Instruction Manual May 2008

milltronics

ILE-61

Safety Guidelines: Warning notices must be observed to ensure personal safety as well as that of

others, and to protect the product and the connected equipment. These warning notices are

accompanied by a clarification of the level of caution to be observed.

Qualified Personnel: This device/system may only be set up and operated in conjunction with this

manual. Qualified personnel are only authorized to install and operate this equipment in accordance with

established safety practices and standards.

Unit Repair and Excluded Liability:

• The user is responsible for all changes and repairs made to the device by the user or the user’s

agent.

• All new components are to be provided by Siemens Milltronics Process Instruments Inc.

• Restrict repair to faulty components only.

• Do not reuse faulty components.

Warning: This product can only function properly and safely if it is correctly transported, stored,

installed, set up, operated, and maintained.

This product is intended for use in industrial areas. Operation of this equipment in a residential area

may cause interference to several frequency based communications.

Note: Always use product in accordance with specifications.

Copyright Siemens Milltronics Process

Disclaimer of Liability

Instruments Inc. 2008. All Rights Reserved

This document is available in bound version and in

electronic version. We encourage users to purchase

authorized bound manuals, or to view electronic versions

as designed and authored by Siemens Milltronics Process

Instruments Inc. Siemens Milltronics Process Instruments

Inc. will not be responsible for the contents of partial or

whole reproductions of either bound or electronic

versions.

While we have verified the contents of this

manual for agreement with the

instrumentation described, variations

remain possible. Thus we cannot

guarantee full agreement. The contents of

this manual are regularly reviewed and

corrections are included in subsequent

editions. We welcome all suggestions for

improvement.

Technical data subject to change.

MILLTRONICS®is a registered trademark of Siemens Milltronics Process Instruments Inc.

Contact SMPI Technical Publications European Authorized Representative

at the following address:

Technical Publications Siemens AG

Siemens Milltronics Process Instruments Inc. Industry Sector

1954 Technology Drive, P.O. Box 4225 76181 Karlsruhe

Peterborough, Ontario, Canada, K9J 7B1 Deutschland

Email: techpubs.smpi@siemens.com

• For a selection of Siemens Milltronics level measurement manuals, go to:

www. siemens.com/processautomation. Under Process Instrumentation, select

Measurement

• For a selection of Siemens Milltronics weighing manuals, go to:

www. siemens.com/processautomation. Under Weighing Technology, select

Weighing Systems

© Siemens Milltronics Process Instruments Inc. 2008

and then go to the manual archive listed under the product family.

and then go to the manual archive listed under the product family.

Level

Continuous

Table of Contents

ILE-61 Sensing Head ........................................................................................................... 1

Specifications ......................................................................................................................2

Installation ........................................................................................................................... 4

Sensing Head ........................................................................................................................................... 4

Sensing Plate............................................................................................................................................ 4

Viscous Damper....................................................................................................................................... 5

Interconnection........................................................................................................................................ 5

Non-Hazardous Unit without LVDT Conditioner Card ..........................................................5

Non-Hazardous Unit with Sensing Head Mounted LVDT Conditioner Card ..................6

Non-Hazardous and Hazardous Units with Remote-Located LVDT Conditioner Card 7

Calibration ............................................................................................................................ 8

General....................................................................................................................................................... 8

LVDT Output.............................................................................................................................................. 8

Zero Adjustment ............................................................................................................................8

Span Test .........................................................................................................................................9

Sensing Head Level Test .............................................................................................................9

Integrator Calibration .......................................................................................................................... 10

Maintenance and Spare Parts ........................................................................................ 11

Maintenance .......................................................................................................................................... 11

Spare Parts ............................................................................................................................................. 11

Unit Repair and Excluded Liability ..........................................................................................11

Inner Gasket Placement...................................................................................................................... 12

Range Springs ................................................................................................................... 13

General..................................................................................................................................................... 13

Range Spring Removal......................................................................................................................... 13

Range Spring Replacement................................................................................................................ 13

Flowmeter Recalibration ..................................................................................................................... 13

Troubleshooting ................................................................................................................. 14

Linearity .............................................................................................................................. 15

i

ii

ILE-61 Sensing Head

Notes:

• The ILE-61 Sensing Head is to be used only in the manner outlined in this

manual, otherwise protection provided by equipment may be impaired.

• This product is intended for use in industrial areas. Operation of this equipment

in a residential area may cause interference to several frequency based

communications.

The Milltronics ILE-61 sensing head is an out-of-process sensing element for A, E, and V

Series solids flowmeters. It is used for continuous in-line weighing of powdered or

granular dry bulk solid materials. The material is directed toward the sensing plate. The

horizontal impact force of the material, deflecting the sensing plate, displaces the core of

the sensing head LVDT (linear variable differential transformer). The LVDT output signal is

proportional to material flowrate.

