Siemens ISI EN 50295,50295 Brochure

AS-Interface

according to EN 50295

Siemens IK PI

.

2004

6/2 Introduction

6/2 Transmission technology

6/3 Configuration example

6/4 System components

6/5 Technical specifications

6/6 A/B technique

6/8 AS-Interface Safety at work

6/8 Introduction

6/9 AS-Interface safety monitors

6/11 AS-Interface safe compact modules

6/15 AS-Interface position switches

6/18 AS-Interface cable-operated switches

6/19 AS-Interface light curtains and

light arrays for Category 4

6/24 AS-Interface laser scanner LS4

6/30 AS-Interface EMERGENCY STOP

pushbuttons

6/30 Accessories

AS-Interface Master

6/31 Masters for SIMATIC S5

6/31 CP 2430

6/33 Masters for SIMATIC S7

6/33 CP 142-2

6/35 CP 243-2

6/37 CP 343-2

6/39 CP 343-2 P

ST 70

1

)

Masters for SIMATIC C7

Sec. 8

2

)

AS-Interface network transitions

DP/AS Interface Link 20E

DP/AS Interface Link 65

AS-Interface Slaves

6/41 I/O modules for operation in the field

6/41 Introduction

6/43 Digital I/O modules IP67 – K60

6/51 Digital I/O modules IP68 / IP69K – K60R

6/56 Digital I/O modules IP67 – K45

6/64 Digital I/O modules IP67 –

application modules

6/71 Analog I/O modules IP67 – K60

6/74 Pneumatic I/O modules

6/75 I/O modules for operation

in IP20 control cabinet

6/75 Introduction

6/77 SlimLine

6/88 F90 module

6/93 Flat module

6/94 Special integrated solutions

6/94 AS-Interface Communication modules

AS-Interface Slaves (continued)

6/98 Modules with special functions

6/98 Counter modules

6/100 Earth fault detection modules

6/103 Overvoltage protection module

6/105 AS-Interface motor starters and

IP65/67 load feeders

6/105 AS-Interface compact starters IP65

(400 V AC)

6/113 AS-Interface motor starters IP67 (24 V DC)

6/116 ECOFAST motor and soft starter

6/117 AS-Interface motor starters and

IP20 load feeders

6/117 Load feeder modules IP20

LV 10

3

)

AS-Interface Direct/Reverse Starter

6/121 SIRIUS soft starters

LV 10

3

)

Communications capable contactors

55 to 250 kW

LV 10

3

)

Double relays and transformers

6/122 SIGNUM pushbuttons and

indicator lights

6/122 AS-Interface F-Adapter for

EMERGENCY STOP command devices

6/123 AS-Interface enclosure

6/124 AS-Interface customized enclosures

and front panel modules

6/133 AS-Interface LED displays

6/134 AS-Interface for LOGO!

LV 10

3

)

AS-Interface signal columns

6/135 AS-Interface power supply units

6/135 Introduction

6/136 Power supply units IP20

6/141 Power supply units IP65

6/143 Transmission media

6/143 AS-Interface shaped cable

6/145 System components and accessories

6/145 Repeater/Extender

6/147 Addressing units

6/149 Diagnostic units

6/151 Miscellaneous accessories

6/152 Documentation

1

)

see Catalog ST 70

”Products for Totally Integrated

Automation and Micro Automation“

2

)

see Section 8

3

)

see Catalog LV 10

”Controlgear for Industry“

Siemens IK PI · 2004

6/2

AS-Interface

Transmission technology

Introduction

6

■

Overview

Transmission method

A significant feature of the AS-Interface technology is the use of

a common, two-wire cable for data transmission and distribution

of auxiliary power to sensors/actuators.

An AS-Interface power supply unit, which meets the requirements of the AS-Interface transmission technology, is used for

this system. The AS-Interface shaped cable provides mechanical coding and thus prevents polarity reversal; penetration

terminals are used for simple contacting.

■

Benefits

Cabinets that were previously overflowing with complicated control line wiring and marshalling distributors can now be replaced

by AS-Interface.

The AS-Interface cable can be connected at any point, thanks to

specially developed wiring and connection using the insulation

displacement method.

This concept gives you tremendous flexibility and considerably

cuts costs.

The AS-Interface is a single master system. Communications

processors (CPs) are available for SIMATIC

®

systems which

control process or field communication as masters.

The system expansion now allows double the quantity of slaves

(max. 62) to be operated on AS-Interface. The analog values are

now also preprocessed in the master. For direct connection of

AS-Interface to PROFIBUS DP, DP/AS-Interface Link 20E is

available. Using this DP/AS-Interface link, the AS-Interface can

be used as a subnet for PROFIBUS DP.

The AS-Interface is an open standard. Leading manufacturers

of actuators and sensors support AS-Interface worldwide.

Interested companies can obtain the electrical and mechanical

specifications from the AS-Interface Association on request.

$6,QWHUIDFH

Siemens IK PI · 2004

6/3

AS-Interface

Introduction

Configuration examples

6

■

Function

Operating modes

In general, the master interfaces distinguish between the following operating modes:

I/O data transfer

The inputs and outputs of the binary AS-Interface slaves are

read and written in this operating mode.

Analog value transmission

The AS-Interface masters according to the Complete

AS-Interface Specification V2.1 support integrated analog value

processing. This means that data exchange with analog

AS-Interface slaves (according to analog profile 7.3 or 7.4) is just

as easy as with digital slaves.

Command interface

In addition to the I/O data exchange with binary and analog ASInterface slaves, the AS-Interface masters offer a range of additional functions through the command interface.

This means that, from user programs, slave addresses can be

assigned, parameter values can be transferred and diagnostic

information can be read out.

■

Design

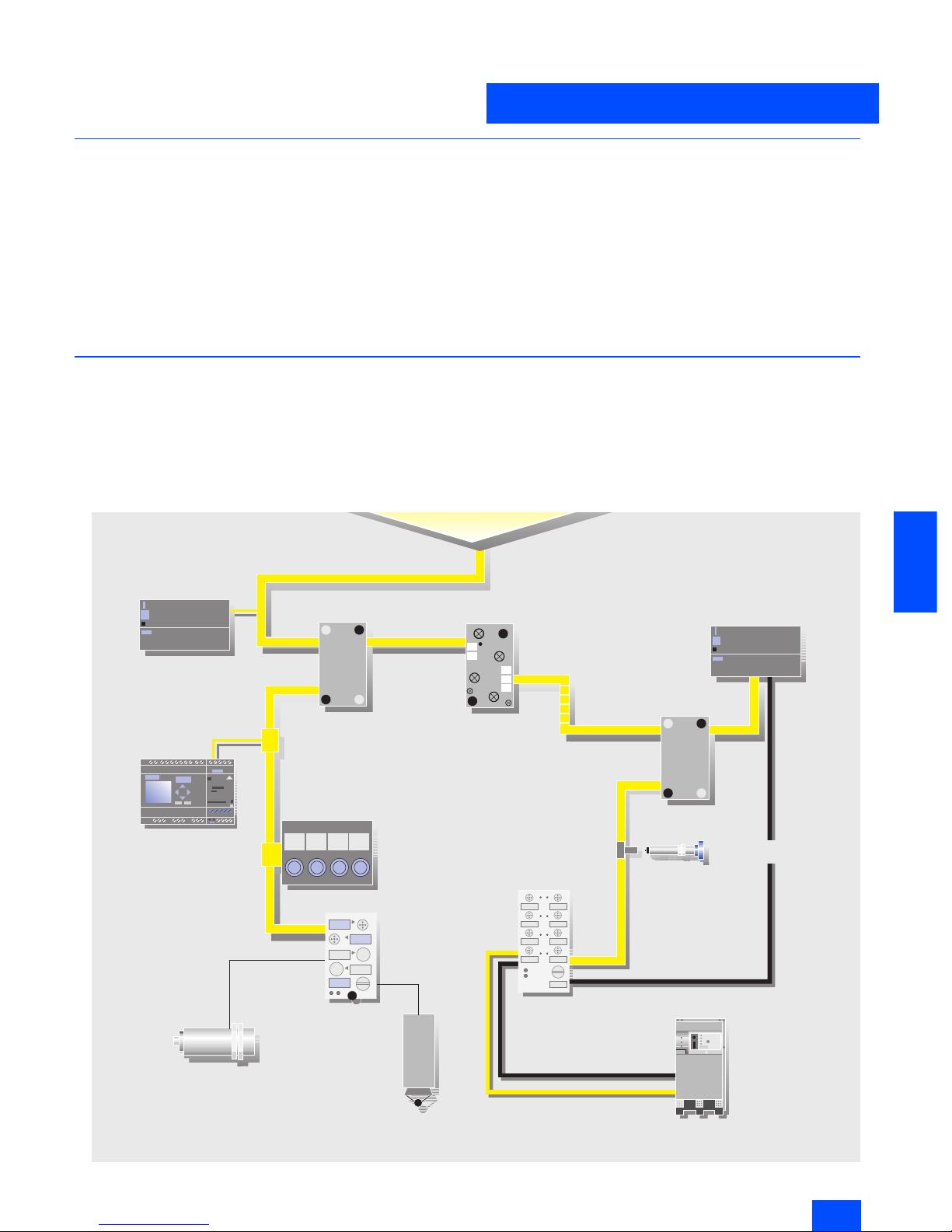

Process or field communication

AS-Interface is used wherever individual actuators and sensors

are physically distributed throughout the machine (e.g. in a bottling plant or on a production line).

AS-Interface replaces complicated wiring harnesses and connects binary and analog actuators and sensors, such as proximity switches, valves or indicator lights, to a controller (e.g. SIMATIC) or PC.

In practice this means: The installation runs without problems

because data and power are transported through a single common cable. No specialist know-how is required for installation

and startup. In addition, the simple installation and clear structuring of the wiring and special cable design not only considerably reduce the risk of faults but also reduce service and maintenance costs.

Example of a system configuration

G_IK10_XX_20027

Connection via AS-Interface cable

AS-Interface distributor

(without AS-Interface chip)

AS-Interface cable

AS-Interface

power section

Branch M12

K60

AS-Interface distributor

(without AS-Interface chip)

Repeater

LOGO!

Operator panel

K45

(with AS-Interface chip)

for connection of

standard sensors

Standard encoders

e.g. position switches

Standard sensor

e.g. inductive BERO

Compact starter IP 65

max 100 m

SONAR BERO

with int. AS-Interface

AS-Interface

power section

Siemens IK PI · 2004

6/4

AS-Interface

System components

Introduction

6

■

Overview

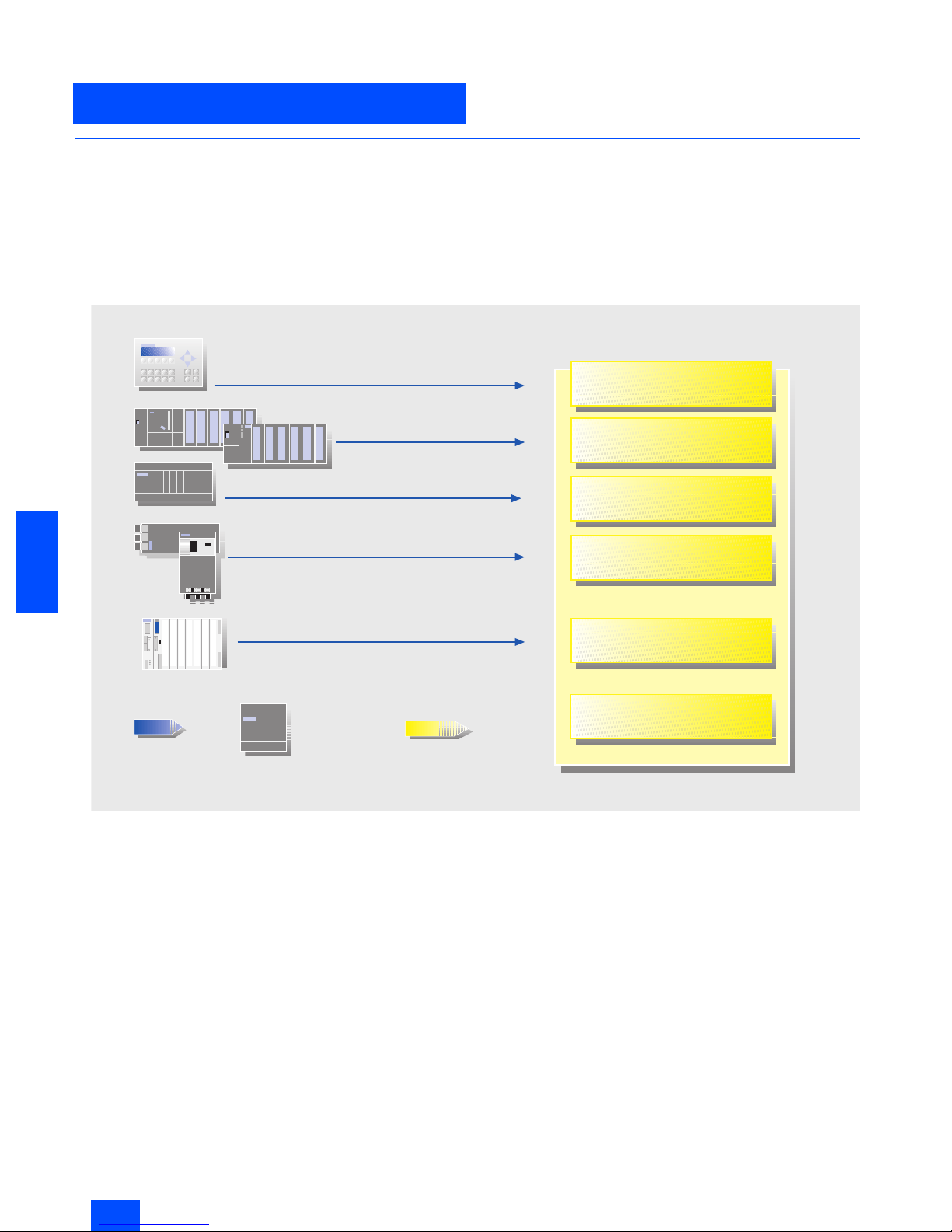

System components

Many system components are available to implement communications. The basic components of a system installation are:

• Master interfaces for central control units such as SIMATIC S5

and SIMATIC S7, distributed I/Os ET 200

®

M/X,

• AS-Interface shaped cables

• Network components such as repeaters/extenders

• The power supply unit for supplying power to the slaves,

modules for connecting standard sensors/actuators

• Actuators and sensors with integrated ASIC slave

• Fail-safe modules for transmission of secure data through

AS-Interface,

• Address programming device for setting the slave address.

AS-Interface master for SIMATIC

0

1

Integrated interface

CP 343-2

CP 243-2

CP 142-2

CP 2430

C7-621 ASi

S5-115U to 155U

ET 200M

S7-200

ET 200X

S7-300

G_IK10_XX_20009

DP/AS-Interface Link 20E

Links

CP 343-2 P

Siemens IK PI · 2004

6/5

AS-Interface

Introduction

Technical specifications

6

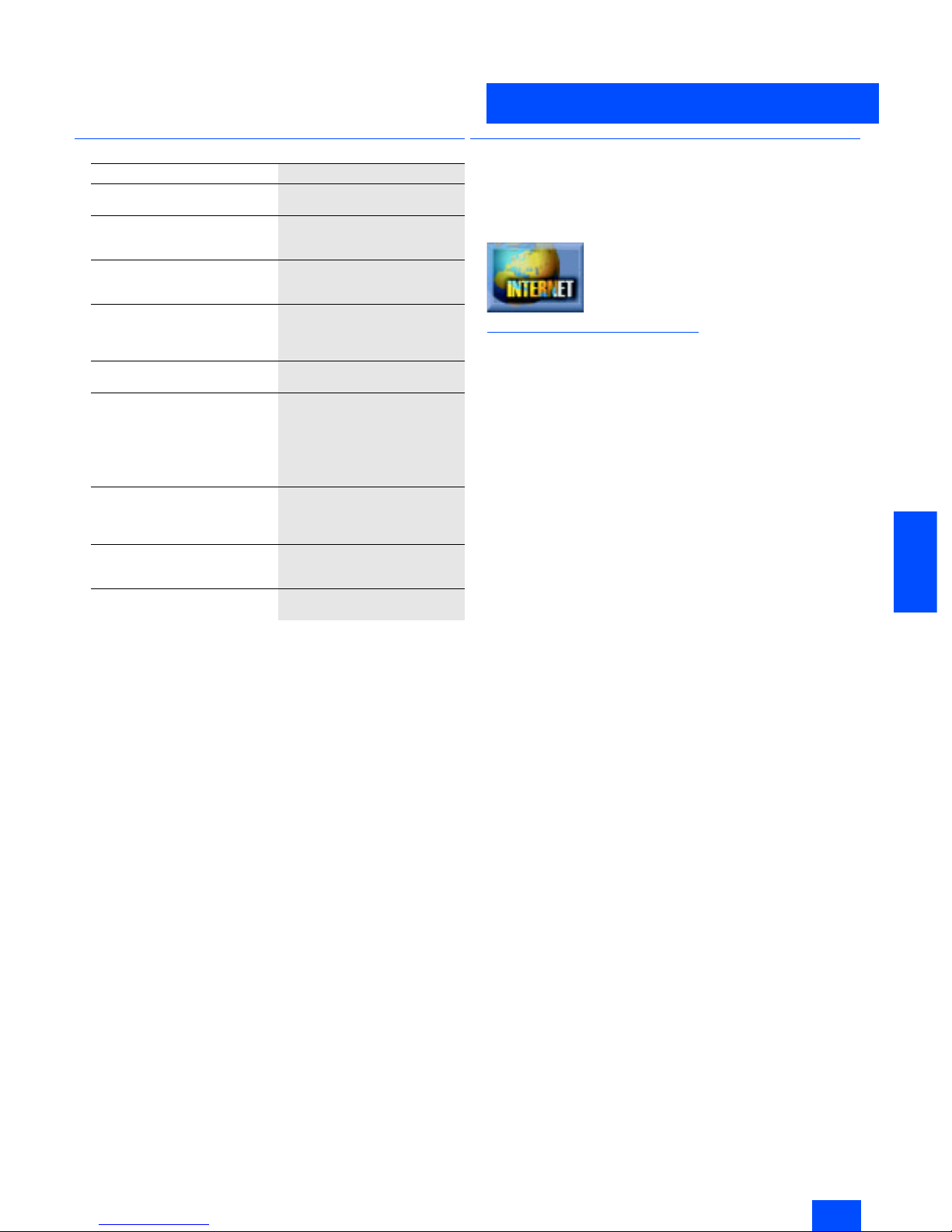

■

Technical specifications

■

More information

Please note the operating framework conditions in each case for

the specified SIMATIC NET products (Order No. 6GK..., 6XV1...),

which you will find on the Internet page listed below.

