Page 1

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

SIMATIC NET

Industrial Ethernet / PROFIBUS

IE/PB LINK PN IO

Operating Instructions

11/2017

C79000

Preface

Application and properties

1

LEDs, connectors, buttons

2

Installation, connecting up,

commissioning

3

Configuration and operation

4

Diagnostics and

maintenance

5

Technical data

6

Approvals

7

Accessories

A

Documentation references

B

-G8976-C393-02

Page 2

Siemens AG

Division Process Indust ries and Drives

Postf ach 48 48

90026 NÜRNBERG

GERMANY

C79000-G8976-C393-02

Ⓟ

Copyright © Siemens AG 2016 - 2017.

All rights res erved

Legal information

Warning notice system

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

Qualified Personnel

personnel qualified

Proper use of Siemens products

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

Trademarks

Disclaimer of Liability

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

The product/system described in this documentation may be operated only by

task in accordance with the relevant documentation, in particular its warning notices and safety instructions.

Qualified personnel are those who, based on their training and experience, are capable of identifying risks and

avoiding potential hazards when working with these products/systems.

Note the following:

documentation. If products and components from other manufacturers are used, these must be recommended

or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

for the specific

11/2017 Subject to change

Page 3

Preface

Validity of this manual

IE/PB LINK PN IO without bus adapter

IE/PB LINK PN IO with bus adapter

This document contains information on the following product:

IE/PB LINK PN IO

Article Article number 6GK1 411-5AB10

Hardware product version 1

Firmware version V3.0

Link between Industrial Ethernet and PROFIBUS with PROFINET IO functionality

On the front of the housing, you will see the firmware version and the hardware product

version printed as a placeholder "X". If the printed text is, for example, "

placeholder for hardware product version 1.

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

", X is the

3

Page 4

Preface

Product names and abbreviations

Purpose of the manual

Cross references

New in this release

Replaced edition

Current manual release on the Internet

● LINK

In this document, the name "LINK" is used in place of the full product name

"IE/PB LINK PN IO".

● STEP 7

The short form of the configuration tool is used for the following products:

– STEP 7 V5.x

– STEP 7 Professional

The short form "STEP 7" is used only when the product is self explanatory in the context.

● PST

Primary Setup Tool

As an alternative to STEP 7, you can use the PST to configure the address and

PROFINET parameters.

This manual describes the properties of this module and supports you when installing and

commissioning it.

The required configuration steps are described as an overview and there are explanations of

the relationship between firmware functions and configuration.

You will also find information about the diagnostics options of the device.

In this manual there are often cross references to other sections.

To be able to return to the initial page after jumping to a cross reference, some PDF readers

support the command <Alt>+<Left arrow>.

● Editorial revision

● New LED description

● Changes in the operating behavior of the C-PLUG

Edition 11/2016

You will also find the current version of this manual on the following Internet page of

Siemens Industry Online Support:

IE/PB LINK PN IO

4 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 5

Preface

Requirements for use of the module

Innovations and compatibility with the previous version (6GK1 411-5AB00)

Note

Make sure that you read the information relating to enhanced functions and restrictions in the

section

Required experience

Sources of information and other documentation

License conditions

Note

Open source software

The product contains open source software. Read the license conditions for open source

software carefully before using the product.

Security information

Link: (https://support.industry.siemens.com/cs/ww/en/ps/15406/man)

You will find the requirements for using the module in the section Requirements for use

(Page 19).

You will find the functions of the module in the section Communication services and other

properties (Page 15).

Replacing a module (Page 73).

To install, commission and operate the LINK, you require experience in the following areas:

● Automation engineering

● STEP 7 V5.x / STEP 7 Professional

You will find an overview of further reading and references in the Appendix Documentation

references (Page 89).

You will find license conditions in the following document on the supplied data medium:

● OSS_IEPB-LINK_86.pdf

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines and networks.

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

5

Page 6

Preface

Firmware

SIMATIC NET glossary

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines

and networks. Systems, machines and components should only be connected to the

enterprise network or the internet if and to the extent necessary and with appropriate security

measures (e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit

Link: (http://www.siemens.com/industrialsecurity)

Siemens’ products and solutions undergo continuous development to make them more

secure. Siemens strongly recommends to apply product updates as soon as available and to

always use the latest product versions. Use of product versions that are no longer supported,

and failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

Link: (http://www.siemens.com/industrialsecurity).

The firmware is signed and encrypted. This ensures that only firmware created by Siemens

can be downloaded to the device.

Explanations of many of the specialist terms used in this documentation can be found in the

SIMATIC NET glossary.

You will find the SIMATIC NET glossary here:

● SIMATIC NET Manual Collection or product DVD

The DVD ships with certain SIMATIC NET products.

● On the Internet under the following address:

Link: (https://support.industry.siemens.com/cs/ww/en/view/50305045)

IE/PB LINK PN IO

6 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 7

Table of contents

Preface ................................................................................................................................... 3

1 Application and properties .........................................................................................................11

2 LEDs, connectors, buttons ........................................................................................................21

3 Installation, connecting up, commissioning ..................................................................................31

4 Configuration and operation ......................................................................................................45

1.1 Application, modes and operating modes........................................................................... 11

1.2 Communication services and other properties.................................................................... 15

1.3 Performance data .............................................................................................................. 17

1.3.1 Characteristics of S7 communication ................................................................................. 17

1.3.2 Characteristics of data record routing................................................................................. 17

1.3.3 Total number of connections .............................................................................................. 18

1.3.4 Characteristic data for PROFINET IO ................................................................................ 18

1.3.5 Characteristic data of the C-PLUG ..................................................................................... 18

1.3.6 Update time for parallel operation of PROFINET IO with other services ............................. 19

1.4 Requirements for use ........................................................................................................ 19

2.1 LED displays of the LINK ................................................................................................... 21

2.2 LED displays of the bus adapter ........................................................................................ 25

2.3 Interfaces, bus adapters, buttons ....................................................................................... 26

2.4 X80: External power supply ............................................................................................... 27

2.5 Maintenance mode ............................................................................................................ 28

3.1 Important notes on using the device .................................................................................. 31

3.1.1 Notices on use in hazardous areas .................................................................................... 31

3.1.2 Notes on use in hazardous areas according to ATEX / IECEx ............................................ 33

3.1.3 Notices regarding use in hazardous areas according to UL HazLoc ................................... 33

3.1.4 Notes on use in hazardous areas according to FM ............................................................. 34

3.2 Overview: Installation, configuration, commissioning .......................................................... 35

3.3 Installing and connecting up the LINK ................................................................................ 36

3.4 PG/PC connector .............................................................................................................. 37

3.5 C-PLUG ............................................................................................................................ 38

3.6 Commissioning and startup of the LINK ............................................................................. 42

3.7 Changing from RUN to STOP ............................................................................................ 44

4.1 Security recommendations ................................................................................................ 45

4.2 IP configuration ................................................................................................................. 47

4.2.1 Configuring the IP address ................................................................................................ 47

4.2.2 Restart after detection of a duplicate IP address in the network.......................................... 48

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

7

Page 8

Table of contents

5 Diagnostics and maintenance ................................................................................................... 69

6 Technical data........................................................................................................................ 77

4.2.3 Remove retentive storage of the IP address if there are duplicate addresses ......................48

4.3 Assign the address and network parameters with the Primary Setup Tool (PST) .................48

4.4 Configuration with STEP 7 V5.5 .........................................................................................51

4.4.1 Configuring the LINK ..........................................................................................................51

4.4.2 Use as PROFINET IO device and as gateway ....................................................................52

4.4.3 Commissioning the LINK as a PROFINET IO device ..........................................................53

4.4.4 Use only as a gateway in standard operation ......................................................................53

4.4.4.1 Creating a station and networking the LINK ........................................................................53

4.4.4.2 Setting object properties on the LINK..................................................................................54

4.4.4.3 Configuring the Ethernet interface ......................................................................................55

4.4.4.4 Configuring the PROFIBUS interface ..................................................................................55

4.4.4.5 Commissioning the LINK as a gateway ...............................................................................55

4.4.5 Configuring bus adapters....................................................................................................56

4.5 Configuration with STEP 7 Basic / Professional ..................................................................57

4.5.1 Configuring the LINK ..........................................................................................................57

4.5.2 Use as a PROFINET IO device ..........................................................................................57

4.5.3 Use only as a gateway in standard operation ......................................................................59

4.5.4 Configuring bus adapters....................................................................................................59

4.5.5 Commissioning the LINK as a PROFINET IO device ..........................................................60

4.5.6 Commissioning the LINK in standard mode ........................................................................61

4.6 Identification and maintenance data ...................................................................................61

4.6.1 Reading out and entering I&M data ....................................................................................61

4.6.2 Data record structure for I&M data ......................................................................................64

4.7 Time-of-day synchronization ...............................................................................................65

4.8 Overview: Access to the LINK as proxy ..............................................................................67

5.1 Diagnostics options ............................................................................................................69

5.2 Clearing and for resetting to factory settings .......................................................................70

5.3 Loading firmware ................................................................................................................71

5.4 Upload tp PG/Upload from device.......................................................................................73

5.5 Replacing a module ............................................................................................................73

5.5.1 Resetting address data.......................................................................................................73

5.5.2 Replacing older modules ....................................................................................................73

5.5.3 Replacing a module without PG/PC ....................................................................................74

5.6 SNMP ................................................................................................................................75

6.1 Technical specifications of the LINK ...................................................................................77

6.2 Pinout of the Ethernet interface ..........................................................................................79

6.3 Pin assignment of the PROFIBUS interface ........................................................................79

IE/PB LINK PN IO

8 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 9

Table of contents

7 Approvals...............................................................................................................................81

A Accessories ............................................................................................................................85

B Documentation references ........................................................................................................89

Index .....................................................................................................................................91

A.1 BusAdapter ....................................................................................................................... 85

A.2 C-PLUGs........................................................................................................................... 86

B.1 /1/...................................................................................................................................... 89

B.2 /2/...................................................................................................................................... 90

B.3 /3/...................................................................................................................................... 90

B.4 /4/...................................................................................................................................... 90

B.5 /5/...................................................................................................................................... 90

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

9

Page 10

Table of contents

IE/PB LINK PN IO

10 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 11

1

1.1

Application, modes and operating modes

Basic function

Modes

PROFINET IO proxy

Standard mode (gateway)

Note

Changing the mode with Clear/Reset

If you want to change the configured mode of the LINK, you need to clear/reset the LINK.

