Siemens LCM-OAVS 570-804PA Installation Instructions Manual

Installation Instructions

Document No. 570-114

October 26, 2016

LCM-OAVS Room Pressurization with,

Two Venturi Air Valves (One Exhaust,

One Supply) and HW Reheat (including

BTU Compensation)

BACnet LCM-OAVS with HW Reheat

and Two Venturi Air Valves — One

Exhaust, One Supply Applications 6750

(RTS) 6756 (BTU)

This controller requires Offboard Air

Module(s) (ordered and shipped

separately

570-804PA

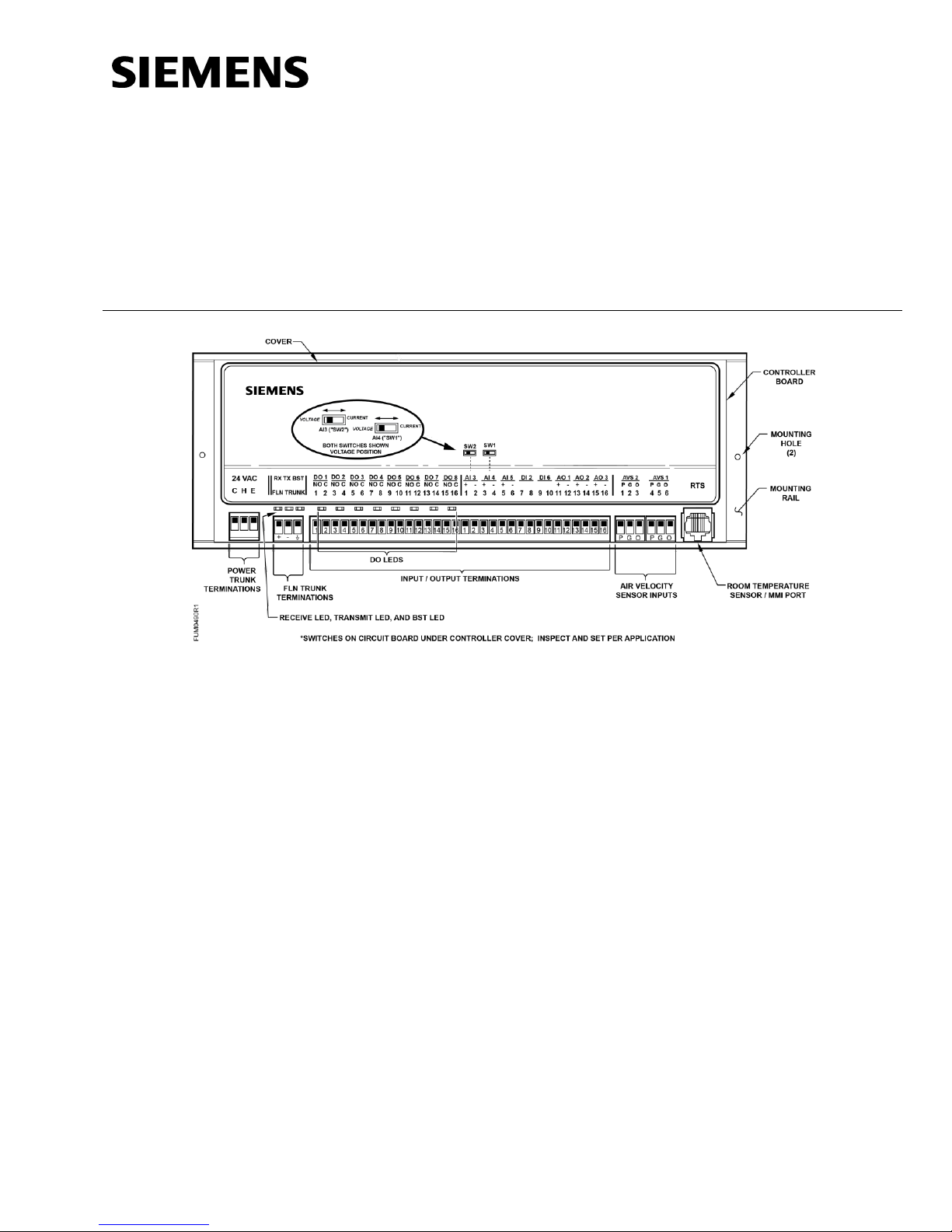

Generic Controller I/O Layout. See Wiring Diagram for application specific details.

