Page 1

MicroMix 5

Shaker

User’s Manual

Document number: 600885-0001

Revision A

Date: March 2007

Copyright © 2006 by Siemens Medical Solutions Diagnostics. All rights reserved.

Page 2

Copyright © 2006 by Siemens Medical Solutions Diagnostics. All rights rese rved.

This manual, and the software described in this manual, are copyrighted. No part of this manual

or the described software may be copied, reproduced, translated or reduced to any electroni c

medium or machine-readable form without the prior written consent of Siemens Medical Solutions

Diagnostics except that you may make one copy of the program CD solely for back-up purposes.

IMMULITE® is a registered trademark of Siemens Medical Solutions Diagnostics.

All other products mentioned are trademarks of their respective companies.

Siemens Medical Solutions Diagnostics

Certificate No: UQA0113493

Siemens Diagnostics' quality products are manufactured under a quality

system that is registered to ISO 13485:2003.

Page 3

Table of Contents

Table of Contents 3

1. Introduction 4

2. Performance Characteristics and Specifications 6

Technical Specifications 6

Mechanical Specifications 6

Environmental Specifications 7

Controller 7

Power Supply 7

3. Installation 8

Unpacking 8

Requirements 9

Setting Up 10

4. Principles of Operation 13

5. Control Panel 14

Function Key [Function] 14

Digit Control Keys [Right], [Left] 15

Start/Stop Key [Start/Stop] 15

6. Operating Instructions 16

Recommended Default Settings 17

RS232 17

7. Operating Precautions and Limitations 18

General 18

Operation 18

Defects and Abnormal Stresses 18

8. Hazards 19

Environmental 19

Electrical 19

9. Service and Maintenance 20

Sensor Test 20

