Siemens interranger DPS300 Instructional Manual

Instructional Manual March 2008

interranger

DPS300

Safety Guidelines

Warning notices must be observed to ensure personal safety as well as that of others, and to protect the product and the connected equipment.

These warning notices are accompanied by a clarification of the level of caution to be observed.

Qualified Personnel

This device/system may only be set up and operated in conjunction with this manual. Qualified personnel are only authorized to install and

operate this equipment in accordance with established safety practices and standards.

Warning: This product can only function properly and safely if it is correctly transported, stored, installed, set up, operated, and maintained.

This product is intended for use in industrial areas.

Note: Always use product in accordance with specifications.

Copyright Siemens Milltronics Process

Disclaimer of Liability

Instruments Inc. 2008. All Rights Reserved

This document is available in bound version and in

electronic version. We encourage users to purchase

authorized bound manuals, or to view electronic versions as

designed and authored by Siemens Milltronics Process

Instruments Inc. Siemens Milltronics Process Instruments

Inc. will not be responsible for the contents of partial or

whole reproductions of either bound or electronic versions.

MILLTRONICS®is a registered trademark of Siemens Milltronics Process Instruments Inc.

While we have verified the contents of this

manual for agreement with the instrumentation

described, variations remain possible. Thus we

cannot guarantee full agreement. The contents of

this manual are regularly reviewed and

corrections are included in subsequent editions.

We welcome all suggestions for improvement.

Technical data subject to change.

Contact SMPI Technical Publications at the following address:

Technical Publications

Siemens Milltronics Process Instruments Inc.

1954 Technology Drive, P.O. Box 4225

Peterborough, Ontario, Canada, K9J 7B1

Email: techpubs.smpi@siemens.com

• For a selection of Siemens Milltronics level measurement manuals, go to:

www. siemens.com/processautomation. Under Process Instrumentation, select

listed under the product family.

• For a selection of Siemens Milltronics weighing manuals, go to:

www. siemens.com/processautomation. Under Weighing Technology, select

archive listed under the product family.

Level Measurement

Continuous Weighing Systems

and then go to the manual archive

and then go to the manual

© Siemens Milltronics Process Instruments Inc. 2008

TABLE OF CONTENTS

Table of Contents.....................................................................................................3

Specifications...........................................................................................................5

Electronics............................................................................................................5

Programmer .........................................................................................................6

Transducer ...........................................................................................................6

Options.................................................................................................................7

Cable....................................................................................................................8

Introduction..............................................................................................................9

About This Manual................................................................................................9

About The InterRanger DPS300.........................................................................10

Important InterRanger DPS300 Features ...........................................................13

Programmable Features.....................................................................................14

As a System .......................................................................................................15

Application Planning ..............................................................................................16

Circular Clarifiers................................................................................................16

Rectangular Clarifiers.........................................................................................18

Application Example...............................................................................................22

Installation..............................................................................................................24

Location..............................................................................................................24

Optional Mounting Assembly..............................................................................25

Optional Skimmer Guard....................................................................................29

Transducer Mounting..........................................................................................33

Assembly............................................................................................................35

Communication...................................................................................................39

Level System Synchronization............................................................................40

Power .................................................................................................................40

Programming .........................................................................................................42

Display................................................................................................................42

Keypad – Program Mode....................................................................................43

Programming Security........................................................................................45

Quick Start Parameters .........................................................................................46

Operation................................................................................................................49

Display................................................................................................................49

Keypad – Run Mode...........................................................................................50

System Performance Evaluation.........................................................................51

7ML19981BC01 3 InterRanger DPS300

Performance Test Results.................................................................................. 52

Application Parameters ........................................................................................ 53

Volume Parameters (P050 to P055) .................................................................. 53

Reading Parameters (P060 to P062) ................................................................. 55

Failsafe Parameters (P070 to P072).................................................................. 56

Relay Parameters (P100 to P104, P110 to P113, P129).................................... 58

mA Output Parameters (P200 to P203, P210 to P215, P219)............................ 64

Enhancement Parameters .................................................................................... 68

Data Logging Parameters (P300 and P302) ...................................................... 68

Profile Records (P330 to P337) ......................................................................... 69

Installation Records (P340 to P342)................................................................... 72

Range Calibration Parameters (P650 to P654) .................................................. 72

Temperature Compensation Parameters (P660 to P664) .................................. 74

Rate Parameters (P700 to P707)....................................................................... 75

Measurement Verification Parameters (P710 to P713) ...................................... 77

Display Parameters (P730 to P733, P740)......................................................... 78

Peripheral Communication Support Parameters (P740 to P772) ....................... 79

SmartLinx® Parameters (P790 to P792)........................................................... 81

Echo Processing Parameters (P800 to P807).................................................... 81

Advanced Echo Processing (P810 to P853) ...................................................... 83

Test Parameters (P900 to P913)........................................................................ 90

Measurement Parameters (P920 to P923)......................................................... 92

Master Reset (P999).......................................................................................... 93

Technical Reference ............................................................................................. 95

Transmit Pulse................................................................................................... 95

Echo Processing................................................................................................ 96

Distance Calculation .......................................................................................... 97

Sound Velocity................................................................................................... 97

Scanning............................................................................................................ 97

Volume Calculation............................................................................................ 97

Communication Support..................................................................................... 98

Maintenance ........................................................................................................ 102

Troubleshooting Guide....................................................................................... 103

DEFAULT PARAMETER SETTINGS ................................................................... 106

Programming Charts........................................................................................... 107

InterRanger DPS300 4 7ML19981BC01

Electronics

SPECIFICATIONS

Power:

Environmental:

!

!

!

!

Scan Points:

Accuracy:

Resolution:

Memory: ! EEPROM (non-volatile) no back-up battery required

Programming:

Display:

Temperature :

Compensation

! 2 TS-3 temperature sensors, max.

! programmable fixed temperature

!

area

!

100/115/200/230 V AC ±15%, 50/60 Hz, 31 VA

!

location ! indoor / outdoor

altitude ! 2000 m max

ambient temperature

relative humidity

NEMA 4X / IP65 enclosure)

installation category

!

pollution degree:

!

2 points per DPS300

!

1% of program range* or 2 cm (0.8”), whichever is greater

(ideal conditions)

via removable programmer and / or Dolphin Plus interface package

!

custom graphics, backlit LCD with 51 x 127 mm (5 x 2”) viewing

!

-50 to 150 °C (-58 to 302 °F)

!

integral transducer sensor

! -

20 to 50°C (-5 to 122 °F)

!

suitable for outdoor (Type 4X /

!

II

!

4

!

1% of program range* or 2 cm (0.8”),

whichever is greater (ideal

conditions)

Temperature Error:

Outputs: ! transducer drive:

! 1 form “C” SPDT contact per relay,

! rated 5 A at 250 V AC, non-inductive

!

relays: ! 4 alarm/control relays

!

mA output:

! 0.1% resolution

! 0-20 or 4-20 mA, scalable

! 750 Ω, isolated, 30 V rms

* program range is defined as the empty distance to the face of the transducer

(P006) plus any range extension (P801).

!

with compensation:

!

fixed temperature:

!

150 to 315 V peak

!

2 outputs max.

!

0.1% of range

!

0.22% / °C deviation from

programmed temperature.

7ML19981BC01 5 InterRanger DPS300

Communications:

(see Options)

! Dolphin compatible

! proprietary bipolar current loop for BIC-2 communication

Enclosure: ! Type 4 / NEMA 4 / IP65

! 285 mm W x 209 mm H x 92 mm D (11.2” W x 8.2” H x 3.6” D)

! polycarbonate

!

SmartLinx ® compatible

!

RS-232 / 485 port

Weight:

Approvals:

Programmer

Power: may be supplied with either:

Ambient Temperature:

Keypad:

Interface:

!

2.7 kg (6 lb)

!

*, CSA

CE

*EMC performance available upon request.

! 3 V Lithium (non-replaceable)

or

!

9 V (ANSI/NEDA 1604, PP3 or equivalent)

!

-20 to 50°C (-5 to 122°F)

!

20 keys with tactile feedback

!

non-invasive, digital, infra-red

NRTL/C

Enclosure:

! 67 mm W x 100 mm H x 25 mm D (2.6” W x 4” H x 1” D)

! ABS plastic

Weight:

!

general purpose

!

150 g (0.3 lb)

Transducer

Model:

Beam angle:

(in water)

Range:

Refer to the associated instruction manual for wiring only (not installation).

!

Echomax® XCT-12

! 30

! 1 to 30m (3.3 to 99’)

°

InterRanger DPS300 6 7ML19981BC01

Options

Skimmer Guard

! for protecting the transducer and allowing it to slide over the

skimmer as it passes.

Mounting Assembly

!

for securing and positioning the transducer in the clarifier.

Temperature Sensor:

!

model TS-3

Buffered Interface Converter:

!

BIC-II, DPS300 bipolar communication current loop to remote

RS232 or RS422 port

SmartLinx® Modules

!

protocol specific modules for interface with popular industrial

communication systems. Refer to associated product

documentation.

Dolphin Plus:

!

Windows®-compatible interface and infrared ComVerter link

. Refer to associated product documentation.

Cable:

Skimmer Guard

Model: ! Type A for 20cm (8”) skimmers

Temperature: ! -40 to 80 °C (-40°C to 176°F)

Construction: ! stainless steel hinged conduit with guard, and neoprene

hinge boot

Connection: ! transducer: 1” NPT or BSP coupling

Articulation: ! ± 90° off vertical

Weight: ! Type A: 1.4 kg (3 lb)

! Type B: 2.1 kg (5 lb)

Mounting Assembly

Application: ! railings, typically 50mm dia. pipe or less, 2 rails spaced 432

Temperature: ! -40 to 80°C (-40 to 176°F)

Construction: ! epoxy coated aluminum, with stainless steel hardware

Weight: ! 6.5 kg (15 lbs)

!

to suit transducer, temperature sensor, instrumentation and

communication

! Type B for 40cm (16”) skimmers

! conduit: ¾” NPT or BSP coupling

to 610mm (17 to 24”)apart on centre

7ML19981BC01 7 InterRanger DPS300

Cable

Transducer: ! RG-62 A/U (or equivalent), 365m (1,200 ft) max.