LVDT

moving beam travel

impact force

sensing plate

The ILE-61 sensing head is used with Milltronics E-300 (general purpose), A-300 (aerated

gravity conveyor), and V-300 (vertical material drop) dry solids flowmeters.

.

E-300

7ML19985CX01 Milltronics ILE-61 – INSTRUCTION MANUAL Page 1

A-30 0

V-3 00

Specifications

Operating Range

• 0 to 20 t/h (0 to 22 STPH) min., 0 to 300 t/h (0 to330 STPH) max.

Product

• fine powder to 25 mm (1")

Product Temperature

• -40 to +232 °C (-40 to +450 °F)

Ambient Temperature

• -40 to +60 °C (-40 to +140 °F)

Accuracy

• ± 1 % of full scale, higher accuracy with linearizing function of integrator

Repeatability

•± 0.2 %

Range Spring

• selected to suit application

Construction

• dust-tight cast aluminum frame with fiberglass rear cover

Mounting

•base mount

Sensor Type

• LVDT (linear variable differential transformer)

LVDT Excitation

• 2.50 V AC @ 2.9 kHz (supplied by Flowmeter Integrator or LVDT Conditioner Card)

LVDT Output

• 0 - 0.75 V AC @ 2.9 kHz

Damping Fluid

• 10 - 100 cm2/s (1000 - 10 000 cs) silicone, (Dow Corning 200 recommended)

Options

• Epoxy paint, synergistic polymer, or PFA coating of external aluminum casting

surfaces

• Epoxy painted mild steel or stainless steel rear cover

Approvals

•CE

• Optional CSA. Class I, Groups C and D; Class II, Groups E, F, and G

Page 2 Milltronics ILE-61 – INSTRUCTION MANUAL 7ML19985CX01

Sensing Plate

Construction

• 304 (1.4306) stainless steel

Options

• 316 (1.4404) stainless steel

• UHMW polyurethane or Ceramic Tile abrasion resistant lining

• Synergistic polymer or PFA coating for low cohesion and friction

LVDT Conditioner Card

Power

• ± 5 V DC (typically from Siemens Milltronics integrator)

Ambient Temperature

• –40 to +50 °C (–40 to +122 °F)

Input

• 0 to 1.0 V from LVDT

Output

• 0 to 50 mV to Milltronics SF 500 (maximum 300 m (1000 ft) separation between

Conditioner Card and integrator)

Approvals

•CE

Enclosure

• NEMA 4 (remote mounted unit)

Cable

For connection between LVDT Conditioner Card and Integrator

•Belden®1 8404, 4 conductor, shielded 20 AWG (0.5 mm2) or equivalent, 150 m (500 ft)

maximum

• Belden 9260, 6 conductor, shielded 20 AWG (0.5 mm

maximum

For connection between LVDT and remote LVDT Conditioner Card,

or directly between LVDT and Integrator

• Belden 8404, 4 conductor, shielded 20 AWG (0.5 mm2) or equivalent, 300 m (1000 ft)

maximum

1.

Belden is a registered trademark of Belden Wire & Cable Company.

7ML19985CX01 Milltronics ILE-61 – INSTRUCTION MANUAL Page 3

2

) or equivalent, 300 m (1000 ft)

