SIMATIC

Industrial monitors

IFP1900 INOX PRO

Compact Operating Instructions

07/2019

A5E35751632

Preface

Product description

1

Safety instructions

2

Installing the device

3

Commissioning the device

4

Maintaining and repairing the

device

5

Specifications

6

Technical support

A

IFP1900 INOX PRO

-AC

Siemens AG

Digital Industries

Postfach 48 48

90026 NÜRNBERG

GERMANY

A5E35751632-AC

Ⓟ

Copyright © Siemens AG 2019.

All rig

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

07/2019 Subject to change

hts reserved

Preface

Validity

This document applies to devices with the designation IFP1900 INOX PRO, article numbers:

● IFP1900 INOX PRO Stand variant with operator controls, article number

6AV7484-6AB00-0AA0

● IFP1900 INOX PRO Support arm variant, article number with operator controls, article

number 6AV7484-6AB10-0AA0

● IFP1900 INOX PRO Stand variant without operator controls, article number

6AV7484-6AB01-0AA0

● IFP1900 INOX PRO Support arm variant, article number 6AV7484-6AB11-0AA0

In relation to the operation, the IFP1900 INOX PRO is identical with the base unit IFP1900

Touch Standard.

This document describes the mechanical and electrical differences between the device and

the base device IFP1900 Touch Standard.

Conventions

Figures

The notes contained in this document take precedence over the information contained in the

documentation of the basic device, in the release notes and in the online help.

You can find the documentation of the basic device on the Internet at the following address:

Operating Instructions Industrial Flat Panels IFP, IFP PRO, IFP ETH

(http://support.automation.siemens.com/WW/view/en/65288650)

The term "device" is also used instead of the product designation in this document.

"Windows 7" is used as an abbreviation for "Windows 7 Ultimate".

This document contains figures of the device described. The figures can deviate from the

particularities of the delivered device.

IFP1900 INOX PRO

Compact Operating Instructions, 07/2019, A5E35751632-AC

3

Table of contents

Preface ........................................................................................................................................ 3

1 Product description ....................................................................................................................... 5

2 Safety instructions ......................................................................................................................... 9

2.1 Intended use ....................................................................................................................... 9

2.2 General safety instructions .................................................................................................. 9

2.3 Notes about usage .............................................................................................................11

3 Installing the device ..................................................................................................................... 12

3.1 Permitted mounting positions..............................................................................................12

3.2 Mounting and connecting the device ...................................................................................12

3.3 Dismantling the device .......................................................................................................18

4 Commissioning the device ........................................................................................................... 19

5 Maintaining and repairing the device ............................................................................................. 20

5.1 General information on maintenance and servicing .............................................................20

5.2 Cleaning .............................................................................................................................20

5.2.1 Cleaning the device ............................................................................................................20

5.2.2 Clean screen ......................................................................................................................21

5.2.3 Chemical Resistance ..........................................................................................................22

5.2.4 Working with stainless steel surfaces..................................................................................22

5.3 Resetting the device to factory settings ...............................................................................24

5.4 Repair ................................................................................................................................24

6 Specifications ............................................................................................................................. 25

6.1 Certificates and approvals ..................................................................................................25

6.2 Guidelines and declarations ...............................................................................................26

6.3 Dimension drawings ...........................................................................................................27

6.3.1 IFP1900 INOX PRO ...........................................................................................................27

6.3.2 Mechanical interface of the device ......................................................................................28

6.4 Technical specifications ......................................................................................................28

6.4.1 General technical specifications .........................................................................................28

6.4.2 Environmental conditions....................................................................................................30

6.5 Description of the interfaces ...............................................................................................31

6.5.1 Pin assignment of the internal terminal strip ........................................................................31

A Technical support........................................................................................................................ 32

A.1 Service and support ...........................................................................................................32

