Page 1

MICROMASTER 430

7.5 kW - 250 kW

使用说明书

版本

12/02

用户文件

订货号: 6SE6400-5AE00-0MP0

Page 2

MICROMASTER 430

7.5kW - 250kW

使用说明书

用户文件

概 况

安 装

调 试

MICROMASTER 430

的功能

系统参数

1

2

3

4

5

适用于

变频器类型

MICROMASTER 430 V2.0

版本

12/02

软件版本

故障的排除

MICROMASTER 430

的技术规格

选 件

电磁兼容性

维 护

(EMC)

6

7

8

9

10

采用的标准和缩略语

附 录

版本

12/02

11

Page 3

更多的信息可在互联网上查阅,网址:

http://www.ad.siemens.com.cn/products/sd

核准的西门子软件和培训标准是:

DIN SIO9001,注册登记号: 2160-01

未经书面许可,不得翻印、传播、或使用本手册及其相关内容。违

者将对所造成的损害负法律责任。西门子公司保留一切权利,包括

由专利许可、实用样机注册、或工程设计等所产生的所有权利。

© Siemens AG 2002。保留一切权利。

MICROMASTER® 是西门子公司已注册的商标。

订货号:6SE6400-5AE00-0MP0

本手册中对某些有效的功能可能未加说明。但是,在新的控制装

置中或进行服务时,并不因为西门子公司提供了这些功能而要承

担任何责任。

编审过程中,我们对本手册的内容与所述的硬件和软件的一致性

进行了审核。但是,仍然可能存在矛盾和谬误的地方,不可能保

证它们完全一致。我们将定期检查本手册中涵盖的内容,并在以

后修订的版本中予以必要的修正。欢迎提出改进的建议。

保留不预先通知而修改本手册的权利。

西门子电气传动有限公司

Page 4

版本 12/02 前 言

前 言

用户文件

警 告

!

纽伦堡技术支持部

在安装和调试变频器之前,请您务必阅读以下完全规则和警告,以及设备上粘贴的所有警示标志。

确保警示标志置于醒目的地方,并更换已脱落或损坏的标志。

由以下各处得到的信息也是有效的:

电话: +49

传真: +49

Email: techsupport@ad.siemens.de

星期一至星期五:上午 7:00 至下午 5:00(当地时间)

西门子(中国)有限公司技术支持部

电话: 010-64738566

传真: 010-64719783 64731096

Email: adcs@pek1.siemens.com.cn

互联网地址:

用户可以在以下网址查到技术资料和一般信息:

http://www.siemens.de/micromaster

联系地址:

如果您在阅读本手册时有什么疑问或遇到任何问题,请根据手册附录中提供的地址,与有关的西门

子办事处联系。

(0) 180 5050 222

(0) 180 5050 223

MICROMASTER 430 使用说明书 0-1

6SE6400-5AE00-0MP0

Page 5

报警信息及其含义 版本 12/02

报警信息及其含义

危 险

!

!

!

本手册以及变频器上带有“警示标志”的“危险”是指:如果不遵守有关要求,不采取相应措施,

就会造成死亡或严重的人身伤害。

警 告

本手册以及变频器上带有“警示标志”的“警告”是指:如果不遵守有关要求,不采取相应措施,

就存在造成死亡或严重人身伤害的潜在危险。

注 意

本手册以及变频器上带有“警示标志”的“注意”是指:如果不遵守有关要求,不采取相应措施,

就存在导致轻度或中度人身伤害的潜在危险。

注 意

本手册以及变频器上不带“警示标志”的“注意”是指:如果不遵守有关要求,不采取相应措施,

就存在导致财产损失的潜在危险。

提 示

本手册中的“提示”是指:如果使用者对提示的问题不加注意,就可能出现不希望的结果或状态。

说 明

本手册中的“说明”指出有关产品的重要信息,或者强调手册中需要特别加以注意的问题。

经过认证的人员

本手册以及变频器的标志上所谓“经过认证的人员”是指:在本设备上进行工作的人员必须熟悉设

备的安装、调试和投入运行的步骤和要求,以及可能出现的各种紧急情况。

他(她)们还必须具备下列条件:

1. 受过专门培训并考试合格,能够按照常规和本手册规定的安全操作步骤的要求对电路和设备进

行上电、断电、清扫、接地和线路连接等各种操作。

2. 受过培训,能够按照常规和本手册规定的安全操作步骤的要求正确进行保护设备的维护和使用。

3. 受过急救方面的培训。

PE

=Ground

只能用于指定的应用领域

¾ PE - 通过接地导体的保护性接地,接地导体的截面大小应能保证在短路情况下接地点的电压

不超过 50 伏。通常,该点用于变频器的接地。

¾

本变频器只能用于手册中指明的应用领域,而且只能与西门子公司推荐和认可的器件和部件一起使用。

-

接地点,其参考电压可达到与地电压相同的值。通常,该点用于电动机的接地。

0-2 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 6

版本 12/02 安全指导

安全指导

以下的“警告”、“注意”和“说明”是为了您的安全而提出的,是防止设备或与其连接的部件受到

损伤而采取的一项措施。在处理 MICROMASTER 430 变频器的相关事项时,通常都要涉及本节中

列出的“警告”、“注意”和“说明”,它们分为以下几类:常规的、有关运输和存放、调试、操作、

维修以及拆卸和废品处理的。

特殊的“警告”、“注意”和“说明”:适用于特殊的操作,放在有关章节的开头,并在该章节需要

的地方再加以重复或补充。

请仔细阅读这些“警告”、“注意”和“说明”,因为它们为您提供了人身完全的保障,并且有助于

延长 MICROMASTER 430 变频器以及与之连接的设备的使用寿命。

常规的

警 告

!

¾ 本设备带有危险电压,而且它所控制的是带有危险电压的转动机件。如果不遵守“警告”的

规定,或不按本手册的要求进行操作,就可能会造成死亡,严重的人身伤害或重大的财产损

失。

¾ 只有经过认证合格的专业人员才允许操作本设备,并且在使用设备之前要熟悉本手册中所有

的安全说明和有关安装,操作和维护的规定。正确地进行搬运装卸,就位安装和操作维护,

是实现本设备安全和成功地投入运行的可靠保证。

¾ 注意触电的危险。即使电源已经切断,变频器的直流回路电容器上仍然带有危险电压。因此,

在电源关断 5 分钟以后才允许打开本设备。

¾ 以“马力”为单位的额定功率是根据西门子的 1LA 电动机给出的,而且仅仅是指导性的;它

们不一定与 UL 或 NEMA 以马力为单位的额定功率一致。

!

注 意

¾ 防止儿童和公众接触或接近本设备!

¾ 本设备只能按照制造商规定的用途来使用。未经授权的改装或使用非本设备制造商所出售或

推荐的零配件,可能导致火灾、触电和其它伤害。

提 示

¾ 请将本手册放在变频设备附近容易找到的地方,保证所有的使用人员都使用方便。

¾ 在处于运行状态的带电设备上进行测量或测试时,必须遵守安全法规 VBG4.0 的规定,特别

是其第§8 节关于“带电部件上工作时允许的安全距离”的规定。实际操作时,应该使用适当

的电子器具。

¾ 在安装和调试变频器之前,请您务必仔细阅读这些安全规则和警告,以及设备上粘贴的所有

警示标志。确保警示标志置于醒目的地方,并更换已经脱落或损坏的标志。

MICROMASTER 430 使用说明书 0-3

6SE6400-5AE00-0MP0

Page 7

安全指导 版本 12/02

有关运输和存放的

警 告

!

有关调试的

¾ 正确的运输、存放、就位和安装,以及细心地操作和维护,对于变频器的正常和安全运行是

至关重要的。

注 意

¾ 在运输和存放期间要保证变频器不致遭受物理性的冲击和振动。也必须保证它不受雨淋和不

放在环境温度过高的地方

警 告

(参看本手册的表 7-1)

。

!

!

¾ 未经培训合格的人员在变频器的器件/系统上工作或不遵守“警告”中的有关规定,就可能造

成严重的人身伤害或重大的财产损失。只有在设备的设计、安装、调试和运行方面受过培训

的经过认证合格的专业人员才允许在本设备的器件/系统上进行工作。

¾ 输入电源线只允许永久性紧固连接。设备必须接地(按照 IEC 536 Class 1、NEC 和其它适用

的标准)。

¾ 如果采用剩余电流保护器(RCD),必须是 B 型 RCD。设备由三相电源供电,并装有 EMC 滤

波器时,一定不要通过接地泄漏断路器 ELCB 与电源连接(Earth Leakage Cirouit-Breaker-

参看 DIN VDE 0160 标准,第 5.5.2 节和 EN 50178 第 5.2.11.1 节)

¾ 即使变频器处于不工作状态,以下端子仍然可能带有危险电压:

- 电源端子 L/L1,N/L2,L3 或 U1/L1,V1/L2,W1/L3。

- 连接电动机的端子 U,V,W 或 U2/T1,V2/T2,W2/T3。

- 取决于框架尺寸,端子 DC+/B+,DC-,B-,DC/R+或 C/L+,D/L-

¾ 本设备不可作为‘紧急停车机构’使用

注 意

与变频器连接的电源电缆、电动机电缆和控制电缆都必须按照本手册的图 2-13 所示的方式进行连

接,以避免由于变频器工作所造成的感性和容性干扰。

(参看 EN 60204,9.2.5.4)

。

。

0-4 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 8

版本 12/02 安全指导

有关运行的

警 告

!

有关维修的

!

¾ MICROMASTER 变频器是在高电压下运行。

¾ 电气设备运行时,设备的某些部件上不可避免地存在危险电压。

¾ 按照 EN 60204 IEC 204(VDE 0113)的要求,“紧急停车设备”必须在控制设备的所有工作方

式下都保持可控性。无论紧急停车设备是如何停止运转的,都不能导致不可控的或者未曾预

料的再次启动。

¾ 无论故障出现在控制设备的什么地方都有可能导致重大的设备损坏,甚至是严重的人身伤害

(即存在潜在的危险故障),因此,还必须采取附加的外部预防措施或者另外装设用于确保安全

运行的装置,即使在故障出现时也应如此(例如,独立的限流开关,机械联锁等)。

¾ 在输入电源故障之后,一定的参数设置可能会造成变频器的自动再启动。

¾ 为了保证电动机的过载保护能够正确动作,输入变频器的电动机参数必须与实际使用的电动

机完全相符。

¾ 本设备可按照 UL508C 第 42 节的要求在变频器内部提供电动机过载保护功能。根据 P0610

和 P0335,I

参数 P0601 的缺省值来禁止)来实现。

¾ 在采用 H 或 K 型熔断器作为保护器件时

称容量不大于 10,000 安培(均方根值)的地方,最大电压为 460V。

¾ 本设备不可作为‘紧急停车机构’使用

警 告

¾ 设备的维修只能由西门子公司的服务部门,西门子公司授权的维修中心或经过认证合格并得

到授权的人员进行,这些人员应当十分熟悉本手册中提出的所有警告和操作步骤。

¾ 任何有缺陷的部件和器件都必须用相应的备件更换。

¾ 在打开设备进行维修之前,一定要断开电源。

2

t 保护功能是在缺省情况下投入。电动机的过载保护功能也可以采用外部 PTC(用

(参看本手册第 7 章的附表)

(参看 EN 60204,9.2.5.4)。

,本设备适合用于回路对

有关拆卸和废品处理的

注 意

¾ 变频器的包装箱是可以重复使用的。请保管好包装箱以备将来使用或把它返还给制造商。

¾ 易卸螺丝和快速插接器便于您拆卸设备的部件。您可以回收这些拆卸下来的部件,并根据地

方有关部门的要求进行处理,或把它们返还给制造商。

MICROMASTER 430 使用说明书 0-5

6SE6400-5AE00-0MP0

Page 9

安全指导 版本 12/02

0-6 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 10

版本 12/02 目 录

目 录

1 概 况········································································································································· 1-1

1.1 MICROMASTER 430 系列变频器············································································· 1-2

1.2 特 点 ··············································································································· 1-3

2 安 装········································································································································· 2-1

2.1 变频器在长期存放后的安装 ···················································································· 2-3

2.2 变频器运行的环境条件 ·························································································· 2-4

2.3 机械安装 ············································································································ 2-6

2.4 电气安装 ·········································································································· 2-12

3 调 试········································································································································· 3-1

3.1 方框图··············································································································· 3-3

3.2 调试方法 ············································································································ 3-5

3.3 常规操作 ·········································································································· 3-16

4 MICROMASTER 430 的功能 ····································································································· 4-1

4.1 频率给定值(P1000)······························································································ 4-2

4.2 命令源(P0700)···································································································· 4-3

4.3 停车(OFF)和制动功能 ··························································································· 4-3

4.4 控制方式(P1300)································································································· 4-5

4.5 MICROMASTER 430 变频器的操作方式···································································· 4-6

4.6 自由功能块(P2800 ff)························································································· 4-10

4.7 故障和报警 ······································································································· 4-10

5 系统参数 ·····································································································································5-1

5.1 MICROMASTER 系统参数的简要介绍 ······································································· 5-2

5.2 参数概览 ············································································································ 5-3

5.3 参数表(简略形式)································································································· 5-4

5.4 命令和传动数据组-概览 ······················································································ 5-17

6 故障的排除 ·································································································································6-1

6.1 利用状态显示板(SDP)排障 ····················································································· 6-2

6.2 利用基本操作面板(BOP-2)排障 ·············································································· 6-3

6.3 故障信息 ············································································································ 6-4

6.4 报警信息 ·········································································································· 6-10

7 MICROMASTER 430 的技术规格 ····························································································· 7-1

8 选 件········································································································································· 8-1

8.1 各种独立的选件 ··································································································· 8-1

MICROMASTER 430 使用说明书 0-7

6SE6400-5AE00-0MP0

Page 11

目 录 版本 12/02

8.2 各种附属的选件 ··································································································· 8-1

9 电磁兼容性(EMC) ·······················································································································9-1

9.1 电磁兼容性(EMC) ································································································ 9-2

10 维 护······································································································································· 10-1

10.1 更换操作面板 ···································································································· 10-2

10.2 变频器前盖板的拆卸 ··························································································· 10-3

10.2.1 框架尺寸 C 变频器机壳前盖板的拆卸······································································ 10-3

10.2.2 框架尺寸 D 和 E 变频器机壳前盖板的拆卸 ······························································· 10-4

10.2.3 框架尺寸 F 变频器机壳前盖板的拆卸 ······································································ 10-5

10.2.4 框加尺寸 FX 和 GX 变频器机壳前盖板的拆卸···························································· 10-6

10.3 I/O 接口板的拆卸······························································································· 10-7

10.4 ‘Y’接电容器的拆卸 ························································································· 10-8

10.4.1 框架尺寸 C 变频器中‘Y’接电容器的拆卸······························································ 10-8

10.4.2 框架尺寸 D 和 E 变频器中‘Y’接电容器的拆卸 ······················································· 10-9

10.4.3 框架尺寸 F 变频器中‘Y’接电容器的拆卸 ·····························································10-10

10.4.4 框架尺寸 FX 变频器中‘Y’接电容器的拆卸 ··························································· 10-11

10.4.5 框架尺寸 GX 变频器中‘Y’接电容器的拆卸 ···························································10-12

11 采用的标准和缩略语 ················································································································· 11-1

11.1 采用的标准 ······································································································· 11-2

11.2 缩略语············································································································· 11-3

附 录

0-8 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 12

版本 12/02 目 录

插 图

图 2-1 充 电 ················································································································2-3

图 2-2 变频器运行的环境温度 ···························································································2-4

图 2-3 变频器安装地点的海拔高度 ·····················································································2-4

图 2-4 MICROMASTER 430 变频器(框架尺寸 C 至 F)的安装尺寸 ·············································2-7

图 2-5 MICROMASTER 430 变频器(框架尺寸 FX)的安装尺寸 ··················································2-8

图 2-6 MICROMASTER 430 变频器(框架尺寸 GX)的安装尺寸··················································2-9

图 2-7 电子箱中的选件 ·································································································· 2-11

图 2-8 MICROMASTER 430 变频器的接线端子(框架尺寸 C 至 F) ···········································2-15

图 2-9 MICROMASTER 430 变频器的接线图(框架尺寸 FX) ···················································2-16

图 2-10 MICROMASTER 430 变频器的接线图(框架尺寸 GX)··················································· 2-17

图 2-11 电动机和电源的接线方法 ······················································································ 2-18

图 2-12 冷却风机电源电压的匹配 ······················································································ 2-19

图 2-13 把电磁干扰(EMI)的影响降到最小的布线方法 ····························································· 2-21

图 3-1 变频器方框图 ·······································································································3-3

图 3-2 模拟量输入作为数字量输入使用 ···············································································3-4

图 3-3 MICROMASTER 430 变频器的操作面板·····································································3-5

图 3-4 DIP 开关 ·············································································································3-5

图 3-5 用 SDP 进行基本操作·····························································································3-7

图 3-6 基本操作面板(BOP-2)上的按钮 ············································································· 3-10

图 3-7 用 BOP-2 修改参数····························································································· 3-11

图 3-8 典型的电动机铭牌数据举例(在铭牌上列出的详细数据仅为实例) ····································3-15

图 3-9 电动机的过热保护 ······························································································· 3-17

图 4-1 旁路电路 ·············································································································4-6

图 4-2 传动皮带故障的检测 ······························································································4-7

图 4-3 电动机的分级控制 ·································································································4-8

图 4-4 节能方式 ·············································································································4-9

图 5-1 参数概览 ·············································································································5-3

MICROMASTER 430 使用说明书 0-9

6SE6400-5AE00-0MP0

Page 13

目 录 版本 12/02

表 格

表 2-1 MICROMASTER 430 变频器的外形尺寸和拧紧力矩···················································· 2-10

表 3-1 用 SDP 操作时的缺省设置值····················································································3-6