Installation

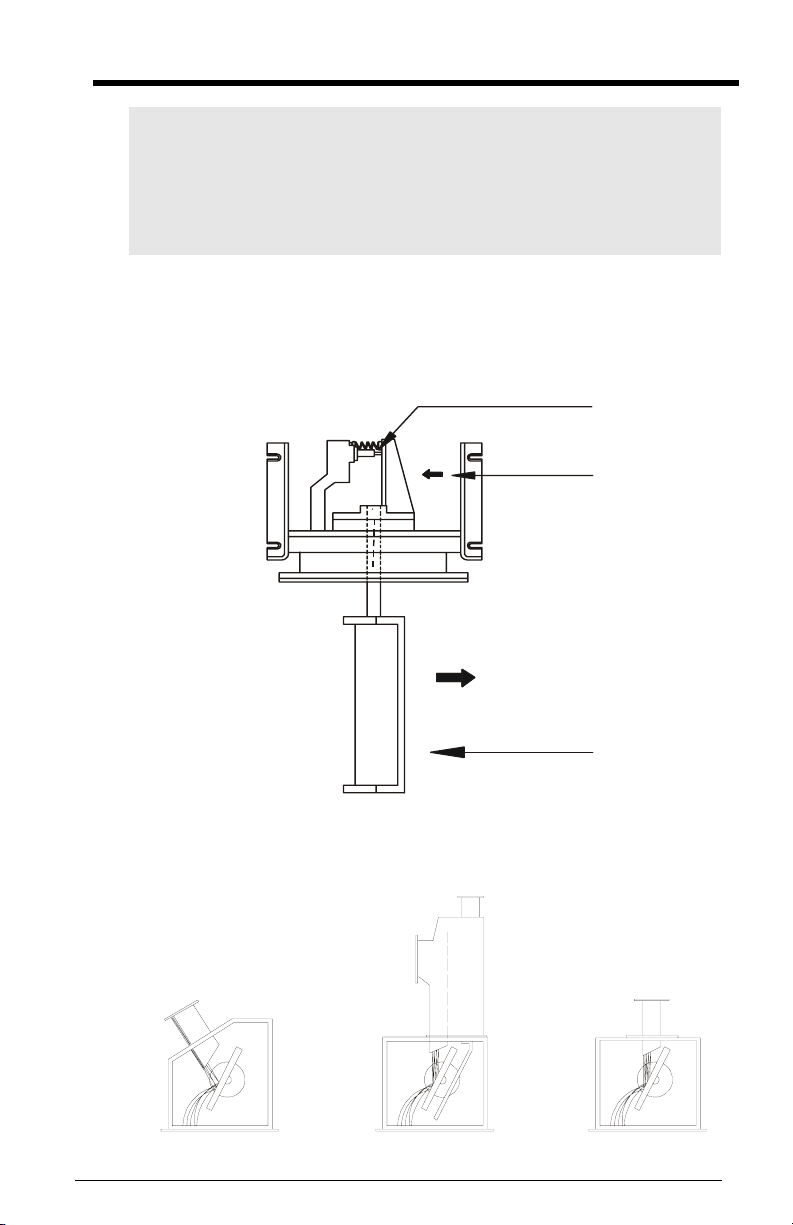

Sensing Head

1. With the flowmeter housing installed, mount the ILE-61 to a rigid support structure.

2. Remove the ILE-61 fibreglass cover. With the outer gasket in place, bolt the ILE-61 to

the housing.

3. Adjust the sensing head leveling hardware (provided) to establish level in both

horizontal planes.

Note: Ensure the sensing head mounting structure is capable of supporting the

dynamic material impact forces as well as the weight of the sensing head.

spirit level

moving beam

(machined

surface)

rigid support

Sensing Plate

1. Open the flowmeter housing access door.

2. With the sensing head cover removed, remove the taper pin.

3. Insert the sensing plate shaft fully into the sensing head socket.

Note: Ensure the sensing plate shaft is installed with the flat side up.

4. Insert the taper pin (flat side down), from the left side.

5. Tighten the right taper pin nut to lock the sensing plate shaft in place.

6. Tighten the left taper pin nut.

shaft

socket

flat side up

taper pin

(flat side down)

Page 4 Milltronics ILE-61 – INSTRUCTION MANUAL 7ML19985CX01

Viscous Damper

1. Remove the 2 damper cover shipping screws. The damper cover will be held up by a

spring.

2. If necessary, top up the damper (to near overflowing) with the damping fluid

supplied.

3. Store the damper cover shipping screws, remaining damper fluid, and filler bottle for

future use.

Note: The damper must be full and free of air bubbles with the damper cover in

the UP position during flowmeter operation.

filler bottle

filler plug

shipping screws

damper cover

Interconnection

Non-Hazardous Unit without LVDT Conditioner Card

* See note below for Encapsulated (Hazardous-rated) LVDT color codes.

to LVDT

G

B

Y

B

R

L

E

K

L

C

O

M

YEL = WHITE

BLU = ORANGE

GRN = YELLOW

cable

clamp

to integrator

(LVDT connection)

N

S

I

G

–

–

*For Encapsulated LVDT (hazardous)

Note: Ground shield at Integrator only.

