Page 1

Page 2

Page 3

SINAMICS

Intelligent Operating Panel 2 (IOP

Operating Instructions

Edition 06/2020, Firmware IOP-2 V2.6

06/2020, FW V2.6

A5E39549448B AH

Changes in this manual

1

Fundamental safety

instructions

2

Safety notes

3

Overview

4

Installation

5

Setup Menu

6

Control menu

7

Menu

8

Options

9

Technical data

10

-2)

Page 4

Siemens AG

Divis

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: (null)

Ⓟ

Copyright © Siemens AG 2020.

All rights reserved

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

ion Digital Factory

07/2020 Subject to change

Page 5

Table of contents

1 Changes in this manual ......................................................................................................................... 5

2 Fundamental safety instructions ........................................................................................................... 7

2.1 General safety instructions ................................................................................................... 7

2.2 Warranty and liability for application examples ..................................................................... 7

2.3 Security information ............................................................................................................ 7

3 Safety notes ........................................................................................................................................... 9

3.1 Warnings and cautions ......................................................................................................... 9

4 Overview .............................................................................................................................................. 11

4.1 Introduction ...................................................................................................................... 11

4.2 Layout and functions ......................................................................................................... 12

4.3 Screen icons ...................................................................................................................... 14

4.4 Menu structure .................................................................................................................. 16

5 Installation ........................................................................................................................................... 17

5.1 Fitting the IOP-2 ................................................................................................................ 17

5.2 Initial set-up ...................................................................................................................... 18

5.3 Changing the Status screens .............................................................................................. 22

5.4 User definable labels on status screen ................................................................................ 24

5.5

6 Setup Menu ......................................................................................................................................... 27

6.1 Example Setups ................................................................................................................. 28

6.1.1 Quick Startup with the IOP-2 .............................................................................................. 31

6.1.2 Advanced Startup with the IOP-2 ........................................................................................ 35

7 Control menu ....................................................................................................................................... 39

7.1 Setpoint ............................................................................................................................ 40

7.2 Reverse .............................................................................................................................. 40

7.3 Jog .................................................................................................................................... 41

7.4 Custom Hand mode ........................................................................................................... 41

Upgrading the IOP-2 firmware ............................................................................................ 25

7.5 Startup in Hand mode ........................................................................................................ 43

7.6 HAND/AUTO disable ........................................................................................................... 44

8 Menu .................................................................................................................................................... 47

8.1 Menu overview .................................................................................................................. 47

8.2 Diagnostics ........................................................................................................................ 48

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

3

Page 6

Table of contents

8.3 Parameters ........................................................................................................................ 51

8.4 Up/Download .................................................................................................................... 54

8.5 Support ............................................................................................................................. 59

8.6 Customer parameter sets ................................................................................................... 61

8.7 Extras Menu ...................................................................................................................... 65

9 Options ................................................................................................................................................ 71

9.1 Door mounting kit ............................................................................................................. 71

9.2 Hand-held device ............................................................................................................... 74

10 Technical data...................................................................................................................................... 79

10.1 Technical specifications ..................................................................................................... 79

Index .................................................................................................................................................... 81

Intelligent Operating Panel 2 (IOP-2)

4 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 7

1

Changes to this manual - Edition 06/2020

Listed below and the specific changes that have been incorporated in this new version of the

IOP-2 Operating Instructions.

Changes

• New topic: Command Line Interface (CLI).

Up/Download (Page 54).

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

5

Page 8

Changes in this manual

Intelligent Operating Panel 2 (IOP-2)

6 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 9

2

WARNING

Danger to life if the safety instructions and residual risks are not observed

• Consider the residual risks for the risk evaluation.

WARNING

emergency off.

2.1 General safety instructions

If the safety instructions and residual risks in the associated hardware documentation are

not observed, accidents involving severe injuries or death can occur.

• Observe the safety instructions given in the hardware documentation.

Malfunctions of the machine as a result of incorrect or changed parameter settings

As a result of incorrect or changed parameterization, machines can malfunction, which in

turn can lead to injuries or death.

• Protect the parameterization against unauthorized access.

• Handle possible malfunctions by taking suitable measures, e.g. emergency stop or

2.2 Warranty and liability for application examples

Application examples are not binding and do not claim to be complete regarding

configuration, equipment or any eventuality which may arise. Application examples do not

represent specific customer solutions, but are only intended to provide support for typical

tasks.

As the user you yourself are responsible for ensuring that the products described are

operated correctly. Application examples do not relieve you of your responsibility for safe

handling when using, installing, operating and maintaining the equipment.

2.3 Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

7

Page 10

Fundamental safety instructions

WARNING

• On completion of commissioning, check all security-related settings.

2.3 Security information

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be connected

to an enterprise network or the internet if and to the extent such a connection is necessary

and only when appropriate security measures (e.g. firewalls and/or network segmentation)

are in place.

For additional information on industrial security measures that may be implemented, please

visit

https://www.siemens.com/industrialsecurity (https://www.siemens.com/industrialsecurity

).

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply the latest updates may increase customer’s exposure to

cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

https://www.siemens.com/industrialsecurity

(https://new.siemens.com/global/en/products/services/cert.html#Subscriptions

).

Further information is provided on the Internet:

Industrial Security Configuration Manual

(https://support.industry.siemens.com/cs/ww/en/view/108862708

)

Unsafe operating states resulting from software manipulation

Software manipulations, e.g. viruses, Trojans, or worms, can cause unsafe operating states

in your system that may lead to death, serious injury, and property damage.

• Keep the software up to date.

• Incorporate the automation and drive components into a holistic, state-of-the-art

industrial security concept for the installation or machine.

• Make sure that you include all installed products into the holistic industrial security

concept.

• Protect files stored on exchangeable storage media from malicious software by with

suitable protection measures, e.g. virus scanners.

Intelligent Operating Panel 2 (IOP-2)

8 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 11

3

DANGER

Ensuring a safe and stable state

potentially dangerous conditions exist.

WARNING

command source from the PLC.

WARNING

appropriate protection measures, e.g. virus scanners.

3.1 Warnings and cautions

Warnings and cautions

During commissioning of the converter it is essential to ensure that the system is in a safe

and stable state, as some commissioning processes have the potential to start the motor.

Therefore it is important to secure any loads and ensure that should the motor start, no

The converter will stop if the IOP-2 is removed when in Hand mode

When the IOP-2 is in Hand mode, that is, when the command source is switched to Hand

and all OFF and RUN commands are given via the IOP-2 buttons.

When in the Hand mode, if the IOP-2 is removed from the converter, the converter will stop

within a few seconds of the IOP-2 being removed.

Before removing the IOP-2, ensure that the IOP-2 is placed in AUTO mode and receiving its

Risk of death due to software manipulation when using exchangeable storage media

Storing files onto exchangeable storage media amounts to an increased risk of infection of

the commissioning PCs, e.g. with viruses or malware. Incorrect parameter assignment can

cause machines to malfunction, which can lead to injuries or death.

• Protect files stored on exchangeable storage media from malicious software using

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

9

Page 12

Safety notes

WARNING

Risk of death due to software manipulation when using exchangeable storage media

Note

•

• The IOP-2 will set the USS PZD (P2012) length to 4 when connected to the converter.

3.1 Warnings and cautions

Storing the parameterization (incl. Safety Integrated parameterization) on exchangeable

storage media carries the risk that the original parameterization (with Safety Integrated) will

be overwritten, for example, by the IOP-2 of another drive without Safety Integrated.

Incorrect parameter assignment can cause machines to malfunction, which can lead to

injuries or death.

• Ensure that only the IOP-2 that belongs to the respective converter is used.

• Ensure that only trained or authorized personnel have access to the enclosures, cabinets

or electrical equipment rooms.

The IOP-2 can be fitted to and removed from the converter while power is applied.

Intelligent Operating Panel 2 (IOP-2)

10 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 13

4

4.1 Introduction

Compatibility

The Intelligent Operator Panel 2 (IOP-2) has been designed to enhance the interface and

communications capabilities of SINAMICS Inverters.

The IOP-2 connects to the Inverter through an RS232 interface. It has been designed to

automatically recognize the following devices from the SINAMICS range:

• SINAMICS G120 CU230P-2

• SINAMICS G120 CU240B-2

• SINAMICS G120 CU240E-2

• SINAMICS G120 CU250S-2

• SINAMICS G120C

• SINAMICS G120D-2 CU240D-2*

• SINAMICS G120D-2 CU250D-2*

• SINAMICS ET 200pro FC-2*

• SINAMICS G110D*

• SINAMICS G110M*

• SINAMICS G120X

• SINAMICS G120XA

*Denotes Control Units that require the IOP-2 Hand-Held Kit to connect the IOP to the Control

Unit.

Hand-Held Kit order number: 6SL3255-0AA00-4HA1.

Optical cable order number: 3RK1922-2BP00

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

11

Page 14

Overview

Note

IOP functional support

•

•

•

– The selected functional group filtering of the parameters.

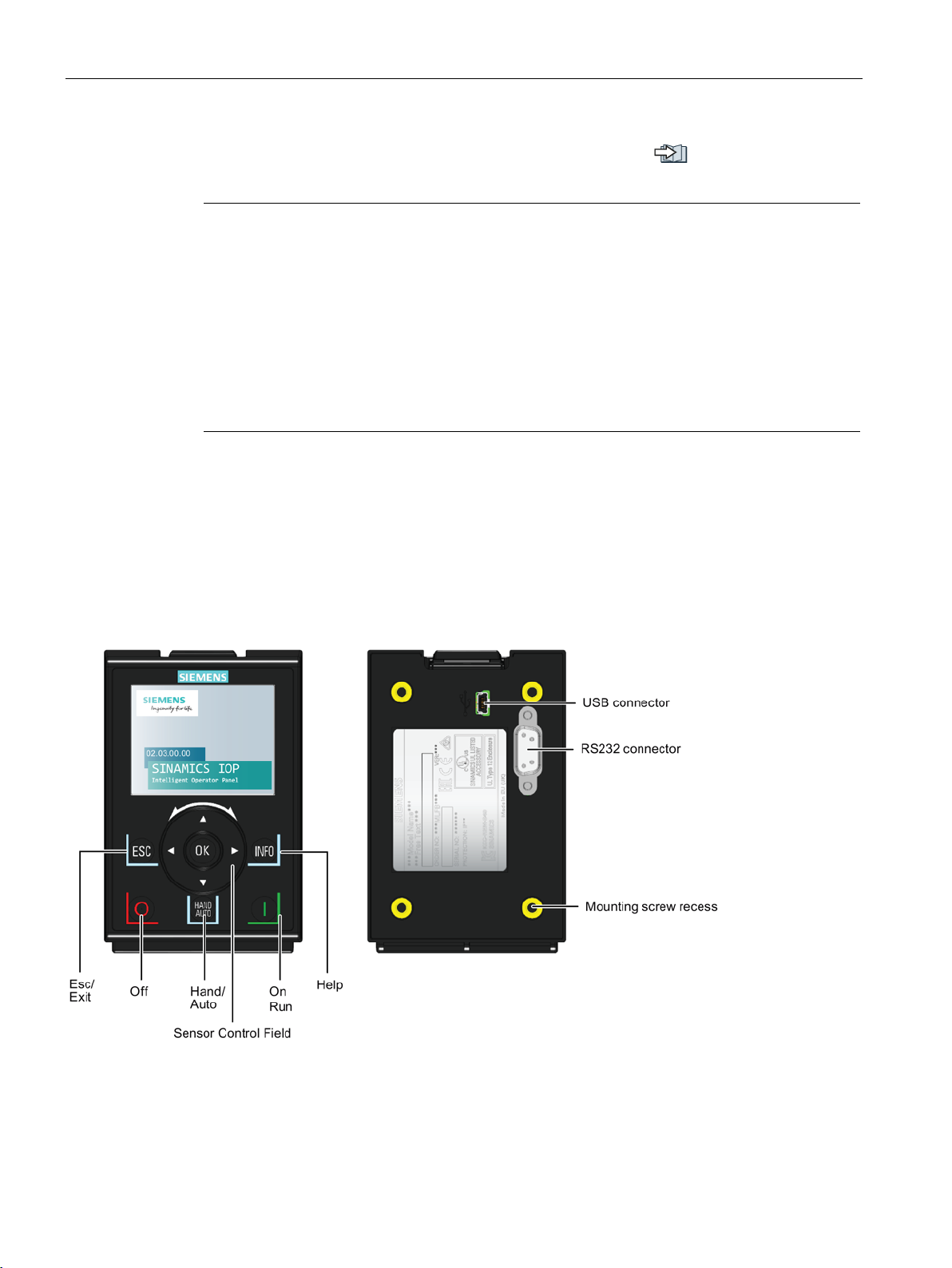

4.2 Layout and functions

For information on firmware and language upgrades, please see Upgrading the IOP-2

firmware (Page 25).