Alarm Test 20

EPROM Software Version Display 21

10. Appendix: Forms 22

11. Technical Assistance 25

MicroMix 5 ♦ 3

Page 4

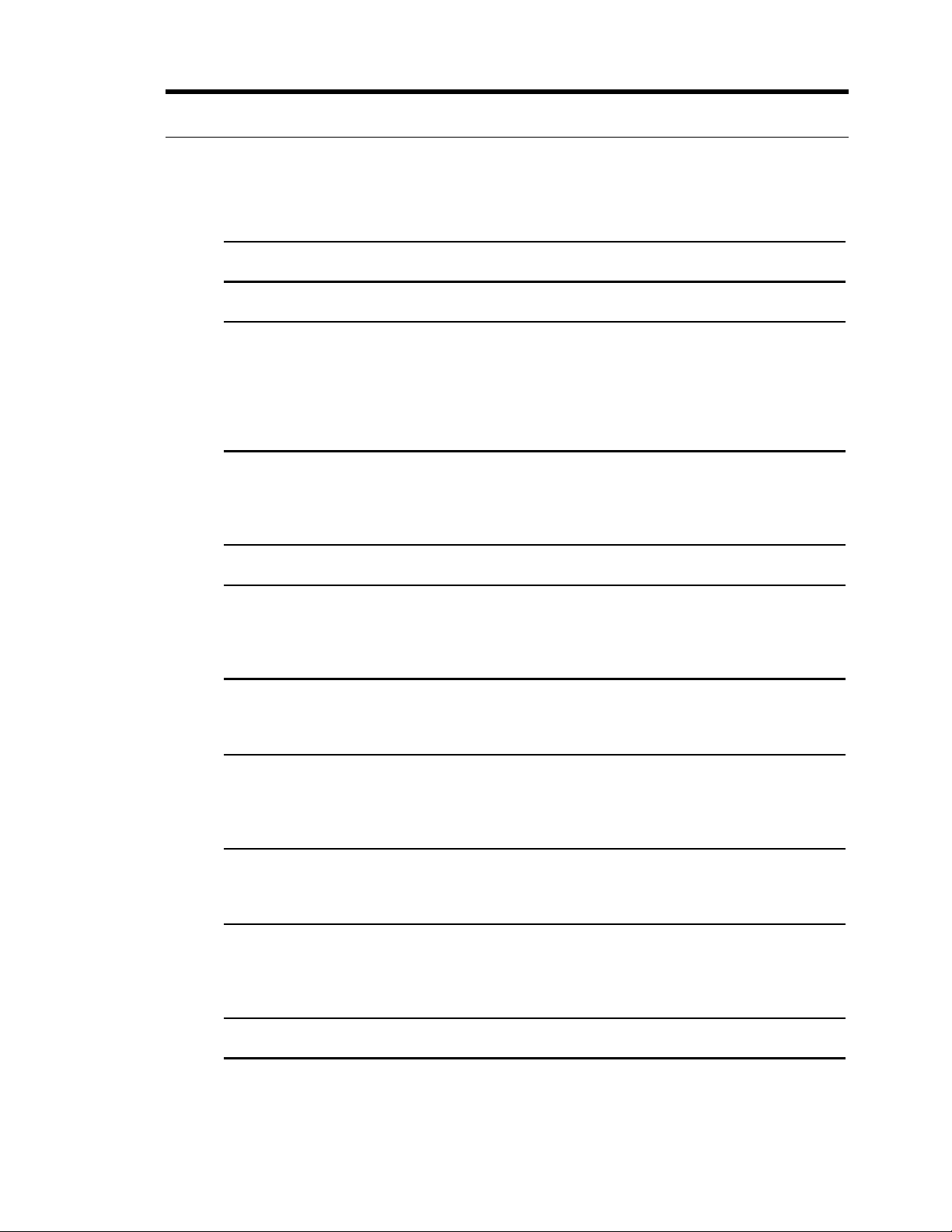

1. Introduction

The MicroMix 5 (Catalog number: MMIX5) is a fully programmable

microplate and tube shaker. It allows complete control over the

amplitude, frequency, direction of rotation and duration of shaking. The

shaker has a capacity of four 96-well microplates, 120 tubes in one rack

(Rack 513) or up to two racks (Rack 500) of 96 tubes, and can also shake

tubes in foam racks.

This manual describes the installation, operation and maintenance of the

MicroMix 5. Before operating the MicroMix 5, read this manual in its

entirety, as it contains information necessary to ensure safe operation.

A set of preset shaking cycle patterns, called

memory. The user can select from a range of variables in the

Amplitude and Time display modes to create an optimal Mix mode

which suits a specific liquid viscosity and fill volume.

Not all tubes or wells in a microplate achieve resonance at the same

frequency. Unlike most shakers, the MicroMix 5 shakes through a range

of frequencies, ensuring that all tubes or wells in a microplate are mixed

uniformly.

The MicroMix 5 consists of a base unit containing the control electronics,

the electromechanics, a panel-mounted keypad and a Liquid Crystal

Display (LCD). The base unit supports a lightweight but robust shaking

table with plate-retaining strips, which can be exchanged for a mat and

locators for shaking tubes.

The MicroMix 5 has a separate desktop power supply.

Forms, are stored in

Form,

4 ♦ MicroMix 5

Figure 1: MicroMix 5 Shaker

Page 5

Introduction (cont.)