See transducer instructions for short extensions

(in grounded metal conduit, separate from other wiring)

MA Output: ! Belden 8760, shielded / twisted pair, 18 AWG (0.75mm

equivalent

Maximum separation 1,500 m (5,000 ft)

Synchronisation: ! Belden 8760, shielded / twisted pair, 18 AWG (0.75mm

equivalent

RJ-11 Port: ! No shielded cable necessary

Maximum length 3m

Bipolar Current Loop: ! Belden 8760, shielded / twisted pair, 18 AWG (0.75mm

equivalent

Maximum separation 1,500 m (5,000 ft)

RS-232 Link ! Belden 8770, shielded / twisted pair, 18 AWG (0.75mm

equivalent

Maximum separation 15 m (50 ft)

RS-485 Link: ! Belden 8770, shielded / twisted pair, 18 AWG (0.75mm

equivalent

Maximum separation 1,200 m (4,000 ft)

2

) or

2

) or

2

) or

2

) or

2

) or

InterRanger DPS300 8 7ML19981BC01

About This Manual

This instruction manual provides information specific to the InterRanger DPS300

(Dual Point Sludge) monitoring system.

Introduction introduces installers and operators to the DPS300,

Installation provides a step by step procedure to install the

Programming defines program mode display and keypad functions,

Quick Start Parameters details the minimum programming required to get

Operation defines RUN mode display and keypad functions,

INTRODUCTION

with brief descriptions of key features.

DPS300.

and general programming information.

started.

including the RUN mode entry procedure and

performance evaluation recommendations.

Application Parameters details the programmable features which may be

used to alter Run mode display, failsafe, relay, and

mA output operation.

Enhancement Parameters defines the programmable features used to enhance

RUN mode operation. (Typically used as directed by

the Troubleshooting Guide).

Technical Reference provides detailed information for complex features

and provides application examples.

Troubleshooting Guide provides a quick reference to installation modification

and programming remedies to overcome challenging

operating conditions.

Specifications lists the environmental, physical, and operational

characteristics associated with the DPS300.

Programming Chart provides a convenient space to record all

programming for future reference.

7ML19981BC01 9 InterRanger DPS300

About The InterRanger DPS300

Note:

• The InterRanger DPS300 is to be used only in the manner outlined in this

instruction manual.

• This product is intended for use in industrial areas. Operation of this equipment

in a residential area may cause interference to several frequency based

communications.

This microprocessor based level monitor is designed specifically for the

measurement of sludge blanket levels in wastewater clarifiers. A DPS300 level

monitor, and Siemens ultrasonic transducer, accurately monitor the sludge blanket

level without contacting the blanket.

The DPS300 transmits electrical pulses to the transducer. The transducer

converts the electrical pulses to ultrasonic pulses, which are emitted from the

transducer face. The DPS300 measures the time from pulse emission to reception

of the echo from the sludge interface. The time measured, is used to calculate the

distance from the transducer face to the sludge blanket.

The distance calculation is dependent upon the sound velocity through the

wastewater in the clarifier, which is in turn dependent upon the temperature of the

wastewater. The transducer, having an integral temperature sensor, and being

immersed into the wastewater, also monitors the temperature of the wastewater.

The transducer transmits the temperature to the DPS300, where velocity

compensation is applied to the level measurement calculation.

Nominally speaking, the DPS300 is capable of detecting down to 4% solids, in up

to 30m of turbid wastewater, and 0.2% solids in 5 m of clear wastewater.

This material and measurement range versatility is accomplished by using

Siemens patented Sonic Intelligence™. Sonic Intelligence provides high

measurement reliability, regardless of changing conditions in the clarifier.

InterRanger DPS300 10 7ML19981BC01

By using ultrasonic echo ranging principles with Sonic Intelligence and velocity

compensation, the DPS300 provides outstanding measurement accuracy, up to

1% of range, depending on process conditions.

The distance calculation may be converted to space, material level, material

volume, or remaining capacity. The Reading chosen (and operating data) for each

clarifier is displayed on the Liquid Crystal Display (LCD).

The relays and mA outputs may be used as preset (or programmed as desired) to

activate alarms and/or operate remote monitoring equipment and/or process

control equipment.

As well, the DPS300 may be connected to a Milltronics BIC-II (Buffered Interface

Converter) to provide RS-232 and/or RS-422 communications for host computers,

Distributed Control Systems, and special (capable of operating as a host device)

Programmable Logic Controllers.

Programming can be done locally using the portable programmer keypad, or

remotely through optional Dolphin software or SmartLinx

®

.

• The programmer transmits the keypad entries via infrared link to the DPS300, and

can be removed when not in use.

• Dolphin allows programming either through the portable ComVerter and infrared

link or hardwired via the RS-232/485 communication port.

• SmartLinx

®

provides protocol specific hardware and software for interface with

popular industrial communication systems.

7ML19981BC01 11 InterRanger DPS300

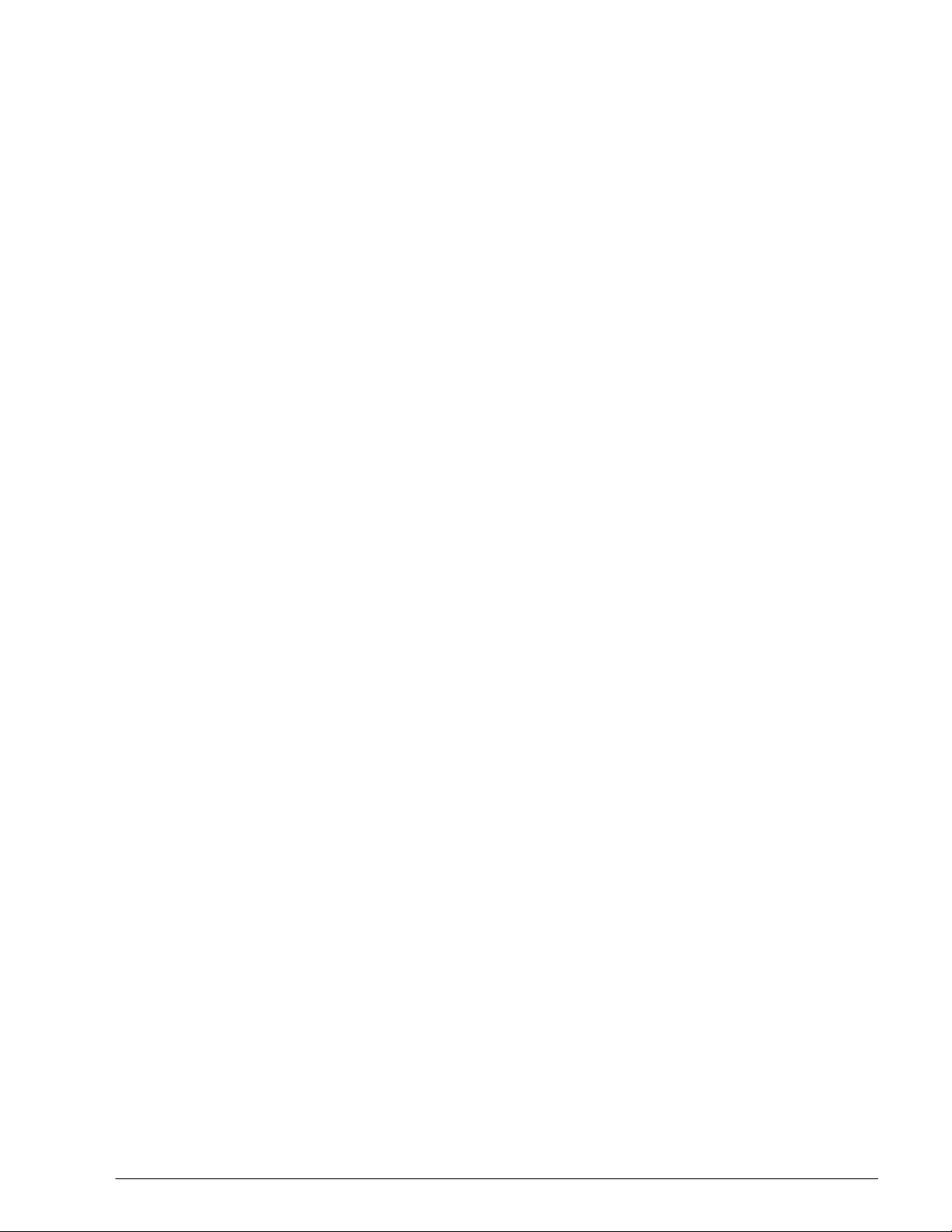

DPS300 Communication Overview

r

Plant-wide

control system

network

0/4—20mA

(PLC or DCS)

RS-232 or 485

(local)

or

SmartLinx®

Bipola

current loop

(remote)

RS-232 or 422

or

InterRanger DPS300 12 7ML19981BC01

Important InterRanger DPS300 Features

Fixed Features

Enclosure: Corrosion resistant, dust and liquid tight.

Backlit LCD: Large digits for Reading and programming value

displays.

Illuminated LCD insures readability under all lighting

conditions.

Custom Graphic Symbols for continuous indication of

operating conditions.

Programmer: 20 keys for easy access to programming and

operating functions.

Magnetic mounting and infrared interface permit

removal on programming completion.

Scanning: Capable of scanning two clarifiers, with the addition of

a second transducer.

Communications: SmartLinx® Compatible

Communications ready when equipped with an

appropriate Siemens SmartLinx module.