Note that this deletes the configuration data, see also the

to factory settings

The LINK is a gateway that connects the two network types Industrial Ethernet and

PROFIBUS.

The LINK allows access to all PROFIBUS nodes connected to the underlying PROFIBUS

network.

The LINK has the design of the SIMATIC ET 200SP device family.

You can use the LINK in the following modes:

●

●

You specify the mode in the configuration. For the "PROFINET IO proxy" mode, you need to

configure the LINK as a PROFINET IO device. This procedure is described in the section

Configuration and operation (Page 45).

section Clearing and for resetting

(Page 70).

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

11

Page 12

Application and properties

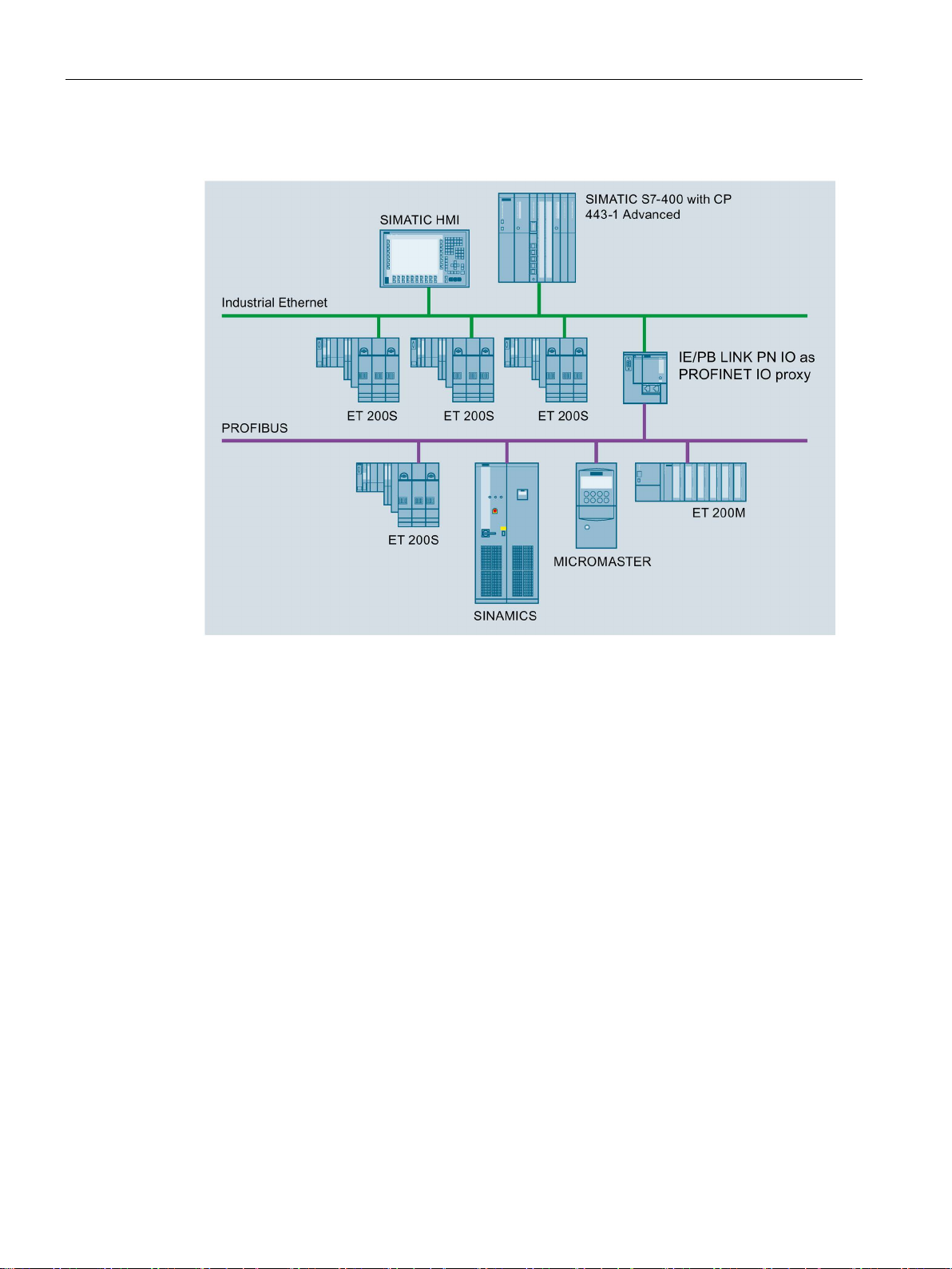

Gateway as PROFINET IO proxy

1.1 Application, modes and operating modes

Figure 1-1 IE/PB LINK PN IO as PROFINET IO proxy

The LINK provides the connection between a PROFINET IO controller on Industrial Ethernet

and PROFIBUS slaves visible as PROFINET IO devices via the LINK.

From the perspective of the PROFINET IO controller there is no difference between

accessing PROFINET IO devices on Industrial Ethernet and DP slaves on PROFIBUS.

The LINK adopts the role of a proxy for the DP slaves connected to PROFIBUS.

As a PROFINET IO proxy, the LINK supports among other things the following functions:

● PG/OP communication, e.g. for loading programs and configuration data.

● Data record routing, among other things, for configuring field devices, for example with

SIMATIC PDM.

● Gateway to a DP master system

● S7 routing

IE/PB LINK PN IO

12 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 13

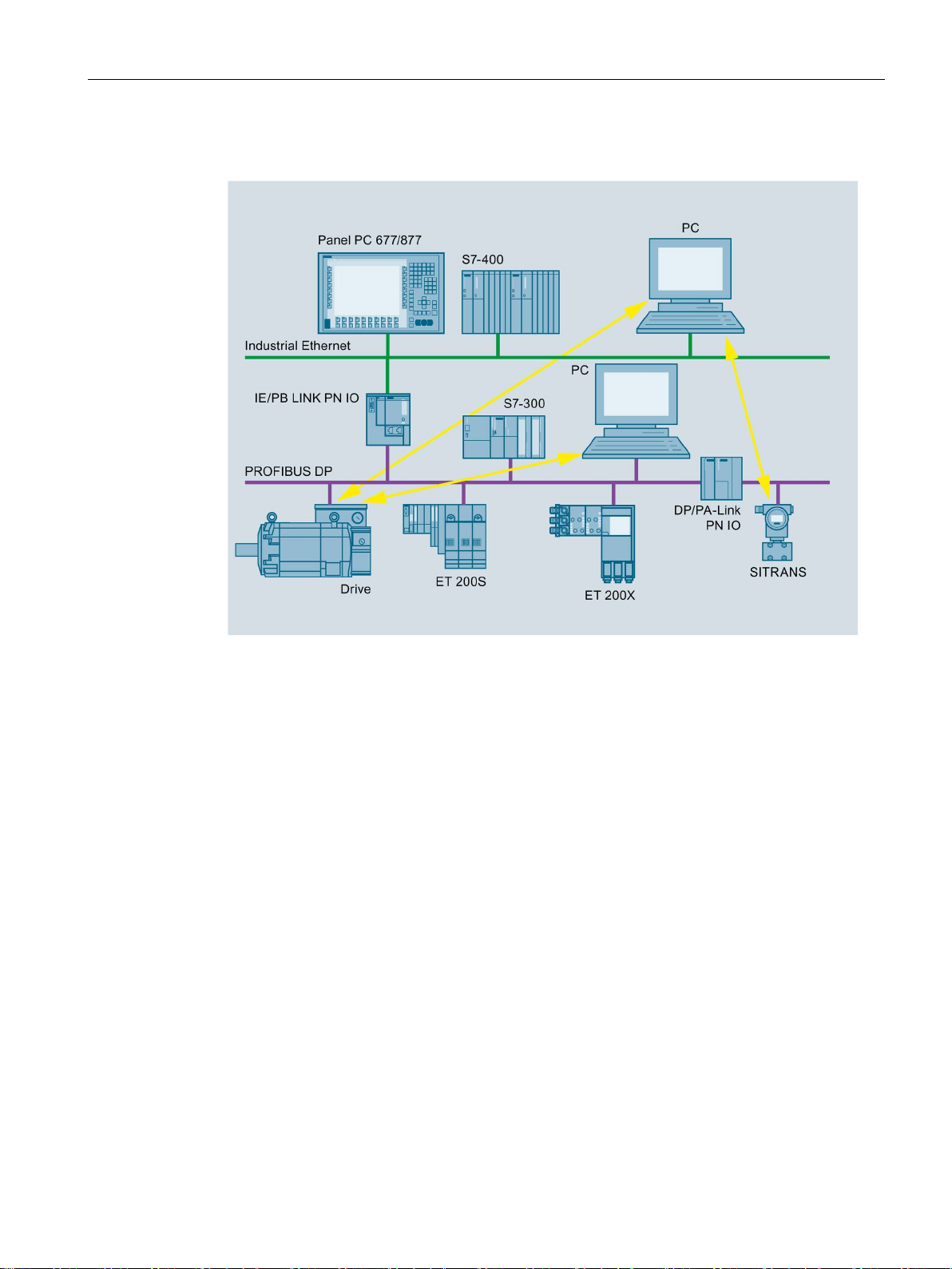

Application and properties

Gateway in standard operation

1.1 Application, modes and operating modes

Figure 1-2 IE/PB LINK PN IO as gateway in standard operation

In standard operation, the LINK supports the following functions:

● PG/OP communication, e.g. for loading programs and configuration data.