Drives with SINAMICS firmware 4.7 SP3 or above will support the new commission

processes of "Quick Startup" and "Advanced Startup".

Drives with GP firmware prior to version 3.4 are not fully supported by the IOP-2.

The actual menu structure and functionality of the IOP-2 will be influenced by the

following factors:

– The software version and type of Control Unit to which the IOP-2 is fitted.

– The firmware and software version of the IOP-2.

4.2 Layout and functions

Overview

Figure 4-1 Layout of the IOP-2

The physical layout of the IOP-2 is shown below:

Intelligent Operating Panel 2 (IOP-2)

12 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 15

Overview

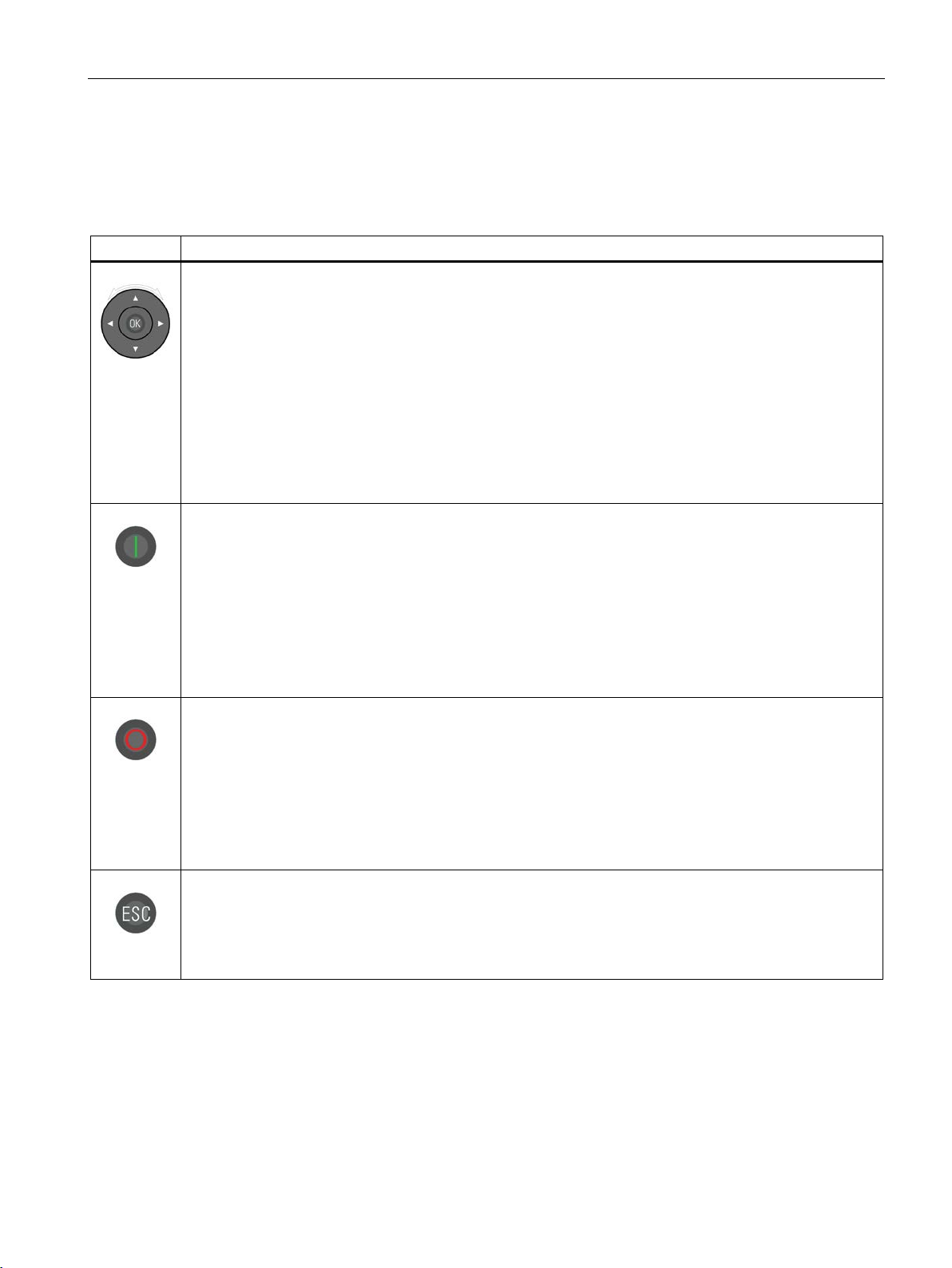

Key

Function

The Sensor Control Field has the following functions:

The ON key has the following functions:

When the converter is running in HAND mode, the motor stops when switched to AUTO.

The OFF key has the following functions:

down time set in parameter P1121.

The ESC key has the following functions:

When using the ESC key in the parameter editing mode, no data is saved unless the OK key is pressed first.

4.2 Layout and functions

The IOP-2 is operated by using a Sensor Control Field and five additional buttons. The specific

functions of the Sensor Control Field and buttons are shown in the table below.

Table 4- 1 Function of the IOP-2 controls

• In a menu, sliding your finger around the Sensor Control Field changes the selection.

• When a selection is highlighted, pressing the OK button in the centre of the Sensor Control Field confirms

the selection.

• When editing a parameter, sliding your finger around the Sensor Control Field changes the displayed

value; clockwise increases the value and anti-clockwise decreases the displayed value.

• When editing parameter or search values there is a choice to edit individual digits using the arrow keys or

an entire value using the Sensor Control Field. The speed with which you slide your finger around the

Sensor Control Field increases or decreases the speed of movement of the cursor.

• The Sensor Control Field has integrated arrows which can be used to navigate through the menus and

individual digits in the inputs fields.

• In AUTO mode can be changed by pressing the HAND/AUTO key.

• In HAND mode the converter is started - the converter status icon starts turning.

Notes:

For Control Units with firmware versions less than 4.0:

When running in AUTO mode, HAND mode cannot be selected unless the converter is stopped.

For Control Units with firmware versions 4.0 or greater:

When running in AUTO mode, HAND mode can be selected and the motor will continue to run at the last

selected setpoint speed.

• If pressed for longer than 3 seconds the converter will perform an OFF2; the motor will then coast down

to a standstill. Note: 2 presses of the OFF key within 3 seconds will also perform and OFF2.

• If pressed for less than 3 seconds the following actions will be performed:

– If in AUTO mode the screen will display an information screen stating that the command sources is

AUTO and can be changed using the HAND/AUTO key. The converter will not be stopped.

– If in HAND mode the converter will perform an OFF1; the motor will come to a standstill in the ramp-

• If pressed for less than 3 seconds the IOP-2 returns to the previous screen or if a value has been edited,

the new value is not saved.

• If pressed longer than 3 seconds the IOP-2 returns to the status screen.

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

13

Page 16

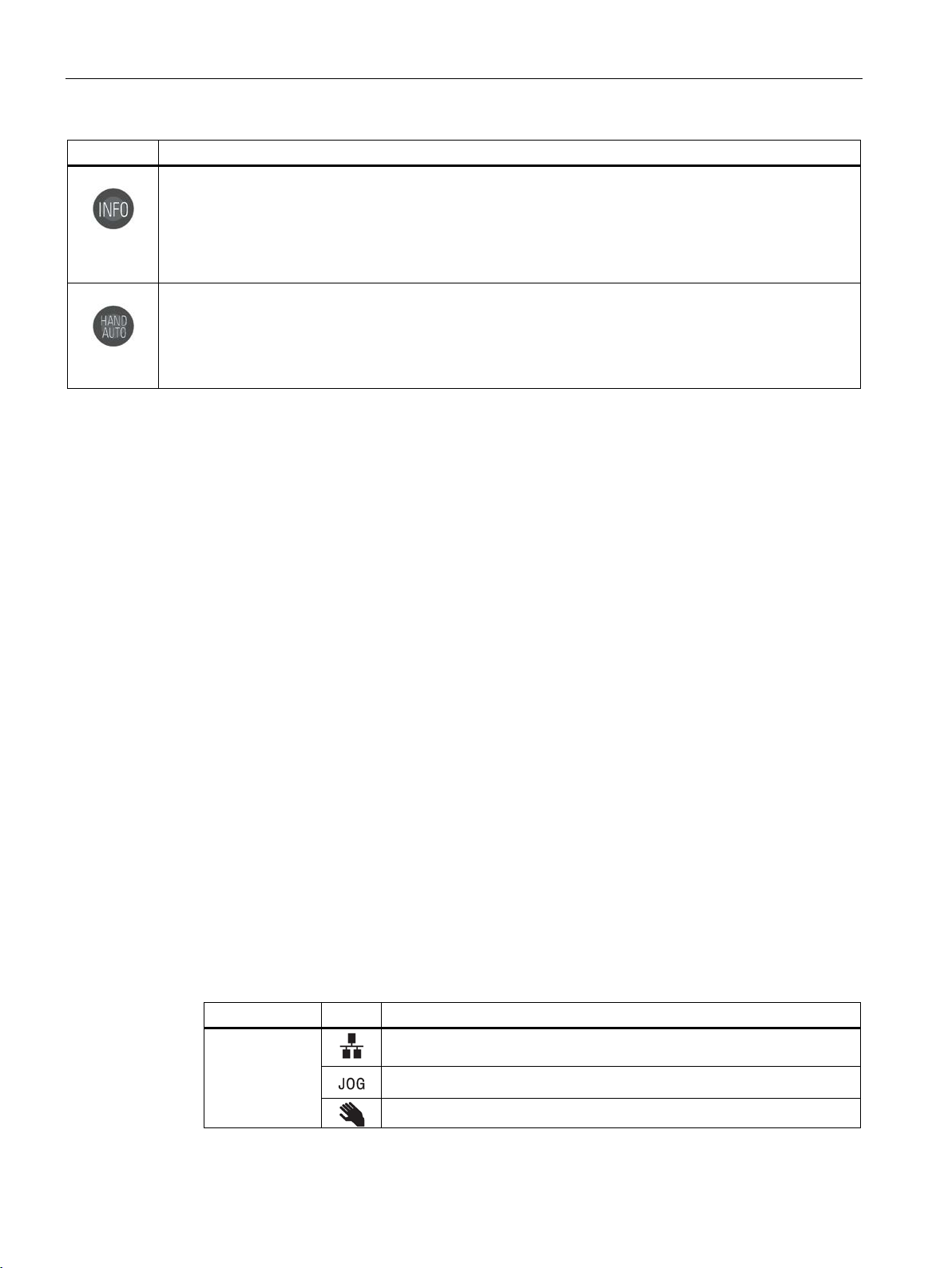

Overview

Key

Function

The INFO key has the following functions:

The HAND/AUTO key switches the command source between HAND and AUTO mode.

the standard status screen.