Milltronics Peripherals

The communication port provides connection for

RS-232, RS-485 or Milltronics bipolar current

loop. The current loop provides remote

communication via Milltronics BIC II to the

peripheral device. The BIC II converts the current

loop to RS-232 or RS-422 signal

Dolphin Compatible Communications

Dolphin Plus is Windows95®-compatible

software. It offers local interface through the

infrared ComVerter, or remote connection

through the RS-232 or RS-485 port. The software

provides an easy means for programming,

uploading, or downloading parameters.

Reliability: Sonic Intelligence™ ensures all measurements are

accurate and reliable.

Immune to power interruptions. All programming is

stored indefinitely. Dynamic operating data is retained

for one hour and updated immediately on power

resumption.

7ML19981BC01 13 InterRanger DPS300

Programmable Features

Typically, a very small percentage of the programmable features require operator

alteration. However, for demanding measurement requirements any operator

programmable feature may be adjusted as desired.

Following is a list of some of the features that make the DPS300 easy to program,

yet versatile enough to handle complex level measurement requirements.

General Features

Direct Access: Any operator programmable feature may be accessed

Scroll Access: Single button “scroll forward”, single button “scroll

Operation: Select “level”,”space”,or ”distance”.

Material: Select clarifier type; automatically adjusts echo

Units: Display Readings in m, cm, mm, ft, in, %, or any other

directly.

back”, to key features.

processing for the type of clarifier.

units desired.

Additional Features (Use as Desired)

Failsafe: Numerous failsafe options for process control

Relays: 8 functions including level, rate of change, pump

Fixed or independent on/off setpoints

mA outputs: Based on level, space, or distance.

4 range selections, 0-20, 4-20, 20-0, or 20-4 mA.

Adjustable range and over-range limits.

equipment activation.

control, temperature and more.

InterRanger DPS300 14 7ML19981BC01

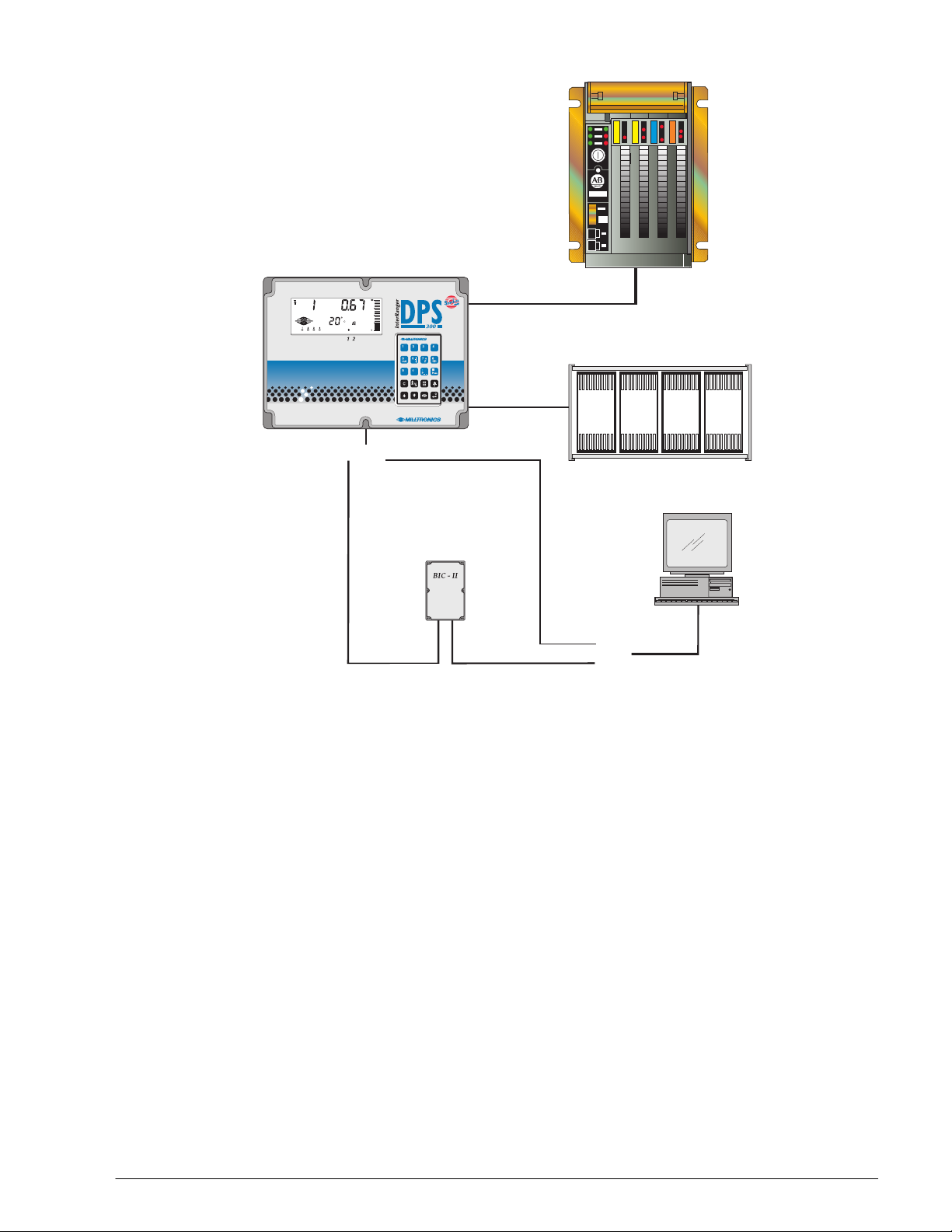

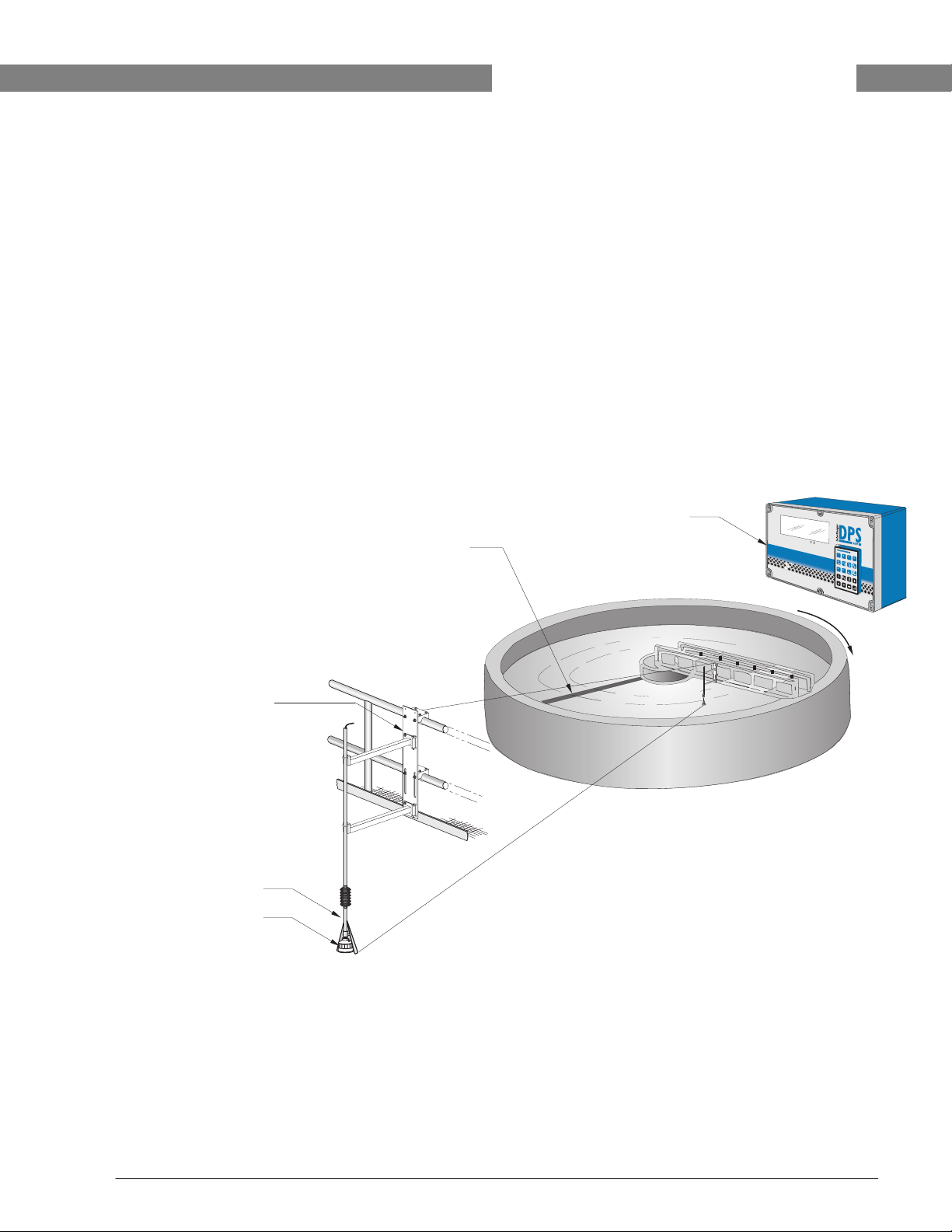

As a System

s

d

y

r

As a system, the DPS300 is made up of:

minimum maximum

one DPS300 one DPS300

one XCT-12 transducer two XCT-12 transducers

one Skimmer Guard per transducer

one Mounting Assembly per transducer

one SmartLinx communications module

DPS300

mounting

plate

custome

conduit

Optional Siemen

Skimmer Guar

The Skimmer Guard

protects the transducer b

allowing it to ride over a

passing skimmer.

DPS300

Siemens Mounting Assembly

Mounts the transducer to

handrails along the clarifier

walkway or bridge.

Siemens XCT-12

The ultrasonic transducer used with the DPS300. If

the DPS300 is programmed to monitor two clarifiers,

then two transducers are required.

Note:

Operation of the transducer requires that the face be

immersed 3 to 6 cm into the clarifier wastewater.

DPS300 System Integration

• Assemble the transducer to the Siemens Skimmer Guard if provided. Otherwise

install directly to your conduit with a ¾” to 1” NPT or BSP reducer.

