Page 1

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

SIMATIC Industrial PC SIMATIC IPC427C

SIMATIC

Industrial PC

SIMATIC IPC427C

Operating Instructions

Introduction

Safety Instructions

_____________

_____________

Description

_____________

Application planning

_____________

Installing/mounting

_____________

Connecting

_____________

Commissioning

_____________

Integration into an

Automation System

_____________

Functions

_____________

Expansions and

Configurations

_____________

Maintenance and Service

_____________

Alarm, error and system

messages

_____________

Troubleshooting/FAQs

_____________

Technical specifications

_____________

Dimension drawings

_____________

Detailed descriptions

_____________

Appendix

_____________

ESD guidelines

_____________

List of abbreviations

_____________

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

A

B

C

04/2009

A5E02414743-01

Page 2

Legal information

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

CAUTION

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

NOTICE

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be adhered to. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Industry Sector

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E02414743-01

Ⓟ 04/2009

Copyright © Siemens AG 2009.

Technical data subject to change

Page 3

Table of contents

1 Introduction................................................................................................................................................

1.1 Preface...........................................................................................................................................

1.2 Guideline to the Operating Instructions .........................................................................................

2 Safety Instructions.....................................................................................................................................

2.1 General safety instructions ............................................................................................................

3 Description...............................................................................................................................................

3.1 Overview ......................................................................................................................................

3.2 Applications..................................................................................................................................

3.3 Features.......................................................................................................................................

3.4 Windows Embedded Standard 2009 ...........................................................................................

3.5 Design..........................................................................................................................................

3.5.1 External Design............................................................................................................................

3.5.2 Connection components ..............................................................................................................

3.5.3 Operator controls .........................................................................................................................

3.5.4 Status displays.............................................................................................................................

4 Application planning.................................................................................................................................

4.1 Transport......................................................................................................................................

4.2 Unpacking and checking the delivery unit ...................................................................................

4.3 Ambient and Environmental Conditions.......................................................................................

7

7

8

9

9

11

11

12

13

15

17

17

18

19

20

21

21

22

24

5 Installing/mounting...................................................................................................................................

5.1 Permitted mounting positions.......................................................................................................

5.2 Mounting information ...................................................................................................................

5.3 Mounting the device.....................................................................................................................

5.4 Mounting on DIN rails ..................................................................................................................

5.5 Mounting with mounting brackets ................................................................................................

5.6 Upright mounting..........................................................................................................................

6 Connecting ..............................................................................................................................................

6.1 Connecting peripheral equipment................................................................................................

6.2 Connecting the 24 V DC power supply........................................................................................

6.3 Protective ground connection ......................................................................................................

6.4 USB strain-relief...........................................................................................................................

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

25

25

27

27

28

30

32

33

33

34

35

36

3

Page 4

Table of contents

7 Commissioning ........................................................................................................................................ 37

7.1 Note before commissioning......................................................................................................... 37

7.2 Commissioning - Windows Embedded Standard 2009 .............................................................. 38

7.2.1 Basic commissioning - initial startup ........................................................................................... 38

7.3 Commissioning - Windows XP Professional............................................................................... 40

7.3.1 Basic commissioning - initial startup ........................................................................................... 40

7.3.2 Setting up the language selection for Windows XP Professional / Embedded Standard........... 41

7.4 Commissioning - other operating systems.................................................................................. 42

7.4.1 Commissioning - guide................................................................................................................ 42

8 Integration into an Automation System .................................................................................................... 43

8.1 Overview ..................................................................................................................................... 43

9 Functions................................................................................................................................................. 45

9.1 Monitoring Functions................................................................................................................... 45

9.1.1 Introduction ................................................................................................................................. 45

9.1.2 Temperature monitoring/display ................................................................................................. 46

9.1.3 Watchdog (WD)........................................................................................................................... 47

9.2 Enhanced Write Filter (EWF) ...................................................................................................... 48

9.3 File Based Write Filter (FBWF) ................................................................................................... 50

9.4 SRAM buffer memory.................................................................................................................. 52

9.5 Battery monitoring ....................................................................................................................... 53

9.6 Operation without monitor and keyboard.................................................................................... 54

10 Expansions and Configurations ............................................................................................................... 55

10.1 Open the device (front panel) ..................................................................................................... 55

10.2 Memory expansion ...................................................................................................................... 57

10.2.1 Installing the memory module ..................................................................................................... 57

10.3 Installing PCI-104 / PC/104 Plus modules .................................................................................. 59

10.3.1 Notes on the modules ................................................................................................................. 59

10.3.2 Mounting PCI-104 or PC/104 Plus modules ............................................................................... 60

10.4 Installing/Removing Compact Flash Cards................................................................................. 62

10.4.1 Installation options for Compact Flash cards.............................................................................. 62

10.4.2 Installing/removing an accessible Compact Flash card.............................................................. 63

10.4.3 Installing/removing a built-in Compact Flash card ...................................................................... 66

11 Maintenance and Service ........................................................................................................................ 67

11.1 Removing and Installing Hardware Components........................................................................ 67

11.1.1 Repairs........................................................................................................................................ 67

11.1.2 Preventive maintenance.............................................................................................................. 68

11.1.3 Replacing hard disk or SSD drive ............................................................................................... 69

11.1.4 Replace the backup battery ........................................................................................................ 71

11.2 Reinstalling the operating system ............................................................................................... 73

11.2.1 Windows Embedded Standard 2009 .......................................................................................... 73

11.2.1.1 General installation procedure .................................................................................................... 73

11.2.1.2 Restoring the software to factory state using the Restore DVD ................................................. 74

11.2.2 Windows XP Professional........................................................................................................... 76

11.2.2.1 General installation procedure .................................................................................................... 76

SIMATIC IPC427C

4 Operating Instructions, 04/2009, A5E02414743-01

Page 5

Table of contents

11.2.2.2 Restoring the Software to Factory State Using the Restore DVD ...............................................77

11.2.2.3 Setting up the operating system via the Recovery CD/DVD .......................................................

79

11.3 Partitioning data media ................................................................................................................

11.3.1 Setting up the partitions under Windows Embedded Standard 2009..........................................

11.3.2 Setting up the partitions under Windows XP Professional ..........................................................

11.4 Installing drivers and software .....................................................................................................

11.4.1 Driver installation under Windows Embedded Standard 2009 ....................................................

11.4.2 Installing drivers and software .....................................................................................................

11.5 Installing updates .........................................................................................................................

11.5.1 Updating the operating system ....................................................................................................

11.5.2 Installing or updating application programs and drivers ..............................................................

11.5.3 Performing a BIOS update...........................................................................................................

11.6 Data backup .................................................................................................................................

11.6.1 Creating an image........................................................................................................................

12 Alarm, error and system messages .........................................................................................................

12.1 Boot error messages....................................................................................................................

13 Troubleshooting/FAQs.............................................................................................................................

13.1 General problems ........................................................................................................................

13.2 Problems when using modules of third-party manufacturers ......................................................

14 Technical specifications...........................................................................................................................

14.1 General specifications..................................................................................................................

14.2 Power requirements of the components ......................................................................................

81

81

82

83

83

83

84

84

84

85

86

86

87

87

89

89

90

91

91

95

14.3 Integrated DC power supply ........................................................................................................

15 Dimension drawings ................................................................................................................................

15.1 Overview of the dimensional drawings ........................................................................................

15.2 Dimension drawings of the device ...............................................................................................

15.3 Dimension drawings of the device with mounting brackets .........................................................

15.4 Dimensional drawings of the device with vertical mounting angles...........................................

15.5 Dimensional drawings of the device with expansion frames .....................................................

15.6 Dimension drawing of the blanking plate ...................................................................................

16 Detailed descriptions .............................................................................................................................

16.1 Internal components ..................................................................................................................

16.1.1 Overview of internal components...............................................................................................

16.1.2 Technical features of the motherboard ......................................................................................

16.1.3 External ports.............................................................................................................................

16.1.3.1 Overview ....................................................................................................................................

16.1.3.2 COM1/2......................................................................................................................................

16.1.3.3 DVI-I ...........................................................................................................................................

16.1.3.4 Ethernet......................................................................................................................................

16.1.3.5 USB............................................................................................................................................

16.1.3.6 PROFIBUS.................................................................................................................................

16.1.3.7 CAN bus.....................................................................................................................................

16.1.4 Internal ports ..............................................................................................................................

16.1.4.1 Overview ....................................................................................................................................

96

97

97

98

99

101

102

103

105

105

105

106

107

107

107

108

109

109

110

110

111

111

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

5

Page 6

Table of contents

16.1.4.2 Compact Flash card interface ................................................................................................... 111

16.1.4.3 PCI-104 or PC/104-Plus interface (PCI part)............................................................................ 112

16.2 BIOS Setup ............................................................................................................................... 113

16.2.1 Overview ................................................................................................................................... 113

16.2.2 Starting BIOS Setup.................................................................................................................. 114

16.2.3 BIOS Setup menus ................................................................................................................... 115

16.2.4 Main menu................................................................................................................................. 117

16.2.5 Advanced Menu ........................................................................................................................ 122

16.2.6 Security menu ........................................................................................................................... 125

16.2.7 Boot menu................................................................................................................................. 126

16.2.8 Version menu ............................................................................................................................ 130

16.2.9 Exit Menu .................................................................................................................................. 131

16.2.10 Default BIOS Setup entries....................................................................................................... 132

16.3 System resources ..................................................................................................................... 135

16.3.1 Currently allocated system resources....................................................................................... 135

16.3.2 System resources used by the BIOS/DOS ............................................................................... 136

16.3.2.1 PCI Interrupt Lines .................................................................................................................... 136

16.4 I/O Address Areas..................................................................................................................... 137

16.4.1 Overview of the internal module registers................................................................................. 137

16.4.2 Watchdog enable register / 066h select register (read/write, address 062h) ........................... 138

16.4.3 Watchdog trigger register (read only, address 066h) ............................................................... 138

16.4.4 CAN base address register (write only, address 066h) ............................................................ 139

16.4.5 Output register LED 1 / 2 (read/write, address 404Eh)............................................................. 140

16.4.6 Battery status tab (read-only, address 50Fh)............................................................................ 141

16.4.7 SRAM address register............................................................................................................. 142

A Appendix................................................................................................................................................ 143

A.1 Guidelines and declarations...................................................................................................... 143

A.2 Certificates and approvals......................................................................................................... 144

A.3 Service and support .................................................................................................................. 146

B ESD guidelines ...................................................................................................................................... 147

B.1 ESD Guidelines............................................................................................................

............. 147

C List of abbreviations............................................................................................................................... 149

C.1 Abbreviations ............................................................................................................................ 149

Glossary ................................................................................................................................................ 155

Index...................................................................................................................................................... 167

SIMATIC IPC427C

6 Operating Instructions, 04/2009, A5E02414743-01

Page 7

Introduction

1.1 Preface

Objective of this documentation

These operating instructions contain all the information you need for commissioning and

operation of the SIMATIC IPC427C.

It is intended both for programming and testing personnel who commission the device and

connect it with other units (automation systems, programming devices), as well as for service

and maintenance personnel who install add-ons or carry out fault/error analyses.

Basic knowledge requirements

A solid background in personal computers and Microsoft operating systems is required to

understand this manual. General knowledge in the field automation control engineering is

recommended.

Scope of validity of this document

The operating instructions are valid for all supplied variations of the SIMATIC IPC427C and

describe the delivery status as of May 2009.

1

Position in the information landscape

The documentation for the SIMATIC IPC427C includes the following sections:

● SIMATIC IPC427C, Operating Instructions (Compact)

● SIMATIC IPC427C, Operating Instructions

The documentation is supplied in German and English with the device in electronic form as a

PDF file on the "Documentation and Drivers" DVD.

Conventions

The term "PC" or "device" is sometimes used to refer to the SIMATIC IPC427C product in

this documentation.

History

Currently released versions of this operating manual:

Edition Comment

04/2009 First edition

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

7

Page 8

Introduction

1.2 Guideline to the Operating Instructions

1.2 Guideline to the Operating Instructions

Contents format Table of Contents

Contents Organization of the documentation, including the index of pages and chapters

Introduction Purpose, layout and description of the important topics.