Function

Icon

Remarks

Command

Auto - the converter receives the command signals from the network

controller

Displayed when the JOG function is active

Hand - the converter is under control of the IOP-2

4.3 Screen icons

• Displays additional information for the currently selected item.

• Pressing the INFO key again will display the previous screen.

• Pressing the INFO key during power-up of the IOP-2 will place the IOP-2 in DEMO mode. To exit DEMO

mode, power-cycle the IOP-2.

• HAND sets the command source to the IOP-2.

• AUTO sets the command source to an external source, for example, fieldbus.

Note: When switching from the HAND mode back to the AUTO mode, the setpoint screen will change back to

Locking and unlocking the keypad

The keypad can only be locked once the power-up cycle has been completed. If the keys are

activated before the power-up cycle is completed, the IOP-2 will enter the DEMO mode.

To lock the IOP-2 keypad press ESC and INFO simultaneously for 3 seconds or more. To

unlock the keypad press ESC and INFO simultaneously for 3 seconds or more.

DEMO mode

DEMO mode allows the IOP-2 to be used for demonstration purposes without affecting the

converter to which it is connected. Menus can be navigated and functions selected, but all

communications with the converter are blocked to ensure that the converter does not react

to any commands issued from the IOP-2.

To enter the DEMO mode it is necessary to do a long press of the ESC key or INFO key during

the power-up cycle. The IOP-2 must be power cycled again to exit the DEMO mode.

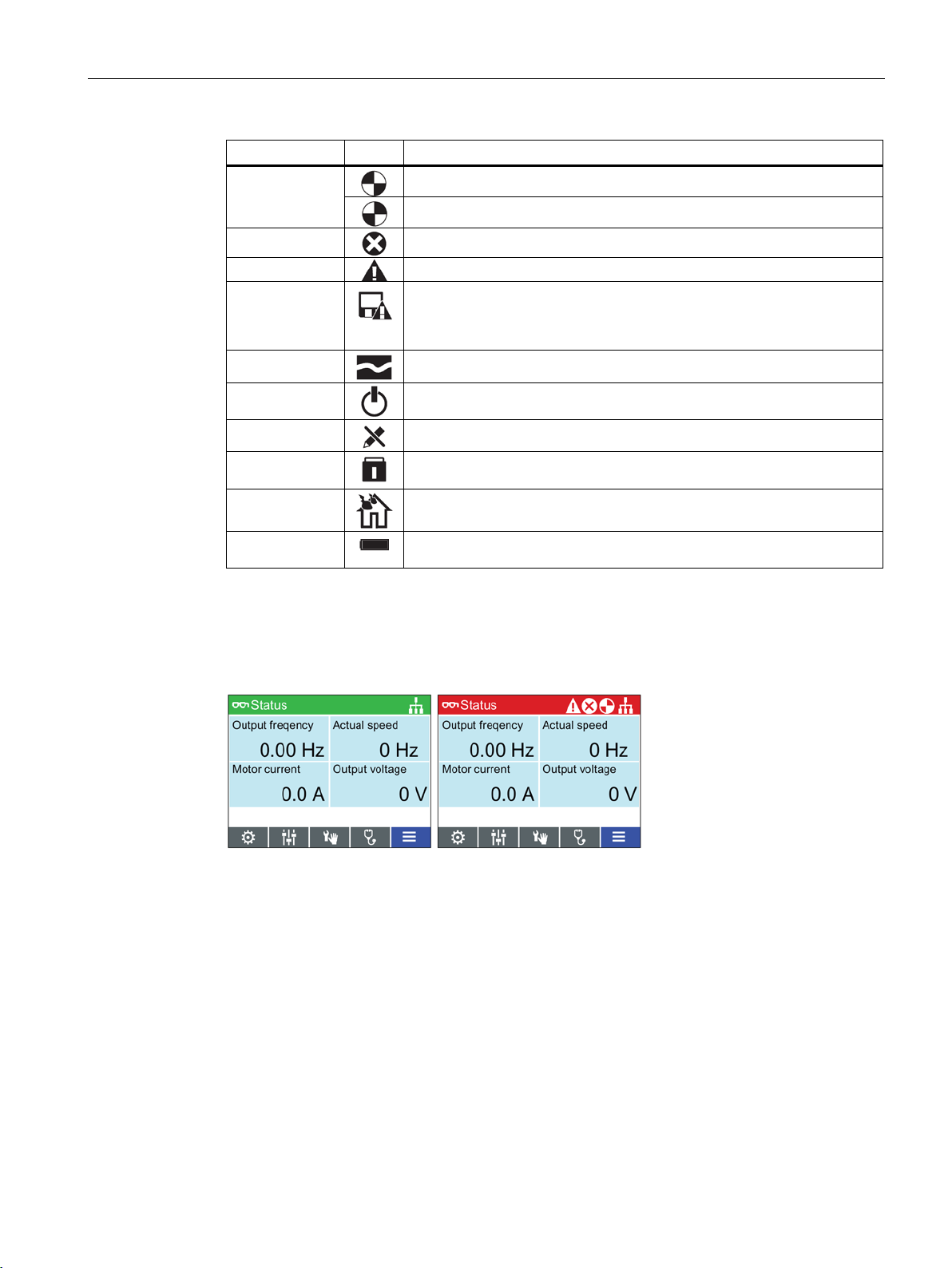

4.3 Screen icons

Overview

The IOP-2 displays a number of icons at the top right-hand edge of the display to indicate

various states or current conditions of the converter. These icons are explained in the table

below.

Table 4- 2 Screen icons

source

Intelligent Operating Panel 2 (IOP-2)

14 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 17

Overview

Function

Icon

Remarks

Inverter status

Icon rotates when the motor is running

Fault pending

Alarm pending

Saving to RAM

Indicates that all recent changes to parameters have been saved in RAM

must be performed.

PID autotuning

Hibernation

mode

Write Protection

Parameters cannot be modified.

Know How

Protection

Parameters cannot be viewed or modified.

ESM Essential Services Mode

Battery

condition

The battery status is only shown when the IOP-2 Hand-held kit is used.

Red

Error status: Indicates a fault is active and the Control Unit is in an error condition.

White

Neutral status: The IOP-2 has no connection to the Control Unit.

Green

Run status: The converter is running with no active faults. Active alarms will be

displayed on the status bar.

Blue

Blue denotes the selected item on the screen.

4.3 Screen icons

only. In the event of a power failure, then all recent changes saved to

RAM will be lost. To prevent loss of parameter data a RAM-to-ROM save

Screen faults and alarm indicators

When a fault or an alarm is active on the converter the top label on the screen will turn red.

The top label will remain red until the fault or warning has been acknowledged or rectified.

Figure 4-2 Fault and alarm notifications

Use of screen colours

A brief explanation of the use of the different colours on the screen is given below:

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

15

Page 18

Overview

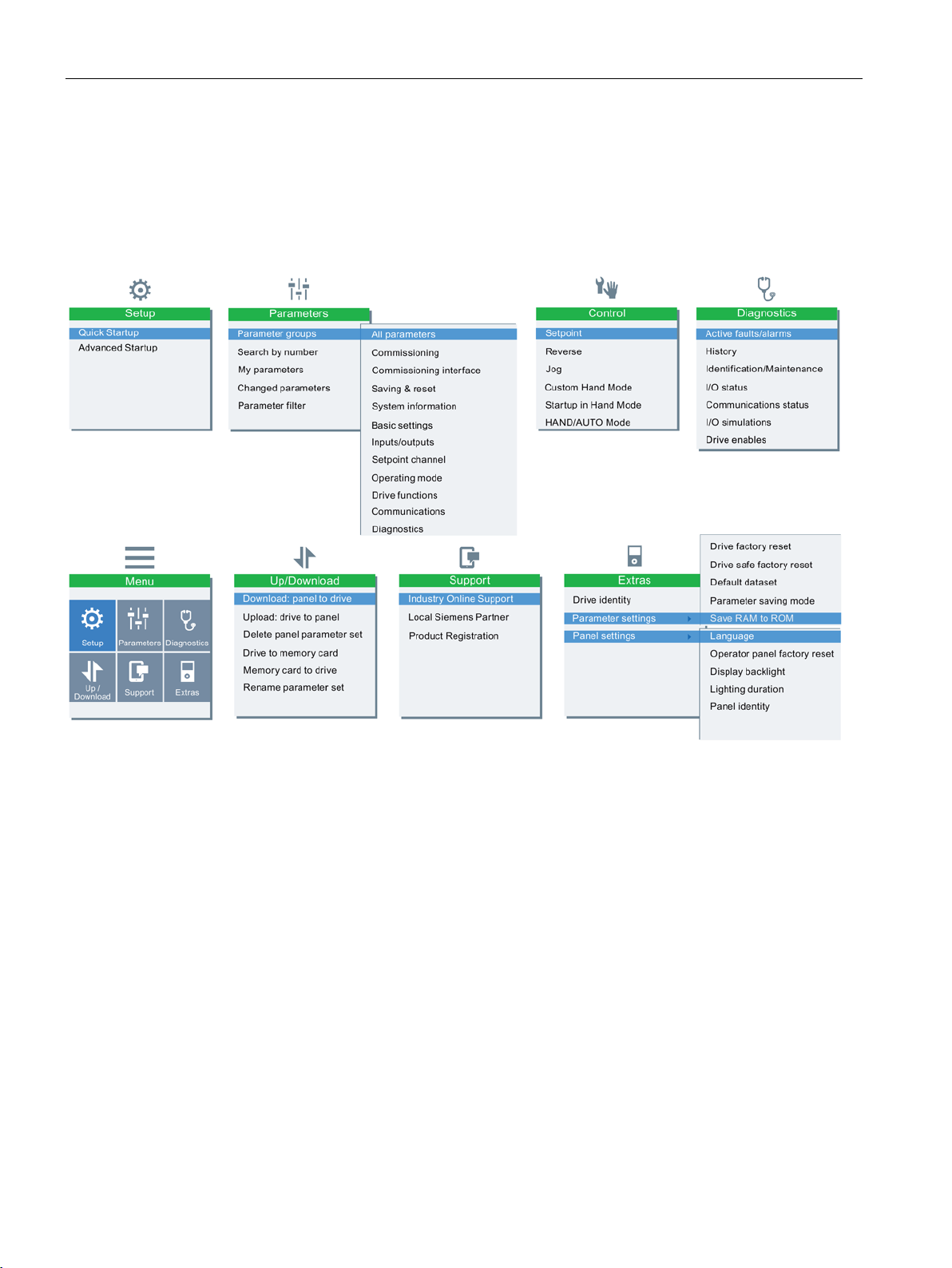

4.4 Menu structure

4.4 Menu structure

Overview

The Menu structure of the IOP-2 is shown in the figure below.