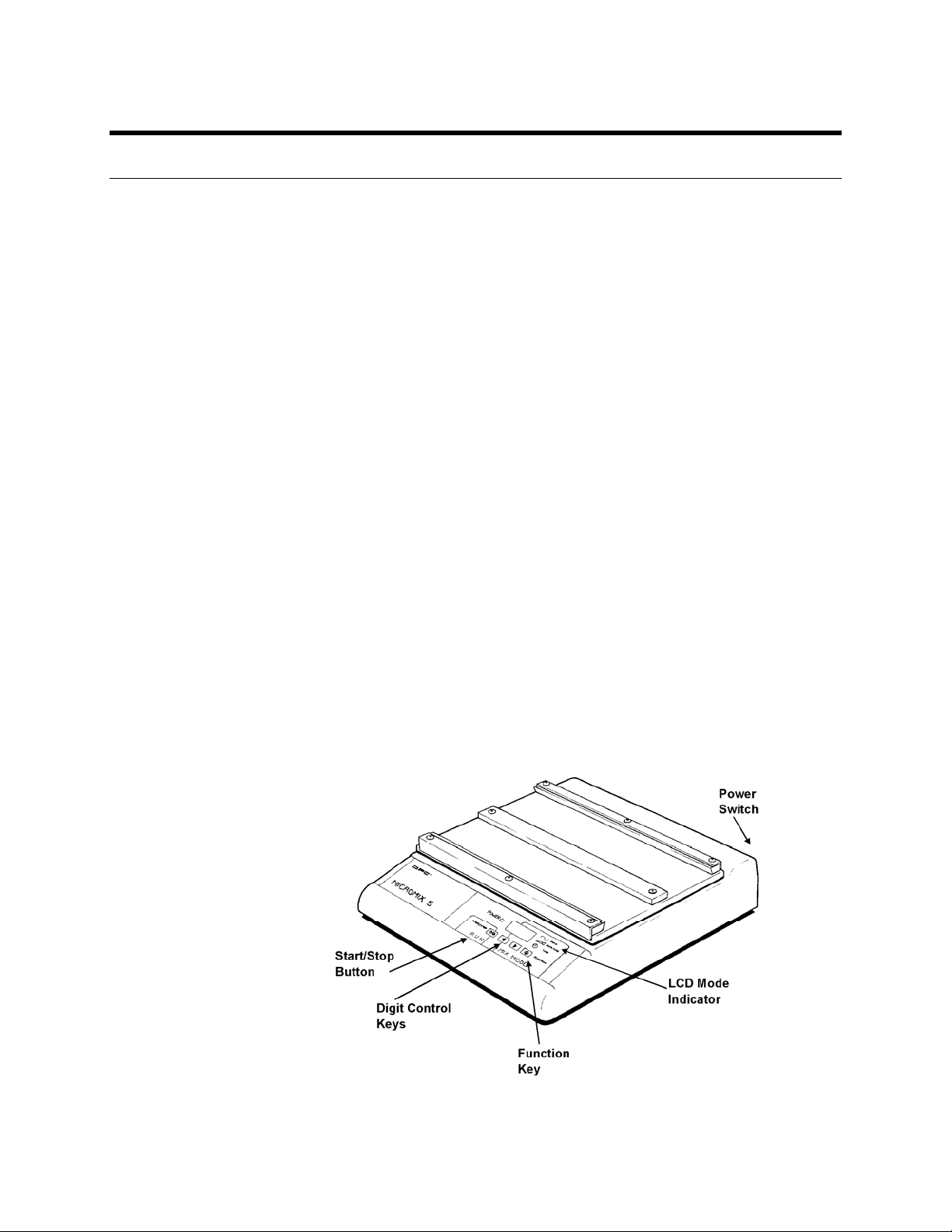

Tube Racks

(RACK 500, RACK 513)

Foam Racks for Tubes

Figure 2: MicroMix 5 in Tube Shaking Configurations

MicroMix 5 ♦ 5

Page 6

2. Performance Characteristics

and Specifications

Technical Specifications

The following are technical characteristics and specifications of the

MicroMix 5:

• Maximum power consumption: 50 VA

• Power voltage: 90 – 260 VAC, 47 Hz – 63 Hz

• Power inlet at rear panel of power supply module

• Maximum peak-to-peak shake amplitude: 2.5 mm

• Shaking mode: horizontal plane, circular

• Shaker orbital speed range (frequency): 300 – 1800 rpm (5 – 30 cycles

per second)

• Maximum capacity:

4 microplates

2 RACK 500 with 96 tubes per rack

1 RACK 513 with 120 tubes per rack

2 foam decanting racks with 100 tubes each

• Maximum shake mass:

2 kg evenly distributed on shaking table from 5 Hz – 20 Hz

0.5 kg evenly distributed on shaking table from 20 Hz – 30 Hz

Mechanical Specifications

The following are mechanical characteristics and specifications of the

MicroMix 5. The mechanical and electrical components are fixed to a

metal base plate. This is covered by a polyurethane foam case. The

microplates are supported on an aluminum table. Other characteristics

are:

• Footprint: 410 mm deep × 345 mm wide excluding power supply

6 ♦ MicroMix 5

• Height: 96 mm (overall height to seat of microplate)

• Weight: 6.7 kg; shipping weight: 8 kg

Vibration through the work surface is dampened by using feet made of

special isodamped material.

Page 7

Environmental Specifications

• Operating temperature: 0 to 40°C

• Storage temperature: –25 to 50°C

• Humidity: 10 to 90% RH, non-condensating

• RFC/EMI: Complies with EMC Directive 89/336/EEC

FCC 20780 Class B

VDE 0871 Level A

Controller

The controller comprises three main components:

1. Power inlet system, which consists of:

DC socket

Power switch

Interference suppression filter

Power Supply

2. Controller printed circuit board, incorporating front panel controls

and indicators

3. Drive electromagnets

This is a modular bench-top switched mode power supply and features:

• International Electrotechnical Commission (IEC) inlet

• Fusing

• Interference suppression

• DC output cable and plug

MicroMix 5 ♦ 7

Page 8

3. Installation

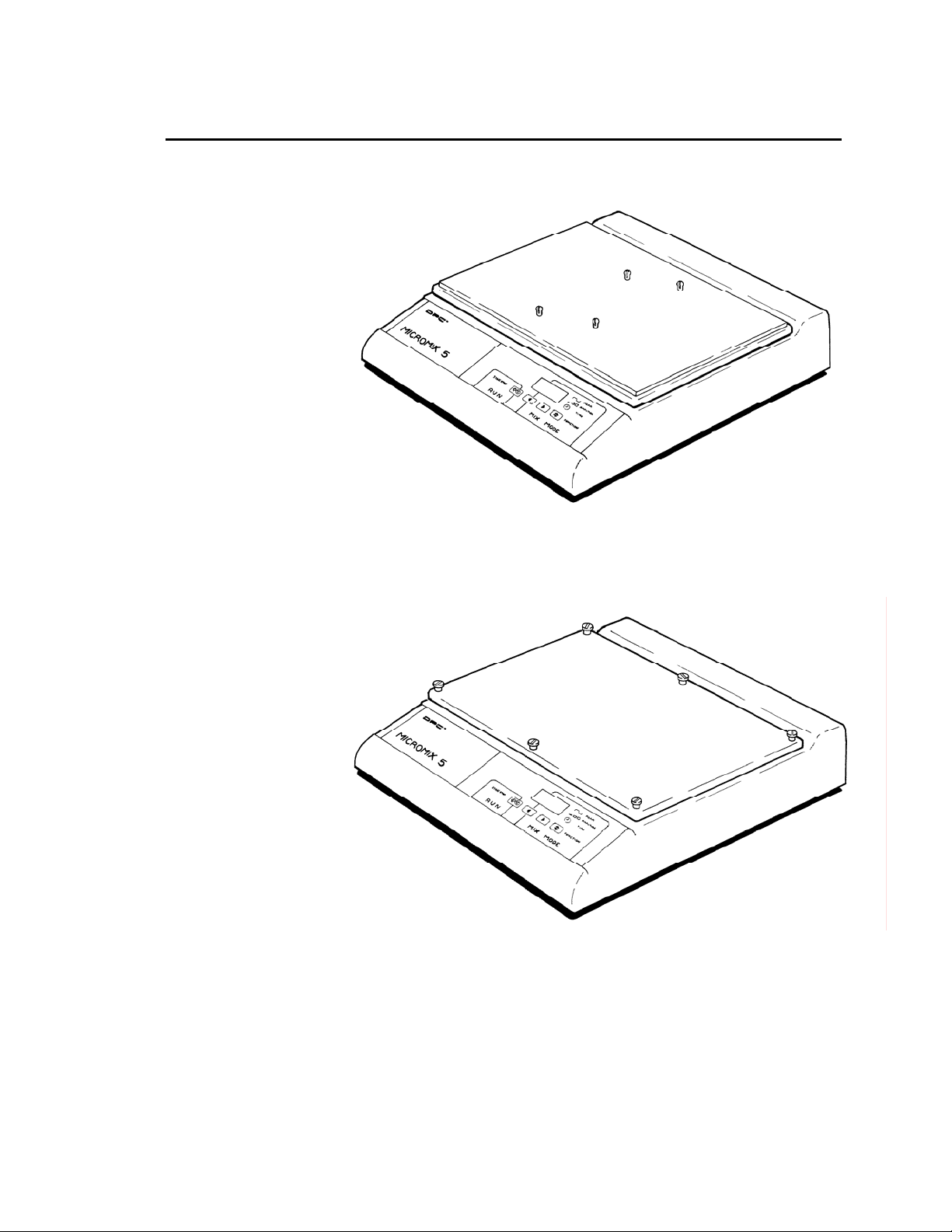

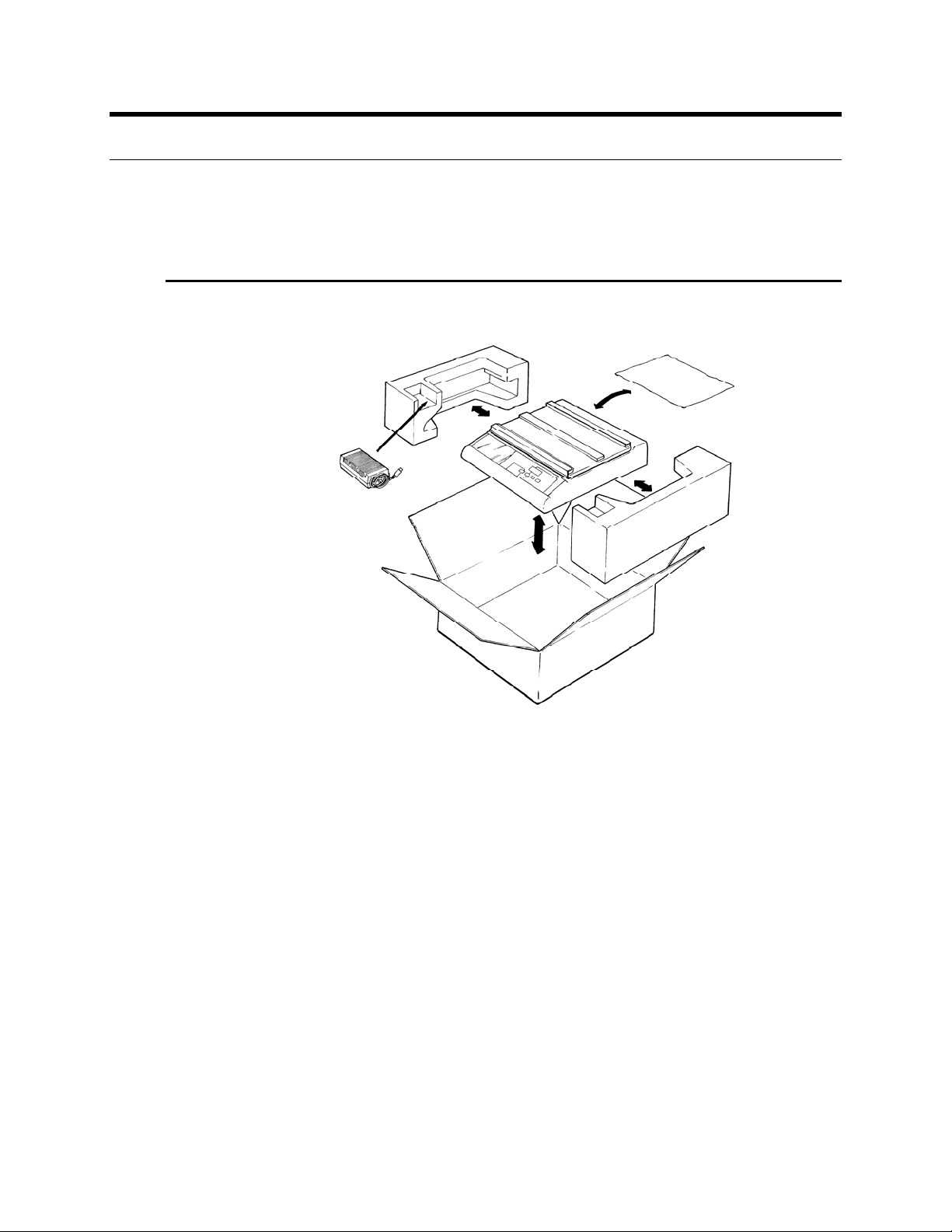

Unpacking

Follow Figure 3 for unpacking instructions.

Figure 3: Unpacking

The main box should consist of the following:

• MicroMix 5 Shaker

• Bench-top power supply

• Power cord, appropriate to your country

• Black foam mat (MAT 25)

• MicoMix 5 Shaker User's Manual

The accessories pack should consist of the following:

• Five rack pillars

• Seven shoulder screws and washers

• Small allen key screwdriver

8 ♦ MicroMix 5

Page 9

Requirements

Before plugging the external power supply into the Shaker and

connecting to an appropriate outlet, ensure that the following

requirements are met:

Site

The unit should be located on a level work surface free from strong

sources of electromagnetic interference, e.g. centrifuge motors.

The proper work surface should measure as follows:

Height: 20 cm (8 inches)

Depth: 45 cm (18 inches)

Width: 36 cm (14 inches)

Power Supply

Only the supplied power supply should be used. The power supply unit

accepts a supply voltage from 90 to 260 VAC and a frequency from 47 to

63 Hz. No adjustment is required.

CAUTION: This equipment requires connection to a properly grounded

power source for safety reasons.

MicroMix 5 ♦ 9

Page 10

Setting Up

The MicroMix 5 may be reconfigured to shake microtiter plates, or tubes