Safety instructions Refers to all the valid technical safety aspects which have to be adhered to while installing,

commissioning and operating the product/systemin and in reference to statutory

regulations.

Description Fields of application, the features and the structure of the product/system

Application planning Aspects of storage, transport, environmental and EMC conditions to be considered in the

preparatory stage

Mounting Product installation options and installation instructions

Connecting Options of connecting the product and connection instructions

Commissioning Commissioning the product/system.

Integration Options of integrating the product into existing or planned system environments/networks

Functions Monitoring and display functions

Expansions / configurations Procedure for installing expansion devices (memory, modules).

Maintenance and service Replacement of hardware components, restoring and setup of the operating system,

installation of drivers and software

Alarm, error and system

messages

Troubleshooting Problems, cause, remedy

Technical specifications General specifications in compliance with relevant standards and current/voltage values

Dimension drawings Dimensions of the device and of modules

Detailed descriptions Structure, function and features of vital components, distribution of system resources and

Appendix Guidelines and certifications, service and support, notes on retrofitting.

ESD guidelines General ESD guidelines.

Error messages from booting

use of the BIOS Setup routine

SIMATIC IPC427C

8 Operating Instructions, 04/2009, A5E02414743-01

Page 9

Safety Instructions

2.1 General safety instructions

Repairs

CAUTION

Please observe the safety instructions on the back of the cover sheet of this

documentation. You should not expand your device unless you have read the relevant

safety instructions.

This device is compliant with the relevant safety measures to IEC, EN, VDE, UL, and CSA. If

you have questions about the validity of the installation in the planned environment, please

contact your service representative.

Only authorized personnel are permitted to repair the device.

2

Unauthorized opening of and improper repairs to the device may result in substantial

damage to equipment or endanger the user.

System expansions

Only install system expansion devices designed for this device. The installation of other

expansions can damage the system and violate the radio-interference suppression

regulations. Contact your technical support team or where you purchased your PC to find out

which system expansion devices may safely be installed.

CAUTION

If you install or exchange system expansions and damage your device, the warranty

becomes void.

WARNING

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

9

Page 10

Safety Instructions

2.1 General safety instructions

Battery

This device is equipped with a Lithium battery. Batteries may only be replaced by qualified

personnel.

ESD directives

CAUTION

There is the risk of an explosion if the battery is not replaced as directed. Replace the

battery only with the same type or with an equivalent type recommended by the

manufacturer. Dispose of used batteries in accordance with local regulations.

WARNING

Risk of explosion and release of harmful substances!

For this reason, do not burn lithium batteries, do not solder on the cell body, do not open,

do not short circuit, do not reverse polarity, do not heat above 100°C, dispose of correctly,

and protect against direct sunlight, dampness and dew.

Modules containing electrostatic sensitive devices (ESDs) can be identified by the following

label:

Strictly follow the guidelines mentioned below when handling modules which are sensitive to

ESD:

● Always discharge your body´s static electricity before handling modules that are sensitive

to ESD (for example, by touching a grounded object).

● All devices and tools must be free of static charge.

● Always pull the mains connector and disconnect the battery before installing or removing

modules which are sensitive to ESD.

● Handle modules fitted with ESDs only by their edges.

● Do not touch any connector pins or conductors on modules containing ESDs.

SIMATIC IPC427C

10 Operating Instructions, 04/2009, A5E02414743-01

Page 11

Description

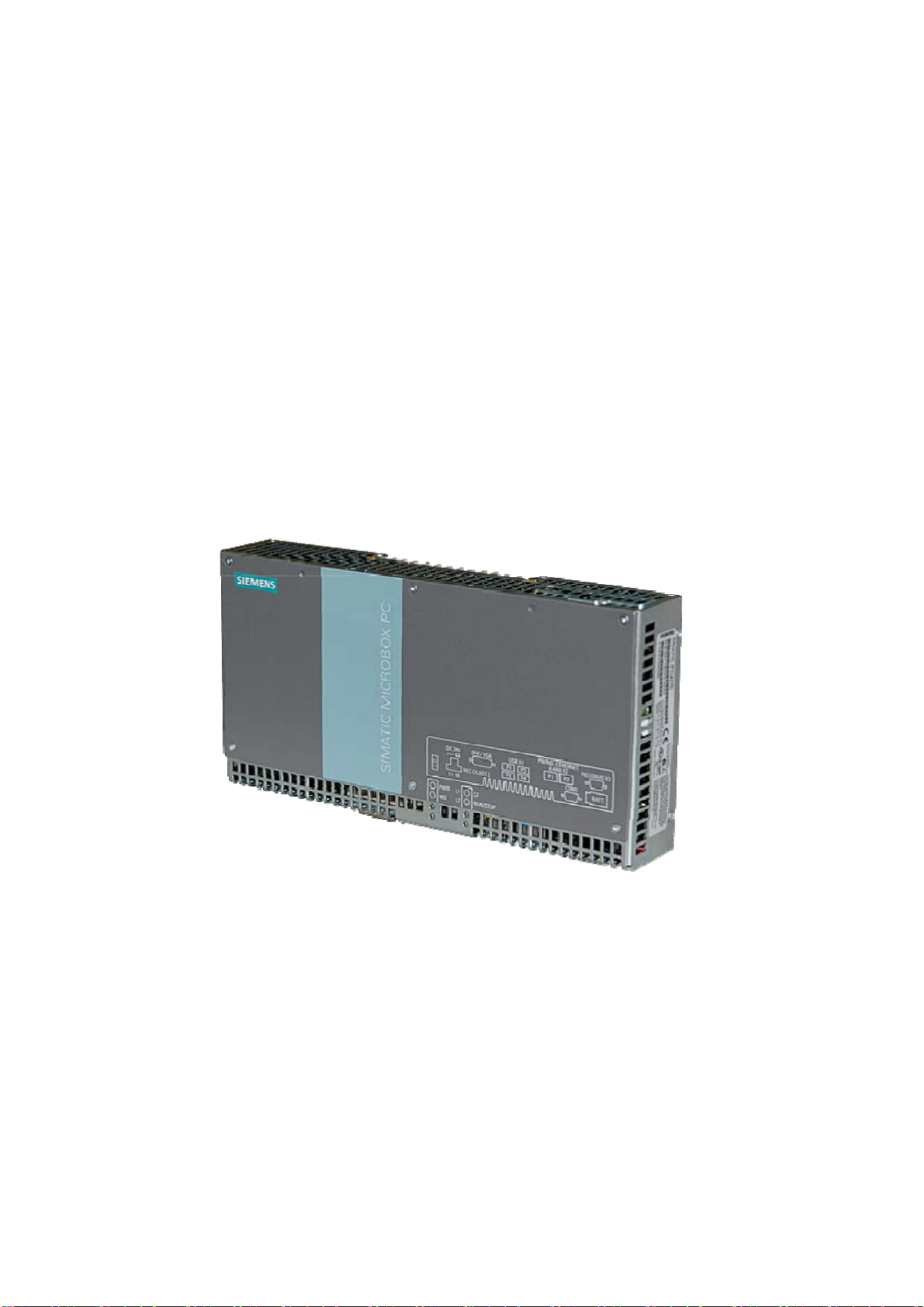

3.1 Overview

The SIMATIC IPC427C provides high-level industrial performance.

● Compact design

● Maintenance-free operation

● High degree of ruggedness

3

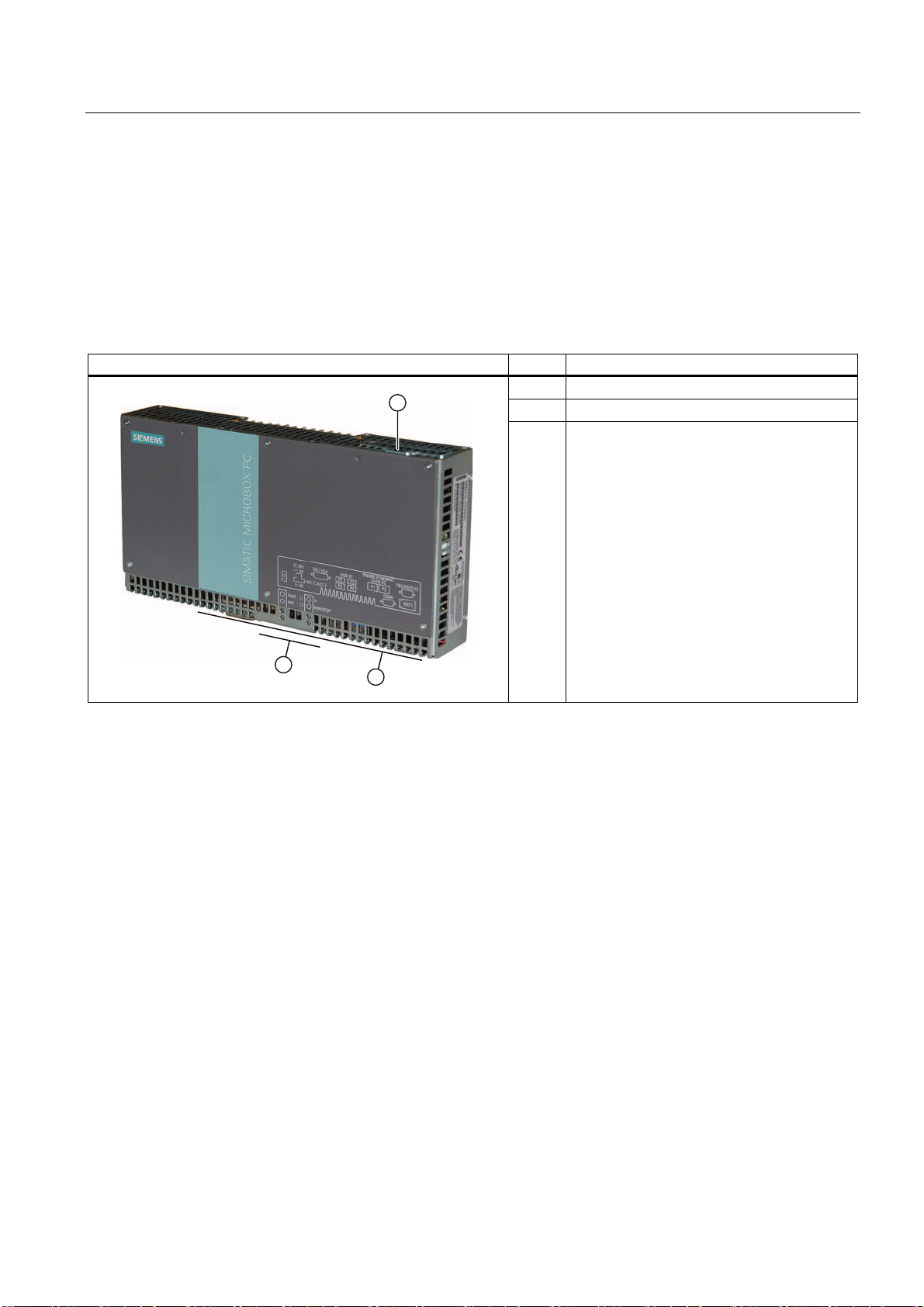

Figure 3-1 SIMATIC IPC427C

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

11

Page 12

Description

3.2 Applications

3.2 Applications

The device provides industrial PC systems for high-performance and space-saving

applications in particular in the field of machine, systems and switchgear cabinet

engineering:

● Measuring and controlling of process and machine data (for example, automated washing

systems, assembling machines, packaging machines)

● Operating and visualization tasks with separate display / monitor solutions (information

terminals, large-scale displays in automotive production)

● Data logging and processing (for example, system data logging, distributed process

control)