表 3-2 用 BOP-2 操作时的缺省设置值 ················································································3-9

表 7-1 MICROMASTER 430 变频器综合技术数据··································································7-2

表 7-2 电源端子的拧紧力矩 ······························································································7-3

表 7-3 随着脉冲频率的增加,变频器输出电流降低 ································································7-3

表 7-4 MICROMASTER 430 变频器的技术规格·····································································7-4

表 9-1 通用工业型产品(变频器不带滤波器,外接有相应的电源滤波器) ······································9-3

表 9-2 具有滤波器的工业型产品 ························································································9-4

表 9-3 适用于居民区、商业和轻工业的带有滤波器的产品 ·······················································9-5

表 9-4 产品型号表 ··········································································································9-6

0-10 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 14

版本 12/02 概 况

1 概 况

本章的内容有:

MICROMASTER 430 系列变频器的主要特点。

1.1 MICROMASTER 430 系列变频器··············································································1-2

1.2 特 点 ················································································································1-3

MICROMASTER 430 使用说明书 1-1

6SE6400-5AE00-0MP0

Page 15

概 况 版本 12/02

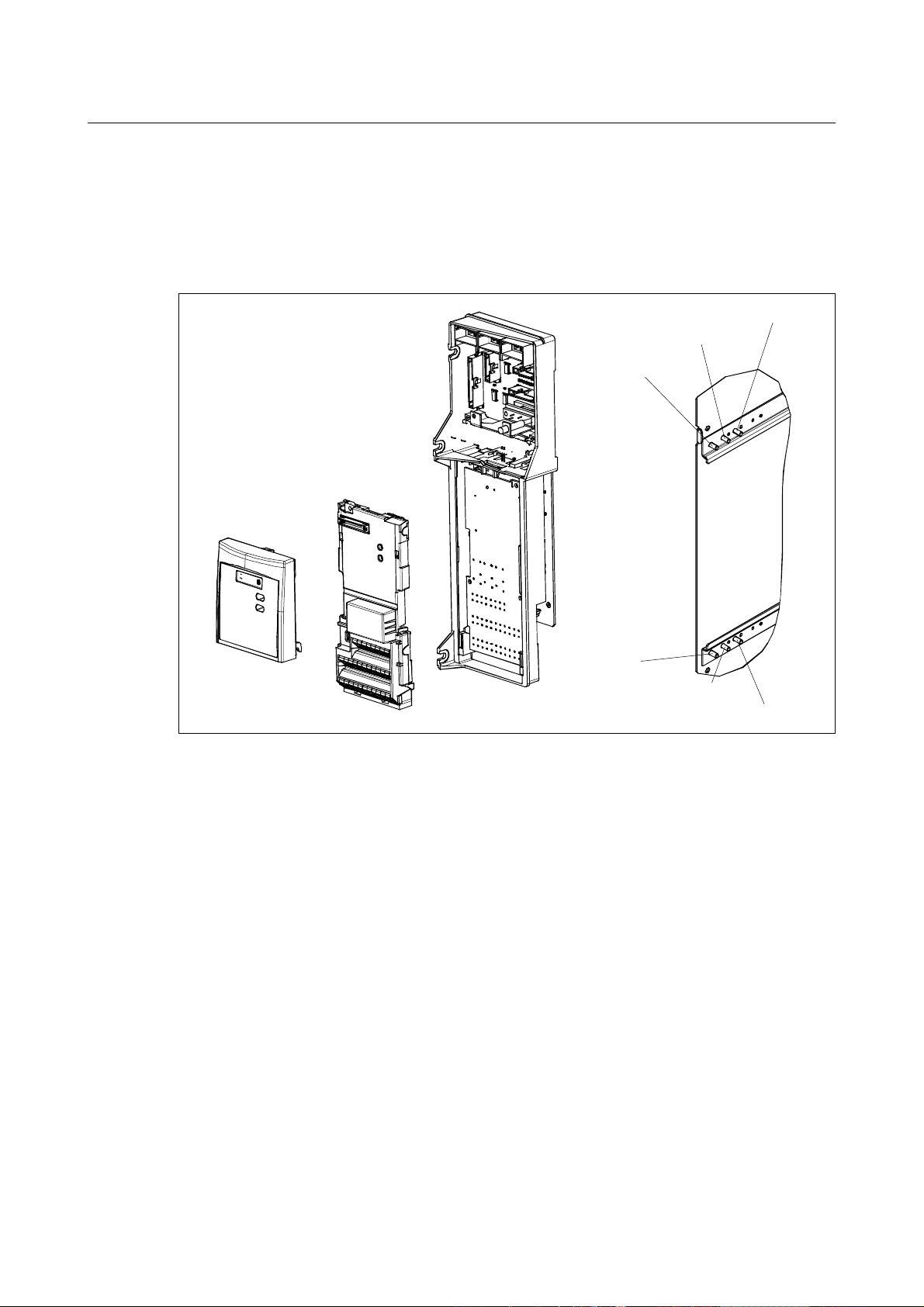

1.1 MICROMASTER 430 系列变频器

MICROMASTER 430 是用于控制三相交流电动机速度的变频器系列。本系列有多种型号,额定功

率范围从 7.5kW 到 250kW,可供用户选用。

在采用变频器的出厂设定功能和缺省设定值时,MICROMASTER 430 变频器特别适合用于水泵和

风机的驱动。

本变频器由微处理器控制,并采用具有现代先进技术水平的绝缘栅双极型晶体管(IGBT)作为功率

输出器件。因此,它们具有很高的运行可靠性和通用性。采用脉冲频率可选的专用脉宽调制方法,

可使电动机低噪声运行。全面而完善的保护功能为变频器和电动机提供了良好的保护。

1-2 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 16

版本 12/02 概 况

1.2 特 点

主要特性

¾ 易于安装

¾ 易于调试

¾ 牢固的 EMC 设计

¾ 可由 IT 电源供电

¾ 对控制信号的快速实时响应

¾ 参数设置的范围很广,确保它可对广泛的应用对象进行配置

¾ 电缆连接简便

¾ 具有多个继电器输出

¾ 具有多个模拟量输出(0~20mA)

¾ 6 个带隔离的数字输入,并可在 NPN 与 PNP 模式间切换

¾ 2 个模拟输入:

♦ AIN1:0~10V,0~20mA 和-10~+10V

♦ AIN2:0~10V,0~20mA

¾ 2 个模拟输入可以作为第 7 和第 8 个数字输入

¾ BiCo 技术

¾ 模块化设计,配置非常灵活

¾ 开关频率高,因而电动机运行的噪声低

¾ 详细的变频器状态信息和全面的信息功能

¾ 有多种选件供用户选用:用于与 PC 通讯的通讯模块,基本操作面板(BOP-2)和用于进行现场

总线通讯的 PROFIBUS 模块

¾ 用于水泵和风机控制时的特点:

♦ 电动机的分级控制(通过输出继电器控制辅助传动系统)

♦ 节能控制方式

♦ 手动/自动控制(手动操作/自动操作)

♦ 传动皮带故障的检测(对水泵无水空转的检测)

♦ 旁路

MICROMASTER 430 使用说明书 1-3

6SE6400-5AE00-0MP0

Page 17

概 况 版本 12/02

性能特征

¾ V/f 控制

♦ 带磁通电流控制(FCC)的线性 V/f 控制,改善了动态响应和电动机的控制特性

♦ 多点 V/f 控制特性

¾ 快速电流限幅(FCL)功能,避免运行中不应有的跳闸

¾ 内置的直流注入制动功能

¾ 复合制动功能改善了制动特性

¾ 斜坡函数发生器

♦ 带平波

♦ 不带平波

¾ 工艺调节器(PID)

¾ 参数组的切换

♦ 电动机数据组(DDS)

♦ 命令数据组和给定值信号源(CDS)

¾ 可变转矩(VT)运行时的特性

¾ 自由功能块

保护特性

¾ 过电压/欠电压保护

¾ 变频器过热保护

¾ 接地故障保护

¾ 短路保护

2

¾ 电动机 I

t 过热保护

¾ PTC/KTY 电动机保护

1-4 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 18

版本 12/02 安 装

2 安 装

本章的内容有:

¾ 有关安装的一般数据

¾ 变频器的外形尺寸

¾ 最大限度地降低电磁干扰影响的布线原则

¾ 关于电气安装的细节

2.1 变频器在长期存放后的安装 ·····················································································2-3

2.2 变频器运行的环境条件 ···························································································2-4

2.3 机械安装 ·············································································································2-6

2.4 电气安装 ···········································································································2-12

MICROMASTER 430 使用说明书 2-1

6SE6400-5AE00-0MP0

Page 19

安 装 版本 12/02

警 告

!

¾ 未经培训合格的人员在变频器的器件/系统上工作或不遵守“警告”中的有关规定,就可能造

成严重的人身伤害或重大的财产损失。只有在设备的设计、安装、调试和运行方面受过培训

的经过认证合格的专业人员才允许在本设备的器件/系统上进行工作。

¾ 输入电源线只允许永久性紧固连接。设备必须接地(按照 IEC 536 Class 1,NEC 和其它适用

的标准)。

¾ 如果采用剩余电流保护器(RCD),必须是 B 型 RCD。设备由三相电源供电,而且带有 EMC

滤波器时,一定不要通过接地泄漏断路器(ELCB)与电源连接(EN 50178 第 5.2.11.1 节)。

¾ 即使变频器处于不工作状态,以下端子仍然可能带有危险电压:

♦ 电源端子 L/L1,N/L2,L3 或 U1/L1,V1/L2,W1/L3。

♦ 连接电动机的端子 U,V,W 或 U2/T1,V2/T2,W2/T3。

♦ 取决于框架尺寸,端子 CD+/B+,DC-,B-,DC/R+或 C/L+,D/L-。

¾ 在电源开关断开以后,必须等待 5 分钟,使变频器放电完毕,才允许开始安装作业。

¾ 本设备不可作为“紧急停车机构”使用

¾ 接地导体的最小截面积必须等于或大于供电电源电缆的截面积。

注 意

连接到变频器的供电电源电缆、电动机电缆和控制电缆必须按照下面图 2-13 所示的方式进行连

接,避免由于变频器工作所造成的感性和容性干扰。

(参看 EN 60204,9.2.5.4)

。

2-2 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 20

版本 12/02 安 装

2.1 变频器在长期存放后的安装

变频器在长期存放以后进行使用时,必须对其内的电容器重新进行充电。要求如下表所示:

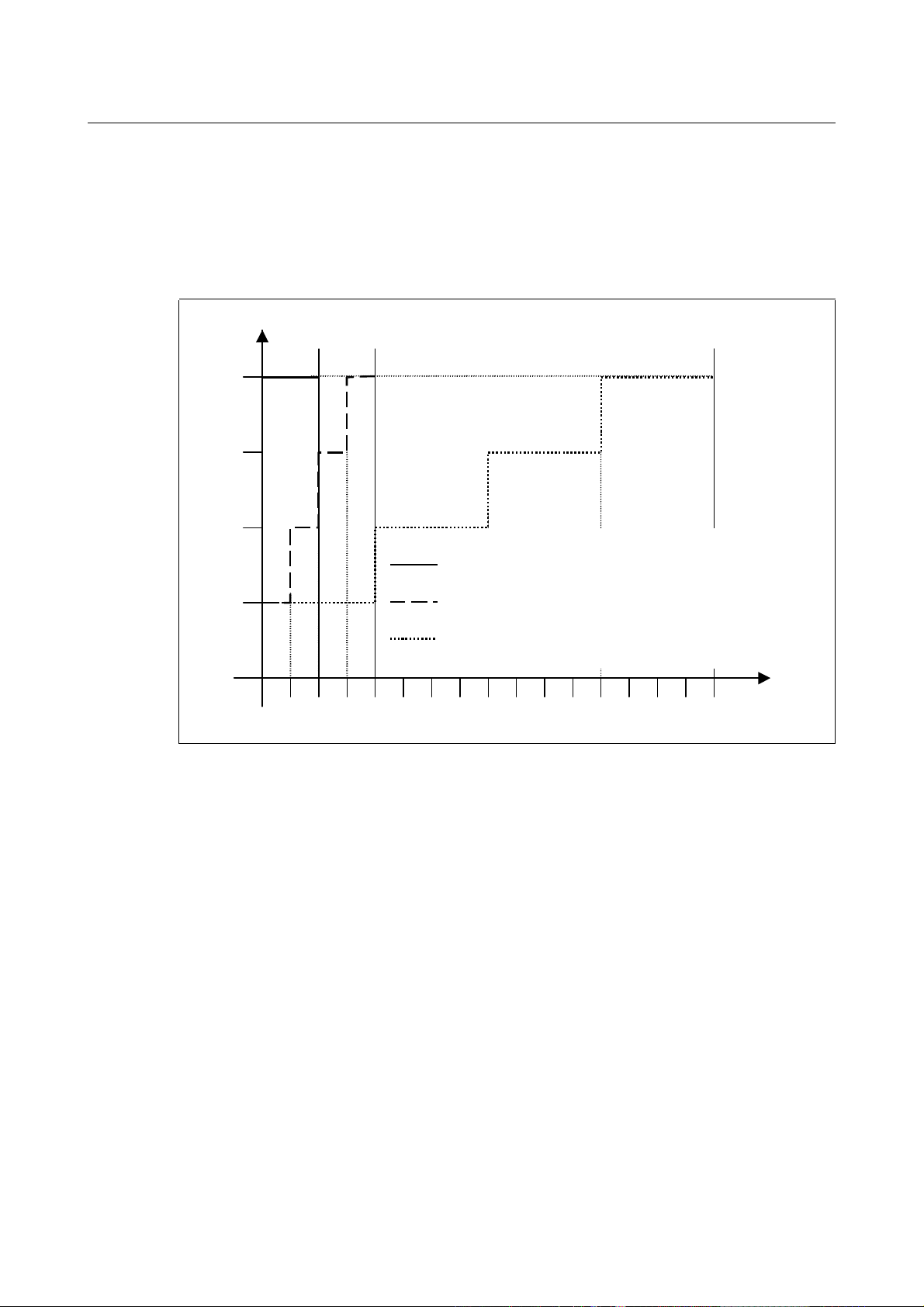

框架尺寸 C 至 F 的变频器:

电压

[%]

100

75

50

0,5 1

图 2-1 充电

框架尺寸 FX 和 GX 的变频器:

变频器在长期存放以后进行使用时,必须在空载情况下施加 85%额定输入电源电压至少 30 分钟,

对其内的电容器重新充电。

存放时间不超过1年无需处理

存放时间为1至2年投运之前,预加电压1小时

存放时间为2至3年

存放时间为3年或3年以上

24 6 8

投运之前,按照曲线充电

投运之前,按照曲线充电

时间t[h]

MICROMASTER 430 使用说明书 2-3

6SE6400-5AE00-0MP0

Page 21

安 装 版本 12/02

2.2 变频器运行的环境条件

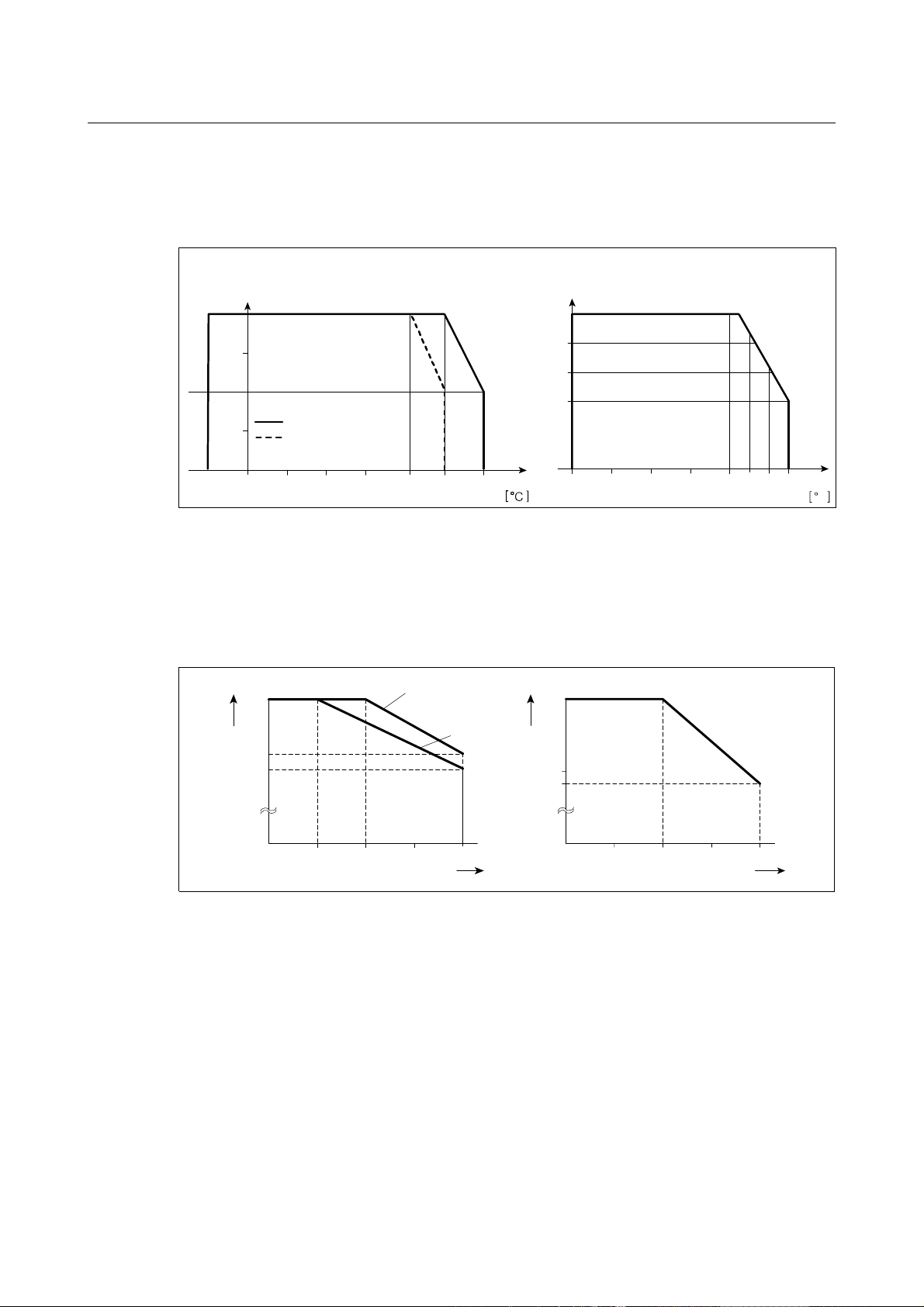

温 度

湿度范围

海拔高度

框架尺寸G至F

允许的输出电流

[%]