● Data record routing, among other things, for configuring field devices, for example with

SIMATIC PDM.

● Gateway to a DP master system

● S7 routing

You will find further details about the functions in the below.

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

13

Page 14

Application and properties

Operating modes

Normal mode

Maintenance mode

Maintenance mode

Maintenance mode after startup

Maintenance mode by pressing the button

1.1 Application, modes and operating modes

The LINK has two operating modes:

●

This is the mode that the LINK adopts during normal operation both in PROFINET IO

proxy and in standard mode.

●

Functions that can only be executed in maintenance mode:

– Firmware download

– Restart

– Resetting to factory settings

Access to the three functions of the maintenance mode depends on how the LINK is set to

the maintenance mode.

●

After startup the LINK is in maintenance mode for 10 seconds and then changes

automatically to normal mode. In this status only the following function can be executed:

– Loading firmware

●

After pressing the button the LINK is in maintenance mode for 10 minutes. The following

functions are possible:

– Restart

– Resetting to factory settings

To change from normal mode to maintenance mode using the button, refer to the section

Maintenance mode (Page 28).

IE/PB LINK PN IO

14 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 15

Application and properties

1.2

Communication services and other properties

Communication services

Industrial Ethernet

PROFINET IO

IP configuration - IPv4

Media redundancy (MRP)

SNMP

LLDP

PROFIBUS

Supported slaves:

Direct data exchange

PROFISAFE

1.2 Communication services and other properties

●

The LINK can be configured as an IO device.

●

The essential features of IP configuration for the LINK:

– The LINK supports IP addresses according to IPv4.

– Address assignment:

The IP address, the subnet mask and the address of a gateway can be set manually

in the configuration.

As an alternative, the IP address can be obtained from a DHCP server or by other

means outside the configuration.

●

Within an Ethernet network with a ring topology, the LINK supports the media redundancy

protocol MRP. You can assign the role of "Client" to the LINK.

●

As an SNMP agent, the LINK supports data queries using SNMP (Simple Network

Management Protocol).

For more detailed information, refer to section SNMP (Page 75).

●

The LINK supports the Link Layer Discovery Protocol.

●

– Slaves according to DP V0

– Slaves according to DP V1

●

The LINK supports direct data exchange in its own DP Master system and in multimaster

systems.

●

The LINK supports applications with PROFISAFE.

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

15

Page 16

Application and properties

Gateway to a DP master system

Data record gateway

Other services and properties

MPI networking (only in standard operation)

PG/OP communication

S7 routing

Time synchronization

Firmware update

C-PLUG as exchangeable storage medium for configuration data

1.2 Communication services and other properties

●

The LINK serves as a gateway between Ethernet and PROFIBUS. The LINK is operated

as an active node on a PROFIBUS network.

●

Field device parameter assignment (data record routing)

You can use the LINK as a router for data records intended for PROFIBUS nodes.

Devices that are not directly attached to PROFIBUS and that therefore do not have direct

access to the PROFIBUS nodes can transfer data records to the field devices via the

LINK, e.g. via SIMATIC PDM (Process Device Manager).

●

The LINK can be selected as a gateway in standard operation between an MPI subnet

and an Ethernet subnet.

To do this, you need to network the PROFIBUS interface of the LINK with the MPI

subnet.

●

– Loading programs and configuration data

– Running test and diagnostics functions

– Operator control and monitoring (HMI systems) of a system.

●

Cross-subnet S7 connections, for example for HMI operation.

The LINK forwards communication via S7 connections. This service is used, for example,

by HMI applications (PC stations).

●

The LINK supports time synchronization using the following methods:

– SIMATIC mode

– NTP

The LINK uses the synchronized time-of-day, for example for forwarding and time

stamping diagnostics buffer entries.

●

The LINK supports firmware updates using the firmware loader. A firmware file can be

loaded from a PC/PG via PROFIBUS, see section Loading firmware (Page 71).

●

The LINK supports storage of configuration data on the optional exchangeable storage

medium C-PLUG. This simplifies replacement of a defective module by simply inserting

the C-PLUG in the new module.

IE/PB LINK PN IO

16 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 17

Application and properties

Independent of media

Redundant power supply

1.3

Performance data

1.3.1

Characteristics of S7 communication

Characteristic

Explanation / values

connections are used.

1.3.2

Characteristics of data record routing

Field device parameter assignment (data record routing)

Characteristic

Explanation / values

PROFIBUS nodes

PROFIBUS nodes via a connection

1.3 Performance data

●

The LINK supports the connection of bus adapter modules of the ET 200SP device

family, for example for connecting to optical networks.

●

The LINK can be connected to a redundant power supply.

Table 1- 1 Number of connections for S7 communication

Maximum number of S7 connections / HMI connections

32

For the S7 communication both configured and unconfigured S7

You can use the LINK as a router for data records intended for field devices (PROFIBUS

nodes):

Devices that are not connected directly to PROFIBUS and therefore have no direct access to

the field devices can send data records to the field devices for example via the LINK using

the SIMATIC PDM (Process Device Manager).

The function is enabled as default.

Maximum number of connections to the

Maximum data record size for parameters sent to

32

244 bytes

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

17

Page 18

Application and properties

1.3.3

Total number of connections

Characteristic

Explanation / values

Note

Note that for every S7 connection used a TCP/IP connection is occupied on industrial

Ethernet.

1.3.4

Characteristic data for PROFINET IO

Characteristic

Explanation / values

(PROFINET IO devices)

Maximum number of DP inputs

2048 bytes

1.3.5

Characteristic data of the C-PLUG

Usable C-PLUGs

C-PLUG 32

C-PLUG 256

1.3 Performance data

Maximum number of:

• S7 connections

• HMI connections

• Data record routing connections

In total 48 in any combination

Table 1- 2 Number of connections for PROFINET IO

Maximum number of DP slaves assigned to the

LINK (DP Master).

64

Maximum number of DP outputs 2048 bytes

The LINK can be operated with the following C-PLUGs:

●

Memory:

– Total capacity: 32 MB

– Free capacity available: 30 MB

●

Memory:

– Total capacity: 256 MB

– Free capacity available: 126 MB

IE/PB LINK PN IO

18 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 19

Application and properties

1.3.6

Update time for parallel operation of PROFINET IO with other services

Configuring a higher update time

Note

Do not set the shortest possible update time

In parallel operation do not set the shortest possible update time but select the next higher

value proposed by STEP 7.

1.4

Requirements for use

Configuration and downloading

1.4 Requirements for use

Recommendation: Avoid writing data cyclically. The flash area allows a limited number of

write cycles.

You will find details in the section C-PLUGs (Page 86).

Dependent on the number of PROFINET IO devices operated in the same Ethernet subnet:

STEP 7 automatically sets the lowest possible value for the update time for the IO devices.

When necessary configure the update time for the IO devices via the properties of the

PROFINET interface in STEP 7:

● STEP 7 V5.x

"IO Cycle"

● STEP 7 Basic / Professional

"Advanced options" > "Real time settings"

In the following cases, configure a higher update time:

● Alongside the cyclic communication via PROFINET IO, you use non-cyclic

communications services, e.g. S7 connections, data record routing, HMI connections.

● Diagnostics or alarm frames occur often in the DP Master system.

You can configure the LINK for all modes via Industrial Ethernet. If you use the device as a

gateway in standard operation, it is also possible to download the configuration data via

PROFIBUS.

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

19

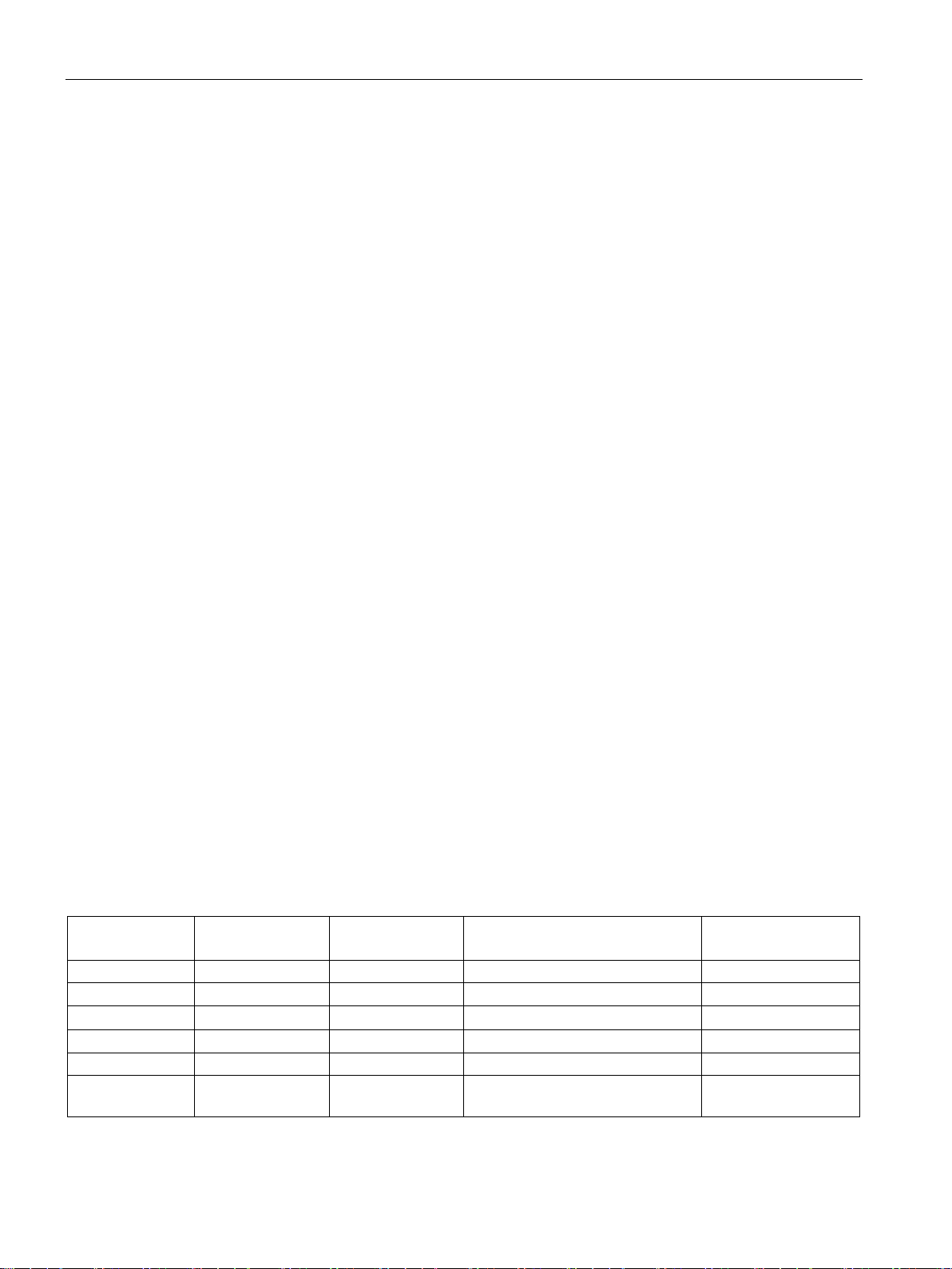

Page 20

Application and properties

STEP 7 versions

STEP 7 versions

Function

The functionality of firmware version V1.0 can be used.