SIMATIC IPC427C

12 Operating Instructions, 04/2009, A5E02414743-01

Page 13

Description

3.3 Features

3.3 Features

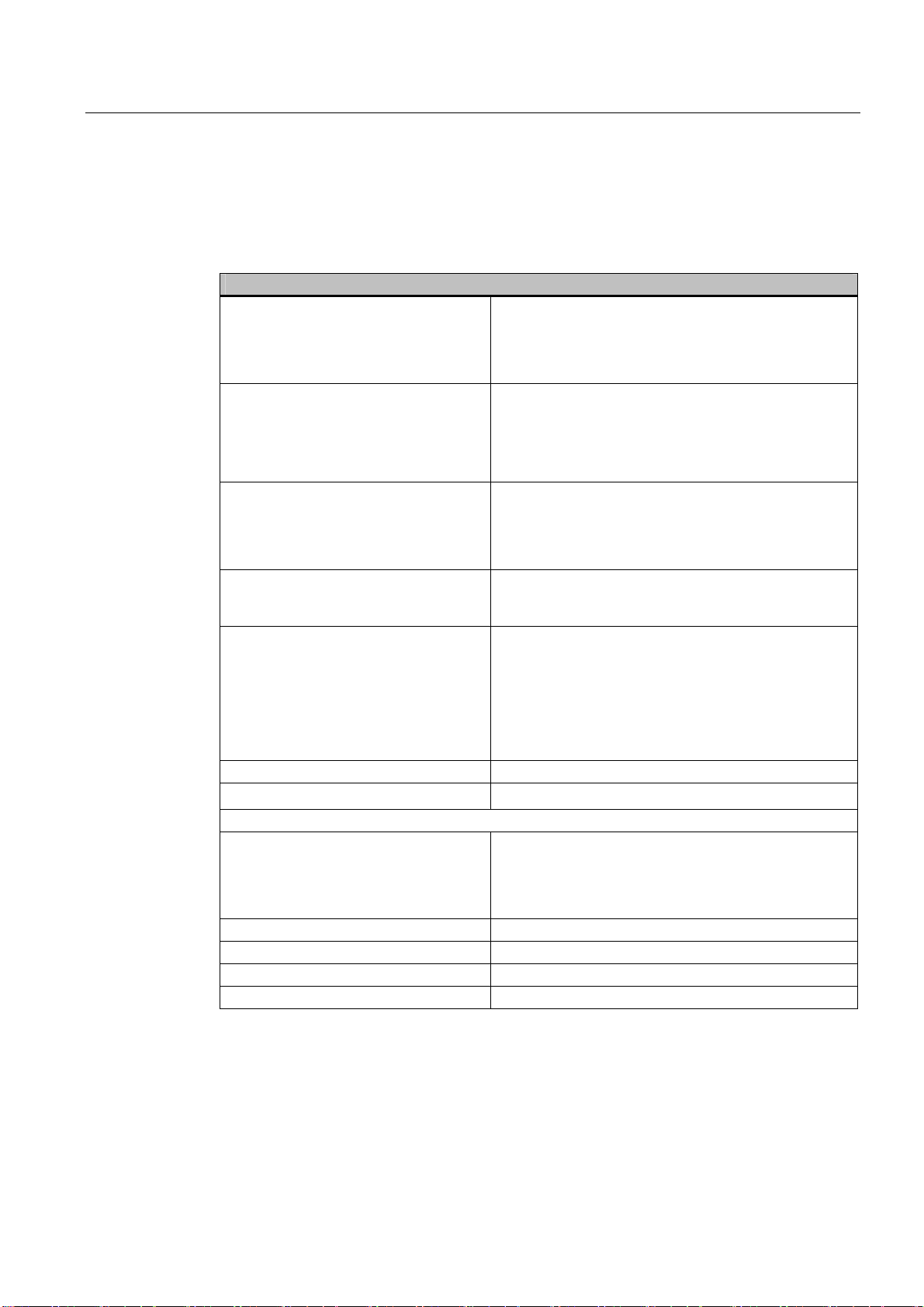

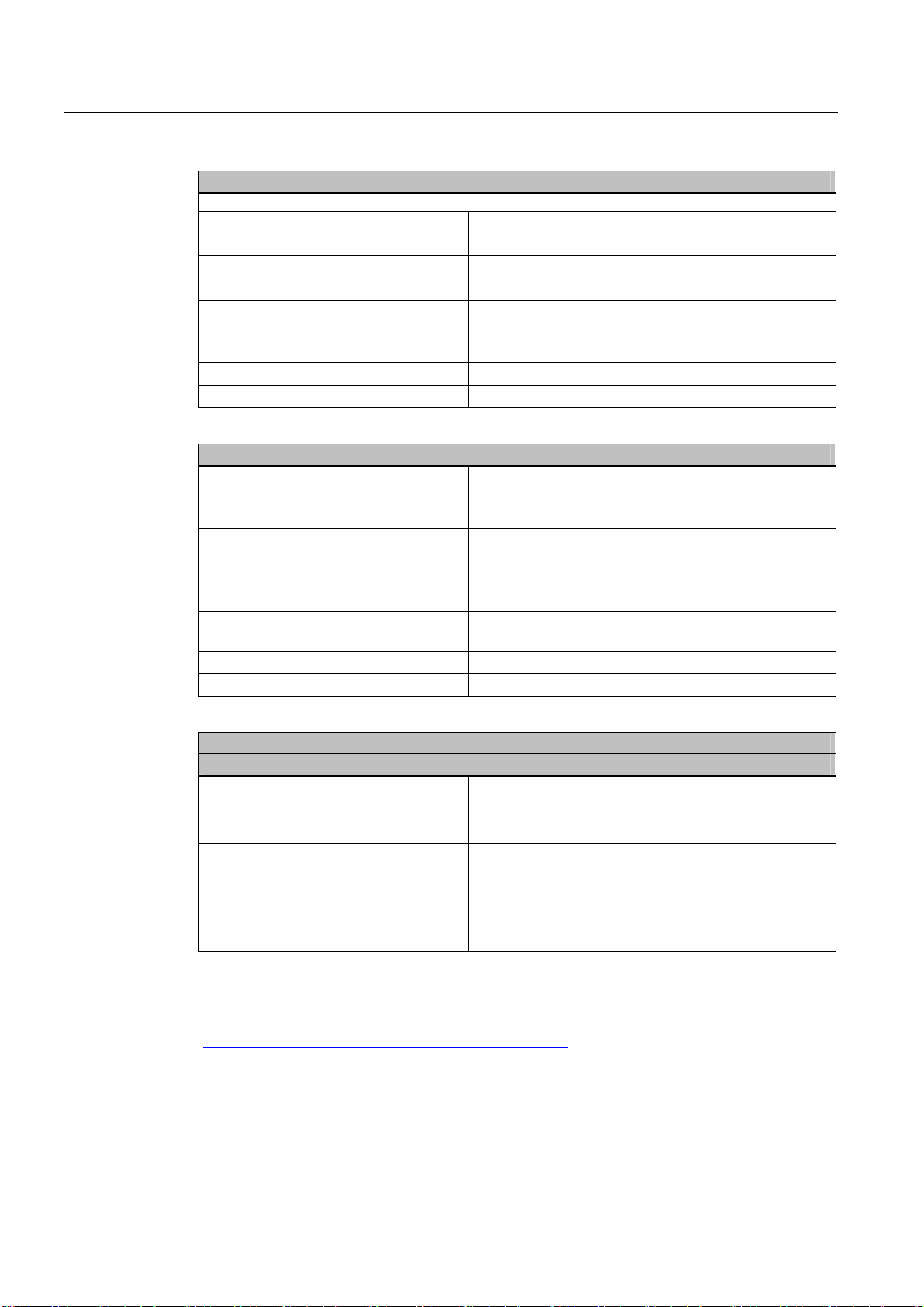

Basic data

Installation / mounting

Processor

Main memory

• Installation on a DIN rail

• Wall mounting

• Vertical mountin

• Hanging assembly

• Intel Celeron M 1.2 GHz, 800 MHz FSB, 1 MB SLC or

• Intel Pentium Core 2 Solo 1.2 GHz, 800 MHz FSB,

3 MB SLC or

• Intel Pentium Core 2 Duo 1.2 GHz, 800 MHz FSB,

3 MB SLC

• 512 MB DDR3-SDRAM SODIMM

• 1 GB DDR3-SDRAM SODIMM

• 2 GB DDR3-SDRAM SODIMM

• 4 GB DDR3-SDRAM SODIMM

Free slots for expansion Up to 3 x PCI/104 modules or 3x PC/104-

(PCI bus only);

installed with expansion frame

Graphics

Power supply 24 VDC (19.2 – 28.8 V) max. 4 A

Conditions of use

Drives and storage media

Compact Flash card

Hard disk ≥ 80 GB SATA HD 2.5" optional

SSD (Solid State Disk) ≥ 32 GB optional

Floppy/CDROM drive Connected via external USB port

USB stick Connected via external USB port

• Integrated Intel GMA4500 graphics

• CRT resolution of 640x480 pixels up to 1920x1200

pixels

• DVI resolution of 640x480 pixels up to 1920x1200

pixels

• 8-512 MB graphics memory taken from main memory

(dynamic UMA)

• Operation without fan

• 256 MByte optional or

• 2 GB optional or

• 4 GB optional or

• 8 GB optional

Plus

module

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

13

Page 14

Description

3.3 Features

Basic data

Ports

Serial COM1 (RS232)

COM2 (RS232); optional

Graphics DVI-I: combined DVI and VGA

USB 4 x USB 2.0 high current

Ethernet 2 x RJ 45 (10/100/1000 Mbps)

PROFIBUS DP 12 Mbps (isolated potential,

compatible to CP 5611), optional

CAN interface Optional

Keyboard, mouse Connected via external USB port

Monitoring and safety functions

Temperature

• When permitted temperature range is exceeded

• Warnings can be analyzed by application program

(local, via LAN)

Watchdog

• Monitoring function for program execution

• Restart can be parameterized in the event of a fault

• Warnings can be analyzed by application program

(local, via LAN)

LED display 4 LEDs for displaying system status

2 of these can be programmed by the user1

Transient voltage interruption Up to 15 ms buffer time at full load

Buffer memory 2 MB battery-buffered SRAM1

Software

Operating systems

Available

• Without

• Windows Embedded Standard 2009

2

Project-specific

• Windows XP Professional MUI SP3 preinstalled

• LINUX

• QNX

• VxWorks

• Others on request

• RMOS3 V3.40 (ordered separately)

1

You can find additional information about addressing the LEDs or the SRAM under a

Windows operating system in the section "Output register LED L1/L2". You can find example

programs for addressing the LEDs under Windows XP and under RMOS3 under the FAQ at

the Customer Support site Industry Automation and Drive Technologies - Homepage

http://www.siemens.com/automation/service&support).

