Page 1

(

IGWiPS200-1

Rev 3

May 2007

) ) ) ) ) ) ) ) ) ) )

( ( ( ( ( ( ( ( ( ( (

INSTALLATION GUIDE

WiPS-200 Series

Wireless Process Solution

Frequency Hopping Spread Spectrum Radio

Two-Way (Multipoint-to-Point) for Monitoring and Control

With Expandable I/O Options

Page 2

Page 3

IGWiPS200-1

TABLE OF CONTENTS

SECTION TITLE PAGE

PREFACE.....................................................................................................................................................2

CONVENTIONS AND SYMBOLS ..............................................................................................................................2

QUALIFIED PERSONS..............................................................................................................................................2

SCOPE ......................................................................................................................................................................3

INTRODUCTION...........................................................................................................................................4

PRODUCT SUPPORT ...............................................................................................................................................6

INSTALLATION............................................................................................................................................7

FCC RULES AND COMPLIANCE..............................................................................................................................8

CSA HAZARDOUS LOCATION PRECAUTIONS ......................................................................................................9

ENVIRONMENTAL CONSIDERATIONS ...................................................................................................................9

ANTENNA CONNECTORS AND SURGE VOLTAGE PROTECTION .....................................................................10

CURRENT (AMPERAGE) BUDGET CALCULATION ..............................................................................................10

USER SUPPLIED MATERIALS ...............................................................................................................................11

I/O MODULE CONFIGURATION SWITCH SELECTIONS ......................................................................................11

A. Analog Output and Digital Output Fault Response Selections.........................................................................12

B. Pulse Input and Pulse Output Mode of Operation Selections ..........................................................................12

C. Setting Module Switches .................................................................................................................................13

MOUNTING THE DIN RAIL .....................................................................................................................................14

MOUNTING A TRANSCEIVER OR I/O MODULE ...................................................................................................14

MOUNTING THE 1/4-WAVE WHIP ANTENNA .......................................................................................................16

WIRING....................................................................................................................................................................16

Transceiver Wiring Examples...............................................................................................................................18

Transceiver RF Link and Output State Wiring Options.........................................................................................22

I/O Expansion Module Wiring Examples ..............................................................................................................22

ASSIGNING AND SETTING I/O MODULE ADDRESSES .......................................................................................27

HAZARD LABEL ......................................................................................................................................................28

ADDING A REMOTE OR SPARE TRANSCEIVER TO YOUR NETWORK .............................................................28

POST INSTALLATION SIGNAL STRENGTH AND LED INDICATIONS..................................................29

TRANSCEIVER RSSI ..............................................................................................................................................29

TRANSCEIVER AND I/O EXPANSION MODULE STATUS LED INDICATIONS ....................................................30

PULSE INPUT MODULE DIAGNOSTIC LED’S .......................................................................................................30

PULSE OUTPUT MODULE DIAGNOSTIC LED’S ...................................................................................................31

SPECIFICATIONS......................................................................................................................................31

WARRANTY ...............................................................................................................................................34

LIST OF FIGURES

FIGURE AND TITLE PAGE

Figure 1 Sample Installation..........................................................................................................................................7

Figure 2 Current (Amperage) Budget Example...........................................................................................................10

Figure 3 Physical Dimensions.....................................................................................................................................14

Figure 4 Module Features ...........................................................................................................................................15

Figure 5 Removing a Connector Block........................................................................................................................17

Figure 6 Transceiver Wiring, 4-20 mA Current Loop with 2-Wire Device ....................................................................18

Figure 7 Transceiver Wiring, 4-20 mA Current Loop with 3-Wire Device ....................................................................19

Figure 8 Transceiver Wiring, 4-20 mA Current Loop with 4-Wire Device ....................................................................20

Figure 9 Analog Output Wiring for a Loop Powered Device, Separate Power Supply ................................................21

Figure 10 Analog Output Wiring for a Loop Powered Device, Transceiver Power Supply ..........................................21

Figure 11 Transceiver Block Diagram .........................................................................................................................22

Figure 12 4-Channel Analog Input Module Wiring.......................................................................................................23

Figure 13 4-Channel Analog Output Module Wiring....................................................................................................23

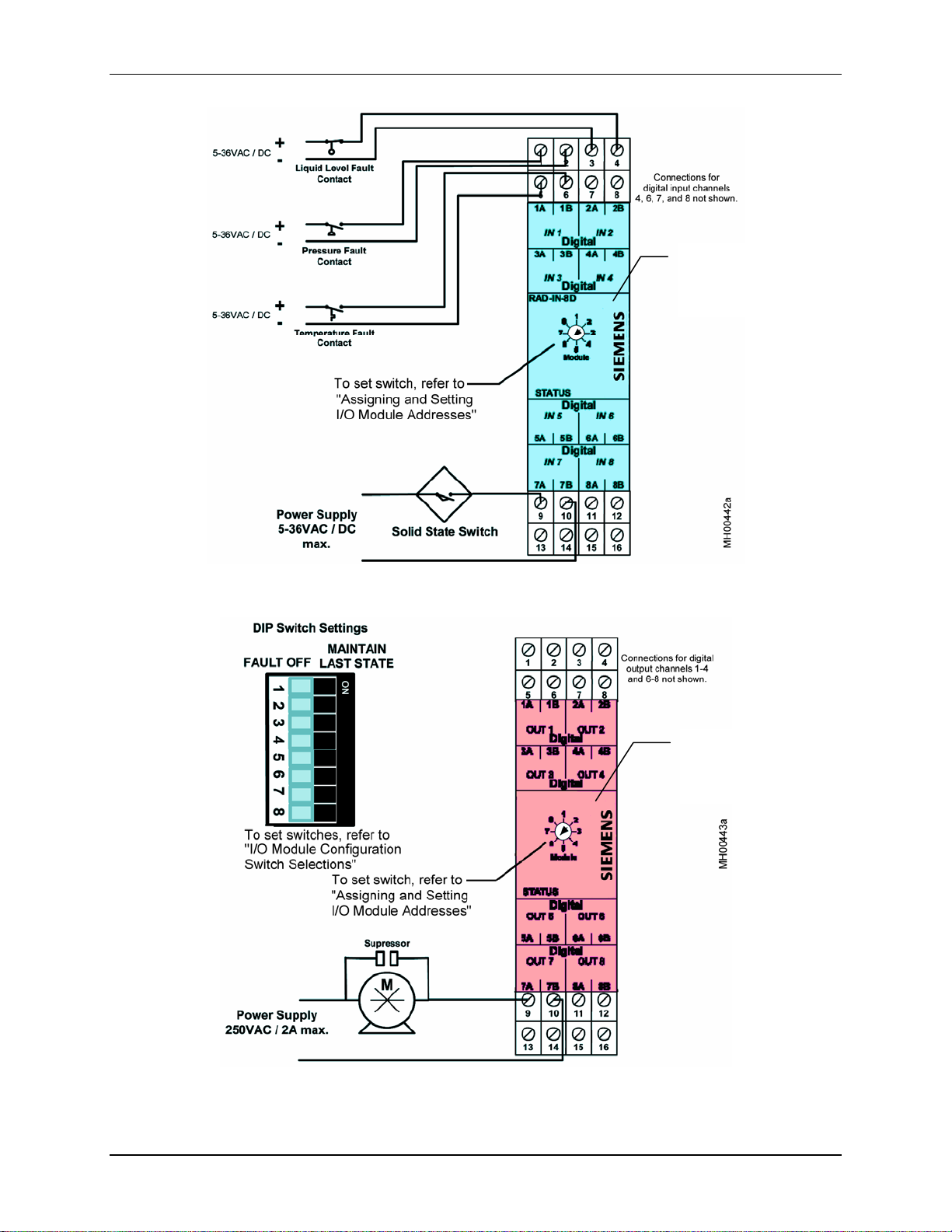

Figure 14 8-Channel Digital Input Module Wiring........................................................................................................24

Figure 15 8-Channel Digital Output Module Wiring.....................................................................................................24

Figure 16 Combination Input and Output Module Wiring ............................................................................................25

Figure 17 2-Channel Pulse Input Module Wiring.........................................................................................................26

Figure 18 2-Channel Pulse Output Module Wiring......................................................................................................26

Figure 19 I/O Module Address Selection Switch .........................................................................................................27

Figure 20 Module Disassembly...................................................................................................................................28

Figure 21 Received Signal Strength Graph.................................................................................................................30

May 2007

1

Page 4

IGWiPS200-1

PREFACE

CONVENTIONS AND SYMBOLS

The following symbols may be used in this manual and may appear on the equipment. The reader should become

familiar with the symbols and their meaning. Symbols are provided to quickly alert the reader to safety related text.

Symbol Meaning

Indicates an immediate hazardous situation which, if not avoided, will result in death or

DANGER

WARNING

CAUTION

CAUTION

NOTICE

IMPORTANT

Note

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Indicates a potentially hazardous situation which, if not avoided, may result in property

damage.

Indicates a potential situation which, if not avoided, may result in an undesirable result or

state.

Identifies an action that should be taken to avoid an undesirable result or state.

Identifies supplemental information that should be read before proceeding.

Electrical shock hazard – Either symbol indicates the presence of an electrical shock

hazard. The associated text states the nature of the hazard.

Explosion hazard – Symbol indicates that the danger of an explosion hazard exists. The

associated text states the nature of the hazard.

Electrostatic discharge – The presence of this symbol indicates that electrostatic

discharge can damage the electronic assembly.

Pinch hazard – Symbol indicates that a pinch hazard exists if correct procedures are not

followed.

QUALIFIED PERSONS

The described equipment should be installed, configured, operated, and serviced only by qualified persons thoroughly familiar

with this manual. A copy of this manual is supplied with the equipment. The current version of the manual, in Portable Document

Format (PDF), can be downloaded from the Siemens Internet site; see Product Support in this manual.

For the purpose of this manual and product labels, a qualified person is one who is familiar with the installation, assembly,

commissioning, and operation of the product, and who has the appropriate qualifications for said activities such as:

• Training, instruction, or authorization to operate and maintain devices/systems according to the safety standards for

electrical circuits, high pressures, and corrosive, as well as, critical media.