7ML19985CX01 Milltronics ILE-61 – INSTRUCTION MANUAL Page 5

R

L

E

U

D

flowmeter

terminal

block

E

E

X

X

C

C

+

–

Non-Hazardous Unit with Sensing Head Mounted LVDT

/

Conditioner Card

• Not applicable to Hazardous-rated units

• LVDT to LVDT Conditioner Card connections are made by Milltronics

LVDT

Milltronics LVDT Conditioner Card

LVD T IN TE GR ATO R

C.T.S

E

E

C

X

X

O

C

C

M

+

-

S

I

H

G

L

-

D

S

I

G

E

X

C

O

C

+

M

S

S

E

H

I

X

L

G

C

D

+

-

RED

BLUE

YELLOW

BLACK

GREEN

11 14 12

SF 500

Integrator

111

-LOAD CELL-

EXCITATION

SHLD

V+

122

S+

S-

V-

*

133

14

15

16

17

18

LCA+

LCA-

LCB+

LCB-

4

SHLD

-LOAD CELL INPUTS-

SHLD

5

6

LCC+ SIG

7

LCC- COM

8

LCD+ CNST

9

LCD-

10

*Where separation between the integrator and LVDT conditioner exceeds 150 m (500 ft):

• Remove the jumpers SF 500 terminal 11/12 and 13/14

• Run additional conductors:

- from SF 500 terminal 12 to conditioner terminal block marked“Integrator +EXC”

- from SF 500 terminal 13 to conditioner terminal block marked “Integrator –EXC”

For further connection information on specific LVDTs, consult Siemens Milltronics.

♦

Note:

1. Shields are common, but not grounded to chassis. Run cable shields

through SHLD terminals and ground at Integrator only.

2. Ensure that connection between TB 2 and TB 17 is made.

Page 6 Milltronics ILE-61 – INSTRUCTION MANUAL 7ML19985CX01

Non-Hazardous and Hazardous Units with Remote-

/

Located LVDT Conditioner Card

*LVDT

Milltronics LVDT Conditioner Card

(in non-hazardous location)

SF 500

Integrator

E

X

C

+

**

RED

BLUE

YELLOW

GREEN

LCA+

LCA-

LCB+

LCB-

4

5

SHLD

6

LCC+ SIG

7

LCC- COM

8

LCD+ CNST

-LOAD CELL INPUTS-

LCD-

SHLD

9

10

-LOAD CELL-

**For Encapsulated LVDT (hazardous)

**Junction box included with hazardous-rated unit.

LVD T IN TE GR ATOR

C.T.S

E

X

C

-

EXCITATION

SHLD

S

C

I

H

O

G

L

M

-

D

111

V+

122

S+

S-

133

V-

14

15

16

17

18

YEL = WHITE

BLU = ORANGE

GRN = YELLOW

S

I

G

E

E

X

X

C

O

C

C

+

-

M

11 14 12

*

S

S

H

I

L

G

D

+

*Where separation between the Integrator and LVDT conditioner exceeds 150 m (500 ft):

• Remove the jumpers SF 500 terminal 11/12 and 13/14

• Run additional conductors:

- from SF 500 terminal 12 to conditioner terminal block marked “Integrator +EXC”

- from SF 500 terminal 13 to conditioner terminal block marked “Integrator –EXC”

For further connection information on specific LVDTs, consult Siemens Milltronics.

♦

Note:

1. Shields are common, but not grounded to chassis. Run cable shields

through SHLD terminals and ground at Integrator only.

2. Ensure that connection between TB 2 and TB 17 is made.

7ML19985CX01 Milltronics ILE-61 – INSTRUCTION MANUAL Page 7

Calibration

General

A test weight is a calibration reference used to simulate a material impact force (test

rate) on the flowmeter sensing plate during the integrator span calibration. The test

weight is also used to perform a test to verify that the flowmeter sensing head is level.

The test rate should be 60 to 80% of the system designrate.

To determine the test rate produced by a specific test weight...

Test Rate (TPH) = Test Weight (grams)

45* grams/ TPH

Alternatively, to determine the test weight required for a specific test rate:

Test Weight (grams) = 45* grams x Test Rate (in TPH)

1 TPH

*Use 60 grams for A-300 flowmeters.

e.g. If the test weight used with an E-300 flowmeter is 7000 grams...

Test Rate = 700 0 grams

45 grams/TPH

Note: Use metric tons per hour (t/h) or short tons per hour (STPH) as applicable for

TPH.

LVDT Output

= 155 TPH

Zero Adjustment

1. Connect a voltmeter across the LVDT green and yellow (or yellow and white) wires.

2. With no load applied to the sensing plate, observe 0.10 V AC on the voltmeter.

Note: If the LVDT output is 0.10 to 0.05 V AC, skip to span test, otherwise, proceed

as follows:

a.Loosen the locknut on the LVDT threaded core.

b.Turn the core in/out of the LVDT until 0.10 to 0.05 V AC is obtained.

c.Tighten the locknut, ensuring the measured value is maintained.

LVDT core

moving beam

locknut

increase decrease

Page 8 Milltronics ILE-61 – INSTRUCTION MANUAL 7ML19985CX01

LVDT

to integrator

LVDT EXC. or

LVD T con dit ion er

card

± 0.05 V AC

>± 0.05 V AC

Span Test

1. Gently push the sensing head moving beam to the right. The LVDT output should

increase steadily until a level of 0.75 to 1.0 V AC is achieved.

2. Gently push the sensing head moving beam to the left. The LVDT output should

decrease steadily until zero is reached and then increase to 0.25 to 0.50 V AC.

3. Ensure the LVDT output always returns to 0.10 to 0.05 V AC, (on the right hand side of

zero), when pressure on the moving beam is released.

Note: The LVDT core must not contact the inside of the LVDT over the range of

core travel. The actual LVDT core travel during this procedure is less than 3 mm

(1/8").

0 . 7 5 0

to

1 . 0 0 0

0 . 0 5 0

to

0 . 1 5 0

Sensing Head Level Test

1. With the voltmeter still connected to the LVDT output, hang the test weight directly

off the sensing plate.

2. Observe the display value does not change by more than 0.01 V AC.

Note: If the change is greater than 0.01 V AC, adjust the sensing head level until

the change with and without the test weight on the sensing plate is less than

0.01 V AC. Remove the test weight and readjust the LVDT output zero, if necessary.

If this procedure is performed after the integrator is calibrated, a new integrator

zero and span calibration, span adjust, and Factoring (if required) should be

performed.

0 . 0 1 5

to

0 . 5 0 0

sensing plate

test weight

changes < 0.01 V AC

7ML19985CX01 Milltronics ILE-61 – INSTRUCTION MANUAL Page 9

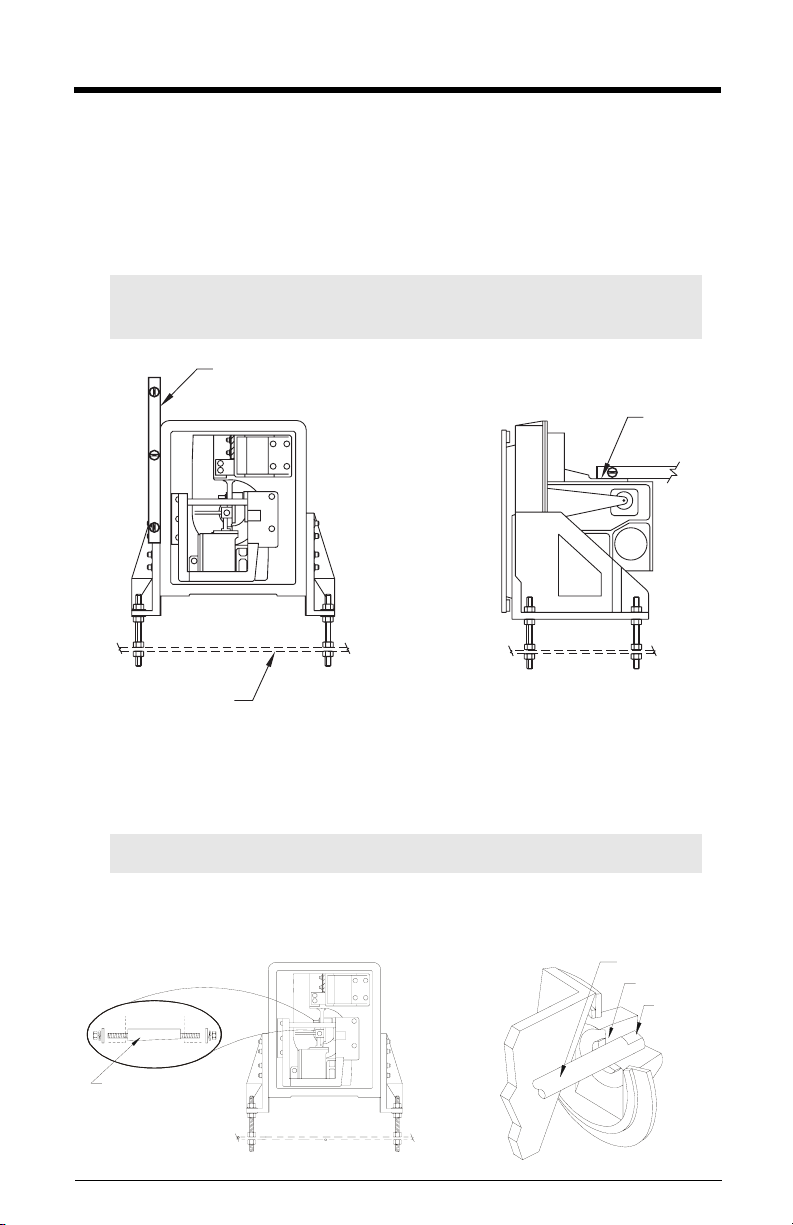

Integrator Calibration

Refer to the flowmeter integrator instruction manual for integrator calibration

instructions.

To apply the test weight for the span calibration:

1. Mount the calibration bracket (stored on the left side of the cast frame).

2. Attach one end of a string (monofilament fishing line or fine flexible cable) to the test

weight.

3. Route the other end of string over the calibration pulley.

4. Attach the free end of the string to the string fixing bolt. Ensure the string rests in the

bolt groove.

Note: Ensure the test weight is suspended free from obstruction.

5. When the calibration is complete, return the calibration bracket to the storage

position.

string fixing bolt

calibration arm

test weight

Note: Accurate calibration is not assured until material tests and a span adjust

are performed.

Page 10 Milltronics ILE-61 – INSTRUCTION MANUAL 7ML19985CX01

Maintenance and Spare Parts

Maintenance

A program of routine maintenance should be established to ensure the highest

achievable level of performance is maintained. Good housekeeping practices in the area

of the flowmeter are recommended.

Maintenance Description Frequency

Regular Monthly Semi-Annual Annual

Clean area around flowmeter

Check sensing place surface*

Check damping fluid

Check sensing head inner gasket

Check sensing plate wear

Check test weight Rate display

Test flowmeter linearity

* Material buildup (if any) in the impact area of the sensing plate should be

removed.

9

999

99 9 9

999

999

999

99

Spare Parts

Milltronics recommends a spare inner and outer gasket, sensing plate, and spare

damping fluid be kept on hand.

Contact Milltronics or your distributor for spare parts ordering information.

Unit Repair and Excluded Liability

9

All changes and repairs must be done by qualified personnel and applicable safety

regulations must be followed. Please note the following:

• The user is responsible for all changes and repairs made to the device.

• All new components must be provided by Siemens Milltronics Process

Instruments Inc.

• Restrict repair to faulty components only.

• Do not re-use faulty components.

7ML19985CX01 Milltronics ILE-61 – INSTRUCTION MANUAL Page 11

Inner Gasket Placement

Should it ever be necessary to replace the sensing head inner gasket, refer to the

Installation and Figures sections of this instruction manual prior to performing the

following procedure.

1. Remove the ILE-61 fibreglass cover, (10 bolts).

2. Bolt down the viscous damper cover to the shipping position, (2 bolts).

3. Remove the sensing plate from the sensing head.

4. Remove the inner retaining ring, (6 bolts).

5. Remove the upper and lower hinge block bolts, (4 per block).

6. a. Hazardous versions, remove the LVDT core and LVDT, (3 bolts), or

b. Non Hazardous, remove the LVDT cable TY WRAPs (2) and disconnect LVDT

connections.

7. While supporting the main assembly, remove the secondary static beam bolts (3 per

side).

8. Draw the main assembly away from the main frame.

Note: The main assembly is heavy and awkward to handle; ensure it is

supported well.

9. Remove the outer retaining ring and inner gasket, (8 bolts).

10. Install the new inner gasket and reverse the procedure (steps 1 through 9).

11. Perform the LVDT output zero procedure.

12. Referring to the integrator instruction manual, perform an integrator zero and span

calibration. Perform a span adjust if calibration accuracy appears affected.

Page 12 Milltronics ILE-61 – INSTRUCTION MANUAL 7ML19985CX01

Range Springs

General

The range spring establishes the range of sensing head moving beam travel for a given

range of material flow. This spring installed, is selected and positioned according to the

specified design rate of the application.

For best operation the range spring should provide 0.75 to 2.4 mm (0.030 to 0.094") of

moving beam travel from the static zero to the design rate operation position. The moving

beam travel may be inferred by the value of the LVDT green and yellow (or yellow and

white) wires.

With the 2.5 V AC, 2.9 kHz LVDT excitation supplied:

• 0.75 mm of moving beam movement = 0.188 V AC

• 2.40 mm of moving beam movement = 0.600 V AC

Should the design rate of the flowmeter application change, it may be necessary to

reposition the original range spring, or select and install another range spring, to obtain

the optimum moving beam travel (LVDT output) range. Moving the range spring to a

location further away from the pivot point leaf spring, increases the maximum flowrate

capacity.

Range Spring Removal

1. Observe the range spring mounting position. (3 positions are available)

2. Loosen the range spring locknut.

3. Remove the range spring center bolt and 4 flange mounting bolts.

4. Remove the range spring from the range spring assembly.

Range Spring Replacement

1. Install the new range spring in the range spring assembly.

2. Mount the range spring assembly by the 4 flange mounting bolts.

3. With the moving beam in the static zero position, turn the range spring until the base

just touches the beam, and then turn 1 complete revolution more.

4. Install the range spring center bolt and tighten the range spring locknut.

Flowmeter Recalibration

After removing and replacing the range spring, the flowmeter and integrator should be

recalibrated.

1. Perform the LVDT output zero procedure. Refer to Calibration.

2. Perform an integrator zero and span calibration. Refer to the integrator manual,

Calibration.

3. Perform a span adjust and factoring as required. Refer to the integrator manual,

Calibration.

7ML19985CX01 Milltronics ILE-61 – INSTRUCTION MANUAL Page 13

Troubleshooting

Every Millltronics ILE-61 sensing head is subjected to extensive quality assurance

procedures to ensure the highest degree of quality, reliability, and performance is

achieved.

The following listing indicates the probable cause, and proper course of action to be

taken should the specified fault symptom occur.

Symptom Cause Action

Integrator Rate display

doesn’t change when sensing

plate is moved

Span adjustment does not

have enough range

Measurement results are not

repeatable

Accuracy varies with material flowrate

Wrong or bad integrator

connection

Viscous damper lid in shipping position

Integrator not prepared for

operation

Range spring not suited to

application

Sensing head not level

Moving beam is mechanically

limited

Leaf springs are damaged

Material flow patterns vary

Non-linear operation Refer to Linearity

Refer to Installation\Integrator LVDT Interconnection

Refer to Installation/ Viscous

Damper

Program and Calibrate the

integrator

Refer to Range Springs

Refer to Installation and

Calibration/Sensing Head

Level Test

Ensure moving beam does not

hit travel stops between -20 %

and 150 % flowrates

Replace leaf springs,

recalibrate flowmeter, and

integrator

Consult Siemens Milltronics

or your distributor

Page 14 Milltronics ILE-61 – INSTRUCTION MANUAL 7ML19985CX01

Linearity

To test linearity, at least 3 test weights are used. Each weight represents a different test

rate. Record the integrator rate display value associated with each test weight applied to

the flowmeter.

If all the recorded display values are accurate, the flowmeter measurement is linear.

e.g. For an E-300 flowmeter Design Rate of 200 TPH, the following three test weights

could be used:

• 9000 g (19.82 lb.) = 100% Design Rate = 200 TPH

• 6750 g (14.87 lb.) = 75% Design Rate = 150 TPH

• 4500 g (9.91 lb.) = 50% Design Rate = 100 TPH

If non-linear results are obtained, ensure:

• at no flow, the moving beam does not rest on the zero stop bolt.

• at 150% Design Rate, the moving beam does not reach the full flow stop bolt.

• at 150% Design Rate, the LVDT output does not exceed 1.0 V AC.

• the damper piston does not touch the damper cylinder wall at any flow rate.

• the LVDT core does not touch the inside of the LVDT at any flow rate.

• the viscous damper fluid is free of large air bubbles and the fluid level is correct.

• the range spring operates in compression from 0 - 150% flow rate.

• the sensing head leaf springs are in good condition.

If the test weight linearity test is successful, yet actual material test results are nonlinear, ensure there is no air circulation in the housing sensing plate area. If there is no

significant air circulation in the flowmeter housing while running material, the material

flow pattern is probably non-linear.

Non-linear material flow patterns can often be corrected by minor modifications to the

material infeed, or upstream piping. Some integrators are equipped with a linearization

function to compensate for non-linear material flow patterns. Stand alone linearizing

devices are also available for this purpose.

Note: Electronic linearization should not be used to correct non-linear test weight

results.

7ML19985CX01 Milltronics ILE-61 – INSTRUCTION MANUAL Page 15

(14.96")

380 mm

(19.29")

490 mm

(13.34")

340 mm

outer

8 mm (0.31" dia. 18 bolts

on 460 mm (18.11") BCD.

sensing head

as req’d

gasket

support plate

(by customer)

500 mm

(see note 2)

(22.05")

(19.64")

560 mm

16 mm (0.63") dia.