Refer to the Skimmer Guard section for dimension and assembly details. Refer to

the XCT-12 manual for connection and wiring details only.

• Assemble the Siemens Mounting Assembly, if provided, to the handrail. And,

mount the transducer (with Skimmer Guard if provided) to the Mounting Assembly.

Otherwise mount the transducer assembly in a secure fashion.

Refer to the Mounting Assembly section for dimensions and assembly details.

• Install the DPS300 and program the unit for your specific application.

Refer to the Application and Parameters sections of this manual.

7ML19981BC01 15 InterRanger DPS300

The DPS300 is designed to detect and measure the sludge blanket in up to two

wastewater clarifiers. The basic requirements of a working DPS system are the

transducers and the associated electronics.

The electronics can be mounted at the clarifier or up to 365 m away from the

transducer. Refer to DPS300 Specifications in this manual.

The transducer is installed such that its face is immersed 3 to 6 cm in the clarifier

wastewater.

Beyond these given requirements, a few practical aspects of the clarifier

application and its operation are of particular concern.

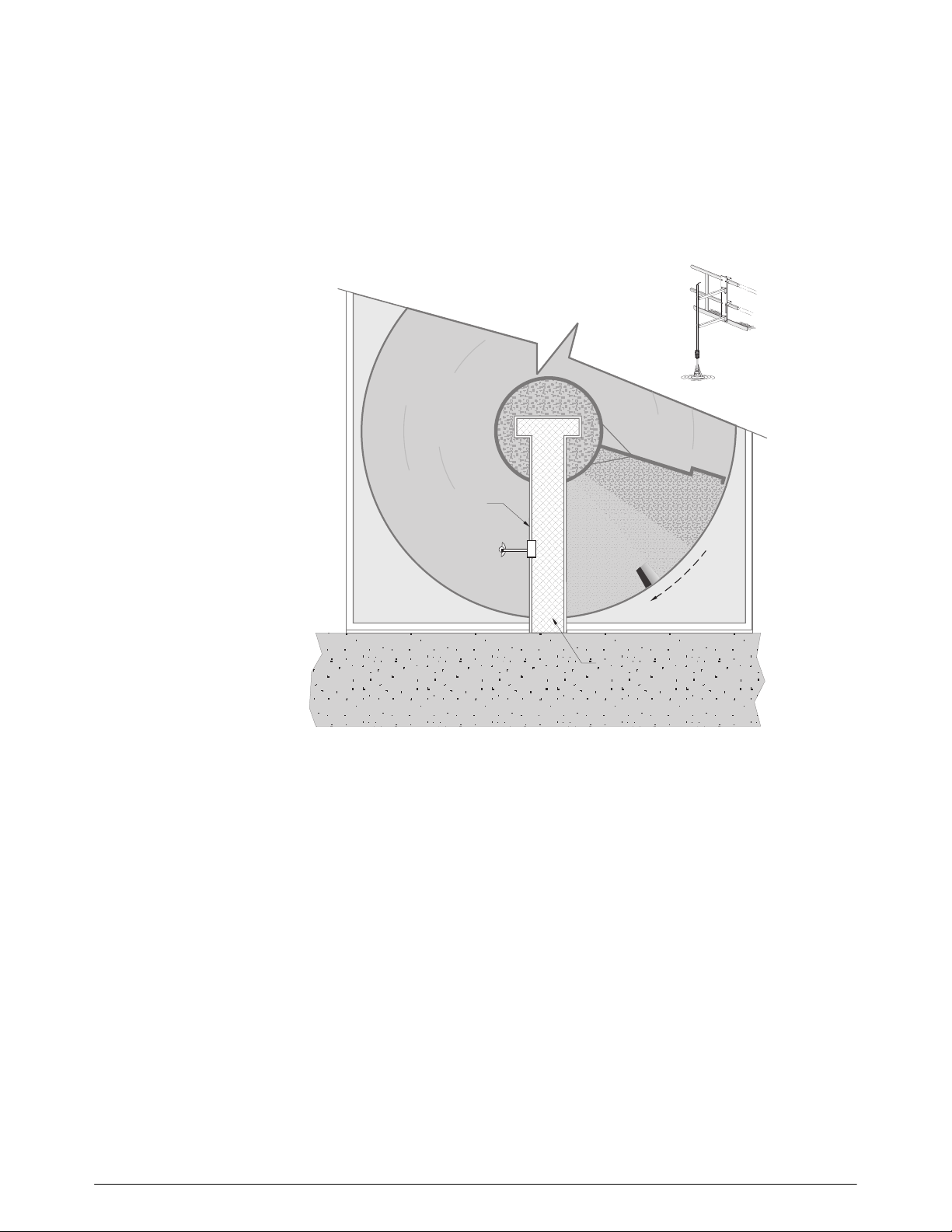

Circular Clarifiers

There are several different types of circular clarifiers, but all operate in the same

basic way and share common design features that will need to be considered

when installing an InterRanger™ DPS300.

Some of these considerations are:

APPLICATION PLANNING

Catwalk, Bridge or Walkway

Most circular tanks have a catwalk that extends into the centre of the tank, usually

with 2" (51 mm) or similar, tubular railings. These railings are the recommended

mounting location for the InterRanger™.

The Siemens Mounting Assembly is available to locate the transducer in this

location.

Inlet

This is where the wastewater flows into the tank. Do not mount the transducer

close to the inlet because the water is aerated and the sludge is disturbed. To

obtain the most accurate readings, the sensor should be located above a relatively

undisturbed portion of the tank where aeration is not present.

Tank sides

The sensor must be mounted at least 1 m (3') from the side of the tank. If the

sensor is mounted closer than this the walls could cause interference and

ultimately lead to inaccurate signals or errors.

Ladders, Beams, Supports, etc.

Be sure that there are no permanent underwater obstructions within 1 m (3') of the

sensor that could disrupt the signal. Obtain drawings and/or consult with plant

personnel to locate any of these structures that may not be visible.

InterRanger DPS300 16 7ML19981BC01

Surface Skimmers

Skimmers are used to remove the scum from the surface of the water in the

clarifier. The scum is skimmed away from the effluent weirs into a trough where it

can be removed easily.

It is important to observe the skimmer action when setting up the InterRanger. If

the best location for the sensor is in the path of the skimmer (often the case) then

the optional Skimmer Guard must be used.

Circular Clarifier

skimmer

handrail

scum trough

mounting

location

bridge

skimmer

direction

Scrapers

Scrapers keep the oldest sludge on the bottom of the tank from hardening and

help to move the sludge into a hopper for pumping.

In circular tanks, the skimmer and scraper are often connected to the same

rotating mechanism radiating from the centre of the tank. Common configurations

could include one or two skimmers and up to four scrapers. Usually these arms

are 90° or 180° apart.

7ML19981BC01 17 InterRanger DPS300

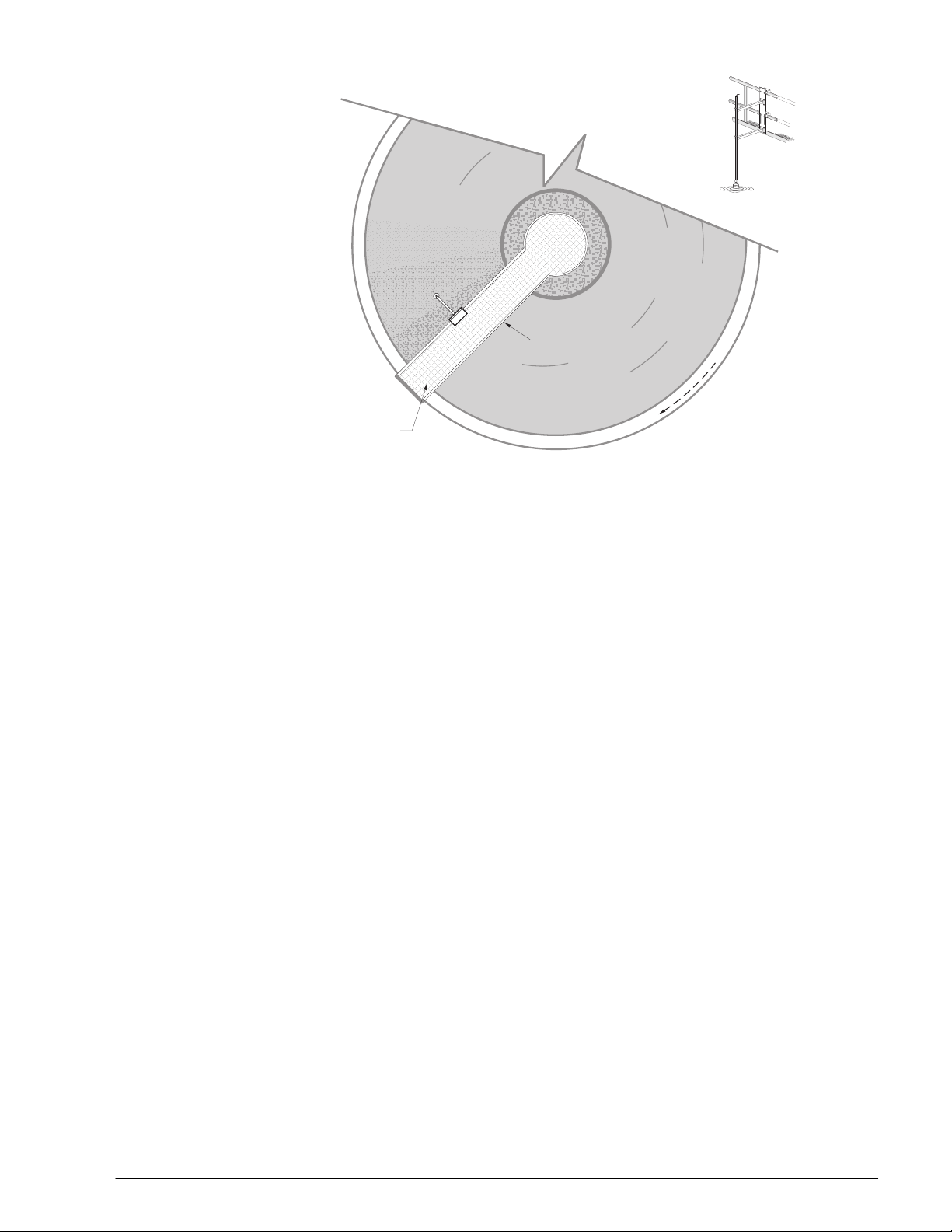

Moving or Travelling Bridges

mounting

location

handrail

bridge

travelling bridge

direction

On some clarifiers the bridge or walkway moves with the skimmer. For clarifiers

with these types of arrangements, care must be taken when choosing a mounting

location. The following items should be considered when choosing a location on

the bridge:

• The transducer should be mounted in front of the bottom scraper mechanism.