Figure 4-3 IOP-2 menu structure

Intelligent Operating Panel 2 (IOP-2)

16 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 19

5

Note

IOP

The IOP-2 has no internal power supply and derives its power directly from the Control Unit of

the converter through the RS232 interface. The IOP

derives its power through the USB connection.

5.1 Fitting the IOP-2

Fitting the IOP-2 to the Control Unit

-2 power supply

To fit the IOP-2 to the converter Control Unit the following procedure should be performed:

-2 can also be connected to a PC and

1. Place the bottom edge of the IOP-2 casing into the lower recess of the Control Unit housing.

2. Push the IOP-2 forward until the top fastening clicks into place on the Control Unit housing.

To use the IOP-2 with a decentralized drive, for example an ET200pro FC-2, an IOP-2

Handheld kit is required and an optical cable. The IOP-2 Handheld kit and optical cable are

fitted as shown in the following figure.

The order details of both the IOP-2 Handheld kit and the optical cable are given in the

Introduction (Page 11).

Figure 5-1 Fitting IOP-2 on CU and ET200pro FC-2

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

17

Page 20

Installation

Note

Saving and cloning of the IOP

All changes made to an IOP

the IO

To copy/clone all this data to another, or multiple IOP

Customer parameter sets (Page 61).

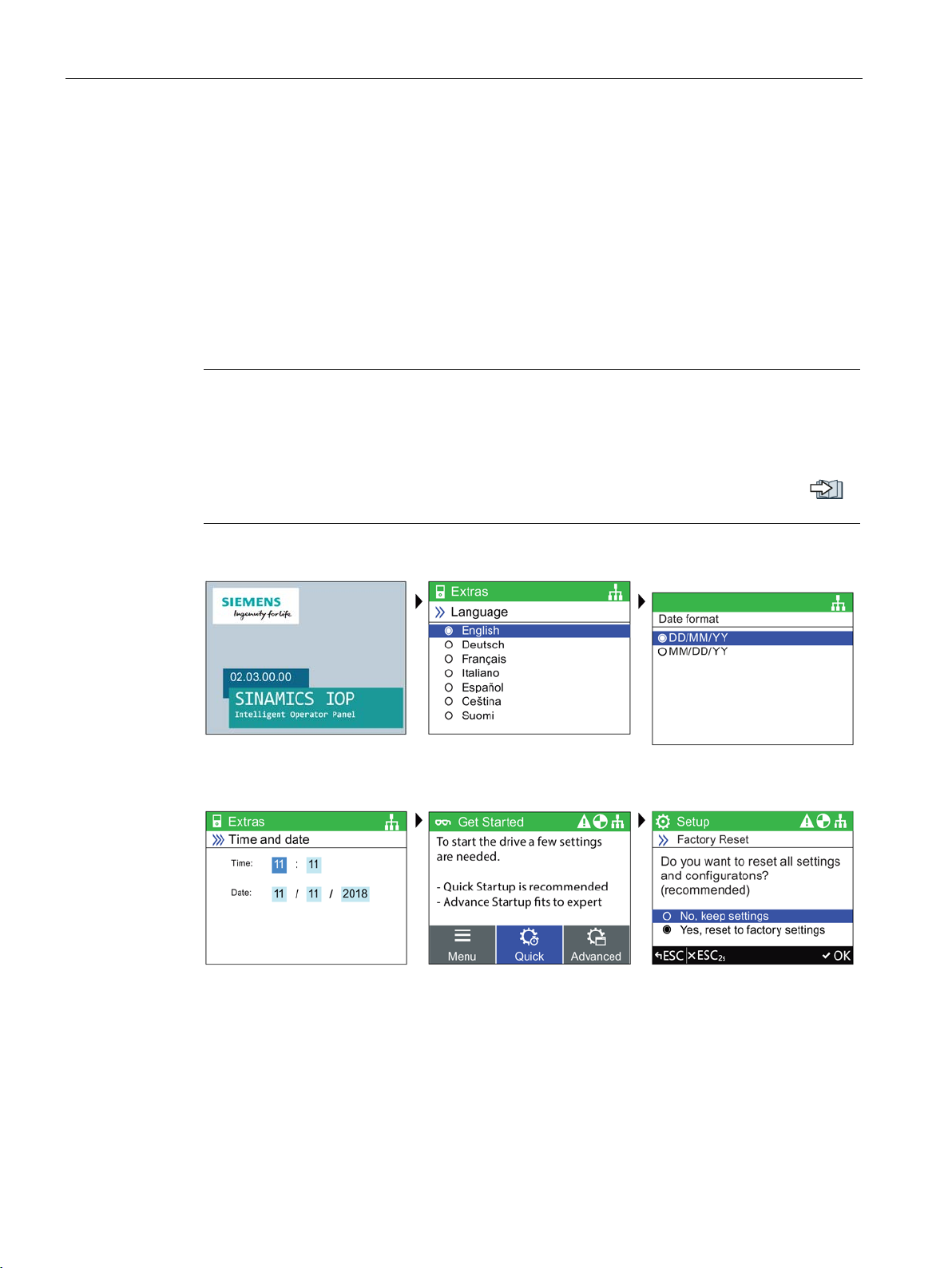

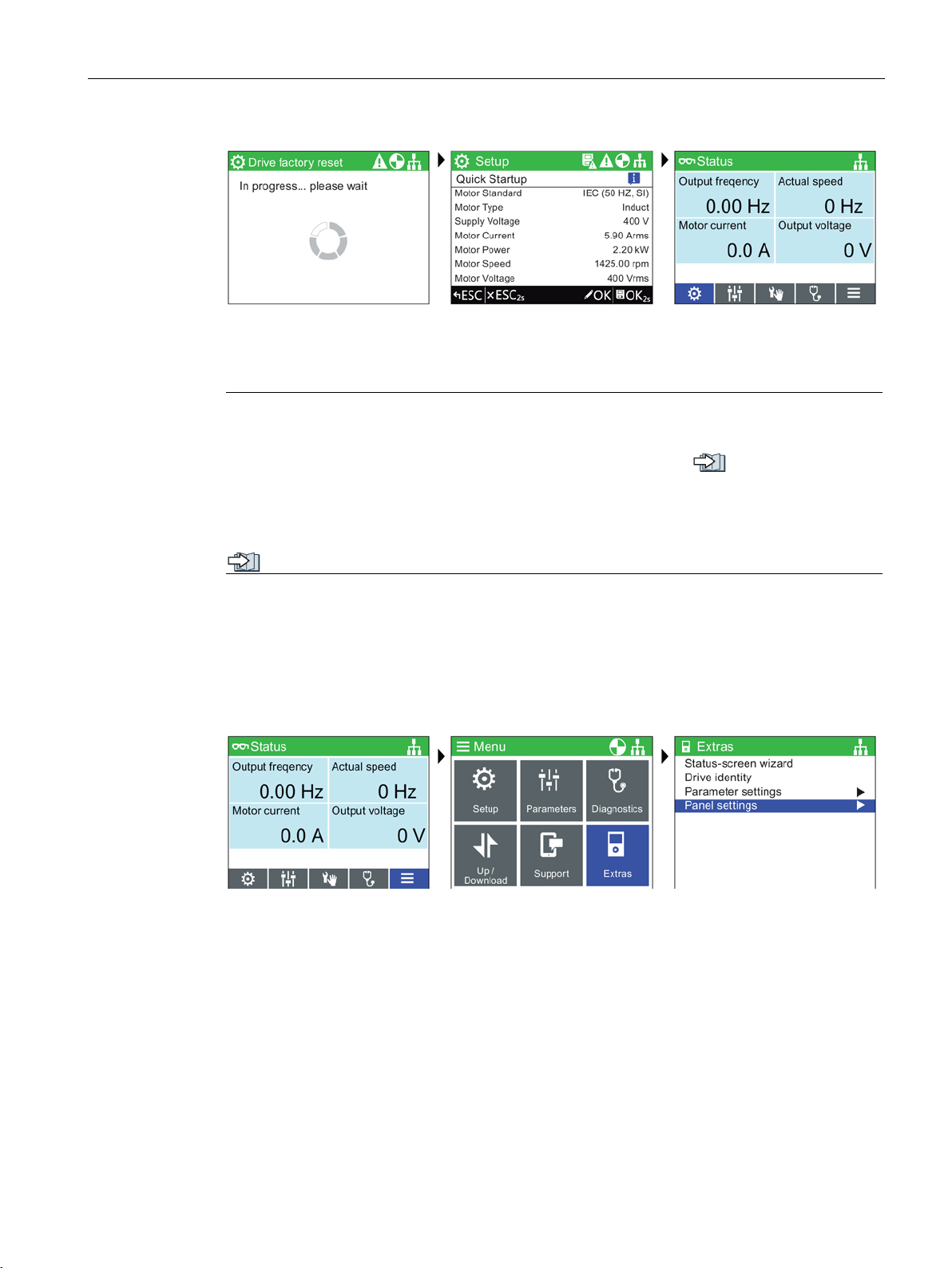

Splash screen is displayed

Select the required language

Select date format

Set correct date and time

Select Quick Startup

Select "Yes, reset to factory

settings"

5.2 Initial set-up

5.2 Initial set-up

Initial set-up sequence

Once the IOP-2 is fitted and powered-up it will automatically detect the type of Control Unit

and Power Module to which it has been fitted. On first-time use, the IOP-2 automatically

displays the option to select the default language and allow the time and date to be set (if the

Control Unit to which the IOP-2 is fitted has a real-time clock). The IOP-2 will then display the

choice between "Quick Startup" or Advanced Startup"; "Quick Startup" is the recommended

selection. The procedure is outlined below.

-2 configuration data

-2 configuration, included all saved parameter sets, are stored in

P-2 file structure in the "user" folder.

-2s, the procedures are shown in

Intelligent Operating Panel 2 (IOP-2)

18 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 21

Installation

Wait until the factory reset is

finished

Change or confirm settings

Status screen on completion

Note

The IOP

Startup setups. For information on Firmware upgrades, please see

2

firmware

The status screen can be reconfigured to show a number of different views and

values; these can be configured using the "Status Screen Wizard" in the "Extras" menu, see

Extras Menu (Page 65).

