Page 1

Restricted © Siemens 2020

siemens.com/industrial-networks© Siemens 2020

Industrial Networks

Driving Digitalization for critical infrastructure

Page 2

Restricted © Siemens 2020

Digitalization and big data address key industry trends

Digitalization

Big Data

Industrie 4.0

Industrial Internet of Things

(IIoT)

Time to market Flexibility Quality Efficiency

• Fast

innovation

• More complex

products

• …

• Individualized

mass

production

• Volatile

markets

• ….

• Closed-loop

quality

• Traceability

• …

• Resource &

energy

efficiency

• Demanded

product /

quantity

• …

Industry trends

Page 3

Restricted © Siemens 2020

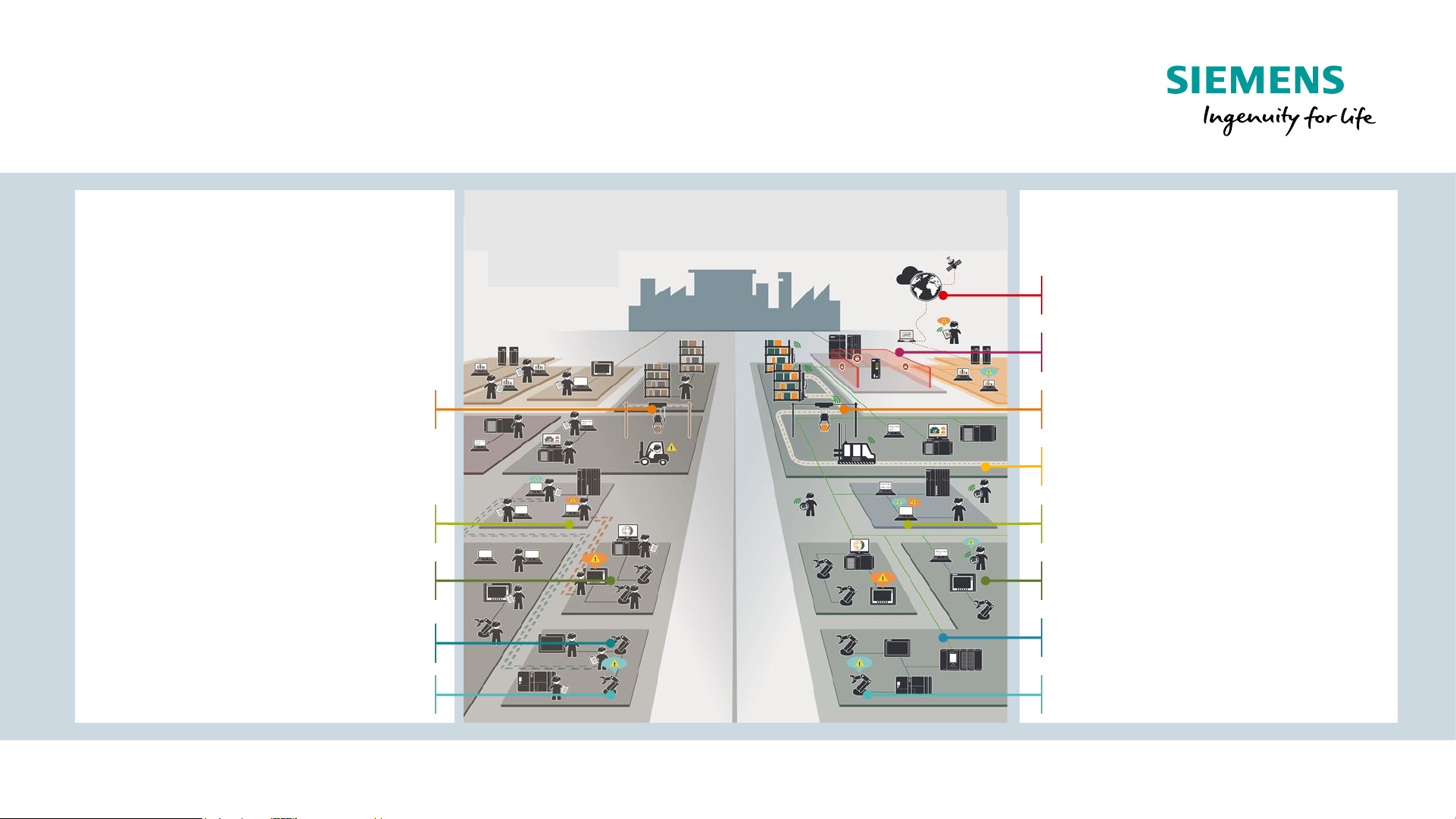

Digitalization will change the way you work…

Yesterday

Non-digital industry

Central alarm reporting

Mobile applications

Full automation

Tomorrow

Digitalized manufacturing

Secured remote access

Interoperability of processes

Manual processes

Separated islands of automation

No central alarms

Legacy systems

Intransparent processes

Industrial security

Full process transparency

Vertical integration

Page 4

Restricted © Siemens 2020

… and this requires powerful communication networks in the

industrial space

High performance

communication networks to

handle massive amounts of data

required

• High speed: Real-time communication

• High data volumes: Large bandwidth

• Protect against spying and attacks:

Secure communication

• Ensured connectivity: Robust and

reliable components and networks

• Flexibility: Plug’n’play, on demand and

easy (re-)configuration

Vertical

integration

Digital models

and

condition data

Horizontal integration

V1.6

Page 5

Restricted © Siemens 2020

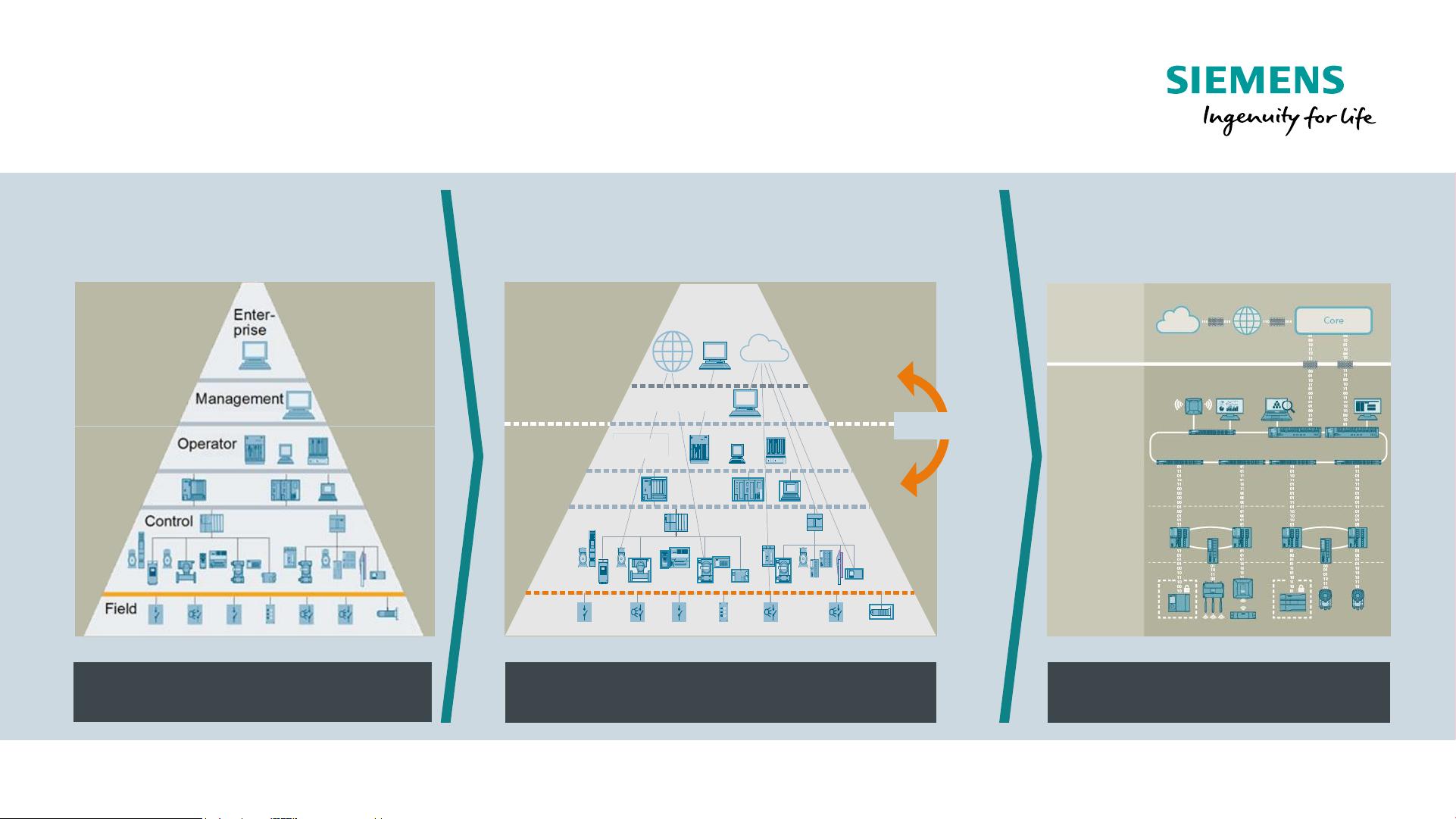

Digitalization results in a closed gap between enterprise and

production layer

Future: Defined interface to

handle complexity

Enterprise

Network

Production

Backbone

Production

Cell

Two dedicated networks with

defined managed interface

Today: Arising challenges through

increasing interoperability

Enterprise

Field

Control

Enterprise

Management

Production

Operator

Challenge to handle complexity of

increasing communication

Interoperability

Yesterday:

Limited interoperability

Limited communication between

enterprise and production layer

Enterprise

Production

Page 6

Restricted © Siemens 2020

Together with our partner network we build

Industrial Networks that fit your future needs

Siemens enables you to meet your Digitalization needs

00110101001110010011010010110110101001010100111000101110110010101001001001001

00110101001110010011010010110110101001010100111000101110110010101001001001001

00110101001110010011010010110110101001010100111000101110110010101001001001001

Expertise in Industrial

Networks

Services, Solutions &

Training

Siemens Industrial Networks

Industrial

Communications

Portfolio

RUGGEDCOM & SCALANCE

Page 7

Restricted © Siemens 2020

Industrial Communication and Identification

Expertise in industrial networks and industrial identification

Process Industries

Industrial Networks

Discrete Industries

Industrial Communication Industrial Identification & Locating

RTLS

Optical Identification

RFID

Security

WirelessRemote

Software