May 2007

2

Page 5

IGWiPS200-1

• For devices with explosion protection: training, instruction or authorization to work on electrical circuits for systems that

could cause explosions.

• Training or instruction according to the safety standards in the care and use of suitable safety equipment.

SCOPE

This manual does not purport to cover all details or variations in equipment or to provide for every possible

contingency to be met in connection with installation, operation, or maintenance. Should further information be

desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the

matter should be referred to a support group listed in the Product Support section of this manual.

The contents of this manual shall not become part of or modify any prior or existing agreement, commitment or

relationship. The sales contract contains the entire obligation of Siemens. The warranty contained in the contract

between the parties is the sole warranty of Siemens. Any statements continued herein do not create new warranties

or modify the existing warranty.

General Warnings and Cautions

WARNING

An explosion-proof device may be opened only after power is removed from the device.

An intrinsically safe device loses its license as soon as it is operated in a circuit that does not meet the requirements

of the examination certificate valid in your country.

The device may be operated with high pressure and corrosive media. Therefore, serious injury and/or considerable

material damage cannot be ruled out in the event of handling of the device.

The perfect and safe operation of the equipment is conditional upon proper transport, storage, installation and

assembly, as well as, on careful operation and commissioning.

The equipment may be used only for the purposes specified in this manual.

CAUTION

Electrostatic discharge can damage or cause the failure of semiconductor devices such as integrated

circuits and transistors. The symbol at right appears on a circuit board or other electronic assembly to

indicate that special handling precautions are needed.

• A properly grounded conductive wrist or heel strap must be worn whenever an electronics module

or circuit board is handled or touched. Static control kits are available from most electrical or electronic supply

companies.

• Electronic assemblies must be stored in static protective bags when not installed in equipment.

Changes for Revision 3, May 2007

Figure 1 updated.

Product Support section updated.

Analog output wiring for a loop power external device added. See Figures 9 and 10.

RF Link contact rating added to Specifications.

May 2007 3

Page 6

IGWiPS200-1

INTRODUCTION

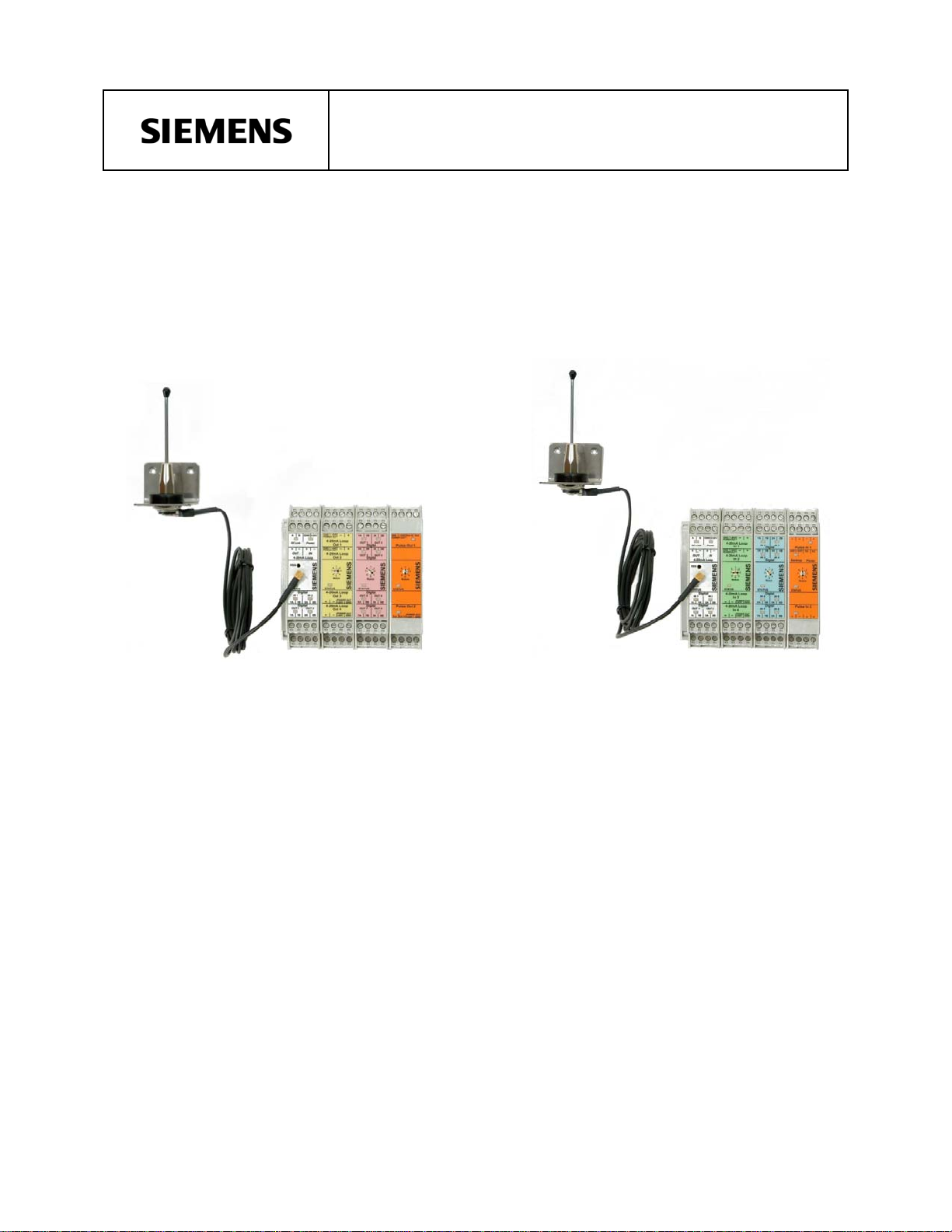

This publication describes installation of the Siemens Wireless

Process Solution (WiPS) 200 Series Two-Way Multipoint-To-Point

Radios and I/O Expansion Modules. Radios (i.e. transceivers)

I/O modules are used to construct a WiPS wireless network for the

gathering and distribution of process related analog, digital, and

pulse/frequency data. Table 1, on the next page, identifies each

WiPS 200 Series model. The table also provides a description of

each item and an order/part number. Shown at right are a

transceiver, the right-most module, and five I/O modules mounted

on a section of DIN rail.

A WiPS wireless network is built using a selection of transceivers,

I/O Expansion modules, and accessories, such as antennas, antenna

cables, and power supplies. Transceivers perform two-way wireless

communications. They also have I/O capability with one analog

input channel, one analog output channel, two digital input channels, and two digital output channels. I/O Expansion

modules perform the bulk of the process data gathering and distribution. A selection of modules is available to

accommodate analog, digital, and pulse/frequency data. Antenna selections include a wide range of omnidirectional

and Yagi directional models. These antennas can be paired with low loss antenna cable to further improve

transmitted signal strength allowing communication over longer distances. Siemens Logo power supplies are

available to power transceivers and I/O Expansion modules. Other accessories include surge voltage protection

adapters and cable connector adapters.

1

and

Transceiver with 1/4-Wave Antenna Typical I/O Expansion Module Siemens Logo Power Supplies

Two types of transceivers are provided: Master and Remote (i.e. Slave

2

). The master transceiver is installed at a

central data collection and processing location, such as a control room. Remote transceivers are installed near field

devices, such as transmitters, counters, motors, fans, conveyer belts, stirrers, and annunciators. Each wireless

network must have one master transceiver and at least one remote transceiver. Up to eight remote transceivers can

be installed on a network allowing access to widely distributed field devices.

Table 1 lists the seven types of WiPS I/O Expansion modules and their model and order numbers. I/O Expansion

modules are added to the wireless network’s Master and Remote transceivers in complementary pairs. Up to eight

I/O Expansion modules of any combination can be connected to a Master transceiver. Eight complementary I/O

Expansion modules can then be connected to up to eight remote transceivers. Thus a total of sixteen modules can be

connected to your WiPS wireless network. As mentioned above, I/O Expansion modules are added to the network in

complementary pairs:

• An input module at the Master transceiver must be complemented by an output module of the same type at a

remote transceiver.

• An output module at the Master transceiver must be complemented by an input module of the same type at a

remote transceiver.

The network can accommodate a maximum of 32 analog signals or 64 digital signals or 16 pulse signals or a

combination of analog, digital, and pulse signals (total of inputs or outputs, not the sum of input and outputs).

1

The terms radio and transceiver are used interchangeably in this guide.

2

The terms remote and slave are used interchangeably in this guide.

May 2007

4

Page 7

IGWiPS200-1

Each transceiver and each I/O Expansion module has bus connectors on both sides of its cover: a male connector on

one side, a female connector on the other. A transceiver and several I/O Expansion modules can be physically

interconnected by way of their bus connectors and then snapped onto a section of DIN rail as a single unit. These

bus connectors carry signal, power, and ground connections between the interconnected devices.

An easy to use wireless network Configurator is available at the Siemens Internet site to help you select remote

transceivers and I/O expansion modules. A master transceiver and one remote transceiver are the configuration

starting point. When adding an I/O module to a remote transducer, the complementary module is automatically

added to the master transceiver. For example, adding an 8-Channel Digital Input Module to a remote transceiver will

cause an 8-Channel Digital Output Module to be automatically added to the master transceiver. The online

Configurator totals the number of I/O Expansion modules and displays a warning if the maximum quantity is

exceeded.