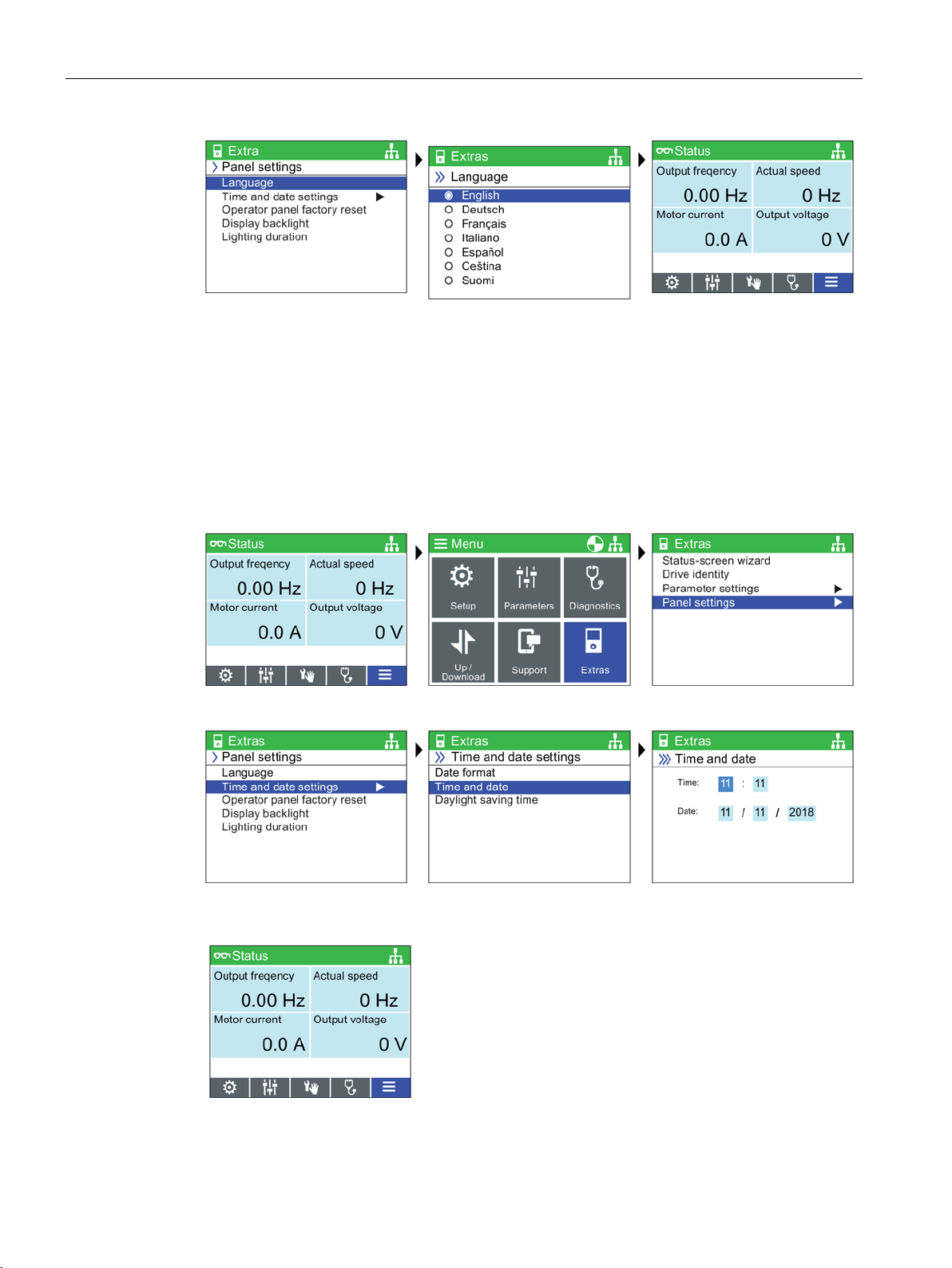

Select Menu

Select Extras

Select Panel settings

5.2 Initial set-up

Language selection

The IOP-2 on first start-up will display the language screen for the user to select their required

language, should you wish to select you language manually, the following actions should be

performed:

-2 is delivered with all available languages and the Quick Startup and Advanced

Upgrading the IOP-

(Page 25).

types of

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

19

Page 22

Installation

Select language

Select required language

Press and hold down ESC for

Status Screen

Select Menu

Select Extras

Select Panel settings

Select Time and date settings

Set the Time and date

settings

Set time and date

Press and hold down ESC for

Status Screen

5.2 Initial set-up

All available languages are delivered with the IOP-2.

Setting time and date

When the IOP-2 is first fitted to a Control Unit, which has a real-time clock, it will

automatically display the time and date screen. Should you wish to manually set the time on

the IOP-2, the following actions should be performed:

Intelligent Operating Panel 2 (IOP-2)

20 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 23

Installation

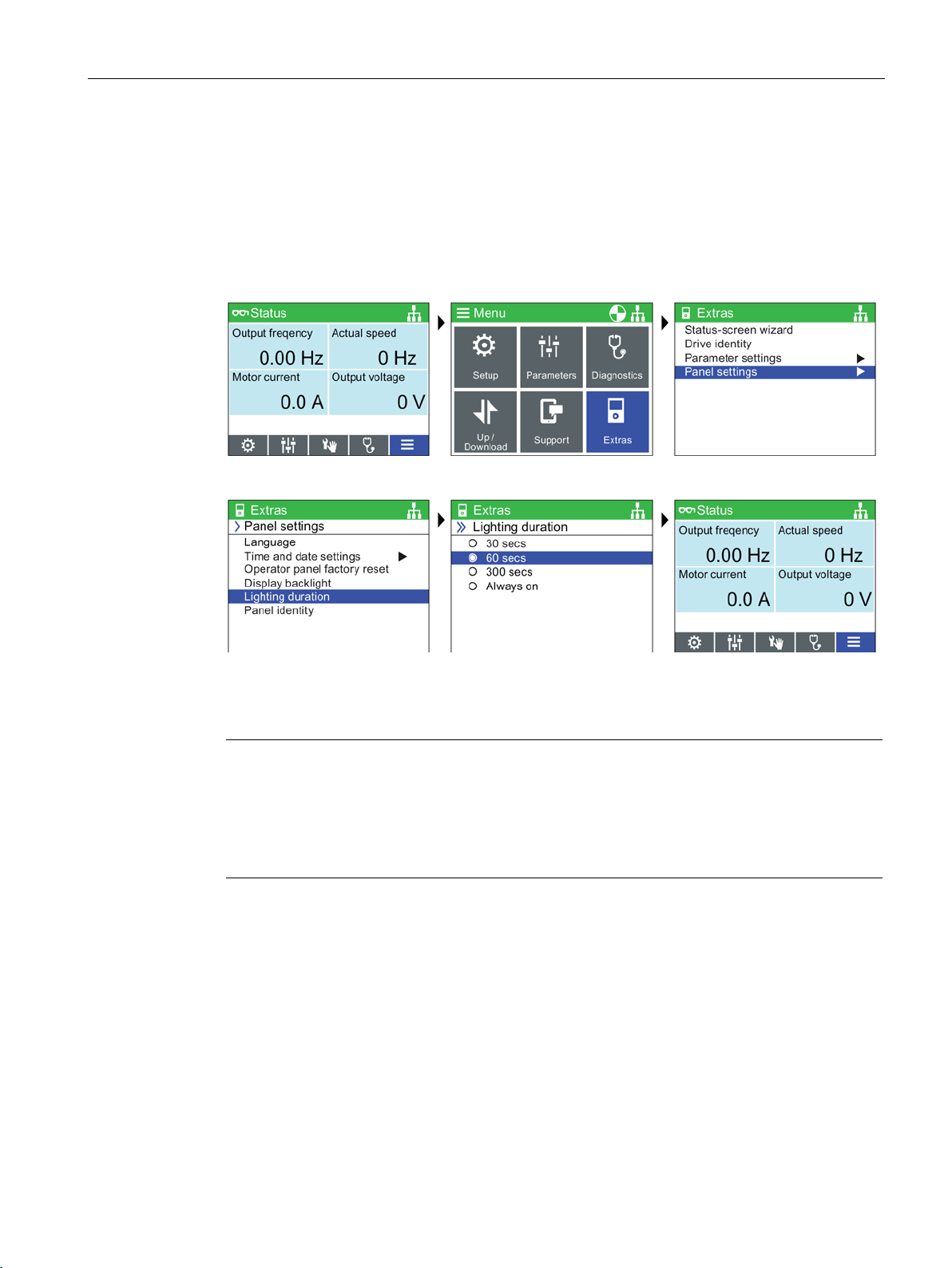

Select Menu

Select Extras

Select Panel settings

Select Lighting duration

Select Lighting duration time

Press and hold down ESC for

Status Screen

Note

Screen will flash when an active fault condition exists

When an active fault condition exists on the IOP

one minute then the screen will start to flash on and off. The screen will dim a few seconds

prior to the lighting duration time

been set to "Always on" the screen will not dim.

5.2 Initial set-up

The settings for time are normally done on the Control Unit if it has a Real-time Clock (RTC). If

the Inverter has an RTC the IOP-2 will take its settings from the Control Unit.

Lighting duration

To set the length of time that the display remains lit, the following actions should be

performed:

-2, if no key has been pressed for more than

-out period. If the screen is set to never dim, that is, it has

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

21

Page 24

Installation

Select Menu

Select Extras

Select Panel settings

Select Display backlight

Select display backlight level

Press and hold down ESC for

Status Screen

5.3 Changing the Status screens

Display backlight

To change the intensity of the backlight, the following actions should be performed:

The display backlight setting will be automatically changed to the "Low" setting after 60

seconds from the last key press to extend the life of the display. When any key is pressed the

backlight setting will automatically return to the user setting.

