Page 1

Operating and

installation instructions

Page 2

2

Abb. 1

ELECTRO

Fig. 1

GAZ

min. 650

min. 550

Page 3

3

Operating modes

Exhaust-air mode:

❑ The extractor-hood fan extracts the

kitchen vapours and conveys them

through the grease filter into the

atmosphere.

❑ The grease filter absorbs the solid

particles in the kitchen vapours.

❑ The kitchen is kept almost free of grease

and odours.

D

When the extractor hood is operated

in exhaust-air mode simultaneously with

a different burner which also makes use

of the same chimney (such as gas, oil or

coal-fired heaters, continuous-flow heaters,

hot-water boilers) care must be taken to

ensure that there is an adequate supply

of fresh air which will be needed by the

burner for combustion.

Safe operation is possible provided that the

underpressure in the room where the

burner is installed does not exceed 4 Pa

(0.04 mbar).

This can be achieved if combustion air can

flow through non-lockable openings, e.g. in

doors, windows and via the airintake/exhaust-air wall box or by other

technical measures, such as reciprocal

interlocking, etc.

If the air intake is inadequate, there is a

risk of poisoning from combustion gases

which are drawn back into the room.

An air-intake/exhaust-air wall box by itself is

no guarantee that the limiting value will not

be exceeded.

Note: When assessing the overall

requirement, the combined ventilation

system for the entire household must be

taken into consideration. This rule does not

apply to the use of cooking appliances,

such as hobs and ovens.

Unrestricted operation is possible if the

extractor hood is used in recirculating mode

– with activated carbon filter.

Instructions for use:

Circulating-air mode:

❑ An activated carbon filter must be fitted

for this operating mode (see Filters and

maintenance).

The complete installation set and

replacement filters can be obtained from

specialist outlets.

The corresponding accessory numbers

can be found at the end of these

operating instructions.

❑ The extractor-hood fan extracts the

kitchen vapours which are purified in the

grease filter and activated carbon filter

and then conveyed back into the

kitchen.

❑ The grease filter absorbs the grease

particles in the kitchen vapours.

❑ The activated carbon filter binds the

odorous substances.

If no activated carbon filter is installed,

it is not possible to bind the odorous

substances in the cooking vapours.

Page 4

4

Before using for the first time

Important notes:

❑ The Instructions for Use apply to several

versions of this appliance. Accordingly,

you may find descriptions of individual

features that do not apply to your

specific appliance.

❑ This extractor hood complies with all

relevant safety regulations.

Repairs should be carried out by

qualified technicians only.

Improper repairs may put the user at

considerable risk.

❑ Before using your appliance for the first

time, please read these Instructions for

Use carefully. They contain important

information concerning your personal

safety as well as on use and care of the

appliance.

❑ Please retain the operating and

installation instructions for a subsequent

owner.

Gas hobs / gas cookers

Do not operate more than 2 gas

cooking areas simultaneously over a period

of max. 15 minutes at maximum thermal

load.

Due to the effect of the heat there is a risk of

burns if the surfaces of the housing are

touched.

❑ Note that one large burner of more than

5 kW (Wok) is equivalent to the power of

2 gas burners.

❑ Never operate a gas cooking area

without a cooking utensil on it. Regulate

the flame in such a way that it does not

project over the cooking utensil.

❑ This appliance is labelled

in accordance with

European Directive

2002/96/EG concerning

used electrical and

electronic appliances

(waste electrical and

electronic equipment –

WEEE). The guideline

determines the framework for the return

and recycling of used appliances as

applicable throughout the EU.

If you encounter a problem

IIf you have any questions or if a fault

occurs, please call Customer Service.

(See list of Customer Service

representatives).

When you call, please quote the following:

E-Nr. FD

Enter the relevant numbers into the box

above. The E-Nr. (product no.) and FD

(production date) are shown on the

nameplate which can be seen inside the

extractor hood after the filter frame has

been detached.

The manufacturer of the extractor

hoods accepts no liability for complaints

which can be attributed to the design

and layout of the pipework.

Page 5

5

Before using for the first time

Safety instructions

Do not flambé food directly under the

extractor hood.

Risk of grease filter catching fire due

! to flames.

The hotplates must always be covered

with a utensil.

Restrictions apply to the use of the

extractor hood over a solid-fuel burner

(coal, wood, etc.). (See Installation

instructions).

The appliance is not intended for use

by young children or infirmed persons

without supervision.