100

75

50

25

0203010 40 50 60-10

恒转矩

变转矩

运行环境温度

框架尺寸FX至GX

允许的输出电流

[%]

100

95

90

85

10 20 30

40 50 55

运行环境温度

C

图 2-2 变频器运行的环境温度

空气的相对湿度≤95%,无凝露。

如果变频器安装在海拔高度>1000m 或>2000m,其输出电流和输入电源电压需降额使用,如下图

所示:

允许的输出电流 允许的输出电流

100

%

85

80

框架尺寸

FX和GX

框架尺寸

C至F

100

%

80

77

0 1000 3000 4000

2000

安装地点的海拔高度(m) 安装地点的海拔高度 (m)

01 000 2000 3000 4000

图 2-3 变频器安装地点的海拔高度

冲击和振动

不允许变频器掉到地下或遭受突然的的撞击。不允许把变频器安装在有可能经常受到振动的地方。

DIN IEC 68-2-6 规定的机械强度如下:

¾ 位移: 0.075mm(10...58Hz)

2

¾ 加速度: 9.8m/s

(> 58…500Hz)

2-4 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 22

版本 12/02 安 装

电磁辐射

不允许把变频器安装在接近电磁辐射源的地方。

大气污染

不允许把变频器安装在存在大气污染的环境中,例如,存在灰尘、腐蚀性气体等的环境中。

水

变频器的安装位置切记要远离有可能出现淋水的地方。例如,不要把变频器安装在水管的下面,因

为水管的表面有可能结露。禁止把变频器安装在湿度过大和有可能出现凝露的地方。

安装和冷却

注 意

变频器不允许卧式安装(水平位置)。

变频器可以一个挨一个地并排安装,中间不需要空隙。

当一台变频器安装在另一台变频器之上时,不能超出规定的环境条件。

无论如何,它们之间必须保证留有以下规定的最小间隙:

¾ 框架尺寸 C: 上部和下部 100mm

¾ 框架尺寸 D,E 上部和下部 300mm

¾ 框架尺寸 F 上部和下部 350mm

¾ 框架尺寸 FX,GX 上部 250mm

下部 150mm

前面 100mm

在变频器附近不要安装有对冷却空气流通造成负面影响的其他设备,确认变频器的冷却风口处于正

确的位置,不妨碍空气的流通。

MICROMASTER 430 使用说明书 2-5

6SE6400-5AE00-0MP0

Page 23

安 装 版本 12/02

2.3 机械安装

警 告

!

从运输托盘上卸下变频器(仅指框架尺寸为 FX 和 GX 的变频器)

¾ 为了保证变频器的安全运行,必须由经过认证合格的人员进行安装和调试,这些人员应完全

了解本使用说明书中提到的警告。

¾ 要特别注意遵守关于在危险电压设备上工作的常规和地方性安装和安全导则(例如,EN

50178),而且要遵守有关正确使用工具和人身防护装置(PPE)的规定。

¾ 即使变频器不处于运行状态,其电源输入线,直流回路端子和电动机端子上仍然可能带有危

险电压。因此,断开开关以后还必须等待 5 分钟,保证变频器放电完毕,再开始安装工作。

¾ 变频器可以一个挨一个地并排安装,中间不需要空隙。当一台变频器安装在另一台变频器之

上时,必须保证不超过规定的环境条件。无论如何它们之间要留有下面规定的最小间隙:

♦ 框架尺寸为 C 时 上部和下部 100mm

♦ 框架尺寸为 D,E 时 上部和下部 300mm

♦ 框架尺寸为 F 时 上部和下部 350mm

♦ 框架尺寸 FX 和 GX 时 上部 250mm

下部 150mm

前面 100mm

¾ 如果卸下了前面的盖板(仅指框架尺寸为 FX 和 GX 的变频器),风机的叶片便显露出来。当风

机正在转动时,存在着造成人身伤害的危险。

!

运输过程中,是用两个铁质固定卡件将变频器固定在运输托盘上。

警 告

注意,变频器的重心不在它的中部,因此,在起吊运输托盘时,设备有可能突然改变位置,并倒向

一侧。

1. 将吊车的起吊钢缆与变频器上的 2 个起吊环结牢(框架尺寸为 FX 的变频器(图 2-9),框架尺寸

为 GX 的变频器(图 2-10))。

2. 将前盖板顶部的两个紧固螺栓卸下。

3. 拧松运输托盘上铁质固定卡件的螺栓,将变频器吊离运输托盘。

4. 在安装工作结束并接线完毕以后,将前盖板的两个紧固螺栓固定在门的底部。

2-6 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 24

版本 12/02 安 装

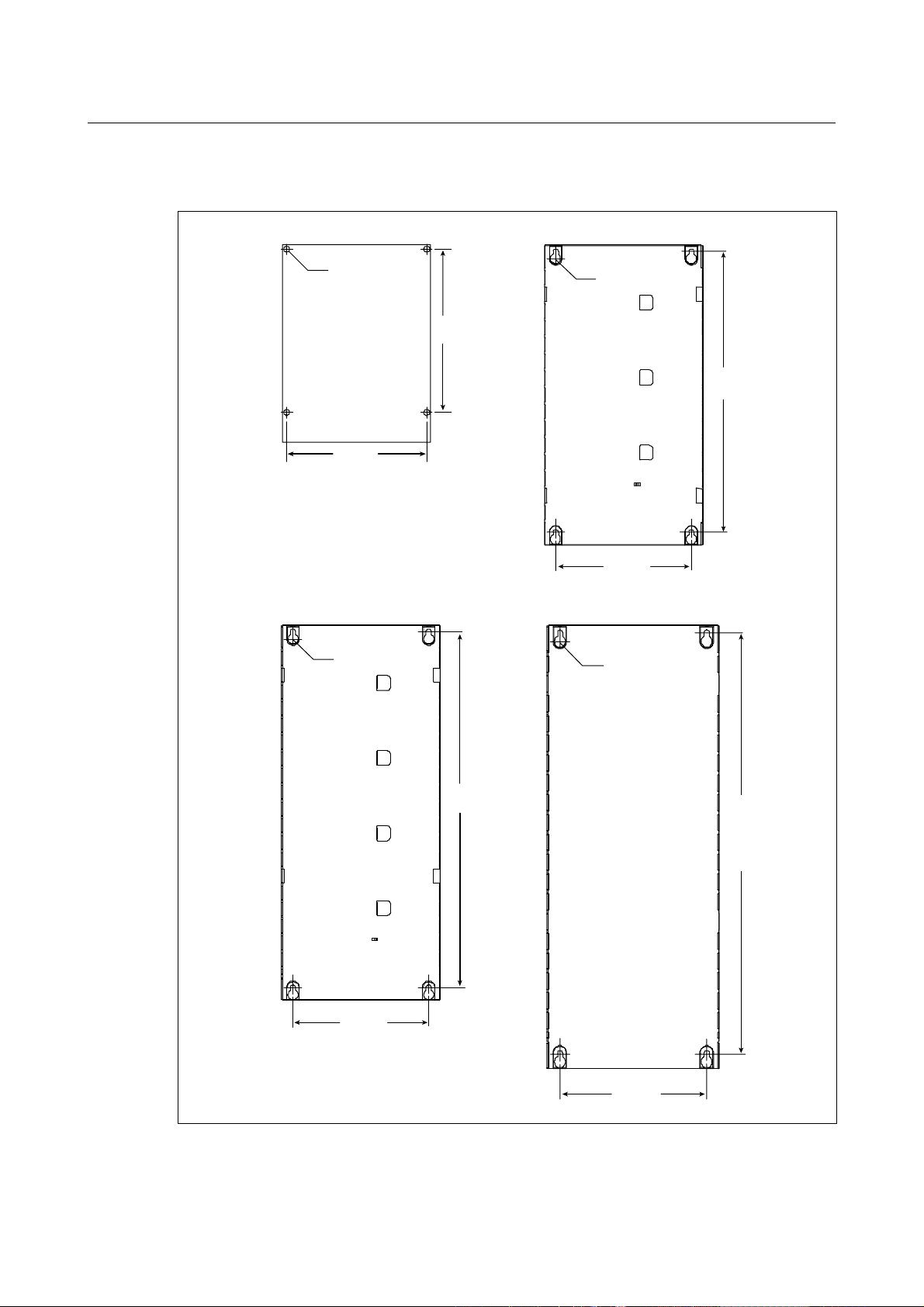

框架尺寸 C 至 F

框架尺寸C 框架尺寸D

5.5 mm

Ø

0.22"

174 mm

6.85"

204 mm

8.03"

Ø

17.5 mm

0.68"

486 mm

19.13"

235 mm

9.25"

框架尺寸E 框架尺寸F

17.5 mm

Ø

0.68"

616.4 mm

24.27"

15 mm

Ø

0.59"

810 mm

31.89"

带滤波器

时高度为

1110 mm

43.70"

235 mm

9.25"

300 mm

11.81"