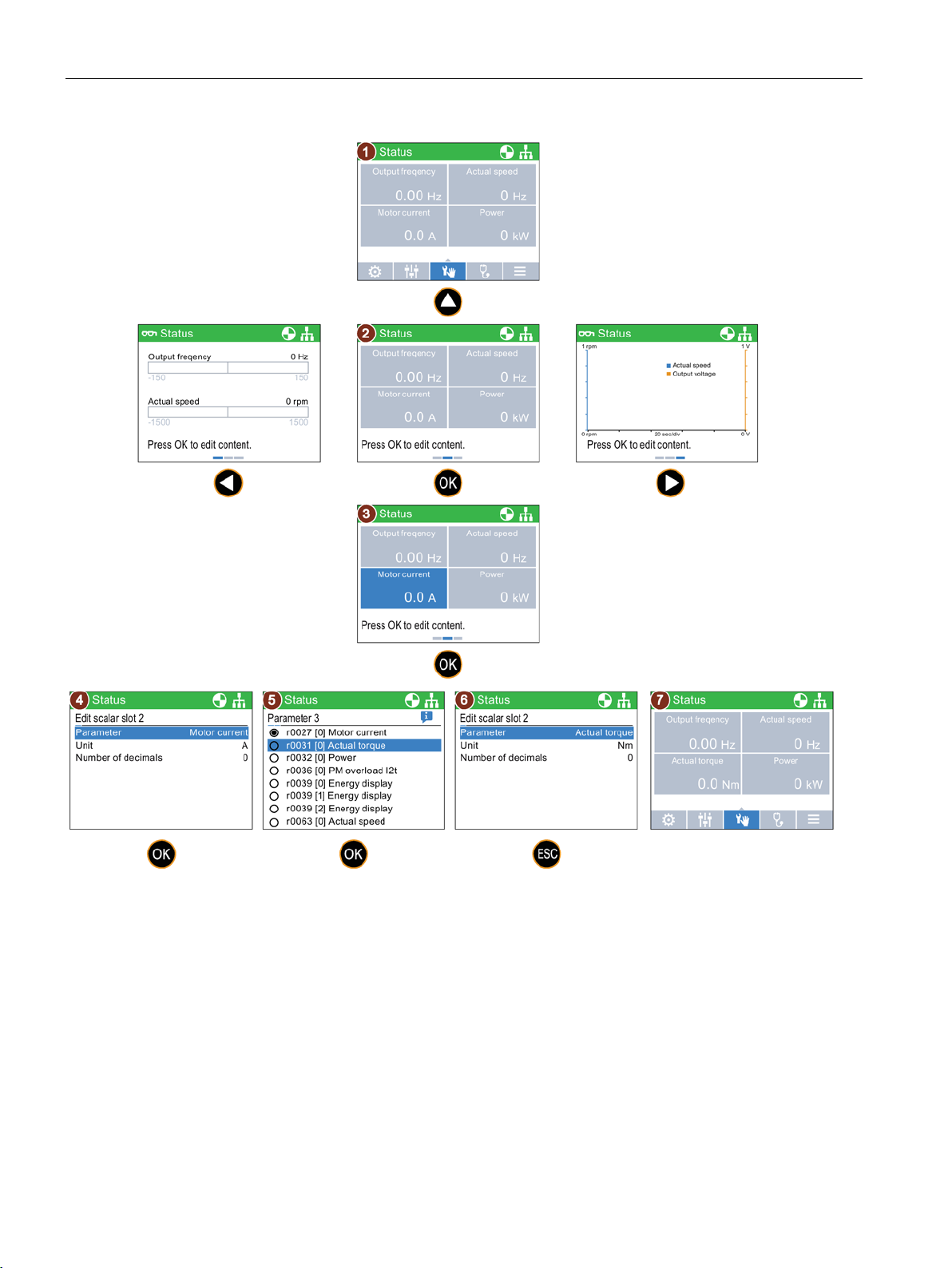

5.3 Changing the Status screens

Changing the status screens

The status screens of the IOP-2 can show three different styles of screens.

• Bar graph view - This shows the selected data on up to two separate sliding bar scales.

• Scalar view - This shows the selected data as numerical values in up to four separate

quadrants on the screen.

• Trend view - This shows the selected data as two separate real-time plots on the screen.

Intelligent Operating Panel 2 (IOP-2)

22 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 25

Installation

5.3 Changing the Status screens

Select a different status screen

To select a different status screen the following procedure should be performed:

1. When the status screen is displayed, use the UP arrow key to enter the screen selected

mode.

2. Using the LEFT and RIGHT arrow keys, select the required status screen.

3. Press ESC or the DOWN arrow key to accept the new status screen and exit the screen

selection mode.

Modify the display data

To modify the data that is displayed on the status screen, the following procedure should be

performed:

1. Use the UP key to enter the status screen selection mode.

2. Press OK to edit the displayed data.

3. Use the arrow keys to navigate around the screen until the data you wish to change is

highlighted. Press OK to edit the highlighted data.

4. Press OK to edit the parameter to be displayed.

5. Select the new parameter you wish to be displayed. Press OK to accept the new selection.

6. The new parameter selection is shown in the list. Press ESC or the DOWN arrow key to return

to normal functions of the IOP-2.

7. The status screen is shown with the new data values and the screen menu is shown.

An overview of the basic procedures is shown in the figure below.

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

23

Page 26

Installation

5.4 User definable labels on status screen

Figure 5-2 Selecting and modifying the IOP-2 status screens

5.4 User definable labels on status screen

User definable labels

User defined labels allow the user to customize the labels that appear on the status screen of

the IOP-2.

There are a maximum of four labels that can be defined and they are located on the IOP-2 in

the "cps" folder. The IOP-2 must be connected to the PC via the USB connection and in "Mass

Intelligent Operating Panel 2 (IOP-2)

24 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 27

Installation

5.5 Upgrading the IOP-2 firmware

Storage" mode to access the files on the IOP-2.The files are basic text files and can be opened

with any basic text editor. The default label names are "default", when the labels have the

"default" text, the IOP-2 will ignore the labels. There are the following restrictions when

creating your own labels:

• A maximum of 20 characters for each label name.

• The characters that can be used conform to the normal windows file naming conventions.

• The number of labels are restricted depending on the type of status screen view that is

selected in the "Status screen wizard". See

Extras Menu (Page 65).

The four files are named:

• BotLeft.txt

• BotRight.txt

• TopLeft.txt

• TopRight.txt

The file names relate to the area of the status where they will appear.

Simply selected the file you wish to use as a label; open it with a text editor, change the

name and then save it back to the same location in the IOP-2 file system. If the file name

itself is changed the IOP-2 will not recognize the label.

An example of the status screen with new label names (using all four text files) is shown in

the figure below.

Figure 5-3 Example of defining your own labels

5.5 Upgrading the IOP-2 firmware

Upgrading the IOP-2 firmware

The IOP-2 contains firmware, which can be upgraded by the user by means of a firmware

upgrade. To perform the upgrade of the IOP-2 firmware the following steps should be

performed.

1. Plug the IOP-2 into a PC using the USB connection. Note: Connect the IOP-2 only to an

internal USB interface. Do not use an USB interface which is connected to your PC externally

(e.g. via a docking station, external USB-Hub or desktop PCs with front sockets).

2. The IOP-2 will automatically enter the "Mass Storage" mode.

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

25

Page 28

Installation

Note

English language is mandatory

The English language file is essential to the correct functioning of the IOP

cannot be deleted.

5.5 Upgrading the IOP-2 firmware

3. Open the file explorer on the PC.

4. Navigate to the IOP-2 (removable media). Note: Back up data (e.g., readme, parameter

records) that you will need later on the connected PC.

5. Format the IOP-2 (do not use quick formatting). Set the size of the allocation units to 2048

bytes (FAT Standard).

6. Go to the Service and Support site at the link shown below.

7. Download the zip file with the current firmware of the IOP-2 into a folder on the PC and

unpack it into a separate directory.

8. Copy the downloaded files from the PC directory directly into the IOP-2 folder (the copying

process takes approximate 6 minutes).

9. When the copying has been completed, wait approximate 5 seconds before disconnecting

the IOP-2 from the USB port. The new firmware is now available on the IOP-2 and you can

now connect the IOP-2 to a SINAMICS G inverter.

10.When you turn on the SINAMICS G inverter, the IOP-2 will automatically upgrade.

Only IOP-2 firmware update packages obtained through the Siemens Service and Support

website at the following link should be used:

IOP-2 firmware download: IOP-2 Firmware upgrade

(https://support.industry.siemens.com/cs/ww/en/view/109762019

Reading the OSS License

The IOP-2 contains open-source software (OSS). The OSS comprises open-source text and

satisfies special license terms. If you wish to read the license terms, see: efs/readme_OSS.zip

on the IOP-2.

-2 and therefore

)

Intelligent Operating Panel 2 (IOP-2)

26 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 29

6

WARNING

not produce an unpredicted or unsafe effect on personnel, equipment or premises.

WARNING

Safe and stable state of the converter

dangerous conditions exist.

CAUTION

Default datasets

changed to the other datasets, the Setups may not function correctly.

Overview

The IOP-2 Setups are question-driven environment that assist the user to set-up various

functions and applications of the converter.

Motor Identification (Motor ID) function will run automatically

Using the "Standard Drive Control" or "Dynamic Drive Control" in Quick Startup, the Motor ID

function, if selected, is activated at the end of the commissioning squenence.

The motor identification (motor ID) function, after the completion of the Quick Startup,

upon the first startup, will start automatically after approx. 8 to 30 s and accelerate the

motor to the setpoint speed.

This action must be taken into account when the Quick Startup procedure has been

completed, to ensure that the first ON/RUN command when given for your application, does

During the setup of the converter it is essential to ensure that the system is in a safe and

stable state, as some setup processes have the potential to start the motor. Therefore it is

important to secure any loads and ensure that should the motor start, no potentially

The Setups use the default Drive datasets (DDS0 and CDS0), if the default datasets are

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

27

Page 30

Setup Menu

CAUTION

application.

6.1 Example Setups

6.1 Example Setups

Overview of Setup

The following example of how Setup work on the IOP-2 are purely for demonstration purpose

only.

Before setting up an application

Prior to using Setup, it is essential that the user's Control Unit and Power Module have been

installed and wired correctly, in accordance with the requirements of the user's application.

This is extremely important in the case of setting up safety-integrated applications. All

inputs and outputs must be defined and configured before any setting up can take place,

including the observation and adherence of all local, national and international safety

regulations required for the user's application and all devices utilized by the user's

Quick Startup/Advanced Startup

Quick Startup

The Quick Startup procedure is all the user needs to setup the converter in quickly and easily.

The Quick Startup allows the user to configure the following converter data:

• Motor Standard

• Motor Type

• Supply Voltage

• Motor Current

• Motor Power

• Motor Speed

• Motor Voltage

• Motor Frequency

• Minimum Frequency

• Maximum Frequency

• Ramp-up Time

• Ramp-down Time

• I/O Setup

Intelligent Operating Panel 2 (IOP-2)

28 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

The default settings of the converter will be automatically read into the IOP-2, but it is

recommended that you check that these settings are correct for your converter by comparing

the settings with the data from the converter and motor rating labels.

Page 31

Setup Menu

6.1 Example Setups

Advanced Startup

The Advanced Startup provides the user with a more comprehensive range of settings that

can be configured for specific requirements and applications. The settings that are available

are as follows:

• Drive Information: This displayed detailed information about the connected Control Unit

and Power Module.

• Factory Reset: This allows the converter to be reset to the factory default settings.

• Hardware options: This allows the configuring of and Output Filter and a Braking Resistor.

• Control Type: This allows the selection of the control types, Standard Drive Control,

Dynamics Drive Control and Expert. A brief explanation of each Control Type is given

below.

• Motor Data: This allows the user to configure the Motor settings which consist of the data

presented in the Quick Setup.

• Limit Settings: This gives the user the opportunity to setup the dynamics settings of the

converter.

• Optimization: This allows the user to optimize the converter for technological applications

and ensure that the correct motor data will be used.

Control Types

• I/O Setup: This allows the user to configure the Input and Output settings of the converter.

The I/O configuration is pre-assigned using macros so that no further settings are

necessary.

• Fieldbus Setup: This allows the user to configure the interface settings.

• Application Setup: This allows the user to configure the application specific functions of

the converter.

For more detailed information of the application classes, see the document at the link below:

Application classes (https://support.industry.siemens.com/cs/ww/en/view/109480663

)

Standard Drive Control

• Standard Drive Control is preset for the Power Modules PM240, PM240-2 and G120C in

frame sizes FSA-C. This application class can, for example, be used for the following

applications:

– Pumps, fans and compressors with flow characteristic

– Wet or dry beam technology, mills, mixers, kneaders, crushers, agitators

– Horizontal conveyor technology (conveyor belts, roller conveyors, chain conveyors)

– Basic spindles

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

29

Page 32

Setup Menu

WARNING

setting for p1900 = 2.

Note

Macro source selection

During the Quick Startup process, the user will be presented with a list of preset macros that

determine the configuration of the converter. Every Control Unit Operating Instructions

contain a list of the macros that are specific for that particular Contro

wiring configurations for each macro. For further information, see the relevant Operating

Instructions.