(

2

MUI: Multi Language User Interface; 5 languages (English, German, French, Spanish,

Italian)

SIMATIC IPC427C

14 Operating Instructions, 04/2009, A5E02414743-01

Page 15

Description

3.4 Windows Embedded Standard 2009

3.4 Windows Embedded Standard 2009

The supplied Windows Embedded Standard has the product version 2009. The overview

shows the basic device functions under Windows Embedded Standard 2009:

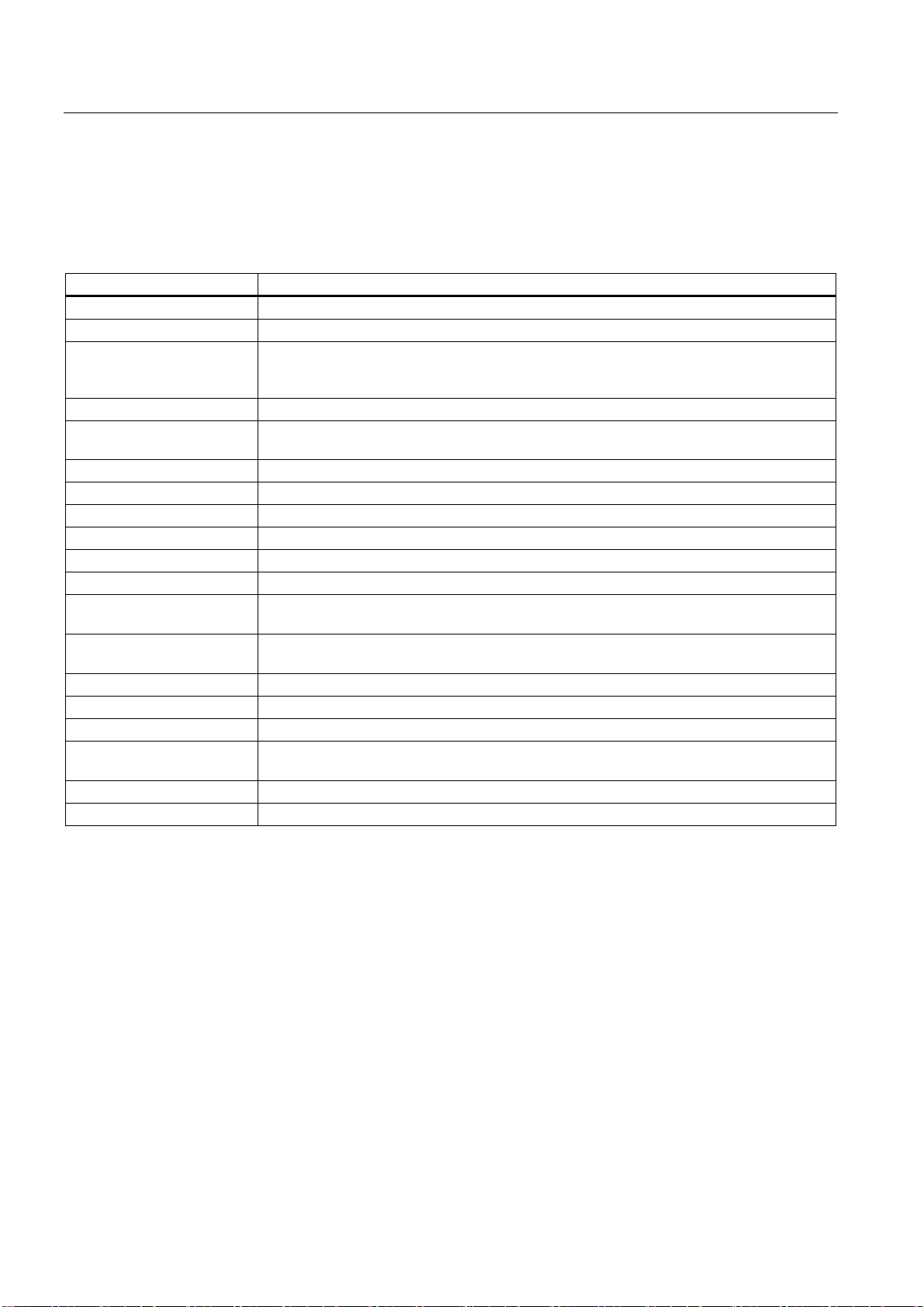

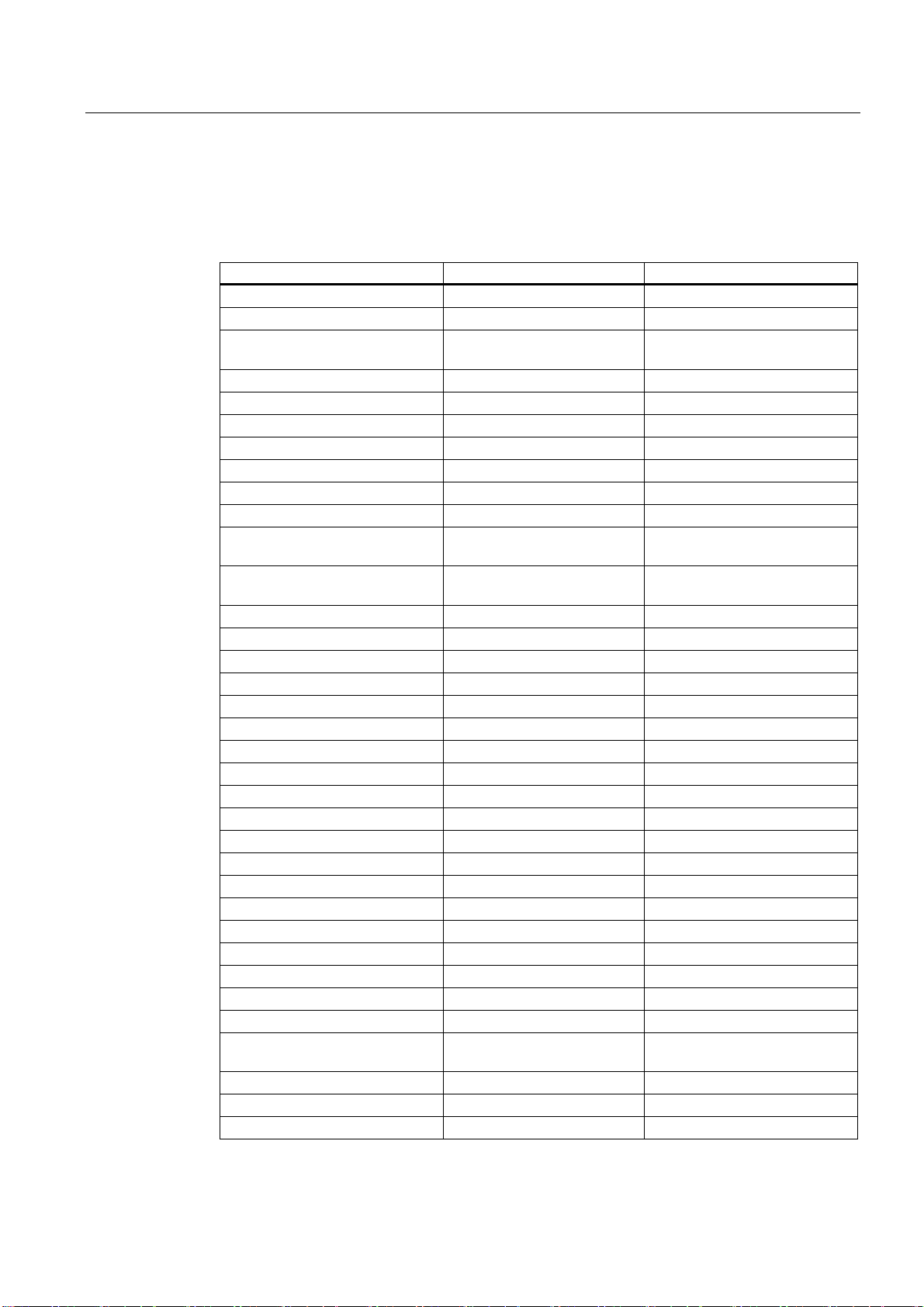

Function Hard disk / SSD version Compact Flash card version

Enhanced Write Filter (EWF) In RAM RAM(REG) In RAM RAM(REG)

SIMATIC IPC DiagBase Available V 1.2 Available V 1.2

Pagefile Deactivated in favor of the

EWF

System Restore Core Available Available

File based Writefilter (FBWF) Available Available

Registryfilter Available Available

Device Update Agent (DUA) Available Available

HORM Available Available

Telnet Server Available Available

Windows Backup Available Available

User Mode Driver Framework

(UMDF)

MUI GER/FRA/ITA/SPA

Administrator Account Available Available

User Account Available Available

Explorer Shell Available Available

Internet Explorer (IE) Available, IE7 Available, IE7

Internet Information Server (IIS) Available V 5.1 Available V 5.1

Terminal Services Available Available

Bluetooth Available Available

Wireless Network Support Available Available

Windows Firewall Available Available

Windows Security Center Available Available

MSN Explorer Available Not available

Outlook Express Available Available

Administrative Tools Available Available

SMS Advanced Client Available Not available

Remote Desktop Available V 6.0 Available V 6.0

Remote Assistance Available Available

.NET Framework Available, V3.5 Not available

ASP.NET Available, V3.5 Not available

Windows .NET Messenger Available V 4.7 Available V 4.7

Code pages/User

Location/Keyboard

Disk Management Services Available Available

Windows Installer Service Available V 3.1 Available V 3.1

Class Installer Available Available

Available Available

Default language: English

Available Selection available

Deactivated in favor of the EWF

GER

default language: English

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

15

Page 16

Description

3.4 Windows Embedded Standard 2009

Function Hard disk / SSD version Compact Flash card version

CoDevice Installer Available Available

Windows Movie Maker Available V 2.1 Not available

Media Player Available, V11.0 Available, V11.0

Windows Media Player Tour Available Not available

DirectX V9.0c V9.0c

Accessories Available Available

Help files for all components Available Not available

Games Available Not available

Fonts 316 118

Windows XP Tour Available Not available

Microsoft Silverlight Available V 1.0 Available V 1.0

NetMeeting Available V 3.1 Available V 3.1

Note

Activation of "HORM" and creation of a "Hiber File"

When "HORM" is activated, the "Hibernate" function can be used for Windows Embedded

Standard 2009:

• EWFMGR C: /activatehorm

"Hibernate" is activated following a restart. The system then always boots from this file.

SIMATIC IPC427C

16 Operating Instructions, 04/2009, A5E02414743-01

Page 17

Description

3.5 Design

3.5 Design

3.5.1 External Design

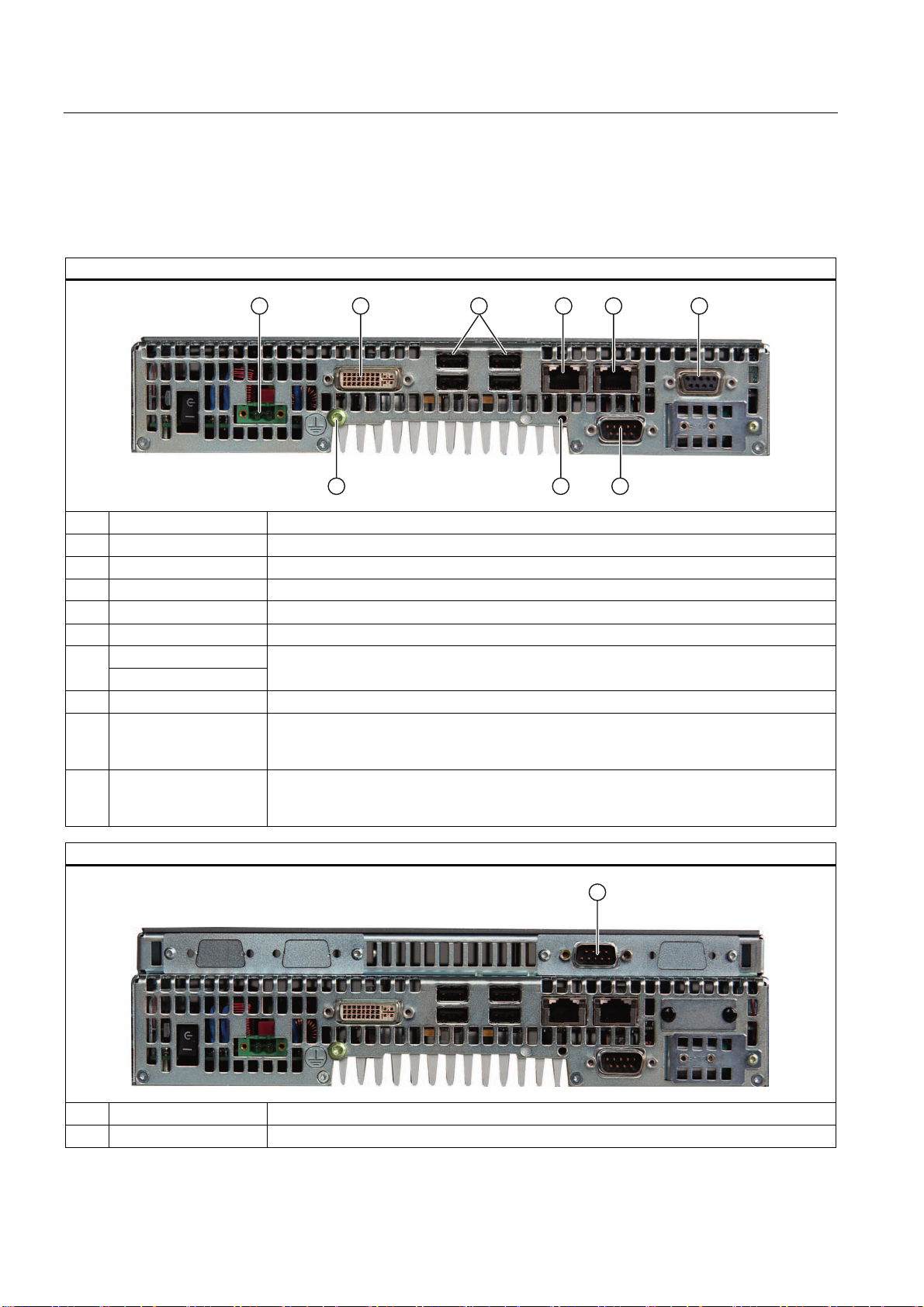

Device components Pos Description

① Cover plate for Compact Flash module

② Connection elements

③ Status displays

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

17

Page 18

Description

3.5 Design

3.5.2 Connection components

Ports and power supply

Location of connection elements (version with PROFIBUS or CAN)

