Page 1

663

5

24191 - San Andrés del Rabanedo

León - España

www.simelec.es

Avda. San Ignacio de Loyola,185

Tel.: +34 987 248 305

Email: simelec@simelec.es

OZZ7E5

OZZ7CF

Central communication

unit

with integrated web server function

The central communication unit OZW775 in plants is used together with SyncoTM

700 devices, RXB/RXL room controllers and the Synco

unit. Key features:

• Remotely operate and monitor up to 250 Synco devices in a KNX network via

ACS software and/or via web browser.

• Link to an operator station (PC/laptop with ACS) via direct connection (USB)

or telephony (RS-232 modem).

• Link to a web browser via Ethernet (Ethernet card OZZ7E5 required) and/or

via direct connection or telephony.

• Customizable user profiles for web operation.

• Customizable user texts for inputs, outputs, function blocks.

• Send fault status messages to operator stations, SMS recipients,

pagers, fax machines, e-mail recipients (message receivers).

• Periodically send system reports to message receivers.

• Storage of the last 500 faults and messages (history).

• 4 message receivers with configurable receiver types and

transmission times.

• 8 digital inputs for fault and operational status contacts.

• 8 universal inputs, configurable for analog, digital and pulse signals.

• 5 runtime totalizer meters, automatically send service alarms.

• 8 meters for pulse signals from heat, water, gas or electricity meters.

• 4 seven-day time switches to switch consumers via relays.

• 6 relays for use with 7-day time switches or as fault relays.

• 5 offline trends with 50,000 recorded values.

TM

living central apartment

OZW775

V2.0

CE1N5663en

29.10.2008

Building Technologies

HVAC Products

Page 2

Use

Buildings • Office and administrative buildings, residential housing.

• Schools, gymnasiums, leisure facilities, hotels.

• Municipal buildings, industrial buildings.

Building operators

• Building maintenance companies, facility management.

• Real estate agencies.

• District heating companies, installers, end customers.

Functions

Basic functions Basic functions of the central communication unit OZW775:

• Monitor KNX network member devices and acquire fault statuses in HVAC plants via

digital and universal inputs.

• Signal faults via direct connection to local operator station and/or via modem to

operator stations, SMS recipients, pagers, fax machines, email recipients.

• Central communication unit V2.0 with web server: Send faults to web browser via

Ethernet and/or direct connection or modem.

• Operate HVAC plants and equipment with operator stations and/or web browser, and

display process values on operator stations and/or web browser.

• Function "Clock time master" for default system time (date and time) to KNX network

member devices.

• Function "System clock" with adjustable time zone and daylight saving/standard time

changeover.

Faults

Fault sources

• "System" fault source

The central communication unit detects device failures and faults on the KNX

network listed in the unit’s device list.

• "Local" fault source

The central communication unit identifies internal faults and fault states at the digital

and universal inputs configured as fault inputs (fault source "Local"). Typical faults at

digital and universal inputs:

− Overload signals from thermal cutouts.

− Error states signaled by switches or monitors.

− Limit value violations.

− Fault states of aggregates and plants.

− Common messages from external plants.

Fault indication Depending on the fault's source, the central communication unit indicates faults either

via "Local" or "System" LED. The "Local" LED also indicates state "Hours run for

service reached".

Fault relays

You can configure two relay outputs as fault relays. As a result, faults can be indicated

by optical or acoustic alarm equipment in addition to LEDs.

Fault status message

Faults can also be sent as text messages via PC or modem interface. For messages

via modem, both the number of repetitions and the modem message interval can be

parameterized.

2/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 3

Fault acknowledgement

A

The "Local" LED blinks to indicate that a fault is unacknowledged. The LED continues

to be lit until the fault is no longer pending even after the fault is acknowledged with the

"Ack" button. "Ack" resets the fault relay if a fault relay is configured.

The same applies to unacknowledged "System" faults in the event of a configured fault

relay. Without fault relay, a "System" fault is acknowledged automatically, i.e. the

"System" LED is lit immediately (no blinking until acknowledged).

External fault acknowledgement is possible via digital input, provided the input is

connected to input "Ack" on function block "Faults".

System report The central communication unit can generate system reports and periodically send the

system operating state to different types of message receivers.

History The history includes the last 500 events on faults, fault messages, and system reports.

The events are entered in the circular message buffer of the central communication

unit. The history data can be read via web browser and the ACS software.

Offline trend "Offline trend" allows logging values for selected data points of the central

communication unit and for Synco devices listed in the device list. The ACS7 software

is necessary to define trends and trend displays on an operator station as well as to

specify data exports (e.g. to Excel).

5 offline trends can be defined and run at the same time. One trend may contain 10,000

values (number of data points x number of samplings).

Central communication unit memory to log for each trend: Examples

• 1 data point at 30 second intervals for 83 hours.

• 6 data points at 30 second intervals for 27 hours.

• 10 data points at 5 minute intervals for 7 days.

The number of values that can be logged is reduced if text information (e.g. input

names, aggregate names for runtime totalization) is also recorded.

Ordering and delivery

When ordering, provide both name and product number (ASN):

• Central communication unit OZW775

The central communication unit is delivered in a box. The following are inserted in the

package:

• Installation instructions G5663 (multilingual).

• CD with ACS700 software.

Commissioning instructions C5663 saved as a PDF file on the CD.

ccessories

Order the following accessories separately:

• Ethernet card OZZ7E5

• CF card (Compact flash card) OZZ7CF

Note

The CF card contains the latest firmware version and web server data. See document

G5663 on firmware updates and preparing web server data.

3/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 4

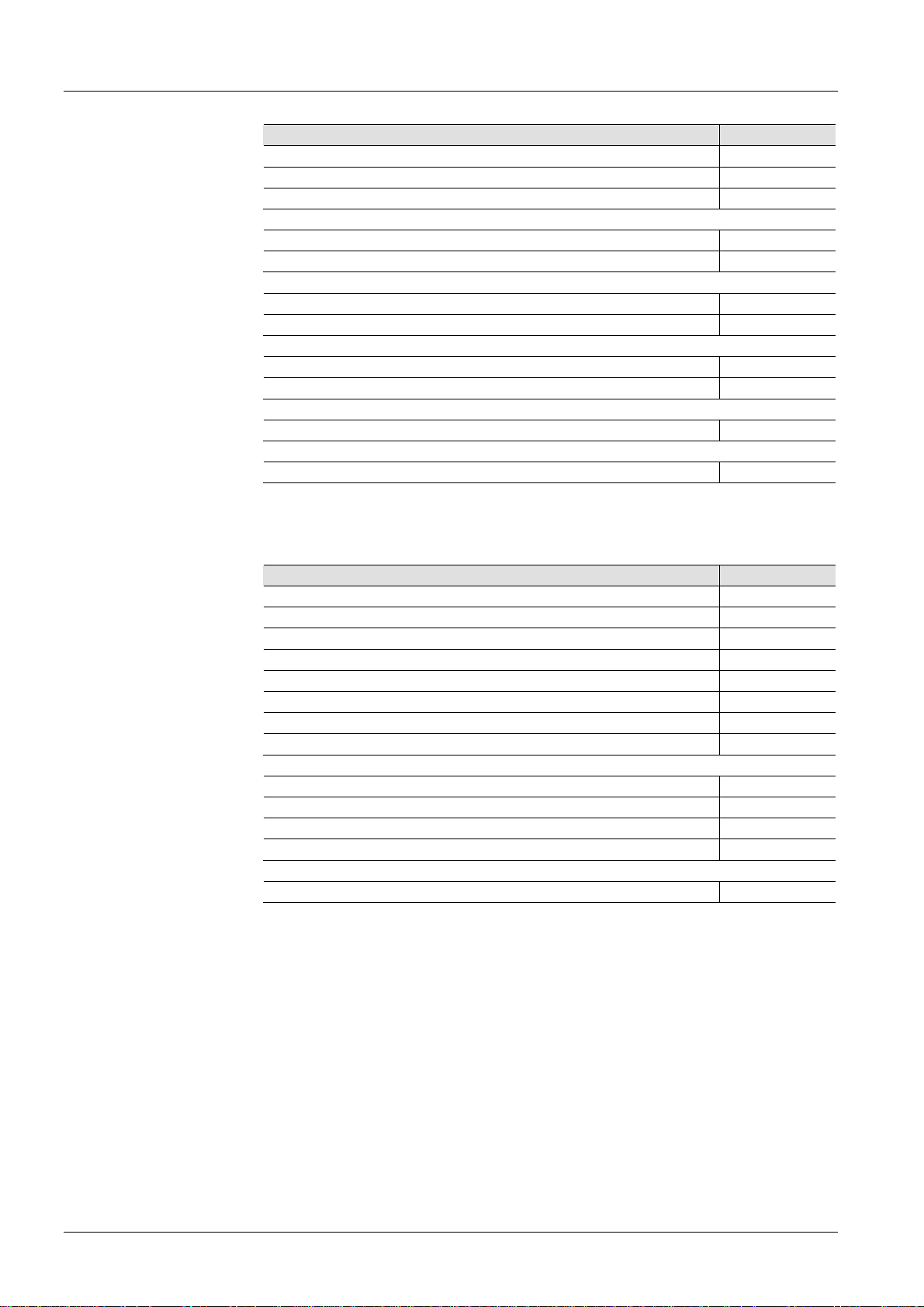

Product documentation

A

Central communication

unit OZW775

Document type Document no.

Data sheet

Installation instructions (package insert)

Commissioning instructions

Ethernet card OZZ7E5

Mounting instructions (package insert)

Information on OZZ7E5: See this document and Æ

CF card OZZ7CF

Operating instructions (package insert)

Information on OZZ7CF: See this document and Æ

KNX bus

Data sheet

Basic documentation

CS7… software

Data sheet

Service tool OCI700.1

Data sheet

Synco products The following Synco products can be integrated in a KNX network:

Synco 700 devices

Product Data sheet no.

Universal controller RMU7x0, RMU7x0B

Heating controller RMH760, RMH760B

Boiler sequence controller RMK770

Central control unit RMB795

Switching & monitoring device RMS705

Bus operator unit RMZ792

Room unit QAW740

Central communication unit OZW771

Synco RXB/RXL

Room controller RXB21.1, RXB22.1

Room controller RXL21.1, RXL22.1

Room controller RXB24.1

Room controller RXL24.1

Synco 900, Synco living

Central apartment unit QAX910

N5663

G5663

C5663

M5673

G5663

B5674

G5663

N3127

P3127

N5640

N5655

N3144, N3150

N3131, N3133

N3132

N3121

N3123

N3113

N1633

N3117

N3873

N3877

N3874

N3878

N2707

4/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 5

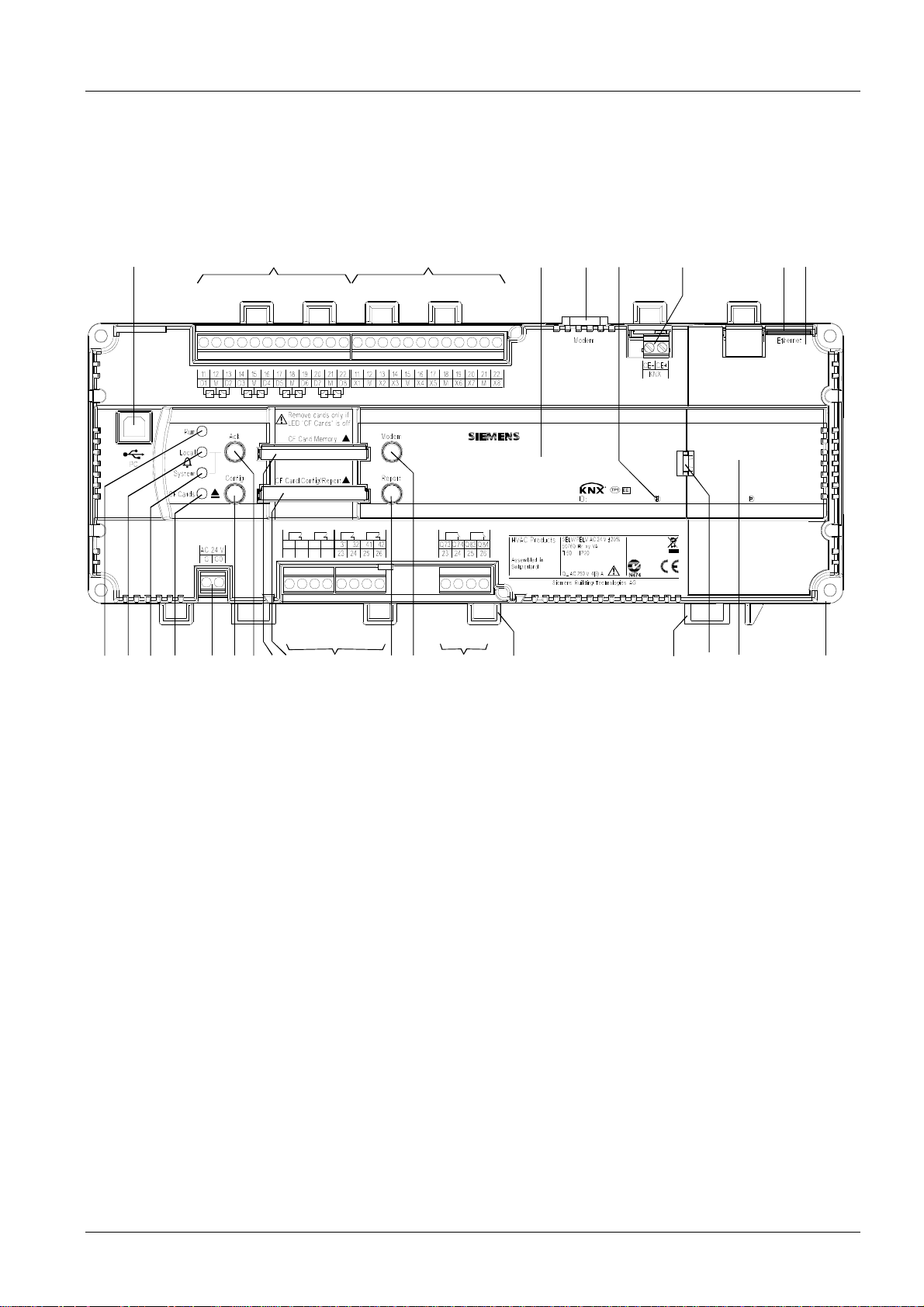

Mechanical design

Basic design

The central communication unit consists of the housing lower section with printed circuit

boards and connection terminals. The upper housing section contains the printed circuit

boards. The LEDs, operating buttons, interfaces, and slots for the CF cards (compact

flash memory cards) are integrated in the upper housing section. These elements and

the connection terminals are labeled on the front of the housing. The shape and dimensions of the housing sections conform to DIN 43880 (size 2).

12

Q

11 12 21 22

Q

QQ QQQQ

18 19 20 21

34567

OZW775 OZW775

OZW775

040601A001001

XXXXXXXXXXXX HEX

8

XX:XX:XX:XX:XX:XX

9

10

11 12 13 14 15

161718

19

20 21

22 23 24 25 26 27

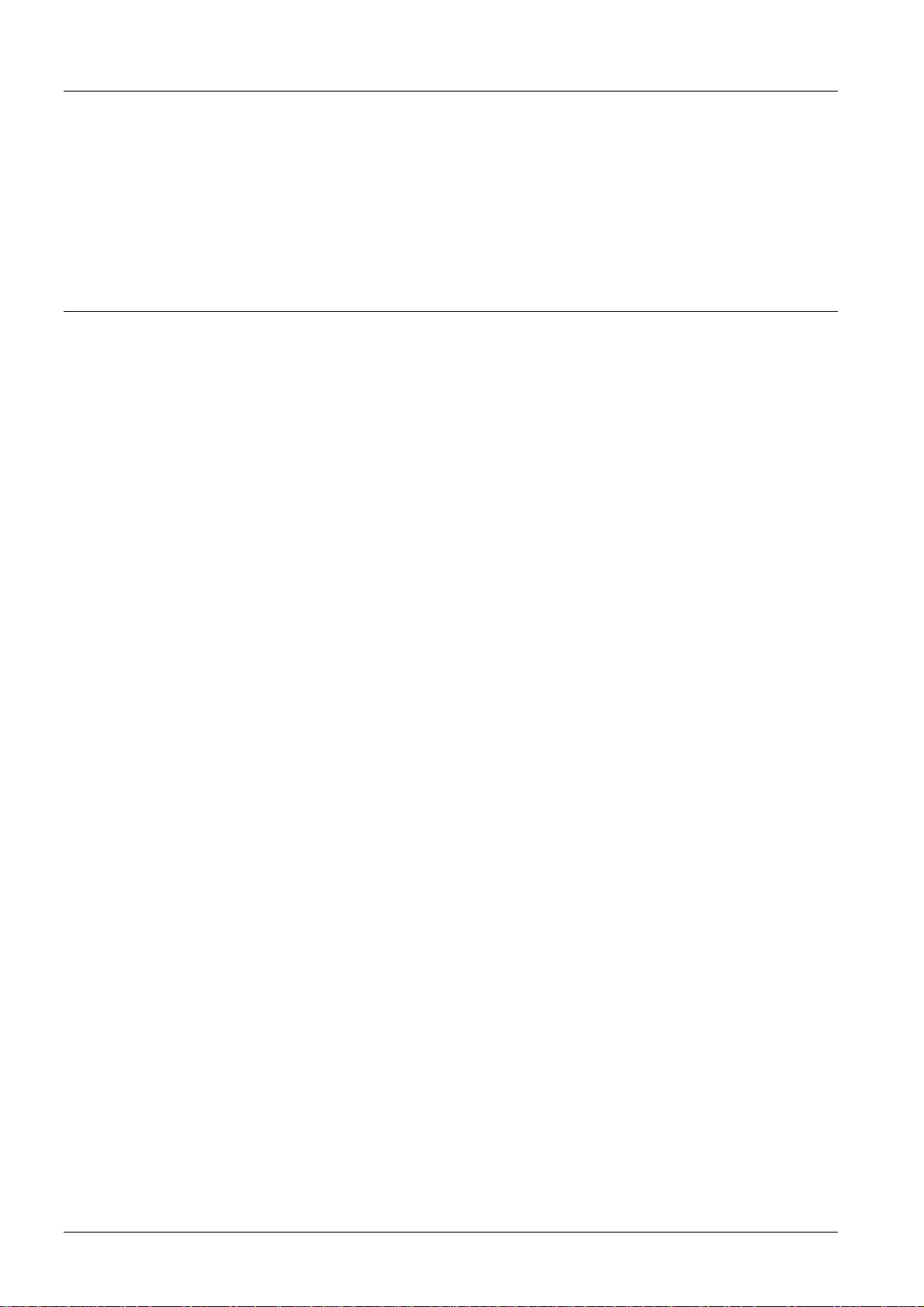

Position Labeling Element

1 PC USB interface

2 D1...D8 M Connection terminal digital inputs (M = ground)

3 X1...X8 M Connection terminals universal inputs (M = ground)

4 Upper housing section

5 Modem RS-232 interface

6 KNX LED (green/red) Bus voltage, data exchange via KNX (green) / unit in addressing mode (red)

7 CE- CE+ KNX (Konnex) connection terminals

8 Ethernet Ethernet plug RJ45 on Ethernet card OZZ7E5 (order card separately)

9 XX:XX:XX:XX:XX:XX MAC address (Media Access Control address, 48 bits)

10 Run LED (green) Operating voltage applied (lit), communicating with ACS (flashing)

11 Local LED (red) Central unit faults or faults at fault inputs, or "Hours run for service reached"

12 System LED (red) Device faults in the KNX network

13 CF cards LED (green) CF card integrated (lit), CF card being integrated or removed (flashing)

14 G G0 Connection terminals for AC 24 V operating voltage

15 Config Button Integrate or remove CF card

16 Ack Button Acknowledgement of "Local" fault, fault relay "System"

17 CF card memory Slot for CF card (web server data)

18 CF Card Config/Report Slot for CF card (firmware update)

19 Q11,Q12 Q21,Q22

Q31,Q32 Q41,Q42

20 Report Button For function, see “Button combinations“

21 Modem Button initializes modem, checks connection to the modem (short) / sends system report (long)

22 Q73,Q74 Q83,Q84 Connection terminals for 2 relays with NO contact

23 Lug for cable tie (cable strain relief)

24 Fastening spring to mount the central communication unit to a standard rail TH 35-7.5

25 Snap cover

26 Cover (can be opened without tools if Ethernet card OZZ7E5 needs to be inserted)

27 Lower housing section

Connection terminals for 4 relays with NC contacts

5663Z01

5/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 6

Technical design

Inputs and outputs

Digital inputs

Universal inputs

Relay outputs

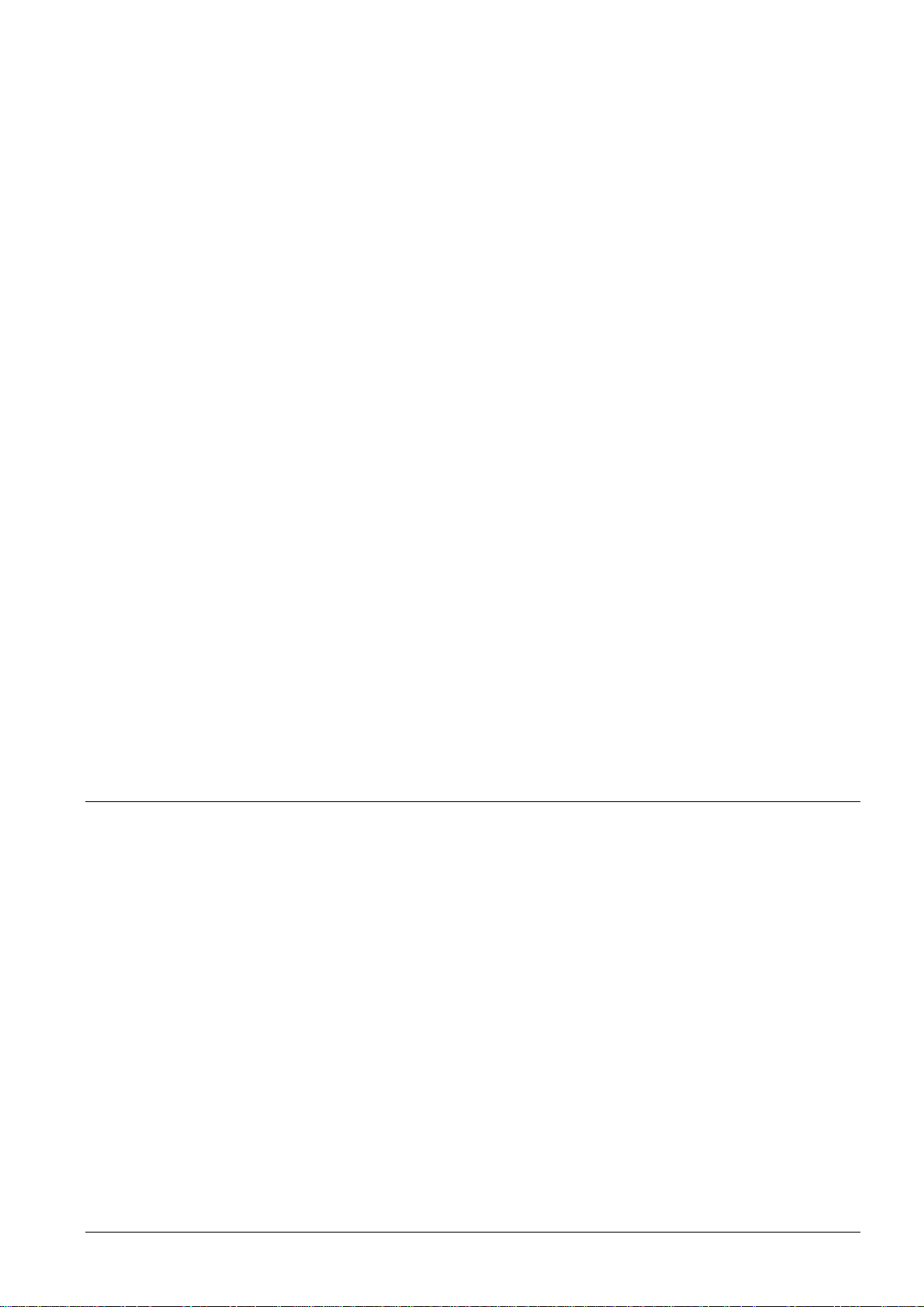

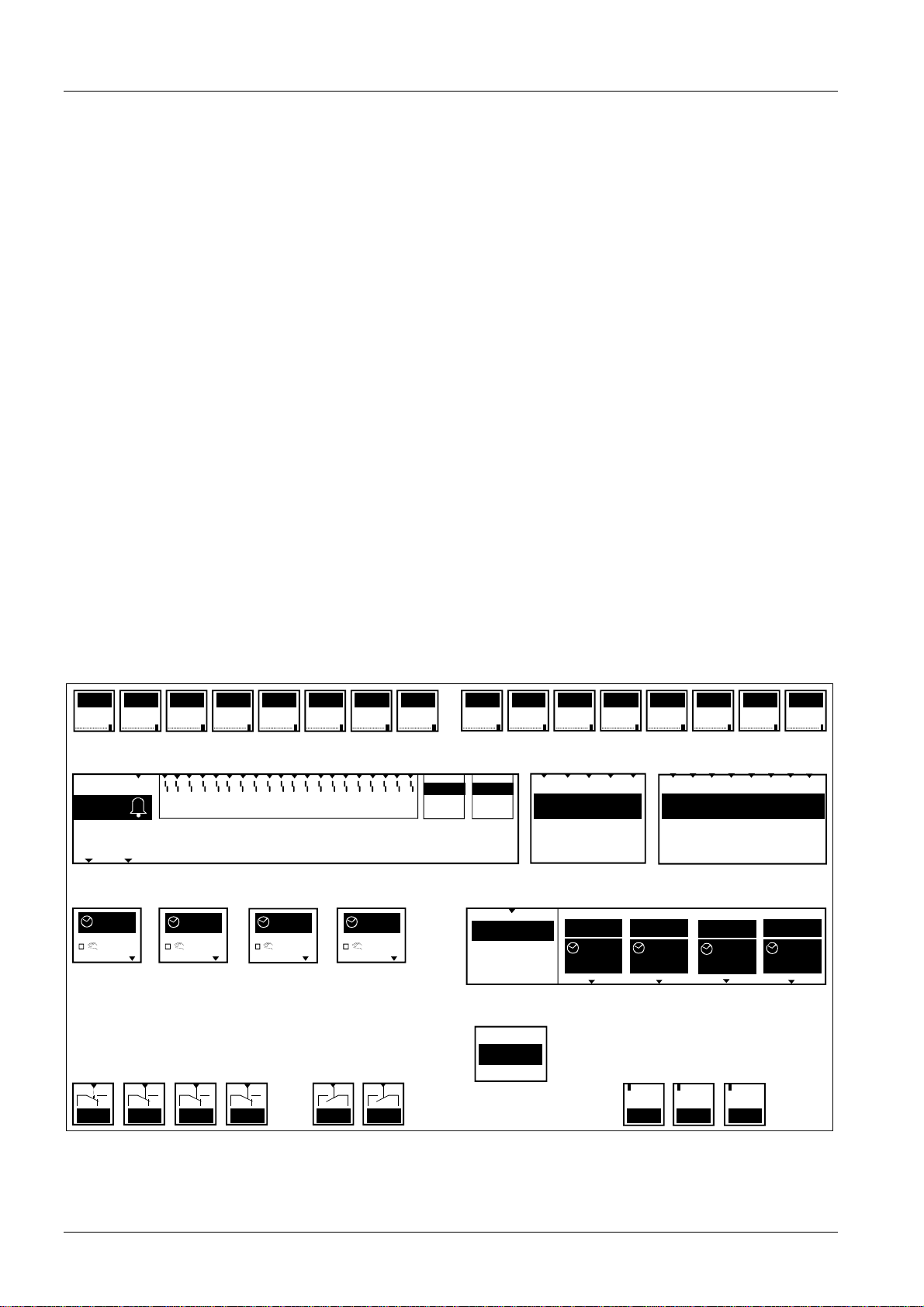

The central communication unit contains various function blocks (FB). The functionality

of the unit can be extended by connecting (binding) the digital inputs N.D1…N.D8 and

the universal inputs N.X1…N.X8 to the FB inputs "d", "x", and "i" (see figure and

function block description).

The digital inputs N.D1…N.D8 help connect potential-free status contacts. They act as

fault inputs when connecting digital inputs to FB "Faults". When connected to FB

"Operating hours", the number of operating hours of aggregates (burners, pumps, fans,

etc.), can be counted.

The universal inputs N.X1…N.X8 can be configured for potential-free status and

counting impulse contacts and analog signals from sensors and transmitters.

Universal inputs configured for status contacts (digital) or limit values (analog) and

connected to FB "Faults" act as fault inputs.

When universal inputs are configured for operating status contacts of aggregates and

connected to FB "Operating hours", the operating hours can be acquired.

When universal inputs are configured for counting pulses and connected to FB

"Meters", consumption values (heat, gas, electricity, etc.) can be acquired.

The outputs of relays N.Q1…N.Q4 have NC contacts, those of relays N.Q7, N.Q8 have

NO contacts. To signal faults (e.g. with signal lamps, horns), relay 1 and/or relay 2 of

FB "Faults" are connected to one of the relays N.Q_.

If one of the relays N.Q_ is connected to an FB "7-day time switch with control switch",

relay N.Q_ in "Auto" position operates as per the time switch program, else per the

control switch position "Off" or "On".

N.D1 N.D2 N.D3 N.D4 N.D5 N.D6 N.D7 N.D8

dddd

d

Ack

Faults

Relay 1 Relay 2

Q

On/Off

1

N.Q1 N.Q2

Inputs, outputs and function blocks of the OZW775 central communication unit.

1234567891011

Q

Q Q

Q

Input identifier

xxx xxxxx x x x xxx

On/Off On/Off On/Off

Q

N.Q3

Q

N.Q4

ddd d

xxxxxx

12

32

Q Q

131415

N.Q7

171819

16

4

Q

20

QQ

N.Q8

N.X1 N.X2 N.X3 N.X4 N.X5 N.X6 N.X7 N.X8

System

Intern

Message receivers

System report

xxxxxxxx

d

dddd

1

234

Operat ing hours Me t er s

Ein/Aus

Receiv e r 1

1

d

iiiiiiii

5

Receiv e r 2

On/Off

a

d

r

e

a

n

l

C

ccc

c c

PC USB

1

On/Off

2

d

e

a

n

l

C

2345 6

Receiv er 3

On/Off

a

r

c

Modem Ethernet

d

e

n

a

l

C

a

r

78

Receiv e r 4

On/Off

43

e

a

l

C

c

a

d

r

n

5663B01en

6/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 7

Function blocks

FB "Faults"

FB "Operating hours"

FB "Meters"

FB "7-day time switch

with operation selector"

FB "System report"

FB "Message receivers"

FB "Faults" is designed for 20 fault inputs. Inputs N.D1…N.D8 (digital) and N.X1…N.X8

(digital/analog) are connected to FB inputs "x". "Relay 1" and/or "Relay 2" is activated

depending on fault priority and source.

FB "Faults" handles faults and failures of the Synco devices (“System“ faults) listed in

the device list as well as faults at the fault inputs and faults of the central

communication unit ("Local" faults)..

To facilitate external fault acknowledgement, a digital input must be connected to input

"Ack". External fault acknowledgement acts like pressing the "Ack" button.

FB "Operating hours" can handle up to 5 runtime totalizers. The operational status

contacts of the aggregates are connected to FB inputs "d" via the digital inputs

N.D1...N.D8 or N.X1...N.X8 (configured as digital inputs).

If a service interval is defined, the “Local“ LED indicates when the number of operating

hours is reached and, if configured, a service alarm is issued.

FB "Meters" can handle up to 8 counting values. The universal inputs N.X1…N.X8

(configured as counting pulses) are connected to the FB inputs "i". The acquired

counting pulses from heat, water, gas, electricity meters are converted to consumption

values, e.g. energy in Wh, kWh or volume in m

3

. The 15 monthly values along with

readout dates are stored.

The 4 FB "7-day time switch with control switch" allow for switching various consumers

in dependence of time via the relays N.Q_. Each 7-day time switch allows for programming up to 6 switching points (3 "On", 3 "Off". Additionally, a configurable operation

selector with positions "Auto" / "Off" / "On" is integrated.

If a time switch output "Q" is connected to a relay input, position "Auto" ensures that the

relay is energized and deenergized as per the time program, or the relay is constantly

deenergized or energized.

In FB "System report", the time the message is sent (hh:mm) and the message cycle

interval (1...255 days) for sending system reports can be programmed. A system report

is sent to one or several message receivers depending on fault priority (urgent/not

urgent).

FB "Message receivers" is subdivided into 4 receivers. Message suppression via input

"d" acts on all receivers. You can set both receiver type and fault priority individually for

each receiver. Each receiver has a "Time switch with calendar" to program three

sending times per day and holidays/special days.

Example: All fault messages from Monday through Friday 08:00 - 18:00 are sent to

receiver "Service business receiver", e.g. to a fax machine. Outside these hours, the

fault status messages are sent to receiver "24-hour service", e.g. SMS to mobile phone.

The outputs "c" of FB "Message receivers" are connected to inputs "c" of the PC USB,

modem, or Ethernet interfaces. The PC USB interface is designed for local commissioning, operation and monitoring (alarming).

Remote operation and monitoring are possible via modem (dial-up) and, at the same

time, via Ethernet (Internet/intranet) to one (or several) web browsers.

7/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 8

Interfaces The central communication unit has three interfaces to communicate between unit and

user, and the interface or connection for the KNX bus.

PC

The "PC" interface is intended to directly connect a central communication unit to a

local operator station. A USB cable, type A-B, is required to this end.

Modem

The "Modem" interface is intended to connect a modem via RS-232. When communicating via modem, the following message recipients are supported: Operator stations

(PC/laptop with ACS software), SMS recipients, pagers, fax machines.

Ethernet

The interface labeled "Ethernet" corresponds to a RJ45 plug on the Ethernet card

OZZ7E5. Order the card separately and insert in the central communication unit. A

network cable Cat-5 is required to connect to the Ethernet (Ethernet category 5 cable).

KNX

The"KNX" labeled connection terminals CE+ and CE- are intended for the KNX bus.

For more information on the KNX bus, see data sheet N3127.

Parallel operation

We speak of parallel operation if one central communication unit is operated with two or

multiple operator stations. Also, e.g. with one operator station via USB, and/or via

modem, and/or via Ethernet.

Operation

Communication connections for local operation (USB), and for remote operation via

modem and Ethernet.

8/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 9

Monitoring,

alarming

Communication connections for local monitoring and alarming (USB), and for remote

operation via modem and Ethernet.

Parameter settings for

message receivers

The following table lists all parameters for the communication connections that can be

set in each message receiver.

Receiver type Interface Modem type Transmission protocol

--- (Default) - - Email Ethernet xx SMTP

ACS alarm

Mobile phone

Fax machine

Pager

USB xx

Modem Analog/ISDN

GSM

Ethernet xx

Modem Analog/ISDN TAP

UCP

GSM

Modem Analog Fax protocol

GSM Fax protocol

SMS GSM service

Modem Analog/ISDN TAP

GSM TAP

SMS GSM service

ACS protocol

SMS GSM

No other selection

- Value cannot be set or not value entry required

xx No modem required

Bold/Italics Default value

Example: Receiver type = Email

Interface = Ethernet (Default if receiver type = Email)

Transmission protocol = SMTP (Default if receiver type = Email)

9/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 10

Mounting notes

Installation notes

You must mount the central communication unit in a cabinet or control panel. Make

sure service can easily access the unit.

• Standard mounting On standard rail TH 35-7.5

• Screwed-on mounting Screwed to rear wall

• Mounting position Horizontal only

• Mounting and dimensions See "Dimensions"

Important notes

Observe the following important notes for mounting and installation:

• The central communication unit must

be mounted in a cabinet or control panel,

as when mounted on a freely accessible wall, the relay output terminals

carrying mains voltage (bottom of the unit, terminals not covered) are not

protected against electric shock hazard.

• Run fuses, switches, wiring and earthing as per local regulations for electrical

installations.

• The relay contacts of the central communication unit can switch either mains

voltage or

low-voltage. Applying both mains and low voltage is not permitted.

• You must connect circuits with relay contacts Q11, Q12 through Q41, 42 to the

same mains phase.

• You must connect circuits with relay contacts Q73, Q74 and Q83, Q84 to the

same mains phase.

• Connect only potential-free contacts to digital inputs D1…D8 and universal

inputs X1…X8 (configured for digital inputs signals).

• We do not recommend plant monitoring via PC interface in environments with

strong electromagnetic interference (e.g. in industrial environments with

electrical welding equipment).

Operating voltage The central communication unit operates on AC 24 V and must meet requirements for

SELV/ PELV (safety extra low-voltage / protective extra low-voltage).

Use only safety isolating transformers suited for 100 % duty (as per

EN 61558-2-6).

Wiring Plan sufficient space around the unit for easy wiring. The unit’s terminals are arranged

to eliminate cross-wiring of input and output lines to prevent faulty wiring to the greatest

extent possible.

The terminals for digital inputs, universal inputs, and the KNX bus are located at the top

of the unit (low-voltage side). The terminals for AC 24 V operating voltage and relay

outputs carrying mains voltage are located at the bottom (mains voltage side).

Connecting terminals

The terminals are designed for wire diameters of min. 0.8 mm or cross-sections of

0.5...2.5 mm

2

. See "Technical data".

10/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 11

Commissioning notes

A

A

uthorized staff Only authorized staff may commission and parameterize the central communication

unit as well as start the web server.

Select telephone service

provider and modem

You must select the telephone service provider and modem depending on the message

receiver type prior to commissioning. If you use a GSM modem, make sure that the

SIM card allows for data communication and that it is not protected by a PIN code.

IP address Before activating the web server via the web browser on Ethernet, the network system

administrator must assign the IP address for the central communication unit.

Commissioning

Commission the central communication unit locally via PC interface using a PC/laptop.

The service tool ACS must be installed on the PC/laptop.

You need a USB cable, type A-B, to locally connect the PC interface of the

communication unit to the PC/laptop.

The installation instructions G5663xx (enclosed with unit), topic “Commissioning“ also

point out important commissioning issues.

Parameterization Parameterize the central communication unit locally via PC interface using a PC/laptop

and service tool ACS.

Read the commissioning instructions C5663 for the associated procedure. The commissioning instructions PDF file is saved to the CD supplied with the unit. You can also

download the PDF file from www.siemens.com/synco

Web server

Local activation

Locally activate the web server following

commissioning and parameterization of the

central communication unit.

You need a USB cable, type A-B, to locally connect the PC interface of the communication unit to the PC/laptop.

The installation instructions G5663xx (enclosed with unit) stress the following issues:

• Insert Ethernet card.

• Update firmware.

• Prepare web server data.

• Start web browser with IP address 192.168.250.1 and login.

ctivate via

Ethernet connection

See the commissioning instructions C5663 for information on how to activate the web

server via Ethernet connection (Ethernet card OZZ7E5). The PDF file of the commissioning instructions are saved on the CD supplied with the unit. You can also download

the PDF file from www.siemens.com/synco

11/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 12

LED displays

A

A

Run (green) Dark No operating voltage AC 24 V or unit is starting.

Lit Unit ready to operate.

Flashing Communicating with ACS.

Local (red)

Dark No fault (normal operating state).

Lit Central communication unit faults and/or signal at fault inputs "Hours run for

service reached".

Flashing Fault unacknowledged.

System (red)

Without configured fault relay "System" in the OZW775:

Dark No fault (normal operating state).

Lit Device fault in KNX network.

With configured fault relay "System" in the OZW775:

Dark No fault (normal operating state).

Lit Device fault in KNX network, fault relay acknowledged.

Flashing Device fault in KNX network, fault relay unacknowledged.

CF cards (green)

Dark No CF card integrated.

Lit CF card integrated.

Flashing CF card is being integrated or removed

(after pressing button "long" on "Config").

KNX (green/red)

Dark No bus power supply.

Steady green Bus power supply available.

Flashing green Data exchange via KNX.

Steady red Unit in addressing mode.

Operating buttons

Pressing the button briefly ("short") means <2 seconds, "long" >4 seconds.

Config Short No function.

Long Integrate or remove CF card (or both CF cards).

ck

Short Acknowledge "Local" fault, fault relay "System".

Long See “Button combinations“.

Report

Short No function.

Long See “Button combinations“.

Short Initializes modem, checks modem connection. Modem

Long Initializes modem, sends system report to configured receivers.

Button combinations For button combinations, always press "long" (>4 seconds).

ddressing mode

Simultaneously press "Modem" and "Report" (programming mode).

Restart central unit

Simultaneously press "Modem" and "Ack".

Default state

Simultaneously press "Modem", "Ack", and "Config".

Note: All configuration data and settings are reset. The device list and all unsent

messages are deleted. History data is not deleted.

12/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 13

General notes

Maintenance The OZW775 central communication unit requires no maintenance (no battery

changes, no fuses). Clean the housing only with a dry cloth.

Repair

The central communication unit OZW775 cannot be repaired in the field. If faulty, return

to the Repair Center of the relevant Siemens Regional Company.

Disposal

The central communication unit is subject to directive 2002/96/EEC (WEEE, Waste of

Electrical and Electronic Equipment).

"Dispose of the device as electronic waste in compliance with European directive

2002/96/EEC (WEEE) and not as municipal waste. Observe all relevant national

regulations and dispose of the unit correctly. Comply with all local and currently valid

legislation".

Technical data

Power supply G, G0

Functional data

Digital inputs D1...D8

Universal inputs X1...X8

Operating voltage

Rated voltage as per EN 60950-1

Safety extra low-voltage (SELV) / protective extra low-voltage

(PELV) as per

Requirements for external safety isolating transformer

(100 % duty, max. 320 VA)

Frequency 50 / 60 Hz

Power consumption OZW775 20 VA

Supply line fusing

Clock reserve

OZW775 device list Up to 250 Synco devices

Number

Contact sensing

Voltage

Current

Requirements for status / fault contacts

Signal coupling

Type of contact

Insulating strength against mains potential

Permissible resistance

Contact closed

Contact open

Number

Sensors

Passive

Active

Transmitter

Active

Contact sensing status / impulse contacts

Voltage

Current

Requirements for status contacts

Signal coupling

Type of contact

Insulating strength against mains potential

46 h typical, min. 12 h

AC 24 V ± 20 %

AC 24 V

HD 384

EN 61558-2-6

Max. 10 A, transformer on primary

side

8 (terminals D1...D8 and 1 ground

connection for 2 terminals each)

DC 16.5 V

Typically 8 mA

Potential-free

Maintained contact

AC 3750 V as per EN 60950-1

Max. 200 Ω

Min. 50 kΩ

8 (terminals X1...X8 and 1 ground

connection for 2 terminals each)

LG-Ni1000, T1, Pt1000

DC 0...10 V

DC 0...10 V

DC 16.5 V

Typically 1 mA, max. 6 mA

Potential-free

Maintained contact

AC 3750 V as per EN 60950-1

13/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 14

Universal inputs

continued

Relay outputs

Q1_,Q2_,Q3_,Q4_,Q7_,Q8_

AC 230 V

Connecting terminals

Inputs and outputs

PC interface

Modem interface

Requirements for pulse inputs

Signal cables

Signal coupling

Type of contact

Mechanical signal source (Reed contact)

Max. pulse frequency

Min. pulse duration

Electronic signal source

Max. pulse frequency

Min. pulse duration

Insulating strength against mains potential

Line length for:

Passive sensor signals LG-Ni 1000, T1, Pt 1000

Active signals DC 0…10 V

Status and impulse contacts

Number

Relay with NC contact

Relay with NO contact

External supply line fusing

NC contact, non-renewable fuse (slow)

NO contact, non-renewable fuse (slow)

Automatic line cutout

Release characteristic

Line length Max. 300 m

Relay contact data

Switching voltage

AC current (NC)

AC current (NO)

At 250 V

At 19 V

Switch-on current

Contact life at AC 250 V

At 0.1 A ohm.

At 0.5 A ohm.

At 2 A ohm.

At 4 A ohm.

Red. fact. at ind. (cos φ = 0.6)

Insulating strength between:

Relay contacts and system electronics (reinforced insulation)

Neighboring relay contacts (operational insulation)

Screw terminals for:

Solid / stranded wire (twisted or with ferrule)

1 solid / stranded wire per terminal

2 solid / stranded wires per terminal (max. 2)

Interface

Standard

Device class

Baud rate

Connecting cable for operator station

Cable length

Cable type for connection to PC/laptop

Cable type for connection to OZW775

Interface

Standard

Baud rate

Connecting cable for modem

Cable length

Cable type for connection to OZW775

Recommendation: Shielded cables

Potential-free

Impulse contact

25 Hz

20 ms (incl. max. 10 ms bounce time)

100 Hz

5 ms

AC 3750 V as per EN 60950-1

Max. 300 m

See data for signal-sending device

300 m

4 (terminals Q11,Q12 Q21,Q22,

2 (terminals Q73,Q74 Q83,Q84)

Max. 3.15 A

Max. 5 A

Max. 13 A

B, C, D as per EN 60898

Max. AC 250 V, min. AC 19 V

Max. 2 A ohm., 2 A ind. (cos φ = 0.6)

Max. 4 A ohm., 3 A ind. (cos φ = 0.6)

Min. 5 mA

Min. 20 mA

Max. 10 A (1 s)

Guide values:

2 x 10

2 x 10

4 x 10

3 x 10

6 x 10

3 x 10

0.85 (NC and NO)

AC 3750 V, as per EN 60950-1

AC 1250 V, as per EN 60950-1

Min. Ø 0.8 mm

0.5...2.5 mm

0.5...1.5 mm

USB V1.1 (universal serial bus)

RNDIS (remote network device

Interface specification)

Max. 12 Mbps (full speed)

Max. 5 m

USB type A

USB type B

RS-232, V.24 / EIA 232D

Max. 115 kbaud

Max. 15 m

D-sub 9-pin, plugs

Q31,Q32 Q41,Q42)

7

switchings (NC and NO)

6

switchings (NC)

6

switchings (NO)

5

switchings (NC)

5

switchings (NO)

5

switchings (NO only)

2

2

14/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 15

Protocols to send

messages

KNX bus

Ethernet

Ethernet card OZZ7E5

Ambient conditions

Degree of protection

Standards

Materials and colors

Dimensions

Protocol support for connection via

Leased line telephone service provider

GSM telephone service provider, additional

Interface type

2-wire bus

Bus load number OZW775

Decentralized bus power supply, can be switched off

Permissible line length and cable types See data sheet N3127

Interface type

Bit rate

Protocol

Connection

Cable type

Cable length

Ethernet cable for:

Point-to-point connection

Multi-connection (e.g. to switchbox)

Operation to

Climatic conditions

Temperature (housing and electronics)

Humidity

Mechanical conditions

Transport

Climatic conditions

Temperature

Humidity

Mechanical conditions

Degree of protection when mounting:

Rear wall in cabinet or control panel

Front panel cutout for display and operation

Safety class II as per EN 60950-1

Product safety

For information technology equipment

Electromagnetic compatibility

Immunity OZW775

Immunity PC interface

Emissions

Home and Building Electronic System (HBES)

conformity

EMC directive

Low voltage directive

-conformity

Australian EMC Framework

Radio Interference Emission Standard

Environmental compatibility

The environmental product declaration CE1E5663en

contains data on environmentally compatible product design

and assessments (RoHS compliance, materials composition,

packaging, environmental benefit, disposal)

Housing lower and upper section

Length x width x height (max. dimensions) 298 mm x 128 mm x 77 mm

Size 2 as per DIN 43880

Polycarbonate, RAL 7035 (light-gray)

UCP (universal computer protocol)

TAP (telocator alphanum. protocol)

FAX protocol (fax class 2 or 2.0)

AT+ (extended AT command set)

TP1 (twisted pair, 1 cable pair)

CE+, CE- (non exchangeable)

E 0.3

DC 30 V / 25 mA

100BaseTX, IEEE 802.3 compatible

10 Mbps

TCP/IP

RJ45 plug (screened)

Standard Cat-5, UTP or STP

Max. 100 m

Crossed cable

Straight cable

IEC 60 721-3-3

Class 3K5

0 ...50 °C

5...95 % r. h. (non-condensing)

Class 3M2

IEC 60 721-3-2

Class 2K3

− 25...+ 70 °C

< 95 % r. h.

Class 2M2

IP 20 as per EN 60529

IP 30 as per EN 60529

EN 60950-1

EN 61000-6-2

EN 61000-6-1

EN 61000-6-3

EN 50090-2-2

2004/108/EC

2006/ 95/ EC

Radio communication act 1992

AS/ NZS 3548

ISO 14001 (Environment)

ISO 9001 (Quality)

SN 36350 (Environmentally

compatible products)

2002/95/EC (RoHS)

15/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 16

Weight OZW775

Weight OZZ7E5

Weight OZZ7CF

Terms and abbreviations

Central communication unit OZW775

With packaging, installation instructions and CD

Packaging Cardboard box

Ethernet card OZZ7E5

With packaging, mounting instructions

Packaging Cardboard box

CF card OZZ7CF

With packaging, operating instructions

Packaging Plastic bag

Extended command language for modems: Attention+

Global system for mobile communication GSM

Integrated services digital networks ISDN

Internet protocol IP

Shielded twisted pair STP

Simple mail transfer protocol SMTP

Short message service SMS

Telocator alphanumeric protocol TAP

Transmission control protocol TCP

Universal computer protocol UCP

Universal serial bus USB

Unshielded twisted pair UTP

AT+

0.825 kg

1.185 kg

0.018 kg

0.044 Kg

0.010 kg

0.022 Kg

16/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 17

Connection diagrams

Connection diagram

Connection diagram

G

D2MD3 D4

Q11

Q12

Q21

MD5

D6 D8MMD1

Q22 Q31

D7

Q32G0

X1 M

Q41 Q42

X2

X3 M X4 X5 M X6 X7 M X8 CE- CE+

Q73

Q74

Q83 Q84

D1…D8 Digital inputs

X1…X8 Universal inputs

M Ground for digital inputs, measuring ground for universal inputs

CE- KNX bus connection (negative)

CE+ KNX bus connection (positive)

G, G0 Operating voltage AC 24 V

Q… Relay outputs

G

AC 24 V

G

G0

F1

F2

Q11

Q12

Q21

Q22

Q31

B1

B2 N2

0...10 V

RS-232

X3.......X8X1D3.......D8D2MD1

Q32

Q41

Q42

Q73

Q74

CE-X2M

Q83

Q84

RJ45Modem

Ethernet

5662G02

N3

KNX

Ethernet

RJ45CE+Modem

Ethernet

N1

Pin assignment

Ethernet card OZZ7E5

Modem connection,

central communication

unit

G0

5663A02

K1

L

N N

K2

L

K3

N1 Central communication unit OZW775

N2, N3 Synco device in KNX network

F1, F2 Device with potential-free contact output

B1 Sensor with passive signal

B2 Transmitter with active signal

K1, K2 Contactor (control by relay with NC contact)

K3 Contactor (control by relay with NO contact)

RJ45 plug (screened), standard assignment as per AT&T256.

1

2345678

1 Tx + 5 Not used

2 Tx – 6 Rx –

3 Rx + 7

3206Z01

5663Z21

4 Not used 8

Not used

Not used

Modem connection (D-pins, 9-pin), interface definition as per RS-232.

6789

23

45

1

1 DCD Data carrier detect 6 DSR Data set ready

2 RXD Received data 7 RTS Request to send

3 TXD Transmit data 8 CTS Clear to send

4 DTR Data terminal ready 9 NC Not connected

5663Z22

5 GND Signal ground

17/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

Page 18

Dimensions

TH35-7.5

298

78

Standard mounting on standard rail TH 35-7.5

1

2

3

Screwed-on mounting

128

298

35

5.3

44

111

128

5663Z04

==

45

5663M02

5663M01

1

==

100

5663Z05

2

Dimensions in mm

©2005-2008 Siemens Switzerland Ltd

18/18

Building Technologies Central communication unit OZW775 V2.0 CE1N5663en

HVAC Products 29.10.2008

www.sbt.siemens.com/ Subject to change

==

287

5663M04

Loading...

Loading...