Additional information is available in the Internet under:

http://www.siemens.de/simatic-net/ik-info

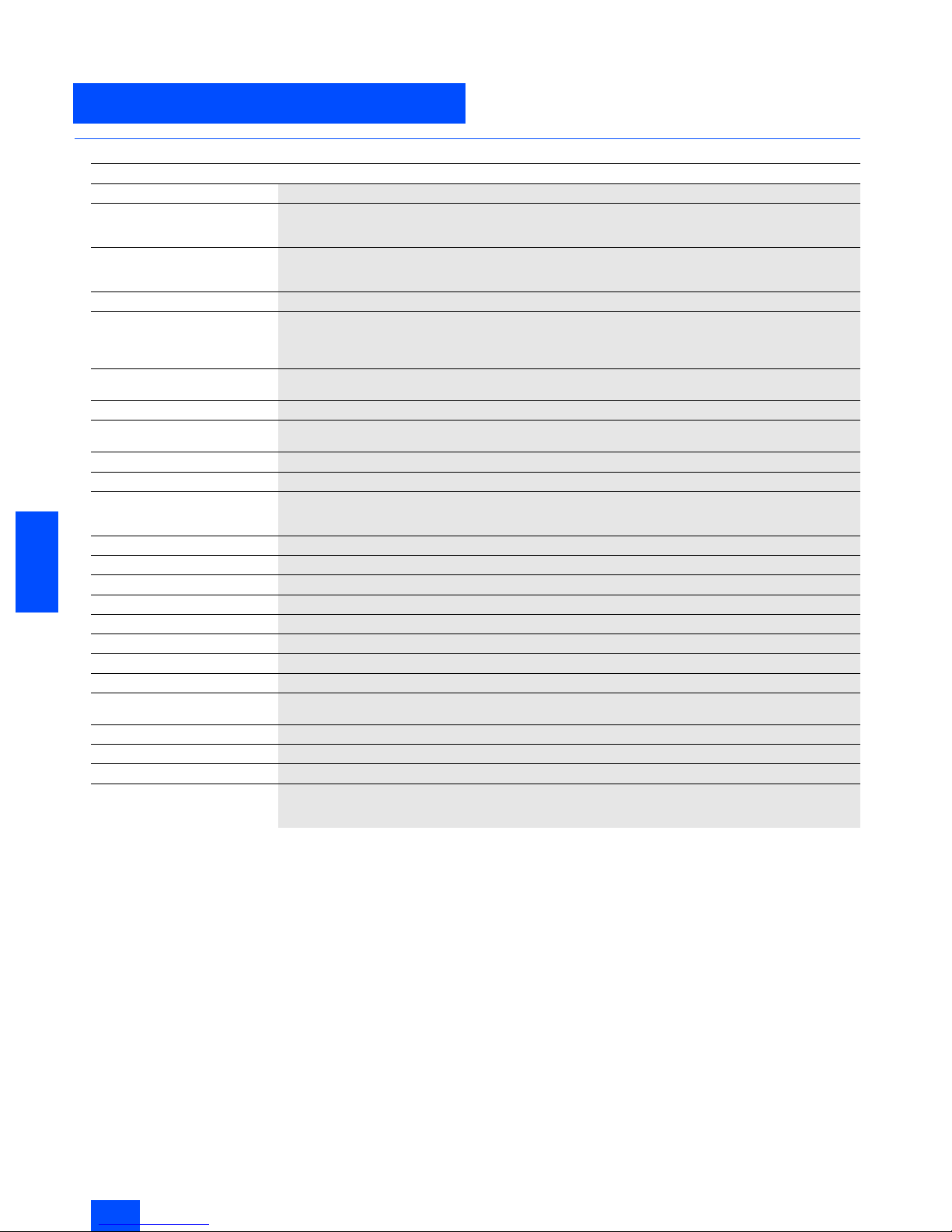

Standard EN 50295

Topology

Bus, star or tree topology

(like electrical installation)

Transmission medium

Unshielded two-wire cable

(2 x 1.5 mm

2

) for data and

auxiliary power

Connection method

Contacting of the AS-Interface

cable using the insulation

displacement method

Permissible cable length max.

100 m w/o repeater/extender

500 m range with repeater/

extender (parallel connection

of repeaters)

Cycle time max.

5 ms with full expansion,

10 ms using A/B method

Number of stations max.

31 slaves accord. to Complete

AS-Interface Spec. V2.0 ;

62 slaves accord. to Complete

AS-Interface Spec. V2.1

(A/B method),

integrated analog value

transmission

Number of binary

sensors/actuators

Max. 124 I/124 O

modules according to spec. V2.0;

Max. 248 I/186 O

modules according to spec. V2.1

Access procedure

Cyclical master-slave polling

method, cyclical acceptance

by host (PLC, PC)

Error correction

Identification and repetition of

faulty messages

Siemens IK PI · 2004

6/6

AS-Interface

A/B technique

6

■

Overview

The A/B technique concept

The AS-Interface specification 2.1 allows a doubling of network

stations from 31 to 62. The 31 addresses that can be assigned

in an AS-Interface network can be split into two mutually independent sub-addresses, e.g. in 1A and 1B.

If this is utilized for all 31 slaves, up to 62 slaves can be connected within an AS-Interface network. The so-called A/B slaves

can each have up to four inputs and three outputs.

Another new feature of the new AS-Interface specification V2.1

is integrated analog value transfer. In this case, integrated

means that no special function blocks are required in order to

access the analog values. Accessing data is therefore just as

easy in the case of analog values as it is with digital values. Integrated analog value transfer can be used with analog slaves

that support Proifiles 7.3 and 7.4.

AS-Interface master

To operate A/B slaves in an AS-Interface network, master modules working according to the specification 2.1 must also be

used. The A/B technique is supported by the SIMATIC S7

masters and the DP/AS-Interface links from Siemens. To masters

that do not support specification 2.1, only standard and A slaves

can be connected.

The sub-address of A/B slaves is set to “A” by default.

Masters and slaves that are already working to the new specifi-

cation are identified accordingly in the catalog.

Addressing A/B slaves

A/B slaves can be addressed like standard slaves via all commercial AS-Interface addressing units conforming to specification 2.1. AS-Interface addressing units that do not conform to the

new specification 2.1 can readdress A/B slaves only as A slaves.

As far as addressing is concerned, an analog slave is like a standard slave. Up to 31 analog slaves can therefore be operated in

one AS-Interface segment.

Communication cycle

Standard slaves are polled in every cycle (max. cycle time:

5ms).

If only an A or B slave is installed at an address, this slave is also

polled in every cycle (max. cycle time: 5 ms).

If an A/B slave pair is installed at an address, slave A is polled in

one cycle, slave B in the next (max. cycle time: 10 ms).

If only standard and/or A slaves are installed in a network, the

cycle time is the same as for standard masters (max. cycle time:

5 ms).

■

Benefits

• Lower costs for masters and power supply units

• Enhanced decentralization in installations with numerous,

widely distributed signals

• Existing AS-Interface systems can be expanded further

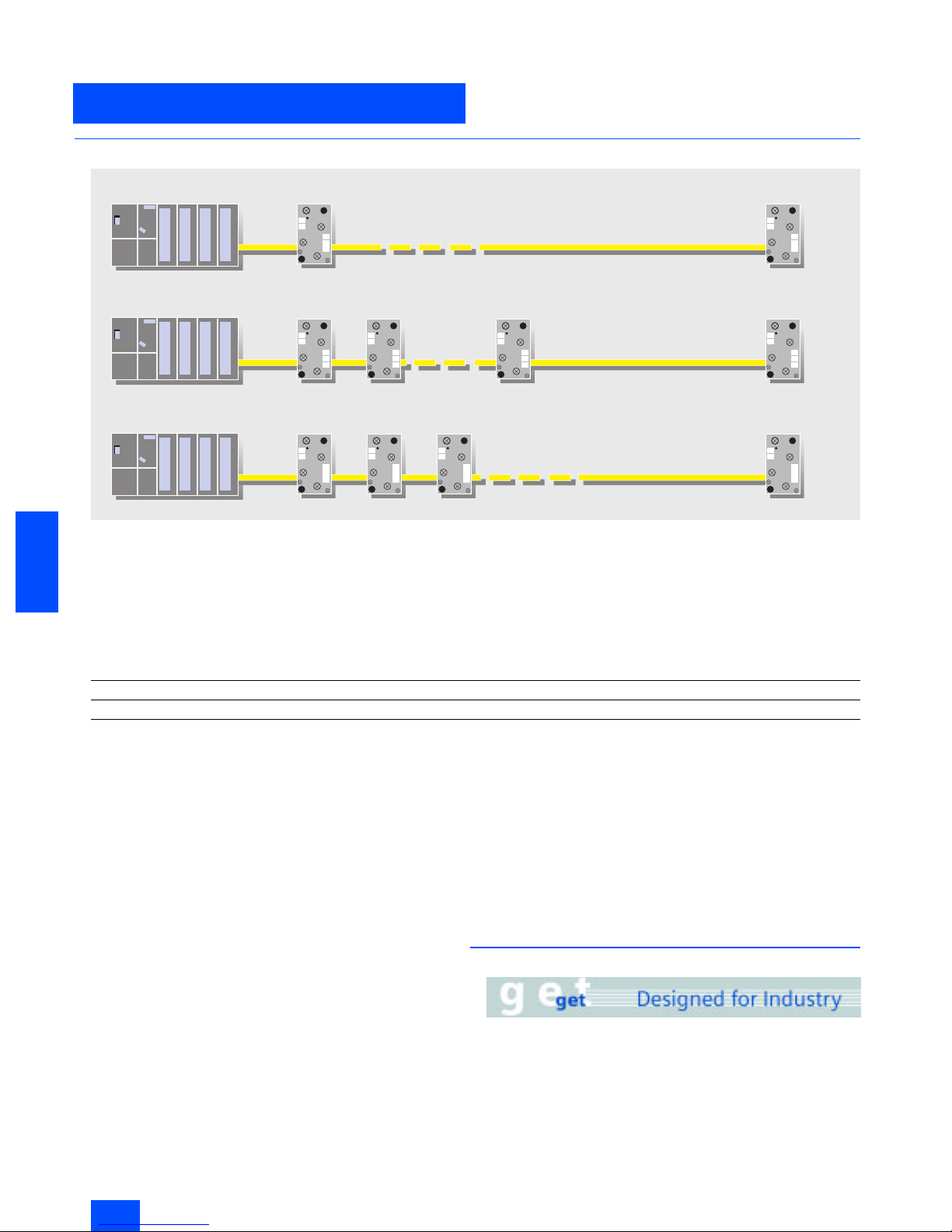

G_IK10_XX_20020

Previously 31 nodes

Slave 1

with A/B slaves max. 62 nodes:

Mixed operation also permissible:

Slave 31

Slave 1A Slave 31B

Slave 1 Slave 31

Slave 1B Slave 31A

Slave 2A Slave 2B

Slave type Number of slaves Number of inputs Number of outputs

AS-Interface standard Standard slave Up to 31 31 x 4 = 124 31 x 4 = 124

AS-Interface version 2.1 A/B slave Up to 62 62 x 4 = 248 62 x 3 = 186

Siemens IK PI · 2004

6/7

AS-Interface

A/B technique

6

■

Selection and Ordering data

1) Start of delivery: approx. end of 2003.

Design Order No.

Master according to Specification 2.1

CP 243-2

Master for SIMATIC S7-200

6GK7 243-2AX01-0XA0

CP 343-2

Master for SIMATIC S7-300

6GK7 343-2AH00-0XA0

CP 343-2 P

master for SIMATIC S7-300

configuration with STEP 7

6GK7 343-2AH10-0XA0

DP/AS-Interface Link 20E

Gateway for transition from AS-Interface to PROFIBUS DP

6GK1 415-2AA01

A/B slaves

3RK2 200-0CQ20-0AA3

K45 compact module

• 4 inputs

- M12 connection

3RK2 200-0CQ20-0AA3

- M8 screw-type connection

3RK2 200-0CT20-0AA3

- M8 snap-on connection

3RK2 200-0CU20-0AA3

•2 x 2 inputs

3RK2 200-0CQ22-0AA3

• 3 outputs

3RK2 100-1EQ20-0AA3

• 2 outputs / 2 inputs 1)

3RK2 400-1BQ20-0AA3

3RK2 400-1HQ00-0AA3

K60 compact module

• 8 inputs /2 outputs

3RK2 400-1HQ00-0AA3

• 8 inputs

3RK2 200-0DQ00-0AA3

• 4 inputs/ 3 outputs

3RK2 400-1FQ03-0AA3

3RK2 200-0CE02-0AA2

Slimline S22.5

• 4 inputs

- Screw-type terminals 1)

3RK2 200-0CE02-0AA2

- Cage Clamp terminals 1)

3RK2 200-0CG02-0AA2

3RK2 400-1FE00-0AA2

Slimline S45

• 4 inputs/ 3 outputs

- Screw terminals

3RK2 400-1FE00-0AA2

- Cage Clamp terminals

3RK2 400-1FG00-0AA2

Siemens IK PI · 2004

6/8

AS-Interface

Introduction

AS-Interface Safety at work

6

■

Overview

Safety included

The Safety at Work concept supports the direct integration of

components with relevance for safety, such as emergency stop

switches, protective cover switches or safety light barriers, in the

AS-Interface network. These are fully compatible with the familiar

AS-Interface components (masters, slaves, power supply units,

repeaters, etc.) in accordance with EN 50295 and are operated

in conjunction with them on the yellow AS-i cable.

The signals from the safety sensors are evaluated by a safety

monitor. This not only monitors the switching signals of the safety

sensors but also continuously checks that data is being transferred correctly. The safety monitor has one or two release circuits in a two-channel configuration which can be used to bring

the machine or installation into a safe state. Sensors and monitors can be connected at any point on the AS-Interface network.

It is also possible to use several monitors in the same network.

A failsafe controller or a special master is not necessary. The

master handles safety slaves in the same manner as all other

slaves and only receives the safety data for information purposes. They can therefore be used to expand any existing

AS-Interface network.

Safety at Work guarantees a maximum response time of 40 ms.

This is the time between application of the signal to the input of

the safe slave and switching off the output at the safety monitor.

Tested safety

The system has been tested and approved by the German

Technical Inspectorate (TÜV). The transmission technique for

signals with relevance for safety is designed to allow applications to be implemented up to category 4 in accordance with

EN 954-1.

Software

The safety-related applications can be configured using the

configuration software and then transferred into the monitor.

Moreover, the software can also be used for online diagnostics.

■

Benefits

• A failsafe PLC or special master is not required.

• Simple system structure due to standardized AS-Interface

technique.

• Safe and non-safe data on the same bus.

• Existing systems can be expanded quickly and easily.

• Safe signals can be combined in groups.

• Integration of the safety signals in the plant diagnostics concept.

• Approved up to category 4 acc. to EN 954-1.

• Safety at Work is certified by the German Technical Inspectorate (TÜV).

■

Application

Integrated safety systems using AS-Interface can be used in applications for which EMERGENCY-STOP pushbuttons, protective

door locks, Stop category 0 and 1, two-handed operation and

light arrays are currently installed.

■

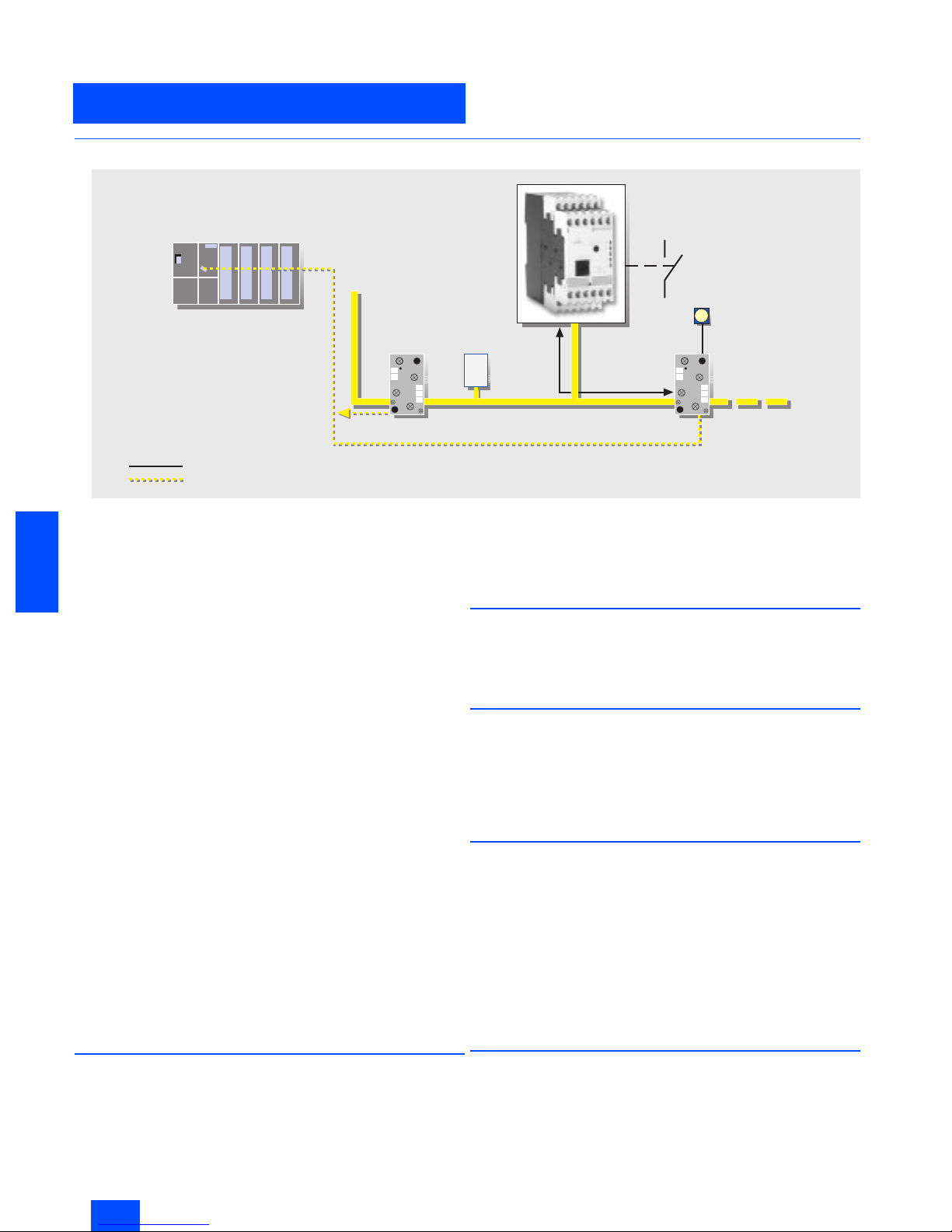

Design

The safety system is constructed in the same manner as the now

familiar installation of AS-Interface.

The family of safe AS-Interface products comprises the safety

monitor that monitors the safe stations. The spectrum of safe stations comprises the safe modules and the safety-related sensors

with an integrated interface.

■

Function

Following a master call, the safe stations transmit their information, like the standard stations, to the master. The safety monitor

monitors this transfer from the safe stations to the master and

switches

• to the EMERGENCY-STOP status (in the case of faults in safe

stations) or

• to the safe status (in the case of a wire break).

The safety monitor is configured using software. The configuration comprises the input signals of the safe stations and the internal functions of the safety monitor. The safety monitor offers

OR logic, AND logic, timer functions, buffer storage, etc.

■

Integration

For integration of the safety system into AS-Interface, the existing infrastructure such as the master and the power supply unit

can continue to be used. For the safety system, the safety monitor is integrated as a monitoring component and the safe station

is integrated as the interface between the safe sensors and the

system. The safe sensors can be used as before.

G_IK10_XX_20021

Standard PLC

Standard master

Standard slave

Security monitor

Secure slave

with EMERGENCY-OFF

Signal evaluation of secure slave/security monitor

Master information (through regular I/O transfer)

Power section

Siemens IK PI · 2004

6/9

AS-Interface

AS-Interface Safety at work

AS-Interface safety monitors

6

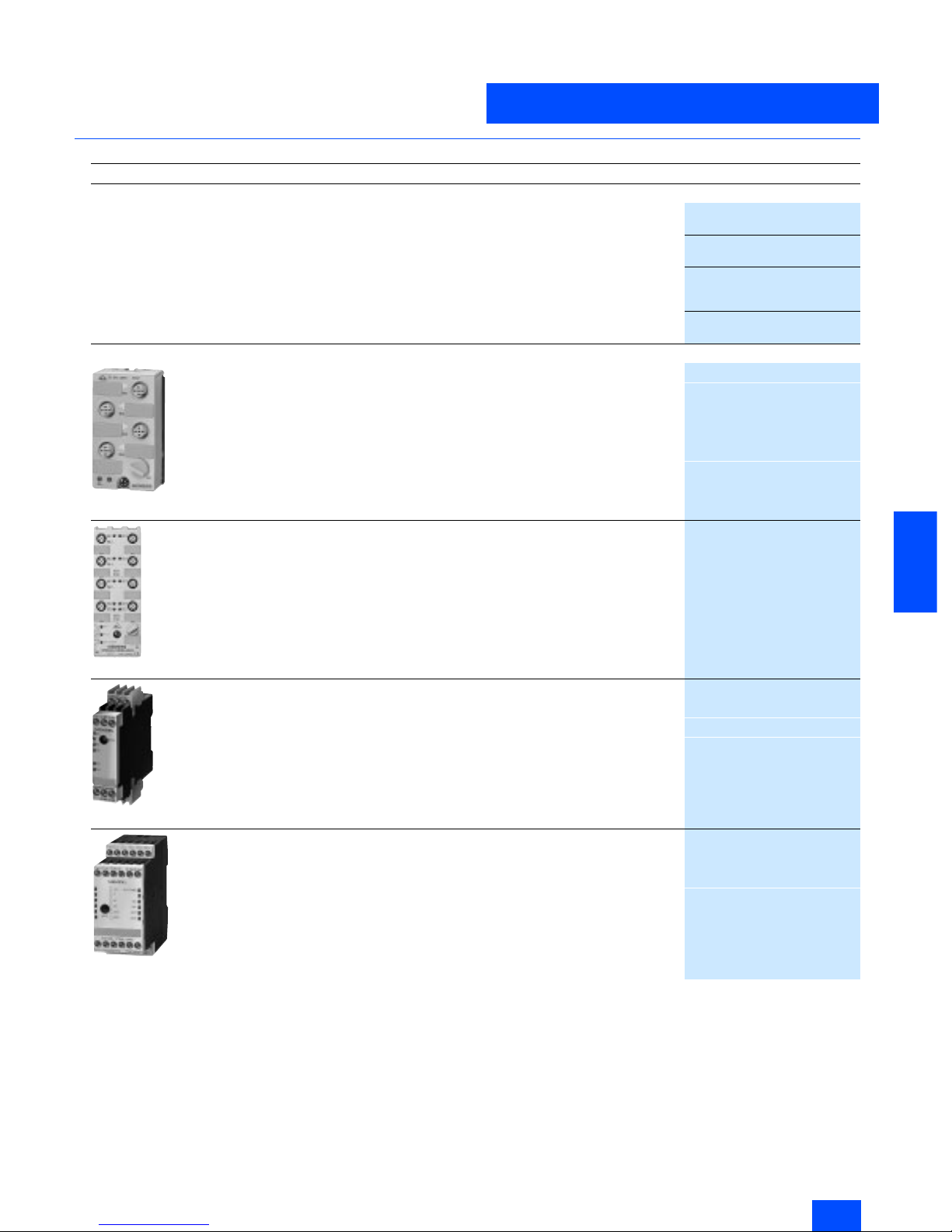

■

Overview

The safety monitor is the core component of Safety at Work. A

safe application is configured with a PC via the safety monitor.

Various different application-specific operating modes can be

used. These include the EMERGENCY-STOP function, tumbler,

two-handed operation as well as selection of Stop category

0 or 1.

In order to fully utilize the AS-Interface diagnostic capability, the

monitor can also be operated with AS-Interface addresses as an

alternative.

Two versions of the monitor are available:

• Safety monitor with one two-channel release circuit

• Safety monitor with two two-channel release circuits

■

Function

Safety monitor with enlarged functions

Logical OR operation

In this logical operation up to six elements can be OR gated.

(Until now, only two elements could be OR gated).

Logical AND operation

In addition to the standard AND gating in the main path of an

enabling circuit, an AND operation can be inserted into an OR

operation. More than two elements can be gated in this AND.

Buffer

Temporary shutdowns are stored in a buffer for the purpose of

diagnostics.

Number of devices

The number of devices that the safety monitor can process has

been increased from 32 to 48. Applications that are larger and

more complex can now be simulated in the safety monitor.

Timer functions

Timers are offered with the functions

• Delayed switching-on

• Delayed switching-off and

• Pulse.

Compatibility

Any configurations that have been previously created can be

loaded into the "new" safety monitor without changes.

■

Technical specifications

Safety monitor

3RK1 105

Rated operational current

•Ie/AC-12 up to 250 V, 2 A

•I

e

/AC-15 115 V, 2A

230 V, 2A

•I

e

/DC-12 up to 24 V, 3 A

•I

e

/DC-13 24 V, 1 A

115 V, 0.1 A

230 V, 0.05 A

• Response time

< 40 ms

• Ambient temperature in °C

0 to +60

• Storage temperature in °C

-40 to +85

Siemens IK PI · 2004

6/10

AS-Interface

AS-Interface safety monitors

AS-Interface Safety at work

6

■

Selection and Ordering data

■

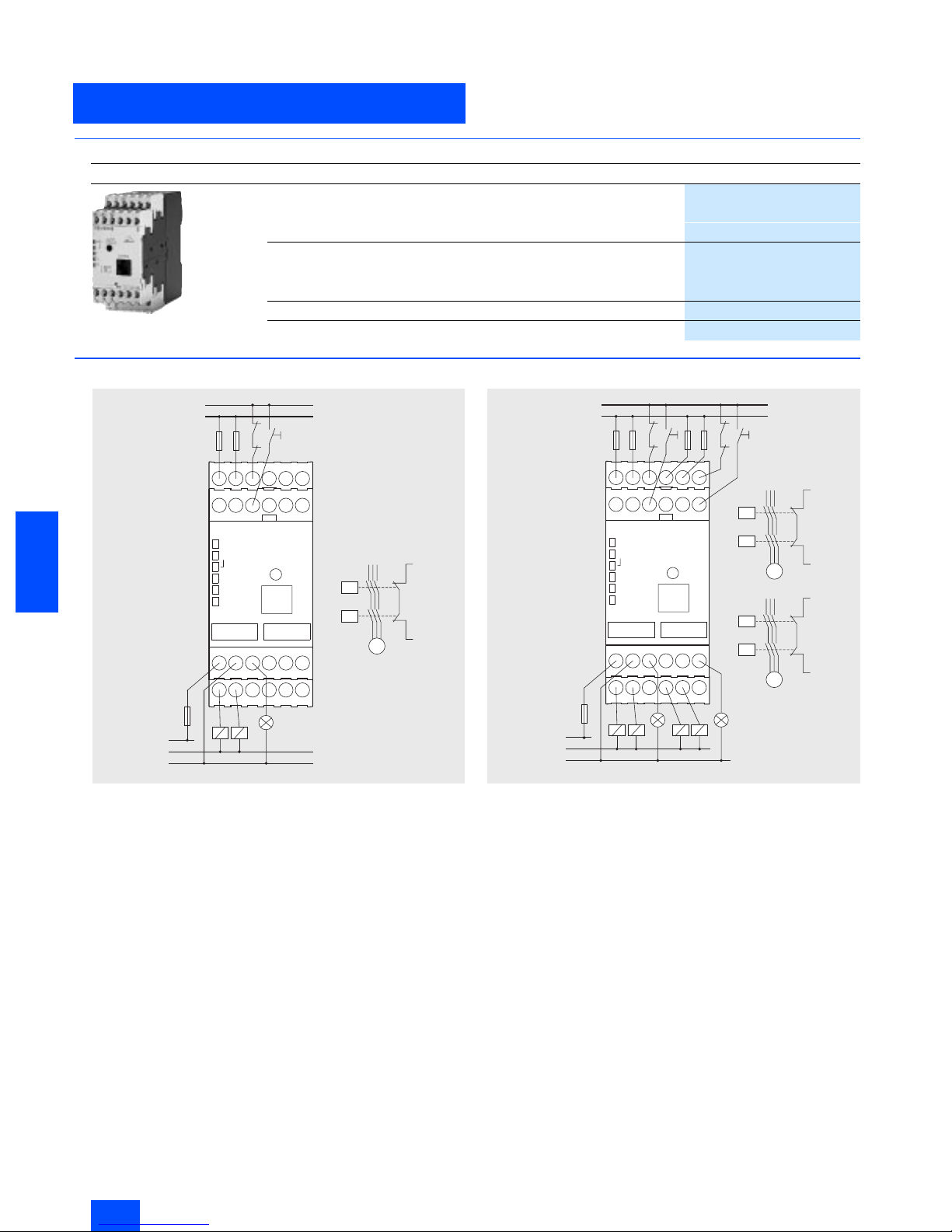

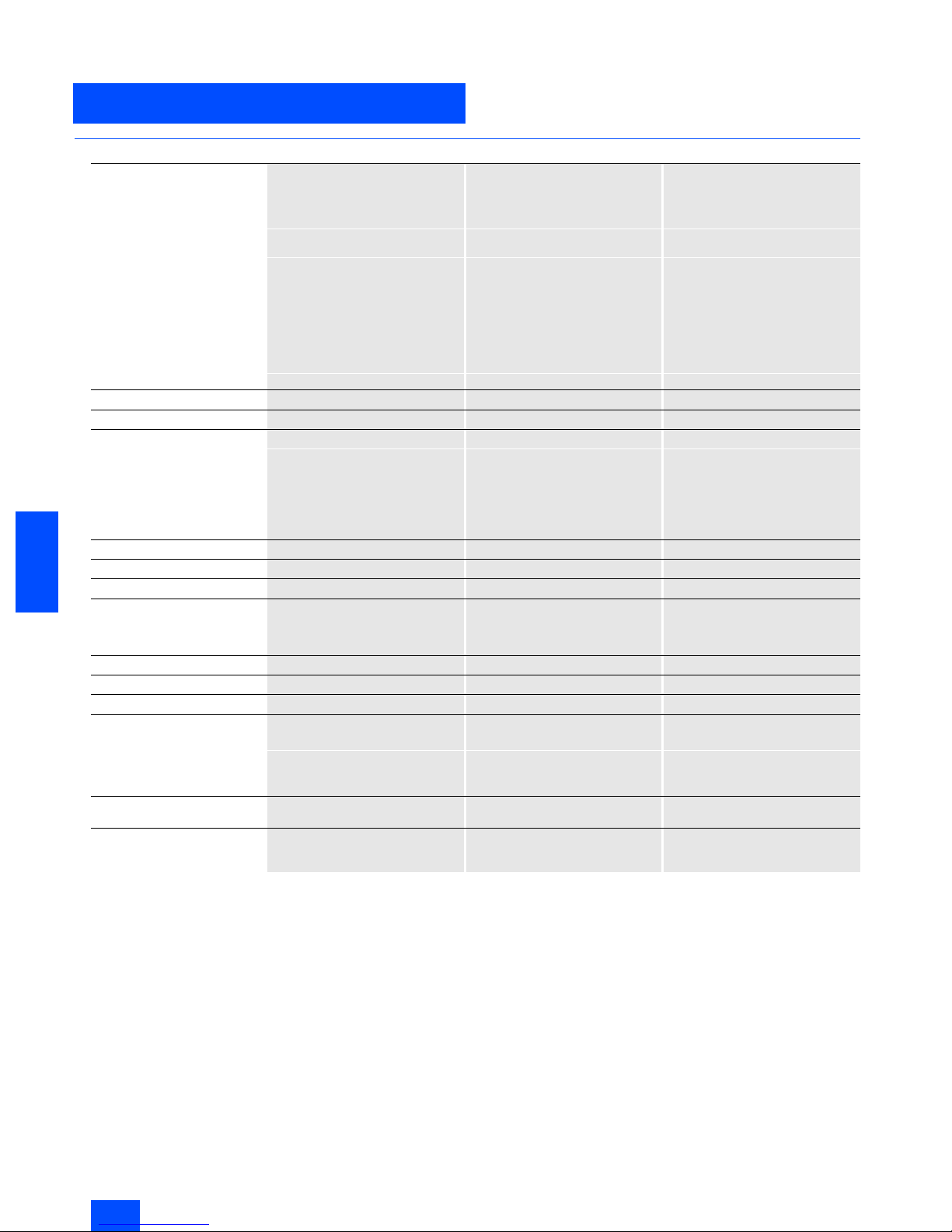

Dimensional drawings

Safety monitor with one release circuit

Safety monitor with two release circuits

Design

Order No.

Safety monitor

Safety monitor

• One enabling circuit

3RK1 105-1AE04-0CA0

• Two enabling circuits

3RK1 105-1BE04-0CA0

Safety monitor with extended functionality

• One enabling circuit

3RK1105-1AE04-2CA0

• Two enabling circuits

3RK1105-1BE04-2CA0

Configuration software

3RK1 802-2FB06-0GA0

Cable set

3RK1 901-5AA00

L/+

L

K1

K2

Start 1

1.13 1.23 1.Y1

AS-i+AS-i-

1.Y2

AS-i

1

2

3

L+ M 1.32

1.14

1.24

PE

K1 K2

L+

M/N

M

K1

K2

M

L+

1.Y1

g_nsa0_xx_00356

L/+

L

Start 2

Start 1

K1

K2

K3

K4

1.13 1.23 1.Y1

AS-i+ AS-i- 1.Y2

AS-i

1

2

3

K1

K2

L+ M 1.32 2.32

1.14 1.24 PE 2.14 2.24

K1

K2 K3 K4

L+

M/N

M

L/+

1.Y1

M

K3

K4

L/+

M

2.Y1

g_nsa_xx_00357

Siemens IK PI · 2004

6/11

AS-Interface

AS-Interface Safety at work

AS-Interface safe compact modules

6

■

Overview

The compact module product family will be supplemented with

safe modules:

• The K45F safe compact module is equipped with two "safe" inputs. For operation up to category 2 acc. to EN 954-1, each input can be separately assigned. If category 4 is required, a

two-channel input is available on the module.

• The K60F safe compact module has, in addition to the two safe

inputs, also two standard outputs.

■

Technical specifications

K45F safe compact module K60F safe compact module K60F safe compact module

PNP transistor PNP transistor PNP transistor

Standard assignment Standard assignment Standard assignment

2 safe inputs 2 safe inputs,

2 standard outputs

2 safe inputs,

2 standard outputs with U

Aux

3RK1 205-0BQ00-0AA3 3RK1 405-0BQ00-0AA3 3RK1 405-0BQ00-0AA3

AS-Interface chip

SAP 4 SAP 4 SAP 4

Operational voltage

in accordance with AS-Interface

specification in V

26.5 to 31.5 26.5 to 31.5 26.5 to 31.5

Total current input in mA

£

45

£

270

£

270

Input connection

PNP PNP PNP

Inputs

• Sensor supply via AS-Interface -- -- --

•Sensors

Mechanical switching contact Mechanical switching contact Mechanical switching contact

• Voltage range in V

-- -- --

• Current carrying capacity for all

inputs (T

u

£

40 °C) in mA

-- -- --

• Switching level High in V

Contact open/closed Contact open/closed Contact open/closed

• Input current Low/High in mA

- / /

peak

³ 5 - / /

peak

³ 5 - / /

peak

³ 5

Pin assignment inputs

Pin1 and 2 = Terminal/switching

contact

Pin3 and 4

Terminal/switching contact

Pin5 = Not assigned

Pin1 and 2 = Terminal/switching

contact

Pin3 and 4

Terminal/switching contact

Pin5 = Not assigned

Pin1 and 2 = Terminal/switching

contact

Pin3 and 4

Terminal/switching contact

Pin5 = Not assigned

Siemens IK PI · 2004

6/12

AS-Interface

AS-Interface safe compact modules

AS-Interface Safety at work

6

■

Technical specifications (continued)

Outputs

• Type of output -- Electronics Electronics

• Current carrying capacity

DC 12/13 in A

-- 2 --

• Current carrying capacity typ.

(max. 4 A per module) in A

-- Max. 0.18 Max. 4

• Pin assignment outputs

-- 3 = "–"

4 = Output

5 = Earth connection

3 = "–"

4 = Output

5 = Earth connection

• Short-circuit protection

-- Built-in Built-in

• Inductive interference protection (free-wheeling diode)

-- None Built-in

• External voltage supply

24 V DC

-- -- Via black AS-Interface flat cable

• Watchdog

-- Built-in Built-in

I/O configuration

0 7 7

ID/ID2 code

B B B

Assignment of data bits

• Socket 3 and 4 Not assigned (closed) Not assigned (closed) Not assigned (closed)

• Socket 5

Not assigned (closed) Pin 4 = OUT1 (D0)

Pin 2 = Not assigned (closed)

Pin 4 = OUT1 (D0)

Pin 2 = Not assigned (closed)

• Socket 6

Not assigned (closed) Pin 4 = OUT2 (D1)

Pin 2 = Not assigned (closed)

Pin 4 = OUT2 (D1)

Pin 2 = Not assigned (closed)

• Socket 7 and 8

Not assigned (closed) Not assigned (closed) Not assigned (closed)

AS-Interface certificate

Ye s Yes Yes

Approvals

UL, CSA UL, CSA UL, CSA

Degree of protection

IP67 IP67 IP67

Earth connection

-- PIN 5 of each M 12 socket is

connected to the grounding plate in

the mounting plate via a pin

(outputs only sockets 5 and 6).

PIN 5 of each M 12 socket is

connected to the grounding plate in

the mounting plate via a pin

(outputs only sockets 5 and 6).

Ambient temperature in °C

-25 to +85 -25 to +85 -25 to +85

Storage temperature in °C

-40 to +85 -40 to +85 -40 to +85

Number of I/O sockets

2 4 4

Status indication

• I/O display Yellow LED Yellow LED Yellow LED

• U

Aux

-- -- Green LED

• AS-Interface/diagnostics

display

Green/red LED Green/red LED Green/red LED

Connection

via mounting plate for K45 compact

module

via mounting plate for K60 compact

module

via mounting plate for K60 compact

module

Addressing

Front addressing socket,

after the 15th addressing,

the module keeps the last address

Front addressing socket,

after the 15th addressing,

the module keeps the last address

Front addressing socket,

after the 15th addressing,

the module keeps the last address

Siemens IK PI · 2004

6/13

AS-Interface

AS-Interface Safety at work

AS-Interface safe compact modules

6

■

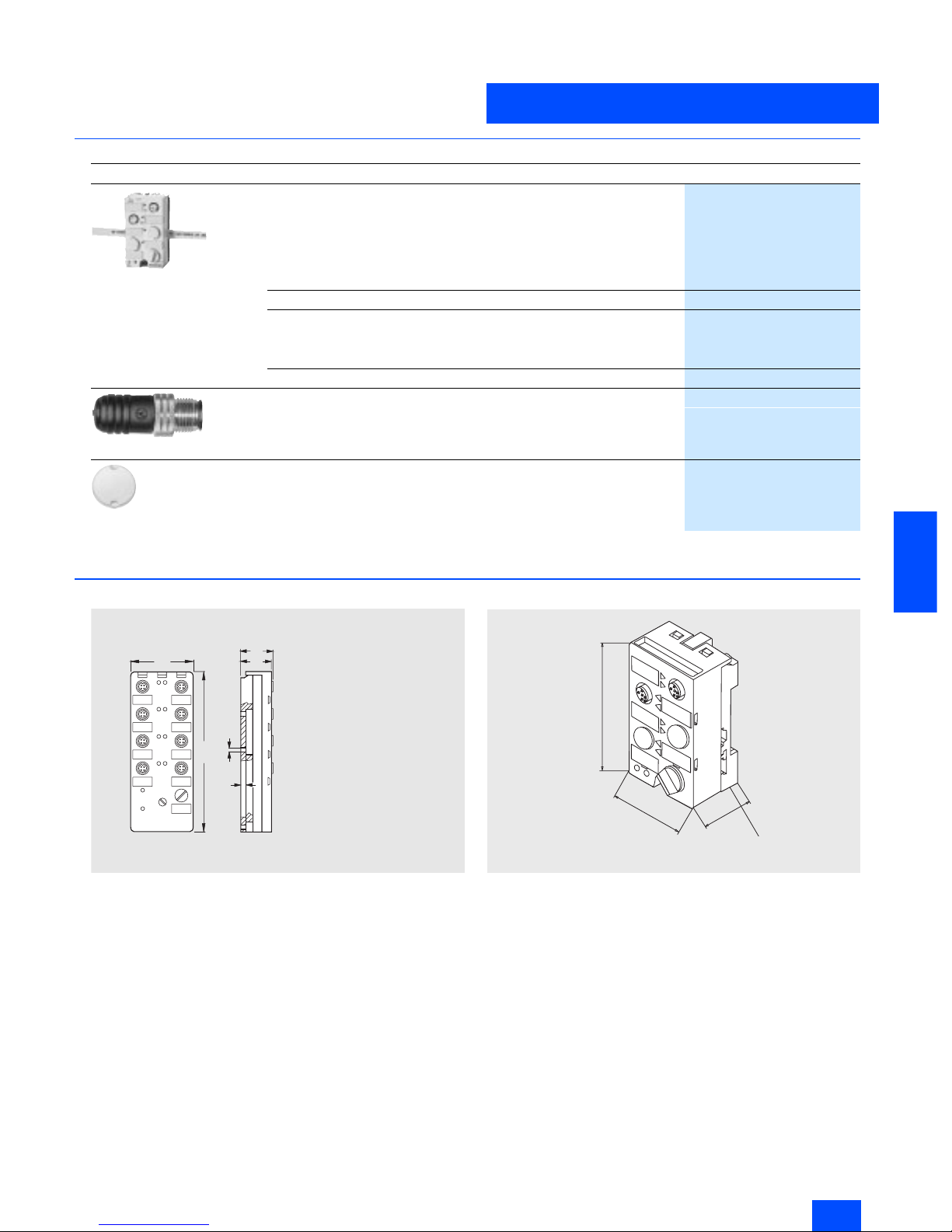

Selection and Ordering data

1) Modules supplied without mounting plate.

■

Dimensional drawings

K60F safe module

K45F safe module

Design

Order No.

3RK1 205-0BQ00-0AA3

K45F safe compact module

1)

2FE

3RK1 205-0BQ00-0AA3

K45 mounting plate

3RK1 901-2EA00

K60F safe compact module

1)

• 2FE/2A

3RK1 405-0BQ00-0AA3

• 2FE/2A with U

Aux

3RK1 405-1BQ00-0AA3

K60 mounting plate

3RK1 901-0CA00

3RK1 901-1AA00

Input bridge for K45/K60F

• Black version

3RK1 901-1AA00

• Red version

3RK1 901-1AA01

3RK1 901-1KA01

AS-Interface M12 sealing caps, protected against manipulation

For spare M12 sockets

(one packing contains ten sealing caps)

3RK1 901-1KA01

N S A 0 _ 0 0 0 2 6

Æ

4 , 5

3 1

2 9

5

1 5 2

6 0

S i d e v i e w w i t h

m o u n t i n g p l a t e

3 R K 1 9 0 1 - 0 C A 0 0

45

80

30

Mounting plate

3RK1901-2EA00

Siemens IK PI · 2004

6/14

AS-Interface

AS-Interface safe compact modules

AS-Interface Safety at work

6

■

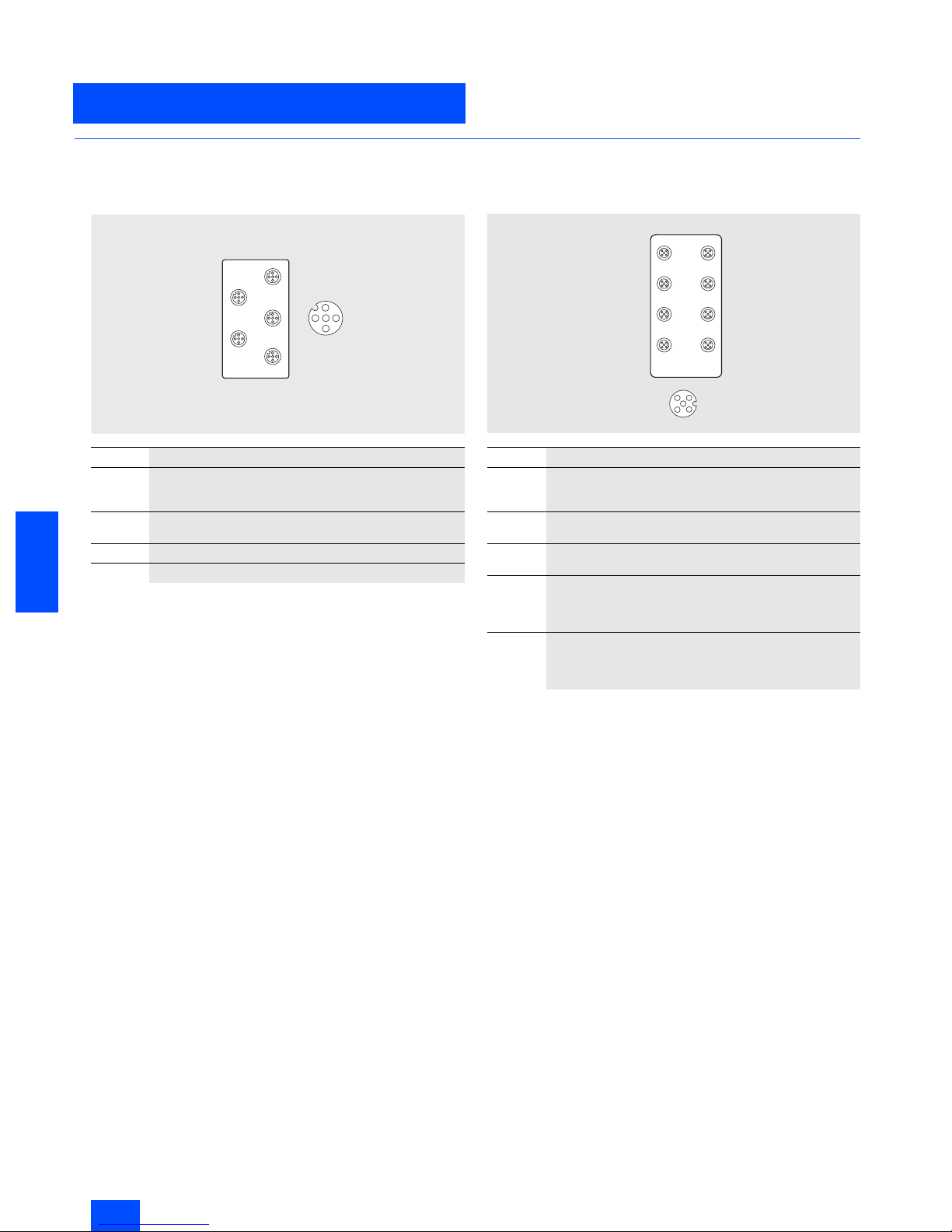

Schematics

Logical assignments

K45F Safe Compact Module

If only one single-channel switch will be connected to the module, this must be connected to Channel 1. The second channel

must be bridged. This can be performed with the M12 connector

3RK1901-1AA00 on Socket 2.

Pin 3 of Socket 1 is connected to Pin 1 of Socket 2 and Pin 4 of

Socket 1 is connected to Pin 2 of Socket 2. If both socket pairs

are assigned, the inputs are linked.

K60F Safe Compact Module

Pin 3 of Socket 1 is connected to Pin 1 of Socket 2 and Pin 4 of

Socket 1 is connected to Pin 2 of Socket 2. If both socket pairs

are assigned, the inputs are linked.

Socket Assignment / data sheet / function

1

Pin 1 and Pin 2: affects bits D0 and D1 = Channel 1

Pin 3 and Pin 4: affects bits D2 and D3 = Channel 2

Pin 5 not assigned

2

Pin 1 and Pin 2: affects bits D2 and D3 = Channel 2

Pin 5 not assigned

3

Unused

4

Unused

²

1

2

3

4

ADDR

1

2

3

4

G_NSA0_XX_00355

Socket Assignment / data sheet / function

1

Pin1 and Pin 2: affects bits D0 and D1 = Channel 1

Pin 3 and Pin 4: affects bits D2 and D3 = Channel 2

Pin 5: unused

2

Pin 1 and Pin 2: affects bits D2 and D3 = Channel 2

Pin 5: unused

3/4/7 and

8

Not assigned, factory sealed

5

Pin 4: Output 1

Pin 3: -Pin 5: Ground

Pin 1 and Pin 2: unused

6

Pin 4: Output 2

Pin 3: -Pin 5: Ground

Pin 1 and Pin 2: unused

3

4

2

N S A _ 0 0 3 5 8

1

3

7

5

1

4

8

6

2

Siemens IK PI · 2004

6/15

AS-Interface

AS-Interface Safety at work

AS-Interface position switches

6

■

Overview

Position switch from left to right:

Standard / Standard, with M12 connector / with tumbler

It is also possible now to directly connect SIGUARD position

switches via the standard AS-Interface with safety-oriented communication. In this case, the safety functions no longer have to

be conventionally wired up.

Position switches convert the mechanical positions of moving

machine components into electrical signals.

■

Application

Position switch with separate actuator

The position switches with separate actuator are used in applications in which the position of doors, covers or guards has to

be monitored for safety reasons.

The position switch can only be switched using the associated

coded actuator. It is not possible to bypass it manually or using

a tool.

Position switch with tumbler

The position switches with tumblers are special safety devices

that prevent the inadvertent or intentional opening of protective

doors, guards or other covers when a dangerous state exists,

e.g. for coastdown movements of the switched-off machine.

The safety switch with tumbler has two main tasks:

• Enabling the machine when the protective device is closed

and locked

• Disabling the machine when the protective device is open

The position switch can only be switched using the associated

coded actuator. It is not possible to bypass it manually or using

a tool.

■

Selection and Ordering data

Design

Order No.

AS-Interface position switch, standard

Via AS-Interface F adaptor

With direct connection of AS-Interface to Safety at Work

For use up to Category 2 acc. to EN 954-1

IP65

3SF3 200-6EV00-0BA1

• Molded plastic enclosure, EN 50 047, 31 mm wide, slow-action contact, two NC

- Overtravel plunger

3SF3 200-6CV00-0BA1

- Roller plunger

3SF3 200-6DV00-0BA1

- Roller lever

3SF3 200-6EV00-0BA1

- Angular roller lever

3SF3 200-6FV00-0BA1

- Swivel lever

3SF3 200-6GV00-0BA1

• Molded plastic enclosure, EN 50 047, 31 mm wide, snap action contact, one NC

- Overtravel plunger

3SF3 200-1CV00-0BA1

- Roller plunger

3SF3 200-1DV00-0BA1

- Roller lever

3SF3 200-1EV00-0BA1

- Angular roller lever

3SF3 200-1FV00-0BA1

- Swivel lever

3SF3 200-1GV00-0BA1

Forced opening IEC 60947-5-1, Appendix K.

Siemens IK PI · 2004

6/16

AS-Interface

AS-Interface position switches

AS-Interface Safety at work

6

■

Selection and Ordering data (continued)

Design

Order No.

3SF3 120-6GW00-0BA1

• Metal enclosure, EN 50 041, 40 mm wide, slow-action contact, two NC

- Overtravel plunger

3SF3 120-6CV00-0BA1

- Roller plunger

3SF3 120-6DV00-0BA1

- Roller lever

3SF3 120-6EV00-0BA1

- Angular roller lever

3SF3 120-6FV00-0BA1

- Swivel lever

3SF3 120-6GW00-0BA1

• Metal enclosure, EN 50 041, 40 mm wide, snap action contact, one NC

- Overtravel plunger

3SF3 120-1CV00-0BA1

- Roller plunger

3SF3 120-1DV00-0BA1

- Roller lever

3SF3 120-1EV00-0BA1

- Angular roller lever

3SF3 120-1FV00-0BA1

- Swivel lever

3SF3 120-1GW00-0BA1

AS-Interface position switch, standard, with M12 connector

M12 connector for connecting an additional position switch

Direct connection of AS-Interface to Safety at Work

For use up to Category 4 acc. to EN 954-1

IP65

3SF3 210-0DV00-0BA2

• Molded plastic enclosure, EN 50 047, 50 mm wide, slow-action contact, 1 NC

- Overtravel plunger

3SF3 210-0CV00-0BA2

- Roller plunger

3SF3 210-0DV00-0BA2

- Roller lever

3SF3 210-0EV00-0BA2

- Angular roller lever

3SF3 210-0FV00-0BA2

- Swivel lever

3SF3 210-0GV00-0BA2

• Molded plastic enclosure, EN 50 047, 50 mm wide, snap-action contact, 1 NC

- Overtravel plunger

3SF3 210-1CV00-0BA2

- Roller plunger

3SF3 210-1DV00-0BA2

- Roller lever

3SF3 210-1EV00-0BA2

- Angular roller lever

3SF3 210-1FV00-0BA2

- Swivel lever

3SF3 210-1GV00-0BA2

3SF3 100-0EV00-0BA2

• Metal enclosure, EN 50 041, 56 mm wide, slow-action contact, 1 NC

- Overtravel plunger

3SF3 100-0CV00-0BA2

- Roller plunger

3SF3 100-0DV00-0BA2

- Roller lever

3SF3 100-0EV00-0BA2

- Angular roller lever

3SF3 100-0FV00-0BA2

- Swivel lever

3SF3 100-0GW00-0BA2

• Metal enclosure, EN 50 041, 56 mm wide, snap-action contact, 1 NC

- Overtravel plunger

3SF3 100-1CV00-0BA2

- Roller plunger

3SF3 100-1DV00-0BA2

- Roller lever

3SF3 100-1EV00-0BA2

- Angular roller lever

3SF3 100-1FV00-0BA2

- Swivel lever

3SF3 100-1GW00-0BA2

Forced opening IEC 60947-5-1, Appendix K.

Siemens IK PI · 2004

6/17

AS-Interface

AS-Interface Safety at work

AS-Interface position switches

6

■

Selection and Ordering data (continued)

1) 1) Accessories, technical data, contact travel, circuit diagrams and

dimensional drawings for the specified basic switch can be found in

the Catalog LV 10, Edition 2004, Section AS-Interface Safety Systems.

Design

Order No.

AS-Interface position switch, with separate actuator

With direct connection of AS-Interface to Safety at Work

For use up to Category 2 acc. to EN 954-1

IP65, Slow-action contact, 2 NC

• Molded plastic enclosure, side operation, fixing acc. to EN 50 047

3SF3 200-6XX03-0BA1

• Molded plastic enclosure, front operation, fixing acc. to EN 50 047

3SF3 200-6XX04-0BA1

• Molded plastic enclosure, side and front operation, 52 mm wide

- 30 N extraction force

3SF3 243-0XX00-0BA1

- 5 N extraction force

3SF3 243-0XX40-0BA1

- Automatic ejection

3SF3 243-0XX30-0BA1

• Metal enclosure, fixing acc. to EN 50 041

3SF3 120-6XX00-0BA1

Actuator

• Standard, Width/length of enclosure 79 mm

3SX3 197

• With crosswise fixing, Width/length of enclosure 50 mm

3SX3 206

• Universal radius, Width/length of enclosure 80 mm

3SX3 203

3SF3 257-6XX00-0BA2

AS-Interface position switch with separate actuator and M12 connector

M12 connector for connecting an additional position switch

Direct connection of AS-Interface to Safety at Work

For use up to Category 4 acc. to EN 954-1

IP65, Slow-action contact, one NC

Molded plastic enclosure

Side and front operation

52 mm wide

• 30 N extraction force

3SF3 257-6XX00-0BA2

• 5 N extraction force

3SF3 257-6XX40-0BA2

• Automatic ejection

3SF3 257-6XX30-0BA2

Actuator

• Standard, Width/length of enclosure 27 mm

(r

min

= 150 mm)

3SX3 218

• Universal radius, Width/length of enclosure 33 mm

(r

min

= 45 mm)

3SX3 228

3SF3 750-6XX00-0BA1

AS-Interface position switch, with separate actuator and tumbler

With direct connection of AS-Interface to Safety at Work

For use up to Category 4 acc. to EN 954-1

IP65, Pg 13.5, Solenoid voltage 24 V DC

Monitoring of actuator and solenoid position

• Plastic housing

- Locking force 1200 N, locked by spring force

3SF3 760-6XX00-0BA1

- Locking force 1200 N, locked by magnetic force

3SF3 750-6XX00-0BA1

Actuator

•Standard,

3SX3 252

• with crosswise fixing

3SX3 253

•radius

3SX3 254

3SF3 830-6XX00-0BA1

• Metal housing

- Locking force 1200 N, locked by spring force

3SF3 860-6XX00-0BA1

- Locking force 1200 N, locked by magnetic force

3SF3 850-6XX00-0BA1

- Locking force 2000 N, locked by spring force

3SF3 840-6XX00-0BA1

- Locking force 2000 N, locked by magnetic force

3SF3 830-6XX00-0BA1

Actuator

• Standard, length 79 mm

3SX3 197

- for left approach direction, length 132 mm

3SX3 207

- with crosswise fixing, length 50 mm

3SX3 206

• Universal radius, length 80 mm

3SX3 203

Forced opening IEC 60947-5-1, Appendix K.

Siemens IK PI · 2004

6/18

AS-Interface

AS-Interface cable-operated switches

AS-Interface Safety at work

6

■

Overview

It is also possible to connect AS-Interface cable-operated

switches via the standard AS-Interface with safety-oriented communication.

In this case, the safety functions no longer have to be conventionally wired up.

■

Application

SIGUARD cable-operated switches are used for monitoring or

for EMERGENCY-STOP facilities on particulary endangered system sections.

As the effective range of a cable-operated switch is limited by

the length of the cord, large systems can also be protected.

Specifications

Switches with latching for implementation in EMERGENCY-STOP

equipment correspond to the EN 418 standard.

■

Function

The safety contacts of the AS-Interface cable-operated switch

are positively driven.

The AS-Interface cable-operated switches are ready to operate

after pretensioning of the pull-wire or the rope.

When the rope is pretensioned, it must be released before the

cable-operated switch can be returned to the original state.

■

Selection and Ordering data

1) Accessories, technical specifications, contact travel, circuit diagrams

and dimensional drawings are given for the specified basic switch in

Catalog LV 10 Section AS-Interface Safety Systems

Design

Order No.

AS-Interface cable-operated switch

With direct connection of AS-Interface to Safety at Work

Metal housing with dust protection

Implementable up to Category 4 to EN 954-1

IP65

Latching to EN 418

Pushbutton release

2 NC contacts

• For cable lengths up to 10 m,

with adjustment window

3SF2 120-1BF00-0BA1

• For cable lengths up to 25 m,

with adjustment window

3SF2 150-1BF00-0BA1

• For cable lengths up to 50 m

3SF2 140-1BF00-0BA1

Forced opening IEC 60947-5-1, Appendix K.

Siemens IK PI · 2004

6/19

AS-Interface

AS-Interface Safety at work

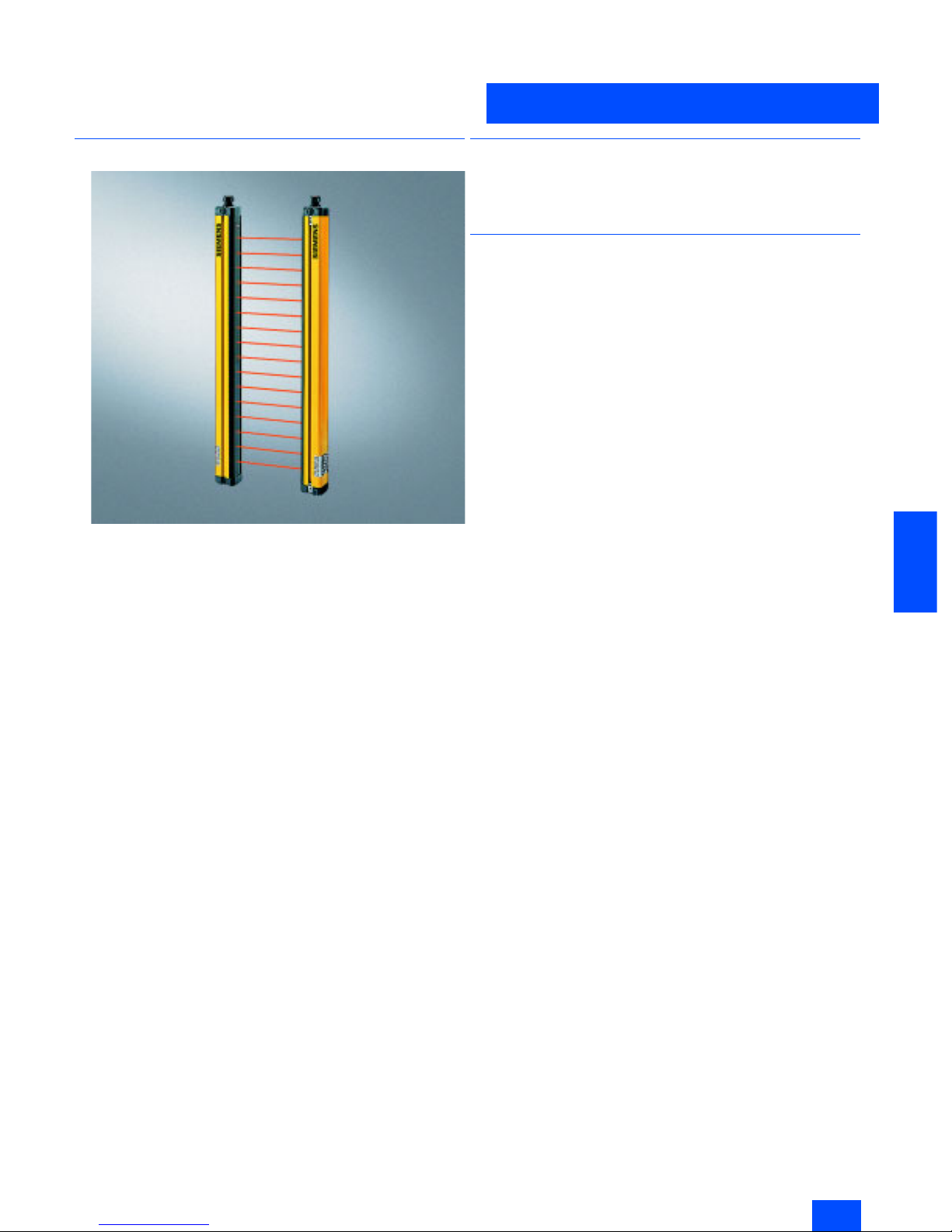

AS-Interface light curtains and light arrays

for Category 4

6

■

Overview

The light curtains and light arrays of Category 4 acc. to EN 9541 offer active optical protection for persons at machines. They

can be connected to AS-Interface directly and safely as an option.

SIGUARD light curtains and light arrays are

• active opto-electronic protective devices (AOPD),

• comply with Type 4 acc. to EN 61496-1, -2,

• are EU prototype-tested,

• protect the operating personel working on or near dangerous

machines,

• operate contact-free,

• are free of wear in comparison to mechanical systems (e.g.

safety mats).

For further details, see the manual "Safety Integrated“ and the

operating instructions for the respective devices.

■

Benefits

• Double-scan function

• Cascading of host and guest devices

• Two transmission channels

■

Design

A SIGUARD Light Curtain or light array comprises a transmitter

and a receiver that must be mounted opposite each other.

Depending on the resolution and length, a specific number of

transmit and receive diodes are arranged in a vertical row.

The infra-red LEDs of the transmitter send short light pulses that

are received by the receive diodes.

SIGUARD Light Curtains:

• Resolution 14, 30 and 50 mm,

• Length 150 mm to 3 m,

• Cascading of master and slave devices to create larger height

or length of protective zone or for angular arrangement.

SIGUARD Light Arrays:

• 2-, 3- or 4-beam for access protection.

Standards

• EN 61 496-1, -2, IEC 61 496-1, -2 (requirements for non-contact

protection systems)

• EN 999 (incl. calculation of safety clearances)

• EN 954-1 (safety of machines, safety-related parts of controls).

Siemens IK PI · 2004

6/20

AS-Interface

AS-Interface light curtains and light arrays

for Category 4

AS-Interface Safety at work

6

■

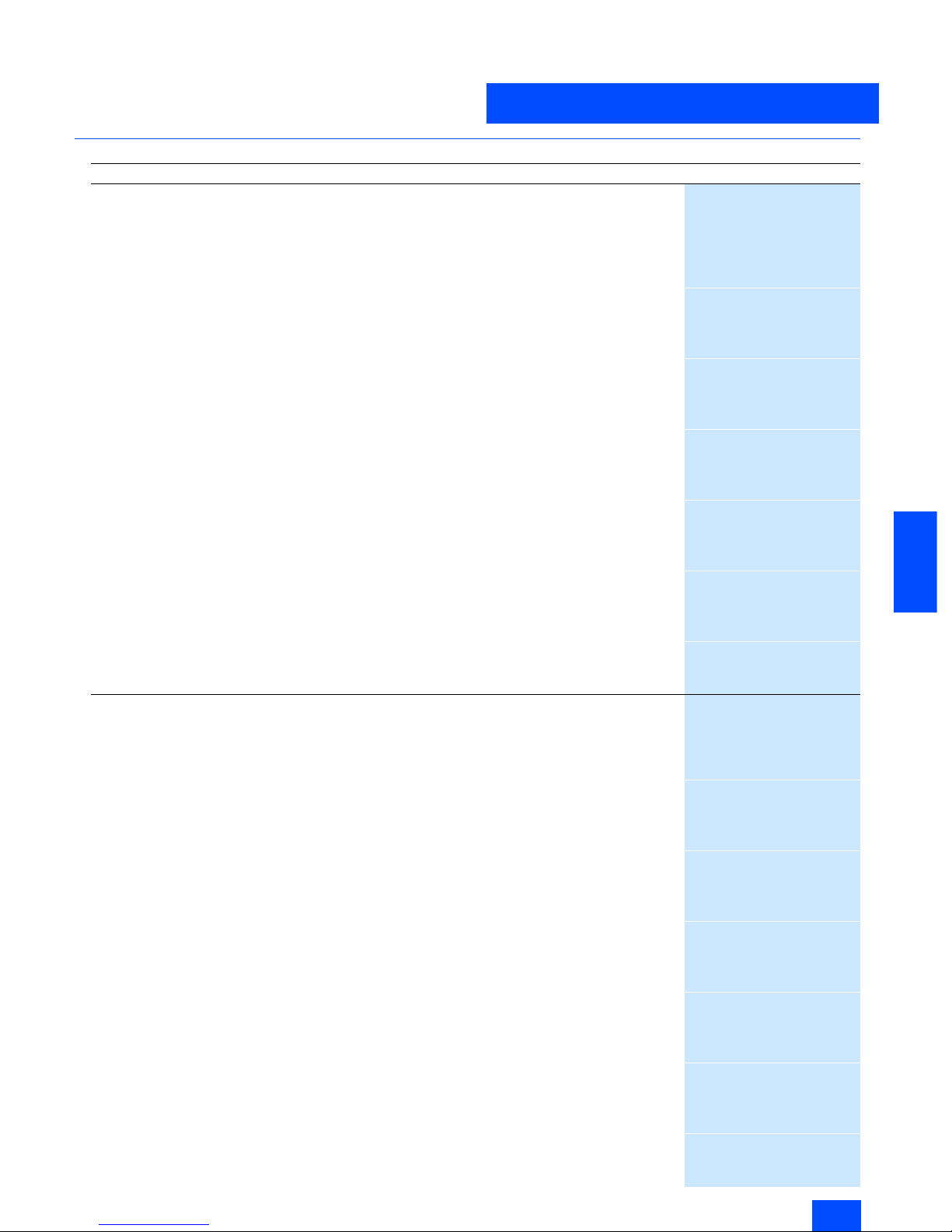

Technical specifications

1) From interruption of the protective zone to the cut-out command on AS-Interface

Technical specifications common to all AS-Interface light curtains and light arrays

Safety classification

Type 4 according to IEC 61496-1, -2 or EN 61496-1 (self-monitoring)

Height of protective zone in mm

150 to 1800 (for series with 14 and 30 mm resolution)

450 to 3000 (for series with 50 mm resolution)

750 to 3000 (for series with 90 mm resolution)

Width of protective zone,

sensing range in m

0.3 to 6 (for series with 14 mm resolution)

0.8 to 18 (for series with 30, 50 and 90 mm resolution as well as for light arrays)

0.6 to 60 (for light arrays)

Detection capability

14 mm, 30 mm, 50 mm or 90 mm or complete persons with 2, 3 or 4 beams

Response time of the

safety equipment in ms

1)

12 to 44, d-scan 15 to 83 (for 14 mm resolution)

12 to 25, d-scan 15 to 44 (for 30 mm resolution)

< 22, d-scan 38 (for 50 mm resolution)

< 18, d-scan 25 (for 90 mm resolution)

Response time of the

complete system

Response time 3SF7842 + response time of AS-Interface safety monitor (max. 40 ms)

Degree of protection

IP65

Supply current in mA

Max. 130 (transmitter)

Max 140 (receiver)

Operating mode

Protection mode without restart lockout

Transmitter/receiver synchronization

Optical synchronization, two transmission channels can be selected

Infra-red disturbance suppression

Two techniques for selection:

Standard = high suppression

d-scan = extremely high degree of suppression

Cross-section in mm

55 * 52

Length in mm

234 to 3084 (depending on height of protective zone)

Air humidity in %

15 to 95

Operating temperature in °C

0 to +55

Storage temperature in °C

-25 to +70

Supply voltage in V

26.5 to 31.6 (according to AS-Interface specification)

ID-code receiver

B

I/O-code receiver

0 (four data bits as outputs)

Slave address receiver

Active bus component, programmed by the user in the range 1 to 31

(delivery status = bus address 0), supply voltage from the AS-Interface network

Slave address transmitter

Passive bus component (no bus address), supply voltage from the AS-Interface network

Cycle time in ms

5 (according to AS-Interface specification)

AS-Interface profile

Safe slave

Electrical connection

M 12 plug:

Pin 1 = ASI+

Pin 3 = ASI-

Siemens IK PI · 2004

6/21

AS-Interface

AS-Interface Safety at work

AS-Interface light curtains and light arrays

for Category 4

6

■

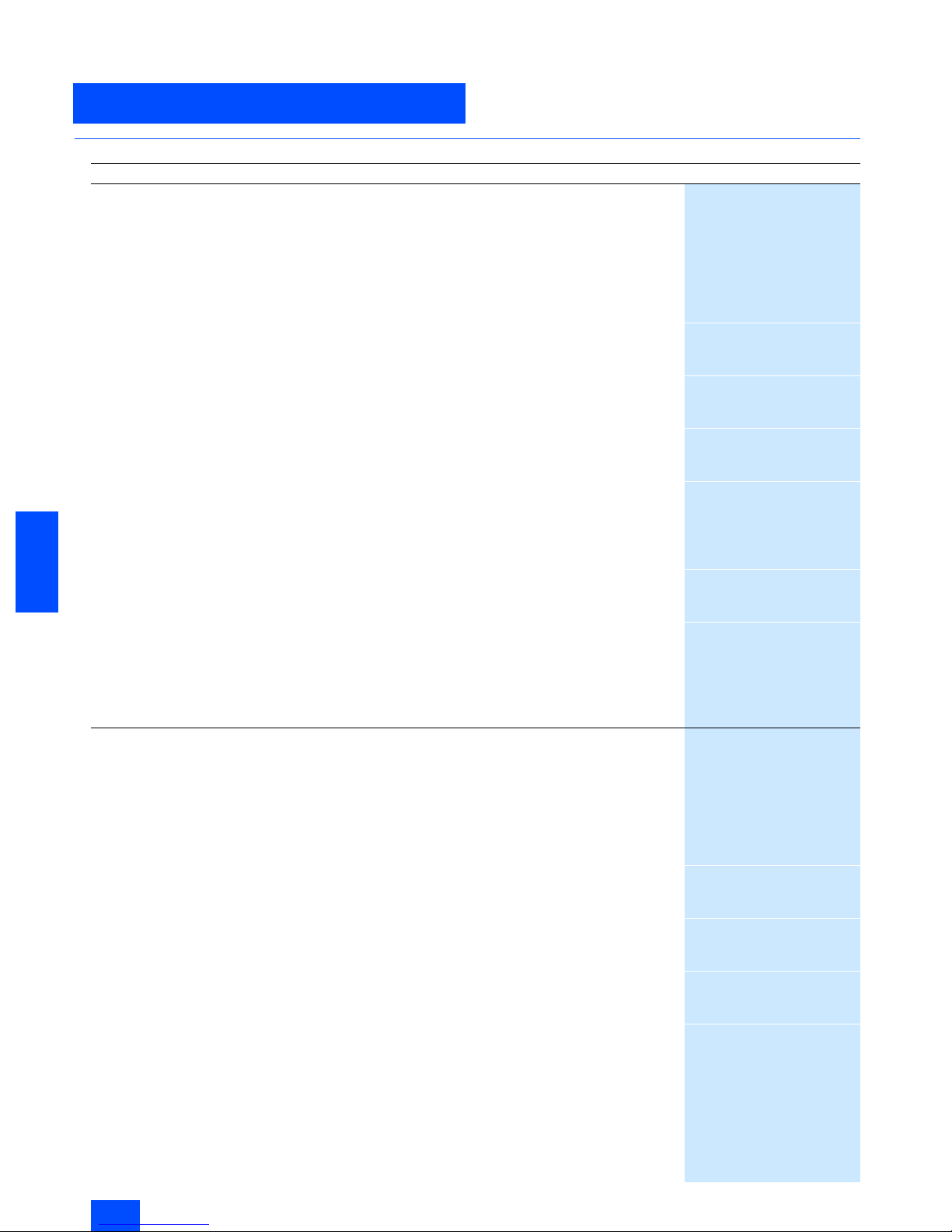

Selection and Ordering data

Design

Order No.

SIGUARD Standard Light Curtain, 14 mm resolution

Type 4 acc. to IEC 61 496-1, -2

Height of light curtain in mm Function

150 Transmitter

3SF7 842-6BB00

150 Receiver

3SF7 842-6BB01

225 Transmitter

3SF7 842-6BC00

225 Receiver

3SF7 842-6BC01

300 Transmitter

3SF7 842-6BD00

300 Receiver

3SF7 842-6BD01

450 Transmitter

3SF7 842-6BE00

450 Receiver

3SF7 842-6BE01

600 Transmitter

3SF7 842-6BF00

600 Receiver

3SF7 842-6BF01

750 Transmitter

3SF7 842-6BG00

750 Receiver

3SF7 842-6BG01

900 Transmitter

3SF7 842-6BH00

900 Receiver

3SF7 842-6BH01

1050 Transmitter

3SF7 842-6BJ00

1050 Receiver

3SF7 842-6BJ01

1200 Transmitter

3SF7 842-6BK00

1200 Receiver

3SF7 842-6BK01

1350 Transmitter

3SF7 842-6BL00

1350 Receiver

3SF7 842-6BL01

1500 Transmitter

3SF7 842-6BM00

1500 Receiver

3SF7 842-6BM01

1650 Transmitter

3SF7 842-6BN00

1650 Receiver

3SF7 842-6BN01

1800 Transmitter

3SF7 842-6BP00

1800 Receiver

3SF7 842-6BP01

SIGUARD Standard Light Curtain, 30 mm resolution

Type 4 acc. to IEC 61 496-1, -2

150 Transmitter

3SF7 842-6DB00

150 Receiver

3SF7 842-6DB01

225 Transmitter

3SF7 842-6DC00

225 Receiver

3SF7 842-6DC01

300 Transmitter

3SF7 842-6DD00

300 Receiver

3SF7 842-6DD01

450 Transmitter

3SF7 842-6DE00

450 Receiver

3SF7 842-6DE01

600 Transmitter

3SF7 842-6DF00

600 Receiver

3SF7 842-6DF01

750 Transmitter

3SF7 842-6DG00

750 Receiver

3SF7 842-6DG01

900 Transmitter

3SF7 842-6DH00

900 Receiver

3SF7 842-6DH01

1050 Transmitter

3SF7 842-6DJ00

1050 Receiver

3SF7 842-6DJ01

1200 Transmitter

3SF7 842-6DK00

1200 Receiver

3SF7 842-6DK01

1350 Transmitter

3SF7 842-6DL00

1350 Receiver

3SF7 842-6DL01

1500 Transmitter

3SF7 842-6DM00

1500 Receiver

3SF7 842-6DM01

1650 Transmitter

3SF7 842-6DN00

1650 Receiver

3SF7 842-6DN01

1800 Transmitter

3SF7 842-6DP00

1800 Receiver

3SF7 842-6DP01

Siemens IK PI · 2004

6/22

AS-Interface

AS-Interface light curtains and light arrays

for Category 4

AS-Interface Safety at work

6

■

Selection and Ordering data (continued)

Design

Order No.

SIGUARD Standard Light Curtain, 50 mm resolution

Type 4 acc. to IEC 61 496-1, -2

Height of light curtain in mm Function

450 Transmitter

3SF7 842-6EE00

450 Receiver

3SF7 842-6EE01

600 Transmitter

3SF7 842-6EF00

600 Receiver

3SF7 842-6EF01

750 Transmitter

3SF7 842-6EG00

750 Receiver

3SF7 842-6EG01

900 Transmitter

3SF7 842-6EH00

900 Receiver

3SF7 842-6EH01

1050 Transmitter

3SF7 842-6EJ00

1050 Receiver

3SF7 842-6EJ01

1200 Transmitter

3SF7 842-6EK00

1200 Receiver

3SF7 842-6EK01

1350 Transmitter

3SF7 842-6EL00

1350 Receiver

3SF7 842-6EL01

1500 Transmitter

3SF7 842-6EM00

1500 Receiver

3SF7 842-6EM01

1650 Transmitter

3SF7 842-6EN00

1650 Receiver

3SF7 842-6EN01

1800 Transmitter

3SF7 842-6EP00

1800 Receiver

3SF7 842-6EP01

2100 Transmitter

3SF7 842-6ER00

2100 Receiver

3SF7 842-6ER01

2400 Transmitter

3SF7 842-6ES00

2400 Receiver

3SF7 842-6ES01

2700 Transmitter

3SF7 842-6ET00

2700 Receiver

3SF7 842-6ET01

3000 Transmitter

3SF7 842-6EU00

3000 Receiver

3SF7 842-6EU01

SIGUARD Standard Light Curtain, 90 mm resolution

Type 4 acc. to IEC 61 496-1, -2

750 Transmitter

3SF7 842-6JG00

750 Receiver

3SF7 842-6JG01

900 Transmitter

3SF7 842-6JH00

900 Receiver

3SF7 842-6JH01

1050 Transmitter

3SF7 842-6JJ00

1050 Receiver

3SF7 842-6JJ01

1200 Transmitter

3SF7 842-6JK00

1200 Receiver

3SF7 842-6JK01

1350 Transmitter

3SF7 842-6JL00

1350 Receiver

3SF7 842-6JL01

1500 Transmitter

3SF7 842-6JM00

1500 Receiver

3SF7 842-6JM01

1650 Transmitter

3SF7 842-6JN00

1650 Receiver

3SF7 842-6JN01

1800 Transmitter

3SF7 842-6JP00

1800 Receiver

3SF7 842-6JP01

2100 Transmitter

3SF7 842-6JR00

2100 Receiver

3SF7 842-6JR01

2400 Transmitter

3SF7 842-6JS00

2400 Receiver

3SF7 842-6JS01

2700 Transmitter

3SF7 842-6JT00

2700 Receiver

3SF7 842-6JT01

3000 Transmitter

3SF7 842-6JU00

3000 Receiver

3SF7 842-6JU01

Siemens IK PI · 2004

6/23

AS-Interface

AS-Interface Safety at work

AS-Interface light curtains and light arrays

for Category 4

6

■

Selection and Ordering data (continued)

Design

Order No.

SIGUARD Light Array

Type 4 acc. to IEC 61 496-1, -2

Sensing range in m Function

18 Transmitter

3SF7 842-6SE00

18 Receiver

3SF7 842-6SE01

18 Transmitter

3SF7 842-6PG00

18 Receiver

3SF7 842-6PG01

18 Transmitter

3SF7 842-6MH00

18 Receiver

3SF7 842-6MH01

60 Transmitter

3SF7 842-6SE50

60 Receiver

3SF7 842-6SE51

60 Transmitter

3SF7 842-6PG50

60 Receiver

3SF7 842-6PG51

60 Transmitter

3SF7 842-6MH50

60 Receiver

3SF7 842-6MH51

Siemens IK PI · 2004

6/24

AS-Interface

AS-Interface laser scanner LS4

AS-Interface Safety at work

6

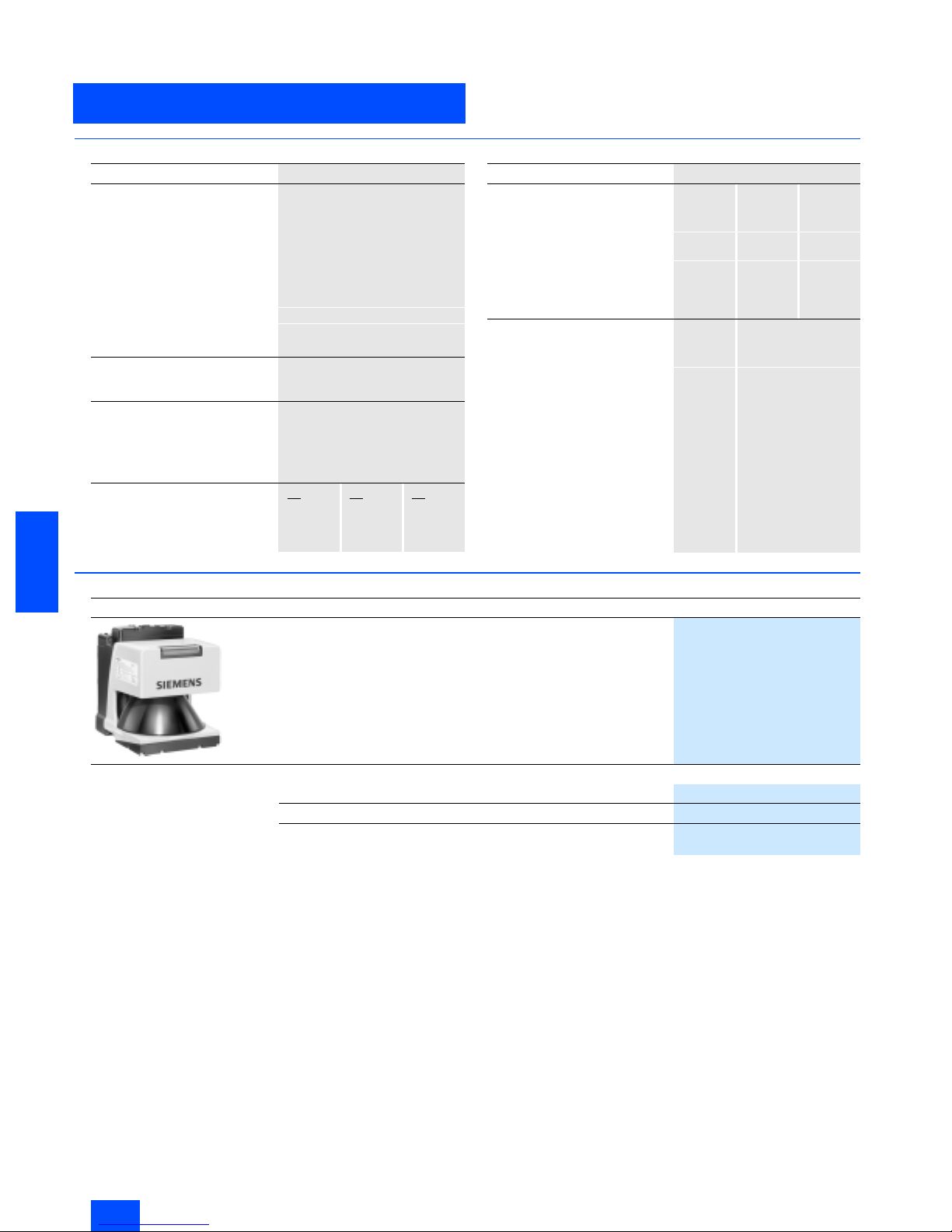

■

Overview

The LS4 Laser Scanner is an optical distance sensor. The device

periodically transmits light pulses within an operating range of

190°.

If the pulses hit an obstruction or a person, the light is reflected

and then received and evaluated by the LS4 laser scanner. The

scanner calculates the precise coordinates of the obstruction

"seen" from the light propagation time.

If the obstruction or the person is located within defined ranges,

a Stop function is executed. Switch-off is then performed via the

safe interface within the system response time.

The Stop function is reset when the protective zone is free again,

depending on the operating mode, either automatically or following acknowledgement.

Accessories

Accessories include a twistable mounting support, suitable preassembled connecting cables in diverse lengths as well as

spare parts.

Siemens IK PI · 2004

6/25

AS-Interface

AS-Interface Safety at work

AS-Interface laser scanner LS4

6

■

Application

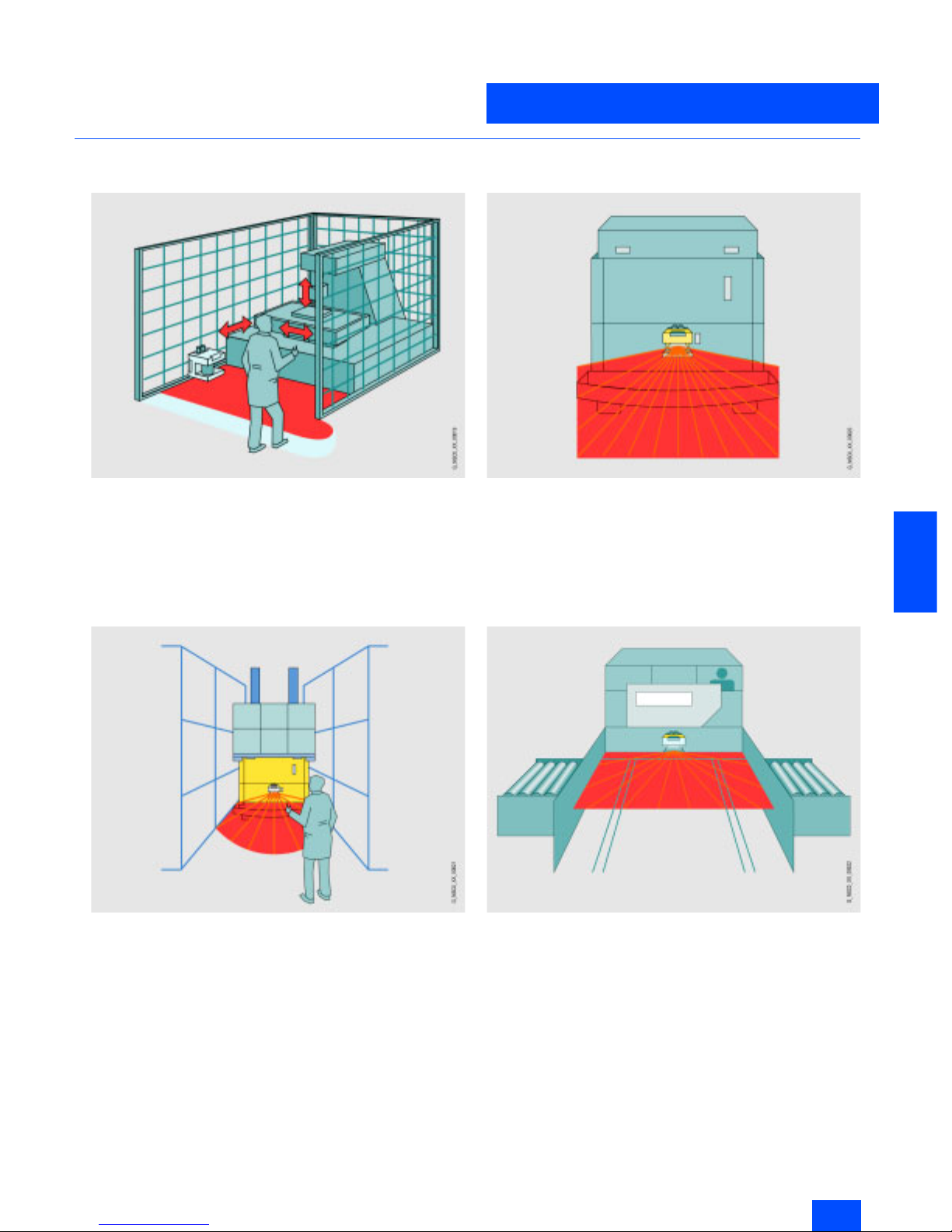

Horizontal danger zone protection

Reliable detection of persons and objects in danger zones of

machines and plants

Flexible configuration of any protection and warning zones to a

great extent

Horizontal danger zone protection with several zones

to be protected

Safe detection of persons in various danger zones by switching

over protection zones

Better availability when specifically securing only live zones

Route monitoring for driverless transport systems

Detection of persons and objects that approach the vehicle

The laser scanner offers a greater protection range than

bumpers and therefore permits higher speeds.

Collision protection for shifting units

Protection of persons who are in the path of the vehicle

Objects in the path of the vehicle are detected early; damage to

the vehicle or load is therefore prevented.

Further applications

• All types of hazardous area protection,

• Room protection and access protection,

• Projecting object monitoring (protection of machines and

persons)

• Non-safety-related measurement or recognition tasks

(e. g. distance, position or contour recognition)

Siemens IK PI · 2004

6/26

AS-Interface

AS-Interface laser scanner LS4

AS-Interface Safety at work

6

■

Function

Function principle

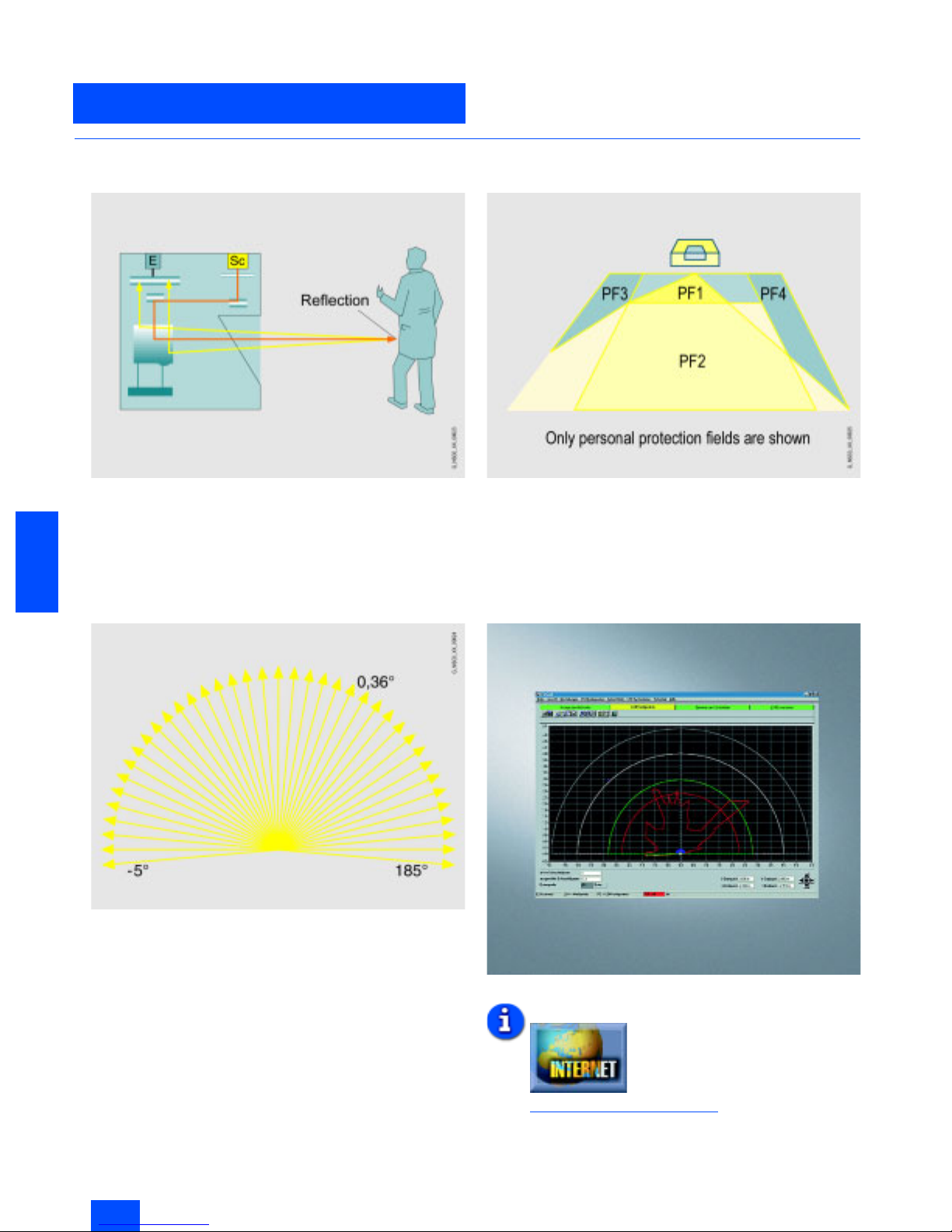

Bundled light pulses are created via a laser diode with coupled

transmission optics. These are diverted by a rotating mirror in

such a way that within 40 ms a light pulse is triggered in all angle

segments (scan rate: 25 scans/s). If the light pulse hits an object

or a person, the light is reflected and acquired and evaluated by

the scanner.

Measuring pulse propagation time

The SIGUARD LS4 laser scanner operates by measuring the

pulse propagation time. When extremely short light pulses are

emitted, a time difference occurs between the transmitted and

received light pulse. The propagation time of the light pulse is a

direct measurement of the target distance.

The operating range of the scanner (190°) is subdivided into

angle segments of 0.36°.

Protection and warning field pairs

The device has 4 switchable protection and warning field pairs.

LS4Soft operating software

The SIGUARD LS4 laser scanner must be parameterised using

the associated LS4Soft software. The personal protection and

warning fields required are set in this manner. Also configuration

parameters, such as automatic/manual start, response time and

restart time can be parameterised.

Additional information is available in the Internet under:

http://www.siemens.de/laserscanner

Siemens IK PI · 2004

6/27

AS-Interface

AS-Interface Safety at work

AS-Interface laser scanner LS4

6

■

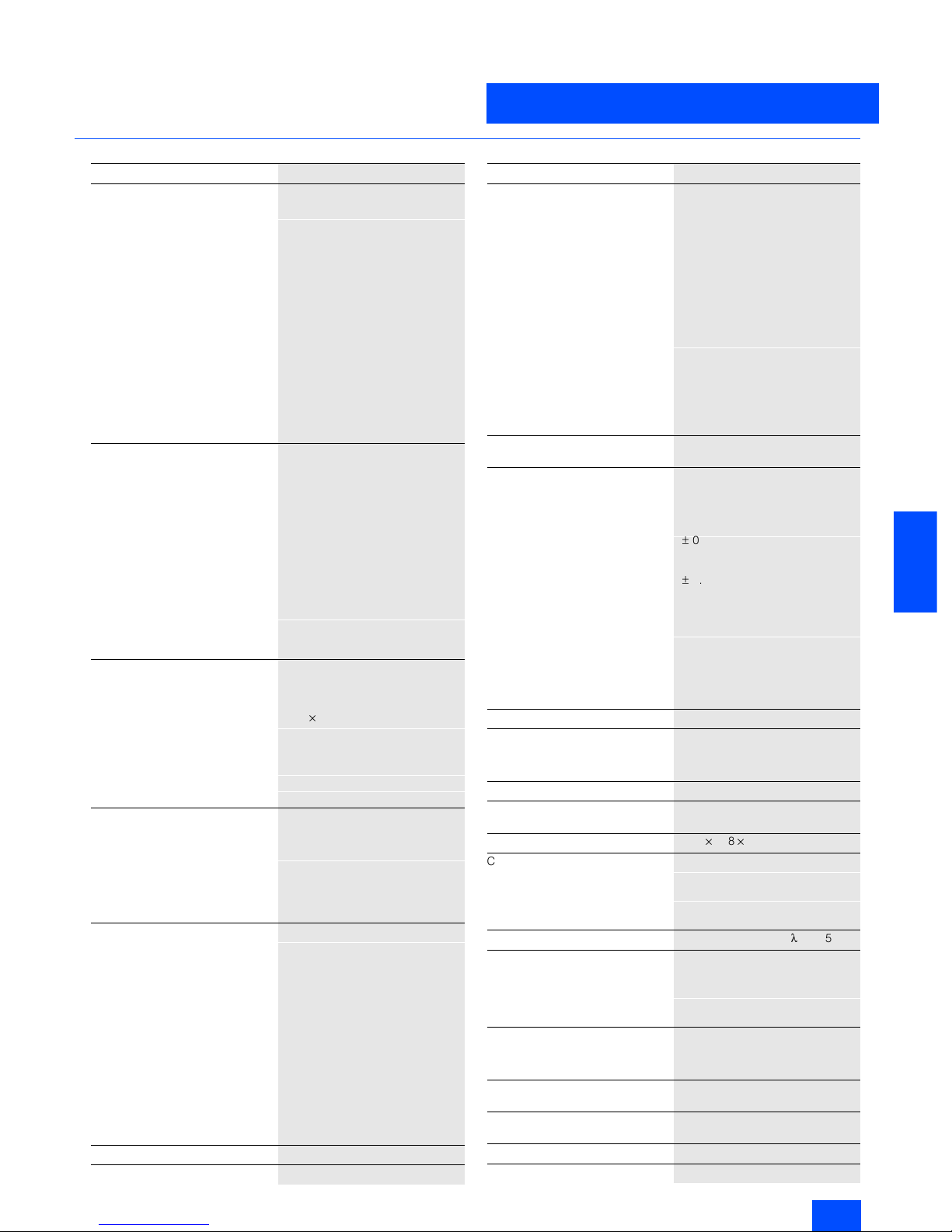

Technical specifications

LS4-4 AS-Interface laser scanner 3SF7 834-6DD00

Protective zone

• Sensing range in m 0 to 4

• Luminance factor in %

Min. 1.8

• Object size (diameter) in mm

70 (cylindrical test object)