Control Applications

6750, 6756

Product Description

The Siemens Venturi Air Valve is a pre-packaged,

easy to install airflow measurement and control

solution. It provides stable and precise airflow

control of room supply, room general exhaust or

fume hood exhaust.

These instructions explain how to field install or

replace the BACnet Laboratory Controller Module

LCM.

This BACnet LCM-OAVS VAV Room Pressurization

Controller with HW Reheat and Two Fast-acting

Venturi Air Valves — One Exhaust, One Supply

features VAV control of a laboratory room with one

supply duct, one exhaust duct, and up to six Fume

Hoods. It uses fast-acting electronic actuators

(shipped separately) to control the supply and

exhaust Venturi air valves.

Item No. 570-114 Rev. CA Page 1 of 8

This controller is built on a BACnet Programmable

TEC (PTEC) platform that supports up to two

Offboard AVS signals; however, Onboard AVS

transducers are not supported. Offboard Air

Module(s) (OAM) house AVS transducers and send

signals to the AVS input(s) on the LCM OAVS

board.

The LCM can operate stand-alone, with a field

panel, or as part of a network.

Product Numbers

See the

Technical Specification Sheet

Configuration and Sizing

section of InfoLink.

Venturi Air Valve for Critical Environments

(149-425) or

in the Critical Environments

Document No. 570-114

Offboard Air Module – two required,

order separately

550-819B

Siemens fast-acting Lab Electronic

Actuator(s) – order and ship separately)

GNP191.1U

CAUTION

Keep the unit in its static-proof bag

until installation.

Otherwise, you run the risk of

damage to the printed circuit board

from electrostatic discharge.

Low cost temporary temperature

sensor, 10K Ω thermistor with

RJ11 (1” long), that enables space

control if the permanent room or

duct sensor is not installed (pack of

25).

540-658P25

Duct Temperature Sensor, NTC

10K Ω Type 2, 3" Probe for

Commissioning only.

QAM1030.008P50

WARNING

Personal injury/loss of life may

occur if you do not follow the

procedures as specified.

CAUTION

Equipment damage or loss of data

may occur if you do not follow the

procedures as specified.

NOTE:

A low-cost temporary RTS (540-658P25)

is available that plugs into the RTS port

on the controller, providing temperature

input and actual space control until a

permanent RTS is installed.

NOTE:

All wiring must conform to national and

local codes and regulations (NEC, CE,

and so on).

Installation Instructions

October 26, 2016

Shipping carton includes a controller assembly, a

mounting rail, and two self-tapping/drilling screws.

Accessories

Prerequisites

Wiring conforms to NEC and local codes and

regulations. For further information, see the

Wiring Guidelines Manual

(Optional)

24 Vac Class 2 power available.

Supply power to the unit is OFF.

Any application specific hardware or devices

Room temperature sensor installed.

installed.

(125-3002).

Warning/Caution Notation

Required Tools and Equipment

Small flat blade screwdriver

3/8-inch open end wrench

Expected Installation Time

30 minutes

Installation Instructions

1. Secure the mounting rail in the controller’s

desired location.

2. Place the ESD wrist strap on your wrist and

attach it to a good earth ground.

3. Remove the controller from the static proof bag

and snap it into place on the mounting rail.

4. If the controller will be used with a field panel,

disconnect the field level network (FLN) trunk

from the field panel.

5. Wire the FLN trunk to the controller. After all

controllers are connected to the FLN, reconnect

the FLN trunk to the field panel.

Needle nose pliers

1/4-inch poly tubing

Page 2 of 8 Siemens Industry, Inc.

Document No. 570-114

CAUTION

DO Wiring – Each DO provides a

Normally Open (NO) terminal and a

Common (C) terminal.

To reduce noise and the potential

for ground loops, both connections

of a 24 Vac load must be wired

directly to the DO terminal on the

controller board.

CAUTION

The fume hood flow module, the

FHC, any 0 to 10 Vdc actuator used

by the LCM, and the LCM cannot

share a single power trunk.

The preferred configuration for

shared power trunks is to use one

trunk for the FFM and FHC and

another trunk for the actuator(s) and

LCM.