Downloading the support package / HSP from the Internet

Installation of Hardware Support Packages

Primary Setup Tool (PST)

1.4 Requirements for use

Below you will find the STEP 7 products required to configure the LINK. If both STEP 7 V5.x

as well as STEP 7 Basic / Professional are named, one of the two products can be used as

an alternative.

STEP 7 V5.3 SP1 LINK with article number 6GK1 411-5AB00

• STEP 7 V5.3 + SP2 + Hotfix 1 + HSP 1007

• STEP 7 Basic / Professional V11

• STEP 7 V5.5 + SP4 + Hotfix 11 + HSP 1101

• STEP 7 Basic / Professional V14 + Update

1 + Support package 0192

LINK with article number 6GK1 411-5AB00

The functionality of firmware version V2.x can be used.

LINK with article number 6GK1 411-5AB10

The functionality of firmware version V3.0 can be used.

You will find the HSP or support package on the following Internet pages of Siemens

Industry Support.

● STEP 7 V5.x

Link: (https://support.industry.siemens.com/cs/ww/en/view/23183356)

● STEP 7 Basic / Professional

Link: (https://support.industry.siemens.com/cs/ww/en/ps/14667/dl)

● STEP 7 V5.x

Install the HSP in STEP 7 / HW Config with the "Options" > "Install Hardware Updates"

menu command.

You will find information in the online help: Keyword "HSP" or "Hardware update").

After installing an HSP, you need to close and restart STEP 7.

● STEP 7 Basic / Professional

Install the support package in STEP 7 from the file system of the engineering station

using the menu command "Options" > "Support packages".

The information system of STEP 7 will provide you with information: Keyword "Support

packages".

Version V4.2.1 is required for configuration with the PST.

You can download the current version from the pages of Siemens Industry Support:

Link: (https://support.industry.siemens.com/cs/ww/en/view/19440762)

IE/PB LINK PN IO

20 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 21

2

2.1

LED displays of the LINK

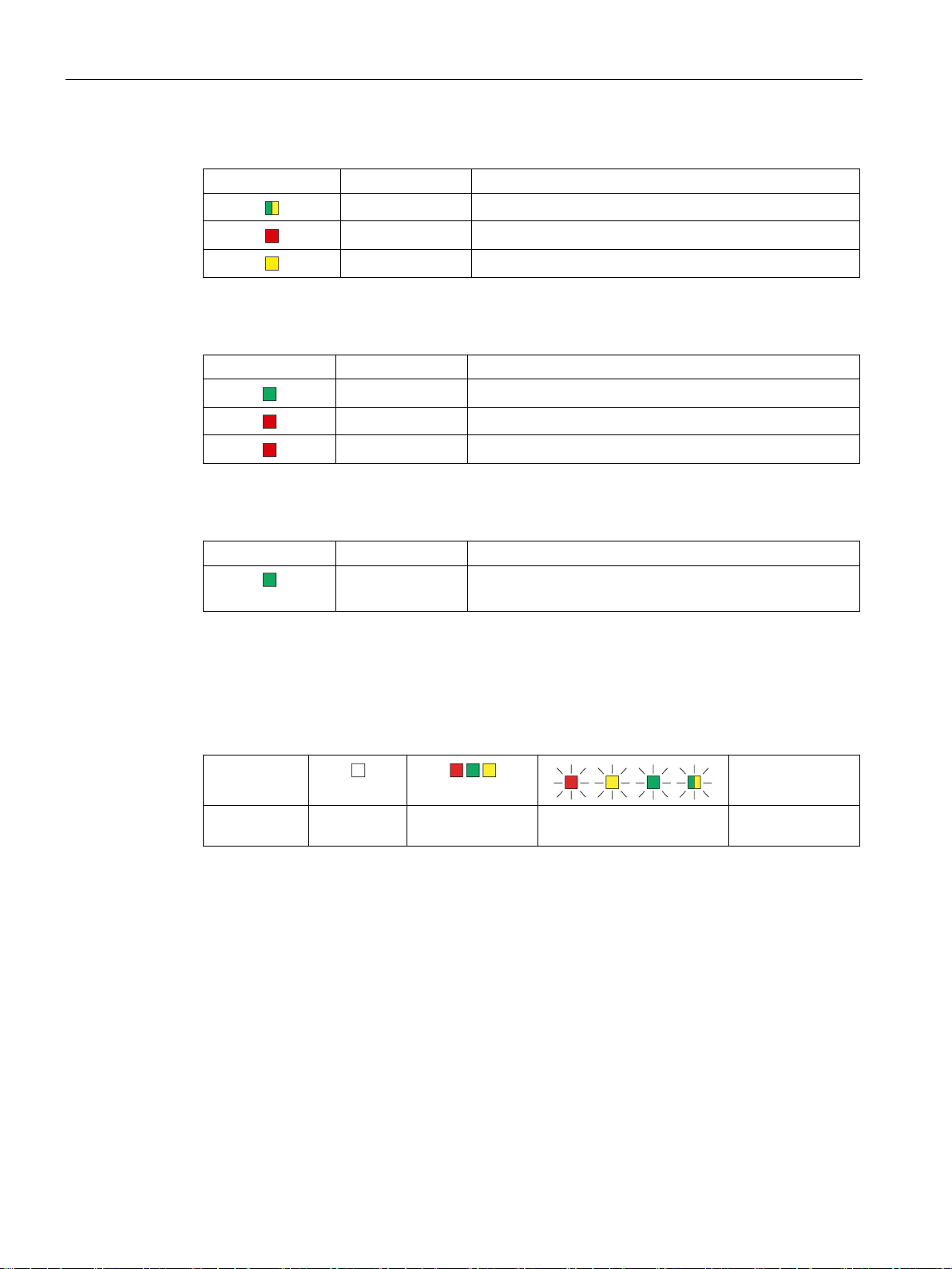

LEDs of the module

No.

LED

Meaning

①

②

(LK1 / LK2)

Figure 2-1 LEDs of the IE/PB LINK PN IO

The module has the following LED groups for displaying the status:

Top LED strip The LEDs show the basic statuses, see table below,

Lower LED strip

Connection status

③

LEDs

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

Status of the connection to Ethernet / PROFINET

The LEDs of the Ethernet ports are lit only when no bus adapter is plugged in.

21

Page 22

LEDs, connectors, buttons

LEDs / colors

Name

Meaning

LEDs / colors

Name

Meaning

LED / color

Name

Meaning

(When using a TS a us adapter "LK1 / LK2" are disabled.)