图 2-4 MICROMASTER 430 变频器(框架尺寸 C 至 F)的安装尺寸

MICROMASTER 430 使用说明书 2-7

6SE6400-5AE00-0MP0

Page 25

安 装 版本 12/02

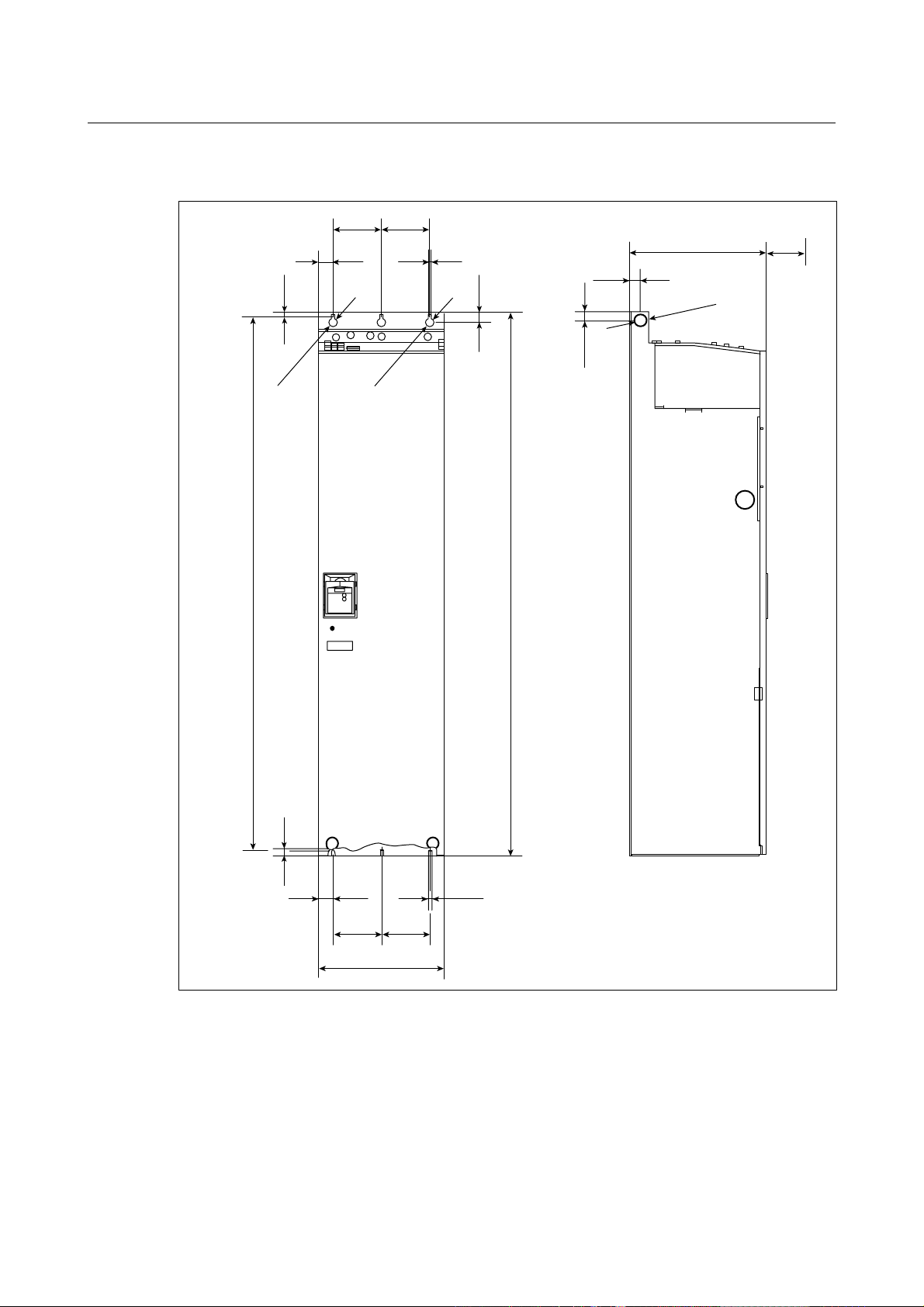

框架尺寸 FX

125125

+2

37

9

356

100

30

12

PE

0

2

Ø

0

2

Ø

1375.5

28

+2

1400

23

0

3

Ø

17

37

9.2

125 125

+2

326

图 2-5 MICROMASTER 430 变频器(框架尺寸 FX)的安装尺寸

2-8 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 26

版本 12/02 安 装

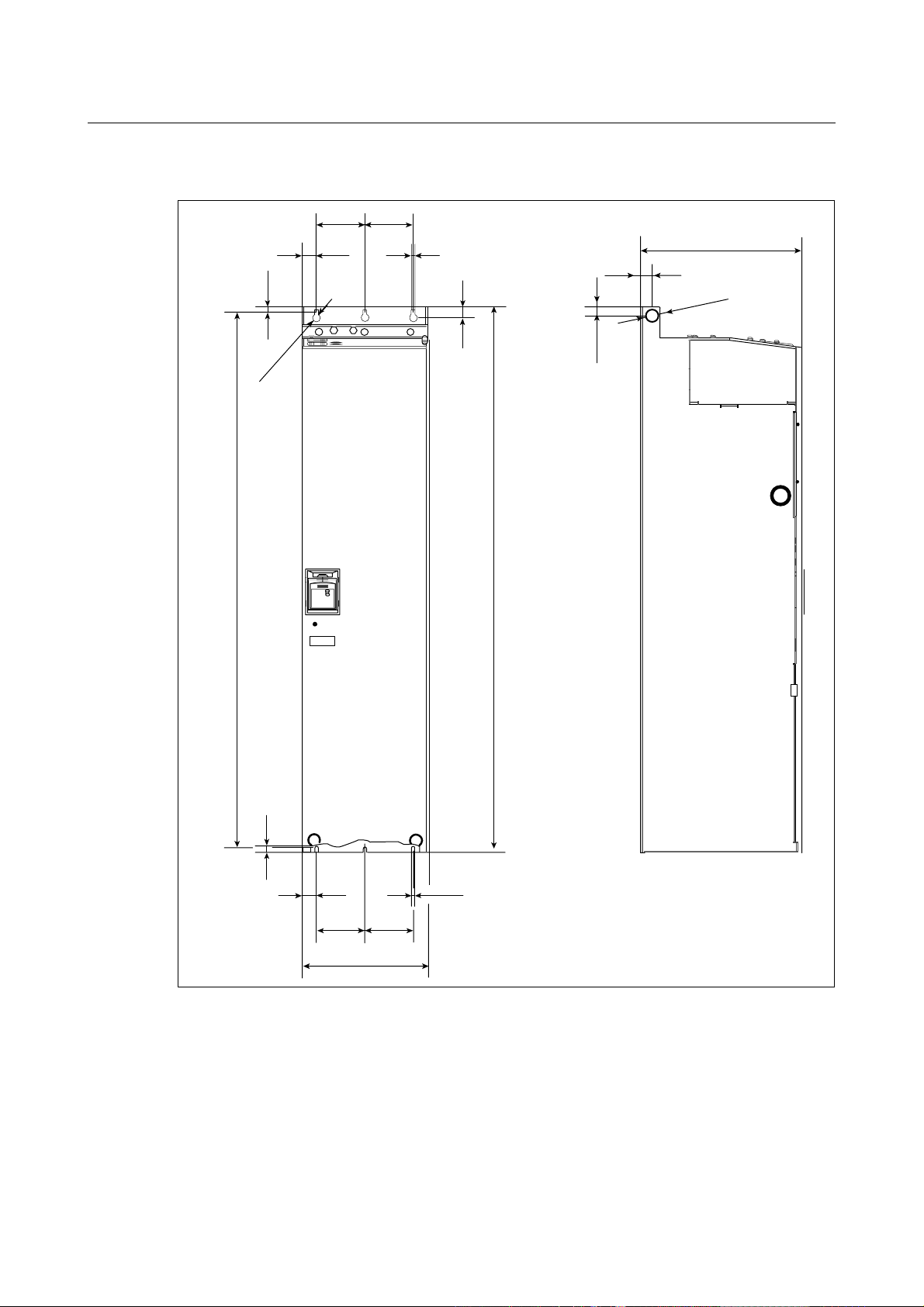

框架尺寸 GX

1508.5

12

Ø

125

37

125

+2

9

545

25

28

PE

0

2

+2

25

8

2

Ø

1533

17

37

125

326

125

+2

9

图 2-6 MICROMASTER 430 变频器(框架尺寸 GX)的安装尺寸

MICROMASTER 430 使用说明书 2-9

6SE6400-5AE00-0MP0

Page 27

安 装 版本 12/02

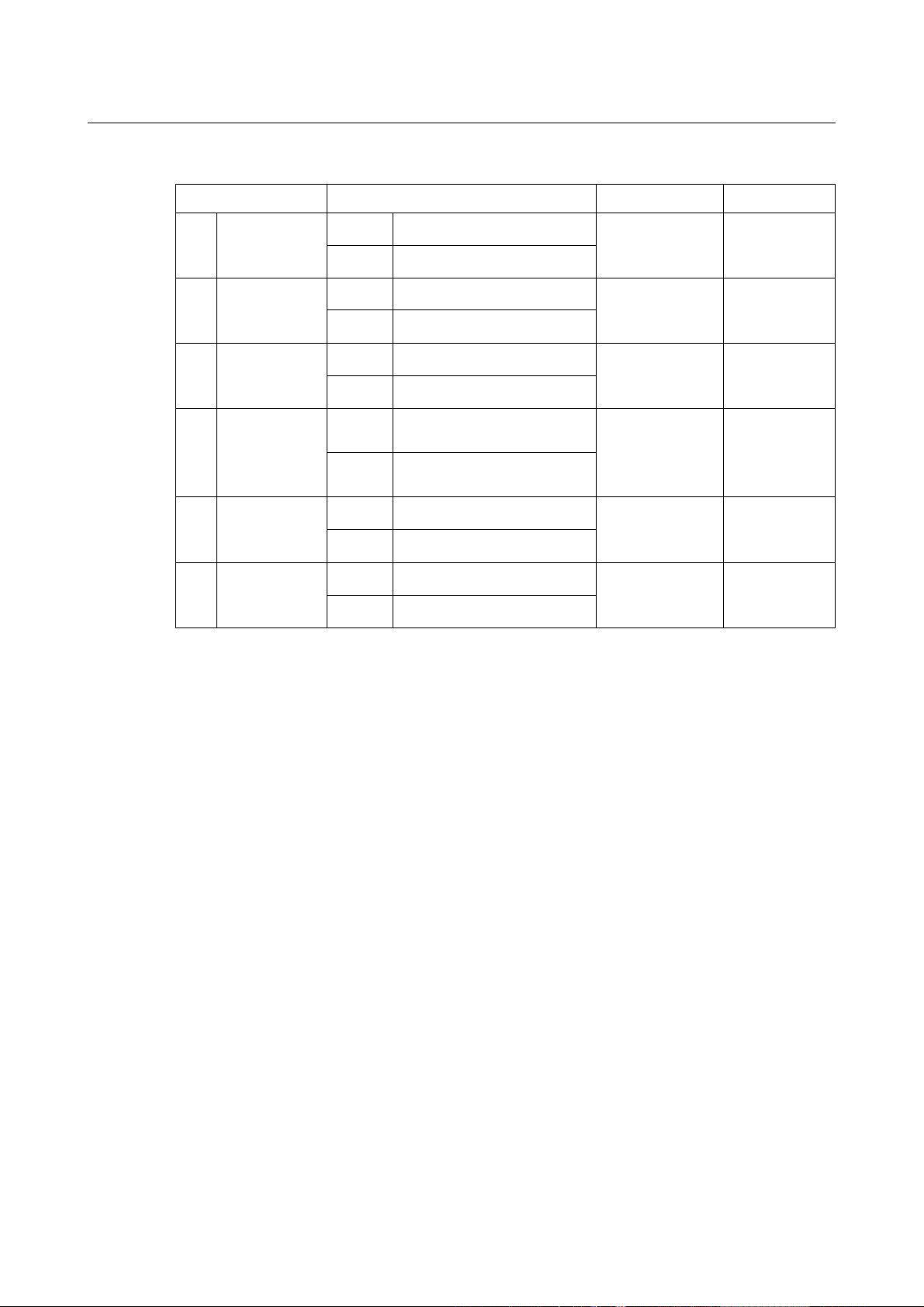

表 2-1 MICROMASTER 430 变频器的外形尺寸和拧紧力矩

框架尺寸 外形尺寸 固定的方法 拧紧力矩

4×M5 螺栓

4×M5 螺母

4×M5 垫圈

4×M8 螺栓

4×M8 螺母

4×M8 垫圈

4×M8 螺栓

4×M8 螺母

4×M8 垫圈

4×M8 螺栓

4×M8 螺母

4×M8 垫圈

6M8 螺栓

6M8 螺母

6M8 垫圈

6M8 螺栓

6M8 螺母

6M8 垫圈

2.5Nm

装垫圈时

3.0Nm

装垫圈时

3.0Nm

装垫圈时

3.0Nm

装垫圈时

13Nm+30%

装垫圈时

13Nm+30%

装垫圈时

C

D

E

F

FX

GX

宽×高×深

宽×高×深

宽×高×深

宽×高×深

宽×高×深

宽×高×深

mm

inch

mm

inch

mm

inch

mm

inch

mm

inch

mm

inch

185×245×195

7.28×9.65×7.68

275×520×245

10.82×20.47×9.65

275×650×245

10.82×25.59×9.65

350×850mm×320

带滤波器时高度为 1150

13.78×33.46×1260

带滤波器时高度为 45.28

326×1400×356

12,80×55,12×12,83

326×1533×545

12,80×60,35×21,46

2-10 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 28

版本 12/02 安 装

2.3.1 电子箱中选件的安装,框架尺寸 FX 和 GX

MICROMASTER 430 变频器前盖板的结构设计是使控制模板(通常是 SDP)几乎与前盖板的开缝同

在一个平面上。

如果电子箱中要安装的选件不止一个,则整个电子箱需靠近后部安装。

安装位置2

安装位置1

标准安装位置

选件的安装

标准安装位置

安装位置1

安装位置2

图 2-7 电子箱中的选件

¾ 卸掉前盖板:

z 拧松前盖板底部的两个螺丝。

z 先向上推然后移走前盖板。

¾ 卸掉电子箱的紧固螺丝。

¾ 如图 2-7 所示,在正确的安装位置用螺丝固定电子箱。

¾ 安装附加的选件。

¾ 重新装上前盖板。

MICROMASTER 430 使用说明书 2-11

6SE6400-5AE00-0MP0

Page 29

安 装 版本 12/02

2.4 电气安装

警 告

!

¾ 变频器必须接地。

¾ 为了保证变频器的安全运行,必须由经过认证合格的人员进行安装和调试,这些人员应完全

了解本使用说明书中提到的警告。

¾ 要特别注意遵守关于在危险电压设备上工作的常规和地方性安装和安全导则(例如,EN

50178),而且要遵守有关正确使用工具和人身防护装置的规定。

¾ 禁止在与变频器连接的电缆上使用高压绝缘测试设备。

¾ 即使变频器不处于运行状态,其电源输入线、直流回路端子和电动机端子上仍然可能带有危

险电压。因此,断开开关以后还必须等待 5 分钟,保证变频器放电完毕,再开始安装工作。

¾ 如果卸下了前面的盖板(仅指框架尺寸为 FX 和 GX 的变频器),风机的叶片便显露出来。当风

机正在转动时存在着造成人身伤害的危险。

注 意

变频器的控制电缆、电源电缆和与电动机的连接电缆的走线必须相互隔离。不要把它们放在同一个

电缆线槽中或电缆架上。

2-12 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 30

版本 12/02 安 装

2.4.1 概 述

警 告

!

不接地电源(IT)供电时变频器的运行

具有剩余电流保护器(RCD)时变频器的运行(框架尺寸 C 至 F)

变频器必须可靠接地。如果不把变频器可靠地接地,装置内可能出现导致人身伤害的潜在危险。

MICROMASTER 4 变频器不允许使用在 IT 电源上。

对于不接地电源,需要从变频器中拆掉‘Y’形接线的电容器。拆卸电容器的操作步骤在 10.4 节

中介绍。

当由不接地电源供电时,如果输入线中有一相接地,MICROMASTER 变频器仍可继续运行。如果

输出有一相接地,MICROMASTER 变频器将跳闸,并显示故障码 F0001。

如果安装了剩余电流保护器 RCD(也称为 ELCB 或 RCCB),您将不会再为 MICROMASTER 变频器

运行中不应有的跳闸而烦恼,但要求:

¾ 采用 B 型 RCD。

¾ RCD 的跳闸限值是 300mA。

¾ 供电电源的中性点接地。

¾ 每台 RCD 只为一台变频器供电。

¾ 输出电缆的长度不超过 50m(屏蔽的)或 100m(不带屏蔽的)。

使用长电缆时的运行

电缆长度不超过以下数值时,所有型号的变频器都将按照技术规格运行:

框架尺寸 C 至 F

¾ 带屏蔽的: 50m

¾ 不带屏蔽的: 100m

框架尺寸 FX 和 GX

¾ 带屏蔽的: 100m

¾ 不带屏蔽的: 150m

如果采用产品样本 DA51.2 中指定的输出电抗器时,所有框架尺寸的 MM430 变频器都可以采用以

下电缆长度:

¾ 带屏蔽的: 200m

¾ 不带屏蔽的: 300m

MICROMASTER 430 使用说明书 2-13

6SE6400-5AE00-0MP0

Page 31

安 装 版本 12/02

2.4.2 电源和电动机的连接

警 告

!

!

电源和电动机端子的接线和拆卸

变频器必须接地。

¾ 在变频器与电源线连接或更换变频器的电源线之前,应断开主电源。

¾ 连接同步电动机或并联连接几台电动机时,变频器必须在 V/f 控制特性下(P1300 = 0,2 或

3)运行。

注 意

电源电缆和电动机电缆与变频器相应的接线端子连接好以后,在接通电源时必须确信变频器的前盖

已经盖好!

提 示

¾ 确信供电电源与变频器之间已经正确接入与其额定电流相应的断路器/熔断器

7 章的表格)

¾ 连接线只能使用 1 级 60/75°C 的铜线(符合 UL 的规定)。电源接线端子的拧紧力矩请查阅后

面的表 7-2。

在拆下前盖板以后(见图 2-8 至图 2-10),可以拆卸和连接 MICROMASTER 430 变频器与电源和

电动机接线端子(参看 10.2 节)。

当变频器的前盖板已经打开并露出接线端子以后,电源和电动机端子的接线方法如图 2-11 所示。

。

(请参看后面第

2-14 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 32

版本 12/02 安 装

框架尺寸C

框架尺寸D和E

框架尺寸F

图 2-8 MICROMASTER 430 变频器的接线端子(框架尺寸 C 至 F)

说 明

DC 接线端子仅限用于测试,不允许用户在这里进行操作控制。而且,也不允许在这里连接制动电

阻等器件。

MICROMASTER 430 使用说明书 2-15

6SE6400-5AE00-0MP0

Page 33

安 装 版本 12/02

吊孔

电源电缆屏蔽层

的接线端子PE

U1/L1,V1/L2,W1/L3的开孔

连接电源电缆端子

连接外部制动单元端子

C/L+D/L-的开孔

电源电缆

U1/L1,V1/L2,W1/L3相

Y形电容器 的接线端子

外部制动单元的连接端子

C/L+D/L-

上调整导轨

上支持螺丝

SDP状态显示板

电子箱

下调整导轨

下支持螺丝

风机螺丝

风机

控制电缆屏蔽层

的接线端子

风机熔断器

变压器适配

电动机电缆

U2/T1,V2/T2,W2/T3相

电动机电缆屏蔽层

的接线端子PE

图 2-9 MICROMASTER 430 变频器的接线图(框架尺寸 FX)

2-16 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 34

版本 12/02 安 装

吊孔

电源电缆屏蔽层

的接线端子PE

U1/L1,V1/L2,W1/L3的开孔

连接电源电缆端子

连接外部制动单元端子

C/L+,D/L-的开孔

电源电缆

U/L1,V1/L2,W1/L3相

Y形电容器的接线端子

外部制动单元的连接端子

C/L+,D/L-

上调整导轨

上支持螺丝

SDP状态显示板

电子箱

下调整导轨

下支持螺丝

风机螺丝

控制电缆屏蔽层

的接线端子

风机熔断器

变压器适配

电动机电缆

U2/T1,V2/T2,W2/3相

电动机电缆屏蔽层

的接线端子PE

图 2-10 MICROMASTER 430 变频器的接线图(框架尺寸 GX)

MICROMASTER 430 使用说明书 2-17

6SE6400-5AE00-0MP0

Page 35

安 装 版本 12/02

框架尺寸 C 至 F

L3

L2

L1

熔断器

1) 带和不带滤波器

接触器

选件,

进线电抗器

PEPE

选件,

滤波器

PE

MICR OMASTE R

L3

U

L2

V

L1

W

PE

1)

电动机

框架尺寸 FX 和 GX

L3

L2

L1

熔断器

不带滤波器

2)

3)

利用接地点将进线电抗器接地

接触器

图 2-11 电动机和电源的接线方法

选件,

滤波器

PEPE

选件,

进线电抗器

3)

MICROMASTER

L3

U

L2

V

L1

W

PE

2)

电动机

2-18 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 36

版本 12/02 安 装

冷却风机电源电压的匹配(只限框架尺寸为 FX 和 GX 的变频器)

变频器内装有一个用于电源电压与冷却风机实际运行电压相匹配的变压器。为了与实际电源电压相

吻合,可能需要重新连接变压器一次侧端子的接线。

图 2-12 冷却风机电源电压的匹配

注 意

如果不按实际电源电压重新连接电源电压的接线端子,冷却风机的熔断器可能熔断。

冷却风机熔断器的更换

框架尺寸 熔断器(每台变频器 2 个) 型 号

FX(110kW VT) 1 A Cooper-Bussmann FNQ-R-1,600 V

FX(132kW VT) 2.5 A Ferraz Gould Shawmut ATDR2-1/2,600 V

GX(160~250kW VT) 4 A Ferraz Gould Shawmut ATDR4,600 V

0V 1L380V

1L400V 1L440V

按输入电压接线

1L480V -

MICROMASTER 430 使用说明书 2-19

6SE6400-5AE00-0MP0

Page 37

安 装 版本 12/02

2.4.3 电磁干扰(EMI)的防护

变频器的设计允许它在具有很强电磁干扰的工业环境下运行。通常,如果安装的质量良好,就可以

确保安全和无故障的运行。如果您在运行中遇到问题,请按下面指出的措施进行处理。

采取的措施

¾ 确信机柜内的所有设备都已用短而粗的接地电缆可靠地连接到公共的星形接地点或公共的接

地母线。

¾ 确信与变频器连接的任何控制设备(例如 PLC)也像变频器一样,用短而粗的接地电缆连接到

同一个接地网或星形接地点。

¾ 由电动机返回的接地线直接连接到控制该电动机的变频器的接地端子(PE)上。

¾ 优先使用扁平导体,因为它们在高频时阻抗较低。

¾ 剥线时尽可能保持线头处整洁,保证未经屏蔽的线段尽可能短。

¾ 控制电缆的布线应尽可能远离动力电缆,使用单独的走线槽;在必须与动力线交叉时,相互

应采取 90°直角交叉。

¾ 尽可能使用屏蔽电缆作为控制回路连接线。

¾ 确信机柜内安装的接触器应是带阻尼的,即是说,在交流接触器的线圈上并联 R-C 阻尼回路;

在直流接触器的线圈上并联‘续流’二极管。安装压敏电阻对抑制过电压也是有效的。当接

触器由变频器的继电器进行控制时,这一点尤其重要。

¾ 接到电动机的连接线应采用屏蔽的或铠装的电缆,并用电缆接线卡子将屏蔽层的两端接地。

!

警 告

在安装变频器时一定要不折不扣地遵守完全规程!

2-20 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 38

版本 12/02 安 装

2.4.4 屏蔽的方法

框架尺寸为 C 时

框架尺寸为 C 时,密封盖组合件是作为可选件供货的。该组合件便于屏蔽层的连接。密封盖安装

的详细说明请查阅随 MM430 变频器一起供货的 CD-ROM 文件(光盘)。

无密封盖组合件时屏蔽层的接线

如果不用密封盖板,变频器可以用图 2-13 所示的方法连接电缆的屏蔽层。

1 输入电源线

2 控制电缆

3 电动机电缆

4 背板式滤波器

5 金属底板

6 使用适当的卡子固定电动机电缆和控制电缆,确保屏蔽层与金属底板可靠连接

7 屏蔽电缆

图 2-13 把电磁干扰(EMI)的影响降到最小的布线方法

框架尺寸为 D,E 和 F 时

密封盖组合件是在变频器出厂时就安装好的。屏蔽连接点的安装与框架尺寸 C 的变频器是一样的。

MICROMASTER 430 使用说明书 2-21

6SE6400-5AE00-0MP0

Page 39

安 装 版本 12/02

框架尺寸为 FX 和 GX 时

导线的屏蔽层需与接线图(参看图 2-9 和 2-10)中所示的屏蔽层连接端子可靠连接。

为此,把电动机电缆绞在一起,并把所有电缆用螺钉一起固定到电机电缆屏蔽层连接端子上。

在采用 EMI(电磁干扰)滤波器时,必须接入进线电抗器。电缆的屏蔽层应紧固在紧靠电抗器的金属

安装面板上。

2-22 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 40

版本 12/02 调 试

3 调 试

本章的内容有:

¾ MICROMASTER 430 变频器的电路图

¾ 调试用选件概览,显示板和操作面板

¾ MICROMASTER 430 变频器快速调试的操作方法

3.1 方框图················································································································3-3

3.2 调试方法 ·············································································································3-5

3.3 常规操作 ···········································································································3-16

MICROMASTER 430 使用说明书 3-1

6SE6400-5AE00-0MP0

Page 41

调 试 版本 12/02

警 告

!