Rugged CommunicationIndustrial Ethernet

Cabling Technology

CPs, Profinet and Profibus

Page 8

Restricted © Siemens 2020

Siemens is your trusted partner for a broad range of reliable

components for industrial communication

Market leading portfolio based on more than 30 years of experience

RUGGEDCOM

Rugged Communication

SCALANCE

Industrial Communication

Siemens

Portfolio

Software

Remote

Security

Wired Wireless

Page 9

Restricted © Siemens 2020

Our products exceed industry specific requirements while

building on existing standards

Industrial Features

• User friendly configuration via

web based management

and TIA Portal

• Ring / redundant topologies

• Fanless design

1)

• Flexible and integrated

diagnostics

• C-PLUG for easy device

exchange

• iPCF for real-time WLAN

incl. safety over WLAN

• Temperature range

up to -40 oC to +85 oC

• 5 years warranty

→ Interoperability

All products are based on

international standards,

e.g. Ethernet, TCP/IP

→ Industry specifications

e.g. ATEX, IECEx, UL,

IEEE 1613, IEC 61850,

IEC 62443/ISA 99

guarantee a perfect fit for

industrial usage

Siemens

Portfolio

Page 10

Restricted © Siemens 2020

SCALANCE –

Industrial Communication portfolio

• High availability

based on industrial features and industrial design

• Fast & easy integration

for new and existing networks based on TIA design

• Easy to use

with configuration via Web Based Management or

TIA Portal

• Easy device replacement

with C-PLUG, also by untrained staff

• For all Ethernet networks

local, wireless and remote

Our Portfolio

Remote

Wired

Wireless

Security

Software

• Industrial features

• Industrial design

• Fast & easy integration

• Indoor and outdoor applications

• Several country approvals

• Real-time capability

• Different medias (DSL, UMTS, LTE)