The sludge becomes very disturbed after the passing of a bottom scraper and a

clean interface will be difficult to detect. Mount the transducer in front of the

scraper, ideally 180° from the scraper or 90° if two scrapers exist.

• Ensure that the transducer will not come into contact with the scum trough.

It is important to observe the bridge motion through at least one complete cycle to

ensure that the transducer and/or the mounting assembly will not collide with any

structures in the tank.

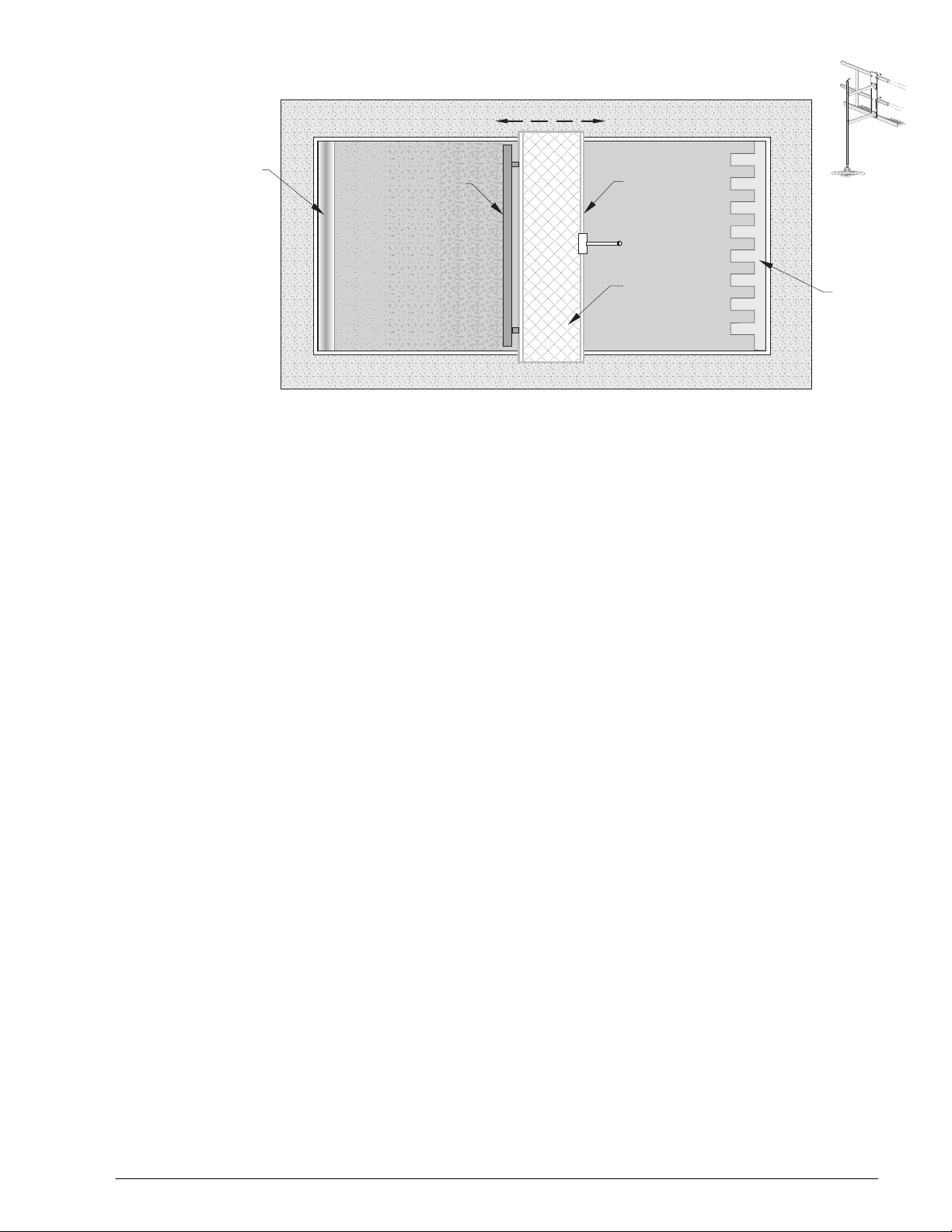

Rectangular Clarifiers

There are several different types of rectangular clarifiers, but all operate in the

same basic way and share common design features that will need to be

considered when installing an InterRanger™ DPS300.

Some of the considerations are:

Catwalk, Bridge or Walkway

Some rectangular tanks have a bridge that spans across the entire width of the

tank, usually with 2" (51 mm) or similar, tubular railings. These railings are the

recommended mounting location for the InterRanger™ once a suitable spot has

been found.

The Siemens Mounting Assembly is available to secure the transducer in this

location.

InterRanger DPS300 18 7ML19981BC01

Inlet

r

This is where the wastewater flows into the tank. Do not mount the transducer

close to the inlet because the water is aerated and the sludge is disturbed. To

obtain the most accurate readings, the sensor should be located above a relatively

undisturbed portion of the tank where aeration is not present.

Tank sides

The sensor must be mounted at least 1 m (3') from the side of the tank. If the

sensor is mounted closer than this, the walls could cause interference and

ultimately lead to inaccurate signals or errors.

Ladders, Beams, Supports, etc.

Be sure that there are no underwater obstructions within 1m (3') of the sensor that

could disrupt the signal. Obtain drawings and/or consult with plant personnel to

locate any of these structures that may not be visible.

Surface Skimmers

Skimmers are used to remove the scum from the surface of the water in the

clarifier. They are usually short fences called “flights” that are pulled along the top

of the water with a chain mechanism in rectangular tanks. The scum is skimmed

away from the effluent weirs into a trough where it can be removed easily. It is

important to observe the skimmer action when setting up the InterRanger. If the

best location for the sensor is in the path of the skimmer then the optional

Skimmer Guard must be used.

Rectangular Clarifier

scum

trough

Scrapers

Scrapers keep the oldest sludge on the bottom of the tank from hardening and

help to move the sludge into a hopper for pumping. In rectangular tanks, often the

scrapers are also the skimmers. They run along the bottom on a chain mechanism

for the length of the tank, up the side and then along the top to pull the scum into a

trough.

skimmer direction

mounting location

flights

handrail

effluent

wei

7ML19981BC01 19 InterRanger DPS300

Moving or Travelling Bridges

r

scum

trough

skimme

bridge movement

handrail

mounting

location

travelling

bridge

effluent

weir

For clarifiers with these types of arrangements, care must be taken in choosing a

mounting location. The following items should be considered when choosing a

location on the bridge:

• The transducer should be mounted behind (after) the surface skimmer (if present).

This is to help minimize the amount of potential scum build-up on the transducer.

• The transducer should be mounted in front of the bottom scraper mechanism.

The sludge becomes very disturbed after the passing of a bottom scraper and a

clean interface will be difficult to detect. Mount the transducer in front of the

scraper, not behind.

• The transducer should not be mounted near any siphoning-type outlet.

Some clarifiers utilize a siphoning technique to maintain sludge levels. Do not

locate the transducer near these outlets as the sludge is more disturbed there.

Location

• Ensure the transducer will not come into contact with effluent weirs or scum

troughs at either end of the bridge travel.

It is important to observe the bridge motion through at least one complete cycle to

ensure that the transducer and/or the mounting assembly will not collide with any

structures in the tank.

An average sludge level reading will be displayed for the location at which the

transducer is installed. This location may have to be compromised for practical

reasons, pertaining to the physical installation of the transducer, and physical or

operational characteristics of the clarifier.

We suggest these examples:

Skimmers

Where surface skimmers are in use, the optional Skimmer Guard should be used

to protect the transducer and from passing skimmers.

InterRanger DPS300 20 7ML19981BC01

Mounting

If the Skimmer Guard is required, it can be field installed in a manner suitable for

the clarifier installation and its surroundings. Consult with your mechanical

department or contractor.

The Mounting Assembly provides a method of installing the transducer or

Skimmer Guard to clarifier handrails.

As mentioned, mounting of the transducer must take into account several

considerations.

• vertical adjustment of the transducer so that it is immersed in the clarifier water 3

to 6 cm.

Siemens Mounting Assembly provides this.

• horizontal adjustment of the transducer so that it can be extended away from the

clarifier wall or handrail

Siemens Mounting Assembly provides this.

• articulation of the transducer conduit so that, where skimmers are in use, the

transducer is deflected out of the way as the skimmer passes.

Siemens Skimmer Guard provides this.