in racks or foams. The instrument is supplied preset to shake microtiter

plates.

10 ♦ MicroMix 5

Figure 4: Microtiter Plate Shaking

Items Required

1. One perspex center strip

2. Two side foam strips

3. Six large allen screws

4. Two small allen screws

5. Two plastic strips

6. Six spacers

7. One small allen key screwdriver

(Item 7 is in the accessory pack.)

Page 11

Setting Up (cont.)

Figure 5: Tubes, Foam Shaking

Items Required

1. Six shoulder screws

2. One black foam Mat. MAT 25 (250 × 334 mm, 10 × 12.5 inches)

3. One small hex key screwdriver

Ensure that when fitting screws they are not cross-threaded into the

shaker table top.

CAUTION: Do Not Overtighten the Screws

MicroMix 5 ♦ 11

Page 12

Setting Up (cont.)

Figure 6: Tubes, Rack Shaking

Items Required

1. One black foam Mat. MAT 25 (250 × 334 mm, 10 × 12.5 inches)

2. Four rack pillars

When rack pillars are unused, they may be stored at the rear of the

shaker. Caution must be exercised so as not to damage the threaded part

of the pillars.

Figure 7: Rack Pillar Storage Location

12 ♦ MicroMix 5

Page 13

4. Principles of Operation

Four diagonally arranged electromagnets fixed to the base are directed

towards four pole pieces fixed to the shaking table. The electromagnets

are activated and deactivated sequentially, so that the table shakes with

an orbital motion. The table is mounted on rubber mounts, which ensure

that the table moves only on a horizontal plane.

Motion is accurately controlled by a microcontroller. The amplitude is

detected using a proximity sensor, and is maintained, regardless of the

load, within the recommended operating range through dynamic

feedback techniques.

The low inertia of the table enables the frequency and direction of

mixing to be altered almost instantaneously. This also minimizes the

reaction to the shaker body and transmission of vibration to the work

surface.

The user may select one of a number of

Amplitude and Time (duration of shaking). A total of 60 Forms are

preset, with a subset of these optimized for plate shaking, tube shaking

and constant speed shaking. The default shaker settings

Amplitude and Time)

reprogrammed by the user.

selected when the shaker is switched ON may be

Forms and may also set the

(Form,

MicroMix 5 ♦ 13

Page 14

5. Control Panel

Figure 8: Control Panel

Legend

[Start/Stop] [Left]

[Function] [Right]

Function Key [Function]

The [Function] key is used to select any of three functions in which

preset values may be chosen by the operator. The function selected is

shown by the function indicator (appearing in the Mode Indicator

window) which moves sequentially between Form, Amplitude and

Time at each press of the key. The [Function] key also serves as a pause

control in RUN mode with a toggle action. Key depression is

acknowledged by a short audible "blip" unless the sounder is muted.

Form

The maximum number of Forms given with the MicroMix 5 is 60. Form

value 60 sets the instrument to TIMER mode only.

Form affects the following:

14 ♦ MicroMix 5

• Speed Shake direction

• Rest period between changing directions

See the Appendix for further details.

Page 15

Function Key (cont.)

Amplitude

The Amplitude selection ranges from 1 – 9, where 1 = minimum

amplitude, and 9 = maximum amplitude

Time

The timer has a range of 1 – 199 minutes. The value counts down to zero

from all nonzero values at the rate of 1 per minute after the [Start/Stop]

key has been depressed. Setting Time to "0" places the instrument in

continuous shaking mode. To stop continuous shaking, press the

[Start/Stop] key.

See the Appendix for further details.

Digit Control Keys [Right], [Left]

With the function indicator at the desired position, the Form, Amplitude

or Time number as indicated in the LCD may be adjusted by means of

the digit control keys as follows:

[Right] increases the value

[Left] decreases the value

A quick key depression changes the digit by one, while depressing the

key longer than 0.7 seconds causes an acceleration through the numerical

values. Digit wraparound is featured, i.e. each function returns to its

minimum value after passing its maximum value.

Start/Stop Key [Start/Stop]

Shaking and/or timing is started by depressing and releasing this key,

and may be stopped at any time by depressing the key again. As the time

counts down, the function indicator flashes every 2 seconds.

When Time = 0, the alarm sounds and shaking ceases.

When the shaker/timer or alarm is stopped by this key, the READY

mode is resumed with all the previously set parameters.

MicroMix 5 ♦ 15

Page 16

6. Operating Instructions

The power switch at the rear of the unit should be OFF (O) while

connecting the power supply to the shaker. The DC power supply input

may then be connected to the outlet.

1. Turn the power switch to ON (I). The controller produces two short

audible "blips"; the power ON indicator LED lights and the LCD

panel indicate a number with the function indicator on Form.

2. The recommended Form and Amplitude settings should be selected

and used for all assays, unless otherwise advised.

The Time setting should be adjusted according to assay instructions.

This is done by pressing the [Function] key to select Time, and using the

[Right], [Left] keys to select the appropriate value in minutes.

The default Time setting, 0, leaves the instrument in continuous shaking

mode.

3. Press the [Start/Stop] button to begin shaking.

4. Shaking action may be paused by pressing the [Function] key while

shaking is in action. The PAUSE mode is indicated by the function

indicator set at Time flashing at approximately three times per

second, and an audible warning consisting of 5 "ticks" per second.

In PAUSE mode, the timer is frozen and no power is applied to the

shaker table. Shaking and time countdown (where applicable) resumes

upon pressing the [Function] key a second time.

After switching the power OFF (O), a minimum interval of 5 seconds

should elapse before turning the power ON (I) again.

Sounder Mute

Switching the instrument ON while depressing the [Left] key mutes the

sounder until the instrument is switched OFF and switched ON

normally.

Resetting Power Up Setting

Switching the Instrument ON while depressing the [Left] and [Right]

keys will enable the default settings at power up to be changed. Using

the control panel, select the desired Form, Amplitude and Time.

Pressing the [Start/Stop] key will start the shaker with these parameters,

and permanently save them in internal memory (EPROM). The saving

mechanism is then disabled, and any other function selected will not be

saved.

16 ♦ MicroMix 5

When the instrument is subsequently switched ON it will default to the

new settings. To save a new set of default parameters, the procedure

must be repeated after switching on the instrument.

Page 17

Recommended Default Settings

The recommended parameters to obtain various modes of shaking for

assays are as indicated:

• For microtiter plate shaking, Form 20, Amplitude 5 may be used.

Other combinations may be considered as follows, Form 8, 22, 21, 17,

20 — all at Amplitude 5.

• For shaking tubes in TUBE DECANTING Foams with Siemens

Diagnostics assays use Form 25, Amplitude 7.

• For shaking tubes in RACK 500 or RACK 513 use Form 24,

Amplitude 7.

NOTE: The shaker will not be able to maintain full shake amplitude with

certain combinations of load, and selected Forms and Amplitude

settings above 7. Do not exceed the mass, as stated in the Technical

Specifications section.

RS232

There is an RS232 connector on the rear of the instrument to externally

control the shaker.

For further information please contact your Siemens Diagnostics

Distributor.

MicroMix 5 ♦ 17

Page 18

7. Operating Precautions and Limitations

General

Before operating the MicroMix 5, read this manual in its entirety, as it

contains information necessary to ensure safe operation.

Operation

Control samples and calibrators supplied with

should be processed by the MicroMix 5 in the same manner as test

samples. Strictly follow the instructions in the package inserts provided

by the manufacturer. Do not use magnets or magnetized items except

approved magnetic test tube racks near the equipment. Protection from

extremes of temperature and electrical interference is essential for proper

operation.

The instrument should be unpacked and installed in accordance with the

"Installation" section.

Ensure that the microplates are properly secured to the shaker platform

before operating the MicroMix 5.

Ensure that the racks are properly seated on the shaker platform pillars

before operating the MicroMix 5.

Ensure that foam decanting racks are properly affixed to the shaker

platform before operating the MicroMix 5.

Do not exceed the maximum volume of 300 µL per well in a standard 96well flat-bottom microplate.

in vitro diagnostic test kits

Defects and Abnormal Stresses

18 ♦ MicroMix 5

Whenever it is likely that the instrument's safe operation is

compromised, it should be made inoperative and secured against any

unintended operation.

The instrument's safety could be compromised, for example, if the

instrument:

• shows visible damage

• fails to perform the intended functions

• has been stored for a long time under unfavorable conditions

• has been subjected to severe transport stresses

Page 19

8. Hazards

Environmental

Infectious clinical samples and corrosive chemicals are commonly used

with this equipment. Although the shaker is designed to avoid spillage

under recommended working conditions, at higher amplitude settings

spillage may occur; hand and eye protection and laboratory coats

appropriate to the application should always be worn. If the shaker

platform comes into contact with spilled liquid, it should be cleaned

appropriately to avoid hazards.

Electrical

There are no USER SERVICEABLE PARTS within the MicroMix 5 and its

power supply.

Never substitute a different cable for the power cord supplied with the

instrument. The power cord should only be plugged into a power outlet

with a proper ground.

The precautions for using any electrical equipment apply to this device.

Do not use it during electrical storms. Do not touch switches or electrical

outlets with wet hands. Switch the instrument OFF (O) before

disconnecting.

MicroMix 5 ♦ 19

Page 20

9. Service and Maintenance

The MicroMix 5 is a highly reliable unit. This is achieved by the choice of

well-proven components, the small number of moving parts, the

minimal use of connectors and maximum use of digital techniques. The

microcontroller, driver system, associated electronics and front panel

controls and indicators are incorporated on a single printed circuit

board.

There are no USER SERVICEABLE PARTS within the MicroMix 5.

Authorized personnel only should carry out any necessary repairs to the

unit, as these may involve the use of specialized equipment and fixtures.

The following diagnostic modes may be terminated and regular

operation continued by depressing the [Start/Stop] key.

Sensor Test

Alarm Test

Perform the following Sensor Test at 6-month intervals:

1. Switch the instrument ON (I) while depressing the [Function] key.

This causes the LCD panel to indicate a value between 110 and 195

derived from the proximity sensor used for feedback control. The

value on the LCD panel should be noted.

2. Move the shaking platform by hand in the horizontal plane. This

causes the value to change on the LCD panel. When the shaking

platform is resting in its equilibrium state, the value indicated

should be between +/–10 of the previously indicated value. See

item 1.

3. If the displayed value is outside the stated limits, contact your

National Distributor for assistance.

For this optional test, switch the instrument ON while depressing the

[Right] key. This starts the alarm, which produces circular, sequential

patterns on the LCD with a repeated audible tone of four short "blips"

and one long “blip.”

20 ♦ MicroMix 5

Page 21

EPROM Software Version Display

Switch the instrument ON (I), while keeping the [Left] and [Function]

keys depressed. The EPROM software version is now displayed, e.g.

1.06. This is accompanied by a “chirping” sound. The mode may be

terminated by pressing the [Start/Stop] key. The instrument is now

ready for normal operation.

This feature is useful for checking the software version without having to

remove the instrument's cover or controller board.

MicroMix 5 ♦ 21

Page 22

10. Appendix: Forms

The following table illustrates the available Forms. The MicroMix 5

offers a total of 60 preset Forms. Further details are available upon

request from your distributor.

FORM

1 5 30 2 0.12 1.0

2 5 10 2 0.13 1.0

3 7.5 12.5 2 0.19 0.9

4 10 15 2 0.25 0.8

5 12.5 17.5 2 0.32 0.7

6 15 20 2 0.39 0.6

7 17.5 22.5 2 0.44 0.5

8 20 25 2 0.50 0.5

9 22.5 27.5 2 0.50 0.5

10 25 30 2 0.50 0.5

11 5 10 3 0.13 1.0

12 7.5 12.5 3 0.19 0.9

13 10 15 3 0.25 0.8

14 12.5 17.5 3 0.32 0.7

15 15 20 3 0.39 0.6

16 17.5 22.5 3 0.44 0.5

17 20 25 3 0.50 0.5

18 22.5 27.5 3 0.50 0.5

19 25 30 3 0.50 0.5

20 20 25 3 7.0 0.2

21 20 25 2 1.75 0.3

22 20 25 2 0.25 0.5

23 8 11.5 2 0.10 1.0

24 11 14.5 2 0.10 1.0

25 13 18 2 0.10 1.0

26 8 11.5 3 0.10 1.0

27 11 14.5 3 0.10 1.0

FRQ1

(Hz)

FRQ2

(Hz)

MODE

RAMP

(Hz/sec)

GAP

(sec)

22 ♦ MicroMix 5

Page 23

Appendix: Forms (cont.)

Fixed Speed Forms

Form

28 5 1 300

29 5 0 300

30 6.5 1 390

31 6.5 0 390

32 8.5 1 510

33 8.5 0 510

34 10 1 600

35 10 0 600

36 11.5 1 690

37 11.5 0 690

38 13.5 1 810

39 13.5 0 810

40 15 1 900

41 15 0 900

42 16.5 1 990

43 16.5 0 990

44 18.5 1 1110

45 18.5 0 1110

46 20 1 1200

47 20 0 1200

48 21.5 1 1290

49 21.5 0 1290

50 23.5 1 1410

51 23.5 0 1410

52 25 1 1500

53 25 0 1500

54 26.5 1 1590

55 26.5 0 1590

56 28.5 1 1710

57 28.5 0 1710

58 30 1 1800

59 30 0 1800

60 TIMER MODE

FRQ1/FRQ2

(Hz)

MODE

Speed

(RPM)

MicroMix 5 ♦ 23

Page 24

Appendix: Forms (cont.)

Form Parameter Definitions

FRQ1: Start Frequency (orbital speed)

FRQ2: End Frequency (FRQ2 ≥ FRQ1)

Defining FRQ1 and FRQ2 sets up a range of shaking frequencies in Hz

(cycles per second).

MODE

0 Constant direction, constant speed (clockwise).

1 Constant direction, constant speed (counter-clockwise).

2 Ramp frequency up, ramp frequency down, wait, change direction.

3 Ramp frequency up, wait, change direction, ramp frequency down,

wait, change direction.

RAMP: Frequency ramp rate (speed of change from one frequency to the

next through the range). Hertz per second.

GAP: Non-shaking period prior to change of direction. Seconds.

RPM: Speed of rotation for forms 0 and 1. Revolutions per minute.

Form 60

Selecting Form value 60 places the instrument in TIMER mode. No

shaking takes place in this mode. The instrument counts down from a set

time value, emitting an audible "tick" every second, while the function

indicator blinks.

The display shows the time remaining until the alarm sounds.

Starting and stopping the TIMER mode is detailed in the "Start/Stop

Key" section under "Control Panel."

Selecting Form 60 and setting the Time value to 0 activates the alarm

immediately.

If the sounder has been muted, no seconds will be heard "ticking" during

the TIMER mode, nor will there be an audible alarm when the time runs

out.

24 ♦ MicroMix 5

Page 25

11. Technical Assistance

For questions regarding the MicroMix 5 and its operation, or for service,

contact Technical Service at Siemens Diagnostics or your National

Distributor.

Tel: 973.927.2828

Fax: 973.927.0697

MicroMix 5 ♦ 25

Loading...

Loading...