6.1 Example Setups

Dynamic Drive Control

• Dynamic Drive Control is preset for the Power Modules PM240, PM240-2 and PM330 in

frame sizes ≥ FSD. This application class can, for example, be used for the following

applications:

– Pumps and compressors with displacement machine

– Rotary furnaces

– Extruders

– Centrifuges

Expert

• Expert is fixed assigned to the Power Modules PM230, PM250 and PM260 as soon as for

G120D, G110M and ET200pro FC-2. This setting corresponds to the existing Setup and

will also be assigned to existing projects. It allows the flexibly setup of the converter, but

requires a detailed understanding of the drive.

Motor data identification (motor ID)

When selecting motor data identification (motor ID) with subsequent ramp-up to the

setpoint speed (p1900 = 11 or 12; 12 = standard setting based on SINAMICS Firmware V4.7

SP3 with "Standard Drive Control" and "Dynamic Drive Control"), the motor is, upon the first

Power ON command, directly accelerated to the setpoint speed, following a short delay time

caused by the motor ID (approx. 15 to 30 s). From SINAMICS Firmware V4.7 SP6 the default

l Unit and show the

Intelligent Operating Panel 2 (IOP-2)

30 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 33

Setup Menu

NOTICE

motor rating label, an example of which is included in the Operating Instructions for your

"Installation" section of the Operating Instructions for your converter.

6.1 Example Setups

Info Screens

Info Screens (Information Screens) are accessed with a press of the INFO button. There may

be multiple INFO screens and these you can navigated between each screen using the arrow

keys.

Figure 6-1 Using the INFO button

6.1.1 Quick Startup with the IOP-2

Quick Startup

Requirements prior to using the Quick Startup

• The user must be fully conversant with all safety instructions as detailed in the

"Fundamental Safety Instructions" section of the Operating Instructions for your

converter.

• The converter must be installed and checked as per the relevant instructions in the

"Installation" sections of the converter Operating Instructions.

• Macro source selection: During the Quick Startup process, the user will be presented

with a list of preset macros that determine the configuration of converter. Every Control

Unit Operating Instructions contain a list of the macros that are specific for that

particular Control Unit and show the wiring configurations for each macro. For further

information, see the relevant Operating Instructions.

• The information required to be input into the Quick Startup process can be found on the

converter.

• If the motor is to operate with the "87 Hz characteristic"; You need to use the "Advanced

Startup" process and you need to connect the motor in Delta (Δ), this is shown in the

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

31

Page 34

Setup Menu

Select Setup

Select Quick Startup

Select Factory Reset (yes or

no)

Factory Reset begins

Select Motor Standard

Select mains frequency and

units

Select Motor Type

Select Input Mode

Enter Motor Data or Motor

Code

Select Supply Voltage

Enter Supply Voltage from

rating label

Select Motor Current

6.1 Example Setups

Intelligent Operating Panel 2 (IOP-2)

32 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 35

Setup Menu

Enter Motor Current from

rating label

Select Motor Power

Enter Motor Power from

rating label

Select Motor Speed

Enter Motor Speed from

rating label

Select Motor Voltage

Enter Motor Voltage from

rating label

Select Motor Frequency

Enter Motor Frequency

Select Min. Freq.

Enter the required Min. Freq.

Select Max. Freq.

6.1 Example Setups

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

33

Page 36

Setup Menu

Enter the required Max. Freq.

Select Ramp-up Time

Enter required Ramp-up Time

Select Ramp-down Time

Enter required Ramp-down

Time

Select I/O Setup

Select the required Macro

Save the Settings

Saving Settings in progress

Settings have been saved

Motor ID ran on next ON

command

Setup up completed

6.1 Example Setups

Intelligent Operating Panel 2 (IOP-2)

34 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 37

Setup Menu

The settings for the function at the default settings.

The settings for the function have been changed and saved.

The settings for the function must be checked to ensure the safety settings are correct.

The settings for the function must be checked and corrected if necessary.

This icon indicates that information is available on the selected function by pressing the

INFO key.

6.1 Example Setups

6.1.2 Advanced Startup with the IOP-2

Advanced Startup overview

Advanced Startup is a commissioning process for all application which provides a high degree

of flexibility when dealing with the converter settings. The provided settings allow an

optimized adaption of the converter to the target application.

The setup process will guide the user through the commissioning process by presenting a

number of categories where the user can choose the necessary options and values to

commission the converter and motor.

At the conclusion of the setup process, the data can be saved to the converter's memory.

Setup Icons

The setup process uses a number of very important icons to indicate the status of the

settings. A description of the various icons is given below.

Advanced Startup

The Advanced Startup process is outlined below and is should be remembered that the

screenshots are for example purposes only and may vary from your own IOP-2 display,

depending on the firmware version and the actual converter that is being commissioned.

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

35

Page 38

Setup Menu

Advanced Startup Menu

This screen lists all the advanced settings that are available for

the user to modify for their sp

Drive Information

This screen provides general information concerning the used

converter configuration (Power Module, Control Unit and the

Intelligent Operator Panel IOP

Factory Reset

This function resets all the parameters to their factory default

settings. Any safety parameters that have been modified

not be reset.

It is recommended that you reset to the factory settings before

commissioning the converter.

Hardware Options

This screen gives the user the opportunity to setup the

converter options, for example, an Output Filter or a Braking

Resistor.

Control Type

This screen allows the application class to be set.

Depending on the particular Power Module, the converter

selects the right application class and assigns the motor control

the appropriate default settings.

6.1 Example Setups

ecific application.

-2).

will

Intelligent Operating Panel 2 (IOP-2)

36 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 39

Setup Menu

Motor Data

The motor data stored here corresponds to the 4

standard motor with the same converter power.

For dynamic applications and when other OEM motors are in

operation, adaptation of the settings will need to be made.

Limit Settings

This screen give the user the opportunity to setup the dynamics

settings of t

motor speed, ramp

ramp

Optimisation

This screen makes is possible to optimise the converter for the

technological applications and ensures that the correct motor

data will be used.

I/O Setup

This screen allows the I/O configuration to be defined. The I/O

configuration is pre

settings are necessary.

Fieldbus Setup

This screen allows the communications interface settings on

the converter to be configu

6.1 Example Setups

-pole SIEMENS

he motor, for example, minimum and maximum

-up and ramp-down timings and OFF-3

-down time.

-assigned using macros so that no further

red.

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

37

Page 40

Setup Menu

Application Setup

This screen allows the applications specific functions to be

config

presented with some default applications functions, depending

on the type of Control Unit that is being used. The user can

setup their own list of functions using the "Adjust function list"

feature which allows functions to be added to or removed from

the displayed list. A grey tick is displayed beside the functions

that have not been configured using the IOP

function has been configured using the IOP

shown beside the fu

If a function is removed from the list

disabled and the settings restored to the factory defaults for

that specific function.

6.1 Example Setups

ured. When "Application Setup" is selected, the user is

nction in the list.

-2 and when a

-2, a green tick is

- the function will be

Intelligent Operating Panel 2 (IOP-2)

38 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 41

7

Overview

The Control menu allows the user to change the following settings in real-time:

• Setpoint

• Reverse

• Jog

• Custom Hand mode

• Startup in Hand mode

• Hand/Auto disable

The control menu is accessed from the menu at the bottom-centre of the Status screen, as

shown below.

Figure 7-1 Select Control Menu

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

39

Page 42

Control menu

Select Control

Select Setpoint

Use Touch-wheel to set the

Setpoint

Note

Setpoint in Hertz (Hz) for SINAMICS CU230P

The setpoint screen by default displays the motor speed as a percentage of the total possible

speed of the motor.

This behaviour changes for the SINAMICS CU230P

displayed in Hertz (Hz).

Select Control

Select Reverse

Select Off or On

7.1 Setpoint

7.1 Setpoint

Setting the Setpoint

The setpoint value determines the speed at which the motor runs as a percentage of its full

range of motion.

To change the setpoint, the following actions should be performed:

7.2 Reverse

Setting Reverse

The function of the reverse command is to set the direction of rotation of the motor from its

normal forward motion.

To reverse the direction of the motor, the following actions should be performed:

-2

-2 where the default setpoint value is

Intelligent Operating Panel 2 (IOP-2)

40 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 43

Control menu

Select Control

Select Jog

Select Off or On

Note

Selection of Jog frequencies

It is important that the Jog parameters P1058 (Jog right) and P1059 (Jog left) are set to the

required frequencies for the users application. The default jogging setpoint for both

parameters is 5

When the Jog left and Jog right (Jog1 and Jog 2) have been set; it is necessary to do a long

press of the "INFO" key to select the other jog mode.

7.3 Jog

7.3 Jog

Setting Jog

The Jog function, when selected will allow the motor to be manually rotated by a predetermined value with each press of

continuously until

is released.

To enable or disable the Jog function, the following actions should be performed:

. If is pressed continuously, the motor will rotate

Hz (150 rpm).

7.4 Custom Hand mode

Overview

The custom hand mode allows the user to setup a command source and setpoint source

directly from the Intelligent Operator Panel 2 (IOP-2).

When the custom hand mode has been set, the IOP-2 Sensor Control Field can be used as the

setpoint source.

The Auto mode is unaffected by any changes made by the custom hand mode function.

A breakdown of all the interconnection inputs are given in the table below.

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

41

Page 44

Control menu

Standard interconnection

mode

Bit0

ON/OFF key

->

Bit0

ON/OFF1

Bit1

Two quick press of the OFF key

->

Bit1

OFF2

Bit2

A long press of the OFF key

->

Bit2

OFF3

Bit3

Reserved

->

Bit3

Inhibit/enable operation

Bit4

Reserved

->

Bit4

Ramp-function generator enable

Bit5

Reserved

->

Bit5

Continue ramp-function generator

Bit6

Reserved

->

Bit6

Setpoint enable

Bit7

Alarms menu acknowledge all

faults

->

Bit7

Acknowledge faults

Bit8

Jog 1 (Control menu)

->

Bit8

Jog 1

Bit9

Jog 2 (Control menu)

->

Bit9

Jog 2

Bit10

Reserved

->

Bit10

Control by PLC

Bit11

Change direction (Control menu)

->

Bit11

Direction of rotating - reversed

Bit12

Reserved

->

Bit12

Speed control enable

Bit13

Reserved

->

Bit13

Motorized potentiometer, setpoint,

increase

Bit14

Reserved

->

Bit14

Motorized potentiometer, setpoint,

decrease

Bit15

Reserved

->

Bit15

CDS selection

Standard interconnection

r8541

Speed setpoint from IOP-2

Connector Inputs (CI)

p8543

Effective speed setpoint in Custom

Hand mode

N_soll OP

-> Speed setpoint

Select Control

Select Custom Hand Mode

Select Custom Hand Mode On

7.4 Custom Hand mode

An example of setting up the custom hand mode is given in the instructions below.

Table 7- 1 Interconnection inputs for Status Word 1 in Custom Hand mode

r8540 STW 1 from IOP-2 Binector Inputs (BI) p8542 Effective STW1 in Custom Hand

Setting up Custom Hand mode example

Intelligent Operating Panel 2 (IOP-2)

42 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 45

Control menu

Select Control Parameter

Select required function

Select source of command

signal

Select the input that will

receive command signal

Select Setpoint Parameter

Select the setpoint signal

source

Select the input to receive the

setpoint signal

7.5 Startup in Hand mode

7.5 Startup in Hand mode

Overview

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Once the setpoint signal input has been selected, the IOP-2 will return to the Setpoint

selection screen then press ESC for >3 secs, to return to the status screen.