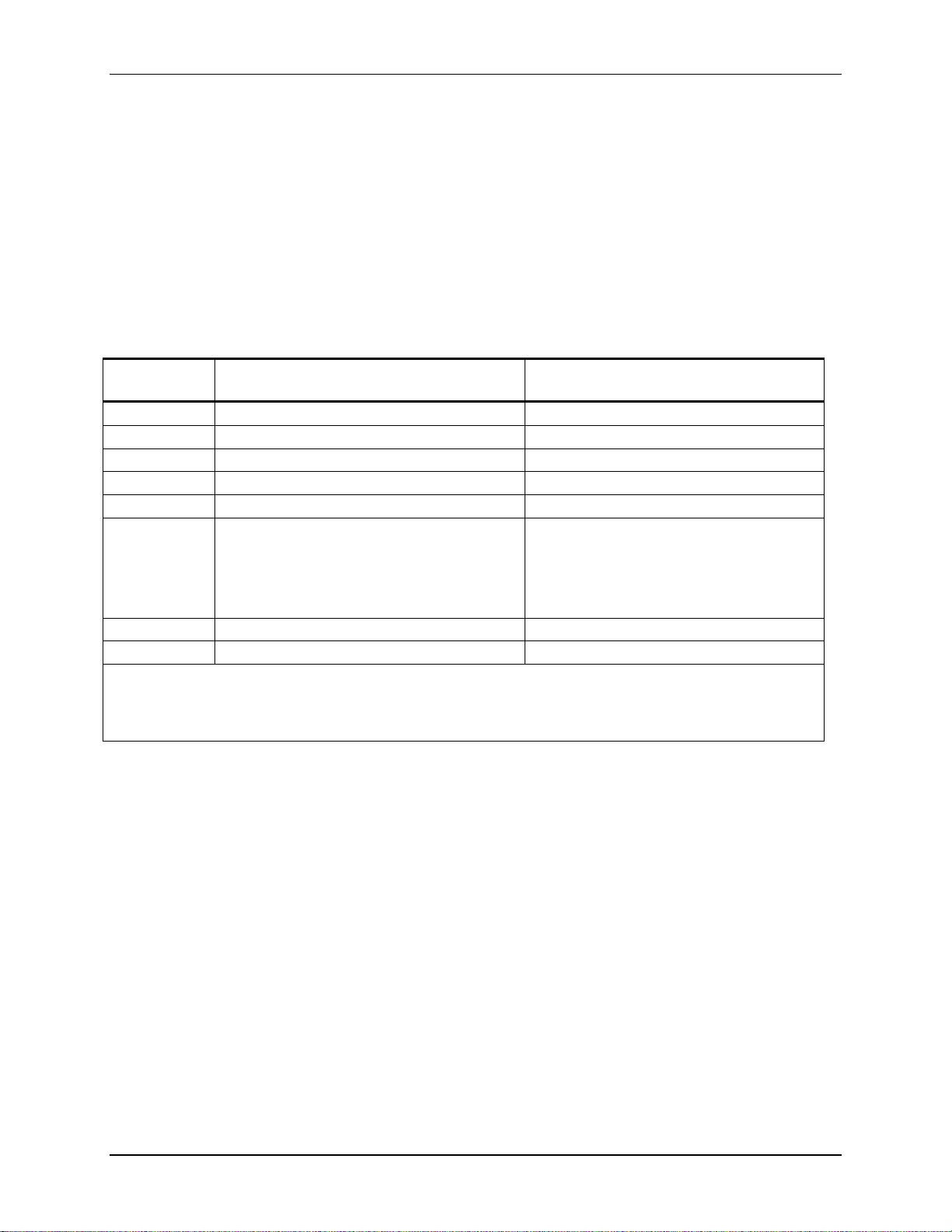

Table 1 WiPS Series 200 Multipoint-To-Point Transceivers and I/O Expansion Modules

WiPS Model

Number

Transceiver and I/O Expansion Modules

(see Notes below)

Order

Number

WiPS-20 Unconfigured Transceiver TGX:16347-320

WiPS-22 8-Channel Digital Input Module TGX:16347-322

WiPS-23 8-Channel Digital Output Module TGX:16347-323

WiPS-24 4-Channel Analog Input Module TGX:16347-324

WiPS-25 4-Channel Analog Output Module TGX:16347-325

Combination Input/Output Module with: WiPS-26

TGX:16347-326

1 analog input channel

1 analog output channel

2 digital input channels

2 digital output channels

WiPS-27 2-Channel Pulse Input Module TGX:16347-327

WiPS-28 2-Channel Pulse Output Module TGX:16347-328

Notes:

Order antennas, antenna cable, power supplies, and other accessories separately.

Siemens Logo power supply is part number 6EP13311SH02.

All 200 Series transceivers and I/O Expansion module have bus connectors for distribution of power and data.

A WiPS Series 200 transceiver is a frequency hopping spread spectrum radio designed for professional installation

and integration with other products. When installed with an approved antenna and cable, the system integrator needs

to make sure that the unit’s FCC label is clearly visible on the outside of the integrated product. WiPS is approved

within the 902 to 928 MHz ISM band under 47CFR15.247 of the FCC Rules and Regulations.

Frequency hopping spread spectrum technology was originally developed by the U.S. military to prevent

interference or interception of radio transmissions on the battlefield. Frequency hopping devices concentrate their

full power into a very narrow signal and randomly hop from one frequency to another within a designated frequency

band. If they encounter interference on a particular frequency, the devices error-check the affected data, hop to

another point on the spectrum, and resume communications on subsequent hops. Since there are always spaces

without interference somewhere in the allotted radio spectrum, a frequency hopping device will use those spaces to

complete a transmission.

IMPORTANT

Save this Installation Guide and have it available when installing the above products.

May 2007 5

Page 8

IGWiPS200-1

PRODUCT SUPPORT

When contacting Siemens for support:

• Please have complete product information at hand:

• For hardware, this information is provided on the product nameplate

(part number or model number, serial number, and/or version).

• For most software, this information is given in the Help > About

screen.

• If there is a problem with product operation:

• Is the problem intermittent or repeatable? What symptoms have been observed?

• What steps, configuration changes, loop modifications, etc. were performed before the problem

occurred?

• What status messages, error messages, or LED indications are displayed?

• What troubleshooting steps have been performed?

• Is the installation environment (e.g. temperature, humidity) within the product’s specified operating

parameters? For software, does the PC meet or exceed the minimum requirements (e.g. processor,

memory, operating system)?

• A copy of the product Service Instruction, User’s Manual or other technical publication should be at hand. The

Siemens public Internet site (see the table below) has current revisions of technical publications, in Portable

Document Format, for downloading.

• To send an instrument to Siemens for repair, contact Siemens and request a Return Material Authorization

(RMA).

IMPORTANT

An instrument must be thoroughly cleaned (decontaminated) to remove any process

materials, hazardous materials, or blood born pathogens prior to return for repair. Read and

complete the Siemens RMA form(s).

Contact Information

Telephone +1 800 333 7421

United States

of America

For customer/product support, visit the Siemens Process Instrumentation product support page at

http://www2.sea.siemens.com/Products/Process-Instrumentation/Support/Customer-Support.htm. Select the desired

type of support (e.g. Sales, Technical).

The current revision of this publication and other Siemens WiPS technical publications can be found at

http://www2.sea.siemens.com/Products/Process-Instrumentation/Wireless-Solutions/Wireless+Solutions.htm. Click

on the WiPS series interest (i.e. 100, 200, or 300). The publications are in Portable Document Format (PDF).

Public Internet Site http://www2.sea.siemens.com/Products/Process-

Instrumentation

Repair Service +1 215 646 7400 extension 3187

May 2007

6

Page 9

IGWiPS200-1

INSTALLATION

This section provides installation procedures for a WiPS 200 Series wireless network. A wireless network contains a

master transceiver and up to eight remote (i.e. slave) transceivers. I/O Expansion modules provide the network with

additional analog, digital, and pulse I/O capacity. Transceivers and I/O modules are mounted on user-supplied DIN

rail by the installer. Accessories include antennas (omnidirectional and directional as needed), low-loss antenna

cables, connector adapters, voltage transient suppression adapters, and power supplies.

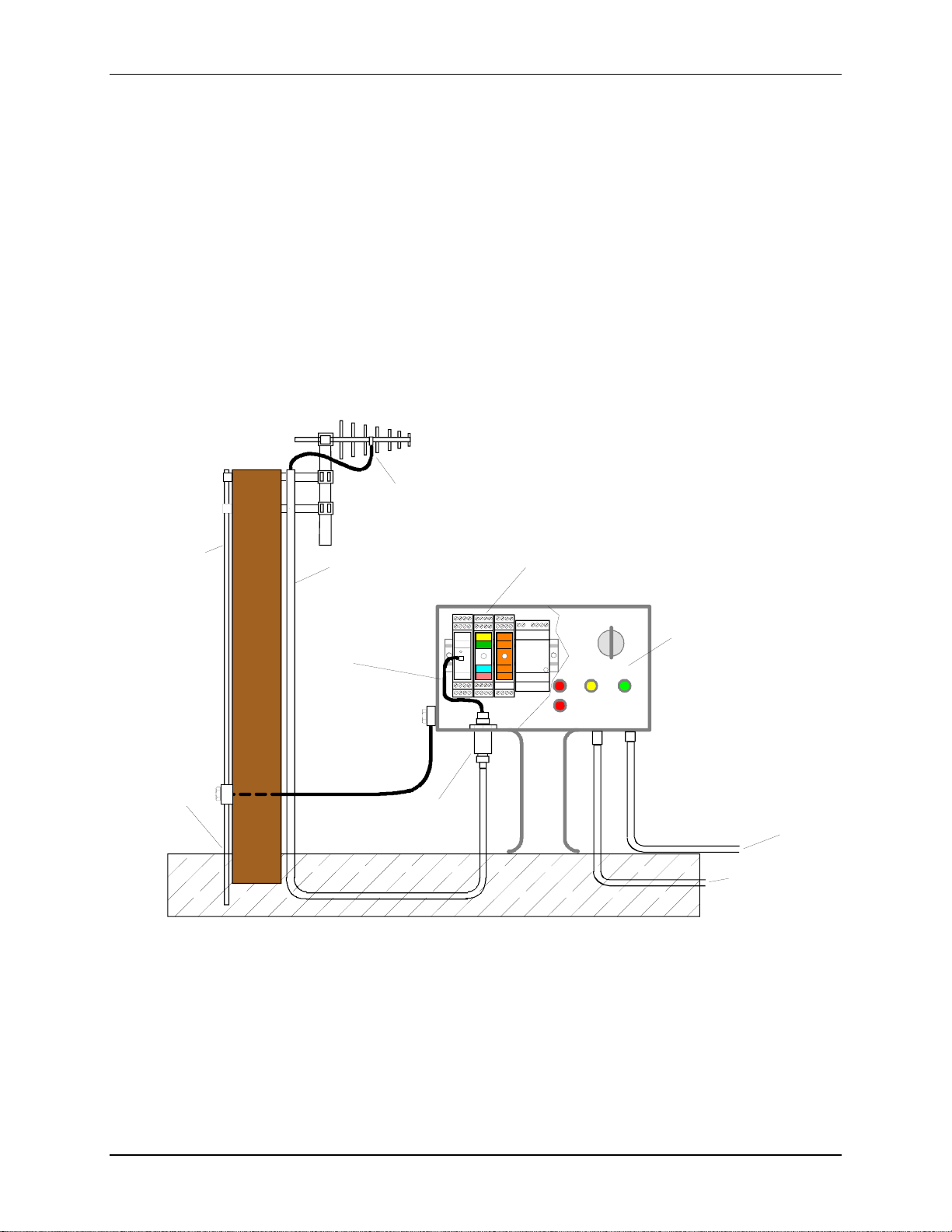

A sample installation is shown in Figure 1. It shows a DIN-rail mounted transceiver and two I/O modules located in

a NEMA 4X rated enclosure. Note the use of a single-point ground system to prevent undesired ground loop

currents. Installation of user-supplied DIN rail and transceiver and I/O modules is discussed later in this section.

