Siemens LMV52 series, LMV52.4 series User Manual

Based on the following

software versions:

LMV50... : V10.20

LMV51... : V05.10

LMV51.3… : V05.10

LMV52.2.. : V05.10

LMV52.4... : V10.20

Int. LR module: V02.10

Int. VSD module: V01.50

A

ZL52...: V05.00

PLL52...: V01.50

CC1A7550.5en

07.07.2015

Building Technologies Division

LMV52…

Burner management system for forced draft

burners

LMV52.4…:

- COx supervision and control

User Manual

The LMV5 and this User Manual are intended for OEMs which integrate the LMV5

in their products!

Note!

This documentation is only valid together with the LMV5... Basic

Documentation P7550.

2/17

Building Technologies Division Anwenderdokumentation LMV5... CC1A7550.5en

Contents 07.07.2015

Contents

1 Supplementary documentation .................................................................... 3

2 Warning notes ................................................................................................ 4

3 Typographical conventions .......................................................................... 4

4 COx supervision and control ........................................................................ 5

4.1 General ............................................................................................................ 5

4.2 Compatibility of the COx functions ................................................................... 5

4.3 Functioning principle of COx supervision ......................................................... 5

4.4 Hardware prerequisite / Connection diagram .................................................. 6

4.5 Operating modes of COx supervision .............................................................. 6

4.5.1 COx Alarm operating mode ............................................................................. 7

4.5.2 COx Control operating mode ........................................................................... 8

4.6 Increasing the manipulated variable in case of COx signal (O2ModOffset,

formerly O2Offset) ........................................................................................... 9

4.7 Setting notes .................................................................................................. 10

4.7.1 Parameterizations .......................................................................................... 10

4.7.2 Setting fuel-air ratio control ............................................................................ 10

4.7.3 Setting the O2 trim controller ......................................................................... 11

4.7.4 Setting the COx supervision .......................................................................... 11

4.8 Display on the AZL52 ..................................................................................... 12

4.9 Displaying the O2 trim controller status ......................................................... 12

5 List of error messages of LMV5 system .................................................... 13

6 Revision history ........................................................................................... 17

3/17

Building Technologies Division User Manual LMV5... CC1A7550.5en

Supplementary documentation 07.07.2015

1 Supplementary documentation

Product type

Type of documentation

Documentation number

AZL5...

User Documentation AZL5... Modbus

A7550

LMV5... User Documentation

Basic diagram of LMV5... for 2 types of gas

A7550.1

LMV5... User Documentation

Basic diagram of LMV5... for 2 types of liquid fuel

A7550.3

LMV5... User Documentation

Assembly of VKF41...C gas damper with ASK33.4 mounting kit

to the SQM45.295A9 actuator

A7550.4

LMV5... Setting Lists (parameter and error list) I7550

ACS450 Operating Instructions J7550

LMV5… Installation Guide J7550.1

LMV5... Data Sheet N7550

LMV5... Basic Documentation P7550

LMV5... Product Range Overview

This document contains a complete overview

Q7550

AZL52 / LMV51 User Manual U7550

AZL52 / LMV51 User Manual U7550.1

AZL52 / LMV52 User Manual U7550.2

AZL52 / LMV52 User Manual U7550.3

AZL52 / LMV50 User Manual U7550.4

AZL52 / LMV50 User Manual U7550.5

4/17

Building Technologies Division User Manual LMV5... CC1A7550.5en

Warning notes 07.07.2015

2 Warning notes

Warning!

The safety, warning, and technical notes given in the Basic Documentation on

the LMV5 (P7550) apply fully to the present document also!

To avoid injury to persons, damage to property or the environment, the following

warning notes must be observed!

The LMV5 is a safety device! Do not open, interfere with or modify the unit.

Siemens will not assume responsibility for any damage resulting from

unauthorized interference!