Young children should be supervised to

ensure they do not play with the appliance.

Light bulbs must always be fitted when

the extractor hood is in use.

Defective bulbs should be replaced

immediately to prevent the remaining bulbs

from overloading.

Never operate the extractor hood

without a grease filter.

Overheated fat or oil can easily catch

fire.

If you are cooking with fat or oil, e.g. chips,

etc., never leave the cooker unattended.

Do not use the appliance if damaged.

The appliance may be connected to

the mains by a qualified technician only.

If the connecting cable for this

appliance is damaged, the cable must be

replaced by the manufacturer or his

customer service or a similarly qualified

person in order to prevent serious injury to

the user.

Dispose of packaging materials

properly (see Installation instructions).

This extractor hood is designed for

domestic use only.

Never allow children to play with the

appliance.

Do not let adults or children operate the

appliance unsupervised:

– if they are mentally or physically unable

to use the appliance safely and correctly,

– if they don’t have the knowledge and

experience to use the appliance safely

and correctly.

Carefully clean the extractor hood

before switching on for the first time.

Do not place any objects on the

extractor hood.

Page 6

6

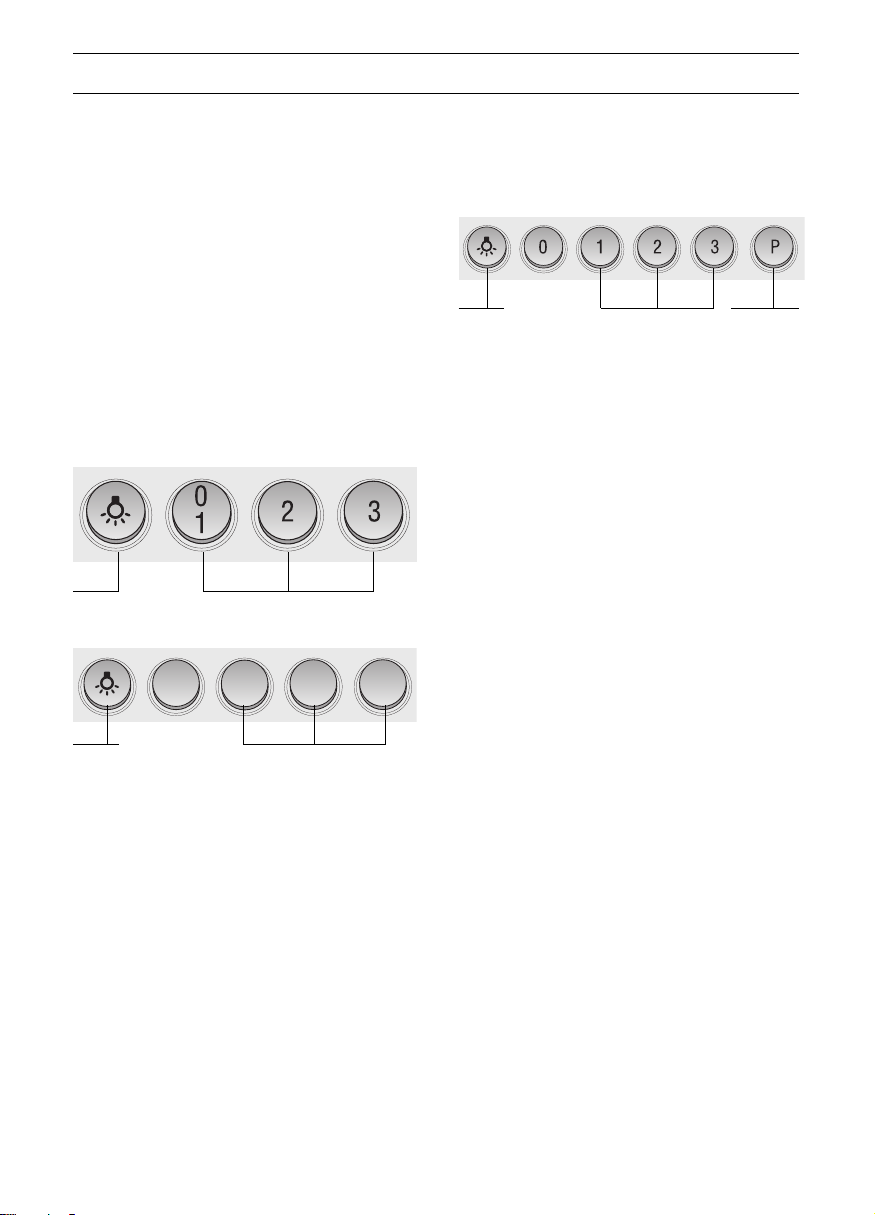

Operating procedure

The most effective method of removing

vapours produced during cooking is to:

❑ Switch the ventilator ON

as soon as you begin cooking.