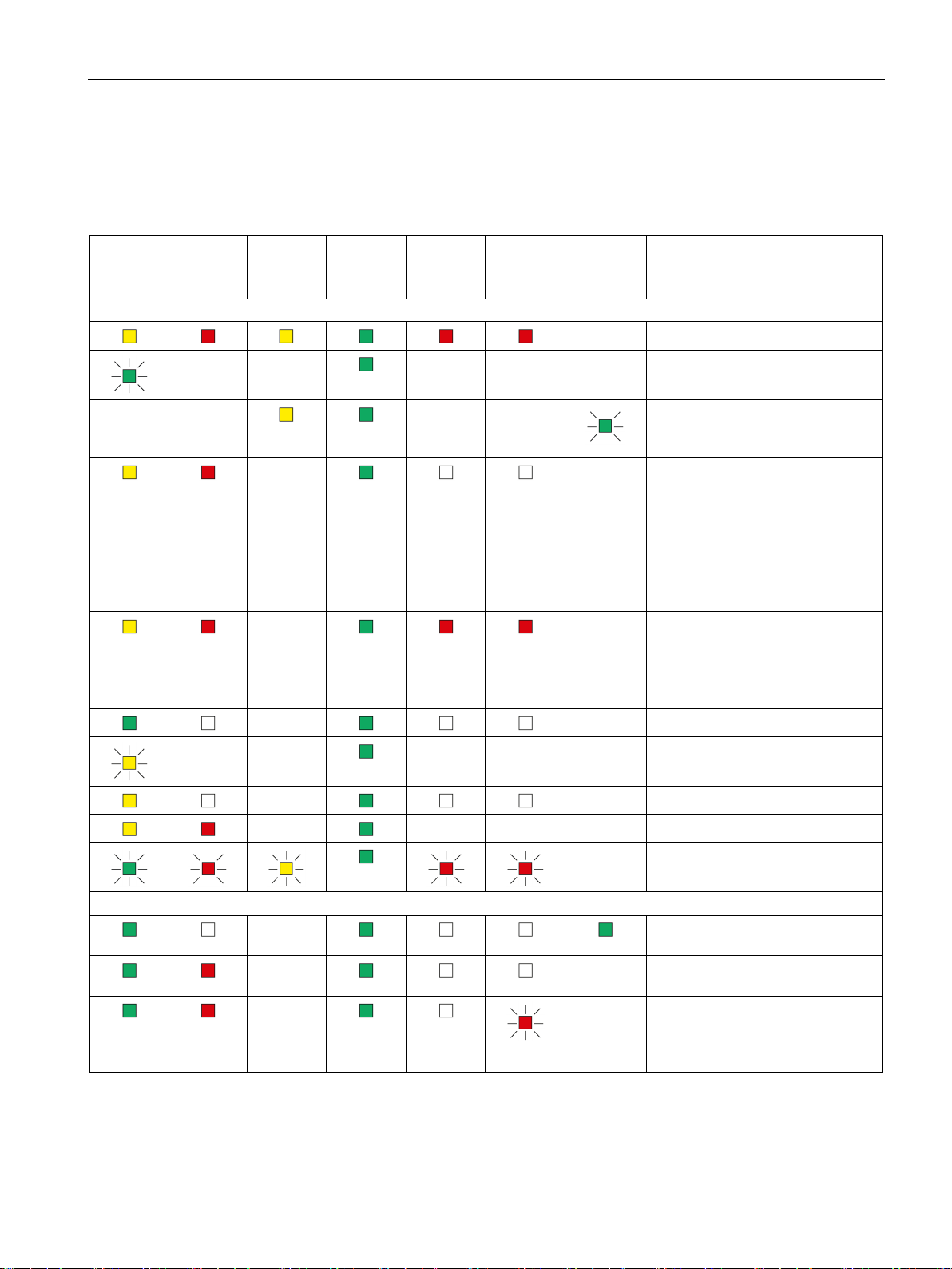

Display of the operating and communications statuses

Symbol

LED status

relevant

2.1 LED displays of the LINK

Table 2- 1 Top LED strip ① - basic statuses

R/S Operating status of the LINK (RUN/STOP)

ER Error

MT Maintenance

Table 2- 2 LED strip ② - basic statuses

PWR Power supply

BF PN PROFINET bus error

BF PB PROFIBUS bus error

Table 2- 3 LEDs of the Ethernet ports ③

LK1 / LK2 Status of the connection to Ethernet/PROFINET

The LED symbols in the following tables have the following significance:

Table 2- 4 Meaning of the LED symbols

OFF ON (steady light) Flashing LED status not

-

IE/PB LINK PN IO

22 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 23

LEDs, connectors, buttons

R/S

green)

ER

MT

PWR

BF PN

BF PB

LK1/LK2 *

Meaning

Startup, operating statuses, errors

ing startup)

-

-

-

Operating statuses, error (PROFIBUS and Ethernet)

tion at port, no data traffic

module (DP slave)

2.1 LED displays of the LINK

The LEDs indicate the operating and communications status of the module according to the

following scheme:

Table 2- 5 Display schemes for detailed module statuses

(yellow /

- -

(red)

- -

(yellow)

-

-

(green)

(red)

- - - Starting up (STOP → RUN)

- -

(red)

(green)

- Turn on (lamp test)

Finding modules on Ethernet

(LK1/LK2 flashes slowly, only dur-

-

-

- Running (RUN) without error

• Distribution of the PROFINET

configuration data during

startup

• Bus adapter configured but not

plugged in.

• Bus adapter plugged in but not

configured.

• Reset to factory settings

• Status following a memory

reset

• Device new and started up

- -

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

-

-

-

- - - Stopping (RUN → STOP)

- Stopped (STOP)

- - - Stopped (STOP) with error

- Module fault / system error

- Running (RUN), problem with a

- Running (RUN), module missing

Running (RUN), Ethernet connec-

on PROFIBUS or is incorrectly

configured (does not apply to

PROFINET IO).

23

Page 24

LEDs, connectors, buttons

R/S

green)

ER

MT

PWR

BF PN

BF PB

LK1/LK2 *

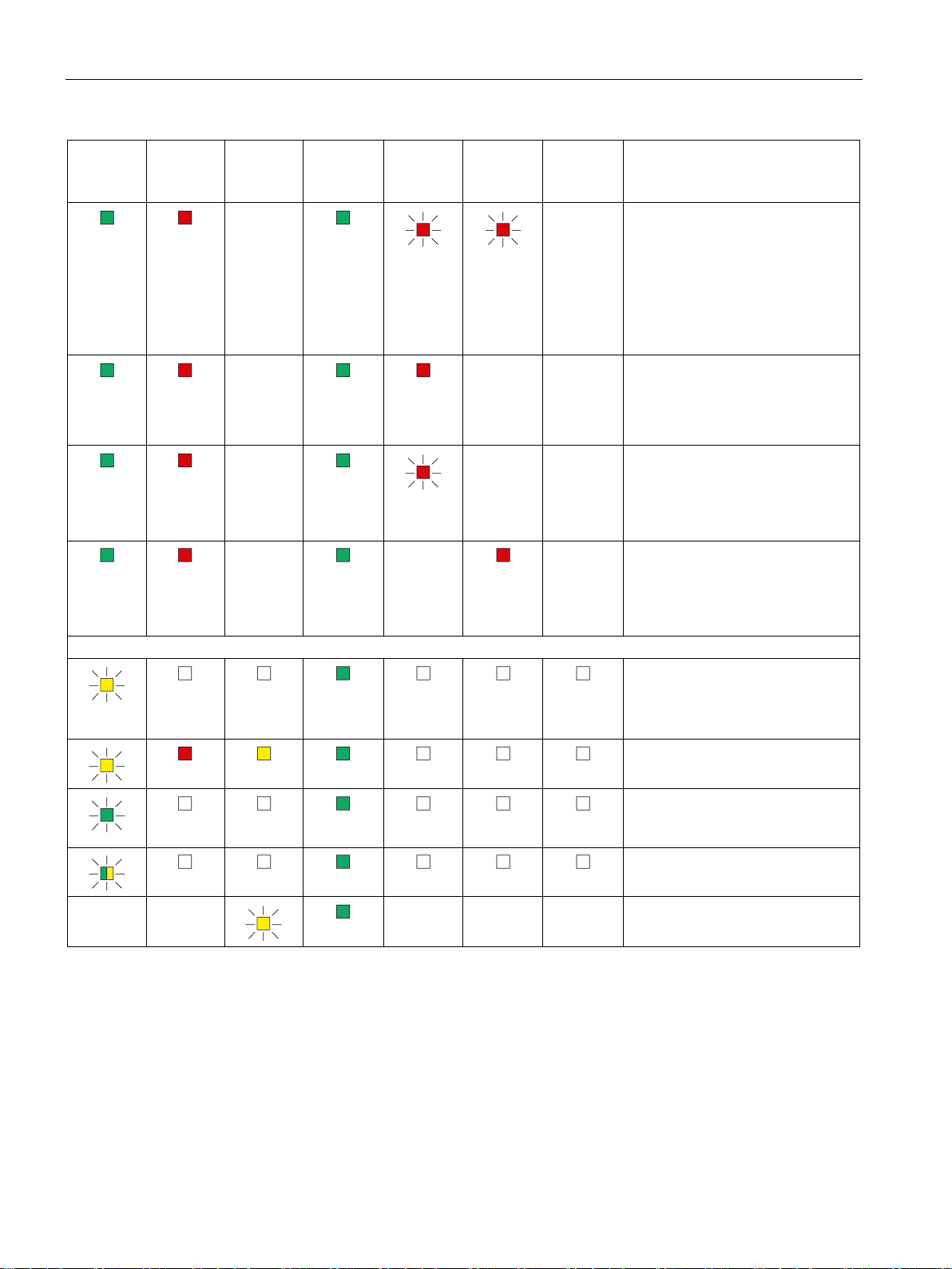

Meaning

Maintenance mode Firmware download , Reset

firmware (Page 71).

after the restart.

2.1 LED displays of the LINK

(yellow /

(red)

(yellow)

-

-

-

-

(green)

(red)

-

(red)

- - Running (RUN) with error.

- - Running (RUN)

(green)

- Running (RUN) with error:

• Error on PROFIBUS that also

affects PROFINET IO (e.g. IO

device).

• Error on PROFINET IO that

also affects PROFIBUS (e.g.

proxy not put into operation).

• Error on PROFINET IO No

logical or physical connection

to the PROFINET IO controller.

• No module on PROFIBUS.

• At least one DP slave is disa-

bled (e.g. via SFC 12).

- Running (RUN)

• Problems on PROFIBUS

• No PROFIBUS configuration to

match system

- -

- - - Maintenance mode (after pressing

Maintenance mode (after startup)

Ready to load a firmware file via

PROFIBUS. See section Loading

Error loading firmware

Status after failed firmware update

When downloading firmware via

PROFIBUS: Firmware is loaded

Loaded firmware not activated.

the button)

IE/PB LINK PN IO

24 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 25

LEDs, connectors, buttons

R/S

green)

ER

MT

PWR

BF PN

BF PB

LK1/LK2 *

Meaning

*

The LEDs LK1/LK2 are also used for the node flash test.

Note

LEDs LK1/LK2 turned off when bus adapters are connected

If bus adapters are connected to the LINK for the Ethernet connection, the LEDs LK1/LK2 of

the LINK are turned off.