7ML19981BC01 21 InterRanger DPS300

APPLICATION EXAMPLE

y

r

r

r

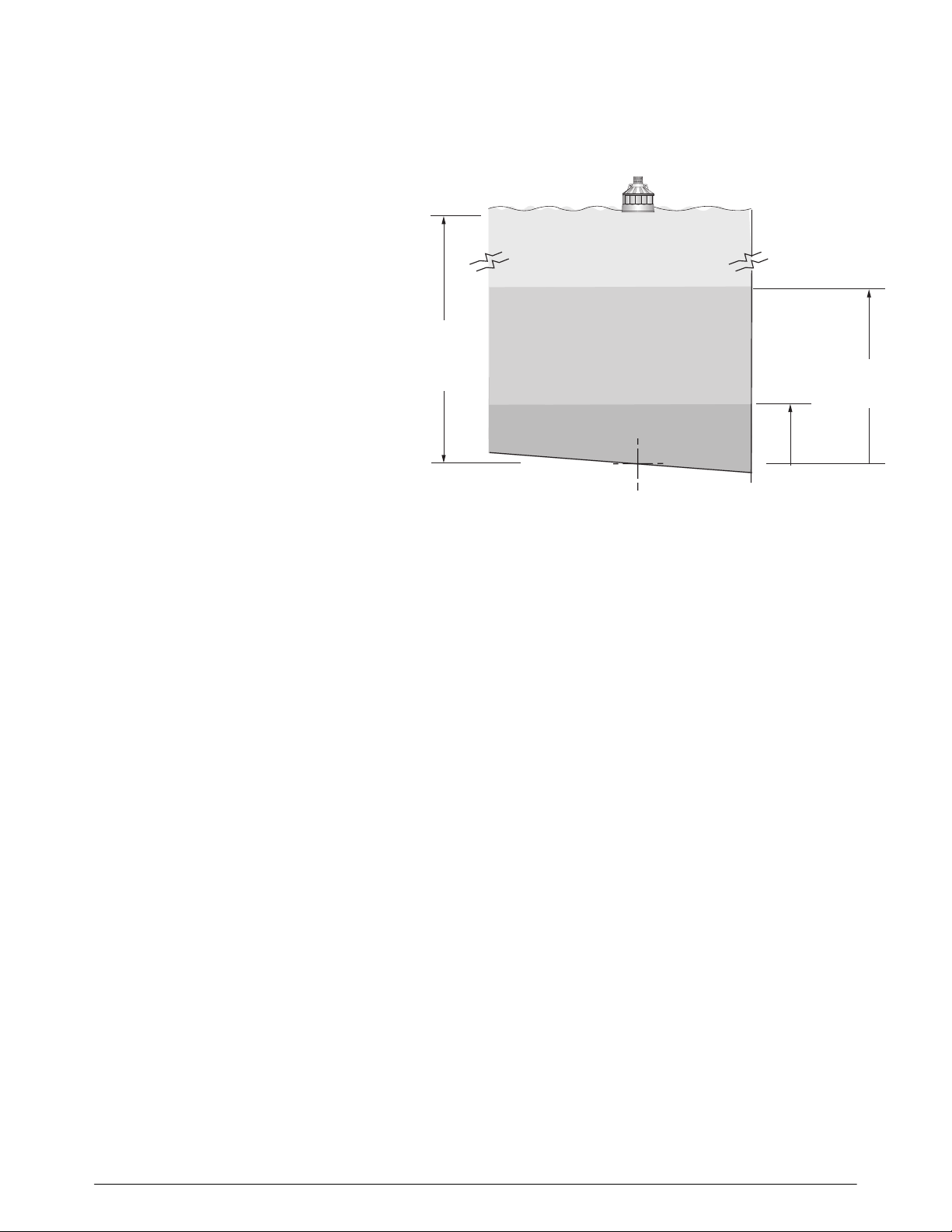

It is desired to measure the sludge blanket in a circular primary clarifier. The

clarifier is equipped with a skimmer, and the depth of wastewater in the clarifier is

approximately 5 m. When the sludge level rises to about 0.3 m, a pump turns on

to pump out the sludge to a level of about 0.1 m. The pump is then turned off.

Set the following parameters as follows:

System requirements:

• one DPS300*

• one XCT-12 transducer

• one Siemens Skimmer Guard

• one Siemens Mounting Assembly

*The DPS300 is a dual point monitor, capable of measuring two clarifiers when the

unit is equipped with two transducers. This example shows the unit used for single

point monitoring but two could be used.

DPS300

Milltronics

Mounting

Assembl

Milltronics Skimme

Guard

XCT-12

transduce

skimme

skimmer

travel

The DPS300 can be

mounted locally on the

clarifier or remotely in a

control room.

Note:

When powered up, the DPS300 will take up to several minutes to lock onto its first

measurement. During this time several errors may be reported. These errors

should be ignored. If errors are reported after the startup period, consult the

Troubleshooting section.

InterRanger DPS300 22 7ML19981BC01

P001 = 1

P002 = 1

P005 = 1

P006 = 4.9,

P110, relay 1 = 1

P111, relay 1 = 50,

sludge level measured from bottom (see P006)

primary clarifier

units in meters

distance from the face

of the transducer to the

bottom of the clarifier

directly beneath

P006 =

4.9 m

relay 1 is assigned to

point 1

P112 =0.3 m,

pump on

P112 =0.1 m,

pump off

relay 1 is assigned for pump control

P112, relay A setpoint = 0.3

sludge level at which the pump turns on

P113, relay B setpoint = 0.1

sludge level at which the pump turns off

7ML19981BC01 23 InterRanger DPS300

Location

Electronics

INSTALLATION

Note:

Installation shall only be performed by qualified personnel, and in accordance with

local governing regulations.

Although the Mounting Assembly provides a mounting plate for external

installation, the unit can also be installed indoors in a controlled environment

comfortable to operating personnel.

If it is required to mount the unit outdoors, the supplied panel can be attached to

the Mounting Assembly.

Regardless, the unit must be mounted in an area that:

• is conformant to the units specifications

• provides clearance to swing open the front cover and perform the required wiring

connections

• provides access for viewing

• is vibration free

Avoid a location that is:

exposed to continuous direct sunlight. (Otherwise, provide a sun shield.)

close to high voltage or current runs, contactors, or SCR control drives

Cable/Conduit Entry Requirements

Determine the number of conduit entries required:

• transducer(s) – one or two transducers

• communications – SmartLinx, RS-485, RS-232, bi-polar

• instrumentation – relay outputs, 4-20 mA

• synchronization – if more than one unit in proximity

• power

Note:

• Transducer cables must be run in a grounded metal conduit, separate from

other wiring, (except TS-3 temperature sensor wiring, if applicable).

• This product is susceptable to electrostatic shock. Follow proper grounding

procedures.

InterRanger DPS300 24 7ML19981BC01

Transducer

As the transducer represents the point of measurement of the sludge blanket, it

should be located where it can give a reliable and meaningful measurement.

The ideal location may be compromised due to structural considerations of the

clarifier, and practicality of installation. Refer to Application Planning on page 16

for more information.

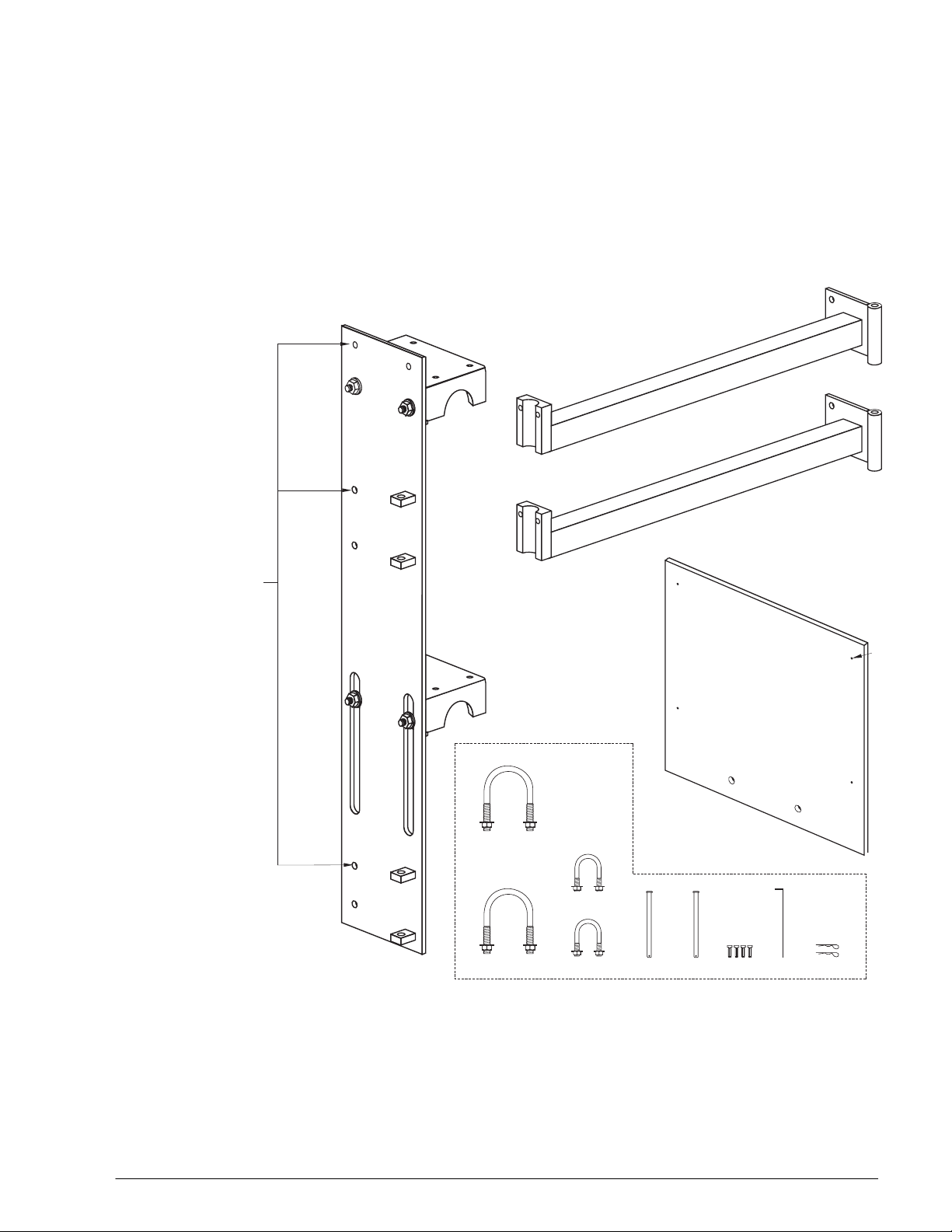

Optional Mounting Assembly

The mounting assembly provides an easy means of extending the transducer out

into the clarifier wastewater by hanging off of nearby handrails.