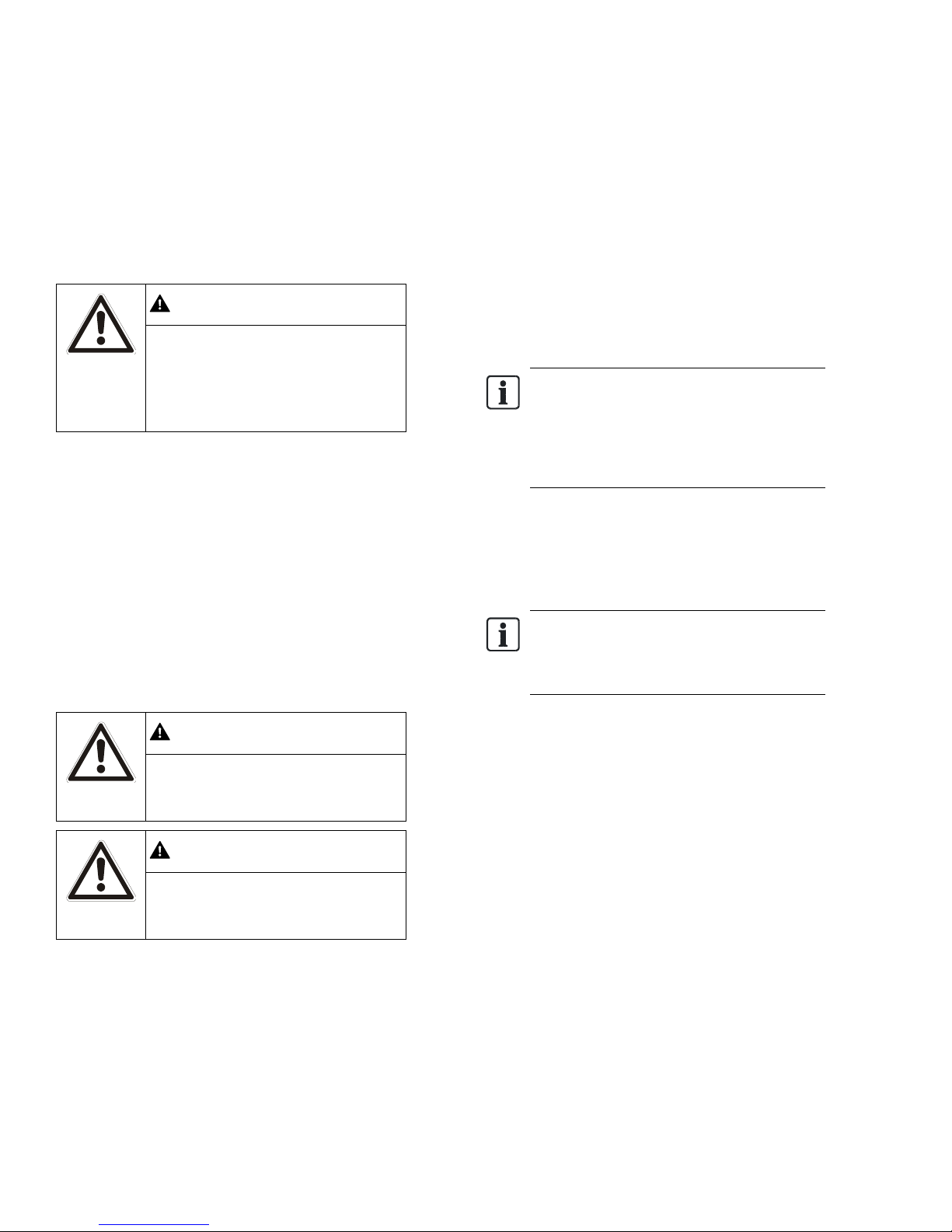

8.

For each Fast Acting Lab Electronic Actuator,

verify that the switches are set as shown in

Figure

Switch Settings for the Fast Acting

Lab Electronic Actuator

.

Supply

Exhaust

Switch Settings for the Fast Acting Lab Electronic

Actuator.

CAUTION

This actuator requires a maximum

of 20 VA, 24 Vac source.

DO NOT connect any other nonisolated devices to the transformer

that powers the electronic actuator

or the hot water valve actuator.

9.

Plug the room temperature sensor cable into

the RTS port.

10.

Connect the power trunk. DO NOT apply

power to the controller without first consulting

the specialist.