(4 levelling rods)

ILE - 61 Sensing Head Outline and Mounting

see note 1

outer gasket

conduit entry

½” NPT internal

sensing

plate

sensing plate

housing (see note 3)

70 mm

(2.76")

(16.54")

(11.81")

420 mm

300 mm

(12.52")

318 mm

(22.05")

560 mm

fibreglass cover

(2.36")

60 mm

Notes:

1. Refer to Flowmeter drawing for sensing head mounting hole to flowguide centre line dimension.

2. Sensing head support plate should be rigid and independent of flowmeter housing.

3. Compress outer gasket to flowmeter sensing plate housing wall. Ensure that the outer gasket seal is dust tight.

FIG. 3A

5

31326556

4

78 49 63

33

68 64

20 21 76

38 47

19 56 65

36

49

35

66

37

53 64 30 39 22 34

arm in operating

position

26272873

41

53 644056 54

10 9

8

56 65

24

51 617375

1

56 65

77

57 65

arm in calibration position

6

11

62 67

42 43 48

56 65

52

12

50

65

2

55

44 45 46

49 53

7

See Detail "A"

3

17

18

ILE - 61 Part Identification Diagram

53 64

71237429

Detail "A"

25

68

49 66

13

15166458

14

60

60 68

54

20 Calibration Pulley

21 Calibration Pulley Shaft

22 String Fixing Bolt

23 Damper Cover

24 Damper Cover Spring

25 Damper Window

26 Damper Shaft

27 Damper Piston

28 Damper Piston Shaft

29 Damper Fill Cap

30 Static Beam Stiffening Rod

31 Outer Leaf Spacer (qty 16)

32 Inner Leaf Spacer (qty 8)

33 Taper Pin

34 LVDT

35 LVDT Spring

36 LVDT Retainer

37 LVDT Transformer

38 Terminal Block (or 38A)

Identification # Description

1 ILE-61 body (cast frame)

2 Mounting Bracket (RH.)

3 Mounting Bracket (LH.)

4 Dynamic Beam (moving)

5 Static Beam (RH.)

6 Static Beam (LH.)

7 Damper Cylinder

8 Top Inner Leaf Spring Bracket

9 Top Outer Leaf Spring Bracket

11 Bottom Inner Leaf Spring Bracket

12 Bottom Outer Leaf Spring Bracket

13 Outer Gasket Outer Ring

14 Outer Gasket Inner Ring

15 Outer Gasket (silicon or neoprene)

16 Inner Gasket Outer Retainer

17 Inner Gasket Inner Retainer

18 Inner Gasket

10 Leaf Spring, qty 4

19 Calibration Arm

ILE - 61 Part Identification Table

Identification # Description

59 Washer, Elongated, SS, (qty 10)

60 Washer, Flat, M8, SS, (qty 30)

61 Washer, Lock, 6.1mm I.D., SS, (qty 2)

62 Washer, Lock, M4, SS, (qty 3)

63 Washer, Lock, M5, SS, (qty 8)

64 Washer, Lock, M8, SS, (qty 32)

65 Washer, Lock, M10, SS, (qty 52)

66 Washer, Plate, M5, SS, (qty 10)

67 Nut, Hex, M6, SS, (qty 1)

68 Nut, Hex, M8x1.25P, SS, (qty 23)

69 Nut, Lock, RS A, (qty 1)

70 Nut, Lock, RS B, (qty 1)

71 O-Ring, Damper Shaft (qty 1)

74 O-Ring, Damper Fill Cap (qty 1)

72 O-Ring, Damper Window (qty 1)

73 O-Ring, Damper Cover (qty 1)

75 Retaining Ring, Damper Spring (qty 1)

Identification # Description

39 Nameplate

40 Fibreglass Cover

41 Cover Gasket

42 LVDT Core

43 LVDT Calibrating Flange

44 Range Spring

45 Range Spring Retainer (RH.)

46 Range Spring Retainer (LH.)

47 Cap Screw M3x20, SS, (qty 2)

48 Cap Screw, M4x10, SS, (qty 3)

49 Cap Screw, M5x16, SS304, (qty 11)

50 Cap Screw, M6x12, SS, (qty 6)

51 Cap Screw, M6x20, SS304, (qty 2)

52 Cap Screw, M8x16, SS, (qty 8)

53 Cap Screw, M8x25, SS, (qty 15)

54 Cap Screw, M8x30, SS, (qty 14)

55 Cap Screw, M10x25, SS, (qty 4)

56 Cap Screw, M10x30, SS, (qty 38)

57 Cap Screw, M10x40, SS, (qty 10)

38A LVDT Conditioner Card

58 Bolt, Hex, M8x45, SS, (qty 18)

Identification # Description

www.siemens.com/processautomation

Siemens Milltronics Process Instruments Inc.

1954Technology Drive, P.O. Box 4225

Peterborough, ON, Canada K9J 7B1

Tel: (705) 745-2431 Fax: (705) 741-0466

Email: techpubs.smpi@siemens.com

Siemens Milltronics Process Instruments Inc. 2008

Subject to change without prior notice

*7ml19985CX01*

Printed in Canada

Rev. 1.1

Loading...

Loading...