Pos Name Description

① 24 VDC Connection for a 24 V DC power supply

② DVI/VGA DVI/VGA connection for CRT or LCD monitor with DVI interface

③ USB 4 USB 2.0 connections, high-speed / low current

④ PN/IND. ETHERNET RJ45 Ethernet connection 1 (exclusive PCI interrupt) for 10/100/1000 Mbps

⑤ PN/IND. ETHERNET RJ45 Ethernet connection 2 (shared PCI interrupt) for 10/100/1000 Mbps

PROFIBUS DP/MPI ⑥

CAN fieldbus

⑦ COM1 Serial port (RS232) 9-pin Cannon connector

⑧ USB strain-relief

fastener

⑨ PE terminal The PE terminal (M4 thread) must be connected to the protective ground conductor of the

Location of the connection elements (second COM interface)

PROFIBUS DP/MPI interface (RS 485 isolated), 9-pin Cannon socket or CAN fieldbus

(on request)

The USB strain relief must be fastened to the device enclosure with an oval-head screw

(M4 thread). The USB cables can be fastened to the strain-relief assembly with a cable

tie.

plant, in which the device is to be installed. The minimum conductor cross-section may not

be less than 2,5 mm2.

Pos Designation Description

① COM2 Serial port (RS232) 9-pin Cannon connector

SIMATIC IPC427C

18 Operating Instructions, 04/2009, A5E02414743-01

Page 19

Description

3.5 Design

3.5.3 Operator controls

On/Off switch

CAUTION

The On/Off switch does not disconnect the device from the supply voltage.

Position of on/off switch Pos Description

① The on/off switch turns off the output voltages of

the power supply but not disconnect from the

supply system.

The delivery condition is: Power switch turned

off.

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

19

Page 20

Description

3.5 Design

3.5.4 Status displays

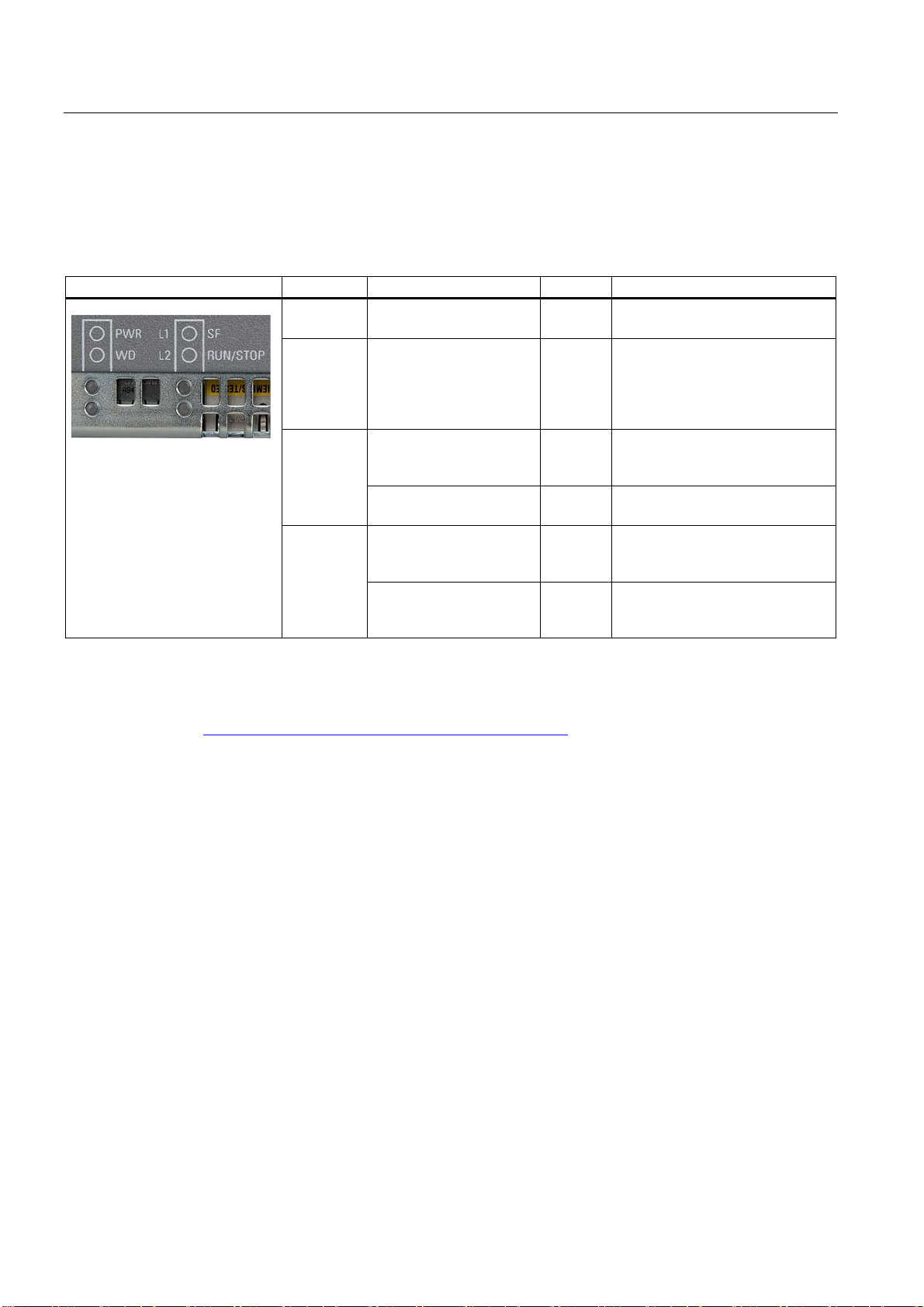

Status displays LED Meaning LED Description

1

You can find additional information about addressing the LEDs or the SRAM under a

PWR Power supply OFF

WD Watchdog status display OFF

L1

SF

L2

RUN/STOP

User LED L1 OFF

Group errors RED Can be controlled by controller

User LED L2 OFF

RUN

STOP

GREEN

GREEN

RED

YELLOW

RED

YELLOW

GREEN

GREEN

YELLOW

Windows operating system in the section "Output register LED L1/L2". Example programs

for addressing the LEDs under Windows XP and under RMOS are available under the FAQ

at the Customer Support site Industry Automation and Drive Technologies - Homepage

http://www.siemens.com/automation/service&support).

(

Standby mode

Supply voltage available

Watchdog disabled Watchdog

enabled, monitoring time not

expired

Watchdog enabled, monitoring

time expired

Can be controlled by user

programs1

program (e.g. WinAC)

Can be controlled by user

programs1

Can be controlled by controller

program (e.g. WinAC)

1

1

SIMATIC IPC427C

20 Operating Instructions, 04/2009, A5E02414743-01

Page 21

Application planning

4.1 Transport

Despite the device's rugged design, its internal components are sensitive to severe

vibrations or shock. You must therefore protect the device from severe mechanical stress

when transporting it.

You should always use the original packaging for shipping and transporting the device.

CAUTION

Risk of damage to the device!

If you are transporting the device in extreme weather conditions with large fluctuations in

temperature, care must be take to ensure that no moisture forms on or in the device

(condensation).

If condensation has developed on the device, wait at least 12 hours before you switch it on.

4

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

21

Page 22

Application planning

4.2 Unpacking and checking the delivery unit

4.2 Unpacking and checking the delivery unit

Unpacking the device

Note the following when unpacking the unit:

● It is advisable not to dispose of the original packing material. Keep it in case you have to

transport the unit again.

● Please keep the documentation in a safe place. It is required for initial commissioning and

is part of the device.

● Check the delivery unit for any visible transport damage.

● Verify that the shipment contains the complete unit and your separately ordered

accessories. Please inform your local dealer of any disagreements or transport damages.

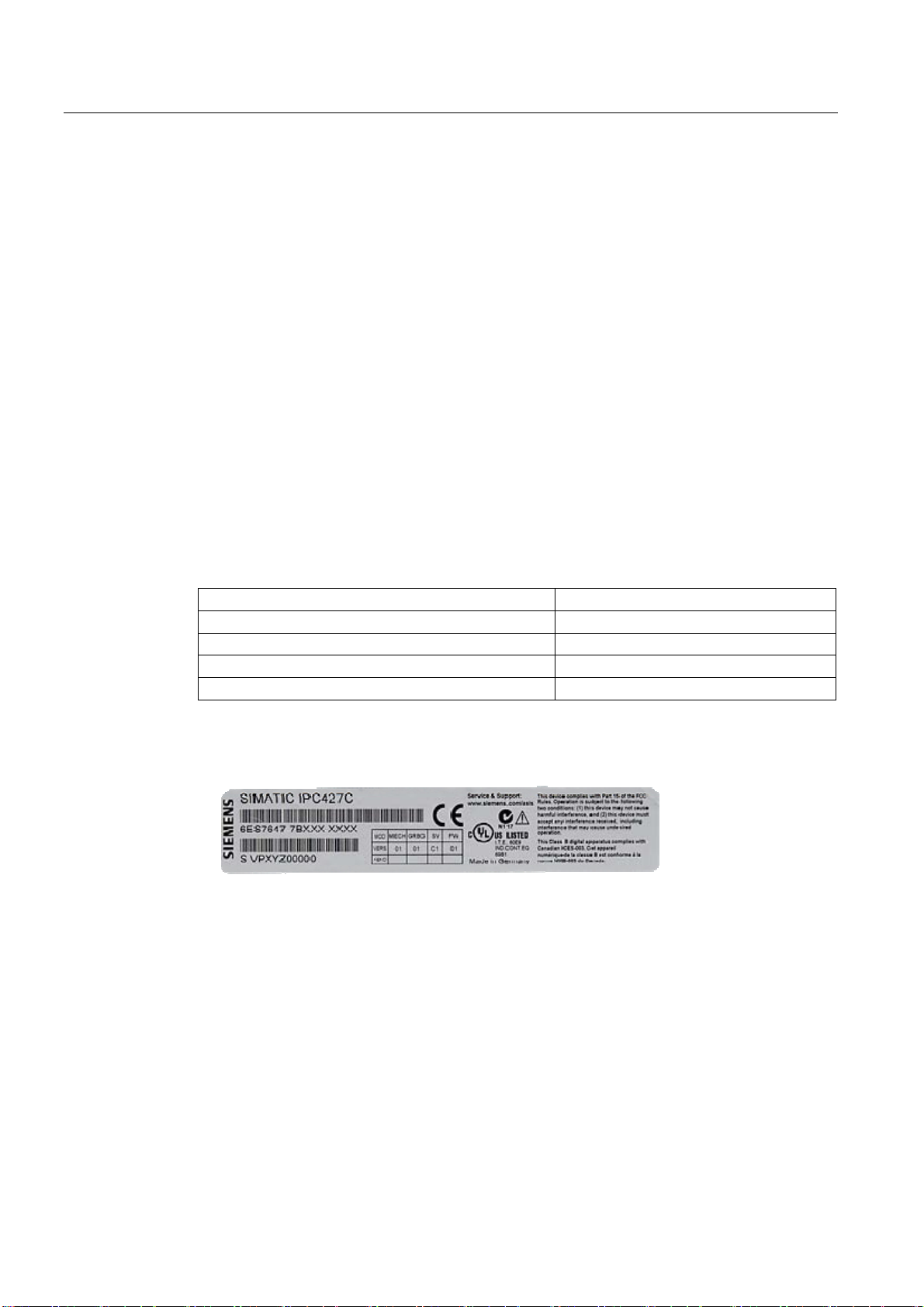

Noting the device identification data

The device can be identified uniquely with the help of these numbers in case of repairs or

theft.