CAUTION

It is important that the neutral that

supplies the TEC must be earth

grounded at the source of the 24

Vac power.

Possible erratic equipment

operation or damage if neutral is not

grounded.

Installation Instructions

October 26, 2016

6. If the controller requires Offboard Air Modules,

install them now following the appropriate

Installation Instructions (see

7. Connect the point wiring (see

Product Numbers

Wiring Diagram

).

s).

Siemens Industry, Inc. Page 3 of 8

The installation is complete.

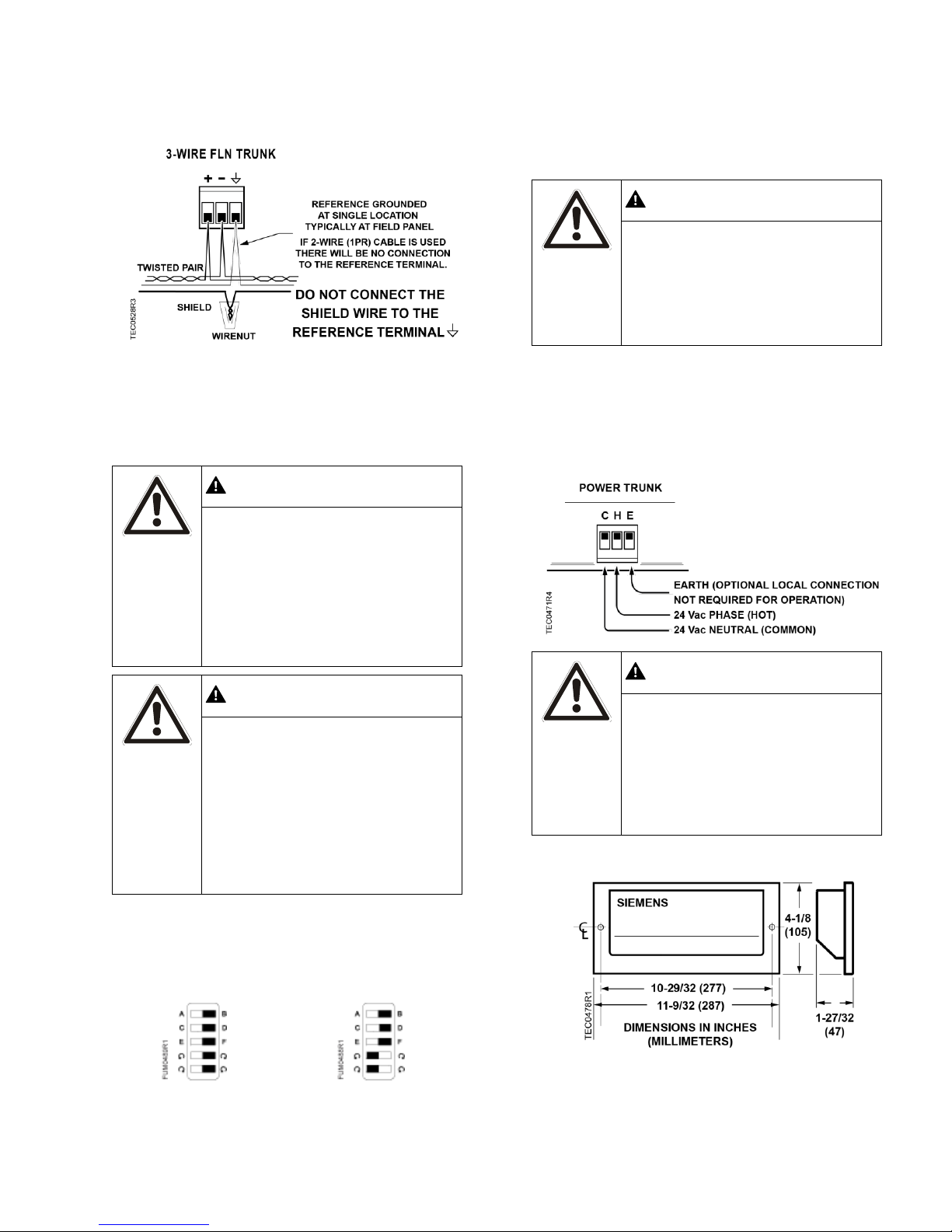

Dimensions.

Loading...

Loading...