The highly directional Yagi antenna, shown below, is used when data transmission over longer distances is

necessary. An omnidirectional whip antenna is used for shorter distances and when a circular radiation pattern is

desired, often due to the wide physical distribution of remote transceivers. Regardless of antenna type, a surge

arrestor is highly recommended, particularly in out-of-doors installations, to protect the connected transceiver from

very large voltages induced by lightning strikes and other electromagnetic events.

Directional Yagi antenna and mounting hardware shown.

Omnidirectional antennas also available.

Grounding

Cable & Rod

Used with

a nonconductive

structure

(wood pole).

Single

Point

Ground

Optional pigtail

Pole

adapter - Type-N

to MCX

Optional COAXTRAB

surge arrester - type-N

connectors

Cable

(LMR400)

Figure 1 Sample Installation

DIN Rail with Transceiver, I/O Expansion

Modules and Logo power supply.

ON

OFF

User-Supplied

NEMA 4X Enclosure

with Operator

Controls

Signal and data

wiring to PLC

or field devices

AC Power

to Logo

power supply

MG00496a

May 2007 7

Page 10

IGWiPS200-1

DANGER

Electrical shock hazard

Explosion hazard

Will cause death or injury.

• Remove power from all wires and terminals before working on

equipment.

• In a potentially hazardous atmosphere, remove power from equipment

before connecting or disconnecting power, signal, or other circuit.

• Observe all pertinent regulation regarding installation in hazardous area.

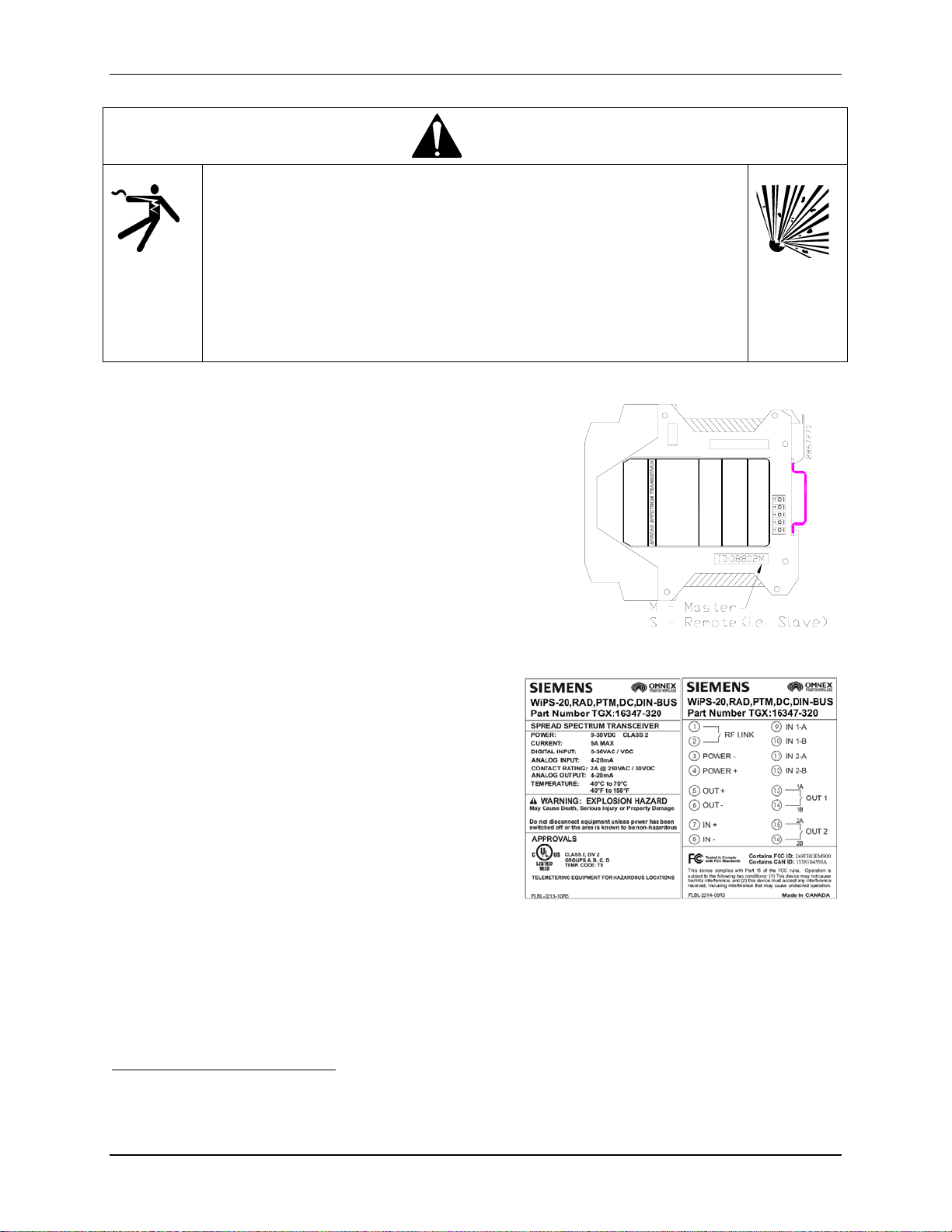

Matched Transceivers

When WiPS transceivers (see Table 1) are ordered, a master transceiver

and up to eight matched remote (i.e. slave) transceivers are supplied.

These transceivers will communicate only with each other.

3

Matched

transceivers have ID labels with the same five digit number. A master

transceiver ID will have an “M” suffix; a remote transceiver will have

an “S” suffix. See the adjacent figure.

Note

When installing several wireless networks, keep track of the

matched transceivers to insure that the proper data is

delivered to the intended controller, PLC, recorder, or field

device.

Nameplate and Wiring Labels

Each transceiver and I/O module has a nameplate label and a

wiring label. The nameplate label carries the module’s part

number, agency approvals, and other data. The wiring label

identifies the connection terminals. Sample labels are shown

here.

To assist module identification, color coded faceplate labels are

provided.

Transceiver – White

4-Channel Analog Input – Green

4-Channel Analog Output – Yellow

8-Channel Digital Input – Blue

8-Channel Digital Output – Pink

Combination Module – Multicolored, by signal type

Pulse Input and Pulse Output – Orange

FCC RULES AND COMPLIANCE

This device complies with 47CFR15.247 of the FCC Rules. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

3

Each transceiver has an internal Hop Key. All transceivers on a WiPS wireless network must have factory programmed Hop

Keys with identical programming allowing them to communicate and exchange data. Hop Keys contain the electronic identifier

and the unique frequency hopping pattern for the transceivers on that WiPS wireless network. For additional details, see Adding

an Extra or Spare Transceiver to Your System later in this Guide.

May 2007

8

Page 11

IGWiPS200-1

Changes or modifications not expressly approved by Siemens will void the user’s authority to operate the

equipment.

This product is intended for fixed installation applications. In order to comply with FCC/ISC adopted RF exposure

requirements, installation of this transmitter system’s antenna must be performed in a manner that will provide at

least a six foot (2m) clearance from the front radiating aperture to any user or member of the public.

FCC 47CFR15.247

ISC RSS 210

UL Class I, Div. 2 (Groups A,B,C,D)

CSA HAZARDOUS LOCATION PRECAUTIONS

This section provides CSA hazardous location precautions that should be observed by the user when installing or

servicing the equipment described in this Instruction. These statements supplement those given in the preceding

section.

Precautions - English

For Class I, Division 2 hazardous locations:

• Use only factory-authorized replacement parts. Substitution of components can impair the suitability of this

equipment for hazardous locations.

For Division 2 hazardous locations:

• When the equipment described in this publication in installed without safety barriers, the following precautions

should be observed. Switch off electrical power at its source (in non-hazardous location) before connecting or

disconnecting power, signal, or other wiring.

Précautions - Français

Emplacements dangereux de classe I, division 2:

• Les pièces de rechange doivent être autorisées par l'usine. Les substitutions peuvent rendre cet appareil

impropre à l'utilisation dans les emplacements dangereux.

Emplacement dangereux de division 2:

• Lorsque l'appareil décrit dans la notice ci-jointe est installé sans barrières de sécurité, on doit couper

l'alimentation électrique a la source (hors de l'emplacement dangereux) avant d'effectuer les opérations

suivantes branchment ou débranchement d'un circuit de puissance, de signalisation ou autre.

ENVIRONMENTAL CONSIDERATIONS

Operate each device within its environmental specifications to help ensure reliable, trouble-free operation with

minimum down time. Refer to the Specifications section for operating temperatures limits, operating humidity, and

maximum moisture content.

CAUTION

Exceeding the specified operating temperature limits can adversely affect performance and

may cause damage to the instrument.

May 2007 9

Page 12

IGWiPS200-1

ANTENNA CONNECTORS AND SURGE VOLTAGE PROTECTI ON

Each transceiver has an MCX female antenna connector. The base 3-1/2", 1/4-wave whip antenna has an MCX male

connector. Optional higher gain antennas and low-loss coaxial cables have type-N connectors. MCX to type-N

adapters and other connector adapters are available. Optional antennas may be accompanied by additional

installation instructions.

If an antenna will be installed out-of-doors or otherwise exposed to surge voltages or strong electromagnetic fields,

such as from a nearby lightning strike, a COAXTRAB Surge Voltage Protection Adapter should be included in the

installation; see Figure 1 for a typical installation. The adapter features a user replaceable gas arrestor tube that

shunts induced high voltage to ground to help protect the transceiver.

Type-N connectors are provided on the adapter; the genders of the two adapter connectors are specified by the

adapter part number. Mount the surge adapter through a bulkhead, through the wall of an enclosure (as shown in

Figure 1), in-line with the antenna cable, on the supplied straight bracket, or on a user-fabricated bracket. Installation

instructions are supplied with the adapter.

CURRENT (AMPERAGE) BUDGET CALCULATION

A common current bus interconnects a transceiver and its connected I/O modules; see Figure 2. The current on this

bus may not exceed 5A. This section shows how to calculate the current flowing on the common current bus. Note

that the calculations in this section are also useful when determining power supply requirements at each transceiver

location.

Figure 2 shows a two-node (remote site and control room) wireless network. The remote site has a remote

transceiver, two input modules, and a power supply. The master transceiver is installed at a control room with two

complementary output modules and a power supply.

The bus current at each transceiver location is calculated by summing the current requirements for the transceiver

and all connected I/O modules. Table 2 lists the current requirements of each module type.

Power Supply

Remote Transceiver

Analog Input Module,

Address 1

Digital Input Module,

Address 2

Power Supply

Master Transceiver

Analog Output Module,

Address 1

Digital Output Module,

Address 2

MG00430a

Remote Site

Common

Current Bus

Control Room

Common

Current Bus

Figure 2 Current (Amperage) Budget Example

Remote Site

As shown in Figure 2, the remote site has one remote transceiver, one analog input module, and one digital input

module. Table 2 shows that the transceiver draws 75 mA, the digital input module 26 mA, and the analog input

module 32 mA plus 20 mA per active channel. The total current (I

) requirement is:

t

It = 75 mA + 26 mA + 32 mA + (4 x 20 mA) = 213 mA

May 2007

10

Page 13

IGWiPS200-1

Control Room

At the control room, there is one master transceiver and complementing I/O: one analog output module, and one

digital output module. The total current requirement is 287 mA [75 mA +100 mA + 32 mA + (4 x 20 mA)].

Table 2 WiPS Module Bus Current Requirements

Module Bus Current Requirement

(in mA @ 24 Vdc)

Transceiver 75 mA average; 200 mA peak*

+ 20 mA per active analog channel

8-Channel Digital Input Expansion Module 26 mA

8-Channel Digital Output Expansion Module 100 mA

4-Channel Analog Input Expansion Module

Module only*

Internal Loop Power**

+ 20 mA per active analog channel

32 mA

4-Channel Analog Output Expansion Module

Module only*

Internal Loop Power**

+ 20 mA per active analog channel

32 mA

Combination Module

Module only*

Internal Loop Power**

+ 20 mA per active analog channel

80 mA

Pulse Input Expansion Module 50 mA

Pulse Output Expansion Module 120 mA

* Base current for module.

** Add 20 mA for each analog channel using internal loop power. Externally powered analog

loops are not added to the calculation.

USER SUPPLIED MATERIALS

A partial list of the materials the user must furnish is provided below. Additional materials may be needed,

depending upon peripheral and accessory equipment and the particular installation.

1. DIN rail(s), mounting hardware, and enclosure(s) appropriate to the environment and hazardous area

certification

2. Signal and power wiring and appropriate tools for wire preparation (e.g. wire cutters and strippers)

3. Conduit tubing, adapters, and outlet boxes and appropriate tools for cutting and routing conduit

4. Circuit protection devices (e.g. fuses, circuit breakers, on-off switches)

Electrostatic Discharge

Semiconductor devices must be protected from electrostatic discharge. A properly grounded conductive

anti-static wrist strap must be worn whenever a circuit board assembly is handled or touched. A service

kit with a wrist strap and static dissipative mat is available from most electronic parts supply companies.

I/O MODULE CONFIGURATION SWITCH SELECTIONS

Configure the following modules before mounting on the DIN rail.4 Field settable switches are provided module

configuration. Default settings are provided.

• 4-Channel Analog Output Module (See Figure 13 on page 23 and paragraph A below.)

• 8-Channel Digital Output Module (See Figure 15 on page 24 and paragraph A below.)

• Combination Input/Output Module (See Figure 16 on page 25 and paragraph A below.)

• 2-Channel Pulse Input Module (See Figure 17 on page 26 and paragraph B below.)

• 2-Channel Pulse Output Module (See Figure 18 on page 26 and paragraph B below.)

4

A module may be configured after installation. However, access to switches may be impeded by adjacent modules.

May 2007 11

Page 14

IGWiPS200-1

A. Analog Output and Digital Output Fault Response Selections

Three I/O modules (4-Channel Analog Output Module, 8-Channel Digital Output Module, and Combination

Input/Output Module) contain DIP switches that may be set by the user to determine the module’s response to the

connected transceiver’s loss of an RF Link or to the loss of an input signal. There is a DIP switch for each signal

channel allowing individual programming of each channel. See Figures 13, 15, and 16 on pages 23, 24, and 25

respectively.

When a loss of RF Link or signal occurs:

• If the DIP switch is set to ON, the default setting, the output from that channel will MAINTAIN LAST STATE.

• If the DIP switch is set to OFF, the output from an analog channel will be 2 mA; the output from a digital

channel will be OFF.

Refer to paragraph C to set the DIP switches.

B. Pulse Input and Pulse Output Mode of Operation Selections

The 2-Channel Pulse Input Module has five sliding-shunt switches, the complementary 2-Channel Pulse Output

Module has four DIP switches. Several switches are used to select mode of operation: counter or frequency. Others

allow selection of coupling, impedance, speed, and sensor input. Setting for Pulse Input and Pulse Output Modules

are detailed below. Refer to paragraph C to set the switches.

Pulse Input Module (See Figure 17 on page 26)

Switch 1 Coupling – AC or DC; Default setting is AC

Set the jumper to AC Coupling if the pulse voltage will never drop below 3.6V with respect to the

transceivers power supply negative. This would apply where there is a DC bias voltage added to the pulse

input voltage, where the DC bias exceeds 3.6V such as in a ground loop condition. All other applications,

including an AC sine wave input, should be set to DC Coupling.

Switch 2 Input Impedance – Low or High; Default setting is High

The Low impedance setting has an input impedance of 1K Ohm and the High setting has an impedance of

90K Ohm. Use the High impedance setting for magnetic transducers to prevent the current draw from

dropping the voltage below the 100 mVAC peak-to-peak minimum. Use the Low impedance setting for

digital and relay interfaces because the additional current draw will prevent electrical noise from causing

false pulse counts.

Switch 3 Operation – Counter or Frequency; Default setting is Counter

Pulse input values are stored in the PLC register in either of two formats: an absolute count of the number of

pulses, which will require that the register be reset periodically to prevent overflow, or a frequency value.

The frequency setting will take the average number of pulses every second.

Switch 4 Speed – Low or High; Default setting is High

The Low speed pulse setting is for a maximum input frequency of 2 Hz with a minimum pulse width of 70

ms. The High speed setting is designed for pulse frequencies up to 32 kHz and requires a minimum pulse

width of 10 microseconds. Use the Low speed setting for mechanical pulse generating devices such as relays

and the high speed setting for all other applications. The Low speed setting prevents contact bounce from

being recorded as pulses.

Switch 5 Sensor Input – Single Ended (Common Mode) or Differential Mode; Default setting is Single

Ended

If the pulse signal is expected to be of negative polarity, with respect to ground, set the module to Differential

mode, whereas if the signal will remain positive at all times, set it to Single Ended (Common Mode).

May 2007

12

Page 15

IGWiPS200-1

Pulse Output Module (See Figure 18 on page 26)

There are two DIP switches for each channel: switches 1 and 2 for channel 1, switches 3 and 4 for channel 2.

Switches 1 (CH1) and 3 (CH2) – Counter or Frequency Mode; Default setting is Counter

When Counter mode is selected, the module will output a specific number of pulses as determined by the

PLC value written to it by the Pulse Input Module. If Frequency mode is selected, the pulse output module

will generate pulses in accordance with the desired frequency, with a 50% duty cycle. In Frequency mode,

the low or high speed switch setting below is ignored.

Switches 2 (CH1) and 4 (CH2) – Low or High Speed Operation; Default setti ng is Hi gh

Set this switch when the channel is set to Counter mode; see preceding paragraph. If High speed is selected

the pulses will be sent at a frequency of 10 kHz with a 50% duty cycle. If Low speed is selected the pulses

will be sent at a frequency of 10 Hz also with a 50% duty cycle.

C. Setting Module Switches

Perform the following steps to change switches from default settings.

1. Place an anti-static wrist strap on your wrist and connect the strap’s ground lead to a good ground. If

the module to be configured is installed on DIN rail, go to step 2; if it has not been installed, go the

step 3.

2. Remove power and signal from the transceiver and all I/O modules, if the module is installed and wired.

At the module to be configured, remove the wired connector block(s) from the module; see Figure 5 on page 17

for photographs (alternatively, label each wire to facilitate reconnection and then disconnect the wires).

Physically separate interconnected modules to disconnect the common current bus connectors. Use a small

straight slot screwdriver to lever the spring-loaded module mounting lip away from the DIN rail allowing that

module to slide on the rail. Remove the module from the DIN rail.

3. Remove the faceplate/circuit board assembly by locating a rectangular recess near the numbered terminals on

the top of the module cover; see the photographs below and Figure 4 on page 15. With a small flat blade

screwdriver, press the tab in the recess inward and pull that corner of the faceplate outward slightly. Repeat this

process at the bottom of the module. Carefully pull the faceplate/circuit board assembly from the cover.

4. Locate the module at hand in Figures 12 through 18 on pages 23 through 26. Set the switches as described in the

appropriate preceding paragraph and figure.

5. Press the faceplate ribbon cable into the module and carefully insert the circuit board into its cover until it snaps

into place. When inserting the circuit board into its cover, be sure the circuit board engages the card guides in

the cover and that the circuit board card edge connector mates with the connector in the cover.

6. If the module was removed from DIN rail in step 2, install the module on the rail. Fully insert the connector

blocks (or connect removed wires).

7. Repeat the above steps for each module containing switches.

8. Remove the anti-static wrist strap from your wrist and install the DIN rail and module(s).

Press Tab

Faceplate /

Circuit Board

Assembly

in Recess

at Top

then at

Bottom

May 2007 13

Page 16

IGWiPS200-1

MOUNTING THE DIN RAIL

At each installation site, mount the DIN rail and DIN rail mount modules (e.g. transceiver, I/O modules, power

supply) in a NEMA enclosure appropriate for the environment and hazardous area classification. Refer to Figure 3

for transceiver and I/O module dimensions. Allow room for:

o Physically mounting and wiring the modules and for antenna, power, ground and signal wire runs

o Accessories (e.g. low loss cable and MCX to N-type connector adapter, surge voltage protection adapter)

o Conduit adapters

o Operator controls

o Circuit protection/safety devices (e.g. switches, circuit breakers, or fuses)

o Other items as determined by the installer/user.

Fasten the DIN rail to a rigid panel within the enclosure using user-supplied hardware. An enclosure is required in a

hazardous area installation. In a non-hazardous area, a secure enclosure can provide safety for area personnel and it

restricts access to the equipment.

IMPORTANT

The DIN rail must be grounded. When mounting the DIN rail in a non-conductive

enclosure, install a ground wire between the rail and the single point ground.

DIN Rail Mount Transceiver or I/O Expansion Module

Figure 3 Physical Dimensions

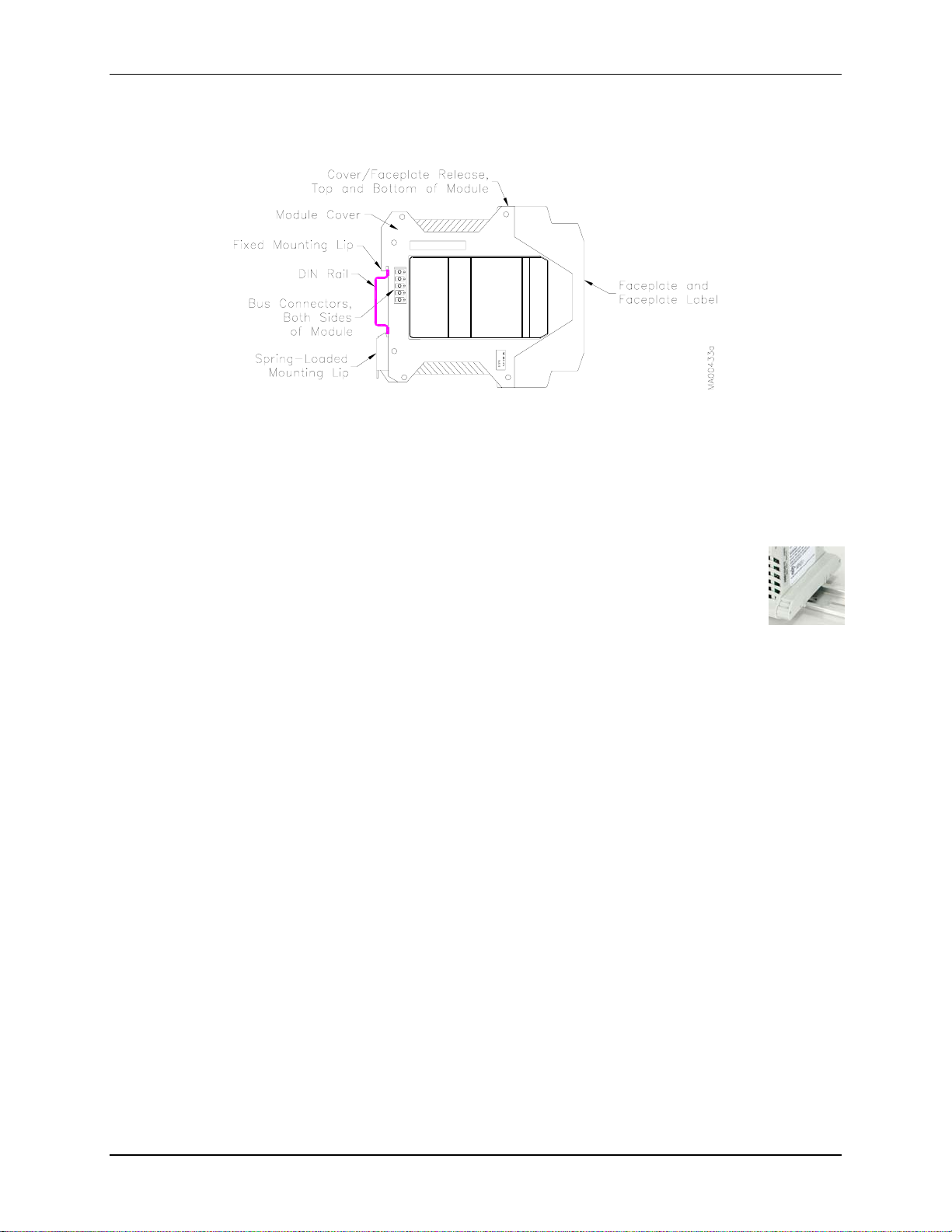

MOUNTING A TRANSCEIVER OR I/O MODULE

I/O Expansion Modules may be mounted on a section of DIN rail in any sequence. Mount the Transceiver at either

end of the row of up to 8 I/O modules, to ensure sufficient heat dissipation.

IMPORTANT

If a module contains configuration switches that have not been set, refer to I/O Module

Configuration Switch Selections on page 11 before installing the module on DIN rail. A list

of modules with configuration switches is provided in the referenced section.

At each installation site, the transceiver and I/O modules are interconnected by built-in bus connectors; see Figure 4

below. Each module has male bus connectors on one side and female bus connectors on the other. When mounting

modules on a DIN rail, be sure to correctly orient modules so they interconnect and the module faceplates are

oriented for easy reading. Refer to the following procedures to install modules.

May 2007

14

Page 17

IGWiPS200-1

Each module has a moveable, spring-loaded mounting lip to assist in mounting a module, sliding a module along the

DIN rail, and removing a module from the DIN rail. This lip has a slotted tab so the blade of a small screwdriver can

be inserted and the lip levered away from the rail.

Figure 4 Module Features

To mount a row of up to 8 modules on a DIN rail:

1. Interconnect the modules by mating the bus connectors.

2. Hook the fixed mounting lips, see Figure 4, on the DIN rail.

3. Press the assembly onto the DIN rail. The spring-loaded mounting lips will snap onto the rail. Do not use

excessive force.

4. A transceiver is supplied with a bus connector cover, shown at right. Place the cover over the

exposed male bus connectors at one end of a group of modules.

To add a module to a row:

1. Note the gender of the installed module’s bus connector.

2. Orient the module and hook the module’s fixed mounting lip on the DIN rail.

3. Press the module against the DIN rail until the spring-loaded mounting lip snaps onto the rail.

4. Slide the module to one side until the bus connector mates with the adjacent module. A module will easily slide

on the DIN rail if the spring-loaded lip is levered away from the rail.

5. As required, place a bus connector cover (supplied with a transceiver) over the exposed male bus connectors at

one end of a group of modules.

To remove a module from the DIN rail:

1. Separate the module to be removed from adjacent modules. To move a module, use a small straight-slot

screwdriver to lever the spring loaded mounting lip slightly away from the rail and slide the module along the

DIN rail until the bus connectors separate. Be sure the bus connectors on both sides of the module to be

removed are fully disengaged from adjacent modules.

2. On the module to be removed, lever the moveable, spring-loaded mounting lip away from the DIN rail. Then

pull the module from the DIN rail.

May 2007 15

Page 18

IGWiPS200-1

MOUNTING THE 1/4-WAVE WHIP ANTENNA

Mount the 3-1/6" (80.4 mm) high, omnidirectional whip antenna5, shown at right, within 5' (1.5m) of the

transceiver to allow the supplied 6' (2m) cable to easily reach between the antenna and transceiver. A

mounting bracket and three screws are supplied. Antenna spacing (transmitter to receiver) should not

exceed 600' to 1000' (183m to 305m). Line of sight is not a requirement.

Incorrect antenna placement and positioning can have a significant impact on the performance of the

system. Keep the omnidirectional antenna vertical and mounted as high as possible.

1. Fasten the supplied right-angle bracket to a rigid, vibration-free surface such that the antenna is oriented

vertically.

2. Unscrew the black disk from the antenna cable end. Insert the antenna cable stud into the large center hole in

the bracket and thread the disk onto the stud. The shallow shoulder on the disk should be toward the bracket

surface. Refer to the cover of this publication.

3. Center the disk in the hole using the shallow shoulder on the disk to assist centering and then tighten the disk.

The supplied hex wrench can be inserted in a hole in the disk perimeter to help tighten the disk. Do not over

tighten. The threaded stud must not be in contact with the grounded bracket.

4. Thread the antenna onto the stud and tighten.

5. Once the transceiver is installed, plug the MCX male connector on the end of the antenna cable into the MCX

female connector on the transceiver faceplate.

WIRING

This section provides wiring guidelines for the transceiver and I/O Expansion modules.

A wireless network contains a master transceiver and up to eight matched remote transceivers. These transceivers

will communicate only with each other. Refer to Installation, Matched Transceivers for additional information.

Before wiring transceivers, confirm that the ID numbers match and that the installed locations are correct. This is

particularly important when installing several wireless networks.

These devices must be wired in accordance with Class 1, Div. 2 wiring methods as described in the National

Electrical Code, Article 501-4(b) or the authority having jurisdiction.

DANGER

Electrical shock hazard

Explosion hazard

Will cause death or injury.

• Remove power from all wires and terminals before working on

equipment.

• In a potentially hazardous atmosphere, remove power from equipment

before connecting or disconnecting power, signal, or other circuit.

• Observe all pertinent regulations regarding installation in a hazardous

area.

5

For other antenna models, refer to the appropriate antenna Data Sheet for specifications and mounting dimensions. Additional

installation information may be provided with the antenna.