IFP1900 INOX PRO

4 Compact Operating Instructions, 07/2019, A5E35751632-AC

1

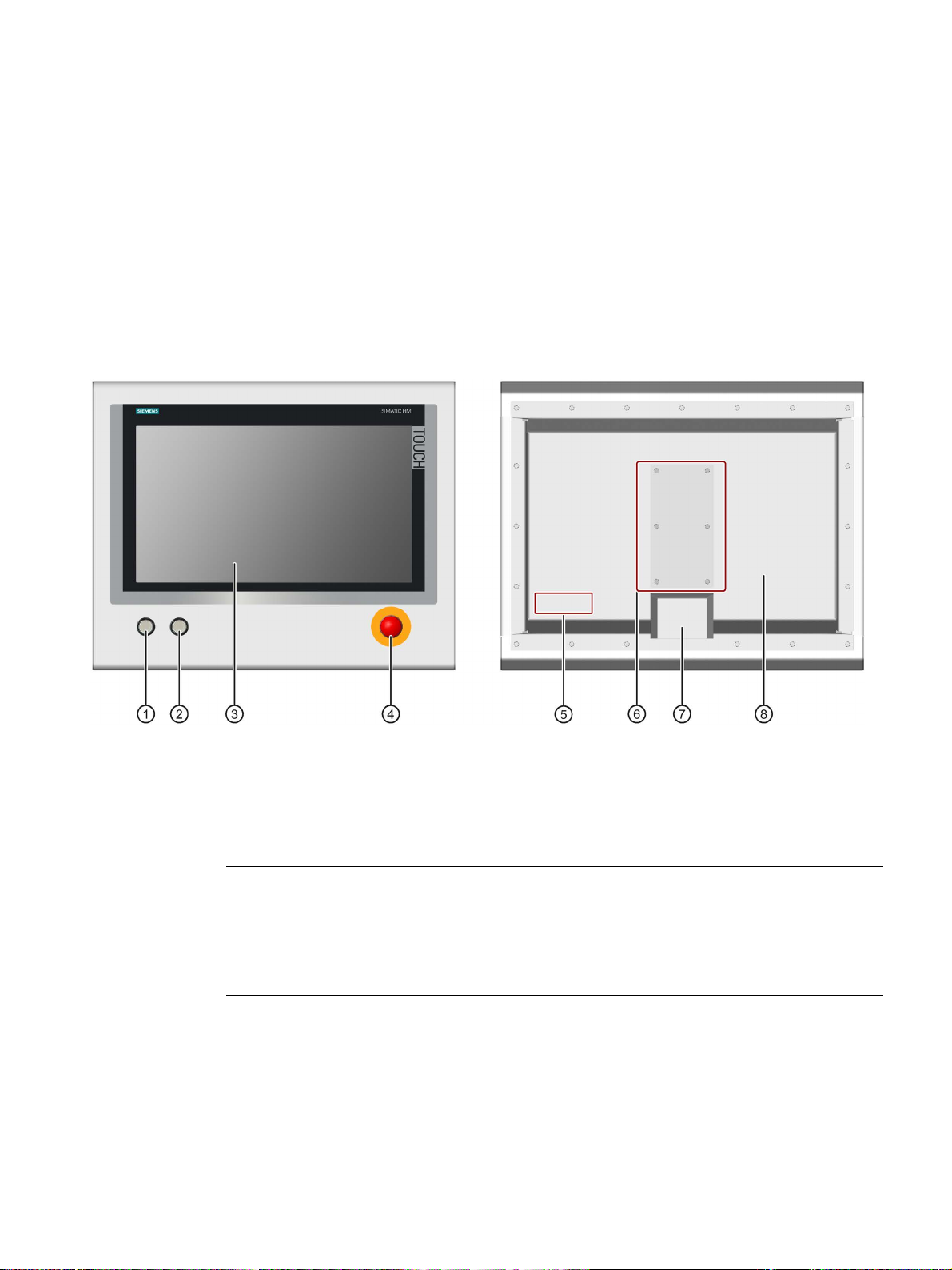

①

Illuminated pushbutton 1 "left" with green LED

⑤

Position of nameplate and approvals

②

Illuminated pushbutton 1 "right" with red LED

⑥

Connection compartment

③

Display with touch screen

⑦

Mechanical interface for fastening

④

EMERGENCY OFF button 1

⑧

Rear panel

Note

EMERGENCY OFF button

The connections of the EMERGENCY OFF button are wired to pins

in the connection compartment.

The EMERGENCY OFF button is not connected with the electronics inside the device.

The IFP1900 INOX PRO devices are mounted to a support arm or stand by means of the

mechanical interface. The IFP1900 INOX PRO devices are not intended for installation in a

control cabinet.

The figures below show the front view and rear view using a device with operator controls

and stand mounting as an example.

1

Only for devices with operator controls

IFP1900 INOX PRO

Compact Operating Instructions, 07/2019, A5E35751632-AC

1-4 of the terminal strip

5

Product description

•

INOX stainless steel, material number 1.4301

•

FPM (fluorinated rubber)

•

Polyester

•

IP66 all

•

2 illuminated pushbuttons, 1 EMERGENCY OFF button, wired to

internal terminal strip 1

•

For stand mounting, analogous for support arm mounting

Note

Accessories are intended only for the INOX devices listed above and not in general for other

PRO devices (standard).

Features

Properties of the IFP1900 INOX PRO:

Enclosure material:

Scope of delivery

Accessories

Sealing material:

Front membrane:

Degree of protection:

-based

-round

Front operator controls:

Mechanical interface:

1

Internal plug-in terminal strip only for devices with operator controls, pin assignment of the

internal terminal strip, see section "Pin assignment of the internal terminal strip (Page 31)"

● 1 x IFP1900 INOX PRO

● 1 x 2-pin connecting terminal for the 24 V DC power supply

● 1 x 20-pin connecting terminal, matching the internal 20-pin terminal strip of the device

● 1 x seal for mechanical interface

Mounting kit for stand mounting

A mounting kit is available for pedestal mounting of the device. Mounting kit contents:

● 1 stainless steel tube with flange: Length 500 mm, outer diameter 48.3 mm, inner

diameter 40 mm.

The mechanical interface of the stainless steel tube with flange fits the mechanical

interface of the device.

● 4 hexagon screws M5×25 made of stainless steel

● 1 flat seal

Article number 6AV7675-1GB00-0AA0

IFP1900 INOX PRO

6 Compact Operating Instructions, 07/2019, A5E35751632-AC

Product description

Mounting kit for support arm mounting

A mounting kit is available for support arm mounting of the device. Mounting kit contents:

● 1 stainless steel tube with flange: Length 500 mm, outer diameter 48.3 mm, inner

diameter 40 mm.

The mechanical interface of the stainless steel tube with flange fits the mechanical

interface of the device.

● 1 adapter support arm

● 8 hexagon screws M5×20 made of stainless steel

● 2 flat seals

Article number 6AV7675-1GB10-0AA0

Service pack

The service pack contains:

● 1 spare seal for the connection compartment cover of the device

● 6 screws for the connection compartment cover of the device

● 1 spare seal for the mechanical interface of the device

● 4 screws for fastening the stainless steel tube with flange from a mounting kit to the

mechanical interface of the device

● 1 connecting terminal for the power supply

● 1 terminal block for the terminal strip in the connection compartment

● Documentation

Article number 6AV7675-1JD20-0AA0

Service pack 2, only in combination with the service manual

The service pack 2 contains:

● 1 spare seal for the rear panel of the device

● 4 spare screws for the rear panel of the device

● 1 spare seal for the mechanical interface of the device

● 4 screws for fastening the stainless steel tube with flange from a mounting kit to the

mechanical interface of the device

● 1 connecting terminal for the power supply

● Documentation

Article number 6AV7675-1JD21-0AA0

IFP1900 INOX PRO

Compact Operating Instructions, 07/2019, A5E35751632-AC

7

Product description

WARNING

Opening the device and working on the opened device may only be carried out by qualified

and correspondingly trained personnel

Service pack 3, in connection with devices for support arm mounting

Service pack 3 contains:

● 1 spare seal for the connection compartment cover of the device

● 1 spare seal for the mechanical interface of the device

● 1 spare seal for support arm mounting

● 8 screws M5 x 20 mm for support arm mounting

● 6 screws for the connection compartment cover of the device

● 1 connecting terminal for the power supply

● 1 terminal block for the terminal strip in the connection compartment

● Documentation

Article number 6AV7675-1JD20-1AA0

Service manual

A service manual that describes the following maintenance work is available for the IFP1900

INOX PRO:

● Replacing the seal of the rear panel

● Replacing defective operator controls in the device front

● Converting a device for stand mounting into a device for support arm mounting and vice

versa

The service manual describes, amongst other points, the opening of the device and

working on the wiring or on electronic components in the inside of the device. Injuries or

material damage may result if the work is not carried out correctly.

The work described in the service manual may only be carried out by qualified specialist

personnel who have been trained correspondingly by Siemens.

The service manual is available online under "Product Support" next to this document in the

same branch of the product tree.

IFP1900 INOX PRO

8 Compact Operating Instructions, 07/2019, A5E35751632-AC

2

WARNING

Improper use can endanger safety.

WARNING

Performing a function test when installing the device in machines or systems

2.1 Intended use

The IFP1900 INOX PRO touch screen front panel devices are designed to be used for highperformance visualization tasks (operator control and monitoring) and in ambient conditions

such as those found in the food, beverage and pharmaceutical industries.

Improper use of the device endangers safety and can result in personal injury or damage to

property.

Any use deviating from the intended use is not permitted.

Operate the device only in accordance with its intended use.

Also see the information in the section "Cleaning the device (Page 20)".

Particular attention has been paid during design of the HMI devices to ensure that the front

panel is easy to clean and can be disinfected when needed. The devices with stainless steel

front have therefore been developed according to DIN EN 1672-2 "Food Processing

Machinery - Safety and Hygiene Requirements".

2.2 General safety instructions

Following the results of a risk analysis, additional protection equipment on the machine or

the system is necessary to avoid endangering persons. In particular, the programming,

parameter assignment and wiring of the inserted I/O must be executed in accordance with

the safety performance identified by the necessary risk analysis (SIL, PL or Cat.). The

intended use of the device has to be ensured.

The proper use of the device has to be verified with a function test on the system. These

tests help you to identify programming, parameter assignment and wiring errors. The test

results have to be recorded and, if necessary, entered into the safety verification

documents.

IFP1900 INOX PRO

Compact Operating Instructions, 07/2019, A5E35751632-AC

9

Safety instructions

WARNING

Risk of explosion, personal injury or material damage in the case of a defective touch

screen

2.2 General safety instructions

Defective touch screen

The application of excessive force to the device front can destroy the device touch screen,

for example, piercing the front membrane or breaking the touch screen carrier plate. There

is a risk of explosion, injury and food contamination with additional consequential and

health damage.

Make sure that excessive force cannot be applied to the device front.

If the device touch screen is defective, decommission the affected machine immediately

and replace the device at once. When replacing the device, please note the chapter

"Repair (Page 24)".

ESD

Electrostatically sensitive components include almost all electrical, electronic, optoelectronic

and electromechanical components. These components are sensitive to overvoltage for

technical reasons and their function may be impaired or destroyed by electrostatic discharge.

Observe the regulations governing the handling of ESD components.

Industrial Security

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions constitute one element of such a concept.

Customers are responsible for preventing unauthorized access to their plants, systems,

machines and networks. Such systems, machines and components should only be

connected to an enterprise network or the internet if and to the extent such a connection is

necessary and only when appropriate security measures (e.g. firewalls and/or network

segmentation) are in place.

For additional information on industrial security measures that may be implemented, please

visit (http://www.siemens.com/industrialsecurity).

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends that product updates are applied as soon as they are

available and that the latest product versions are used. Use of product versions that are no

longer supported, and failure to apply latest updates may increase customer’s exposure to

cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under (http://www.siemens.com/industrialsecurity).

IFP1900 INOX PRO

10 Compact Operating Instructions, 07/2019, A5E35751632-AC

Safety instructions

CAUTION

Safety-relevant mechanisms not visible or operable

NOTICE

HMI device approved for indoor use only

Note

Operate the device only in a normal atmospheric environment

The technical characteristics of the device described in the operating instructions are

guaranteed if you operate the device in normal ambient air conditions with usual air

composition.

2.3 Notes about usage

Disclaimer for third-party software updates

This product includes third-party software. Siemens AG only provides a warranty for

updates/patches of the third-party software, if these have been distributed as part of a

Siemens software update service contract or officially released by Siemens AG. Otherwise,

updates/patches are undertaken at your own risk. You can find more information about our

Software Update Service offer on the Internet at Software Update Service

(http://www.automation.siemens.com/mcms/automation-software/en/software-update-

service).

Notes on protecting administrator accounts

A user with administrator privileges has extensive access and manipulation options in the

system.

Therefore, ensure there are adequate safeguards for protecting the administrator accounts

to prevent unauthorized changes. To do this, use secure passwords and a standard user

account for normal operation. Other measures, such as the use of security policies, should

be applied as needed.

2.3 Notes about usage

Position the device in such a manner that safety-related mechanisms such as a mains

isolation switch remain visible, accessible and operable.

The HMI device may be damaged if operated outdoors.

Operate the HMI device indoors only ("Indoor use only").

IFP1900 INOX PRO

Compact Operating Instructions, 07/2019, A5E35751632-AC

11

3

3.1 Permitted mounting positions

The device may only be operated in landscape format with a maximum inclination of ±30° to

the vertical.

Permissible ambient temperature: 0 ... 45 °C

3.2 Mounting and connecting the device

This section describes how to mount and connect the device correctly, using stand mounting

as an example. Mounting on a support arm is carried out in the same way. All the work steps

in this chapter have to be carried out sequentially for complete mounting of the device.

Requirement

● A stand with a mechanical interface suitable for the mechanical interface of the device;

see section "Mechanical interface of the device (Page 28)".

● The following lines are routed through the stand:

– Protective conductor, minimum cross-section of 2.5 mm

– Lines for the external power supply, voltage-free

– Lines for the front operator controls

– All required data lines

● Four hexagon screws M5 according to screw standard ISO 4017, material X5CrNi18-10

2

The length of the screws have to be dimensioned so that the penetration depth of the

screw thread in the device-side flange lies in the range of 6 to 10 mm.

IFP1900 INOX PRO

12 Compact Operating Instructions, 07/2019, A5E35751632-AC

Installing the device

Note

The device is fastened to a stand or a support arm via the mechanical interface with four

screws.

Siemens AG assumes no liability for the consequences of a faulty installation.

WARNING

The device must be mounted securely

NOTICE

Placing the device on its front can damage operator controls

3.2 Mounting and connecting the device

Opening the connection compartment and installing the device

Inadequately dimensioned fastening material may cause the device to fall down. Serious

bodily injury may result.

Make sure that fasteners are adequately dimensioned during installation of the device.

Make sure to consider the weight of the device and the forces acting on the device when

dimensioning the fasteners. This applies in particular to dynamic load of the device.

Observe any further statutory specifications applying at the location of use of the device

and further applicable regulations with regard to the fastening of the device.

If you place the device on its front before or during the installation, the operator controls on

the front can be damaged.

Place the device on a soft and elevated surface so that the front operator controls do not

contact the working area and are not damaged.

IFP1900 INOX PRO

Compact Operating Instructions, 07/2019, A5E35751632-AC

13

Installing the device

3.2 Mounting and connecting the device

Procedure

1. Open the connection compartment. To do so, remove the 6 screws on the device rear

that are marked in the following figure and remove the connection compartment cover

and associated seal.

2. Place the supplied seal for the mechanical interface with its smooth side onto the stand.

Center the openings of the seal and of the mechanical interface of the stand.

3. Route the lines from the stand through the opening of the mechanical interface of the

device into the connection compartment.

4. Place the mechanical interface of the device onto the mechanical interface of the stand.

Take the following into account:

– The seal has to lie exactly in the mechanical interface of the device.

– The lines must not be squeezed. Hold the lines slightly tensioned while placing the

device on the stand.

5. Fasten the device to the mechanical interface of the stand using the four M5 screws.

Insert the screws from below through the mechanical interface and tighten the screws

with a torque of 3.5 Nm. The degree of protection IP66 is only ensured with this torque.

The device is mounted on the stand. The following steps describe the installation in the

connection compartment.

IFP1900 INOX PRO

14 Compact Operating Instructions, 07/2019, A5E35751632-AC

Installing the device

①

Connection for the 24 V DC power supply

⑤ USB 2.0 interfaces, high current

②

Ethernet interface

⑥ USB type B interface

③

Reset button

⑦ Connection for protective conductor

④

(only for devices with operator controls)

Note

Use copper cables on connectors with terminal connections

Use copper (Cu) cables for all supply lines that are connected to the

e.g. 24

Note

External interface cable

Lay external interface cables only indoors or up to a maximum length of 42.6

3.2 Mounting and connecting the device

The following figure shows the position of the interfaces.

Connecting cables

Use only shielded standard cables as data connecting cables, order information is available

on the Internet Industry Mall (https://mall.industry.siemens.com).

DisplayPort interface ⑧ Internal terminal strip, 20-pin

device with terminals,

V DC power supply cables on the 24 V DC power supply connector.

m outdoors.

IFP1900 INOX PRO

Compact Operating Instructions, 07/2019, A5E35751632-AC

15

Installing the device

WARNING

Electric shock and fire hazard when protective conductor is not connected

WARNING

Risk of fire and electric shock

NOTICE

Safe electrical isolation

3.2 Mounting and connecting the device

Connecting the device and closing the connection compartment

Important notes on connecting

The protective conductor connection is needed to protect the device and helps ensure that

interference signals generated by power lines, signal lines or lines to I/O devices are safely

discharged to earth.

The protective conductor connection on the device must be connected to the protective

conductor of the control cabinet or system in which the device is installed.

High voltage may be present in a defective device, which can cause fire or an electric

shock if touched. Death and serious bodily injury can result.

• Connect the device to the protective conductor before you put it into operation.

• Never operate the device without protective conductor.

• If a device is defective, remove it from operation without delay and label it accordingly.

Risk of electric shock if the device is opened incorrectly or defective. There is also a risk of

fire if the device or connecting lines are damaged.

You should therefore protect the device as follows:

• Always pull out the power plug when you are not using the device or if the device is

defective. The power plug must be freely accessible.

• Connect the device to a protective conductor as instructed (see "Connecting the

protective conductor").

• Use a central isolating switch in the case of cabinet installation.

The device may only be connected to a 24 V DC power supply that meets the requirements

of a safe extra-low voltage (SELV) according to IEC/EN/DIN EN/UL 60950-1 or the

requirements of a secure extra-low voltage (SELV/PELV) according to IEC 61131-2.

The power supply must meet the requirements of NEC Class 2 or LPS according to

IEC/EN/DIN EN/UL 60950‑1.

The supplying source must be fused for a power rating < 240 VA;

recommended fuse rating ≤ 8 A.

IFP1900 INOX PRO

16 Compact Operating Instructions, 07/2019, A5E35751632-AC

Installing the device

3.2 Mounting and connecting the device

Procedure

1. Connect the protective conductor to the protective conductor connection ⑥. The

protective conductor connection is identified by the following symbol:

The following applies for devices with a protective earth symbol: The branch circuit which

the protective conductor connection is connected to must be protected with a Branch

Circuit Protective Device of 20 A.

The minimum cross-section of the protective conductor is 2.5 mm

2

.

The protective conductor connection is needed to protect the device and helps ensure

that interference signals generated by power lines, signal lines or lines to I/O devices are

safely discharged to earth.

2. Connect the lines for the power supply via the associated connecting terminal to the

connection for the power supply

①.

Pin assignment: 1=24 V DC, 2=Ground

3. Connect the connectors of the data lines to the corresponding interface.

4. Secure the data lines with cable ties to the fastening elements in the connection

compartment that are marked in the following figure.

5. Place the seal of the connection compartment cover around the connection compartment.

Ensure that the latches of the seal lie in the associated notches and that the seal lies

flush on the device rear panel.

6. Fasten the connection compartment cover with 6 screws. Tighten the screws using a

torque of 3.5 Nm.

IFP1900 INOX PRO

Compact Operating Instructions, 07/2019, A5E35751632-AC

17

Installing the device

3.3 Dismantling the device

3.3 Dismantling the device

The device is generally removed in the reverse order for mounting and connecting.

Procedure

1. Close all open programs on the PC which is connected to the device.

2. Switch off power to the device.

3. When you use the device in a hazardous area, make sure that one of the two following

requirements is met:

i. The area is no longer hazardous.

ii. The device and its plug-in connections are de-energized.

4. Open the connection compartment by removing its cover.

5. If attached, remove all cable ties that were installed for tension relief of the connecting

cables in the connection compartment.

6. Remove all plug-in connectors and the equipotential bonding cable.

7. Remove the device from the support arm or pedestal. Make sure that the connection

cables are not damaged.

8. Fasten the connection compartment cover with 6 screws on the device, torque 3.5 Nm.

IFP1900 INOX PRO

18 Compact Operating Instructions, 07/2019, A5E35751632-AC

4

Note

Requirement

If you operate the device exclusively as monitor and do not change the brightness, you do

not need to commission the device. To use advanced functions of the device, perform the

following commissioning.

● The device is mounted according to the Quick Install Guide.

● The device is connected according to the Quick Install Guide.

The supplied connecting cables are only intended for commissioning and not for

continuous operation.

Procedure

● DVD "Documentation and Drivers" or USB stick with a copy of the DVD

1. Switch on the IPC.

2. Switch on the power supply of the IFP1900 INOX PRO.

3. Insert the "Documentation and Drivers" DVD into the CD/DVD drive of the IPC.

Alternatively, insert the USB stick with the copy of the DVD into a USB port on the device.

4. Follow the instructions for installation.

IFP1900 INOX PRO

Compact Operating Instructions, 07/2019, A5E35751632-AC

19

5

CAUTION

Unwanted reactions when cleaning the device

NOTICE

Damage to the device due to impermissible cleaning agents

5.1 General information on maintenance and servicing

Observe the following when servicing and repairing protective equipment e.g. such as

ground circuits or overvoltage protection components:

● Observe the maintenance and replacement intervals.

● Replace system components, including external cables, fuses and batteries only with

equivalent components approved by the respective manufacturer.

5.2 Cleaning

5.2.1 Cleaning the device

Cleaning Agents

The device is designed for low-maintenance operation. However, it is still necessary to clean

the device regularly.

Clean the entire device thoroughly:

● Before commissioning

● As required, depending on the degree of contamination

● At regular intervals (according to an internal cleaning plan)

You risk unintentional actuation of operator controls if you clean the device while it is

switched on.

You may possibly trigger unwanted actions of the device or controller that are liable to

cause personal injury or damage to the machinery.

Always switch off the device before you clean it.

Impermissible and unsuitable cleaning agents can cause damage the device.

Use dish soap or foaming screen cleaner only as cleaning agents.

IFP1900 INOX PRO

20 Compact Operating Instructions, 07/2019, A5E35751632-AC

Do not use aggressive solvents or scouring powder.

Maintaining and repairing the device

Note

Cleaning methods

In addition to the specifications in this section, the following applies for cleaning the device:

Permitted

DIN

Not permitted

•

•

• You damage the operating front if you clean the device with high pressure equipment. Do

Note

Unintentional responses

When cleaning the touch screen, an unintentional response in the controller can be triggered

by touch

Always open the clean screen or switch off the device before you clean the touch screen

while the system is running.

Cannot be operated when the clean screen is active

When the clean screen is active, operations on the device are not

Wait for the period of the clean screen to lapse. Then you can operate the system again with

the device.

5.2 Cleaning

Procedure

1. Switch off the device.

2. Dampen the cleaning cloth.

3. Spray the cleaning agent on the cloth and not directly on the device.

4. Clean the device with the cleaning cloth.

: Cleaning with strong jet water under increased pressure in accordance with

EN 60529:2014-09, specifications on "IP66".

:

Do not clean the device using aggressive cleaners or detergents, greasing or abrasive

detergents, acids or caustic solutions, leather, scratching or rough rags and equipment.

You can find additional information in the section "Chemical resistance (Page 22)".

Do not clean the device with chlorine or chloride, for example, active chlorine, with laser

or ultrasonic equipment, or with dry ice.

not clean the device thermally, for example, using hot steam equipment, because this

would inevitably damage the operating front and, in particular, the touch sensor system.

5.2.2 Clean screen

If you use the WinCC RT Advanced software in connection with the device, you can clean

the touch screen of the device while it is switched on and the project running. An operating

element must be available in the project that can be used to call the "clean" screen. Once

the clean screen is activated, touch screen operation is locked for a configured period of

time. The time the touch screen is locked can be set between 5 and 30 seconds. The time

remaining for the lockout is indicated by a progress bar.

IFP1900 INOX PRO

Compact Operating Instructions, 07/2019, A5E35751632-AC

ing keys.

possible.

21

Maintaining and repairing the device

5.2 Cleaning

5.2.3 Chemical Resistance

Front membrane

The resistance of the front membrane to various chemicals has been tested to DIN 42 115,

section 2. The front membrane is resistant to the chemicals listed below:

● Alcohol

● Diluted acids

● Diluted caustic solutions

● Ester

● Hydrocarbons

● Household cleaners

You can find information of chemical resistance on the Internet.

Seals

The seals made of FPM (fluorinated rubber) are approved for food according to FDA

CFR21.177.2600 for use with dry, watery and fatty foods.

5.2.4 Working with stainless steel surfaces

Resistance

Information on the resistance of stainless steel:

● The stainless steel surface is not fully resistant against the chemicals listed below:

– Hydrochloric acid

– Sulphuric acid

– Sodium hydroxide

– Chlorine

– Chlorides

Do not clean the stainless steel surface with these chemicals or with similar acids or

caustic solutions.

● Acid steam develops, for example, when tiles are cleaned with hydrochloric acid, and is

also harmful to the stainless steel. If the stainless steel parts are unintentionally

contaminated with hydrochloric acid, rinse these off immediately with plenty of water.

● Clean the stainless steel surface with a cleansing agent without active chlorine.

IFP1900 INOX PRO

22 Compact Operating Instructions, 07/2019, A5E35751632-AC

Maintaining and repairing the device

5.2 Cleaning

Cleaning guidelines

Further information on stainless steel surfaces:

● The surface should be properly ventilated.

● Keep the surface clean. Remove cleaners and food residue immediately. Always avoid

the return of food stuff splashes to the production process.

● If mechanical cleaning is necessary, do not use cleaning equipment made of metal.

– Use brushes made of plastic or natural materials, or a microfiber pad.

– Use plenty of water to clean the surface.

– Make sure that the cleansing agent is completely removed without any residue.

● Make sure surface is not damaged: Do not damage the device during operation, or by

cleaning or repairing it using hard tools, in particular tools made of corrodible materials.

● Make sure that the surface does not come into contact with rusted parts.

This includes water pipes, filings, residue from wire brushes or steel wool. These, as well

as rust films have a corrosive effect on parts made of stainless steel.

– Remove any stains or rust immediately.

– Remove new rust spots with a mild abrasive detergent in order to prevent any further

corrosion.

– Rinse the part thoroughly after you cleaned it.

IFP1900 INOX PRO

Compact Operating Instructions, 07/2019, A5E35751632-AC

23

Maintaining and repairing the device

5.3 Resetting the device to factory settings

5.3 Resetting the device to factory settings

The reset button is used to reset the device to factory settings, for example, when the

IFP1900 INOX PRO can no longer communicate with the IPC for a longer period.

During the reset to factory settings, the IP address of the IFP1900 INOX PRO, for example,

is reset to the default value "192.168.1.2".

Procedure

1. Switch off the device's power supply.

2. Press the reset button with a suitable tool and keep the reset button pressed.

3. Switch on the device's power supply and keep the reset button pressed for an additional

10 seconds.

During this the two LAN LEDs are deactivated briefly.

5.4 Repair

In case of repair, the device must be shipped to the Return Center in Erlangen. Repairs may

only be carried out at the Return Center in Erlangen.

The device described in this document is covered by the conditions of repair and return of

equipment, as follows:

1. You return the defective device to the returned goods center. The address is:

Siemens AG

Digital Factory Retouren-Center

c/o Geis Service GmbH, Tor 1-4

Kraftwerkstraße 25a

91056 Erlangen

Germany

2. After it has been repaired, the device is returned to you. A new device will not be supplied

in exchange.

Depending on the work necessary to repair the device, the Center may decide to give you a

credit note. In this case, it is your responsibility to order a new device.

For additional information, refer to the Internet at Spare parts and repairs

(http://support.automation.siemens.com/WW/view/en/16611927).

IFP1900 INOX PRO

24 Compact Operating Instructions, 07/2019, A5E35751632-AC

6

Note

This section lists the certificates and approvals possible for the

Only those approvals specified on the rear of your device apply to your device.

6.1 Certificates and approvals

A copy of the certificates can be requested from the following address:

Siemens AG

Digital Factory

Factory Automation

DF FA SE R&D

Breslauer Str. 5

DE-90766 Fürth

device.

DIN ISO 9001 certificate

The Siemens quality management system for all production processes (development,

production and sales) meets the requirements of DIN ISO 9001:2000.

This has been certified by DQS (the German society for the certification of quality

management systems).

Certificate registration no. DE-000656 QM08

Software license agreements

If the device is supplied with preinstalled software, you must observe the corresponding

license agreements.

UL approval

Underwriters Laboratories Inc. (UL) in accordance with

● UL508 (Industrial Control Equipment) and

● CSA C22.2 No.142 (Process Control Equipment)

IFP1900 INOX PRO

Compact Operating Instructions, 07/2019, A5E35751632-AC

25

Specifications

Field of application

Requirement for emissions

Requirement for interference immunity

Industrial area

EN 61000-6-4:2007 +A1:2011

EN 61000-6-2:2005

6.2 Guidelines and declarations

ATEX/IECEx approval

Special conditions of use

The SIMATIC Industrial Flat Panel with article number 6AV7484-6AB..-0AA0 including the

top side of the stand provides a degree of protection of at least IP66. The bottom side of the

stand shall be connected to a certified enclosure, providing a degree of protection of at least

IP54 according to IEC 60079-15 for gas and non-conductive dust and IP6X according to IEC

60079-31, for conductive dust, taking into account the environmental conditions under which

the equipment is used.

The equipment shall be installed in such a way that the risk of mechanical danger is low.

To avoid an electrostatic charge, wipe the enclosure surface with a damp cloth only.

When used in an area requiring the use of equipment with EPL Gc:

● The equipment shall only be used in an area of not more than pollution degree 2, as

defined in EN 60664-1.

● Provisions shall be made to prevent the rated voltage from being exceeded by transient

disturbances of more than 119 V.

Under the special conditions mentioned, the following approvals apply to the device:

● II 3 G Ex nA IIC T4 Gc and

II 3 D Ex tc IIIC T70 ºC Dc

ATEX certificate number: DEKRA 16ATEX0045X

Standards: EN 60079-0:2012 +A11:2013, EN 60079-15:2010, EN 6007931:2014

● Ex nA IIC T4 Gc and

Ex tc IIIC T70 ºC Dc

IECEx certificate number: DEK 16.0021X

Standards: IEC 60079-0:2011 (Ed.6), +Corr.1. 2012 +Corr.2. 2013, IEC 60079-15:2010

(Ed. 4), IEC 60079-31:2013 (Ed. 2)

6.2 Guidelines and declarations

Notes on CE marking

This product meets the requirements and safety objectives of the EMC directive 2014/30/EU

(EMC Directive), and is designed for operation in the following fields of application according

to this CE marking:

IFP1900 INOX PRO

26 Compact Operating Instructions, 07/2019, A5E35751632-AC

Specifications

6.3 Dimension drawings

6.3 Dimension drawings

6.3.1 IFP1900 INOX PRO

The figures below show the dimension drawings using a device with operator controls and

stand mounting as an example.

IFP1900 INOX PRO

Compact Operating Instructions, 07/2019, A5E35751632-AC

27

Specifications

Weight

Approx. 15 kg

Quality assurance

In accordance with ISO 9001

IFP1900 INOX PRO

Permitted voltage range

+19.2 V to +28.8 V

Rated current

2.0 A

Inrush current I2t

0.5 A2s

Power consumption 2

40 W

Maximum permitted transients

35 V (500 ms)

Minimum time between two transients

50 s

Internal protection

Electronic

1

2

The power loss generally corresponds to the specified value for power consumption.

6.4 Technical specifications

6.3.2 Mechanical interface of the device

6.4 Technical specifications

6.4.1 General technical specifications

DC power supply

Rated voltage 1

The generation of the supply voltage with the line-side power supply must be realized as safety

extra-low voltage with safe electrical isolation, isolated as SELV according to

IEC/UL/EN/DIN-EN 60950-1.

24 V DC

IFP1900 INOX PRO

28 Compact Operating Instructions, 07/2019, A5E35751632-AC

Specifications

Emission standard

EN 61000-6-4; CISPR 22:2010 Class A; FCC Class A

± 2 kV in accordance with IEC 61000-4-5; asymmetrical surge

length > 30 m

± 8 kV air discharge in accordance with IEC 61000-4-2

10 V, 9 kHz to 80 MHz according to IEC 61000-4-6

Immunity to magnetic fields

100 A/m, 50/60 Hz according to IEC 61000-4-8

Display, resolution

19" diagonal with backlighting, resolution 1366 x 768 pixels

Touch force with test pen; 2 mm diameter: 5 N

Half brightness life time, typical

Min. 50000 h at 50 °C, 50% brightness

ISO 9241-307

USB

2 × USB 2.0, high current

10, 100, 1000 Mbps

Keyboard, mouse

Connection via USB interface

6.4 Technical specifications

Electromagnetic compatibility

Graphics

Immunity with regard to conducted

interference on the supply lines

Noise immunity on signal lines ± 2 kV in accordance with IEC 61000-4-4; burst; length > 3 m

Immunity to electrostatic discharge ± 6 kV contact discharge in accordance with IEC 61000-4-2

Immunity to RF interference 10 V/m, 80 to 2000 MHz

Touch controller Resistive Semtech controller ELO CTR-2216SU-AT-CHP-00

Backlighting (MTBF)

Pixel error class in accordance with

± 2 kV in accordance with IEC 61000-4-4; burst

± 1 kV in accordance with IEC 61000-4-5; symmetrical surge

± 2 kV in accordance with IEC 61000-4-5; symmetrical surge,

80% AM according to IEC 61000-4-3

3 V/m, 2 to 2.7 GHz

Touch screen analog resistive

LED

I

Interfaces

LAN interface X1 P1, RJ45 Intel distance connection via Gigabit Ethernet;

IFP1900 INOX PRO

Compact Operating Instructions, 07/2019, A5E35751632-AC

29

Specifications

Temperature, tested in accordance with IEC 60068-2-1, IEC 60068-2-2

Relative humidity, tested in accordance with IEC 60068-2-78, IEC 60068-2-30

Air pressure, in accordance with IEC 60068-2-13

Vibration, tested according to IEC 60068-2-6

58 to 500 Hz: 10 m/s2, 10 cycles

8.5 to 500 Hz: 10 m/s2

Shock resistance, tested in accordance with IEC 60068-2-27, IEC 60068-2-29

Degree of protection

Explanation

6.4 Technical specifications

6.4.2 Environmental conditions

Climatic ambient conditions

• Temperature gradient in operation

• Ambient temperature in operation

• Temperature during storage/transport

• Storage/transport, gradient

• Operation

• Storage/transport

• Operation

• Storage/transport

Mechanical ambient conditions

• Operation

• Storage/transport

Max. 10 °C/h, no condensation

0 to 45 °C

-20 to +60 °C

Max. 20 °C/h, no condensation

5 to 85% at 30 °C, no condensation

5 to 95% at 25/55 °C, no condensation

1140 to 795 hPa, corresponds to an elevation of -1000 to 2000 m

1140 to 660 hPa, corresponds to an elevation of -1000 to 3500 m

10 to 58 Hz: 0.15 mm

5 to 8.5 Hz: 7 mm

• Operation

• Storage/transport

150 m/s2, 11 ms, 100 shocks per axis

250 m/s2, 6 ms, 1000 shocks per axis

Protection against foreign objects and water

The device meets the requirements according to IEC 60529 and UL50.

All-round When mounted:

• IP66 according to IEC 60529

• Enclosure Type 4X (indoor use only) according to UL50

The degrees of protection can only be guaranteed if the seals are completely flush at the

mechanical interfaces and the associated covers are closed.

The IP66 degree of protection is not covered by the UL approval and was not tested as part

of the UL approval.

Degree of pollution / overvoltage category according to IEC 61131

● Degree of pollution 2

● Overvoltage category II

IFP1900 INOX PRO

30 Compact Operating Instructions, 07/2019, A5E35751632-AC

Specifications

6.5 Description of the interfaces

6.5 Description of the interfaces

6.5.1 Pin assignment of the internal terminal strip

This section applies to devices with operator controls.

The figure below shows the pin assignment of the internal 20-pin terminal strip.

● Pins 1 to 12 are wired with the front operator controls.

● Pins 13 to 20 are not assigned.

IFP1900 INOX PRO

Compact Operating Instructions, 07/2019, A5E35751632-AC

31

A

A.1 Service and support

You can find additional information and support for the products described on the Internet at

the following addresses:

● Technical support (https://support.industry.siemens.com)

● Support request form (http://www.siemens.com/automation/support-request)

● After Sales Information System SIMATIC IPC/PG (http://www.siemens.com/asis)

● SIMATIC Documentation Collection (http://www.siemens.com/simatic-tech-doku-portal)

● Your local representative

(http://www.automation.siemens.com/mcms/aspa-db/en/Pages/default.aspx)

● Training center (http://sitrain.automation.siemens.com/sitrainworld/?AppLang=en)

● Industry Mall (https://mall.industry.siemens.com)

When contacting your local representative or Technical Support, please have the following

information at hand:

● MLFB of the device

● BIOS version for industrial PC or image version of the device

● Other installed hardware

● Other installed software

Tools & downloads

Please check regularly if updates and hotfixes are available for download to your device. The

download area is available on the Internet at the following link:

After Sales Information System SIMATIC IPC/PG (http://www.siemens.com/asis)

IFP1900 INOX PRO

32 Compact Operating Instructions, 07/2019, A5E35751632-AC

Loading...

Loading...