• Transparent connectivity

• Easy enrollment with SINEMA RC

• Transparency for the industrial network

• Integration into HMI / SCADA systems

• Firewall & VPN

• Remote access

• Fits to industrial security concepts

SCALANCE: Industrial Communication

proved to enable communication in

production

Page 11

Restricted © Siemens 2020

Layer 3

Layer 2

managed

Layer 2

unmanaged

Price

Functionality

XR-500

XM-400

XR-300

XC-200

X-000 / XC-100

XB-200

SCALANCE X: The perfect switch for every application

XP-200

XB-100

Page 12

Restricted © Siemens 2020

RUGGEDCOM –

Rugged Communication portfolio for harsh environments

RUGGEDCOM products have set the

standard for communications networks

deployed in harsh environments.

• High reliability for mission critical networks

required in utility environments

• Fully IEC 61850-3 compliant

smooth operation in extreme environmental conditions

• IEEE 1613 rated

No data looses under EMI stress, shock and vibration

• Easy to use

via web-based management or NMS system

• Highest performance for various network types

LAN and WAN, wired, private and public wireless

Our Portfolio

Remote

Wired

Wireless

Security

Software

• IEEE 1588 Time Sync

• IEC 62439 seamless redundancy

• Multi-Service Routing platform

• Utility Grade, Wide Area Private Wireless Solution

• Low latency suitable for Distribution Automation

• Improved reach and “Non-Line of Sight” performance

• Different medias (EoVDSL, UMTS, LTE)

• Transparent connectivity

• High reliability, high bandwidth, low delays

• Ability to manage the network with one tool

• Secure access, data management,

visualization and analytics

• Firewall & VPN / IPsec

• Remote access compliant with NERC-CIP

• Fits to industrial security concepts

Page 13

Restricted © Siemens 2020

Together with our partner network we build

Industrial Networks that fit your future needs

Siemens enables you to meet your Digitalization needs

00110101001110010011010010110110101001010100111000101110110010101001001001001

00110101001110010011010010110110101001010100111000101110110010101001001001001

00110101001110010011010010110110101001010100111000101110110010101001001001001

Expertise in Industrial

Networks

Services, Solutions &

Training

Siemens Industrial Networks

Best-in-class

Communication Portfolio

RUGGEDCOM & SCALANCE

Page 14

Restricted © Siemens 2020

Industrial Networks have critical requirements

which need to be addressed

Determinism

Real-time requirements of automation tasks

High Availability

To avoid significant economic losses or other damages

Robustness

Extreme temperatures, dusty or corrosive environments

Flexibility

Optimization and innovation causes changing production layouts

Security

Threat of unauthorized access; secure remote access, e.g. for OEMs

Mobile Applications

Reliable communication, e.g. for automated guided vehicles, monorails

Safety

Fail-safe communication to provide safety for operators and assets

Enterprise Production

Page 15

Restricted © Siemens 2020

Industrial Networks have critical requirements

which need to be addressed

• Ring redundancy e.g. with MRP, HSR, PRP,…

• Quick and easy replacement with C-PLUG

• Fanless design to avoid downtimes

• FastConnect cables and plugs

• Modularity

• Different interfaces for electrical / optical connections

• Guaranteed switchover times in case of failures or

deterministic roaming for wireless applications

• Security modules which fit to industrial security

concepts

• IWLAN RCoax Cable

for durable wireless connection during movement

• Emergency shutdown over PROFINET

(wired as well as wireless)

Determinism

Real-time requirements of automation tasks

High Availability

To avoid significant economic losses or other damages

Robustness

Extreme temperatures, dusty or corrosive environments

Flexibility

Optimization and innovation causes changing production layouts

Security

Threat of unauthorized access; secure remote access, e.g. for OEMs

Mobile Applications

Reliable communication e.g. for automated guided vehicles, monorails

Safety

Fail-safe communication to provide safety for operators and assets

Page 16

Restricted © Siemens 2020

Making Digitalization work – enabled by structured network

solutions for connecting IT and Production

Enterprise Network:

Based on requirements from enterprise networks

Responsibility of IT

Production Cell:

Based on requirements from production and

automation cells:

Reliable communication as critical factor

Responsibility of production

Recommended solution with two physically separated, but connected communication networks

Production Backbone:

Defined interface between IT and production

Responsibility of production, but in

agreement with IT

OPC UA: OPC Unified Architecture (OPC UA) is an industrial machine to machine communication protocol for interoperability for IIoT and Industrie 4.0

Page 17

Restricted © Siemens 2020

Availability – Avoid stops in production that can result in

large damages

Industrial

• 24/7 availability required

• Fast network recovery time

• Adapted redundancy concepts

• “Surviving” single point of errors

• “Bumpless” processes

(no packet losses,

no failover times)

Importance of Availability

Enterprise

• Recovery times within seconds to

minutes range are accepted

• Irregular downtimes because of SW

roll-outs and security patches are

common

Availability ensured by Siemens

Reliable topology based on

redundancy, including e.g.

• Redundant network concepts

• C-PLUG for immediate device

exchange by untrained staff

• Fanless design

to avoid downtimes

• Redundant power supply

Standby Master Standby Slave

PROFINET/Industrial Ethernet (Twisted Pair)

Industrial Ethernet (Fiber Optic)

Industrial Ethernet

C-PLUG: configuration plug

Page 18

Restricted © Siemens 2020

Enterprise

• Distribution rooms

• Air conditioned, 19” rack mounting

• Temperatures from 0 oC to +45 oC

• AC 115/230 V power supply

Industrial – Harsh environments in

industrial and remote locations

• Temperatures from -40 oC to +85 oC

• Outdoor applications (IP65/67)

• Universal mounting (e.g. horizontal,

vertical, at the ceiling)

• DC 24 V power supply

Importance of Robustness

Robustness – Ensure functionality in industrial

environments

Corrosionresistant

Protection

level up to

IP65/67

EMC / shock

resistant

Temperature

resistant

-40 oC to

+85 oC

Robustness ensured by Siemens

Siemens products are built for industrial environments, e.g.

5 years warranty on functionality of RUGGEDCOM and SCALANCE

Page 19

Restricted © Siemens 2020

Industrial – Optimization and

innovation cause changes in the

production layout

• Flexible network topologies

• Modular components

• Ring- or Line Structures

Importance of Flexibility

Flexibility ensured by Siemens

Flexibility – Ensure easy adaptability of communication to

support ongoing optimizations and changes

• Comprehensive portfolio with

KEY-PLUG for additional functions

• Various mounting options

• Full- or semi modular

(“hot swap functionality”)

• Combo Ports for port granular

choice of different media

• Field assembly plugs for easy

connectivity

• Accessories made for industrial

use cases

KEY-PLUG: enables additional device-specific functions

Enterprise – No need for high

flexibility in layout and cabling

• Structured star topologies at floor,

building, site

• Raised floor for cabling

Leading Portfolio

Accessories

Modular devices

Page 20

Restricted © Siemens 2020

Industrial networks needs to address your key aspects

Main aspects to be considered in network design

Network Management

Highest transparency for

industrial networks and all

connected devices

Remote Communication

Enable secure and reliable

remote access to service plants

and machines

Network Structure

Segmented and redundant

architecture for reliable,

communication networks

Network Security

Enabled by holistic security

concept and security-integrated

portfolio

Functional Safety

Safety-critical applications to

protect personnel and machinery

Mobile Applications

Easy and fast access to your data

or applications from mobile

devices

Cloud Connectivity

Easy and efficient integration of

data points into the cloud

infrastructure

Full TIA Conformity

All components are built and

tested for TIA to achieve

maximum of compatibility

Page 21

Restricted © Siemens 2020

Brad Wilson

System Architect

Email: bradleywilson@siemens.com

Mobile: 0419 828 329

Thank you for your attention!

siemens.com/net

Loading...

Loading...