In this case, the LEDs of the bus adapter need to be evaluated, see section

the bus adapter

2.2

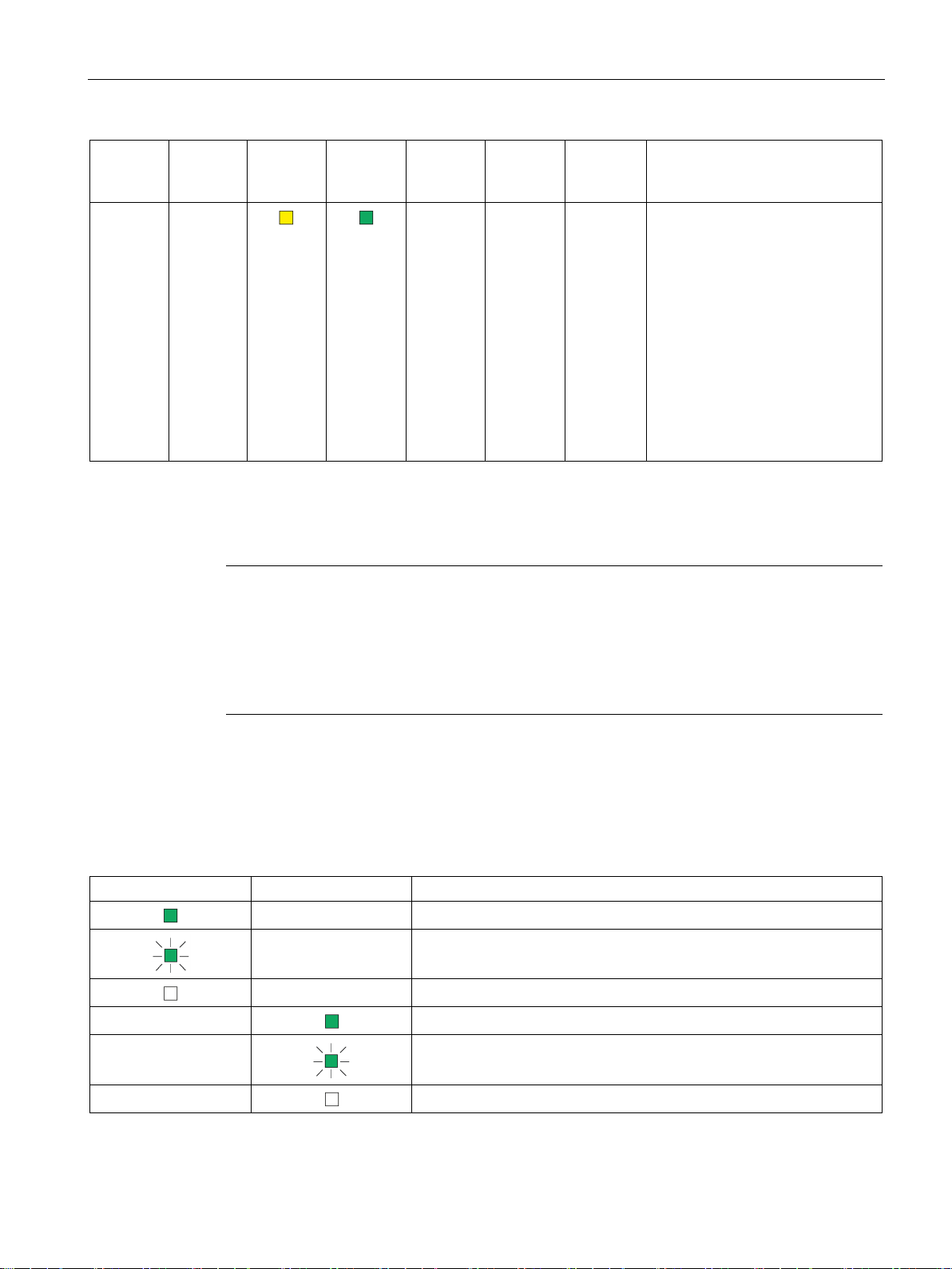

LED displays of the bus adapter

LK1

LK2

Meaning

2.2 LED displays of the bus adapter

(yellow /

- -

The LEDs LK1/LK2 flash very quickly when there is data traffic. When there is a high load. It may not be possible to dis-

tinguish the flashing from steady light.

(red)

(yellow)

(green)

(red)

- - - Maintenance demanded:

(red)

(green)

• Problem with redundant power

supply

• C-PLUG not detected or incor-

rectly formatted

• Program is adopted after re-

start,

(Note: After plugging in a CPLUG after a memory reset a

second restart is necessary.)

• Duplicate database (internal

memory and C-PLUG)

(Page 25).

Table 2- 6 Display scheme of the bus adapter "BA 2xRJ45"

- Ethernet connection at port 1, no data traffic

- Data traffic at port 1

- No Ethernet connection at port 1

-

-

-

LED displays of

Ethernet connection at port 2, no data traffic

Data traffic at port 2

No Ethernet connection at port 2

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

25

Page 26

LEDs, connectors, buttons

LK1

LK2

MT1

MT2

Meaning

2.3

Interfaces, bus adapters, buttons

Interfaces X1 and X2

Interface X3 for for bus adapter

2.3 Interfaces, bus adapters, buttons

Table 2- 7 Display scheme of the optical bus adapter "BA 2xSCRJ"

Ethernet connection at port 1, no data traffic

You will find the technical specifications and assignment of the Ethernet interface X1 and the

PROFIBUS interface X2 in the section Technical data (Page 77).

Data traffic at port 1

No Ethernet connection at port 1

Ethernet connection at port 2, no data traffic

Data traffic at port 2

No Ethernet connection at port 2

Maintenance demanded port 1

Port 1 without maintenance demand

Maintenance demanded port 2

Port 2 without maintenance demand

At the top right beside the PROFIBUS interface, there is the interface X3 for bus adapters of

the ET 200SP device family.

As an alternative, you can use this interface for connection to Ethernet if, for example, you

require an optical connection to the LINK.

The interface is constructed in the ET 200SP design and pin assignment.

You will find further information in the catalog, in Siemens Industry Mall and in the system

manual of the ET 200SP, see /4/ (Page 90) and in the appendix BusAdapter (Page 85).

For information on configuring the bus adapters in STEP 7 V5 refer to the section

Configuring bus adapters (Page 56).

IE/PB LINK PN IO

26 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 27

LEDs, connectors, buttons

Note

Deactivated Ethernet interface

When you plug in a bus adapter, the ports X1P1R

interface of the LINK are deactivated.

Button

WARNING

EXPLOSION HAZARD

2.4

X80: External power supply

External power supply

2.4 X80: External power supply

For information on configuring the bus adapters in STEP 7 Professional refer to the section

Configuring bus adapters (Page 59).

/ X1P2R of the integrated Ethernet

Do not press the button if there is a potentially explosive atmosphere.

The button serves the following purposes:

● Changeover to maintenance mode

● Restart

After the restart a new firmware file can be loaded, see section Loading firmware

(Page 71).

● Resetting to factory settings

For information on using the button and changing to the maintenance mode see the following

section.

The connector X80 (socket) for the external 24 VDC power supply is located on the bottom

of the LINK. The external power supply is redundant (optional use).

The power supply is connected to the LINK with the supplied 4-pin plug-in terminal block.

The plug-in terminal block is designed so that it can only be inserted in one position in the

X80 socket of the LINK.

The connector X80 has electronic reverse polarity protection.

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

27

Page 28

LEDs, connectors, buttons

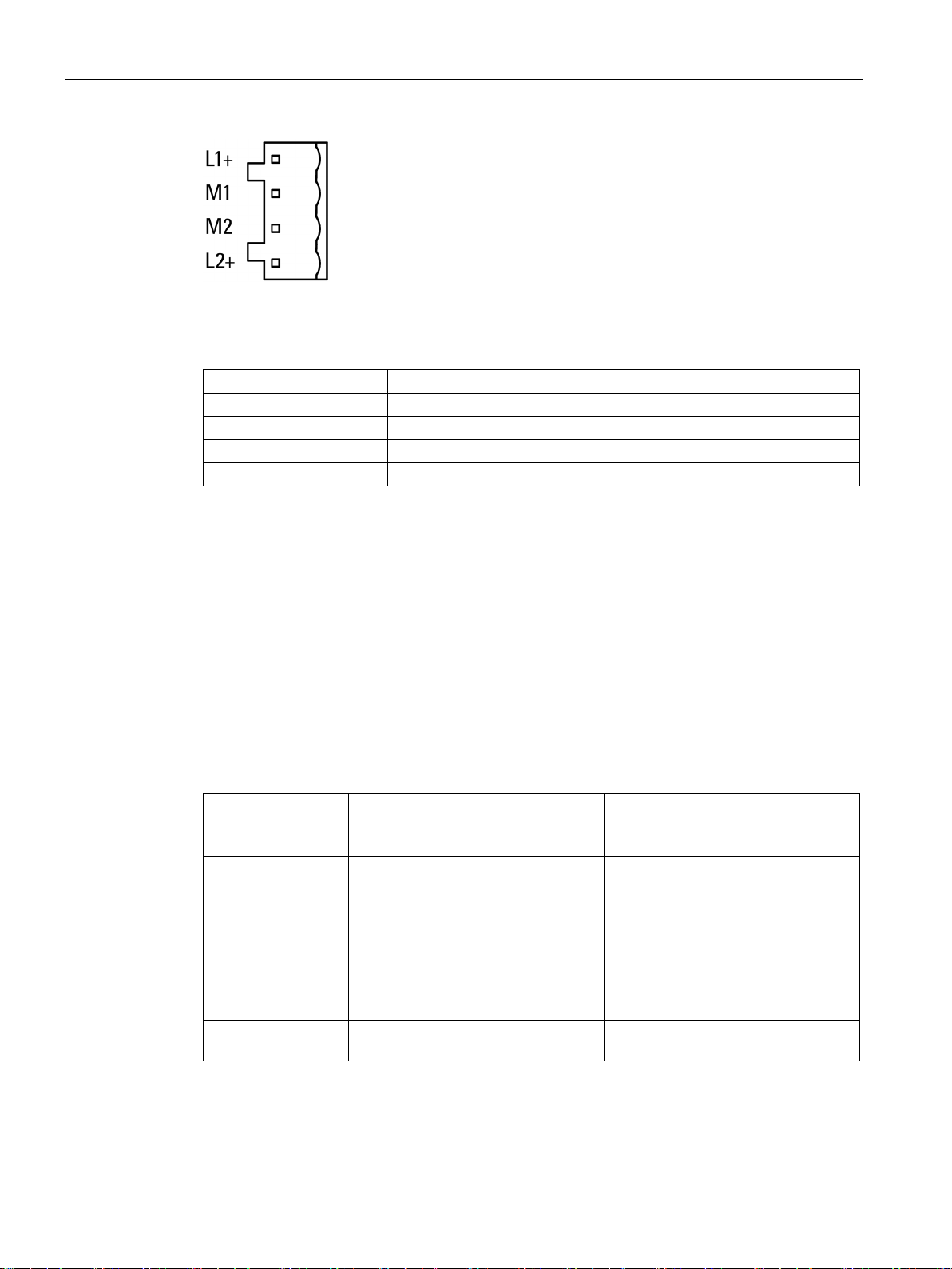

Labeling

Function

L1+

24 V DC

M2

Reference ground

L2+

24 VDC

2.5

Maintenance mode

Changing to the maintenance mode using the button

Operating mode

before pressing the

button

Pressing the button

Effect

minutes.