In this example, the converter is now setup to receive the ON/OFF1 command from Digital

Input 0 (DI0) and the speed setpoint from Analog Input 0 (AI0), from the controlling PLC.

Startup in Hand mode allows the converter, under the control of the Intelligent Operator

Panel (IOP-2), to startup in Hand mode automatically. The command source is then taken

from the off and on buttons of the IOP-2.

An example of setting up the Startup in Hand mode is given in the instructions below.

43

Page 46

Control menu

Select Control

Select Startup in Hand Mode

Set the required speed

setpoint as a percentage

value

Select Control

Select Hand/Auto Disable

Enter password (default:

00000000)

7.6 HAND/AUTO disable

Setting up Startup in Hand mode example

The IOP-2 will automatically return to the Control menu and show that "Startup in Hand

Mode" is "On".

The converter, after a power-cycle will automatically startup in Hand mode, but the attached

motor will not run until the run command is given by the buttons on the IOP-2.

7.6 HAND/AUTO disable

Overview

The HAND/AUTO disable function disables the HAND/AUTO key on the Intelligent Operator

Panel (IOP-2) and pressing the key will not produce any action by the IOP-2.

An example of setting up the Hand/Auto disable mode is given in the instructions below.

Setting up the HAND/AUTO disable function

Intelligent Operating Panel 2 (IOP-2)

44 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 47

Control menu

Select On: Hand/Auto from

PLC or DI

Enter password again or

create a new password

Select signal source

Select input to receive control

signal

Press ESC to return to Control

Menu

Note

Power

When the HAND/AUTO disable function is initiated the function will not become active until a

power

turned off, again, a power

function.

7.6 HAND/AUTO disable

The HAND/AUTO button is now disabled and local control of the IOP-2 cannot be activated by

the HAND/AUTO button. In this example, the converter is now setup to receive the

HAND/AUTO command from Digital Input 1 (DI1).

-cycle required to complete the HAND/AUTO disable function

-cycle of the IOP-2 has been performed. When the HAND/AUTO disable function is

-cycle of the IOP-2 is required to complete the deactivation of the

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

45

Page 48

Control menu

7.6 HAND/AUTO disable

Intelligent Operating Panel 2 (IOP-2)

46 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 49

8

WARNING

Protection of project data files from unauthorized usage

with, for example, the use of credentials.

8.1 Menu overview

Overview

Transportation of project data files have to be secured by technical means, for example,

encrypted/signed emails, encrypted/signed USB-sticks etc., especially in the public internet.

Project data files have to be stored with restricted access within the OEM/end customer

area, for example, access restrictions to SharePoints, databases, etc. by user management

The "Menu" is selected from the five menu options at the bottom of the IOP-2 screen.

When the "Menu" option is selected the following functions are displayed:

• Wizards

• Parameters

• Diagnostic

• Up/Download

• Extras

By sliding your finger around the Sensor Control Field or using the arrow keys, the required

function can be highlighted. Pushing the OK confirms the selection and further sub-menus

will be displayed. Pressing ESC once will return the IOP-2 to the previous screen, a longer

press will return the display to the "Status" screen.

For information on the IOP-2 compatibility, see

Introduction (Page 11).

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

47

Page 50

Menu

•

•

•

•

•

•

• Drive enables

When this option is selected the screen will display any active

faults and alarms that have not yet been acknowledged.

Each fault and alarm can be selected and by pressing the INFO

key

displayed.

When this option is selected the screen will display a list of all

previous faults and alarms with the time that they occurred.

Each fault and alarm can be selected and by pressing the INFO

key

displayed.

Displays specific technical information regarding the Control

Unit and Power Module to which the IOP

displayed. The actual information displayed depends on the

type of Control Unit and Power Module to which the IOP

connected.

8.2 Diagnostics

8.2 Diagnostics

Diagnostics menu

When the diagnostic function is selected the following options are presented:

Active faults/alarms

History

Identification/Maintenance

I/O status

Communications status

I/O simulation

Active faults/alarms

or the OK key, an explanation of the fault or alarm will be

History

or the OK key, an explanation of the fault or alarm will be

Identification/Maintenance

-2 is attached will be

Intelligent Operating Panel 2 (IOP-2)

48 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

-2 is

Page 51

Menu

This option displays a list of the digital and analog inputs and

outputs of the converter and their current status.

This is an information screen and cannot be changed.

Pressing ESC will return the display to the previous menu.

In the example shown opposite, the status of the digital inputs

are displayed.

This option displays the status of the fieldbus interface and the

d

status words and control word lengths.

In the example shown opposite, the status of the fieldbus

communications is shown.

WARNING

Loss of control of the converter

simulation is activated, then only the I/O simulation can be used to stop the converter.

8.2 Diagnostics

I/O status

Communications status

etails of the settings for the data exchange, for example

I/O simulation

If the converter is started using the I/O simulation and the IOP-2 is removed from the

converter it will not be possible to stop the converter running the motor. If the I/O

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

49

Page 52

Menu

The IOP-2 simulation screen allows digital and analog IOs to be

simulated without the requirement for external signals. These

features are of great benefit during commissioning and fault

finding, as the user can quickly simulate a situation without

using w

For example:

•

•

•

Th

•

•

•

The drive enables screen displays a list of all the current

enabling signals for the converter. If the enable signal is

present and active it will be selected

not present and is not active it will be unselected

This screen is read

8.2 Diagnostics

ires, tools and external equipment.

A digital input can be made high without any wires in the

terminals.

An analog input or output can be driven to any value

without any wires in the terminals.

A simulation can be overridden and made high.

e screen presents the following options:

I/O - Three I/Os can be simulated - two digital and one

analog.

Status - this indicates the real-time status of the input or

output. If the square is shaded then the input or output

signal is present. This is a read-only section of the screen.

Control - this column of the screen displays the present

status of the input or output and can be altered.

Drive enables

-only and is for information purposes only.

Intelligent Operating Panel 2 (IOP-2)

50 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

. If the enable signal is

☐.

Page 53

Menu

The parameter menu allows the user extensive functionality

and access to all the converter parameters. When this option is

selected the user is given the opportunity to perform

parameter orientated functions grouped in the following

manner:

•

•

•

•

•

When searching through any large parameter list, the Fast

scroll function will automat

their finger around the Sensor Control Field in a fast motion.

A large blue box will appear on the screen, showing the

current parameter number, with each scroll the number will

increase by 100. When the user stops scrolli

number nearest to the number displayed will be selected.

8.3 Parameters

8.3 Parameters

Parameter menu

For information on IOP-2 compatibility, see Introduction (Page 11).

Parameter groups

Search by number

My parameters

Changed parameters

Parameter filter

Fast scroll

ically start when the user slides

Parameter groups

All parameters

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

This option allows the user access to the individual parameters of the converter. The default

filter is "Standard" which allows the user access to the most frequently used parameters.

Commissioning

This screen displays a complete listing of all the parameters required for quick

commissioning. The parameters are listed in numerical order and can be accessed to either

confirm the set values or modified should there be a need to fine tune the application or

correct any errors in the parameter values.

Commissioning interface

Selects the storage medium for access via the USB mass storage.

ng, the parameter

51

Page 54

Menu

8.3 Parameters

Saving & reset

This option allows the user access to all the parameters regarding the saving and reset

functions of the converter. Each parameter displays it's currently set value and these can be

modified if required.

System information

This screen displays all the parameters that contain system information regarding the

converter. The majority of these parameters are read-only and are for information purposes

only.

Basic settings

Displays the effective Drive Data Set (DDS). Each basic setting can be selected and modified if

necessary.

Inputs/outputs

This option allows access to all the available parameters to configure the digital and analog

I/Os.

The user can navigate through the various inputs and outputs to see the current

configuration of the inputs and outputs and, if necessary access the parameters directly to

modify their values.

Setpoint channels

This option allows the user to display and modify the setpoint parameters.

Operating mode

This option allows the user to display and modify the operating mode parameters.

Drive functions

This option allows the user direct access to the parameters regarding the drive functions.

It is important that if any parameters concerning the above mentioned functions are to be

modified, that the converter/motor system is in a safe state prior to the parameter changes.

Communications

This option allows the user direct access to the parameters that control and configure the

communications fieldbus of the converter. The parameters can be viewed to confirm their

settings and values, they can also be modified if they are not read-only parameters.

Diagnostics

This option allows the user direct access to the parameters that monitor the state of the

system.

All the parameters under these groupings are read-only and cannot be modified.

Intelligent Operating Panel 2 (IOP-2)

52 Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

Page 55

Menu

This option allows the user to search for a specific parameter

number.

If the parameter number does not exist, the screen will display

a choice between "Select a new number" or "Go to the nearest

parameter number".

This option allows the user to select the parameters that they

wish to list. The user is presented with a list of parameters that

can be selected. Once selected

displayed when the "My Parameters" option is selected. There

are additional options that allow the user to manage their list

of pa

Copying the "My Parameters" list to another IOP-2

When a "My Parameters" list is

config.bin

To copy the config.bin, the following procedure should be

performed:

1.

2.

3.

4.

When the "Changed parameters" option is selected the IOP-2

will search the converter parameter list for all the parameters

that have had their values changed from the factory default

settings.

Once the search is complete, the screen will present a list of all

parameters that have changed values.

The individual parameters can be accessed so that their current

values can be displayed and modified if necessary.

8.3 Parameters

Search by number

My parameters

- only those parameters are

rameters.

file on the IOP-2.

Connect the IOP-2 via the USB to your PC (the IOP-2 will

enter "Mass Storage" mode.

Navigate to the config folder (shown in the screenshot).

Copy the config.bin file to a suitable location on your PC.

Disconnect the IOP-2 and connect a new IOP-2 and copy the

config.bin file to the new IOP-2.

Changed parameters

Intelligent Operating Panel 2 (IOP-2)

Operating Instructions, 06/2020, FW V2.6, A5E39549448B AH

created, it saves the lists in the

53

Page 56

Menu

This option allows the user to select the parameter access

level. Standard is the default access level, which gives the

user access to the most frequently used parameters. Expert

level gives access to all available parameters.

The upload and download options allow the user to save

parameter sets to the various memory storage that is

available to the system.

For further information on saving, copying, cloning and

creating custom parameter sets, see

parameter sets (Page 61).

WARNING

Unexpected behavior of converter

the hyperlink below:

8.4 Up/Download

Parameter filter

8.4 Up/Download

Overview

During the transfer of data to and from the converter, it is essential that the transfer is not

interrupted and the process is allowed to be completed. If the process is interrupted, it is

possible that the data could be corrupted and the system may behave in an unexpected

manner. Should an interruption of the transfer process occur, then it is highly

recommended that a factory reset of the converter is performed prior to any further

parameterization or giving the converter control of the application.

Fault screen during up/download

If during the up/download process a fault occurs and the fault screen is displayed, press ESC

if you wish the up/download to be continued. If OK is pressed, it will cancel the

up/download process.

Safety Parameters

If safety parameters are to be downloaded a function test of the safety functions has to be

performed. Please refer to the "Safety Integrated Function Manual" which can be found at

Customer

Safety Integrated Function Manual

(http://support.automation.siemens.com/WW/view/en/50736819