Enter the data in the following table:

Serial number S VP ...

Order number of the device 6ES 7647-7B ...

Microsoft Windows Product Key

Ethernet address 1

Ethernet address 2

You can find the corresponding data here:

● Serial number: The serial number is available on the rating plate on the right side of the

device.

● Order number of the device: The order number is located on the rating plate.

SIMATIC IPC427C

22 Operating Instructions, 04/2009, A5E02414743-01

Page 23

Application planning

4.2 Unpacking and checking the delivery unit

● Ethernet address: The Ethernet address of the device is available in your BIOS Setup

(F2 function key) under Main > Hardware Options > Ethernet 1 Address or

Ethernet 2 Address.

● Microsoft Windows "Product Key" from the "Certificate of Authenticity" (COA): The COA

label is only present in pre-installed Windows Embedded Standard 2009 or

XP Professional and is affixed to the back of the device.

Figure 4-1 COA Label Windows Embedded Standard 2009

Figure 4-2 COA Label Windows XP Pro for Embedded Systems

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

23

Page 24

Application planning

4.3 Ambient and Environmental Conditions

4.3 Ambient and Environmental Conditions

When you plan your project, you should make allowances for:

● The climatic and mechanical environmental conditions specified in the specifications

given in your operating instructions.

● The device is approved for operation in closed rooms only.

● Avoid extreme ambient conditions. Protect the device against dust, moisture and heat.

● Do not place the device in direct sunlight.

● Ensure that the distance to other components or the sides of cabinets is at least 50 mm

above and 100 mm below the device.

● Do not cover the ventilation slots of the device.

● Always observe the mounting positions permitted for this device.

● The connected or built-in peripherals should not introduce a counter emf in excess of

0.5 V into the device.

SIMATIC IPC427C

24 Operating Instructions, 04/2009, A5E02414743-01

Page 25

Installing/mounting

5.1 Permitted mounting positions

NOTICE

The device is approved for operation in closed rooms only.

Ensure that there is a minimum clearance to the other components or the walls of a

housing:

• Below at least 100 mm

• Above at least 50 mm

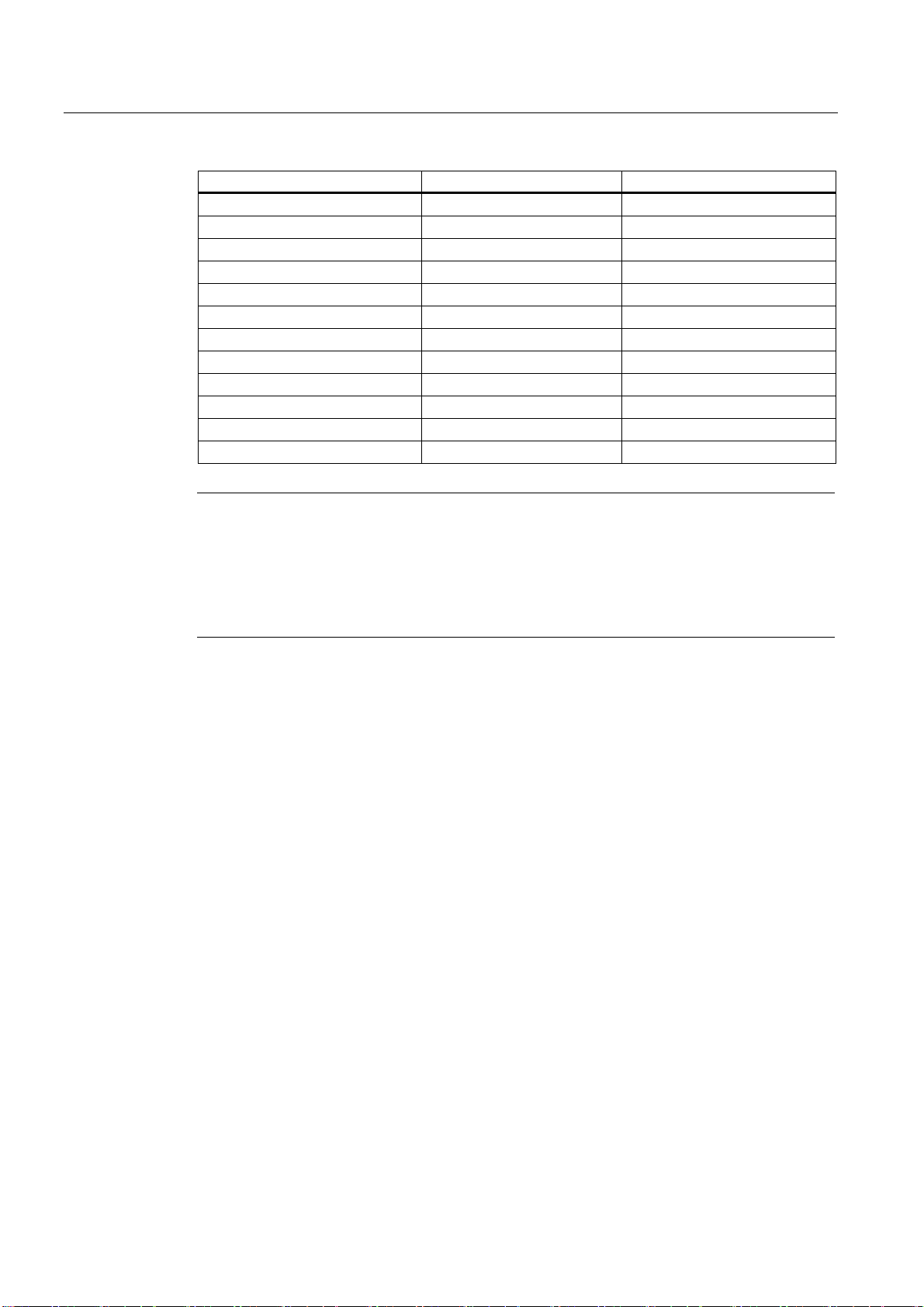

Horizontal (preferred position) Permitted temperatures

5

Operation with hard disk:

• with up to 3 expansion modules

(max. load 9 W): +5 to +40°C

Operation with CompactFlash card and/or SSD drive:

• with up to 3 expansion modules

(max. load 9 W): 0 to +45°C

• with up to 3 expansion modules

(max. load 9 W) in RAL: 0 to +50°C

Operation with Compact Flash cards:

• without expansion modules in RAL: 0 to +55°C

Vertical

(power supply at the top)

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

Operation with hard disk:

• with up to 3 expansion modules

(max. load 9 W): +5 to +40°C

With installed Compact Flash card:

• without expansion modules: 0 to +45°C

Operation with CompactFlash card and/or SSD drive:

• with up to 3 expansion modules

(max. load 9 W) in RAL: 0 to +45°C

Operation with Compact Flash cards:

• with up to 3 expansion modules

(max. load 9 W) in RAL: 0 to +50°C

Notes:

When mounted on a DIN rail, the device should be secured

to prevent shifting (e.g. with a DIN rail ground terminal).

25

Page 26

Installing/mounting

5.1 Permitted mounting positions

Suspended

Upright mounting Permitted temperatures

RAL = Restricted Access Location

(e.g. installation of the unit in a lockable cabinet)

Operation with CompactFlash card and/or SSD drive and

without expansion modules:

0 to +40°C

Note:

Mounting brackets are required if the device is suspended.

Operation with hard disk:

• with up to 3 expansion modules

(max. load 9 W): +5 to +40°C

With installed Compact Flash card:

• without expansion modules: 0 to +45°C

Operation with CompactFlash card and/or SSD drive:

• with up to 3 expansion modules

(max. load 9 W) in RAL: 0 to +45°C

Operation with Compact Flash cards:

• with up to 3 expansion modules

(max. load 9 W) in RAL: 0 to +50°C

NOTICE

The safety and installation instructions for the expansion modules should be followed if the

device is expanded with PCI-104 / PC/104-plus modules.

If necessary, the device should be installed in an enclosure that meets the requirements of

paragraphs 4.6 and 4.7.3 of IEC/UL/EN/DINEN60950-1.

SIMATIC IPC427C

26 Operating Instructions, 04/2009, A5E02414743-01

Page 27

Installing/mounting

5.2 Mounting information

5.2 Mounting information

Before you install the device, read the following mounting instructions.

NOTICE

Adhere to the SIMATIC assembly guidelines and the relevant DIN/VDE requirements or the

country-specific regulations when mounting in switching cabinets.

NOTICE

Ensure that the device is classified as "Open Type" when using the device in the area of

Industrial Control Equipment (UL508). A UL508 conform enclosure is therefore a

mandatory requirement for approval or operation according to UL508.

5.3 Mounting the device

Mounting methods

SIMATIC IPC427C can be mounted on DIN rails, with mounting brackets and in an upright

position.

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

27

Page 28

Installing/mounting

5.4 Mounting on DIN rails

5.4 Mounting on DIN rails

Mounting the device on DIN rails

Note

Use of Siemens 35 mm standard mounting rail is recommended.

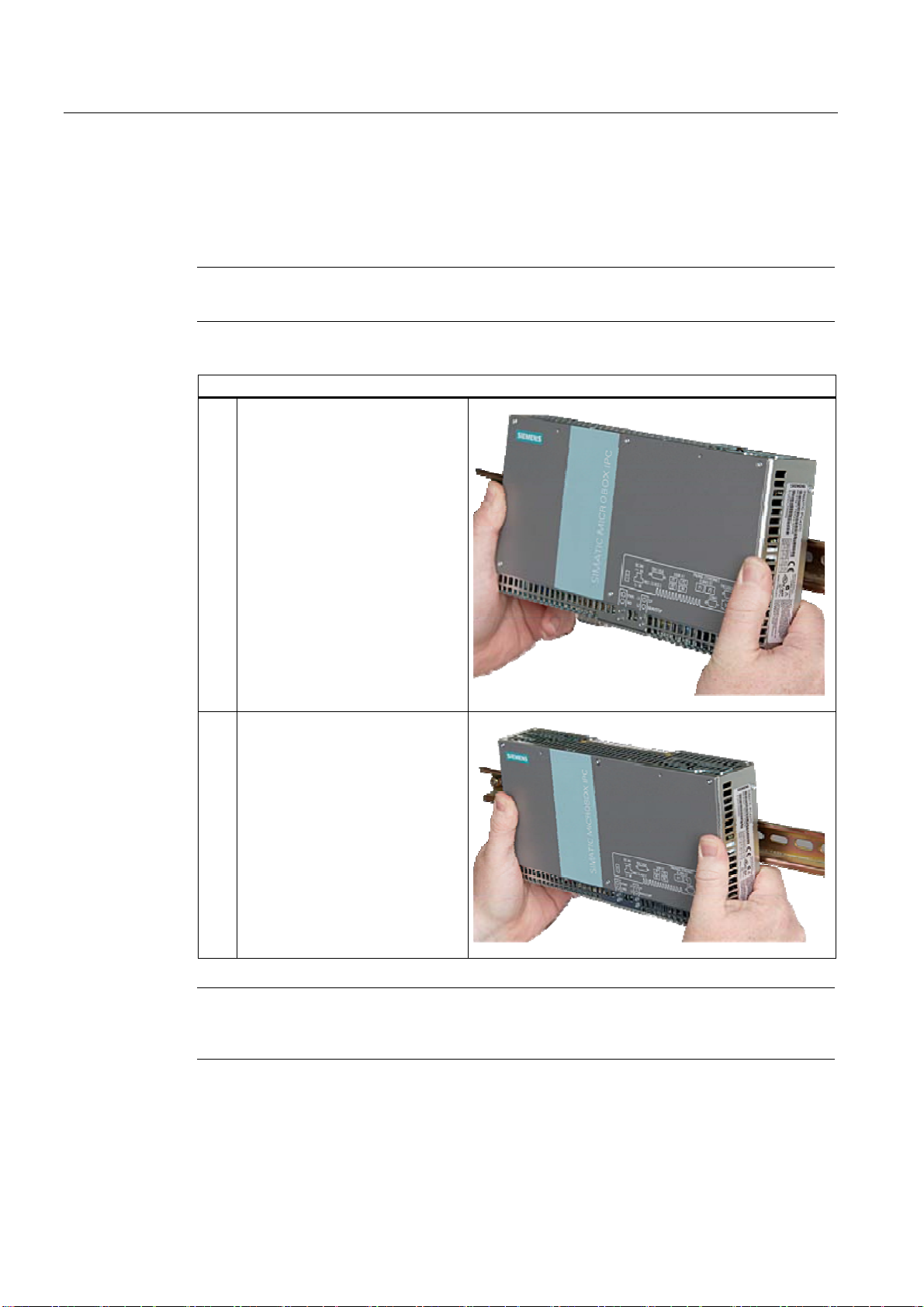

Steps for mounting on DIN rails

1. Set the device inclined on the

upper DIN rail.