• Response time

- Double evaluation (2 scans)

in ms

85

- Adjustable up to 16 scans in ms

645

•Number

4 (selectable via switch inputs)

• Safety category

Category 3 according to

EN 954-1, Type 3 according to

IEC 61496-1 or EN 61496-3

•Output

Safe AS-Interface connection

•Start-up

Start-up testing and start-up

disable can be set separately

•Restart

160 ms to 10 s

(adjustable or manual)

Protective zone supplement

• For deactivated dust suppression

in mm

81

• For activated dust suppression

in mm

- For protective zone size

< 3.5 mm

81

- For protective zone size

> 3.5 mm

98

• Additional for reflectors in mm

- Over 1.2 m behind the

protective zone line

0

- In the protective zone or up to

1.2 m behind the protective

zone line

110

Warning zone

• Sensing range in m 0 to 15

• Luminance factor in %

Min. 20

• Object size in mm

150 ´ 150

• Response time in ms

- Double evaluation (2 scans) 85

- Adjustable up to 16 scans

645

• Number of warning zones

4 (selectable via switch inputs)

•Output

Connection of AS-Interface

Contour measurement

• Sensing range in m 0 to 50

• Luminance factor in %

Min. 20

•Output

RS 232 serial interface

via infra-red interface

• Radial resolution in mm

5

• Lateral resolution in °

0.36

Supply voltage

• Via AS-Interface network in V 29.5 to 31.6 (according to AS-

Interface specification)

• Via AS-Interface auxiliary voltage

in V

Up to DC 30

• Via external supply in V

24 DC (+/-20 %)

•Note

The power supply unit for the

external supply voltage as well as

the AS-Interface power supply

unit for supplying the AS-Interface components must feature

safe mains isolation according to

IEC 60742 and must bridge temporary mains failures of up to

20 ms (e.g. AS-Interface power

pack 3RX9 307-0AA00)

Overcurrent protection

1.25 A fuse, medium-slow

Supply current in mA

Typ . 3 50

LS4-4 AS-Interface laser scanner 3SF7 834-6DD00

Inputs

• Restart/Reset Connection of a command device

for "with restart lockout“ operating

mode and/or device resets,

dynamically monitored,

24 V DC opto-decoupled

• Zone-pair switchover

Selection of zone pairs via

4 control cables with internal

monitoring (one zone pair =

one protective zone and one

warning zone),

24 V DC opto-decoupled

• Signal definition in V

- High (logical 1) 16 to 30

- Low (logical 0)

< 3

• AS-Interface address

programming

Connection of a generally

available AS-Interface address

programmer

RS232 interfaces for each infrared

interface

For device parameterization and

zone function

Optical system

• Angular zone in ° 190

• Angular resolution in °

0.36

• Lateral tolerance in °

- Without mounting system (with

reference to the rear panel of the

housing)

±

0.18

- With mounting system (with reference to the mounting surface)

±

0.22

• Scan rate

25 scans/s or 40 ms/scan

• Laser protection class

- According to standard EN 60825-1, Class 1

(safe for eyes)

- Wave length in nm

905

- Beam divergence in mrad

2

- Time base in s

100

Degree of protection

IP65

Ambient temperature in °C

•Operation 0 to +50

•Storage

-20 to +60

Housing insulation class

Protection class 2

Humidity

Acc. to DIN 40040, Table 10,

Code Letter E (medium dry)

Dimensions (W x H x D) in mm

140 ´ 168 ´ 165

Control cable X3

• Length in m Max. 50 (for cable cross-section

of 0.5 mm

2

, shielded)

•Note

Shield must be connected to PE

at the cabinet end only

Tran sm it te r

Infrared laser diode (l = 905 nm)

Dimension spacing in mm

• Middle of the scan plane to

bottom edge of housing

48,75

• Rear edge of housing to axis of

rotating mirror

101

Housing

•LS4 Cast aluminum, plastic

• AS-Interface rucksack

Plastic, steel connection plate

Vibration stress over three axes

acc. to IEC 60068, Part 2-6

10 to 150 Hz, max. 5 g

Continuous shock over three axes

acc. to IEC 60068, Part 2-29

10 g, 16 ms

Rotating mirror drive

Brushless DC motor

Rotating mirror bearings

Maintenance-free ball bearings

Siemens IK PI · 2004

6/28

AS-Interface

AS-Interface laser scanner LS4

AS-Interface Safety at work

6

■

Technical specifications (continued)

■

Selection and Ordering data

LS4-4 AS-Interface laser scanner 3SF7 834-6DD00

AS-Interface

• ID code B

• I/O code

0 (four data bits as outputs)

• Slave address

Programmed by the user in the

range 1 to 31 (delivery status = 0)

• Cycle time according to

AS-Interface specification in ms

5

• Profiles

Safe slave

• Electrical connection

-X1 M 12 plug, AS-Interface

-X2

M 12 plug, 24 V external

Assignment of data bits D0 ... D3

Protective zone empty:

Code sequence

Protective zone occupied: 0

Assignment of the diagnostic

parameter bits

P0 = Alarm (according to LS4

programming)

P1/2 = SF coding

(see assignment of SF coding)

P3 = LS4-RESET (via PC/ASInterface master call)

Assignment of SF coding

P2

0

0

1

1

P1

0

1

0

1

SF

1

2

3

4

LS4-4 AS-Interface laser scanner 3SF7 834-6DD00

Assignment

PIN1 PIN2 PIN3

• X1 (M12 plug for device

connection)

AS-i+ -- AS-i-

• X2 (M12 connector for external

power supply)

24 V DC

supply

24 V Out Mass

• X3 (M12 socket for protective

zone changeover)

SF pair 1 SF pair 2 SF pair 3

• X4 (AS-Interface addressing

socket)

AS-i+ AS-i- --

Assignment

PIN 4 PIN 5

• X1 (M12 plug for device

connection)

– –

• X2 (M12 connector for external

power supply)

Start/

Reset

PE

• X3 (M12 socket for protective

zone changeover)

SF pair 4 24 V Out

• X4 (AS-Interface addressing

socket)

– –

Design

Order No.

AS-Interface LS4-4 laser scanner

Including LS4soft Software

3SF7 834-6DD00

Accessories

Mounting system

3RG7 838-1AA

Adapter plate

3RG7 838-1AB

PC cable connector

Including plug, 9-pole and optical interface

3RG7 838-1DC

Siemens IK PI · 2004

6/29

AS-Interface

AS-Interface Safety at work

AS-Interface laser scanner LS4

6

■

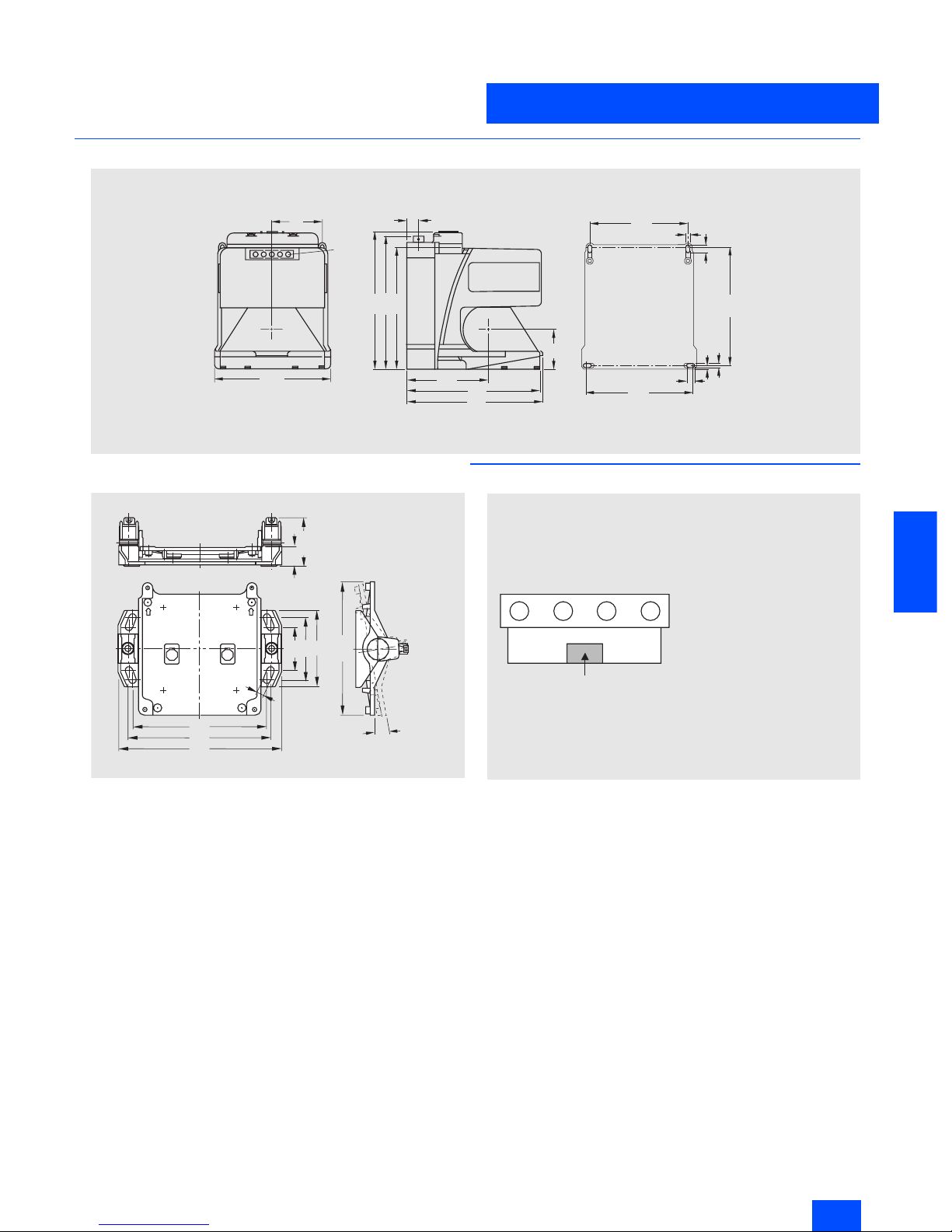

Dimensional drawings

LS4 laser scanner

Assembly system

■

Schematics

N S C 0 _ 0 0 6 3 0

1 4 9

1 6 3

1 6 8

1 0 1

1 6 5

1 6 8

4 9

1 3 , 5

6 1

L E D

( 5 x )

1 4 0

5 , 2

1 4 4

5

9 , 5

1 2 9

5 , 2

1 2 2

9 , 5

23

56,6

51,5

74,4

90

158

166

192

155,4

9°

NSC 00610

9

X 2

N S C 0 _ 0 0 6 3 1 a

X 3 X 4 X 1

O p t i c a l i n t e r f a c e

M 1 2 c o n n e c t o r , A S - I n t e r f a c e

M 1 2 c o n n e c t o r ,

o p t io n a l a u x i l i a r y v o l t a g e

M 1 2 s o c k e t , p r o t e c t i o n f i e l d

c h a n g e - o v e r

A d d r e s s i n g s o c k e t ,

A S - I n t e r f a c e

X 1 :

X 2 :

X 3 :

X 4 :

Siemens IK PI · 2004

6/30

AS-Interface

AS-Interface EMERGENCY STOP pushbuttons

AS-Interface Safety at work

6

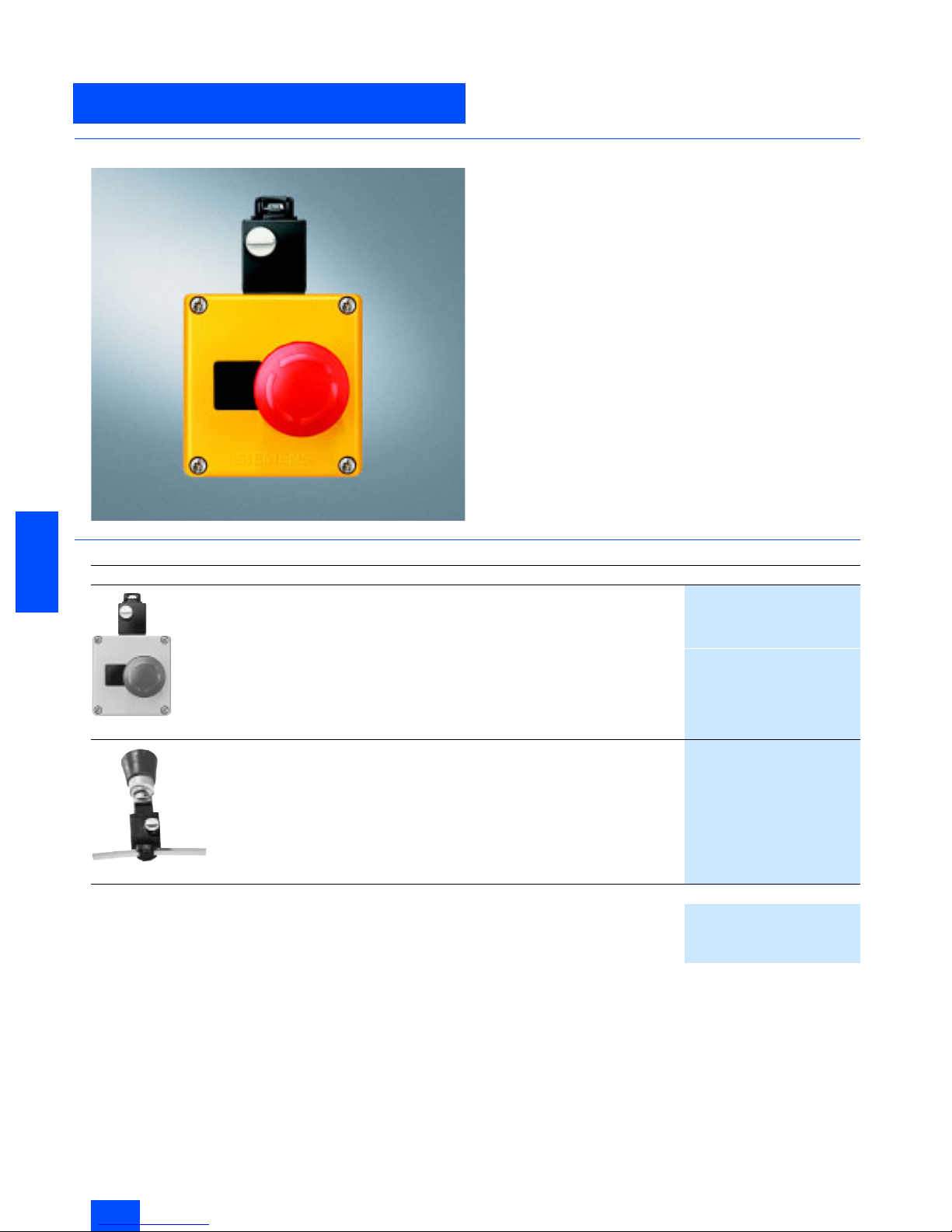

■

Overview

It is also possible now to connect EMERGENCY STOP devices

via the standard AS-Interface with safety-oriented communication. This only applies to EMERGENCY STOP devices of the

SIGNUM 3SB3 command devices for front panel installation and

for installation in an enclosure.

■

Selection and Ordering data

1) See Catalog LV 10, Section Pushbuttons and Indicator Lamps

Design

Order No.

3SF5 801-3AA08

AS-Interface EMERGENCY STOP housing

Two NC contacts

AS-Interface F adaptor

• Yellow cover

3SF5 801-3AA08

• Yellow cover with protective collar

3SF5 801-3AB08

3SF5 402-1AA01

AS-Interface EMERGENCY STOP front plate /

AS-Interface F adaptor

For AS-Interface EMERGENCY STOP

Front panel mounting

EMERGENCY STOP actuator is not included

1)

3SF5 402-1AA01

Accessories

Safety Integrated manual

•German

E20001-A110-M103

• English

E20001-A110-M103-X-7600

Loading...

Loading...