❑ Switch the ventilator OFF

a few minutes after you have finished

cooking.

Setting the required fan speed:

❑ Press the corresponding button.

Lighting:

❑ The light can be switched on at any

time, even though the fan is switched off.

Light

Fan settings

Light

Fan settings

Intensive setting:

❑ Maximum power is obtained at the

intensive setting

P. It is only required for

short intervals.

Light

Fan settings

Intensive

setting

0

123

Page 7

7

Filters and maintenance

Grease filters:

Metal filters are used to trap the greasy

element of the vapours that develop

during cooking.

The filter mats are made from noncombustible metal.

Caution:

As the filter becomes more and more

saturated with grease, not only does the

risk of it catching fire increase but the

efficiency of the extractor hood can also be

adversely affected.

Important:

By cleaning the metal grease filters at

appropriate intervals, the possibility of them

catching fire as a result of a build-up of heat

such as occurs when deep-fat frying or

roasting is taking place, is reduced.

Cleaning the metal grease filters:

❑ In normal operation (1 to 2 hours daily),

the metal grease filter must be cleaned

1 x a month.

❑ The filters can be cleaned in a dish-

washer. It is however possible that they

will become slightly discoloured.

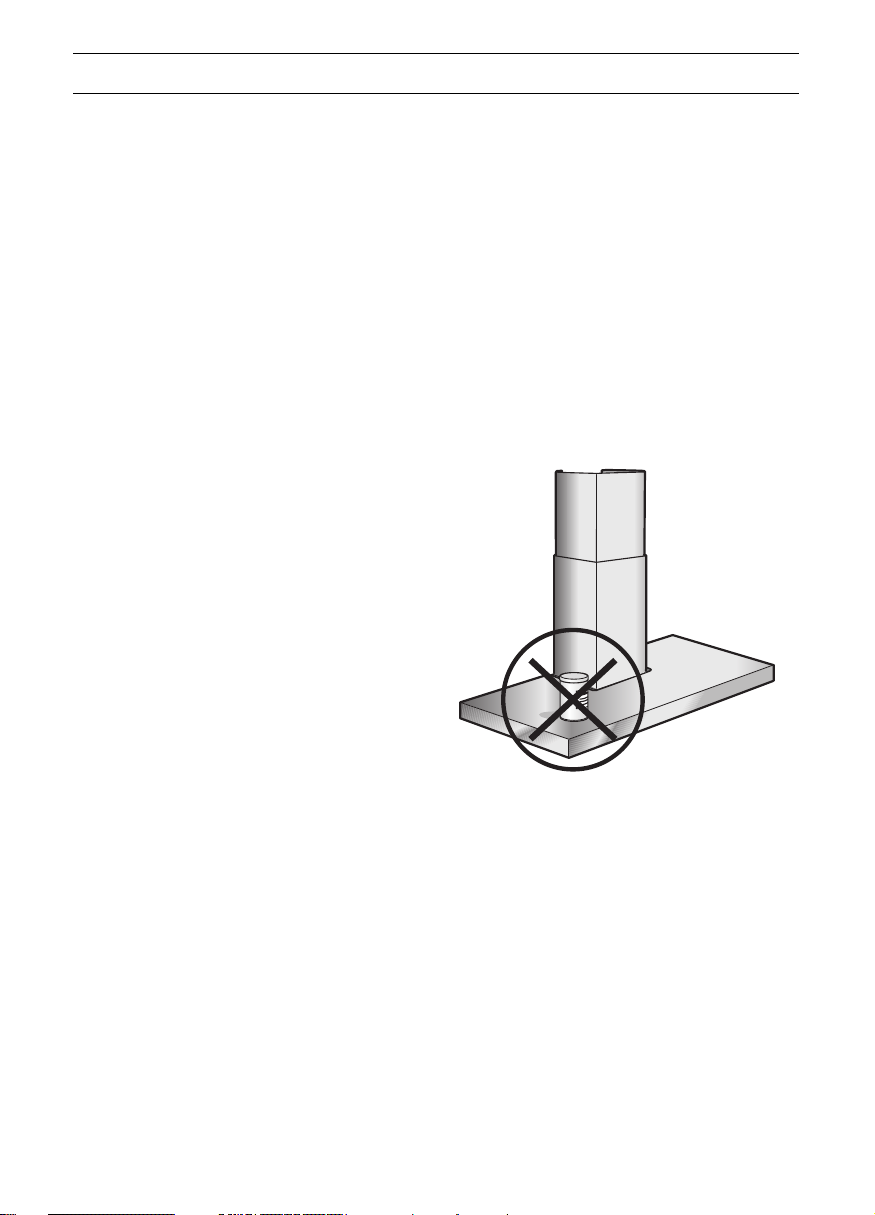

❑ The filter must be placed loosely, and

NOT wedged, in the dishwasher.

Important:

Metal filters that are saturated with

grease should not be washed together

with other dishes etc.

❑ When cleaning the filters by hand, soak

them in hot soapy water first of all.

Do not use aggressive, acidic or caustic

cleaners.

Then brush the filters clean, rinse them

thoroughly and leave the water to drain off.

2. Clean the filters.

3. Insert the clean filters back into the

hood.

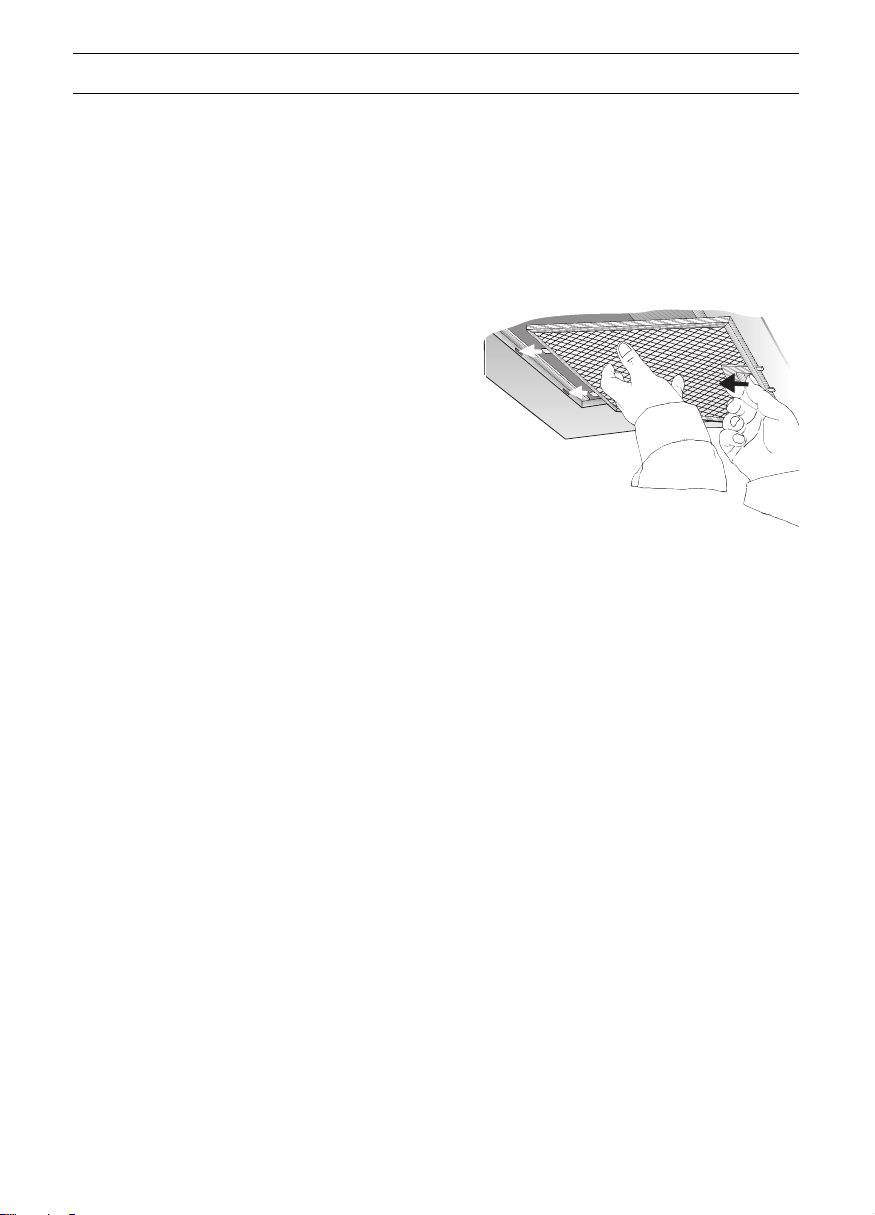

Removing and inserting the metal grease

filters:

Warning: The halogen bulbs must be

switched off and cool.