3 Typographical conventions

Safety notes

This User Manual contains information which must be observed to ensure your

personal safety and to prevent damage to equipment and property. The instructions

and notes are highlighted by warning triangles and arrows and are presented as

follows, depending on the hazard level:

Warning

means that death, severe personal injury or substantial

damage to property can occur if adequate

precautionary measures are not taken.

Note draws your attention to other information about the

product and its handling contained in other pieces of

documentation.

Only qualified personnel are allowed to commission and operate the unit. Qualified

personnel in the context of the safety-related notes contained in this document are

persons who are authorized to commission, ground and tag devices, systems and

electrical circuits in compliance with established safety practices and standards.

Note the following:

The unit may only be used on applications described in the technical documentation

and only in connection with third-party products and components approved or

recommended by Siemens.

The products can only function correctly and safely if shipped, stored, set up and

installed correctly, and operated and maintained as specified.

Qualified personnel

Correct use

5/17

Building Technologies Division User Manual LMV5... CC1A7550.5en

COx supervision and control 07.07.2015

4 COx supervision and control

4.1 General

Note!

The COx sensor is not included in the Siemens AG scope of delivery.

OEM customer is responsible for checking that the sensor is suitable for the

functions described below.

4.2 Compatibility of the COx functions

The new COx functions are available from the following software versions:

- PLL52 from software version V01.40

(as this requires a supply air sensor temperature range of >400 °C).

- LMV52.4 from software version V10.10

4.3 Functioning principle of COx supervision

For the purpose of supervising the COx quantities during combustion, the LMV52.4

offers the option of connecting a COx measurement transducer to the PLL52.

The states of the COx measurement transducer switching output have the following

meanings:

Contact open: COx present

Contact closed: No COx present

These are evaluated by the LMV52.4 when COx supervision is active.

When COx supervision is active, line breaks, faults in the PLL52, and faults in the bus

communication between the LMV52.4 and PLL52 result in a safety shutdown. This is

also the case during O2 trim control.

Warning!

The connections of the COx sensor to the LMV52.4, and the COx functions in

the LMV52.4, are not established in a fail-safe manner.