May 2007

16

Page 19

IGWiPS200-1

Electrical Connections – Power and I/O connections are completed through screw actuated compression terminals.

Connector blocks can be removed from a module for wiring, as shown in the two figures below. Insert a small

straight-slot screwdriver between a connector block and the faceplate and use a gentle prying motion to separate the

connector block from the module. Each connector in a module is uniquely keyed. When installing a connector block,

be sure to fully insert the block in the module.

Connector

Block

Removed

from Module

Figure 5 Removing a Connector Block

A snap-in MCX female connector is provided for the transceiver antenna connection.

Wire Stripping Recommendations:

Screw terminal wiring - 1/4" (6 mm) to 5/16" (8 mm)

Be careful not to nick the conductor or cut away strands.

Wire Selection - Stranded wire is recommended for most connections. Carefully select wire size, conductor

material, and insulation. Some selection considerations are:

• current and voltage to be carried

• total length of each wire run

• whether wire will be bundled or run singly

• indoor or outdoor installation

• temperature extremes (Use supply wires suitable for 5°C (10°F) above ambient temperature.)

• exposure to sunlight

• vibration

• types of contaminates

Wire Routing and Conduit - DC wiring should be separated from AC wiring and away from AC powered

pushbuttons, alarms, annunciators, motors, solenoids, and similar devices. Conduit and raceways are commonly

used for routing wiring. Wiring not installed in conduit or raceway should be clamped or supported approximately

every 12 inches (300 mm).

Power Input Circuit Protection

A circuit protection device must be installed in the power input circuit between the power source and the WiPS

transceiver or I/O module. Locate the protective device in a non-hazardous area unless suitable for use in a

hazardous area. Circuit protection can be provided by a circuit breaker, fuse or on-off switch accessible to the

operator, except where otherwise stated in this guide or by a certifying agency.

• AC to DC (converter) power supply – Typically, this power supply includes a fuse or circuit breaker in its

output circuit and often includes current limiting. An additional protective device at the module enclosure is

recommended. Check power supply specifications carefully.

• Battery power supply – This power system, because of the large amount of energy stored in a battery, must

include circuit protection.

May 2007 17

Page 20

IGWiPS200-1

Transceiver Wiring Examples

Five transceiver wiring examples are provided below. Figures 6, 7, and 8 show typical transceiver wiring for 2-wire,

3-wire, and 4-wire current loops. Figures 9 and 10 show two variations on the wiring for a loop powered external

analog device. Also shown in Figures 9 and 10 is the wiring for an RF Link annunciator, which can be an input to a

PLC or controller or a separate light or siren. A digital output wiring example is provided in Figure 9.

The transceiver is DC-powered, typically by a DIN rail mount power supply, as shown below. The power supply for

the transceiver also powers the connected I/O modules. Power is supplied through the transceiver and across the

common current bus as shown in Figure 2 on page 10.

Figure 6 Transceiver Wiring, 4-20 mA Current Loop with 2-Wire Device

May 2007

18

Page 21

IGWiPS200-1

Figure 7 Transceiver Wiring, 4-20 mA Current Loop with 3-Wire Device

May 2007 19

Page 22

IGWiPS200-1

Figure 8 Transceiver Wiring, 4-20 mA Current Loop with 4-Wire Device

May 2007

20

Page 23

IGWiPS200-1

Figure 9 Transceiver Wiring, Analog and Digital Outputs

Figure 10 Transceiver Wiring, Analog Output Wiring for a Loop Powered Device

May 2007 21

Page 24

IGWiPS200-1

Transceiver RF Link and Output State Wiring Options

This section describes the transceiver RF link status relay and the analog output and digital output wiring options. A

block diagram of the transceiver is shown in Figure 11.

Figure 11 Transceiver Block Diagram

Transceiver RF Link

The RF Link relay has Form A, Normally Open (NO) contacts that close when the transceiver establishes an RF link

with another transceiver. The contacts are often used to turn on a STATUS light, provide a digital status signal to a

controller or PLC, or mechanically disconnect an analog or digital signal, as described below, when an RF link is

lost. Refer to the Specifications section for relay contact rating.

For additional information about RF Link response, refer to Transceiver and I/O Expansion Module Status LEDs on

page 30.

Transceiver Analog and Digital Output Last State Selection

The default state upon loss of RF link for the analog and digital outputs is MAINTAIN LAST STATE. Either an

analog output or a digital output may be wired in series with the RF Link contact to provide a FAULT OFF status

when an RF link is lost. Refer to the Specifications section for relay contact rating.

I/O Expansion Module Wiring Examples

I/O module wiring connections are shown in Figures 12 through 18 on the following pages.

May 2007

22

Page 25

IGWiPS200-1

Green

Faceplate

Figure 12 4-Channel Analog Input Module Wiring

Yellow

Faceplate

Figure 13 4-Channel Analog Output Module Wiring

May 2007 23

Page 26

IGWiPS200-1

Blue

Faceplate

Figure 14 8-Channel Digital Input Module Wiring

Pink

Faceplate

Figure 15 8-Channel Digital Output Module Wiring

May 2007

24

Page 27

IGWiPS200-1

Multiple

Colors

Faceplate

Figure 16 Combination Input and Output Module Wiring

(One Analog Input, One Analog Output, Two Digital Inputs, and Two Digital Outputs)

May 2007 25

Page 28

IGWiPS200-1

Orange

Faceplate

Figure 17 2-Channel Pulse Input Module Wiring

Orange

Faceplate

Figure 18 2-Channel Pulse Output Module Wiring

May 2007

26

Page 29

IGWiPS200-1

ASSIGNING AND SETTING I/O MODULE ADDRESSES

Module addresses are 1 through 8, as shown on the module faceplates in Figure 19. The top row in the figure shows

three I/O modules at a location (for example, at a remote location). The lower row shows the complementary I/O

modules at another location (for example, at the control room); transceivers are not shown. Note that the modules in

each complementary pair are set to the same address. For example, the Analog Output Module at the remote location

(yellow faceplate) and the complementary Analog Input Module at the control room (green faceplate) are set to

address 1. The small triangle symbol points to the selected module address.

When assigning I/O module addresses:

• Assign a module address to each complementary pair of I/O modules on a wireless network.

• An address may be used for only ONE complementary pair on each wireless network.

If module addresses conflict or are improperly set within a complimentary pair, the STATUS LED will light; see the

Transceiver and I/O Expansion Module Status LED Indications section on page 30.

Yellow

Faceplate

Green

Faceplate

A. Three I/O Modules (Remote Location)

B. Three Complementary I/O Modules (Control Room)

Figure 19 I/O Module Address Selection Switch

May 2007 27

Page 30

IGWiPS200-1

HAZARD LABEL

A label, similar to that shown here, is included in a WiPS shipment. The installer or

user should post this label in an appropriate, highly visible location near the WiPS

modules. Possible label mounting locations include: on the outside of an enclosure

housing WiPS modules or inside that enclosure adjacent to the modules.

ADDING A REMOTE OR SPARE TRANSCEIVER TO YOUR NETWORK

When WiPS transceivers are ordered, two or more transceivers are supplied as

matched devices, meaning that they share the same electronic identifier and

frequency hopping pattern. This data is stored in a Hop Key. The Hop Key in a

transceiver can be removed and physically transferred to another transceiver

producing a second matched transceiver. The original matched transceiver will

retain its Hop Key data and operate normally even though the Key has been

removed.

The following procedure describes transferring the Hop Key from a matched transceiver to an unmatched

transceiver (e.g. spare transceiver part number TGX:16347-320) thereby producing another matched transceiver.

The newly matched transceiver can then be used as a remote transceiver in a multipoint-to-point system, a spare

transceiver, or a replacement (master or remote) transceiver. Once the Hop Key is installed in the transceiver and

power is applied, the transceiver will memorize the identification, hop frequencies, and hop sequence of the matched

transceiver. When power is removed, it will retain this information, even if the Hop Key is removed. The newly

matched transceiver and the original matched transceiver will communicate with the other matched transceiver(s).

IMPORTANT

When replacing or adding a transceiver to a wireless network, remember that a network

node can have one (1) master transceiver and up to eight (8) remote transceivers.

To Transfer a Hop Key

1. Place an anti-static wrist strap on your wrist and connect the strap’s ground lead to a good ground.

2. If the transceiver is installed, remove power from the transceiver and all I/O connections.

Remove the wired connector blocks from the transceiver; see Figure 5 on page 17 for photographs

(alternatively, label each wire to facilitate reconnection and then disconnect the wires). Physically separate any

connected I/O modules and remove the transceiver from the DIN rail.

3. Remove the faceplate/circuit board assembly locating a rectangular recess near the numbered terminals on the

top of the transceiver cover (see Figure 4 on page 17 and Figure 20 below). With a small flat blade screwdriver,

press the tab in the recess inward and pull that corner of the faceplate outward slightly. Repeat this process at

the bottom of the transceiver. Carefully pull the faceplate/circuit board assembly from the cover.

Figure 20 Module Disassembly

May 2007

28

Page 31

IGWiPS200-1

4. Locate the Hop Key (a small circuit board) at the rear edge of the top circuit board, see the figure below.

Unplug the Hop Key and set it aside.

Hop Key

Location

5. Carefully insert the faceplate/circuit board assembly in its cover until it snaps into place. When inserting the

assembly into its cover, be sure the circuit board enters the card guides in the cover and the circuit board card

edge connector mates with the connector in the cover.

6. Remove the spare transceiver’s cover as described above in step 3.

7. Insert the Hop Key from the original transceiver into the spare transceiver - carefully align the Hop Key

connector with the main circuit board pins. Carefully insert the faceplate/circuit board assembly in the enclosure

– review step 5 as needed to ensure correct orientation.

8. Label the spare transceiver with the Hop Key 5-digit ID number and suffix (M for master, S for remote).

9. If replacing the original transceiver, mount the spare transceiver on the DIN rail and complete all needed

connections. Otherwise install the original transceiver and complete all needed connections.

10. Remove the anti-static wrist strap from your wrist.

When power is applied to the “spare” transceiver, it will memorize Hop Key data - allow a few seconds after power

up for the data to transfer to transceiver memory.

