Siemens IQHeat User Manual

Doc-1552 2019-01-30

IQHeat

User manual

This manual is published by Cetetherm.

Cetetherm can without further notice make changes and improvements to the content in this manual if it is necessary due to printing

mistakes, wrong information or changes in the hardware or software.

All these types of changes will be included in future release of the manual.

IQHeat

User manual

1

Contents

1 General .................................................................................................................................. 3

1.1 Information about this document ...............................................................................................................3

1.2 Product overview IQHeat cabinets ............................................................................................................4

1.3 DDC1; Processing unit with Display and TCP/IP interface .......................................................................4

2 Communication principles ................................................................................................... 5

2.1 Internal Interface........................................................................................................................................5

2.1.1 LEDs for BSP and BUS diagnostics .....................................................................................................5

2.1.2 Upgrade with SD card ..........................................................................................................................6

3 The control panel .................................................................................................................. 7

3.1 Display/HMI settings ..................................................................................................................................7

3.2 Display layout ............................................................................................................................................8

3.3 Various line types ......................................................................................................................................8

3.4 Setting parameters ....................................................................................................................................9

4 Log in and set the clock ..................................................................................................... 10

4.1 Password and login ................................................................................................................................ 10

4.1.1 Log in ................................................................................................................................................. 10

4.2 Time functions setting of time and date ................................................................................................. 11

4.2.1 Reading date and time ...................................................................................................................... 11

4.2.2 Setting date and time ........................................................................................................................ 11

5 Alarm management ............................................................................................................. 12

5.1 Alarm list ................................................................................................................................................. 12

5.2 Alarm history ........................................................................................................................................... 13

5.3 Settings ................................................................................................................................................... 13

5.4 Alarms and their classification ................................................................................................................ 14

6 General functions ............................................................................................................... 15

6.1 Reading the current temperatures and valve modes ............................................................................. 15

6.2 Frost protection....................................................................................................................................... 15

6.3 System objects ....................................................................................................................................... 16

6.3.1 Plant information ............................................................................................................................... 16

6.3.2 Restoring the start-up settings .......................................................................................................... 16

6.3.3 Language selection ........................................................................................................................... 16

7 Heating circuit ..................................................................................................................... 17

7.1 Operating mode heating ......................................................................................................................... 17

7.2 Heat time program .................................................................................................................................. 18

7.3 Setting the value for the heating circuit .................................................................................................. 19

7.4 Setting the heating curve ........................................................................................................................ 19

7.5 Heating Limit ECO .................................................................................................................................. 20

7.5.1 Setting Heating limit (ECO) ............................................................................................................... 21

7.5.2 Heat limit function .............................................................................................................................. 21

7.6 Parallel offset of heating curve ............................................................................................................... 22

8 Hot water circuit .................................................................................................................. 23

8.1 Hot water operating mode ...................................................................................................................... 23

8.2 Setting the set point for the hot water circuit .......................................................................................... 23

9 Service level ........................................................................................................................ 24

9.1 Change password .................................................................................................................................. 24

9.2 Building time constant ............................................................................................................................ 24

9.3 Frost protection....................................................................................................................................... 25

9.4 Pump and valve exercising .................................................................................................................... 26

9.5 Save and reset start-up settings and factory settings ............................................................................ 26

9.6 Setting up and activating the legionella function .................................................................................... 27

9.7 Change alarm limits for heating, cooling and hot water circuits ............................................................. 28

9.8 Settings hot water circuit ........................................................................................................................ 29

9.9 System objects settings .......................................................................................................................... 29

9.9.1 SMS alarm ......................................................................................................................................... 29

9.10 Communication settings ......................................................................................................................... 30

IQHeat

User manual

2

9.10.1 Set IP address, IP mask and gateway for Advanced WEB module .................................................. 30

9.10.2 Set IP address, IP mask and Gateway for Web onboard ................................................................. 31

9.11 Read and change the MBus parameters ............................................................................................... 32

9.12 Read and change the ModBus parameters ........................................................................................... 32

9.12.1 RS485 ............................................................................................................................................... 32

9.12.2 TCP/IP ............................................................................................................................................... 33

10 Tests .................................................................................................................................... 34

10.1 Testing the wirings ................................................................................................................................. 34

10.2 Testing the pumps .................................................................................................................................. 35

10.3 Testing the valves .................................................................................................................................. 35

11 Exceptions calendar ........................................................................................................... 36

11.1 Exceptions calendar ............................................................................................................................... 36

12 Services for IQHeat ............................................................................................................. 38

12.1 Standard services ................................................................................................................................... 38

12.2 Optional services .................................................................................................................................... 38

13 Troubleshooting .................................................................................................................. 39

14 Options ................................ ................................................................................................ 40

14.1 Expansion module AHU with 14 I/O ....................................................................................................... 40

14.1.1 Setting expansion module's DIP switches ........................................................................................ 41

14.1.2 LEDs for BSP and BUS diagnostics .................................................................................................. 41

14.2 Communication module Web, Adv. Web ............................................................................................... 42

14.2.1 Services associated with Adv Web ................................................................................................... 42

14.3 Communication module BacNet IP ........................................................................................................ 42

14.4 Communication module ModBus ........................................................................................................... 42

14.5 Module MBus.......................................................................................................................................... 42

14.5.1 Services associated with MBus ......................................................................................................... 42

14.6 LEDs for BSP and BUS diagnostics ....................................................................................................... 43

14.6.1 BUS for Adv Web module ................................................................................................................. 43

14.6.2 BUS for BacNet ................................................................................................................................. 43

14.6.3 BUS for ModBus ................................................................................................................................ 43

14.6.4 BUS for MBus .................................................................................................................................... 43

15 Overview of available menus ................................ ............................................................. 44

IQHeat

User manual

3

1 General

IQHeat is an intelligent controller for district heating and cooling substations.

Whether it is energy saving, energy cost reduction or comfort monitoring that is the goal, IQHeat from

Cetetherm is an excellent choice.

IQHeat is fitted with a display.

Communication with the processing unit takes place with ModBus or TCP/IP.

Different methods of communication are available, depending on the external communication modules that are

connected.

Add-on modules give you the option of

• meter data via MBus

• Integrated WEB server where all data and history from IQHeat is available through a simple web

browser without requiring any special software or server connections

• BacNet and LON as well as ModBus give you the option of controlling IQHeat from the central building

automation system.

IQHeat has always a temperature sensor on the primary side supply and return, and on the secondary side

supply and return. The sensors allow for the effective limitation of return temperatures and simple monitoring

and remote troubleshooting of functional or comfort problems.

IQHeat is always factory tested and factory set.

IQHeat are available in different models:

• IQHeat50: serves one heating circuit

• IQHeat60: serves two separate heating circuits

• IQHeat100: serves one heating circuit and one hot water circuit

• IQHeat110: serves two separate heating circuits and one hot water circuit

• IQHeat120: serves three separate heating circuits and one hot water circuit

• IQHeat50 Cooling: serves one cooling circuit

• IQHeat120: serves two separate heating circuits and one hot water circuit

This manual describes all the services, functions and settings that can be made with the processing unit, which

is common to all models of IQHeat.

Not all of the services, functions and settings are utilised by the different models.

1.1 Information about this document

This document describes the built-in display, but all pictures are taken from the web interface.

Images in this document are general images.

Temperatures given in °K, degrees Kelvin, refer to a temperature difference.

IQHeat

User manual

4

1.2 Product overview IQHeat cabinets

For information about the included components, see the respective product documentation.

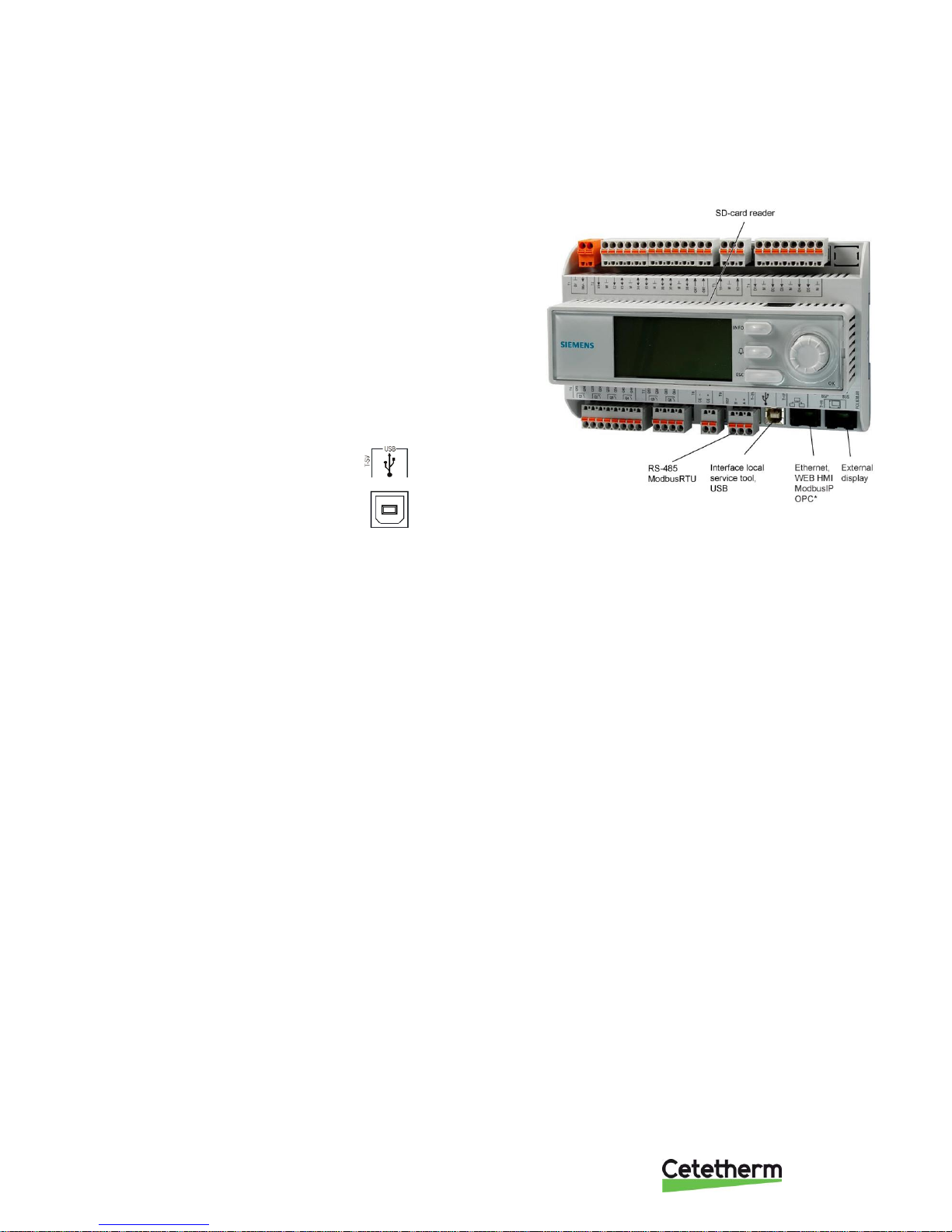

1.3 DDC1; Processing unit with Display and TCP/IP interface

DDC 1, Processing unit is fitted with an integral control panel where the plant values can be read and set.

The processing unit has the following characteristics

• RS-485 ModBus RTU for third party bus

• full modem port RS-232 for remote service

• process bus for connecting room units and external

control panel (DPSU)

• up to three additional communication modules for

integration into the master system

• local service contact for control panel (RJ45) and PC

tools (USB)

• SD card to upgrade applications and software versions

• Ethernet service port (remote or local) via standard web

browser.

USB interface is of the type B output.

IQHeat

User manual

5

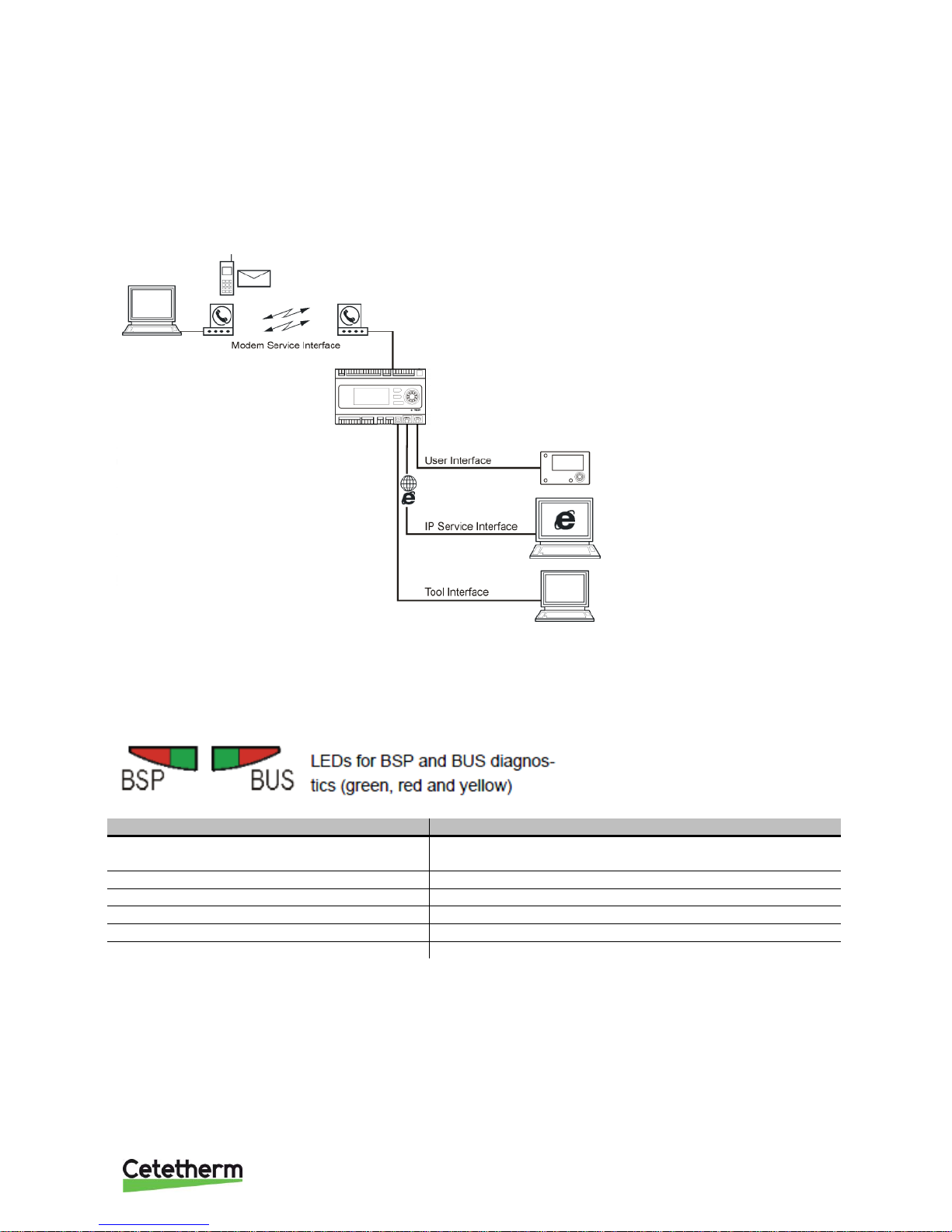

2 Communication principles

2.1 Internal Interface

A ModBus interface is always available in the processing unit. The RS485 interface can be defined as master

or slave; if both master and slave are required, a communication module must be connected with ModBus.

The TCP/IP interface is always the slave – both can be switched off.

2.1.1 LEDs for BSP and BUS diagnostics

The processing unit has two LEDs, BSP and BUS, for diagnostics. The LEDs can light with three different

colours: yellow, green and red.

BSP indicates the status of the internal program in DDC1.

BUS indicates the status of the external communication.

BSP LEDs Start/Stop

Mode

Status LED BSP

Software update mode (download of

application or new software)

LED BSP lights every second alternating between red and

green

No application is loaded

Yellow LED flashing, lights 50 ms and off 1,000 ms

Application loaded but is not in operation

Yellow LED lights

Application is in operation

Green LED lights

BSP error (software error)

Red LED flashes at 2 Hz

Hardware error

Red LED lights

IQHeat

User manual

6

BUS LED

This LED only indicates the status of the integrated modem communication.

The LED does not indicate the status of internal communication (for input/output modules or communication

modules). This status is displayed on each expansion module.

Mode

Status LED BUS

No modem connected, or LED disconnected

Off

Modem connected and initiated, but

communication is not active

Yellow LED lights

Modem connected and communication is

active

Green LED lights

Modem connected but is defective (as well as

supply missing, initialisation is not possible)

Red LED lights

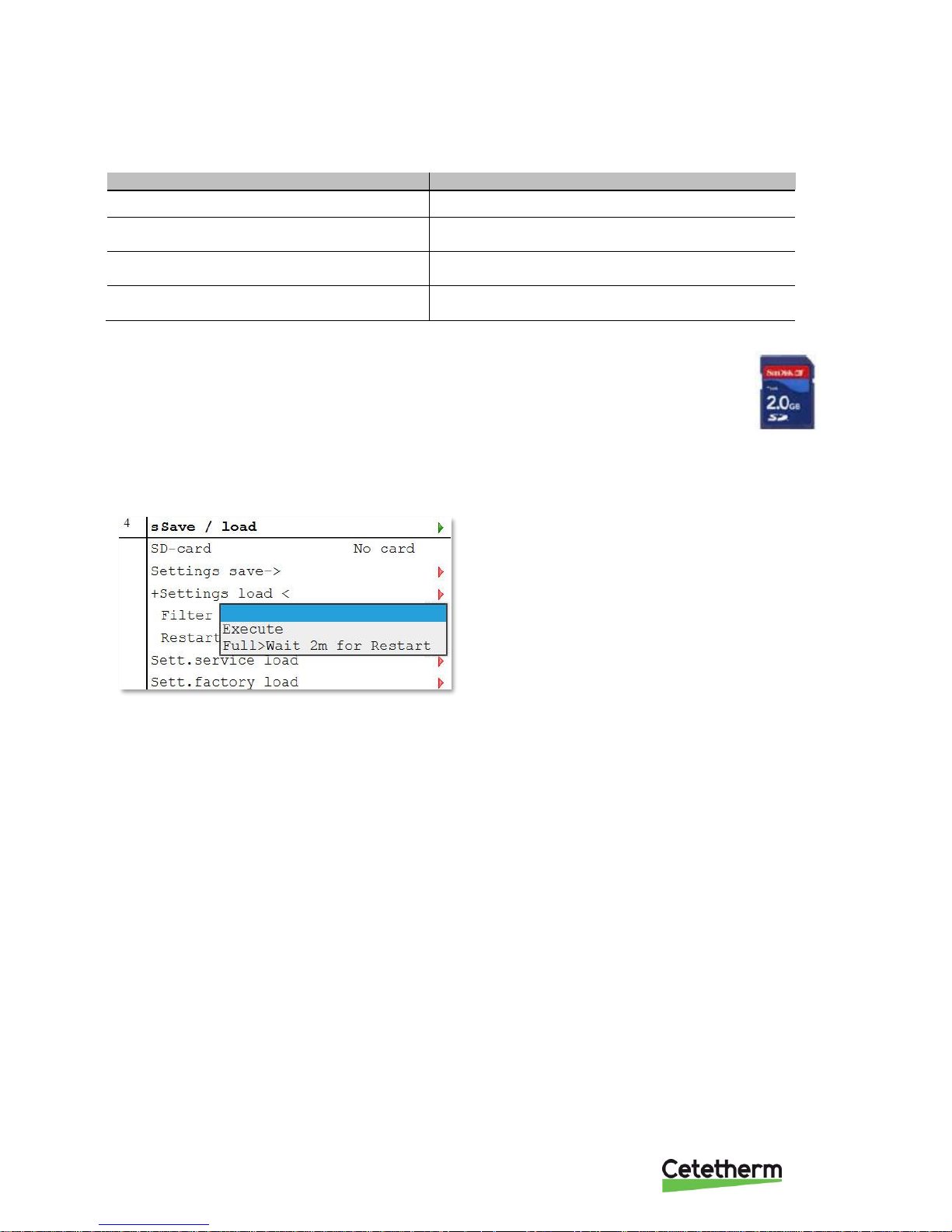

2.1.2 Upgrade with SD card

The processing unit can be upgraded with an SD card (FAT16 model, max 2GB). When

upgrading, connect the SD card to the memory card reader at the top right side of the

processing unit.

The upgrade requires logging in at service level.

There are two options for loading from SD card

• Apply - only control parameters loaded - recommended.

• Full - all settings given new values, including IP addresses and the like.

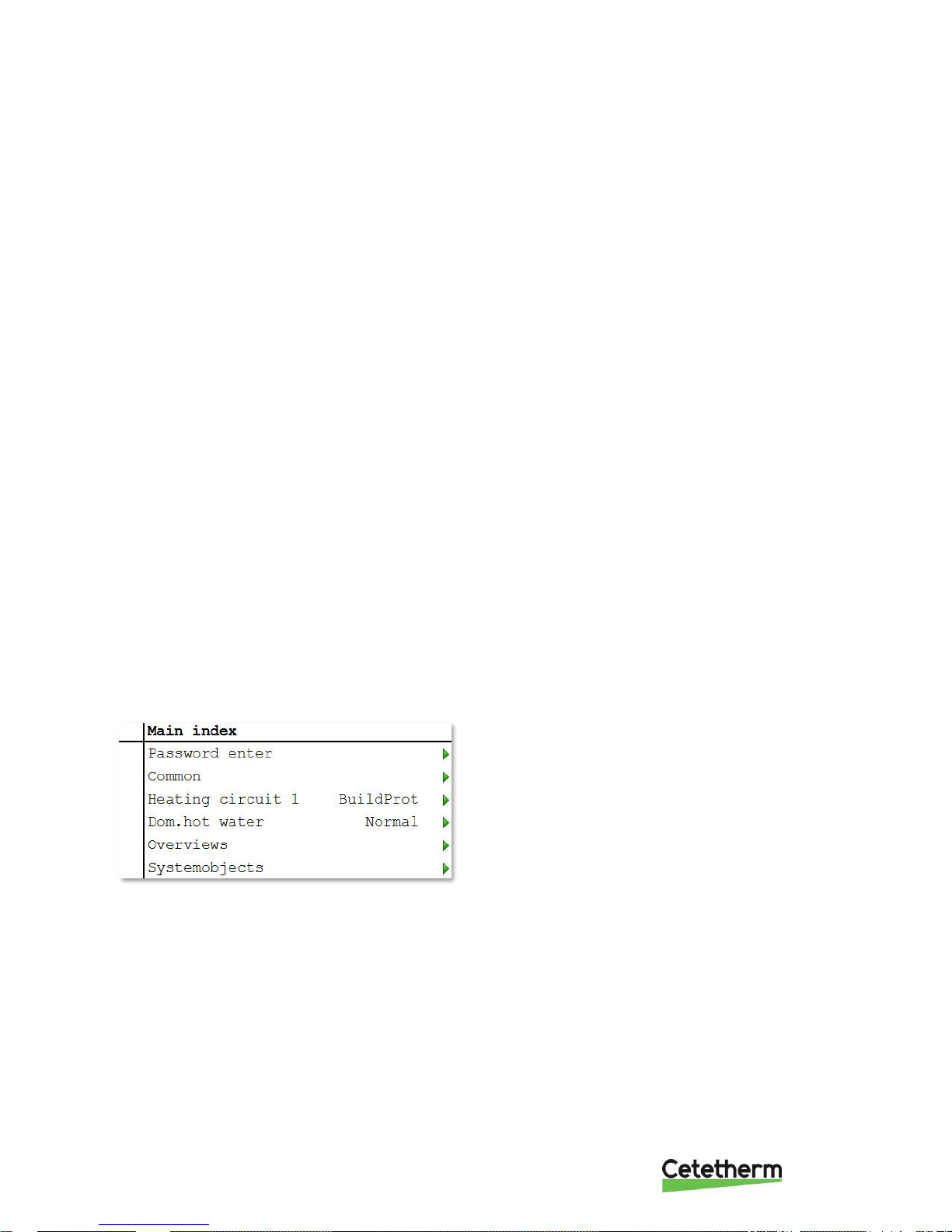

1. From the Main index select Systemobjects.

2. Select Save/load and press OK.

3. Select + Settings load < and press OK.

4. Select from

• Execute- recommended

• Full> Wait 2m for Restart - not recommended

5. From the menu Save/load

select Restart required!, press OK.

6. Select Execute and press OK.

7. The new settings take effect after restart.

NOTE: Connecting and disconnecting during read and write privileges may lead to data loss.

IQHeat

User manual

7

3 The control panel

All images in this document, in the menus in the control panel, are simply example images and should not be

used as a basis for settings.

The control panel is integrated into the processing unit.

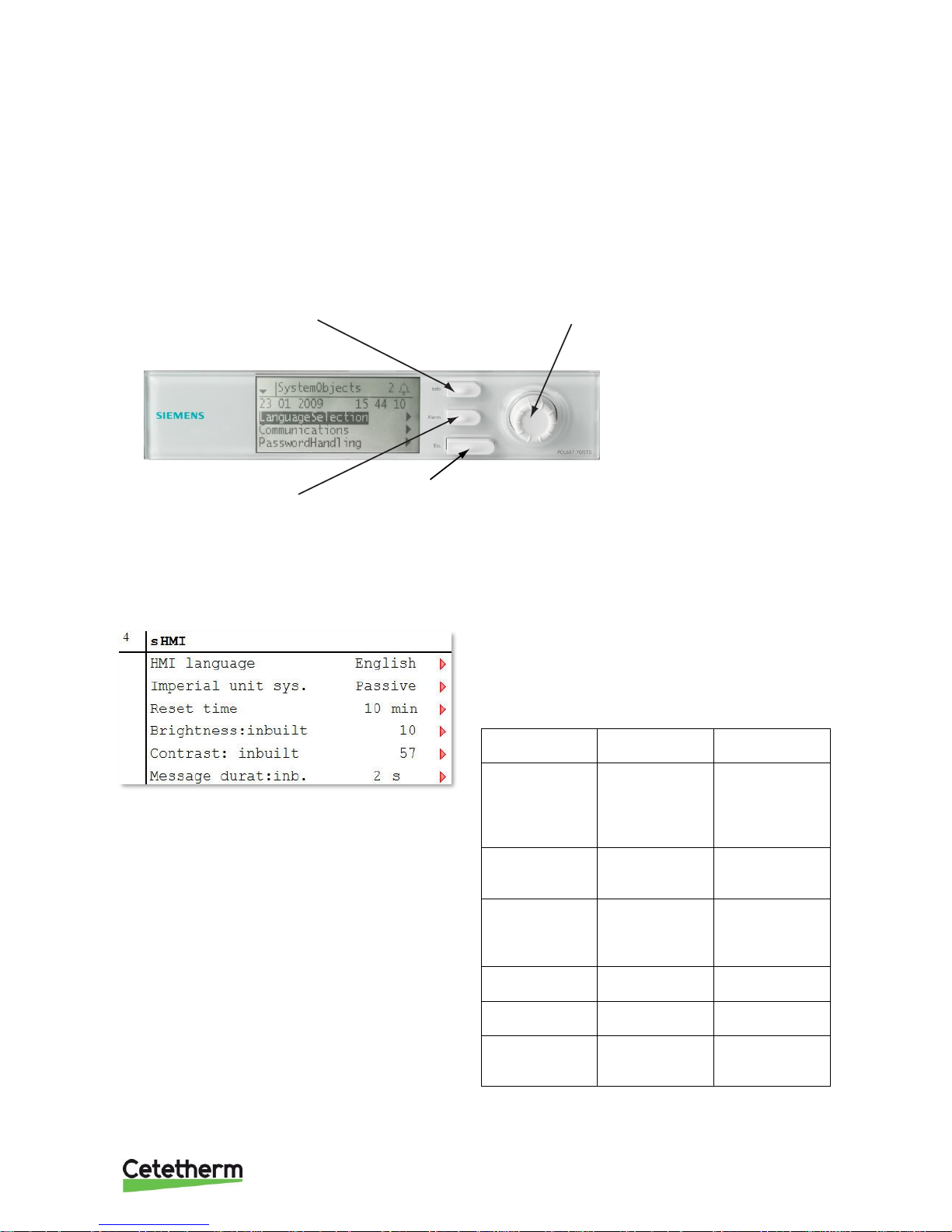

3.1 Display/HMI settings

1. Hold the ESC key down until the menu with HMI

settings appears or from Main Index choose

Systemobjects > HMI.

2. Select HMI settings to change and press OK.

3. Press OK to save the new setting.

4. Press ECS to return to the Main index.

Parameter

Settings

range

Explanation

HMI language

English

Svenska

Suomi

Polski

Select

Imperial unit

sys.

Passive

Active

Passive =

imperial units

e.g. °C.

Reset time

0…30 [min]

Login again is

necessary after

this time of

inactivates.

Brightness:

inbuilt

0…31

Display

brightness.

Contrast:

inbuilt

0…99

Display

contrast.

Message

durat: inb.

0…15 [s]

The time an

error message

is shown.

Info-button

Push to change between

Main overview and

Main index.

Select and OK knob

Turn to select menues, parameters and parameter

values.

Push: to exit the setting page and

adopt a changed value

Extended push: to go to the Password page

ESC-button

Push to go back to last active page or to cancel

Extended push: go back to the Main overvie w.

Alarm button with LED

Off: no alarm

Flashing: ongoing alarm

Permanently lit: Alarm ongoing and

acknowledged

Press to to change between alarm menus

IQHeat

User manual

8

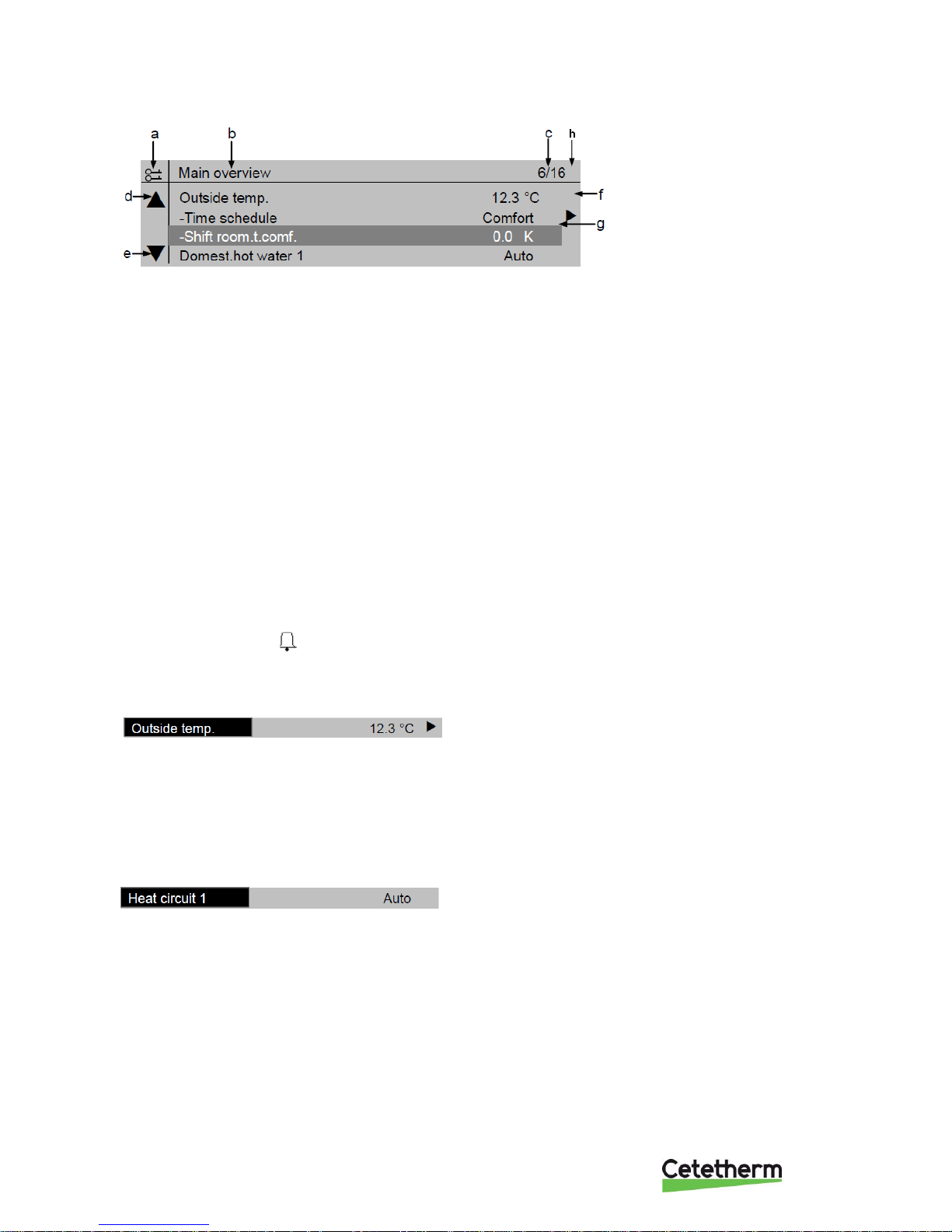

3.2 Display layout

a) current privilege level:

• no symbol - no privilege level

• one key - privilege level 6

• two keys - privilege level 4

• three keys - privilege level 2.

b) title for the displayed page

c) 7 - line number of the selected line

16 - total number of lines on the page

d) scroll arrow up - shows that the page contains additional lines above which appear when you scroll up

e) scroll arrow down - shows that the page contains additional lines below which appear when you scroll

down

f) the arrow means that there are underlying levels below this level to go to

g) current line

h) Alarm indication

3.3 Various line types

Navigation bar:

A navigation bar displays the option on a black

background when it is selected. The current value of

the option appears in front of the navigation arrow.

Navigation:

• select the line: turn the navigation dial

• go to underlying level: press the navigation dial

Viewing bar:

A Viewing bar displays the option on a black

background even when viewing in read-only mode.

The current value of the option appears.

IQHeat

User manual

9

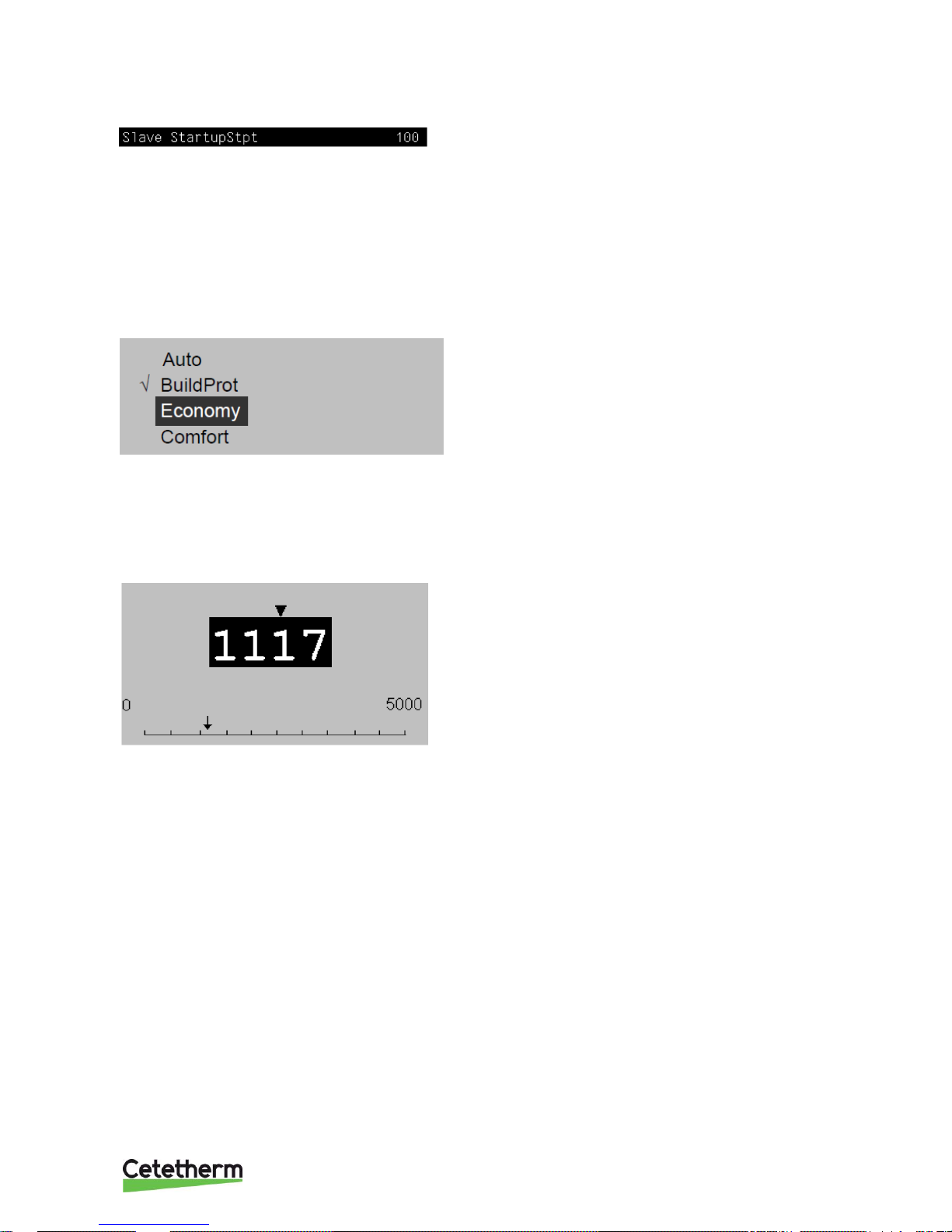

Settings bar:

A setting bar shows the parameter name and the

current value on a black background.

Setting value:

• select the line: turn the navigation dial

• switch settings page: press the navigation dial

• set parameter value: turn the navigation dial

• close the settings page and apply the changed parameter value: press the navigation dial

• close the settings page without applying the changed parameter value: press ESC.

3.4 Setting parameters

When only one value is selectable:

The line with a tick in front (Fire Set point) shows the

set value

Change the value:

• select new value: turn the navigation dial

• apply the new value and close the settings page: press the navigation dial

• keep the old value and close the settings page: press the ESC key.

Setting analogue parameter values:

A scale displays the minimum and maximum values

that can be set.

Change set value:

• change the value below the arrow: turn the navigation dial

• apply the new value and close the settings page: press the navigation dial/OK

• keep the old value and close the settings page: press the ESC key.

IQHeat

User manual

10

4 Log in and set the clock

4.1 Password and login

The controller has password protection, allowing access to different menus.

NOTE: For security reasons must the factory set password be changed the first time the IQHeat starts up.

The following log-in levels are available:

All users: no log-in, no password required

• read access to all menus except the system parameters, configuration and detail menus

• read access to alarm lists and alarm history

End user, level 6, password 1000

• appears with one key in the upper left corner of the display

• all rights as for in "all users"

• read access to all menus except configuration menus

• write access to the main set points (Setpoints/Settings. > Setpoints)

• alarms and alarm history can be acknowledged and reset

Service level, level 4, password 2000

Used for configuring I/Os and system settings. Only qualified service personnel should make changes at this

level.

• appears with two keys in the upper left corner of the display

• all rights as for "End users"

• access to all menus except I/O configuration and system settings

OEM, level 2

• appears with three keys in the upper left corner of the display

• all rights as for System Administrator

• access to all menus and system settings.

Contact Cetetherm if there is a need to change anything at this level.

4.1.1 Log in

1. Keep the OK button pressed to access the

Password menu.

2. The first digit of four is marked with 0.

3. Turn the navigation dial until the desired number

appears.

4. Press OK to proceed to the next digit, continue

until all four are entered correctly and press OK.

The current key symbol will appear in the upper left

corner of the display window.

IQHeat

User manual

11

4.2 Time functions setting of time and date

The controller's clock includes the functions for summer and winter time changes and leap years. The clock has

a backup function to cover at least 24 hours of power cuts.

4.2.1 Reading date and time

1. Press Info to access Main overview.

2. The top line shows the set date and time.

4.2.2 Setting date and time

Requires login at end user level.

1. Press Info until the page with the date and time are displayed.

2. Move the cursor to the line for date and time.

3. Press OK to edit the day.

4. Set the correct day with the navigation dial, press OK to confirm and continue to edit the month and

year.

5. Continue to edit the hours, minutes and seconds in the same way.

6. Exit the menu with ESC.

IQHeat

User manual

12

5 Alarm management

The processing unit alerts for different situations. Alarms are indicated on the control display with the alarm

symbol .

Alarms are divided into three classes:

• A or 1 = Alarm, High

• B or 2 = Alarm, Low

• C or 3 = Alarm, Warning

Active alarms:

• alarm symbol in the display flashes

• alarm button on the control panel flashes

Acknowledged but still active alarm:

• alarm symbol in the display lights

• alarm button on the control panel lights

If a GSM modem is connected to the processing unit, an alarm is sent by text message to the specified

telephone number.

All incoming alarms generate an entry in the Alarm list and in Alarm history. When an alarm is no longer active,

it will disappear from the Alarm list.

The Alarm history contains the same information about the alarm as the Alarm list, i.e. time and date when the

alarm was sent. This also includes information on when the alarm was actioned. Incoming alarms are indicated

by a plus (+) before the name, while actioned are indicated by a minus (-). When the Alarm list is empty, there

should be as many + as – entries in the Alarm history.

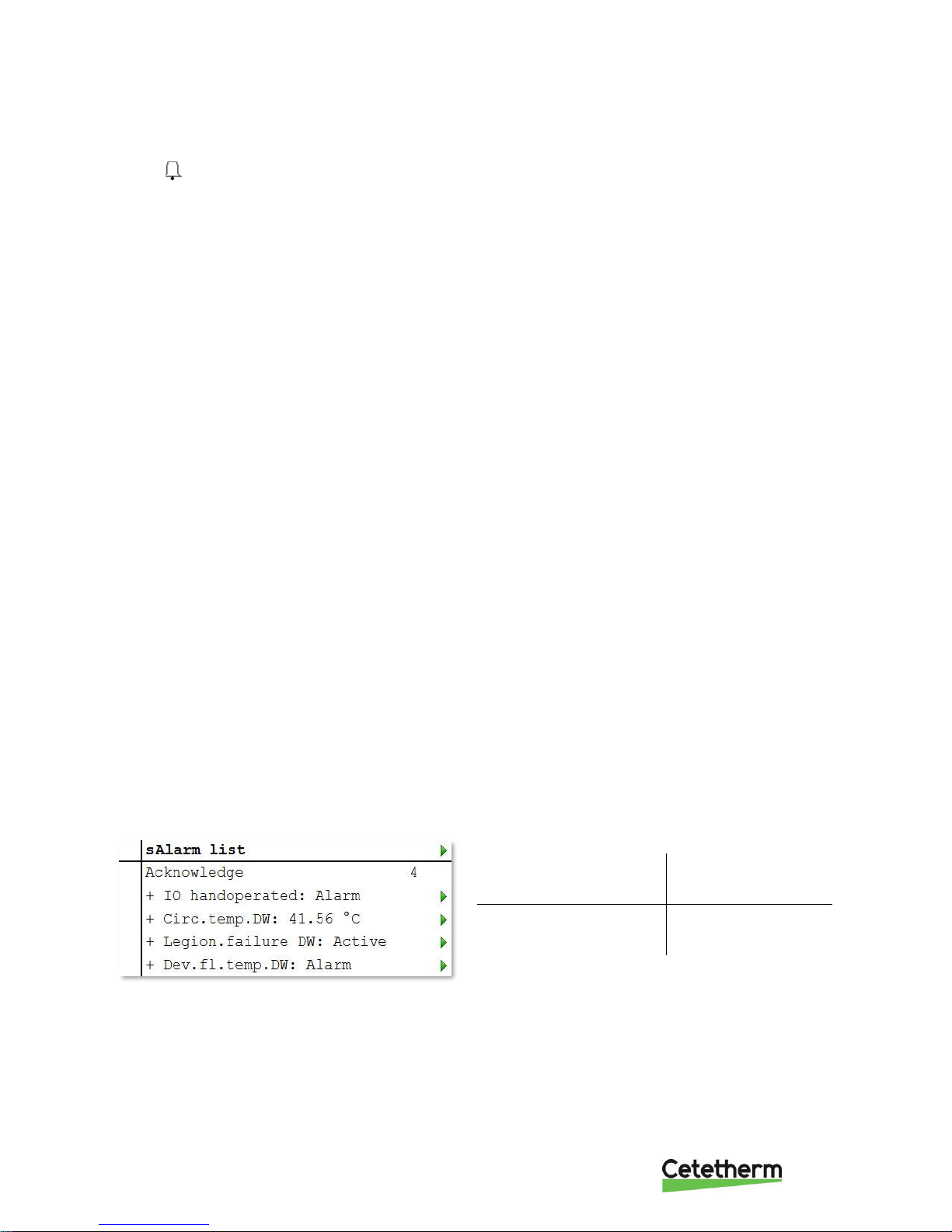

5.1 Alarm list

The Alarm list contains all active alarms, acknowledged and unacknowledged. The Alarm list may contain up to

50 entries.

An alarm will remain in the Alarm list until it has been actioned.

The Alarm list menu has the option of selecting Acknowledge > Execute.

If Execute is selected, this means the alarm is confirmed, the Alarm button switches from flashing to steady

light. All information about the alarms remains.

1. Press the Alarm button once to see the details about the last alarm.

2. Press the Alarm button again to access the Alarm list.

3. A list of all active alarms now appears.

All active alarms correspond to an entry in the Alarm list.

Number of alarms that

are active.

In this example, 4.

+ Alarm name

Ex

+ IO in manual mode

Status

Alarm

IQHeat

User manual

13

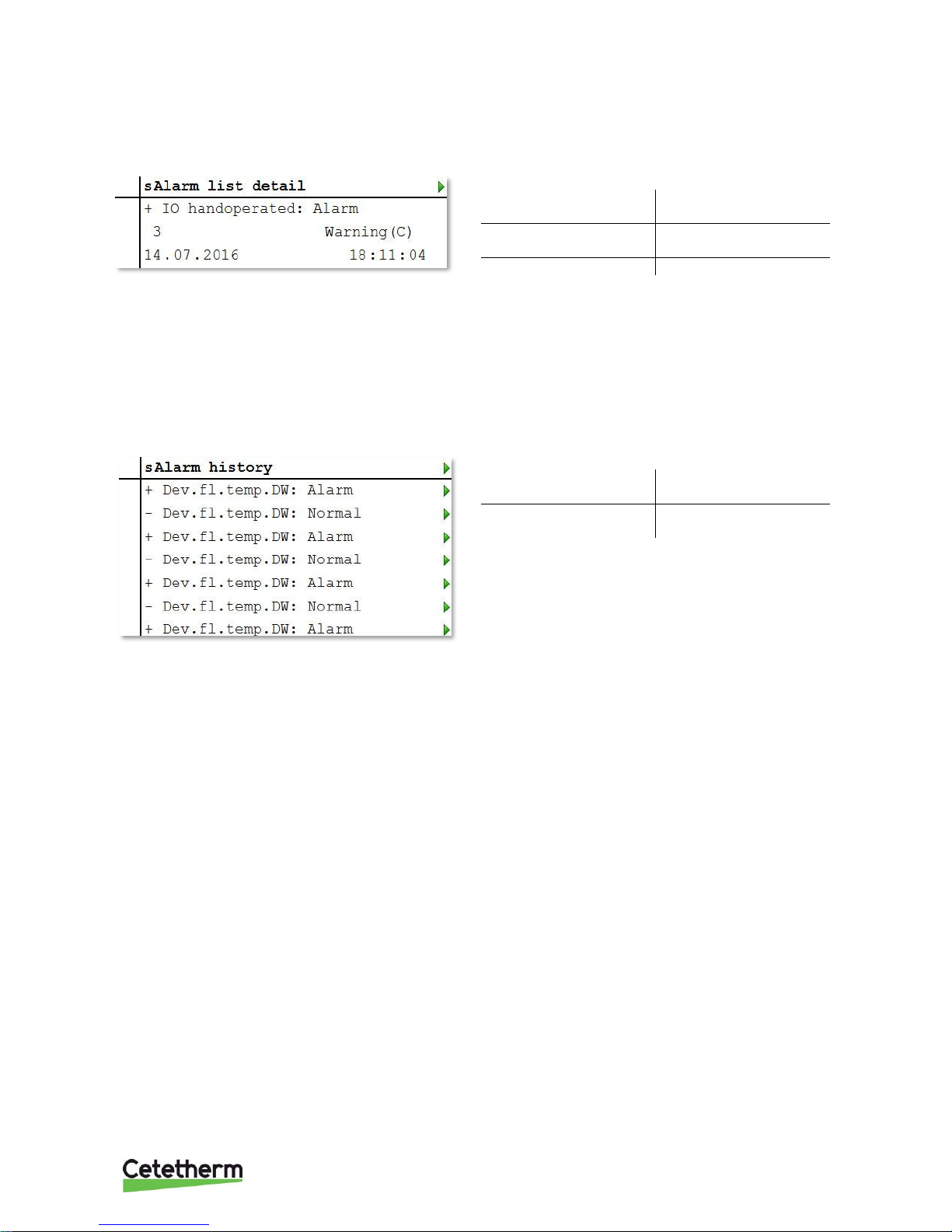

4. To see detailed information about an alarm, select the desired alarm by using the navigation dial and

press OK.

All active alarms have the following information included in the Alarm list.

+ Alarm name

Status

Alarm class

Alarm class

Date

Time

5.2 Alarm history

The Alarm history may contain up to 50 entries.

Each new alarm generates an entry in the Alarm history list. Incoming alarms are indicated by a plus (+) before

the name, while actioned alarms are indicated by a minus (-).

1. Press the Alarm button and choose Alarm history or press Alarm button three times to access the

Alarm history.

2. All alarms, both active and actioned, are now listed.

Number of alarms in the

list.

+/- Alarm name

Status

3. To see detailed information about an alarm, select the desired alarm by using the navigation dial and

press OK.

5.3 Settings

NOTE! Requires login at end user level

In the Alarming, under Advanced, you can see how many alarms there are in the Alarm list and Alarm history.

Here you can also set the sort order for how alarms are presented in the Alarm list and Alarm history. Each list is set

individually, so they may appear differently depending on the list that is opened.

Alarms can be sorted as:

• Sort 1:

▪ Time

▪ Obj.ID

▪ Priority

▪ State

• Sort 2:

▪ Time

▪ Obj.ID

▪ Priority

▪ State

• Descending order:

▪ Passive

▪ Active

NOTE: Resetting the Alarm list and/or Alarm history in the Advanced menu deletes the alarms from the lists.

The alarm indicator remains but the information about the alarm is deleted.

Loading...

Loading...