6/17

Building Technologies Division User Manual LMV5... CC1A7550.5en

COx supervision and control 07.07.2015

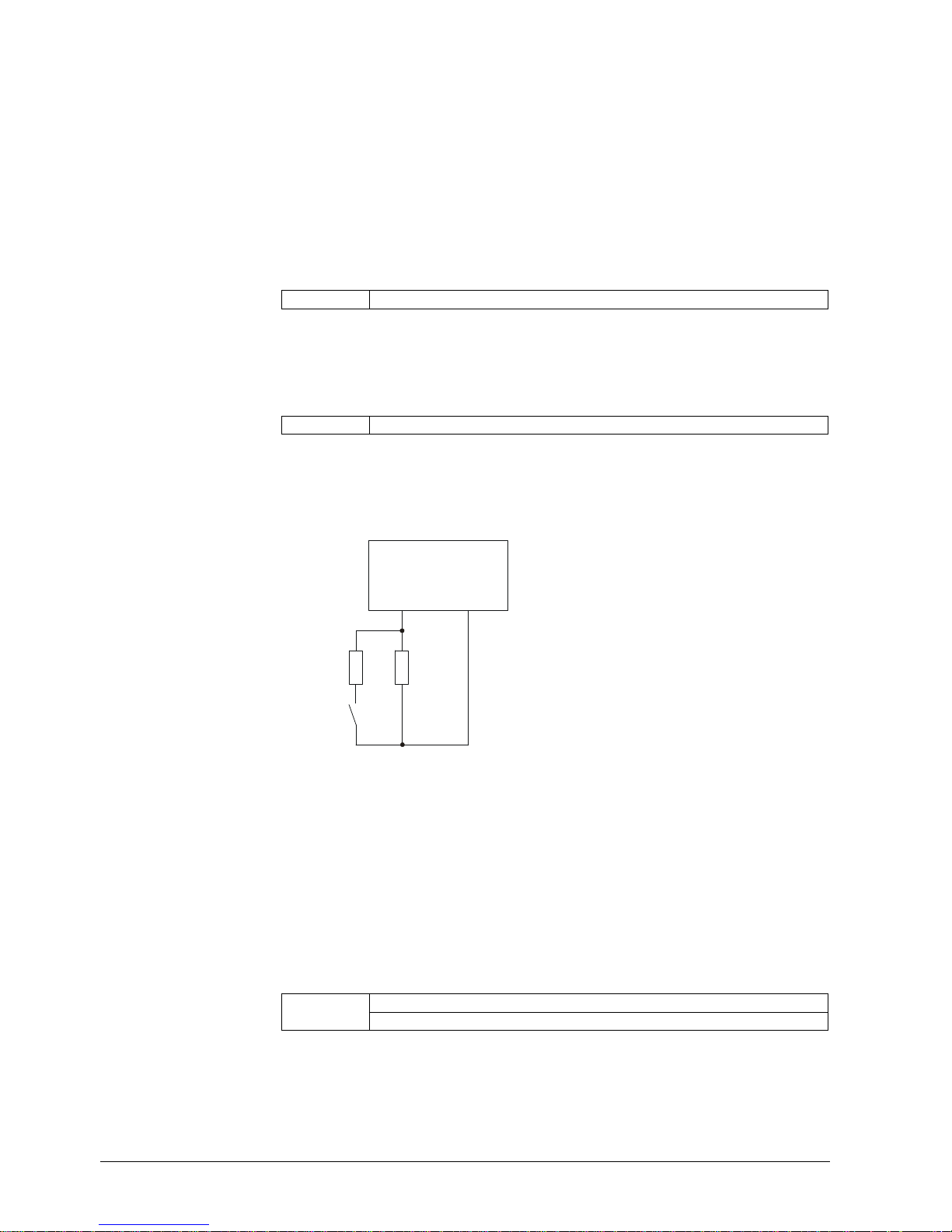

4.4 Hardware prerequisite / Connection diagram

The following hardware is required for COx supervision with LMV52.4:

COx sensor with a potential-free switching contact (NO contact).

The COx limit value at which the contact switches is defined in the COx

measurement transducer.

The COx sensor must be suitable for the fuels being used.

The PLL52, input X87 must be available for the COx sensor connection:

- For this, the supply air temperature sensor for calculating the firing efficiency can,

alternatively, be connected to input X60 of the load controller and activated by

means of the PLL52 parameter AirTempX60PT1000.

Parameter AirTempX60PT1000 (deactivated, activated)

- The Startmode parameter for O2 trim control must be set to standard or

IgnPtWoutTC, as all other start modes require a temperature sensor at input

X87 of the PLL52. In terms of the CO functions, we recommend using the

standard start mode only.

Parameter Startmode (standard, Ign Load TC, IgnPtWithTC, IgnPtWoutTC)

If input X87 on the PLL52 is used to connect the COx sensor, the PLL52 parameter

SupAirTempSens must be set to Pt1000.

COx control is only possible as of PLL52 software version V01.40, as this requires

a temperature range for the supply air temperature sensor of >400 °C.

R1 R2

COxmax

X87

Pin 2

X87

Pin 1

PLL52...

7550d46/0712

- Resistor R1: 7.15 kΩ (±10%)

- Resistor R2: 3.6 kΩ (±10%)

- Relay in no-load status: COx threshold exceeded

- Relay switched: COx threshold not achieved

4.5 Operating modes of COx supervision

With the OptgMode COx parameter, one of the two COx operating modes COx Alarm

or COx Control can be set, and the COx functions deactivated.

Parameter Gas: OptgMode COx (deactivated / COx Alarm / COx Control)

Oil: OptgMode COx (deactivated / COx Alarm / COx Control)

Suggested wiring

Loading...

Loading...