305 w x 292 h mm

(12 w x 11. 5 h ”)

432 to

610 mm

(17–24”)

826 mm

(32.5”)

7ML19981BC01 25 InterRanger DPS300

Mounting Assembly Usage

In clarifiers where skimmers are in use, the transducer must be raised to avoid

damage from the passing skimmer. If you have a Siemens Skimmer Guard, refer

to that manual before installing the Mounting Assembly.

Refer to the DPS300 system manual to determine the appropriate location for

installing the Mounting Assembly.

Components

rail bracket (2)

extension arms (2)

5/16 – 18 x 1 bolt

2 washers (flat)

1 lock nut

(in hardware bag)

base plate (1)

u-bolts

(with nuts & washers)

(4 large & 2 small)

clevis pin (2)

in hardware bag

mounting plate (1)

(for DPS300 electronics)

6-32

hex

bolts

(4)

hitch pin (2)

7/64”

hex

key

6 – 32

threaded

hex bolts in

hardware

bag.

InterRanger DPS300 26 7ML19981BC01

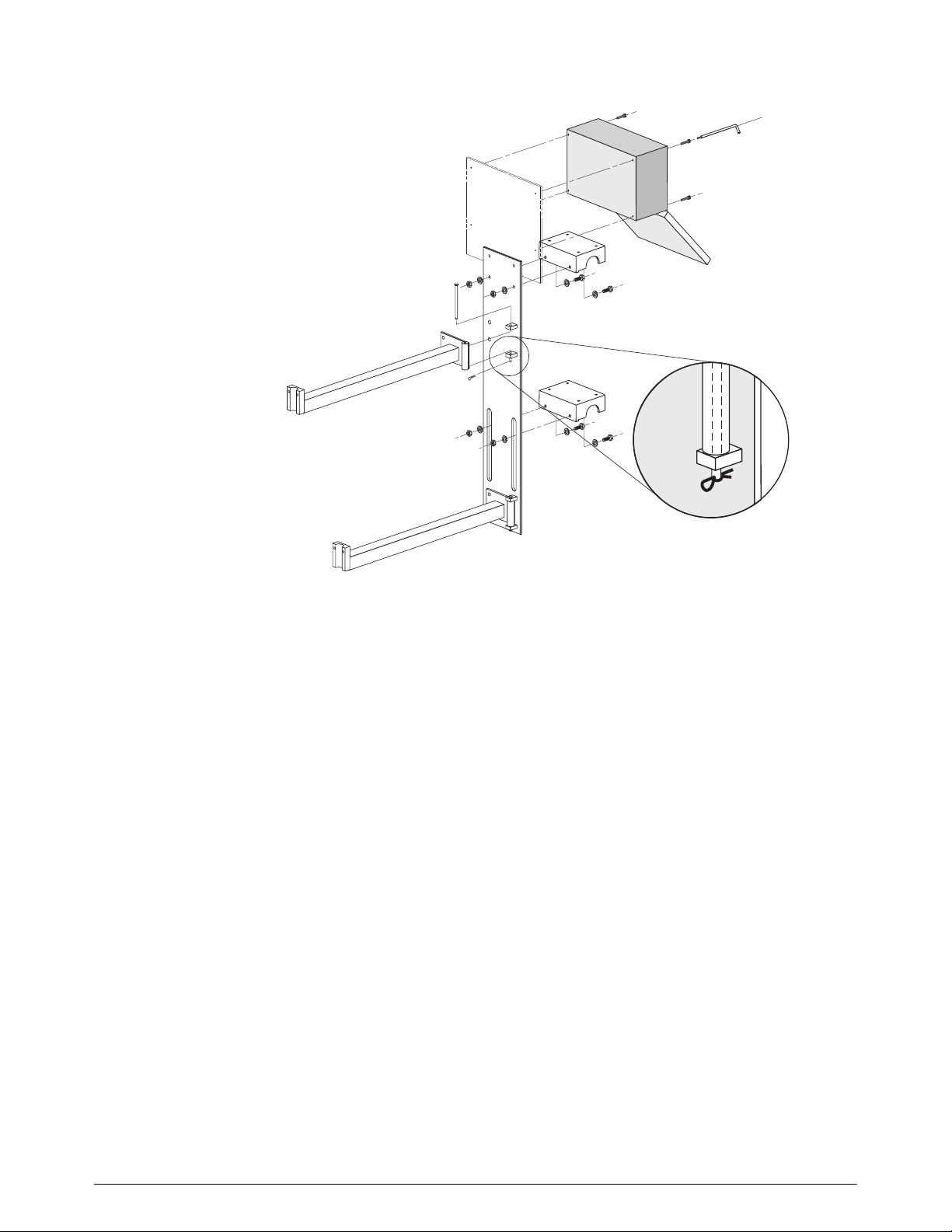

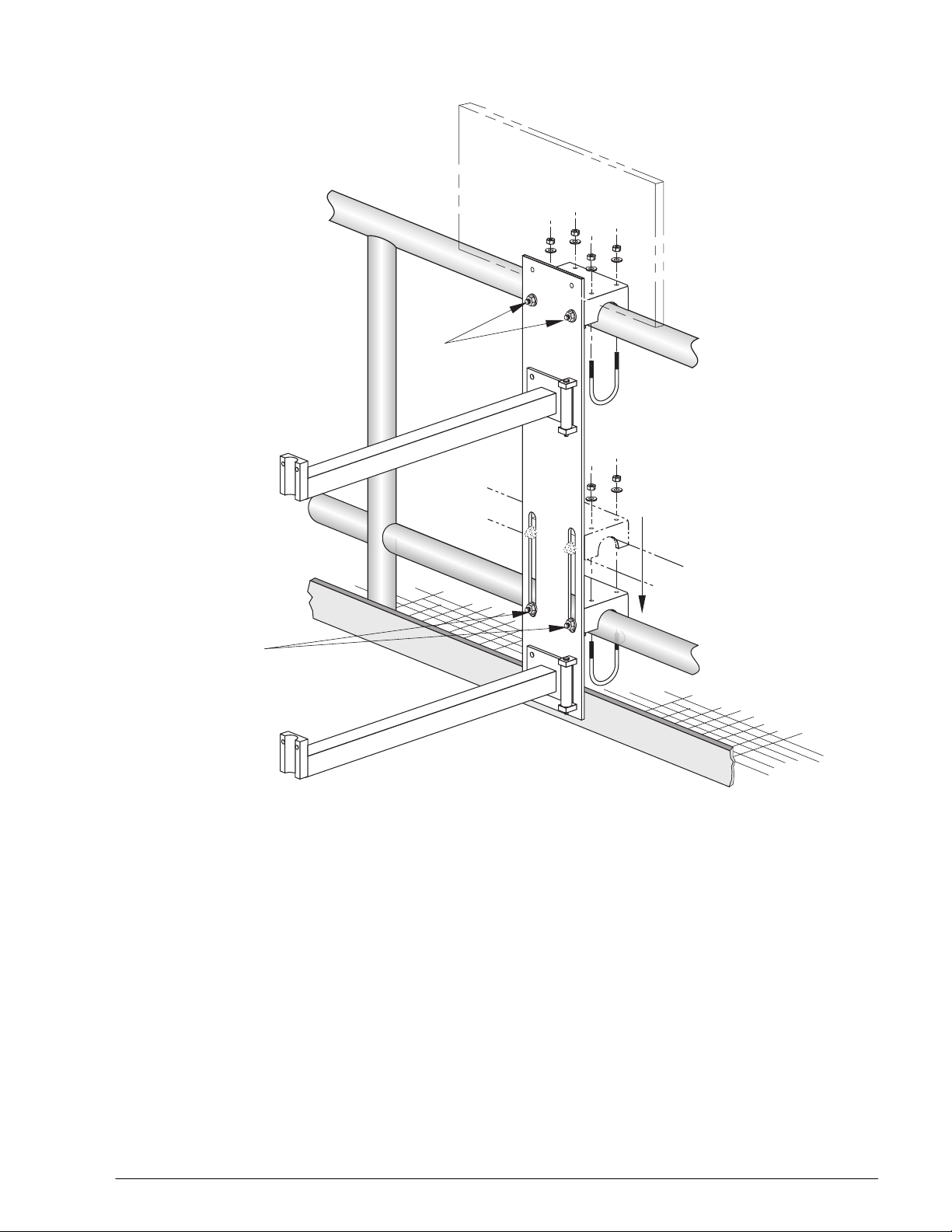

Assembling the Mounting Assembly

4.

1.

2.

1.

3.

2.

Assemble the rail brackets, upper and lower, to the base plate

Assemble the extension arms, upper and lower, to the base plate by mating the arm

and plate hinges and inserting the hinge pins.

Secure each hinge pin by inserting a hitch pin through the hole at the end of the pin.

(Optional) If it is required to mount the DPS300 at the clarifier, then attach the

mounting panel to the base plate. Use the hex bolts provided to mount the

DPS300 to the mounting panel. The DPS300 is pre-drilled with the appropriate

holes.

7ML19981BC01 27 InterRanger DPS300

Mounting Assembly Installation

slip bolts

2.

1.

4.

3.

1.

4.

1. Attach the Mounting Assembly to the clarifier handrail by hanging the upper and lower rail brackets

from the upper and lower rails.

2. The upper rail bracket is fixed. Check that the bolts are securely fastened.

3. Slide the lower rail bracket in position so that it rests on the lower rail. Tighten the slip bolts to

secure the bracket.

4. Insert the four larger u-bolts through the upper and lower brackets, clamping the brackets to the

rails and fasten with the supplied washers and nuts.