2.5 Maintenance mode

Figure 2-2 Redundant power supply

Table 2- 8 Pin assignment of the socket for the power supply

M1 Reference ground

For information on the connector, refer to the section "Installing and connecting up the LINK

(Page 36)".

You will find further data on the power supply in section Technical data (Page 77).

The functions of the maintenance mode are obtained as follows:

Table 2- 9 Functions of the maintenance mode

Normal mode Press the button for 3 seconds The LINK changes to maintenance

mode You can use the following functions:

• Restart

• Resetting to factory settings

Without any further actions, the LINK

returns to the normal mode after 5

IE/PB LINK PN IO

28 Operating Instructions, 11/2017, C79000-G8976-C393-02

Maintenance mode Press the button for 1 second The maintenance mode is extended

by 5 minutes.

Page 29

LEDs, connectors, buttons

Operating mode

before pressing the

button

Pressing the button

Effect

(Page 71).

settings (Page 70).

2.5 Maintenance mode

Maintenance mode Press the button twice briefly within 5

seconds

Maintenance mode Press the button for at least 10 sec-

onds

The LINK restarts.

Following this the LINK remains ready

for new firmware for 10 seconds, see

also section Loading firmware

The LINK is reset to the factory settings.

Note that configuration data is deleted

when you reset, refer to the section

Clearing and for resetting to factory

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

29

Page 30

LEDs, connectors, buttons

2.5 Maintenance mode

IE/PB LINK PN IO

30 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 31

3

3.1

Important notes on using the device

Safety notices on the use of the device

Overvoltage protection

NOTICE

Protection of the external power supply

coupling in of strong electromagnetic pulses onto the power supply cables is possible. This

The connector of the external power supply is not protected from strong electromagnetic

3.1.1

Notices on use in hazardous areas

WARNING

WARNING

EXPLOSION HAZARD

Note the following safety notices when setting up and operating the device and during all

associated work such as installation, connecting up or replacing the device.

If power is supplied to the module or station over longer power cables or networks, the

can be caused, for example by lightning strikes or switching of higher loads.

pulses. To protect it, an external overvoltage protection module is necessary. The

requirements of EN61000-4-5, surge immunity tests on power supply lines, are met only

when a suitable protective element is used. A suitable device is, for example, the Dehn

Blitzductor BVT AVD 24, article number 918 422 or a comparable protective element.

Manufacturer:

DEHN+SOEHNE GmbH+Co.KG Hans Dehn Str.1 Postfach 1640 D-92306 Neumarkt,

Germany

The device may only be operated in an environment with pollution degree 1 or 2 (see IEC

60664-1).

Do not press the button if there is a potentially explosive atmosphere.

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

31

Page 32

Installation, connecting up, commissioning

WARNING

EXPLOSION HAZARD

WARNING

must be connected to the power supply terminals. The power supply unit for the equipment

If the equipment is connected to a redundant power supply (two separate power supplies),

WARNING

EXPLOSION HAZARD

WARNING

EXPLOSION HAZARD

SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION

WARNING

3.1 Important notes on using the device

DO NOT OPEN WHEN ENERGIZED.

The equipment is designed for operation with Safety Extra-Low Voltage (SELV) by a

Limited Power Source (LPS).

This means that only SELV / LPS complying with IEC 60950-1 / EN 60950-1 / VDE 0805-1

power supply must comply with NEC Class 2, as described by the National Electrical Code

(r) (ANSI / NFPA 70).

both must meet these requirements.

DO NOT CONNECT OR DISCONNECT EQUIPMENT WHEN A FLAMMABLE OR

COMBUSTIBLE ATMOSPHERE IS PRESENT.

2 OR ZONE 2.

When used in hazardous environments corresponding to Class I, Division 2 or Class I,

Zone 2, the device must be installed in a cabinet or a suitable enclosure.

IE/PB LINK PN IO

32 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 33

Installation, connecting up, commissioning

3.1.2

Notes on use in hazardous areas according to ATEX / IECEx

WARNING

Requirements for the cabinet/enclosure

WARNING

Cable

exceeds 80 °C, special precautions must be taken. If the equipment is operated in an air

, only use cables with admitted maximum operating temperature

WARNING

Take measures to prevent transient voltage surges of more than 40% of the rated voltage.

3.1.3

Notices regarding use in hazardous areas according to UL HazLoc

WARNING

EXPLOSION HAZARD

3.1 Important notes on using the device

To comply with EU Directive 94/9 (ATEX95), the enclosure or cabinet must meet the

requirements of at least IP54 in compliance with EN 60529.

If the cable or conduit entry point exceeds 70 °C or the branching point of conductors

ambient in excess of 50 °C

of at least 80 °C.

This is the case if you only operate devices with SELV (safety extra-low voltage).

DO NOT DISCONNECT WHILE CIRCUIT IS LIVE UNLESS AREA IS KNOWN TO BE

NON-HAZARDOUS.

This equipment is suitable for use in Class I, Division 2, Groups A, B, C and D or nonhazardous locations only.

This equipment is suitable for use in Class I, Zone 2, Group IIC or non-hazardous locations

only.

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

33

Page 34

Installation, connecting up, commissioning

3.1.4

Notes on use in hazardous areas according to FM

WARNING

EXPLOSION HAZARD

You may only connect or disconnect cables carrying electricity when the power supply is

WARNING

EXPLOSION HAZARD

temperature of the enclosure corresponds to the ambient temperature of the module. Use

3.1 Important notes on using the device

switched off or when the device is in an area without inflammable gas concentrations.

This equipment is suitable for use in Class I, Division 2, Groups A, B, C and D or nonhazardous locations only.

This equipment is suitable for use in Class I, Zone 2, Group IIC or non-hazardous locations

only.

The equipment is intended to be installed within an ultimate enclosure. The inner service

installation wiring connections with admitted maximum operating temperature of at least

30 ºC higher than maximum ambient temperature.

IE/PB LINK PN IO

34 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 35

Installation, connecting up, commissioning

3.2

Overview: Installation, configuration, commissioning

3.2 Overview: Installation, configuration, commissioning

Follow the steps as shown below. Installation and configuration can be performed

independently of each other.

Figure 3-1 Installing, connecting up and configuring the LINK

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

35

Page 36

Installation, connecting up, commissioning

3.3

Installing and connecting up the LINK

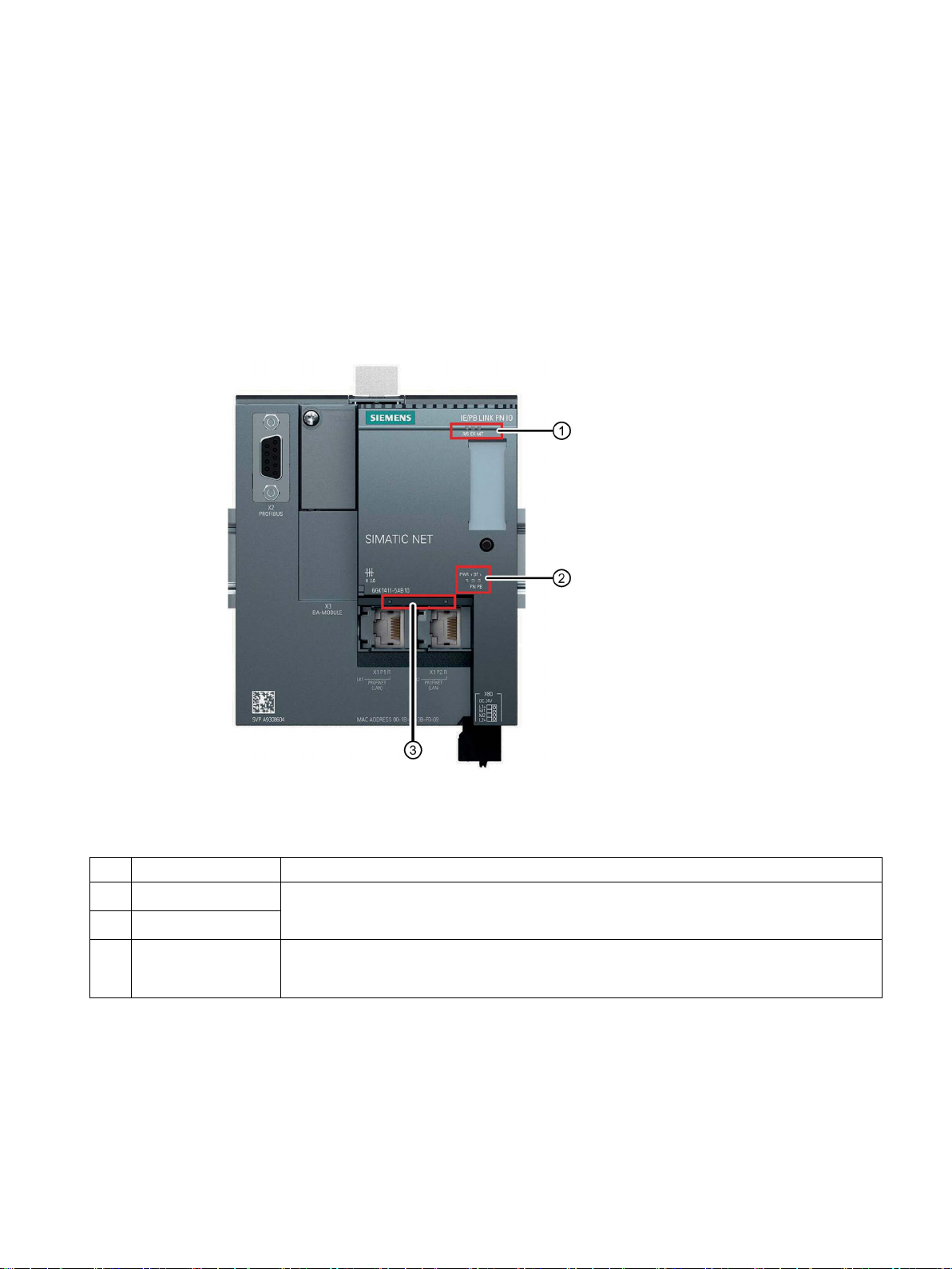

①

X2: PROFIBUS interface: 1 x 9-pin D-sub female connector

②

X3: Interface for ET 200SP bus adapter (behind the labeling plate)