2. Swing the device fully onto the rails

until both clamps completely latch.

Note

To ensure secure mounting on vertical mounting rails, a DIN rail ground terminal should be

mounted beneath the device.

SIMATIC IPC427C

28 Operating Instructions, 04/2009, A5E02414743-01

Page 29

Installing/mounting

5.4 Mounting on DIN rails

NOTICE

The rails are secured to a wall or cabinet similar to mounting with mounting brackets.

Ensure that the wall or ceiling can hold four times the total weight of the device (including

the rails and additional expansion modules). Also see section

brackets (Page

30).

Removing the device from the DIN rail

● Push down the device until the clamps release it.

● Swing the device out of the rails.

Mounting with mounting

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

29

Page 30

Installing/mounting

5.5 Mounting with mounting brackets

5.5 Mounting with mounting brackets

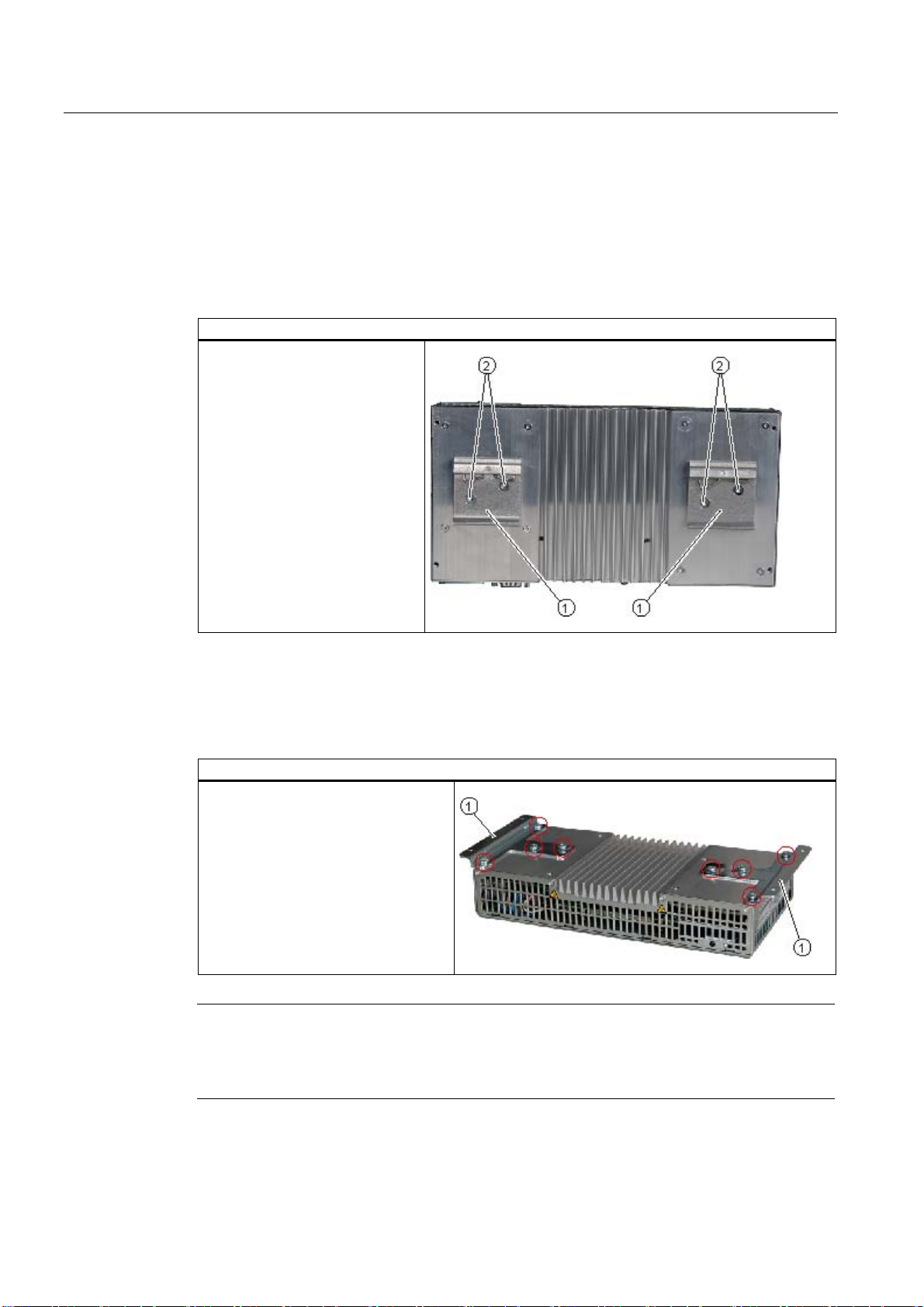

Removing mounting clamps from the device

Two mounting clamps are factory installed on the device for DIN rail mounting. These need

to be removed before mounting the mounting brackets.

Steps for removing the mounting clamps

Remove the four screws ② and

the two mounting clamps ① from

the back of the device.

Installing brackets on the device

Two mounting brackets are included in the device package. They can be installed on the

device with four screws supplied.

Steps for installing the mounting brackets

Install the mounting brackets on the

device.

Note

Required tools

You need a TORX T20 screwdriver to remove the mounting clamps and mount the mounting

brackets.

SIMATIC IPC427C

30 Operating Instructions, 04/2009, A5E02414743-01

Page 31

Installing/mounting

5.5 Mounting with mounting brackets

Mounting/demounting the device

The dimensions of the device with mounting brackets are listed under Dimension drawings of

the device with mounting brackets (Page

Mounting examples

Material Bore diameter Mounting

Concrete

Plasterboard

(min. 13 mm thick)

Metal

(min. 2 mm thick)

8 mm diameter

60 mm depth

14 mm diameter Gravity toggle: 4 mm diameter

5 mm diameter

99).

Dowel: 8 mm diameter

50 mm length

Screws: 4 mm diameter

50 mm length

50 mm length

Metal screws M 4: 4 mm diameter

15 mm length

WARNING

Ensure that the wall or ceiling can hold four times the total weight of the device (including

the cabinet brackets and additional expansion modules).

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

31

Page 32

Installing/mounting

5.6 Upright mounting

5.6 Upright mounting

With the available optional vertical mounting kit you have the possibility to implement a place

saving installation.

Mounting the vertical mounting bracket onto the device

① Device ② Screws ③ Vertical mounting bracket

Note

• Information on installation and operation is available in the supplement of the

accessories.

SIMATIC IPC427C

32 Operating Instructions, 04/2009, A5E02414743-01

Page 33

Connecting

6.1 Connecting peripheral equipment

NOTICE

Connect only peripheral devices approved for industrial applications conforming to

EN 61000-6-2 / IEC 61000-6-2.

Note

Hot-plug peripherals (USB) may be connected while the PC is in operation.

CAUTION

Peripheral devices that are incapable of hot-plugging may only be connected after the

device has been disconnected from the power supply.

6

CAUTION

Strictly adhere to the specifications for peripheral equipment.

Note

A DVI or CRT monitor should be connected and switched on when the device boots in order

for it to be correctly detected by the BIOS and the operating system. The screen may

otherwise remain dark.

NOTICE

The connected or built-in peripherals, such as USB drives, should not introduce a counter

emf into the device.

A counter emf greater than 0.5 V to ground on the + 3.3 VDC / + 5 VDC / + 12 VDC power

rail due to a connected or integrated component can prevent normal operation or even

destroy components of the device.

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

33

Page 34

Connecting

6.2 Connecting the 24 V DC power supply

6.2 Connecting the 24 V DC power supply

To be noted before you connect the device

Note the following in order to operate the device safely and according to regulation:

Connecting

WARNING

The device should only be connected to a 24V DC power supply which satisfies the

requirements of safe extra low voltage (SELV).

If the device is used on a wall, in an open rack or other similar locations, an NEC Class 2

current source is required in order to meet the UL requirements (UL 60950-1). In all other

cases (IEC / EN / DIN EN 609501) either a current source of limited output (LPS = Low

Power Source), or a line-side fuse or a line-side circuit breaker is necessary. The power

needs to be limited to a value below 4.16 A. The fuse value required: Max. 4 A.

Use the special plug supplied to connect the supply voltage. Connect the PE conductors as

described in the next section.

NOTICE

The permitted cable cross-section for the 24 VDC connection is 0.75 mm

2

to 2.5 mm2.

NOTICE

If a CompactFlash card is used in the device, make sure that the card is seated correctly

before you connect it.

Steps for connecting the device to the 24 V DC power supply

1. Switch off the 24 V DC power source.

2. Connect the power supply using the plug

(included in the package).

3. Connect the PE conductor.

3LQ

0LQ

SIMATIC IPC427C

34 Operating Instructions, 04/2009, A5E02414743-01

Page 35

Connecting

6.3 Protective ground connection

6.3 Protective ground connection

The PE terminal (M4 thread) on the device (large surface, large-area contact) must be

connected to the PE conductor on the cabinet or system in which the PC is to be installed.

The conductor cross-section must not be less than 2.5 mm

The PE terminal is needed to protect the device and ensures that interference signals

generated by external power cables, signal cables or cables to the I/O modules are safely

discharged to earth.

Required tool for protective earth terminal: TORX T20 screwdriver

Protective earth terminal

Connect the PE terminal (M4 thread)

① on the device to the PE conductor

on the cabinet or system in which the

PC will be installed. The minimum

conductor cross-section may not be

less than 2,5 mm

2

.

2

.

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

35

Page 36

Connecting

6.4 USB strain-relief

6.4 USB strain-relief

The USB strain-relief provided as an accessory is used to prevent accidental loosening of

the USB cable from the device. A cable binder (not included in the package) is needed to

use this accessory.

To fix the USB strain relief, you will need a TORX T20 screwdriver.

Steps for connecting the USB strain-relief

1. Fasten the USB strain-relief ① to the

device housing with an oval-head

screw (M4 thread).

2. Thread the cable tie ② through the

comb of the USB strain-relief to

clamp the USB cable.

SIMATIC IPC427C

36 Operating Instructions, 04/2009, A5E02414743-01

Page 37

Commissioning

7.1 Note before commissioning

Factory state

The SIMATIC IPC427C is available in the following versions:

● With the Windows Embedded Standard 2009 operating system (pre-installed on

CompactFlash card, SSD drive or the hard disk)

● With the Windows XP Professional operating system (pre-installed on SSD drive or the

hard disk)

● Without operating system

Connections before commissioning

Before connecting the device to the power supply, a DVI or CRT monitor should be

connected in order for it to be correctly detected by the BIOS and the operating system

during startup.

7

CAUTION

Risk of damage to the device

If condensation has developed, wait at least 12 hours before commissioning the device.