InterRanger DPS300 28 7ML19981BC01

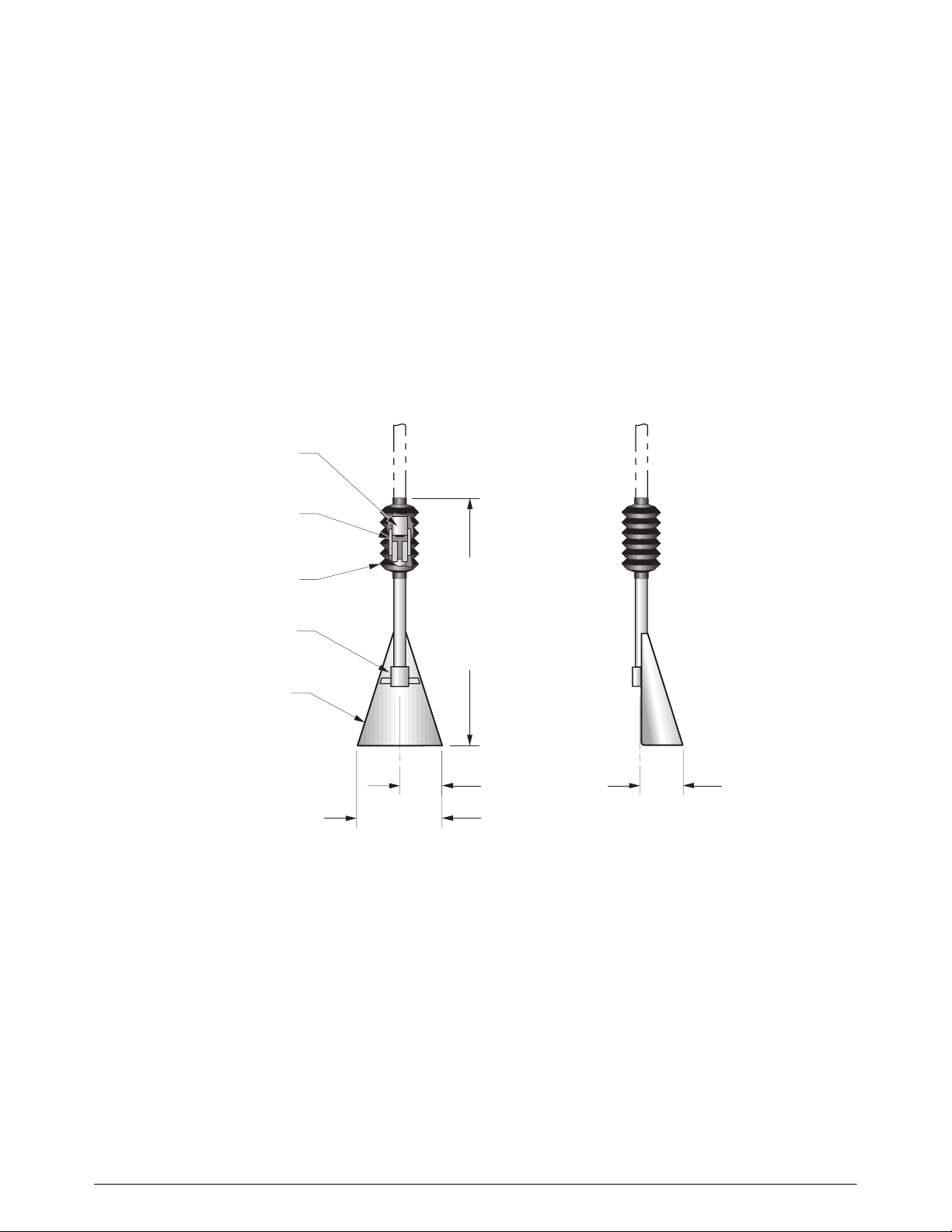

Optional Skimmer Guard

The skimmer guard is designed for use with transducers applied to measurement

of sludge in wastewater clarifiers. The guard provides articulation of the

mechanical and electrical conduit connection to the transducer where skimmers

are in use.

As the skimmer passes, it contacts the skimmer guard and pushes it up and over

the skimmer; effectively clearing the transducer out of harm’s way. Once the

skimmer has passed, the guard is free to fall, re-immersing the transducer into the

clarifier water.

The skimmer guard is available in two sizes:

• Type A – for skimmers 20 cm (8”) or less in cross-sectional height

• Type B – for skimmers 40 cm (16”) or greater in cross-sectional height

conduit coupling,

¾” NPT or BSP

hinge

boot

transducer coupling,

1” NPT or BSP

guard

200 mm

(8”)

Type A:

500 mm (20”)

Type B:

890 mm (35”)

100 mm

(4”)

97 mm

(3.8”)

7ML19981BC01 29 InterRanger DPS300

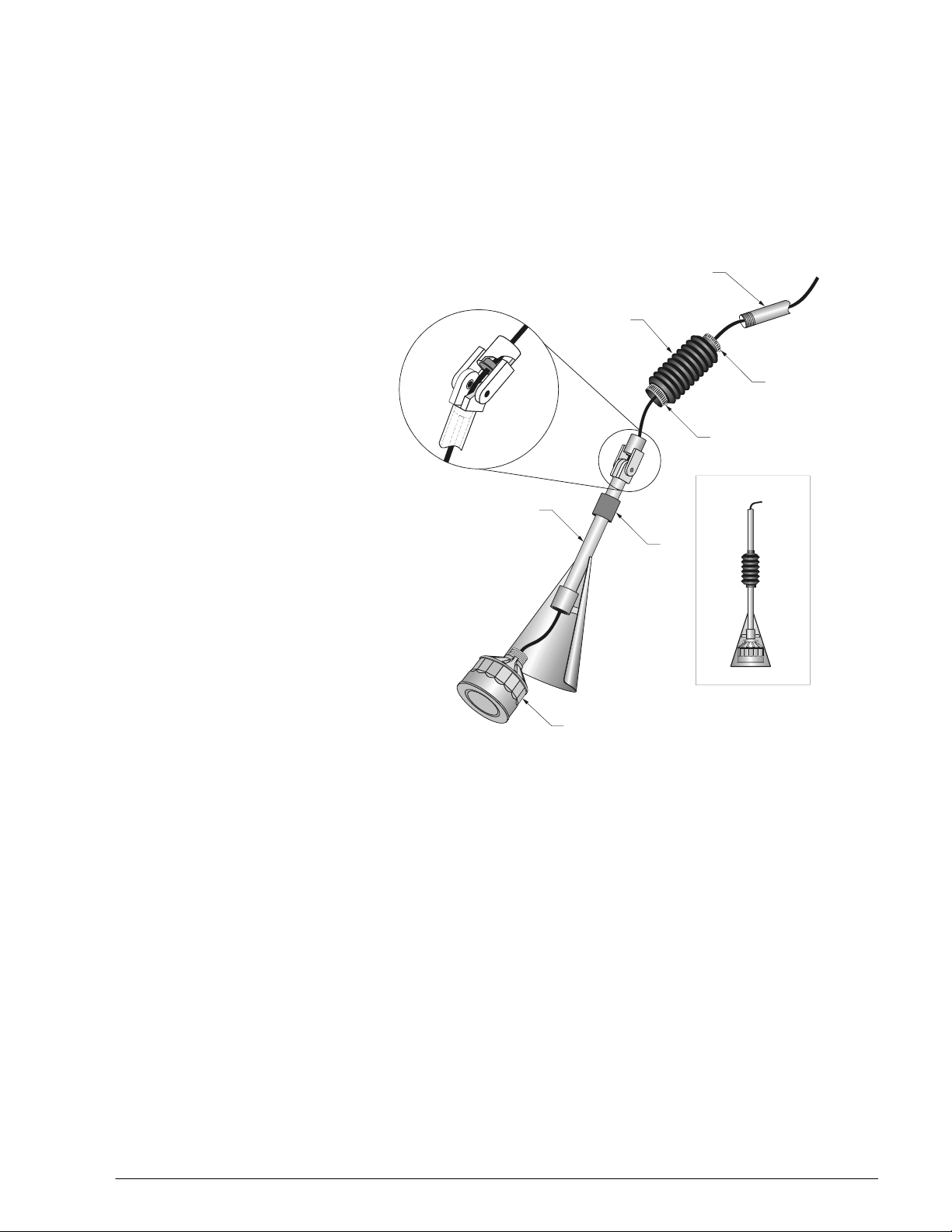

Transducer Assembly

5. Procure a length of corrosion resistant conduit for suspending the transducer and skimmer guard

assembly such that the transducer face will be immersed 3 to 6 cm into the clarifier water.

Siemens suggests ¾” standard stainless steel pipe (schedule 10) cut with ¾” NTP threads.

6. To facilitate running the transducer cable through the conduit, fish a wire through from the hinge

end first.

7. Slide the 2-inch hose clamp over the

knuckle of the Skimmer Guard.

customer conduit

8. Run the transducer cable through the

skimmer guard; starting at the

transducer coupling, through the

conduit and out the hinge.

9. Pull the cable through until the

transducer is pulled up to the

mounting coupling.

10. Screw the transducer into the

mounting coupling and tighten.

skimmer guard

11. Run the transducer cable from the hinge out the conduit

coupling.

12. Pull cable taught insuring that the cable will not

get pinched in the hinge.

13. Run the transducer cable through the

boot and customer conduit.

14. Slide the boot over the end of the customer

conduit, and screw the conduit into the coupling.

boot

1” hose clamp

2” hose clamp

2”

bushing

transducer

15. Slide the boot over the hinge.

The transducer and skimmer guard are now ready for installation.

Location and Installation

If a Mounting Assembly is used …

If a Siemens mounting assembly is being used to mount the Skimmer Guard

assembly, first refer to Optional Mounting Assembly on page 25.

For Location

For recommendations as to the preferred point of installation of the transducer and

skimmer guard, refer to Application Planning on page 16.

InterRanger DPS300 30 7ML19981BC01

Loading...

Loading...