¾ MICROMASTER 变频器是在高电压下运行。

¾ 电气设备运行时,设备的某些部件上不可避免地存在危险电压。

¾ 按照 EN 60204 IEC 204(VDE 0113)的要求,“紧急停车设备”必须在控制设备的所有工作方

式下都保持可控性。无论紧急停车设备是如何停止运转的,都不能导致不可控的或者未曾预

料的再次启动。

¾ 无论故障出现在控制设备的什么地方都有可能导致重大的设备损坏,甚至是严重的人身伤害

(即存在潜在的危险故障),因此,还必须采取附加的外部预防措施或者另外装设用于确保安全

运行的装置,即使在故障出现时也应如此(例如,独立的限流开关,机械连锁等)。

¾ 在输入电源故障之后,一定的参数设置可能会造成变频器的自动再启动。

¾ 为了保证电动机的过载保护功能正确动作,电动机的参数必须准确地配置。

¾ 本设备可按照 UL508C 第 42 节的要求在变频器内部提供电动机保护功能。根据 P0610 和

P0335,I

P0001 的缺省值来禁止)来实现。

¾ 本设备可用于回路对称容量不大于 10,000 安培(均方根值)的地方,在采用 H 或 K 型熔断器

进行保护(参看从第 7 章的附表)时,最大电压为 460V。

¾ 本设备不可作为‘紧急停车机构’使用(

注 意

!

只有经过培训并认证合格的人员才可以在操作面板上输入设定值。任何时候都应特别注意遵守手册

中要求采取的安全措施和给予的警告。

2

t 保护功能是在缺省情况下投入。电动机的过载保护功能也可以采用外部 PTC(用

参看 EN 60204,9.2.5.4

)

3-2 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 42

版本 12/02 调 试

3.1 方框图

PE

电动机

PTC

0-20 mA

max.500Ω

4.7kΩ

min

PNP

或

NPN

1

2

AIN1+

3

AIN1-

4

AIN2+

10

AIN2-

11

DIN1

5

DIN2

6

DIN3

7

DIN4

8

DIN5

16

DIN6

17

9

28

PTCA

14

PTCB

15

AOUT 1+

12

AOUT 1-

13

+10 V

0V

A/D

A/D

光电

隔离

输出24V

(隔离)

输出0V

(隔离)

D/A

CPU

3 AC 380 - 480 V

BOP-2

BOP

串行协议

150.00

=

SI

L/L1,N/L2

PE

or

L/L1,N/L2,L3

~

=

3~

0-20 mA

max.500Ω

30 V DC/5A (电阻负载)

250 V AC/2A(电感负载)

图 3-1 变频器方框图

继电

器1

继电

器2

继电

器3

AOUT 2+

26

AOUT 2-

27

COM

20

NO

19

NC

18

COM

22

NO

21

COM

25

NO

24

NC

23

P+

29

N-

30

RS485

CB

选件

D/A

自动

0-20 mA

电流

0-10 V

电压

不用

(在控制板上)

AIN1AIN2

12

60 Hz

50 Hz

12

DIP开关

DIP开关

(在I/O板上)

PE

U,V,W

M

MICROMASTER 430 使用说明书 3-3

6SE6400-5AE00-0MP0

Page 43

调 试 版本 12/02

3.1.1 端子的标准设定

见图 3-2

3.1.2 模拟输入

模拟输入 1(AIN1)可用于输入信号范围:

0~10V,0~20mA 和-10V~+10V

模拟输入 2(AIN2)可用于输入信号范围:

0~10V 和 0~20mA

模拟量输入通道也可作为数字量输入(D1N7 和 DIN8)使用

如下图:

1

2

10

11

DIN7

1

2

3

DIN8

4

图 3-2 模拟量输入作为数字量输入使用

当 1 个模拟输入配置成 1 个数字输入时,其阈值如下:

1.75V DC=OFF

3.70V DC=ON

当其作为数字输入时,端子 9(24V)也可用于传动系统的模拟输入。端子 2 和 28(0V)必须链接。

3-4 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 44

版本 12/02 调 试

3.2 调试方法

MICROMASTER 430 变频器在标准供货方式时装有状态显示板(SDP)(参看图 3-3),对于很多用

户来说,利用 SDP 和制造厂的缺省设置值,就可以使变频器成功地投入运行,如果工厂的缺省设

置值不适合您的设备情况,您可以利用基本操作板 2(BOP-2)(参看图 3-3)修改参数,使之匹配起

来。BOP-2 是作为选件供货的。您也可以用 PC IBN 工具来调整工厂的设置值,相关的软件在随

变频器供货的 CD-ROM 中可以找到。

注 意

MICROMASTER 430 变频器只能用 BOP-2 进行操作。

MICROMASTER 430 变频器不能用 BOP 或 AOP 进行操作。

SDP BOP-2

图 3-3 MICROMASTER 430 变频器的操作面板

状态显示板 基本操作板

有关更换操作板的操作步骤,请参看本手册的 10.1 节。

提 示

调整电机频率 50/60Hz:位 于 I/O 板下面的 DIP 开关用于调整电机频率(对于更换 I/O 板,见 10.3

节)。

变频器交货时的设置情况下如下:

¾ DIP 开关 2:

Off 位置:

设置电机频率

的DIP开关

欧洲地区缺省值

(50Hz,功率单位:kW)

On 位置:

北美地区缺省值

(60Hz,功率单位:hp)

¾ DIP 开关 1:

不供用户使用。

图 3-4 DIP 开关

MICROMASTER 430 使用说明书 3-5

6SE6400-5AE00-0MP0

Page 45

调 试 版本 12/02

3.2.1 用状态显示板(SDP)调试

SDP 面板上有两个 LED(发光二极管),用于显示变频器当前的

运行状态(请参看本手册第 6.1 节)。在采用 SDP 时,变频器的

预设定值必须与下列电动机数据兼容:

¾ 电动机的额定功率

¾ 电动机的额定电压

¾ 电动机的额定电流

¾ 电动机的额定频率

此外,必须满足以下条件:

¾ 按照线性 V/f 控制特性,由模拟电位计控制电动机速度。

¾ 频率为 50Hz 时最大速度为 1500 转/分(60Hz 时为 1800 转/分),可通过变频器的模拟输入端

用电位计控制。

¾ 斜坡上升时间=10s。

¾ 斜坡下降时间=30s。

在参数表和本手册第 3.2.2 节“用 BOP-2 进行调试的简要说明”中可以找到如何对更复杂的应用

对象进行设置的相关资料。

表 3-1 用 SDP 操作时的缺省设置值

(建议采用西门子的标准电动机)

数字输入 1 5 P0701 =‘1’ ON,正向运行

数字输入 2 *

数字输入 3 7 P0703 =‘9’ 故障确认(复位)

数字输入 4 8 P0704 =‘15’

数字输入 5 16 P0705 =‘15’

数字输入 6 17 P0706 =‘15’

数字输入 7 经由 AIN1 P0707 =‘0’

数字输入 8 经由 AIN2 P0708 =‘0’

端 子 参 数 缺省操作

6 P0702 =‘12’

反向运行

固定频率

固定频率

固定频率

不激活

不激活

*

在标准设置时,改变转动方向是被禁止的。(参数 1110)

3-6 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 46

版本 12/02 调 试

用 SDP 进行基本操作

使用变频器上安装的 SDP 可以进行以下操作:

¾ 启动和停止电动机(外接开关经由数字输入 1(DIN1)进行控制)

¾ 故障复位(外接开关经由数字输入 3(DIN3)进行操作)

按图 3-5 连接模拟输入信号,即可实现对电动机速度的控制。

模拟输出

0-20mA

(500Ω)

图 3-5 用 SDP 进行基本操作

MICROMASTER 430 使用说明书 3-7

6SE6400-5AE00-0MP0

Page 47

调 试 版本 12/02

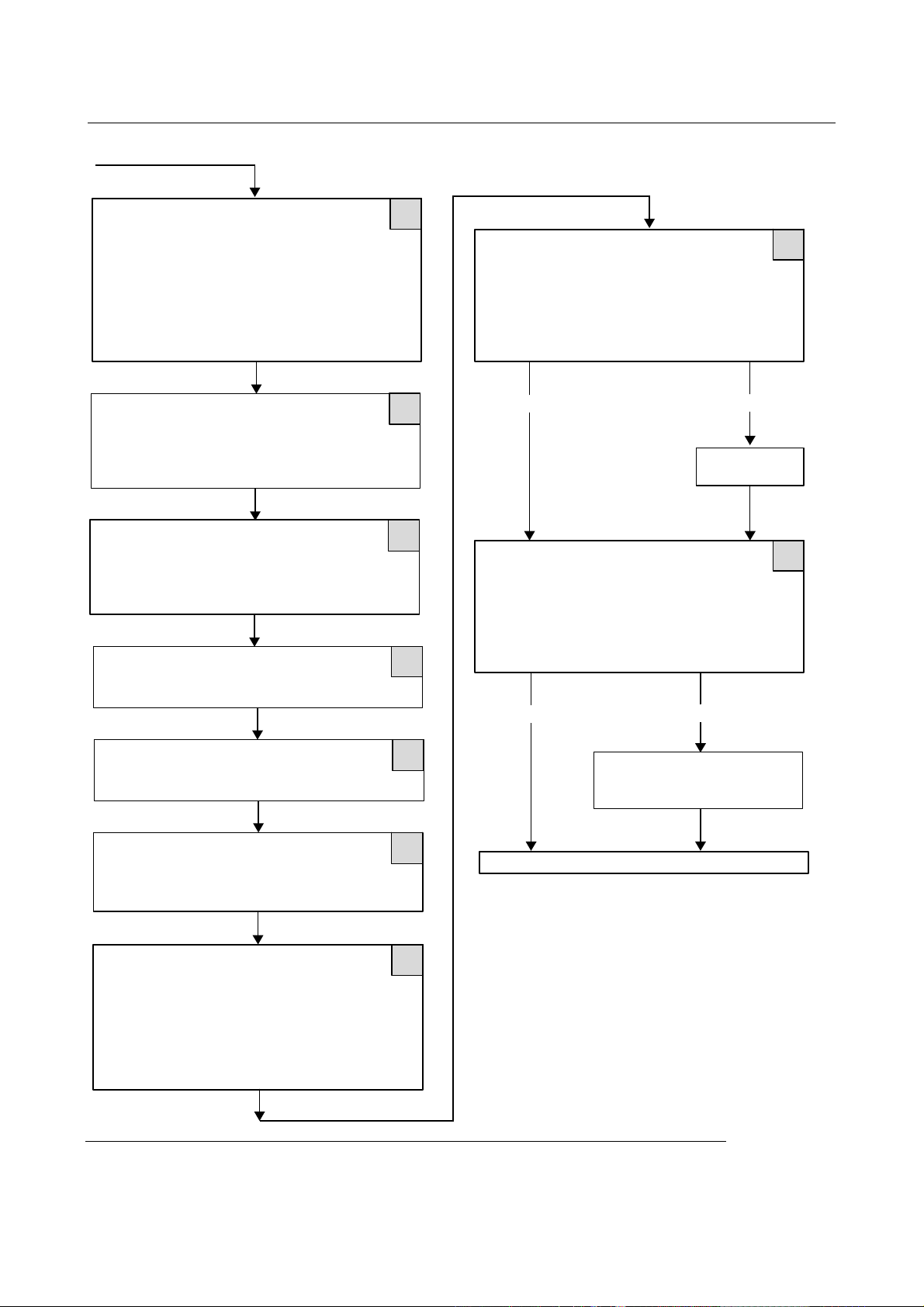

3.2.2 用 BOP-2 进行调试的简要说明

前提条件:

机械和电气安装已经完成。

设置电动机的频率

DIP开关2: OFF=50Hz/ON=60Hz

接通电源

快速调试P0010=1

请参看第3.2.3.1节

通过P0004和P0003进行进一步的调试

参数结构的简要情况在5.3节给出,

参数的详细说明请参看参数表

说 明

我们建议您按照上面的框图进行调试。

3-8 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 48

版本 12/02 调 试

3.2.2.1 用基本操作面板 BOP-2 进行调试

您可以通过基本操作面板 BOP-2 改变变频器的参数值。为

了利用 BOP-2 设定参数,您必须首先拆下 SDP,并装上

BOP-2(参看 10.1 节)。

BOP-2 具有七段码显示的 5 位数字,可以显示参数的序号

和数值,报警和故障信息,以及给定值和实际值。参数组不

能用 BOP-2 存储。

表 3-2 表示由 BOP-2 操作时的工厂缺省设置值。

提 示

¾ 在缺省设置时,用 BOP-2 控制电动机的功能是被禁止的。如果要用 BOP-2 进行控制,参数

P0700 应设置为 1,参数 P1000 也应设置为 1。

¾ 变频器加上电源时,也可以把 BOP-2 装到变频器上,或从变频器上将 BOP-2 拆卸下来。

¾ 如果 BOP-2 已经设置为 I/O 控制(P0700=1),在拆卸 BOP-2 时,驱动装置将自动停车。

表 3-2 用 BOP-2 操作时的缺省设置值

参 数 说 明 缺省值,欧洲(或北美)地区

P0100 运行方式,欧洲/北美 50Hz,kW(60Hz,hp)

P0307 功率(电动机额定值) 因次 kW(Hp)取决于 P0100 的设定值(数值决定于变频器)

P0310

P0311

P1082

电动机的额定频率

电动机的额定速度

电动机最大频率

50Hz(60Hz)

1395(1680)rpm(同变频器有关)

50Hz(60Hz)

注 意

MICROMASTER 430 变频器只能用 BOP-2 进行控制。如果使用 BOP 或 AOP,显示屏上将显示

。

MICROMASTER 430 使用说明书 3-9

6SE6400-5AE00-0MP0

Page 49

调 试 版本 12/02

BOP-2 上的按钮

面板/按钮 功 能 功能的说明

Fn

状态显示

LCD 显示变频器当前的设定值。

启动电动机

按此键启动变频器。缺省值运行时此键是被封锁的。为了使此键的操作

有效,应设定 P0700=1。

OFF1:按此键,电动机将按选定的斜坡下降速率减速停车。缺省值运行

停止电动机

OFF2:按此键两次(或一次,但时间较长)电动机将在惯性作用下自由停

时此键被封锁。为了允许此键操作,应设定 P0700=1。

车。此功能总是“使能”的。

手动方式

用户的端子板(CD S2)和操作板(BOP-2)是命令和设定值信号源。

自动方式

用户的端子板(CD S1) 或串行接口(USS) 或现场总线接口( 例如

PROFIBUS)是命令和设定值信号源。

此键用于浏览辅助信息。

变频器运行过程中,在显示任何一个参数时按下此键并保持 2 秒钟。将

显示以下参数值:

1. 直流母线电压(用 d 表示-单位:V)。

2. 输出电流(A)

3. 输出频率(Hz)

4. 输出电压(用 o 表示-单位:V)。

5. 由 P0005 选定的数值(如果 P0005选择显示上述参数(1~4)中的任何

功 能

一个,这里将不再显示)。

连续多次按下此键,将轮流显示以上参数。

跳转功能:

在显示任何一个参数(r××××或 P××××)时短时间按下此键,将立即跳转到

r0000,如果需要的话,您可以接着修改其它的参数。跳转到 r0000 后,

按此键将返回原来的显示点。

退出:

在出现故障或报警的情况下。按

报警信息复位。

Fn

键可以将操作面板上显示的故障或

访问参数 按此键即可访问参数。

增加数值 按此键即可增加面板上显示的参数数值。

减少数值 按此键即可减少面板上显示的参数数值。

图 3-6 基本操作面板(BOP-2)上的按钮

3-10 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 50

版本 12/02 调 试

用 BOP-2 更改参数的数值

下面的插图介绍更改参数 P0004 数值的步骤。并以 P0719 为例,说明如何修改变址参数的数值。

按照这个图表中说明的类似方法,可以用 BOP-2 更改任何一个参数。

改变 P0004 - 参数过滤功能

操作步骤 结果显示

P

访问参数

1

2

3

4

5

按

直到显示出

按

P

访向参数数值级

按

或 达到所需要的数值

按

P

确认并存储参数的数值

按

P0004

0000

p0004

p0004

0

7

修改变址参数 P0719-选择命令

操作步骤 结果显示

P

访问参数

1

2

3

4

5

6

7

8

按

直到显示出

按

P

访向参数变址级

按

P

显示当前变址下的数值

按

或 选择所需要的数值

按

P

确认并存储这一数值

按

直到显示出

按

P

返回标准的变频器显示(由用户定义

按

P0719

r0000

/给定值信号源

)

0000

p07 1 9

000

0

12

p07 1 9

0000

图 3-7 用 BOP-2 修改参数

说 明

修改参数的数值时,

BOP-2

表明变频器正忙于处理优先级更高的任务。

MICROMASTER 430 使用说明书 3-11

6SE6400-5AE00-0MP0

有时会显示: 。

Page 51

调 试 版本 12/02

改变参数数值中单个数字

为了快速修改参数的数值,可以单独修改显示出的每个数字,操作步骤如下:

确信已处于某一参数数值的访问级(参看上面“用 BOP-2 更改参数的数值”)。

Fn

1.

按

功能键),最右边的一个数字闪烁。

(

按

2.

再按

3.

执行2至4步,直到显示出所要求的数值。

4.

P

按

5.

,修改这位数字的数值。

/

Fn

功能键),相邻的下一位数字闪烁。

(

,退出参数数值的访问级。

说 明

功能键也可以用于确认已发生的故障。

3.2.3 BOP-2 的调试功能

3.2.3.1 快速调试(P0010=1)

在进行快速调试以前,必须已经完成变频器的机械和电气安装工作。

设置参数 P0010(快速调试)和 P0003(选择用户访问级别)是十分重要的。

MICROMASTER 4 变频器有三个用户访问级:标准级,扩展级和专家级。进行快速调试时,访问

级较低的用户能够看到的参数较少。这些参数的数值要么是缺省设置,要么是在快速调试时进行计

算。

快速调试包括电动机的设定参数和斜坡函数的设定参数。

快速调试用参数 P3900 来结束,在它被设定为 1 时,要完成必要的电动机计算,并使其它所有的

参数(P0010=1 不包括在内)复位为工厂的缺省设置。

在 P3900=1,并完成快速调试以后,变频器即已作好了运行准备;只是在快速调试方式下才是这

种情况。

3-12 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 52

版本 12/02 调 试

快速调试(QC)的流程图

P0003 用户访问级

1 标准 级

2 扩展 级

3 专家 级

P0010 开始快速调试

0 准备

1 快速 调试

30 工厂的缺省设置值

P0100 选择 工作地区是欧洲/北美

0 功率 单位为 kW;f 的缺省值为50Hz

1 功率 单位为 hp; f 的缺省值为60Hz

2 功率 单位为 kW;f 的缺省值为60Hz

说明:

P0100的设定值0和1应该用DIP开关来更改,使其设定的值

固定不变。DIP开关用来建立固定不变的设定值。在电源

断开后,DIP开关的设定值优先于参数的设定值。

P0300 选择电动机的类型

1 异步电动机

2 同步电动机

说明:

P0300=2时,控制参数被禁止

P0304 电动机额定电压

设定值的范围:10V~2000V

根据铭牌输入的电动机额定电 压(V)

P0305 电动机额定电流

设定值的范围:0~2倍变频器额定电流(A)

根据铭牌输入的电动机额定电流(A)

P0307 电动机的额定功率

设定值的范围:0.01kW~2000kW

根据铭牌输入的电动机额定功率(kW)

如果P0100=1,功率单位应是hp

2)

2)

1)

1)

1)

访问级

1

P0309 电动 机的额定效率

设定值的范围:0.0~99.9%

根据铭牌输入的以%值表示的电动机额定效率

只有在P0100=1的情况下(电动机的功率单位是hp时)才能

。

看到

1

P0310 电动机的额定频率

设定值的范围:12Hz~650Hz

根据铭牌输入的电动机额定频率(Hz)

1

P0311 电动机的额定速度

设定值的范围:0~40000rpm

根据铭牌输入的电动机额定速 度(rpm)

P0320 电动 机的磁化电流

设定值的范围:0.0~99.0%

是以电动机额定电流(P0305)的%值表示的磁化电流

2

P0335 电动 机的冷却

0 自冷

1 强制 冷却

2 自冷 和内置风机冷却

3 强制 冷却和内置风机冷却

1

P0640 电动机的过载系数

设定值的范围:10.0~400.0%

电动机过载电流的限值,以电动机额定电流(P0305)的%值

。

表示

1

P0700 选择命令源

0 工厂设置值

1 基本操作面板(BOP-2)

1

2 端子(数字输入)

说明:

如果选择P0700=2,数字输入的功能决定于P0701至P0708。

P0701至P0708=99时,各个数字输入端按 照BICO功能进行

。

参数化

1)

2

。

1)

1)

1

1

3

。

2

2

2)

1

P0308 电动 机的额定功率 因数

1)

2

设定值的范围:0.000~1.000

根据铭牌输入的电动机额定功 率因数(cosφ)

。

只有在P0100=0或2的情况下(电动机的功率单位是kW时)

才能看到。

1)电动机的额定性能参数请参看电动机的铭牌

2)与上面列出的设置相比,变频器的参数实际上有更多的设置方案可供选择。详细的设定值选择方法请参看参数表。

MICROMASTER 430 使用说明书 3-13

6SE6400-5AE00-0MP0

Page 53

调 试 版本 12/02

P1000 选择频率给定值

1 电动电位计给定值

2 模拟给定值1

3 固定频率给定值

7 模拟给定值2

说明:

对于给定值的附加设定请参看“参数表”。如果 P1000=1,

频率给定值的选择决定于P0700至P0708的设置。

P1080 电动机最小频率

设定值的范围:0~650Hz

本参数设置电动机的最小频率(0~650Hz);达到这一频率时

电动机的运行速度将与频率的给定值无关

对电动机的正转和反转都是适用的

P1082 电动机最大频率

设定值的范围:0~650Hz

本参数设置电动机的最大频率(0~650Hz);达到这一频率时

电动机的运行速度将与频率的给定值无关。这里设置的值

对电动机的正转和反转都是适用的。

P1120 斜坡上升时间

设定值的范围:0s~650s

电动机从停车加速到电动机最大频率所需的时间。

2)

。这里设置的值

。

1

1

P1910 选择电动机数据辨识

0 禁止

1 所有参数 进行辨识并修改

说明:

电动机数据的辨识必须是在冷态(20℃)下进行。

温度不在允许范围(20℃+5℃)内,则必须修改参数P0625的

电动机运行环境温度值。

1

1

P1910=0 P1910=1

报警码A0541电机

数据辨识功能激活

P3900 结束快速调试

0 结束快速调试,不进行电动机计算或复位为工厂

缺省设置值

1 结束快速调试,进行电动机计算和复位为工厂缺省设

置值

2 结束快速调试,进行电动机计算和I/O复位

3 结束快速调试,进行电动机计算,但不进行I/O复位

P3900=1,2 P3900=3

。

。

。

如果环境

。

1

1

P1121 斜坡下降时间

设定值的范围:0s~650s

电动机从其最大频率减速到停车所需的时间。

P1135 OFF3的斜坡下降时间

设定值的范围:0s~650s

得到OFF3停止命令后,电动机从其最大频率减速到停车所

需的斜坡下降时间。

P1300 控制方式

0 线性V/f控制

1 带FCC(磁通电流控制)的V/f控制

2 抛物线V/f控制

3 可编程特性的V/f控制

5 用于纺织工业的V/f控制

6 用于纺织工业的带FCC功能的V/f控制

19 带独立电压给定值的V/f控制

1

2

快速调试结束,变频器进入“运行准备就绪”状态。

2

接通电动机,开始电动机数据的辨识。

在完成电动机数据的辨识以后,报警

信号A0541消失。

2) 与上面列出的设置相比,变频器的参数实际上有更多的设置方案可供选择。详细的设定值选择方法请参看参数表。

3-14 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 54

版本 12/02 调 试

用于参数化的电动机铭牌数据

图 3-8 典型的电动机铭牌数据举例 (在铭牌上列出的详细数据仅为实例)

提 示

¾ 如果 P0003≥2,只能看到参数 P0308 和 P0309。究竟可以看到其中的哪一个参数,决定于

P0100 的设定值。

¾ P0307 所显示的单位是 kW 或 HP,决定于 P0100 的设定值。详细的资料请参看“参数表”。

¾ 除非 P0010=1,否则是不能更改电动机参数的。

¾ 确信变频器已按电动机的铭牌数据正确地进行了配置。

¾ 注意电动机的星形/三角形接线方式。

3.2.4 复位为出厂时变频器的缺省设置值步骤

为了把变频器的所有参数复位为出厂时的缺省设置值;应按下面的数值设置参数(需使用 BOP-2

或通讯选件):

1.设置 P0010=30

2.设置 P0970=1。

说 明

复位过程约需 3 分钟才能完成。

MICROMASTER 430 使用说明书 3-15

6SE6400-5AE00-0MP0

Page 55

调 试 版本 12/02

3.3 常规操作

有关变频器标准参数和扩展参数的详细说明,请参看“参数表”。

提 示

1. 变频器没有进线主电源开关,因此,当电源电压接通时变频器就已带电。在按下运行(RUN)键,

或者在数字输入端子 5 出现“ON”信号(正向旋转)之前,变频器的输出一直被封锁,处于等待

状态。

2. 如果装有 BOP-2 并且已选定要显示输出频率(P0005=21),那么,在变频器减速停车时,相应

的给定值大约每一秒钟显示一次。

3. 变频器出厂时已按相同额定功率的西门子 4 极标准电动机的常规应用对象进行编程。如果用户

采用的是其它型号的电动机,就必须输入电动机铭牌上的规格数据。关于如何读取电动机铭牌

数据的细节,请参看图 3-8。

4. 除非 P0010=1,否则是不能修改电动机参数的。

5. 为了使电动机开始运行,必须将 P0010 返回“0”值。

用 BOP-2 进行的基本操作

前提条件

¾ P0010=0(运行准备)。

¾ P0700=1(使能 BOP-2 的启动/停止按钮)。

¾ P1000=1(使能电动电位计的给定值)。

I

按下

1.

在电动机转动时按下 键,使电动机升速到

2.

在电动机达到

3.

按

4.

按

5.

用红色按键

6.

绿色按键,启动电动机。

时按下 键,电动机速度及其显示值都降低。

50Hz

Hand

键,激活手动操作方式。

Auto

键,激活自动操作方式。

0

停止电动机。

50Hz。

说 明

允许使用 3 个命令数据组(CDS)。BOP-2 上的手动/自动按钮应在命令数据组 CDS1 和 CDS2 之

间切换。如果选择了命令数据组 CDS3(通过 P0811),BOP-2 的手动/自动按钮将不起作用。详细

情况请参看“参数表”。

3-16 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 56

版本 12/02 调 试

外接的电动机热过载保护

电动机在额定速度以下运行时,安装在电动机轴上的风扇的冷却效果降低。因此,如果要在低频下

长时间连续运行,大多数电动机必须降低额定功率使用。为了保护电动机在这种情况下不致过热而

损坏,电动机应安装 PTC 温度传感器,并把它的输出信号连接到变频器的相应的控制端子上。

TNAT

150

155

TP10409-6

°C

°C

°C

T

PTC

3

R

(kΩ)

2

1

0

0 100 200 300

ID=2mA

ϑ

u

()

°C

PTC/

KTY

Kl.14

Kl.15

5V

574Ω

8

10

B59135

Ω

R

PTC

7

10

6

10

5

10

4

10

3

10

A

D

2

10

1

10

10

50 100 150 200 250

PTC的阈值=4V 1LG/1LA型电动机的PTC特性 KTY84特性

图 3-9 电动机的过热保护

采用 PTC 传感器(P0601=1)

如果电动机的 PTC 已经接到 MICROMASTER 430 变频器的控制端子 14(PTCA)和 15(PTCB),并

且设定 P0601=1 激活 PTC 功能,那么,MICROMASTER 430 将按常规情况工作,端子上的电阻

保持在大约 1500Ω以下。如果超过这一数值,变频器将发出报警信号 A0511,然后出现故障 F0011。

实际电阻的数值不应小于 1000Ω,并且不大于 2000Ω。

采用 KTY84 传感器(P0601=2)

KTY84 必须这样连接,使二极管正向偏置;这就是说,阳极接到端子 14(PTC A),阴极接到端子

15(PTCB)。

如果设定 P0601=2 激活温度监控功能,传感器(也是电动机绕组的温度)的温度测量值将写入参数

r0035。电动机过热保护的动作阈值可以用参数 P0604(缺省值为 130°C)设定。

接线故障

如果变频器到 PTC 或 KTY84 传感器的连线开路或短路,将显示故障状态,其缺省设置为变频器脱

扣。

MICROMASTER 430 使用说明书 3-17

6SE6400-5AE00-0MP0

Page 57

版本 12/02 MICROMASTER 430 的功能

4 MICROMASTER 430 的功能

本章的内容有:

¾ 关于变频器各种控制功能的说明。

¾ 简要说明变频器各种控制方式。

4.1 频率给定值(P1000)·······························································································4-2

4.2 命令源(P0700)·····································································································4-3

4.3 停车(OFF)和制动功能 ····························································································4-3

4.4 控制方式(P1300)··································································································4-5

4.5 MICROMASTER 430 变频器的操作方式·····································································4-6

4.6 自由功能块(P2800 ff)·························································································· 4-10

4.7 故障和报警 ········································································································ 4-10

MICROMASTER 430 使用说明书 4-1

6SE6400-5AE00-0MP0

Page 58

MICROMASTER 430 的功能 版本 12/02

警 告

!

♦ 电气设备运行时,设备的某些部件上不可避免地存在危险电压。

♦ 按照 EN 60204 IEC 204(VDE 0113)的要求,“紧急停车设备”必须在控制设备的所有工作方

式下都保持可控性。无论紧急停车设备是如何停止运转的,都不能导致不可控的或者未曾预

料的再次启动。

♦ 无论故障出现在控制设备的什么地方都有可能导致重大的设备损坏,甚至是严重的人身伤害

(即存在潜在的危险故障),因此,还必须采取附加的外部预防措施或者另外装设用于确保安全

运行的装置,即使在故障出现时也应如此(例如,设置独立的限流开关,机械连锁等)。

♦ MICROMASTER 变频器是在高电压下运行。

♦ 在输入电源故障之后,一定的参数设置可能会造成变频器的自动再启动。

♦ 为了保证电动机的过载保护功能正确动作,电动机的参数必须准确地配置。

♦ 本设备可按照 UL 508C 第 42 节的要求在变频器内部提供电动机保护功能。根据 P0610 和

P0335,I

省值 P0601“电动机温度传感器”禁止)来实现。

♦ 在采用 H 或 K 型熔断器作为保护器件(参看第 7 章的附表)时本设备可用于回路对称容量不大

于 10,000 安培(均方根值)的地方,最大电压为 460V。

♦ 本设备不可作为‘紧急停车机构’使用(

2

t 保护功能是在缺省情况下投入。电动机的过载保护功能也可以采用外部 PTC(由缺

4.1 频率给定值(P1000)

¾ 预设定: 端子 3/4(AIN+/AIN-,0...10V 相当于 0...50/60Hz)

¾ 附加给定值 参看 P1000

说 明

关于 USS,请参看参考手册;关于 PROFIBUS,请参看参考手册和“PROFIBUS 说明书”。

参看 EN 60204,9.2.5.4

)

4-2 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 59

版本 12/02 MICROMASTER 430 的功能

4.2 命令源(P0700)

注 意

斜坡上升/斜坡下降时间和斜坡滤波曲线功能也关系到电动机启动和停车。关于这些功能的详细说

明,请参看参数表中的参数 P1120,P1121,P1130~P1134。

电动机启动

¾ 缺省值: 端子 5(DIN1,高电平)

¾ 附加给定值: 参看 P0700 至 P0708

电动机停车

¾ 有多种方式可以停止电动机:

¾ 缺省值:

♦ OFF1 端子 5(DIN1,低电平)

♦ OFF2 用 BOP-2 上的 OFF(停车)按键控制时,按下 OFF 按键(持续 2 秒钟)或按

两次 OFF(停车)按钮即可。

♦ OFF3 在缺省设置的的情况下无效

¾ 附加给定值 参看 P0700 至 P0708

电动机反向

在出厂时的缺省设置值中这一功能是被禁止的。为了释放这一功能,您必须设定 P1110=0。

¾ 缺省值: 端子 6(DIN2,高电平)

¾ 附加给定值: 参看 P0700 至 P0708

4.3 停车(OFF)和制动功能

4.3.1 OFF1

这一命令(取消“ON”命令而触发的)使变频器在选定的斜坡下降时间内减速至停车。

修改斜坡下降时间的参数见 P1121。

注 意

¾ ON 命令和后续的 OFF1 命令必须来自同一信号源。

¾ 如果“ON/OFF1”的数字输入命令不止由一个数字输入,那么,只有最后一个设定的数字输

入,例如 DIN3 才是有效的。

¾ OFF1 可以用于直流注入制动或复合制动。

MICROMASTER 430 使用说明书 4-3

6SE6400-5AE00-0MP0

Page 60

MICROMASTER 430 的功能 版本 12/02

4.3.2 OFF2

这一命令使电动机依惯性自由停车(脉冲被封锁)。

注 意

OFF2 命令可以有一个或几个信号源。OFF2 命令以缺省方式设置到 BOP-2。即使参数 P0700 至

P0708 之一定义了其它信号源,这一信号源依然存在。

4.3.3 OFF3

OFF3 命令使电动机快速地减速停车。

在设置了 OFF3 的情况下,为了启动电动机,二进制输入端必须闭合。如果 OFF3 已经闭合,电

动机才能启动并可用 OFF1 或 OFF2 方式停车。

如果 OFF3 是开路,电动机是不能启动的。

¾ 斜坡下降时间: 参看 P1135

注 意

OFF3 可以用于直流制动,复合制动或动力制动功能。

4.3.4 直流注入制动

直流注入制动可以与 OFF1 和 OFF3 同时使用。向电动机注入直流电流时,电动机将快速停车,

并在制动作用结束之前一直保持这一直流电流。

¾ “使能”直流注入制动: 参看 P0701 至 P0708

¾ 设定直流制动的持续时间: 参看 P1233

¾ 设定直流制动电流: 参看 P1232

¾ 设定直流制动开始时的频率: 参看 P1234

注 意

如果没有数字输入端设定为直流注入制动,而且 P1233≠0,那么,直流制动将在每个 OFF1 命令

之后起作用,制动作用的持续时间在 P1233 中设定。

4.3.5 复合制动

复合制动可以与 OFF1 和 OFF3 命令同时使用。为了进行复合制动,应在交流电流中加入一个直

流分量。

设定制动电流: 参看 P1236

4-4 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 61

版本 12/02 MICROMASTER 430 的功能

4.4 控制方式(P1300)