NOTICE

Windows Embedded Standard 2009: Read the EWF and FBWF information

Two configurable write filters (Enhanced Write Filter and File Based Write Filter) are

provided with Windows Embedded Standard 2009. Please be aware of this when activating

and using the EWF/FBWF information, otherwise you may experience data loss.

Note

Setting up CompactFlash cards on the employed device

If you want to use CompactFlash cards with the device, they need to be set up on the

device. CompactFlash cards set up on other devices will not boot due to the differing drive

parameters.

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

37

Page 38

Commissioning

7.2 Commissioning - Windows Embedded Standard 2009

7.2 Commissioning - Windows Embedded Standard 2009

7.2.1 Basic commissioning - initial startup

Requirements

● The device is connected to the 24 VDC power supply.

● Equipotential bonding is connected.

● The cables are correctly plugged in.

Configuring the operating system

When the computer is started with the power switch for the first time, the

Windows Embedded Standard 2009 operating system on the Compact Flash card or hard

disk is configured automatically.

Proceed as follows:

1. Switch the device on using the On/Off switch. The PC performs a self-test (POST).

During the self-test, this message appears:

Press F2 go to Setup Utility or

Press ESC go to Boot Manager

2. Wait until this message is cleared, then follow the instructions on the screen.

NOTICE

The device may not be switched off at any time during the installation process.

Do not change the default BIOS settings, otherwise the operating system setup may

become corrupted.

3. Restart

After you have entered all the necessary information and the operating system is

configured, you are prompted to restart the system. Respond to this prompt with Yes.

Note

System startup can take considerably longer than usual for the initial commissioning.

Only a blue or black screen is displayed for several minutes.

When you switch on the PC now, the logon window or the user interface of the

Windows Embedded Standard 2009 operating system is automatically opened when the

startup routine is completed.

Note

To prevent data loss, it is advisable to create an image of your system partition after initial

commissioning.

SIMATIC IPC427C

38 Operating Instructions, 04/2009, A5E02414743-01

Page 39

Commissioning

7.2 Commissioning - Windows Embedded Standard 2009

Switch off the device

When you work with Windows Embedded Standard , always shut down the PC with the

command Start > Shut Down.

Note

The Enhanced Write Filter should be enabled following the installation of Windows

Embedded Standard on a CompactFlash card or SSD drive. When this is enabled, the

device can be switched off with the power switch by disconnecting the power supply.

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

39

Page 40

Commissioning

7.3 Commissioning - Windows XP Professional

7.3 Commissioning - Windows XP Professional

7.3.1 Basic commissioning - initial startup

Requirements

● The device is connected to the 24 VDC power supply.

● Equipotential bonding is connected.

● The cables are correctly plugged in.

Configuring the operating system

When the computer is started with the power switch for the first time, the Windows XP

Professional operating system on the hard disk or SSD drive is configured automatically.

Proceed as follows:

1. Switch the device on using the On/Off switch. The PC performs a self-test (POST).

During the self-test, this message appears:

Press F2 go to Setup Utility or

Press ESC go to Boot Manager

2. Wait until this message is cleared, then follow the instructions on the screen.

NOTICE

The device may not be switched off at any time during the installation process.

Do not change the default BIOS settings, otherwise the operating system setup may

become corrupted.

3. Automatic restart

After you have entered all necessary information and the operating system is configured,

the PC is automatically restarted and displays the user interface of the operating system.

Note

System startup can take considerably longer than usual for the initial commissioning.

When you switch on the PC now, the user interface of the Windows XP Professional

operating system is automatically opened when the startup routine is completed.

Note

To prevent data loss, it is advisable to create an image of your system partition after initial

commissioning.

SIMATIC IPC427C

40 Operating Instructions, 04/2009, A5E02414743-01

Page 41

Commissioning

7.3 Commissioning - Windows XP Professional

Switch off the device

When you work with Windows XP Professional, always shut down the PC with the command

Start > Shut Down. You can then switch off the device with the power switch or by

disconnecting the power supply.

7.3.2 Setting up the language selection for Windows XP Professional / Embedded Standard

The Multilanguage User Interface (MUI) allows you to set up the Windows XP Professional /

Embedded Standard menus and dialogs for additional languages.

Default language of your Windows XP MUI installation is English and a US keyboard layout.

You can change the language in the Control Panel. Select:

Start > Control Panel > Regional and Language Options

Languages, tab Language used in menus and dialogs

field.

For the Regional and Language Options set the default as non-Unicode programs under Advanced in

addition to the language for menus and dialogs.

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

41

Page 42

Commissioning

7.4 Commissioning - other operating systems

7.4 Commissioning - other operating systems

7.4.1 Commissioning - guide

The desired operating system can be installed on the hard disk, CompactFlash card or SSD

drive. A variety of USB devices (hard disk, external floppy or CD-ROM drive, USB stick) or

Compact Flash cards can be used as boot media.

&RPPLVVLRQLQJ

6,0$7,&,3&&

The following provides an overview of the steps involved in commissioning:

Steps Description

1 Select and create a boot

2 Install the operating system

3 Select final boot medium In the BIOS Setup, select the medium on which the operating

Additional information

Further information about installation and commissioning is available in the documentation of

the respective operating system.

6HOHFWLQJFUHDWLQJ

WKHERRWPHGLXP

IRULQVWDOODWLRQ

medium for installation.

on the boot medium.

,QVWDOOLQJWKH

RSHUDWLQJV\VWHP

6HOHFWLQJWKHDFWLYH

ERRWPHGLXP

IURPWKHERRWPHGLXP

Select a suitable boot medium for the operating system to be

used in the BIOS Setup (CD-ROM drive, Compact Flash card,

hard disk or USB device). See Boot menu (Page 126).

If no boot medium is available, one must be created based on

the instructions provided by the respective operating system

documentation.

For example, you can use the SIMATIC PC/PG Image Creator

tool to make a USB stick a bootable medium.

Install the operating system based on the instructions provided

by the respective documentation.

system has been installed.

SIMATIC IPC427C

42 Operating Instructions, 04/2009, A5E02414743-01

Page 43

Integration into an Automation System

8.1 Overview

Options of integration in existing or planned system environments/networks:

Ethernet

The integrated Ethernet port (10/100/1000 Mbps) can also be used for communication and

for data exchange with automation devices such as SIMATIC S7.

For this purpose you require the "SIMATIC NET" software package.

PROFIBUS/MPI

The optional electrically isolated PROFIBUS interface (12 Mbps) can be used to interconnect

distributed field devices or for coupling to SIMATIC S7.

The "SOFTNET for PROFIBUS" software package is required for coupling to S7 automation

systems.

8

CAN

CAN interface for connection to CAN field systems (on request).

RS232

The serial port can be used for data communication (via terminal applications, for example).

Additional information

Additional information is available in the catalog and the online ordering system Industrial

Automation and Drive Technologies (

http://mall.automation.siemens.com).

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

43

Page 44

Integration into an Automation System

8.1 Overview

SIMATIC IPC427C

44 Operating Instructions, 04/2009, A5E02414743-01

Page 45

Functions

9.1 Monitoring Functions

9.1.1 Introduction

Even in its basic version, the device comes with optional monitoring functions. When used in

combination with the appropriate software, the following functions for displaying, monitoring

and controlling are available:

● Temperature monitoring (over / under temperature)

● Monitoring of the battery level

● Monitoring of hard disks, CompactFlash cards and SSD drives with S.M.A.R.T.

functionality

● Watchdog (hardware or software reset of the computer)

● Operating hours meter (information on the cumulative run time)

9

SIMATIC PC DiagBase software

With the SIMATIC PC DiagBase software (included in product package), you can use these

functions for local monitoring. You can use the DiagBase Management Explorer application

for general monitoring or DiagBase Alarm Manager for notification of individual alarms.

Additional information on the functions of the SIMATIC PC DiagBase software is available in

the online help.

SIMATIC PC DiagMonitor software

SIMATIC PC DiagMonitor software is provided on CD (not included in the scope of delivery).

It contains the monitoring software, the software for the stations to be monitored and a library

for creating custom applications.

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

45

Page 46

Functions

9.1 Monitoring Functions

9.1.2 Temperature monitoring/display

Temperature monitoring

The temperature is recorded by means of three thermocouples. The sensors monitor the

processor temperature, the temperature near the RAM module and the motherboard around

the DVI/VGA socket.

If one of the three configured temperature values is exceeded (CPU: 100°C, RAM: 95°C,

motherboard: 95°C), the following fault reaction is triggered:

Reaction Option

The DiagBase or DiagMonitor software is enabled None

The temperature error is retained in memory until temperatures have fallen below the

thresholds and it is reset by one of the following measures:

● Acknowledgment of the error message by the monitoring software

● Restart of the device

SIMATIC IPC427C

46 Operating Instructions, 04/2009, A5E02414743-01

Page 47

Functions

9.1 Monitoring Functions

9.1.3 Watchdog (WD)

Function

If the user program does not respond to the watchdog within the predetermined monitoring

time, the watchdog monitors the program process and informs the user about various

reactions.

After POWER ON of the device or after a HW RESET (cold restart), the watchdog is in idle

state, i.e. a reaction of the WD will not be triggered and the Watchdog LED is switched off.

Watchdog reactions

If the watchdog is not triggered again within the set time, the following reactions will be

triggered:

Reaction Option

Switch watchdog LED to red None

Trigger a PC reset Configurable

Enabling the DiagBase or DiagMonitor software None

Note

If the desired device reset is not performed, go the Advanced menu of the BIOS Setup and

set the SafeCard functions to Enabled. Contact Customer Support for a detailed description

of the Watchdog functions.

WD monitoring times

The monitoring times are defined as follows:

Normal mode: 94 ms, 210 ms, 340 ms, 460 ms, 590 ms, 710 ms, 840 ms and 960 ms.

Macro mode: 2s, 4s, 6s, 8s, 16s, 32s, 48s and 64s.

Note

The watchdog is retriggered if the monitoring time is changed at the active watchdog (that is

while the watchdog is running)!

SIMATIC IPC427C

Operating Instructions, 04/2009, A5E02414743-01

47

Page 48

Functions

9.2 Enhanced Write Filter (EWF)

9.2 Enhanced Write Filter (EWF)

Purpose and function

The EWF (Enhanced Write Filter) is a function that is only available with Windows

Embedded operating systems. It provides write protection that can be configured by the

user.

The Enhanced Write Filter allows you to boot Windows Embedded Standard 2009 from

write-protected media (such as CD-ROM), to write protect individual partitions and adapt the

performance of the file system to your needs (when using CompactFlash cards, for

example).

EWF can be used to minimize write access to Compact Flash cards. This is important

because the write cycles on Compact Flash cards are limited due to technical reasons. We

therefore recommend using EWF if you work with Compact Flash cards.

Set EWF

CAUTION

Activate only one write filter per partition - otherwise you may incur data loss.

Both EWF and FBWF are preinstalled in the SIMATIC IPC images.

Ensure that only one write filter is enabled on a partition, otherwise you may incur data loss.

Note

The Enhanced Write Filter is disabled by default for Windows Embedded Standard 2009.

After the operating system has been set up, you should back up your date and then enable

the EWF.

The EWFMGR.EXE program can be used to install, enable or disable the EWF. Use the

command prompt to call up the program. The following functions are available:

Function Command

Write-protect drive C: Switching on

Write-protect drive C: disable

(modified files are accepted)

Modified files on drive C: Accept

Display information about the EWF drive

Display help

ewfmgr c: -enable

ewfmgr c: -commitanddisable

ewfmgr c: -commit

ewfmgr c:

ewfmgr c: /h

Note

The EWF commands affecting the write protection do not become active until after the next

booting process.

SIMATIC IPC427C

48 Operating Instructions, 04/2009, A5E02414743-01

Page 49

Functions

9.2 Enhanced Write Filter (EWF)

Special features for the use of Enhanced Write Filters (EWF)

● In the event of a power failure, if the EWF is enabled changes made after the boot

sequence on drive C: are lost.

To prevent data loss in the event of a power failure, the use of a USV is recommended.

● You can save the files in the EWF RAM overlay to the Compact Flash card or the hard

disk before you shut down the device. To do so, enter the following command in the

command prompt: