PXC

-

36:

Points 1-

24

Voltage (0-10 Vdc) Resolution: 2.2 mV

Current (4-20 mA) Resolution: 4.4 µA

1K Ni RTD @ 32°F (Siemens, JCI, DIN Ni 1K) Resolution: 0.05 C

1K Pt RTD (375 or 385 alpha) @ 32°F Resolution: 0.08 C (375), 0.13 C (385)

10K NTC Type 2 or Type 3 Thermistor Resolution: 0.02 C to 0.10 C

100K NTC Type 2 Thermistor Resolution: 0.14 C to 0.02 C

Page 32

Hardware Features

Compact Series Specifications

32

| 100

Siemens Industry, Inc.

Technical Reference Manual

145-172

Building Technologies

Restricted

2018-09-25

Operating Environment

Ambient operating environment

Operate in a dry location, which is protected from exposure to salt spray or other corrosive

elements. Exposure to flammable or explosive vapors must be prevented.

Ambient operating temperature 32°F to 122°F (0°C to 50°C)

Ambient operating temperature

with rooftop

(extended temperature) option

-40°F to 158°F (-40°C to 70°C)

Relative Humidity PXC-16 and PXC-24: 5 to 95% rh non-condensing

PXC-36: 5 to 95% rh non-condensing

Shipping and storage environment PXC-16 and PXC-24:

-40°F to 185°F (-40°C to 85°C)

PXC-36:

-13°F to 158°F (-25°C to 70°C)

Mounting Surface PXC-16 and PXC-24:

Direct equipment mount, building wall, or structural member

PXC-36:

Building wall or a secure structure

CE Compliance

Must be installed inside a metal enclosure rated at IP20 minimum

Smoke Control Applications

Requires installation inside a PX series enclosure

Outdoor Applications

Requires installation inside a NEMA-4 rated enclosure, or a similarly-protected

environment

Vibration Compliance to IEC 60721, Class 2M2 and 3M2

Protection to EN60529 IP 20

Agency Listings

UL