MICROMASTER 430 变频器有多种基于 V/f 控制的运行控制方式。各种控制方式如下表所示,附

加给定列在参数表中,在那里也包含了功能图。

¾ 线性 V/f 控制, P1300=0

可用于可变转矩和恒定转矩的负载,例如,运输机和容积式泵类。

¾ 带磁通电流控制(FCC)的线性 V/f 控制, P1300=1

这一控制方式可用于提高电动机的性能和改善其动态响应特性。

¾ 抛物线 V/f 控制 P1300=2

这一方式可用于可变转矩负载,例如,风机和水泵。

¾ 多点 V/f 控制 P1300=3

有关这种运行方式更详细的资料,请参看 MICROMASTER 430 参数表。

¾ 用于纺织机械的 V/f 控制 P1300=5

没有滑差补偿或谐振阻尼。电流最大值 Imax 调节器涉及到电压而不是频率。

¾ 用于纺织机械的带 FCC 功能的 V/f 控制 P1300=6

P1300=1 和 P1300=5 的组合控制。

¾ 带独立电压给定值的 V/f 控制 P1300=19

电压给定值可以由参数 P1330 给定,而与斜坡函数发生器(RFG)的初始频率无关。

MICROMASTER 430 使用说明书 4-5

6SE6400-5AE00-0MP0

Page 62

MICROMASTER 430 的功能 版本 12/02

4.5 MICROMASTER 430 变频器的操作方式

4.5.1 旁路方式

如下图组成一个变频器的旁路电路。

主电源

隔离器件

机械联锁

接触器

功 能

继电器输出

隔离器件

图 4-1 旁路电路

旁路方式是由 MICROMASTER 430 变频器的继电器输出接点控制两个机械上互相联锁的接触器。

此电路可以通过变频器操作电动机,或者不通过变频器而直接由电源向电动机供电。变频器负责接

触器间的切换。

可以采用以下方法来实现两种运行方式的切换:

¾ 变频器来的故障信息

¾ 数字输入信号

¾ 变频器的频率

详细的相关资料请参看“参数表”中的参数 P1260 和下文。

4-6 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 63

版本 12/02 MICROMASTER 430 的功能

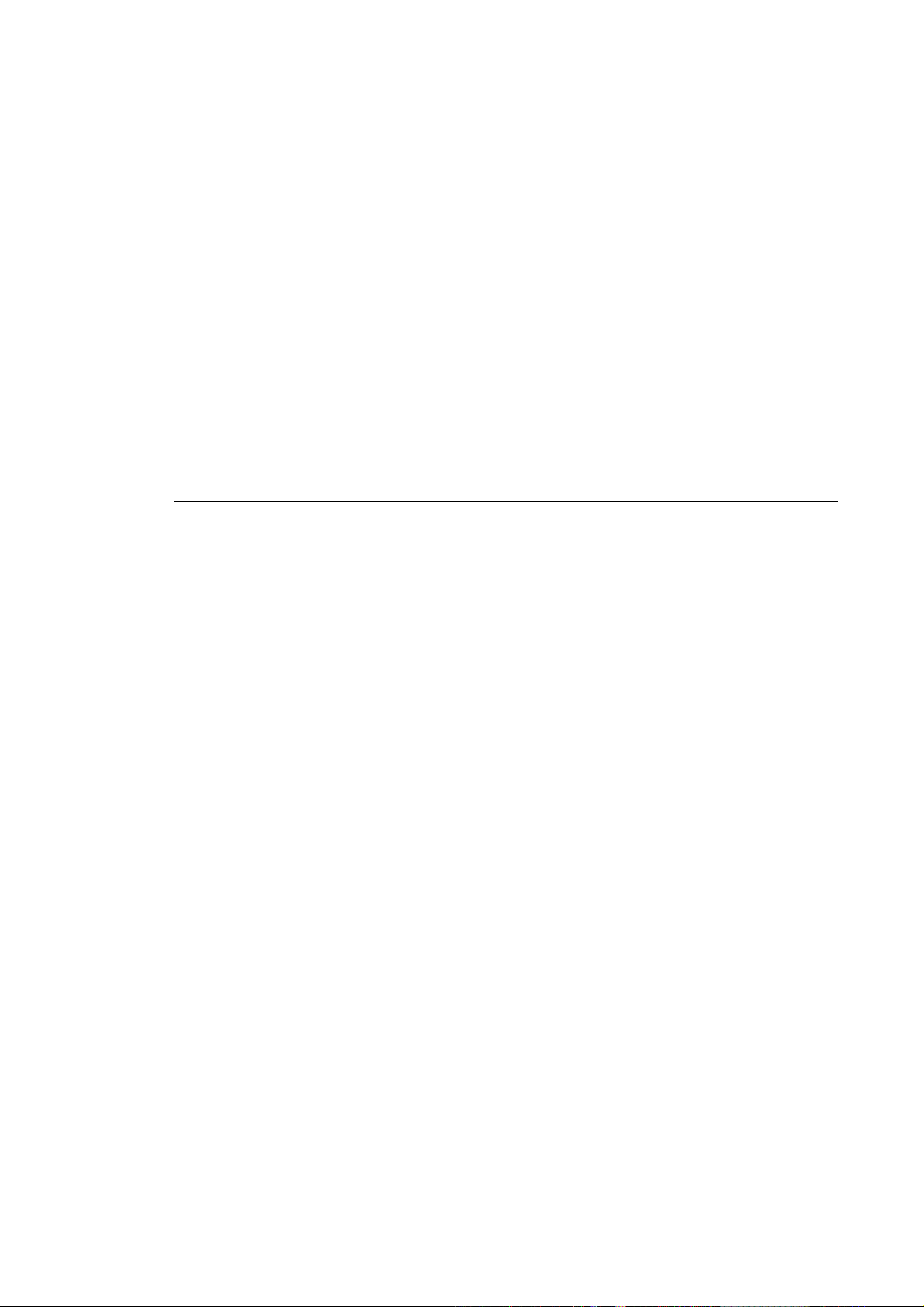

4.5.2 传动皮带故障的检测

这一功能用于识别传动装置机械部分的故障,例如 V-形皮带断裂,水泵无水空转等。

功 能

P2189

转矩上阈值3

P2190

转矩上阈值3

P2187

转矩上阈值2

P2188

转矩下阈值2

P2185

转矩上阈值1

P2186

转矩下阈值1

图 4-2 传动皮带故障的检测

[Nm]

转矩

P2182 P2183 P2184

阈值频率1 阈值频率2 阈值频率3

P1082

最高频率

频率

[Hz]

变频器对其输出转矩带进行监控。由此可以识别变频器是否处于欠负载或过负载运行的状态(例如,

风机不能正确运行)。

这一功能是把当前的速度/转矩曲线与编程的包络线进行比较,从而识别出是否发生了故障。编程

时,利用 3 个支撑点可以确定频率(速度)的上限曲线和下限曲线。此外,还可以定义一个触发这一

功能的死区,从而避免了由于瞬时的转矩变化偶而触发这一故障的检测信号。

详细的相关资料请参看“参数表”中的参数 P2181 和下文。

MICROMASTER 430 使用说明书 4-7

6SE6400-5AE00-0MP0

Page 64

MICROMASTER 430 的功能 版本 12/02

4.5.3 电动机的分级控制

这一功能是变频器利用其继电器输出接点控制多个辅助传动装置,实现多泵循环控制。

主电源

功 能

压力传感器

至变频器的PID

反馈通道输入端

变频器

图 4-3 电动机的分级控制

电动机起动器

在 PID 控制信号作用下,最多可以控制三台辅助电动机。

整个系统包括一台用变频器控制的水泵和三台辅助水泵。各台辅助水泵可以通过接触器或电动机启

动器投入系统运行。接触器和电动机启动器的接通和断开由变频器的输出继电器进行控制。图 4-3

是一个典型的多泵供水系统。

这一功能也可以用于风机和通风井的电动机控制。

有关的资料请参看“参数表”的参数 P2370 和下文。

4-8 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 65

版本 12/02 MICROMASTER 430 的功能

4.5.4 节能方式

节能方式是指当系统处于空载模式下将变频器切换到节能方式

节能

方式

PID

给定值

PID

反馈

%

P2392

*

f

PIDsetpoint

f

Restart

P2390[Hz]

压力稳定

水箱

压力

传感器

f(t)

PID

RFG

f

Motor

电动机

控制

-

-

PID

P2273

Δ

(

PID

PID

限幅

)

负载

PID反馈

(传感器)

PID给定值

t

f

f

Motor

Δ

PID

P1080

PID

激活

f

Restart

=P2000·

P2390+5%

100%

P2390[Hz]=P2000·

P2390

100%

P2391

t

x

节能方式激活

P1080

=

t

x

t

=

y

P1082

f

Restart

P1082

·P1121

·P1120

t

y

PID

激活

t

图 4-4 节能方式

功 能

节能方式扩展了 PID 调节器的功能。

在节能方式下,电动机可以以最小频率运行(运行时间的长短可以预先定义),然后停止电动机。如

果达到了重新启动的频率,电动机将自动再启动。节能方式与电动机的分级控制是互相独立的功能。

两种功能也可以联合起来同时运用。

有关的资料请参看“参数表”的参数 P2390 和下文。

MICROMASTER 430 使用说明书 4-9

6SE6400-5AE00-0MP0

Page 66

MICROMASTER 430 的功能 版本 12/02

4.6 自由功能块(P2800 ff)

利用自由功能块可以实现内部信号(数字输入,给定值,实际值……)的互联,用于特定应用对象的

控制。

4.7 故障和报警

SDP

变频器安装 SDP 时,故障和报警状态是由 SDP 上的两个 LED(发光二极管)来指示的。相关的资料

请参看本手册第 6.1 节。

两个 LED 指示的变频器运行状态如下:

¾ 绿色和黄色 = 运行准备就绪

¾ 仅为绿色 = 变频器正在运行

BOP-2

如果变频器安装了 BOP-2,任何故障状态的详细情况都可以在操作面板上显示出来。故障状态和

报警信息的详细情况请参看第 6 章“故障的排除”。

4-10 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 67

版本 12/02 系统参数

5 系统参数

本章的内容有:

¾ MICROMASTER 430 变频器的参数结构概览

¾ 变频器参数的简表

5.1 MICROMASTER 系统参数的简要介绍 ········································································5-2

5.2 参数概览 ·············································································································5-3

5.3 参数表(简略形式)··································································································5-4

5.4 命令和传动数据组-概览 ······················································································· 5-17

MICROMASTER 430 使用说明书 5-1

6SE6400-5AE00-0MP0

Page 68

系统参数 版本 12/02

5.1 MICROMASTER 系统参数的简要介绍

变频器的参数只能用基本操作面板(BOP-2)或串行通讯接口进行修改。

用 BOP-2 可以修改和设定系统参数,使变频器具有期望的特性,例如,斜坡时间,最小和最大频

率等。选择的参数号和设定的参数值在 5 位数字的 LCD(液晶显示,可选件)上显示。

¾ r××××表示一个用于显示的只读参数,P××××是一个设定参数。

¾ P0010 启动“快速调试”。

¾ 如果 P0010 被访问以后没有设定为 0,变频器将不运行。如果 P3900>0,P0010 被自动置为

0。

¾ P0004 的作用是过滤参数,据此可以按照它们的功能去访问不同的参数。

如果试图修改一个参数,而在当前状态下此参数不能修改,例如,不能在运行时修改该参数

¾

或者该参数只能在快速调试时才能修改,那么将显示

忙碌信息

¾

某些情况下,在修改参数的数值时

示变频器正忙于处理优先级更高的任务。

注 意

-BOP-2

上显示:

,最长可达5秒。这种情况表

MICROMASTER 430 变频器只能由 BOP-2 进行操作。如果用 BOP 或 AOP 进行操作,将显示

5.1.1 访问级

变频器的参数有 3 个用户访问级;即标准访问级,扩展访问级和专家访问级。访问的等级由参数

P0003 来选择。对于大多数应用对象,只要访问标准级(P0003=1)和扩展级(P0003=2)参数就足够

了。

注 意

有些访问级 4 的参数只是用于内部的系统设置,因而是不能修改的。

访问级 4 的参数只有得到授权的人员才能修改。

每组功能中出现的参数号取决于 P0003 中设定的访问级。有关参数的细节,请参看本手册或

CD-ROM 文件(随变频器供货的光盘)中的参数表。

。

5-2 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 69

版本 12/02 系统参数

5.2 参数概览

P0004=2

变频器

P0004=2,P0003=1

变频器的参数访问级1

P0004=2,P0003=2

变频器的参数

P0004 = 0

(无参数过滤功能)

可以直接访问参数。

对于BOP-2

取决于选择的访问级

P0004=2,P0003=3

变频器的参数

访问级1,2和3

访问级1和2

P0004=2,P0003=4

变频器的参数

访问级1,2,3和4

P0004 = 21

报警,警告和监控

P0004 = 20

通讯

P0004 = 13

电动机控制

P0004 = 12

驱动装置的特点

P0004 = 22

PID调节器

P0004 = 10

给定值通道和

斜坡发生器

P0004 = 2

变频器

P0004 = 3

电动机数据

P0004 = 4

速度传感器

P0004 = 5

工艺应用单元

P0004 = 7

命令和数字I/O

P0004 = 8

模拟量I/O

图 5-1 参数概览

MICROMASTER 430 使用说明书 5-3

6SE6400-5AE00-0MP0

Page 70

系统参数 版本 12/02

5.3 参数表(简略形式)

下面表格中的信息说明:

¾ 缺省值: 工厂设置值

¾ Level: 用户访问级

¾ DS 变频器的状态(传动装置的状态),表示参数的数值可以在变频器的这种状态下进行

修改(参看 P0010)

♦ C 调试

♦ U 运行

♦ T 运行准备就绪

¾ QC 快速调试

♦ Q 可以在快速调试状态下修改参数

♦ N 快速调试状态下不能修改参数

常用的参数

参数号 参数名称 缺省值

r0000

P0003

P0004

P0010

变频器(P0004=2)

参数号 参数名称 缺省值

P0100

P3900

参数复位

参数号 参数名称 缺省值

P0970

变频器(P0004=2)

参数号 参数名称 缺省值

r0018

r0026[1]

r0037[2]

r0039

P0040

r0200

P0201

r0203

r0204

r0206

r0207

r0208

驱动装置的显示参数

用户的参数访问级

参数过滤器

调试用的参数

适用于欧洲/北美地区

“快速调试”结束

复位为工厂设置值

固化软件的版本号

CO:直流母线电压实际值

CO:变频器温度[°C]

CO:能量消耗计量表[kWh]

能量消耗计量表清零

功率组合件的实际代码

功率组合件的代码

变频器的实际型号

功率组合件的特征

变频器的额定功率[kW]/[hp]

变频器的额定电流

变频器的额定电压

Level DS QC

- 1 - -

1 1 CUT N

0 1 CUT N

0 1 CT N

Level DS QC

0 1 C Q

0 1 C Q

Level DS QC

0 1 C N

level DS QC

- 3 - -

- 3 - -

- 3 - -

- 3 - 0 3 CT N

- 3 - 0 3 C N

- 3 - -

- 3 - -

- 3 - -

- 3 - -

- 3 - -

5-4 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 71

版本 12/02 系统参数

参数号 参数名称 缺省值

r0209

r0210

r0231[2]

P0290

P0291[3]

P0292

P1800

r1801

P1802

P1820[3]

P1911

r1925

r1926

电动机数据(P0004=3)

参数号 参数名称 缺省值

r0035[3]

P0304[3]

P0305[3]

P0307[3]

P0308[3]

P0309 [3]

P0310[3]

P0311[3]

r0313[3]

P0320[3]

r0330[3]

r0331[3]

r0332[3]

P0335[3]

P0340[3]

P0344[3]

P0346[3]

P0347[3]

P0350[3]

P0352[3]

r0384[3]

r0395

r0396

P0601[3]

P0604[3]

P0610[3]

P0625[3]

P0640[3]

P1910[3]

r9112[3]

变频器的最大电流

电源电压

电缆的最大长度

变频器的过载响应

变频器的保护

变频器的过载报警信号

脉宽调制频率

CO:脉宽调制的开关频率实际值

调制方式

输出相序反向

相数的识别

识别 IGBT 通态电压

识别门控单元死区

CO:电动机温度实际值

电动机额定电压

电动机额定电流

电动机额定功率

电动机额定功率因数

电动机额定效率

电动机额定频率

电动机额定速度

电动机的极对数

电动机的磁化电流

电动机的额定滑差

电动机的额定磁化电流

电动机额定功率因数

电动机的冷却方式

电动机参数的计算

电动机的重量

磁化时间

去磁时间

定子电阻(线间)

电缆电阻

转子时间常数

CO:定子总电阻[%]

CO:转子电阻实际值

电动机的温度传感器

电动机温度保护动作的阈值

2

电动机 I

电动机运行的环境温度

电动机的过载系数[%]

选择电动机数据是否识别

识别定子电阻

t 温度响应

level DS QC

- 3 - 230 3 CT N

- 3 - 2 3 CT N

1 3 CT N

15 3 CUT N

4 2 CUT N

- 3 - 0 3 CUT N

0 3 CT N

3 3 CT N

- 3 - -

- 3 - -

Level DS QC

- 3 - 230 1 C Q

3.25 1 C Q

0.75 1 C Q

0.000 3 C Q

0.0 3 C Q

50.00 1 C Q

0 1 C Q

- 3 - -

0.0 3 CT Q

- 3 - -

- 3 - -

- 3 - 0 3 CT Q

0 3 CT N

9.4 3 CUT N

1.000 3 CUT N

1.000 3 CUT N

4.0 3 CUT N

0.0 3 CUT N

- 3 - -

- 3 - -

- 3 - 0 3 CUT N

130.0 2 CUT N

2 3 CT N

20.0 3 CUT N

110.0 3 CUT Q

0 3 CT Q

- 3 - -

MICROMASTER 430 使用说明书 5-5

6SE6400-5AE00-0MP0

Page 72

系统参数 版本 12/02

编码器(P0004=4)

参数号 参数名称 缺省值

P0400[3]

P0408[3]

P0492[3]

P0494[3]

工艺功能(P0004=5)

参数号 参数名称 缺省值

P0500[3]

命令和数字 I/O(P0004=7)

参数号 参数名称 缺省值

r0002

r0019

r0050

r0051[2]

r0052

r0053

r0054

r0055

r0403

P0700[3]

P0701[3]

P0702[3]

P0703[3]

P0704[3]

P0705[3]

P0706[3]

P0707[3]

P0708[3]

P0718

P0719[3]

r0720

r0722

P0724

P0725

r0730

P0731[3]

P0732[3]

P0733[3]

r0747

P0748

P0800[3]

P0801[3]

P0809[3]

P0810

选择编码器的类型

编码器每转一圈发出的脉冲数

允许的速度偏差

速度信号丢失时进行处理的延迟时间

工艺过程的应用对象

驱动装置的状态

CO/BO:BOP 控制字

CO:激活的命令数据组

CO:激活的驱动装置数据组(DDS)

CO/BO:实际的状态字 1

CO/BO:实际的状态字 2

CO/BO:实际的控制字 1

CO/BO:实际的辅助控制字

CO/BO:编码器的状态字

选择命令源

数字输入 1 的功能

数字输入 2 的功能

数字输入 3 的功能

数字输入 4 的功能

数字输入 5 的功能

数字输入 6 的功能

数字输入 7 的功能

数字输入 8 的功能

CO/BO:手动/自动

选择命令和频率给定值.