1. Press the catch on the grease filters

inwards and fold the filters down.

At the same time take hold of the underside of the grease filters with your other

hand.

Page 8

8

Filters and maintenance

Activated carbon filter:

For neutralizing odours in recirculating

mode.

Caution:

As the filter becomes more and more

saturated with grease, there is an increased

risk of fire and the function of the extractor

hood may be impaired.

Important:

Change the activated carbon filter promptly

to prevent the risk of fire from the

accumulation of heat when deep-fat frying

or roasting.

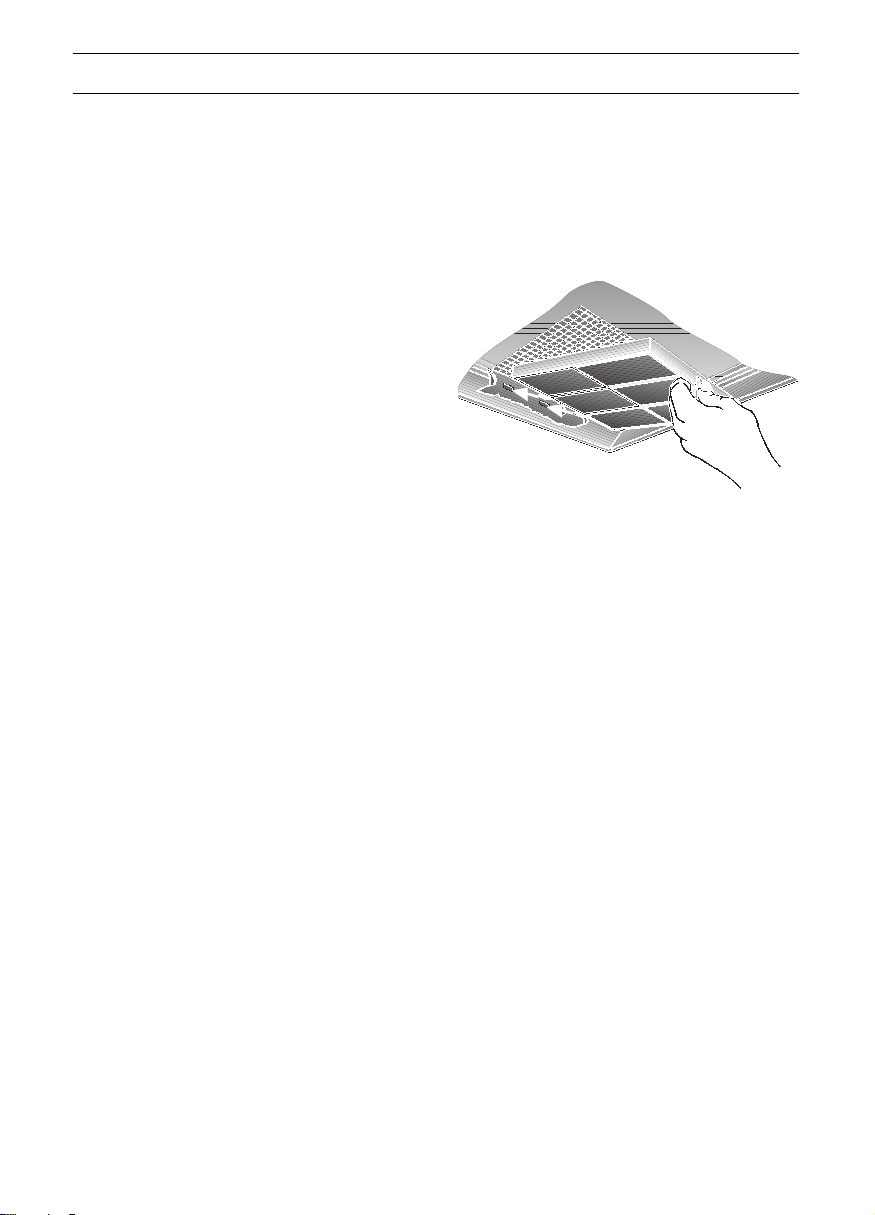

3. Engage the catch.

4. Insert the metal grease filters (see

"Removing and inserting the metal

grease filters").

Replacing the activated carbon filter:

❑ During normal operation (1 to 2 hours

per day) the activated carbon filters

should be replaced approximately 2 x

year.

❑ A replacement filter can be obtained

from any authorized dealer (see optional

accessories).

❑ Use original filters only.

By doing so you will obtain maximum

performance from your extractor hood.

Disposing of the old activated carbon

filter:

❑ There are no pollutants in the activated

carbon filters. They can therefore be

disposed of as part of your normal

domestic refuse.

Installation and removal:

Warning: The halogen bulbs must be

switched off and cool.

1. Remove the metal-mesh filters

(see "Removing and inserting the metalmesh grease filters").

2. Insert the activated carbon filter.

Page 9

9

Cleaning and care

Isolate the extractor hood by pulling out

the mains plug or switching off the fuse.

Do not clean the extractor hood with

abrasive sponges or with cleaning agents

which contain sand, soda, acid or chlorine!

❑ Clean the extractor hood with a hot soap

solution or a mild window cleaner.

❑ Do not scrape off dried-on dirt but wipe

off with a damp cloth.

❑ When cleaning the grease filters, remove

grease deposits from accessible parts of

the housing. This prevents the risk of fire

and ensures that the extractor hood

continues operating at maximum

efficiency.

Clean the operating buttons with a mild

soapy solution and a soft, damp cloth only.

Do not use stainless-steel cleaner to clean

the operating buttons.

Stainless steel surfaces:

❑ Use a mild non-abrasive stainless steel

cleaner.

❑ Clean the surface in the same direction

as it has been ground and polished.

❑ We recommend our stainless steel

cleaner no. 461731.

See enclosed service booklet for order

address.

Aluminium, coated and plastic surfaces:

❑ Do not use dry cloths.

❑ Use a mild window cleaning agent.

❑ Do not use aggressive, acidic or caustic

cleaners.

Observe the warranty regulations in the

enclosed service booklet.

Page 10

10

Replacing the light bulbs

Bulbs:

1. Switch off the extractor hood and pull

out the mains plug or switch off the

electricity supply at the fuse box.

2. Remove the grease filters (see Filters and

Maintenance).

3. Detach the bulb cover.

4. Replace the bulb (commercially available

halogen bulb 230 volt, 28 watt, E 14

bulb holder).

5. Attach the lamp cover again.

6. Re-insert the grease filters.

7. Plug the appliance into the mains or

switch it on at the fuse box.

Halogen bulbs:

1. Switch off the extractor hood and pull

out the mains plug or switch off the

electricity supply at the fuse box.

When switched on, the halogen bulbs

become very hot. Even for some time after

the bulbs have been switched off there is

still a risk of burns.

2. Remove the bulb ring with a screwdriver

or similar tool.

3. Replace the halogen light bulb

(conventional halogen bulb, 12 Volt,

max. 20 Watt, G4 cap).

Caution: Refer for plug-in lampholder.

Take hold of the bulb with a clean cloth.

4. Re-insert the bulb ring.

5. Plug the appliance into the mains or

switch it on at the fuse box.

Note: If the light does not function, check

that the bulbs have been inserted correctly.

Page 11

11

Important information

Installation Instructions:

Additional information concerning gas

cookers:

When installing gas hotplates, comply

with the relevant national statutory

regulations (e.g. in Germany: Technische

Regeln Gasinstallation TRGI).

Always comply with the currently valid

regulations and installation instructions

supplied by the gas appliance

manufacturer.

Only one side of the extractor hood

may be installed next to a high-sided unit

or high wall. Gap at least 50 mm.

Minimum distance on gas hotplates

between the upper edge of the trivet

and lower edge of the extractor

hood: 650 mm, Fig. 1.

Old appliances are not worthless

rubbish. Valuable raw materials can be

reclaimed by recycling old appliances.

Before disposing of your old appliance,

render it unusable.

You received your new appliance in a

protective shipping carton. All packaging

materials are environmentally friendly and

recyclable. Please contribute to a better

environment by disposing of packaging

materials in an environmentally-friendly

manner.

Please ask your dealer or inquire at your

local authority about current means of

disposal.

The extractor hood can be used in

exhaust air or circulating air mode.

The width of the extractor hood must

correspond to the width of the cooking

area.

Always mount the extractor hood over

the centre of the hob.

Minimum distance between electric

hob and bottom edge of extractor hood:

550 mm, Fig. 1.

The extractor hood must not be

installed over a solid fuel cooker – a

potential fire hazard (e.g. flying sparks) –

unless the cooker features a closed,

non-removable cover and all national

regulations are observed.

The smaller the gap between the

extractor hood and hotplates, the greater

the likelihood that droplets will form on the

underside of the extractor hood.

Page 12

12

Prior to installation

Exhaust-air mode

The exhaust air is discharged upwards

through a ventilation shaft or directly

through the outside wall into the open.

D

Exhaust air should neither be directed

into a smoke or exhaust flue that is

currently used for other purposes, nor into

a shaft that is used for ventilating rooms in

which stoves or fireplaces are also located.

Exhaust air may be discharged in

accordance with official and statutory

regulations only (e.g. national building

regulations).

Local authority regulations must be

observed when discharging air into smoke

or exhaust flues that are not otherwise in

use.

D

When the extractor hood is operated

in exhaust-air mode simultaneously with

a different burner which also makes use

of the same chimney (such as gas, oil or

coal-fired heaters, continuous-flow heaters,

hot-water boilers) care must be taken to

ensure that there is an adequate supply

of fresh air which will be needed by the

burner for combustion.

Safe operation is possible provided that the

underpressure in the room where the

burner is installed does not exceed 4 Pa

(0.04 mbar).

This can be achieved if combustion air can

flow through non-lockable openings, e.g. in

doors, windows and via the airintake/exhaust-air wall box or by other

technical measures, such as reciprocal

interlocking, etc.

If the air intake is inadequate, there is a

risk of poisoning from combustion gases

which are drawn back into the room.

An air-intake/exhaust-air wall box by itself

is no guarantee that the limiting value will

not be exceeded.

Note: When assessing the overall

requirement, the combined ventilation

system for the entire household must be

taken into consideration. This rule does not

apply to the use of cooking appliances,

such as hobs and ovens.

Unrestricted operation is possible if the

extractor hood is used in recirculating

mode – with activated carbon filter.

If the exhaust air is going to be

discharged into the open, a telescopic

wall box should be fitted into the outside

wall.

Page 13

13

For optimum extractor hood efficiency:

❑

Short, smooth air exhaust pipe.

❑

As few bends in the pipe as possible.

❑

Diameter of pipe to be as large as

possible and no tight bends in pipe.

If long, rough exhaust-air pipes,

many pipe bends or smaller pipe

diameters are used, the air extraction

rate will no longer be at an optimum

level and there will be an increase in

noise.

The manufacturer of the

extractor hoods accepts no liability

for complaints which can be

attributed to the design and layout of

the pipework.

❑

Round pipes:

We recommend

Internal diameter: 150 mm (at least

120 mm).

❑

Flat ducts must have an internal crosssection that equates to that of round

pipes.

There should be no sharp bends.

l 120 mm approx. 113 cm

2

l 150 mm approx. 177 cm

2

❑

If pipes have different diameters:

Insert sealing strip.

❑

For exhaust-air mode, ensure that

there is an adequate supply of fresh air.

Circulating-air mode

❑ With activated carbon filter if exhaust-air

mode is not possible.

The complete

installation set can be

obtained from

specialist outlets.

The corresponding

accessory numbers

can be found at the

end of these operating

instructions.

Prior to installation

Connecting a l 150 mm exhaust-air

pipe:

❑

Mount the pipe

directly onto the

air outlet on the

hood.

If using an

aluminium pipe,

smooth the

connection area

beforehand.

Connecting a l 120 mm exhaust-air

pipe:

❑ Attach the

reducing

connector directly

to the air pipe.

❑ Attach the

exhaust-air pipe

to the reducing

connector.

Page 14

14

Prior to installation

Preparing the wall

❑ The wall must be flat and perpendicular.

❑ Make sure that the wall can bear the

applied loads.

❑ The provided screws and wall plugs are

suitable for solid masonry. On all other

wall types (e.g. plasterboard, porous

concrete, Poroton bricks) use the

appropriate fasteners.

❑ Ensure that the wall is capable of provi-

ding a firm hold for mounting screws

and plugs.

Electrical connection

WARNING: THIS APPLIANCE MUST BE

EARTHED

IMPORTANT: Fitting a Different Plug:

The wires in the mains lead are coloured in

accordance with the following code:

Green and Yellow – Earth

Blue – Neutral

Brown – Live

Electrical connection

If you fit your own plug, the colours of

these wires may not correspond with the

identifying marks on the plug terminals.

This is what you have to do:

1.Connect the green and yellow (Earth)

wire to the terminal in the plug marked

‘E’ or with the symbol ( ), or

coloured green or green and yellow.

2.Connect the blue (Neutral) wire to the

terminal in the plug marked ‘N’ or

coloured black.

3.Connect the brown (Live) wire to the

terminal marked ‘L’, or coloured red.

The extractor hood should only be connected to an earthed socket that has been

installed according to relevant regulations.

If possible, site the earthed socket directly

behind the chimney panelling.

❑

The earthed socket should be

connected via its own circuit.

❑

If the earthed socket is no longer

accessible following installation of the

extractor hood, ensure that there is a

permanently installed disconnector.

If it is necessary to wire the extractor

hood directly into the mains:

The extractor hood should only be

connected to the electricity supply by a

properly qualified electrician.

A separator must be installed in the

household circuit. A suitable separator is a

switch that has a contact gap of more than

3 mm and interrupts all poles. Such devices

include circuit breakers and contactors.

If the connecting cable for this

appliance is damaged, the cable must be

replaced by the manufacturer or his customer service or a similarly qualified person in

order to prevent serious injury to the user.

Electrical data:

Are to be found on the name plate inside

the appliance after removal of the filter

frame.

Before undertaking any repairs,

always disconnect the extractor hood from

the electricity supply.

Length of the connecting cable: 1.30 m.

This extractor hood corresponds to EC

regulations concerning RF interference

suppression.

Weight in kg:

Exhaust air

Recirculating

air

16,560 cm

70 cm

18,0

17,2 18,7

90 cm 18,7 20,2

We reserve the right to construction changes within the

context of technical development.

Page 15

15

Installation preparations

5. Screw on the fixing bracket for the flue

duct.

6. Screw in the 2 middle screws as an

installation aid, leaving them projecting

by approx. 5 mm.

5

This extractor hood is intended to be

mounted onto the kitchen wall.

1. Remove the grease filter (refer to

Operating Instructions).

2. Draw a line on the wall from the ceiling

to the lower edge of the hood at the

centre of the location where the hood is

going to be mounted.

3. Using the template, mark positions on

the wall for the screws.

Ensure that the minimum distance bet-

ween the hob and the extractor hood is

maintained – 550 mm for an electric hob

and 650 mm for a gas hob. The bottom

edge of the template equates to the lower

edge of the extractor hood.

4. Drill 3x 8 mm holes for the extractor

hood and 2x 8 mm holes for the fixing

bracket for the flue duct and press in

wall plugs flush with the wall.

0

Page 16

16

Installation

7. Remove the protective film from the

extractor hood.

Attach the extractor hood, align and

screw tightly into place.

8. Connect up the air outlet pipe.

9. Connect the hood to the electricity

supply.

10. Put on the enclosed protective

cardboard for the glass plate.

11. Put on the glass plate and remove

protective cardboard.

12. Screw glass plate tightly into place.

2

1

Page 17

17

Installing the flue ducts

4. Place flue ducts on the extractor hood,

push the inner flue duct upwards and

attach the left and right sides to the

fixing bracket.

1. Separate the flue ducts by removing the

adhesive tape.

2. Remove the protective film from the two

flue ducts.

Avoid damage to the sensitive

surface.

Warning: The interior walls of the flue

panelling can have sharp edges – Risk of

injury –.

We recommend that you wear gloves when

installing.

3. Insert one flue duct into the other.

Avoid scratching the flue ducts

when inserting them, e.g. by placing the

installation template as protection over

the edge of the outer flue duct.

Exhaust-air mode: Slots of the inner

flue duct downwards.

Circulating-air mode: Slots of the inner

flue duct upwards.

5. Use 2 screws to attach the sides of the

inner flue duct to the fixing bracket.

6. Insert the grease filter (refer to

Operating Instructions).

Page 18

18

Notes

Page 19

19

Notes

Page 20

20

Notes

Page 21

21

Notes

Page 22

22

Notes

Page 23

23

LZ52250

236

669419

Page 24

9000 416 016

Printed in Germany 0109 Es.

E-Mail: siemens-infoline@bshg.com

Online-Shop: www.siemens-eshop.com

Loading...

Loading...