POST INSTALLATION SIGNAL STRENGTH AND LED INDICATIONS

This section describes a method for determining whether received signal strength is adequate. It also provides status

LED indications that will help to assess whether the wireless network is operating properly.

There are no user serviceable parts within a transmitter or receiver. Should service be needed, see the Product

Support section to contact Siemens.

TRANSCEIVER RSSI

RSSI (Received Signal Strength Indicator) is measured using a DC voltmeter between the provided test point and

power supply ground. The test point is accessed by inserting a positive meter probe into the RSSI receptacle on the

face of the transceiver module and connecting the negative meter probe to the module’s Ground terminal.

The RSSI graph in Figure 21 can be used to test the received signal strength. Ideally, the meter reading should be 2.5

Vdc or more. This represents a 90 dB signal loss and typically indicates that the transceiver has 20 dB fade margin

left until loss of link. It is recommended that a transceiver be set up with no less than a 20 dB margin.

May 2007 29

Page 32

IGWiPS200-1

RSSI vs DC Voltage

4.0

3.0

2.0

-75

1.0

0.0

MG00446a

+DC Volts

-115 -110

-105

-100

Signal Strength (-dBm)

-95 -90 -85

-80

Figure 21 Received Signal Strength Graph

TRANSCEIVER AND I/O EXPANSION MODULE STATUS LED INDICATIONS

Power LED Indicates the presence of power to the module. It is ON when power is present and OFF when

there is no power.

Status LED When flashing rapidly, it indicates an internal error or a module type mismatch. A module type

mismatch occurs when the module address selection for two different modules (i.e. one digital

modules and one analog module are set to the same address or two pairs of modules are sharing

the same address).

RF Link LED Flashes once every two seconds when there is no RF link.

Note: At the Master transceiver, an RF Link failure will not be indicated by the master

transceiver or the connected I/O Expansion Modules until the master has lost RF Link with

all Remote transceivers. A Remote transceiver will indicate a loss of RF Link when it

cannot communicate with the master transceiver.

Flashes rapidly when signal strength is marginal (see the RSSI graph in the Servicing section of

this guide.

ON steady indicates an exceptionally strong RF link.

Most systems will flash occasionally indicating the presence of intermittent interference in the

area.

Digital

Input/Output

OFF means that the digital input or output circuit is Open.

ON means that the digital input or output circuit is Closed.

PULSE INPUT MODULE DIAGNOSTIC LED’S

There are 4 diagnostic LED’s on the pulse input module:

Status LED: On solid when I/O is functional and flashing if there is a conflict with another module.

Backup Power LED: On solid when the backup power supply is powering the module. Off when primary

power is powering the module.

Pulse Input 1 and 2 LEDs: These lights will flicker at a varying frequency when pulses are applied to each

channel:

Frequency Range (Hz) LED Flashing Frequency (Hz)

1 ≤ frequency ≤ 10

10 < frequency ≤ 100

100 < frequency ≤ 1000

1000 < frequency ≤ 32K

1

4

8

On solid

May 2007

30

Page 33

IGWiPS200-1

PULSE OUTPUT MODULE DIAGNOSTIC LED’S

There are 3 diagnostic LED’s on the pulse output module:

Status LED: On solid when I/O is functional and flashing if there is a conflict with another module.

Pulse Input 1 and 2 LEDs: These lights will flicker at a varying frequency depending on the frequency of

pulses being generated:

Frequency Range (Hz) LED Flashing Frequency (Hz)

1 ≤ frequency ≤ 10

10 < frequency ≤ 100

100 < frequency ≤ 1000

1000 < frequency ≤ 32K

1

4

8

On solid

SPECIFICATIONS

Transceiver

Frequency .............................................................902 to 928 MHz industrial, scientific, and medical (ISM) band

Technology...........................................................Frequency Hopping Spread Spectrum

Power Input ..........................................................9-30 Vdc; reverse polarity and surge protected

Power Consumption .............................................75 mA (average), 200 mA (peak) @ 24 Vdc during transmission

(plus I/O modules), 5A (maximum)

Inputs

Analog ...........................................................1, 4 to 20 mA (16-bit, 125 Ohms impedance

Digital............................................................2, 5 to 36 Vac/Vdc (for 120 Vac digital inputs use relays to convert

to specified voltage levels; consult factory for relay options)

Outputs

Analog ...........................................................1, 4 to 20 mA, 12-bit resolution, short circuit protected

Digital............................................................2, 250 Vac / 30 Vdc, 2A dry contact

RF Link .........................................................1, 250 Vac / 30 Vdc, 2A dry contact

Repeatability (4-20 mA Current Loop) ................0.02%

Accuracy (4-20 mA Current Loop) ......................0.2% full scale

Transmitter Power Output ....................................1 Watt (30 dBm)

Range

Standard Omnidirectional Antenna ...............600 to 1000 feet (183m to 305m) in-plant, obstructed LOS

Optional Omnidirectional Antenna ...............4 to 5 miles (6.5 km to 8 km) clear LOS, flat terrain, raised antenna

Optional Yagi Antenna..................................15 to 20 miles (24 km to 32 km) clear LOS, flat terrain,

professional propagation study and installation

Antenna Connector...............................................MCX female, 50 Ohms

Operating Temperature Range..............................-40°C to 70°C (-40°F to 158°F)

Humidity...............................................................20% to 90% non-condensing

Dimensions...........................................................4.5" x 3.9" x 0.9" (114 mm x 99 mm x23 mm)

Faceplate Label Color...........................................White

Weight ..................................................................5.3 oz (150g)

Environmental ......................................................NEMA 1, equivalent to IP 20

Approvals

USA...............................................................FCC 47CFR15.247

Canada...........................................................ISC RSS 210

UL and CUL..................................................Class I, Div. 2, Groups A, B, C, D; Temp. Code T5

CSA ...............................................................Approved

6

6

LOS – Line of Sight between transmitting and receiving antennas

May 2007 31

Page 34

IGWiPS200-1

Digital Input Module

Channels ...............................................................8

Digital Input Voltage Range.................................5 to 30 Vac/Vdc, reverse polarity protected

Input Impedance ...................................................20k Ohms

Input Frequency....................................................DC to 2 Hz

Channel Isolation..................................................Optical

Over-Voltage Rating.............................................100 Vac/Vdc maximum

Power Input ..........................................................12-30 Vdc

Current Consumption ...........................................30 mA maximum

Operating Temperature Range..............................-40°C to 70°C (-40°F to 158°F)

Faceplate Label Color...........................................Blue

Digital (Relay) Output Module

Channels ...............................................................8

Output Terminal ...................................................Dry Contact, normally open

Contact Rating ......................................................250 Vac / 30 Vdc, 2A

Channel Isolation..................................................Full

Power Input ..........................................................12-30 Vdc

Current Consumption ...........................................160 mA maximum

Operating Temperature Range..............................-40°C to 70°C (-40°F to 158°F)

Faceplate Label Color...........................................Pink

Analog Input Module

Channels ...............................................................4

Range....................................................................4-20 mA

Resolution.............................................................16-bit

Input Impedance ...................................................<170 Ohms

Channel Isolation..................................................None (power supply connections are common with transceivers)

Reverse Polarity Protected....................................Yes

Compatibility........................................................2-wire, 3-wire, 4-wire devices

Over-Voltage Rating.............................................42 Vdc maximum

Accuracy...............................................................0.2% of full scale

Repeatability.........................................................0.02% of full scale

Power Input ..........................................................12-30 Vdc

Current Consumption ...........................................130 mA maximum

Operating Temperature Range..............................-40°C to 70°C (-40°F to 158°F)

Faceplate Label Color...........................................Green

Analog Output Module

Channels ...............................................................4

Range....................................................................4-20 mA

Resolution.............................................................16-bit

Channel Isolation..................................................Optical

Short Circuit Protected .........................................Yes

Compatibility........................................................2-wire, 3-wire, and 4-wire devices

Accuracy...............................................................0.2% of full scale

Repeatability.........................................................0.02% of full scale

Power Input ..........................................................9 to 30 Vdc

Current Consumption ...........................................130 mA maximum

Minimum Loop Voltage Drop..............................10 Vdc

Operating Temperature Range..............................-40°C to 70°C (-40°F to 158°F)

Faceplate Label Color...........................................Yellow

May 2007

32

Page 35

IGWiPS200-1

Combination Input/Output Module

Channels ...............................................................1 analog input

1 analog output

2 digital inputs

2 digital outputs

Channel Isolation..................................................All (except for the analog input channel)

Reverse Polarity Protection ..................................Yes

Analog Channel

Range.............................................................4-20 mA

Input Impedance............................................<170 Ohms

Repeatability..................................................0.2% of full scale

Resolution......................................................16-bit

Compatibility.................................................2-wire, 3-wire, 4-wire devices

Over-Voltage Rating .....................................42 Vdc maximum

Digital Input Channel

Input Impedance............................................20k Ohms

Over-Voltage Rating ....................................100 Vac/Vdc maximum

Voltage ..........................................................5 to 36 Vac/Vdc

Digital Output Channel

Contact Rating...............................................250 Vac / 30 Vdc, 2A

Type...............................................................Dry contact, normally open

Power Input ..........................................................12 to 30 Vdc

Current Consumption ...........................................120 mA maximum

Operating Temperature Range..............................-40°C to 70°C (-40°F to 158°F)

Faceplate Label Colors .........................................Analog In section – Green

Analog Out section – Yellow

Digital In section – Blue

Digital Out section - Pink

Pulse Input Module

Channels ...............................................................2

Input Voltage ........................................................3.6 Vdc minimum (Single Edge Mode), 100 mVac P-P

(Differential Mode)

Input Frequency....................................................0-32 kHz

Pulse Width ..........................................................10 μSec minimum

Input Impedance ...................................................1k Ohms (low), 90k Ohms (high), Selectable

Coupling ...............................................................AC or DC, Selectable

Channel Isolation..................................................Optical

Reverse Polarity....................................................Yes, protected

Power Input ..........................................................12-30 Vdc

Backup Power Supply ..........................................12-30 Vdc

Current Consumption ...........................................50 mA maximum

Operating Temperature Range..............................-40°C to 70°C (-40°F to 158°F)

Faceplate Label Color...........................................Orange

Pulse Output Module

Channels ...............................................................2