数字输入的数目

CO/BO:开关量输入值

开关量输入的防颤动时间

选择数字输入的 PNP/NPN 接线方式

数字输出的数目

BI:数字输出 1 的功能

BI:数字输出 2 的功能

BI:数字输出 3 的功能

CO/BO:各个数字量输出的状态

数字输出反相

BI:下载参数组 0

BI:下载参数组 1

复制命令数据组(CDS)

BI:CDS 的位 0(本机/远程)

Level DS QC

0 3 CT N

1024 3 CT N

10.00 3 CT N

10 3 CUT N

Level DS QC

0 3 CT Q

Level DS QC

- 3 - -

- 3 - -

- 2 - -

- 2 - -

- 3 - -

- 3 - -

- 3 - -

- 3 - -

- 3 - -

2 1 CT Q

1 2 CT N

12 2 CT N

9 2 CT N

15 2 CT N

15 2 CT N

15 2 CT N

0 3 CT N

0 3 CT N

0 3 CUT N

0 3 CT N

- 3 - -

- 3 - -

3 3 CT N

1 3 CT N

- 3 - -

52:3 2 CUT N

52:7 2 CUT N

0:0 2 CUT N

- 3 - -

0 3 CUT N

0:0 3 CT N

0:0 3 CT N

0 3 CT N

718:0 3 CUT N

5-6 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 73

版本 12/02 系统参数

参数号 参数名称 缺省值

P0811

P0819[3]

P0820

P0821

P0840[3]

P0842[3]

P0844[3]

P0845[3]

P0848[3]

P0849[3]

P0852[3]

P1020[3]

P1021[3]

P1022[3]

P1023[3]

P1026[3]

P1028[3]

P1035[3]

P1036[3]

P1074[3]

P1110[3]

P1113[3]

P1140[3]

P1141[3]

P1142[3]

P1230[3]

P1270[3]

P2103[3]

P2104[3]

P2106[3]

P2220[3]

P2221[3]

P2222[3]

P2223[3]

P2226[3]

P2228[3]

P2235[3]

P2236[3]

模拟 I/O(P0004=8)

BI:CDS 的位 1

复制驱动装置数据组(DDS)

BI:DDS 位 0

BI:DDS 位 1

BI:ON/OFF1

BI:ON /OFF1,反转方向

BI:OFF2 的第 1 个源

BI:OFF2 的第 2 个源

BI:OFF3 的第 1 个源

BI:OFF3 的第 2 个源

BI:脉冲使能

BI:固定频率选择,位 0

BI:固定频率选择,位 1

BI:固定频率选择,位 2

BI:固定频率选择,位 3

BI:固定频率选择,位 4

BI:固定频率选择,位 5

BI:使能 MOP(升速命令)

BI:使能 MOP(减速命令)

BI:禁止辅加给定值

BI:禁止负向的频率给定值

BI:反向

BI:RFG 使能

BI:RFG 开始

BI:RFG 使能给定值

BI:使能直流注入制动

BI:使能基本服务

BI:故障确认的第 1 个源

BI:故障确认的第 2 个源

BI:外部故障

BI:固定 PID 给定值选择,位 0

BI:固定 PID 给定值选择,位 1

BI:固定 PID 给定值选择,位 2

BI:固定 PID 给定值选择,位 3

BI:固定 PID 给定值选择,位 4

BI:固定 PID 给定值选择,位 5

BI:使能 PID-MOP(升速命令)

BI:使能 PID-MOP(减速命令)

Level DS QC

0:0 2 CUT N

0 2 CT N

0:0 3 CT N

0:0 3 CT N

722:0 3 CT N

0:0 3 CT N

1:0 3 CT N

19:1 3 CT N

1:0 3 CT N

1:0 3 CT N

1:0 3 CT N

0:0 3 CT N

0:0 3 CT N

0:0 3 CT N

722:3 3 CT N

722:4 3 CT N

722:5 3 CT N

19:13 3 CT N

19:14 3 CT N

0:0 3 CUT N

1:0 3 CT N

722:1 3 CT N

1:0 3 CT N

1:0 3 CT N

1:0 3 CT N

0:0 3 CUT N

0:0 3 CUT N

722:2 3 CT N

0:0 3 CT N

1:0 3 CT N

0:0 3 CT N

0:0 3 CT N

0:0 3 CT N

722:3 3 CT N

722:4 3 CT N

722:5 3 CT N

19:13 3 CT N

19:14 3 CT N

参数号 参数名称 缺省值

P0295

r0750

r0752[2]

P0753[2]

MICROMASTER 430 使用说明书 5-7

6SE6400-5AE00-0MP0

变频器风机停机断电的延时时间

ADC 的数目

ADC 的实际输入[V]或[mA]

ADC 的平滑时间

0 3 CUT N

- 3 - -

- 2 - -

3 3 CUT N

Level DS QC

Page 74

系统参数 版本 12/02

参数号 参数名称 缺省值

r0754[2]

r0755[2]

P0756[2]

P0757[2]

P0758[2]

P0759[2]

P0760[2]

P0761[2]

P0762[2]

r0770

P0771[2]

P0773[2]

r0774[2]

P0776[2]

P0777[2]

P0778[2]

P0779[2]

P0780[2]

P0781[2]

定标后的 ADC 实际值[%]

CO:定标后的 ADC 实际值[4000h]

ADC 的类型

ADC 输入特性定标的值 x1[V/mA]

ADC 输入特性定标的值 y1

ADC 输入特性定标的值 x2[V/mA]

ADC 输入特性定标的值 y2

ADC 死区的宽度[V/mA]

信号消失的延迟时间

DAC 的数目

CI:DAC

DAC 的平滑时间

实际的 DAC 输出值 [V] 或[mA]

DAC 的型号

DAC 输出特性定标的值 x1

DAC 输出特性定标的值 y1

DAC 输出特性定标的值 x2

DAC 输出特性定标的值 y2

DAC 死区的宽度

给定值通道和斜坡函数发生器(P0004=10)

Level DS QC

- 2 - -

- 3 - -

0 2 CT N

0 2 CUT N

0.0 2 CUT N

10 2 CUT N

100.0 2 CUT N

0 3 UT N

10 3 CUT N

- 3 - -

21:0 2 CUT N

2 3 CUT N

- 3 - -

0 2 CT N

0.0 2 CUT N

0 2 CUT N

100.0 2 CUT N

20 2 CUT N

0 3 CUT N

参数号 参数名称 缺省值

P1000[3]

P1001[3]

P1002[3]

P1003[3]

P1004[3]

P1005[3]

P1006[3]

P1007[3]

P1008[3]

P1009[3]

P1010[3]

P1011[3]

P1012[3]

P1013[3

P1014[3]

P1015[3]

P1016

P1017

P1018

P1019

r1024

P1025

选择频率给定值

固定频率 1

固定频率 2

固定频率 3

固定频率 4

固定频率 5

固定频率 6

固定频率 7

固定频率 8

固定频率 9

固定频率 10

固定频率 11

固定频率 12

固定频率 13

固定频率 14

固定频率 15

固定频率方式-位 0

固定频率方式-位 1

固定频率方式-位 2

固定频率方式-位 3

CO:固定频率的实际值

固定频率方式-位 4

2 1 CT Q

0.00 3 CUT N

5.00 3 CUT N

10.00 3 CUT N

15.00 3 CUT N

20.00 3 CUT N

25.00 3 CUT N

30.00 3 CUT N

35.00 3 CUT N

40.00 3 CUT N

45.00 3 CUT N

50.00 3 CUT N

55.00 3 CUT N

60.00 3 CUT N

65.00 3 CUT N

65.00 3 CUT N

1 3 CT N

1 3 CT N

1 3 CT N

1 3 CT N

- 3 - -

1 3 CT N

Level DS QC

5-8 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 75

版本 12/02 系统参数

参数号 参数名称 缺省值

P1027

P1031[3]

P1032

P1040[3]

r1050

P1070[3]

P1071[3]

P1075[3]

P1076[3]

r1078

P1080[3]

P1082[3].

P1091[3]

P1092[3]

P1093[3]

P1094[3]

P1101[3]

r1114

r1119

P1120[3]

P1121[3]

P1130[3]

P1131[3]

P1132[3]

P1133[3]

P1134[3]

P1135[3]

r1170

驱动装置的特点(P0004=12)

固定频率方式-位 5

存储 MOP 的给定值

禁止 MOP 反转

MOP 的给定值

CO:MOP 的实际输出频率

CI:主给定值

CI:主给定值定标

CI:辅加给定值

CI:辅加给定值定标

CO:总的频率给定值

最小频率

最大频率

跳转频率 1

跳转频率 2

跳转频率 3

跳转频率 4

跳转频率的带宽

CO:方向控制后的频率给定值

CO:斜坡函数发生器前的频率给定值

斜坡上升时间

斜坡下降时间

斜坡上升初始圆弧时间

斜坡上升最终圆弧时间

斜坡下降初始圆弧时间

斜坡下降最终圆弧时间

圆弧的类型

OFF3 斜坡下降时间

CO:通过斜坡函数发生器后的频率给定值

Level DS QC

1 3 CT N

0 3 CUT N

1 3 CT N

5.00 2 CUT N

- 3 - -

755:0 3 CT N

1:0 3 CT N

0:0 3 CT N

1:0 3 CT N

- 3 - -

0.00 1 CUT Q

50.00 1 CT Q

0.00 3 CUT N

0.00 3 CUT N

0.00 3 CUT N

0.00 3 CUT N

2.00 3 CUT N

- 3 - -

- 3 - -

10.00 1 CUT Q

30.00 1 CUT Q

0.00 2 CUT N

0.00 2 CUT N

0.00 2 CUT N

0.00 2 CUT N

0 2 CUT N

5.00 2 CUT Q

- 3 - -

参数号 参数名称 缺省值

P0005[3]

P0006

P0007

P0011

P0012

P0013[20]

P1200

P1202[3]

P1203[3]

P1210

P1211

P1212

P1213

P1215

MICROMASTER 430 使用说明书 5-9

6SE6400-5AE00-0MP0

选择需要显示的参量

显示方式

背板亮光延迟时间

锁定用户定义的参数

用户定义的参数解锁

用户定义的参数

捕捉再启动

电动机电源:捕捉再启动

搜寻速率:捕捉再启动

自动再启动

自动再启动的重试次数

至第一次再启动的时间

再启动时间增量

使能仃机抱闸

21 2 CUT N

2 3 CUT N

0 3 CUT N

0 3 CUT N

0 3 CUT N

0 3 CUT N

0 3 CUT N

100 3 CUT N

100 3 CUT N

1 3 CUT N

3 3 CUT N

30 3 CUT N

30 3 CUT N

0 2 T N

Level DS QC

Page 76

系统参数 版本 12/02

参数号 参数名称 缺省值

P1216

P1217

P1232[3]

P1233[3]

P1234[3]

P1236[3]

P1240[3]

r1242

P1243[3]

P1253[3]

P1254

r1261

P1260[3]

P1262[3]

P1263[3]

P1264[3]

P1265[3]

P1266[3]

电动机的控制(P0004=13)

参数号 参数名称 缺省值

r0020

r0021

r0022

r0024

r0025

r0027

r0032

r0038

r0056

r0061

r0065

r0067

r0071

r0086

P0095[10]

r0096[10]

P1300[3]

P1310[3]

P1311[3]

P1312[3]

P1316[3]

P1320[3]

P1321[3]

P1322[3]

释放仃机抱闸的延迟时间

斜坡下降后的仃机时间

直流注入制动的电流

直流注入制动的持续时间

投入直流注入制动的起始频率

复合制动电流

Vdc 调节器的配置

CO:Vdc-max 的接通电平

Vdc-max 的动态系数

Vdc 调节器的输出限幅

Vdc 接通电平的自动检测

BO:接触器的控制字

切换控制的信号源

旁路控制的死时

取消旁路的时间

旁路时间

旁路频率

BI:旁路命令

CO:实际的频率给定值

CO:实际频率

转子实际速度

CO:实际输出频率

CO:实际输出电压

CO:实际输出电流

CO:实际功率

CO:实际功率因数

CO/BO:电动机的控制状态

CO:转子实际速度

CO:滑差频率

CO:实际的输出电流限值

CO:最大输出电压

CO:实际的有功电流

CI:PZD 信号的显示

PZD 信号

控制方式

连续提升

加速电压提升

启动电压提升

电压提升结束的频率

可编程 V/f 特性的频率座标 1

可编程 V/f 特性的电压座标 1

可编程 V/f 特性的频率座标 2

Level DS QC

1.0 2 T N

1.0 2 T N

100 3 CUT N

0 3 CUT N

650.00 3 CUT N

0 3 CUT N

1 3 CT N

- 3 - -

100 3 CUT N

10 3 CUT N

1 3 CT N

- 2 - -

0 2 CT N

1.000 2 CUT N

1.0 2 CUT N

1.0 2 CUT N

50.00 2 CT N

0:0 2 CT N

Level DS QC

- 3 - -

- 3 - -

- 3 - -

- 3 - -

- 3 - -

- 3 - -

- 3 - -

- 3 - -

- 3 - -

- 3 - -

- 3 - -

- 3 - -

- 3 - -

- 3 - -

0:0 3 CT N

- 3 - -

1 3 CT Q

50.0 3 CUT N

0.0 3 CUT N

0.0 3 CUT N

20.0 3 CUT N

0.00 3 CT N

0.0 3 CUT N

0.00 3 CT N

5-10 MICROMASTER 430 使用说明书

6SE6400-5AE00-0MP0

Page 77

版本 12/02 系统参数

参数号 参数名称 缺省值

P1323[3]

P1324[3]

P1325[3]

P1330[3]

P1333[3]

P1335[3]

P1336[3]

r1337

P1338[3]

P1340[3]

P1341[3]

r1343

r1344

P1345[3]

P1346[3]

P1350[3]

通讯(P0004=20)

参数号 参数名称 缺省值

P0918

P0927

r0964[5]

r0965 Profibus Profile - 3 - -

r0967

r0968

P0971

P2000[3]

P2001[3]

P2002[3]

P2003[3]

r2004[3]

P2009[2]

P2010[2]

P2011[2]

P2012[2]

P2013[2]

P2014[2]

r2015[8]

P2016[8]

r2018[8]

P2019[8]

r2024[2]

r2025[2]

r2026[2]

r2027[2]

可编程 V/f 特性的电压座标 2

可编程 V/f 特性的频率座标 3

可编程 V/f 特性的电压座标 3

CI:电压给定值

FCC 的启动频率

滑差补偿

滑差限值

CO:V/f 特性的滑差频率

V/f 特性谐振阻尼的增益系数

最大电流(Imax)频率调节器的比例增益系数

最大电流(Imax)频率调节器的积分时间

CO:最大电流(Imax)频率调节器的输出频率

CO:最大电流(Imax)频率调节器的输出电压

最大电流(Imax)电压调节器的比例增益系数

最大电流(Imax)电压调节器的积分时间

软启动电压

CB(通讯板)地址

修改参数的途径

固化软件版本数据

控制字 1

状态字 1

从 RAM 到 EEPROM 的传输数据

基准频率

基准电压

基准电流

基准转矩

基准功率

USS 规格化

USS 波特率

USS 地址

USS PZD 的长度

USS PKW 的长度

USS 停止发报时间

CO:PZD 来自 BOP 链路(USS)

CI:从 PZD 到 BOP 链路(USS)

CO:PZD 来自 COM链路(USS)

CI:从 PZD 到 COM 链路(USS)

USS 报文无错误

USS 拒收报文

USS 字符帧错误

USS 超时错误

Level DS QC

0.0 3 CUT N

0.00 3 CT N

0.0 3 CUT N

0:0 3 T N

10.0 3 CUT N

0.0 3 CUT N

250 3 CUT N

- 3 - -

0.00 3 CUT N

0.000 3 CUT N

0.300 3 CUT N

- 3 - -

- 3 - -

0.250 3 CUT N

0.300 3 CUT N

0 3 CUT N

Level DS QC

3 2 CT N

15 3 CUT N

- 3 - -

- 3 - -

- 3 - -

0 3 CUT N

50.00 2 CT N

1000 3 CT N

0.10 3 CT N

0.75 3 CT N

- 3 - -

0 3 CT N

6 3 CUT N

0 3 CUT N

2 3 CUT N

127 3 CUT N

0 3 CT N

- 3 - -

52:0 3 CT N

- 3 - -

52:0 3 CT N

- 3 - -

- 3 - -

- 3 - -

- 3 - -

MICROMASTER 430 使用说明书 5-11

6SE6400-5AE00-0MP0

Page 78

系统参数 版本 12/02

参数号 参数名称 缺省值

r2028[2]

r2029[2]

r2030[2]

r2031[2]

r2032

r2033