③

X50: Receptacle for C-PLUG (behind the labeling plate);

④

(Page 26).

⑤

X80: Connector for the redundant power supply

⑥

X1: PROFINET interface, 2 x RJ-45 jacks with ring ports X1P1R / X1P2R

Installing and connecting up the LINK

Note

Only wire up the LINK with the power switched off.

3.3 Installing and connecting up the LINK

Button. For information on the functions, refer to the section Interfaces, bus adapters, buttons

Figure 3-2 Connectors of the LINK

Mount the LINK as follows:

1. Mount the LINK on the 35 mm DIN rail.

2. Connect the turned off power supply to the LINK. See section X80: External power supply

(Page 27).

3. Connect the LINK to Industrial Ethernet via one of the RJ-45 jacks (X1).

As an alternative you can use bus adapters at X3, that must be plugged in with the power

turned off. When using bus adapters, the Ethernet interface X1 is inactive.

IE/PB LINK PN IO

36 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 37

Installation, connecting up, commissioning

Note

Using bus adapters

If you use bus adapters instead of the Ethernet interface of the LINK, do not initially plug in

the bus adapters. The procedure is described with the commissioning.

3.4

PG/PC connector

3.4 PG/PC connector

4. When necessary, connect another component to the remaining free RJ-45 jack.

5. Connect the LINK CM to PROFIBUS.

6. Initially leave the power supply turned off.

For information on further commissioning, refer to section Commissioning and startup of the

LINK (Page 42).

To download the STEP 7 configuration data, you can connect the PG or the engineering

station as follows:

● Via Ethernet (recommended)

– To load the LINK in standard mode, you must first supply the LINK with an IP address,

refer to the section Configuring the IP address (Page 47).

– To download the configuration data of the LINK as a PROFINET IO proxy, you must

first assign the LINK its PROFINET device name.

● Via PROFIBUS

To download via PROFIBUS, you must first supply the LINK with the PROFIBUS

address.

For information on downloading see section Commissioning and startup of the LINK

(Page 42).

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

37

Page 38

Installation, connecting up, commissioning

3.5

C-PLUG

Exchangeable storage medium C-PLUG

Area of application

How it works

Inserting and removing the C-PLUG

Note

Insert and remove only when power is off

The C

3.5 C-PLUG

For configuration data, the LINK has an internal memory. As an option, the device can be

operated with a C-PLUG (Configuration Plug). You will find the memory capacity in the

section C-PLUGs (Page 86).

The C-PLUG is an exchangeable medium for storage of the configuration data of the LINK.

This means that the configuration data data remains available if the device is replaced. It is

possible to replace the module without a PG/PC.

The retentive parameters include the entire configuration data and the relevant mode:

Power is supplied by the LINK. The CPLUG retains all data permanently when the power is

turned off.

Flash components are used in the C-PLUG. Note the limited number of times you can write

to the C-PLUG, see section C-PLUGs (Page 86).

-PLUG must be inserted or removed only when the power is off!

Figure 3-3 Left: IE/PB-LINK PN IO without C-PLUG / right LINK with C-PLUG

IE/PB LINK PN IO

38 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 39

Installation, connecting up, commissioning

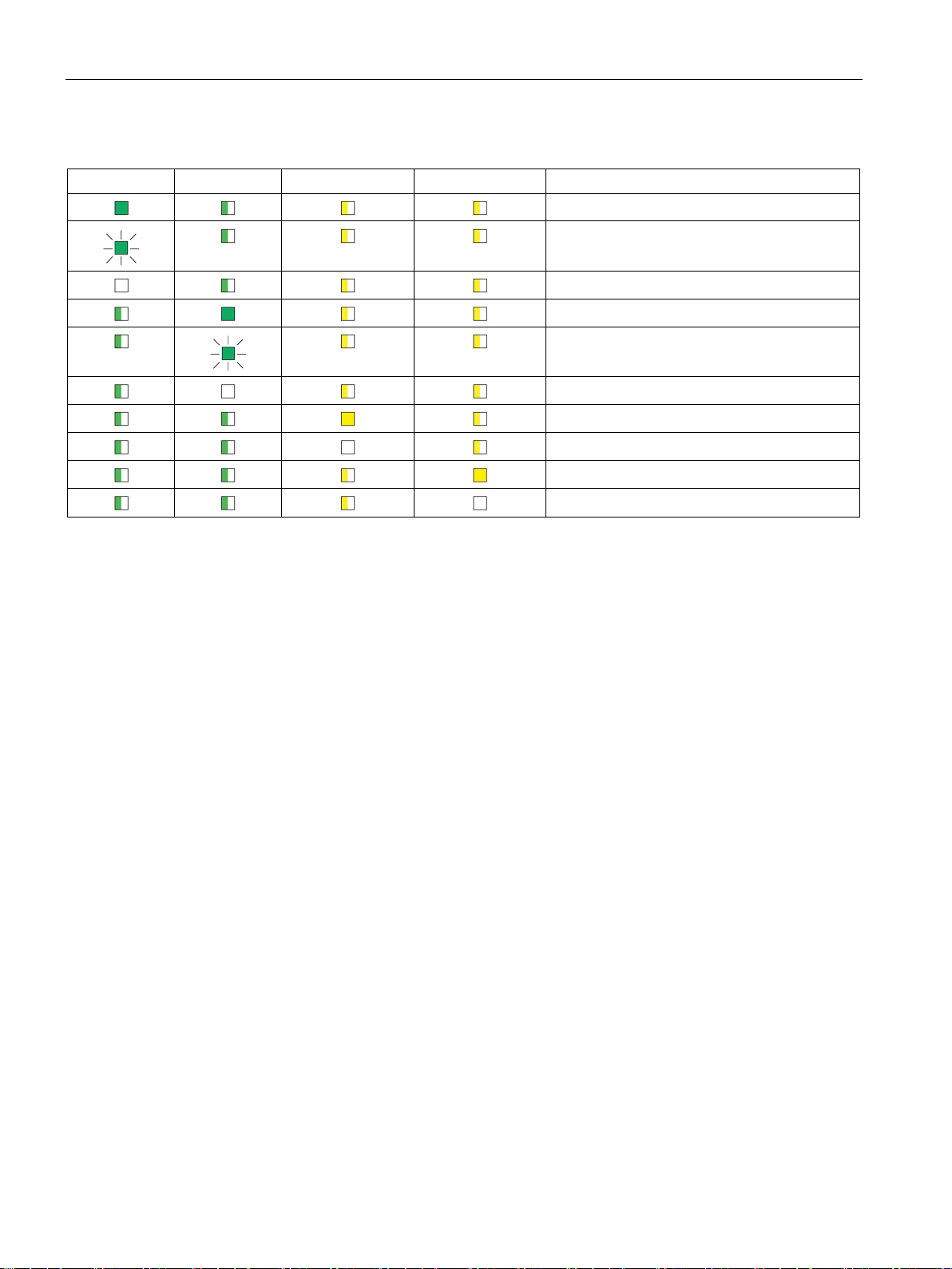

Operating response with the C-PLUG inserted

Status / procedure

Response when adopting data / actions

Result after startup

Operation without C-PLUG

Operation with C-PLUG

fter startup; The LINK runs with

LINK has a C-PLUG inserted after operating without a C-PLUG

3.5 C-PLUG

The slot for the C-PLUG is located on the front: Insert the C-PLUG in the intended

receptacle.

Remove the C-PLUG only if there is a fault on the basic device. Remove the C-PLUG from

the receptacle using a screwdriver.

• Internal memory empty

• No C-PLUG inserted

• Internal memory empty

• Empty C-PLUG is plugged in

• Internal memory empty

• C-PLUG with valid configuration

data is plugged in. 2)

Configuration data is adopted from the

STEP 7 project, Method of adoption

dependent on the mode:

• Use as a gateway: Configuration

data is transferred using the download function of STEP 7.

• Use as PROFINET IO device: Con-

figuration data is transferred from

the PROFINET IO controller.

Configuration data is adopted from the

STEP 7 project, Method of adoption

dependent on the mode:

• Use as a gateway: Configuration

data is transferred using the download function of STEP 7.

• Use as PROFINET IO device: Con-

figuration data is transferred from

the PROFINET IO controller.

Result a

the configuration data stored on the CPLUG.

The LINK runs with the configuration

data transferred to the internal

memory.

The LINK runs with the configuration

data transferred to the C-PLUG. 1)

The LINK runs with the configuration

data existing on the C-PLUG. 1)

1)

• Internal memory with configuration

data

• C-PLUG with different but valid

configuration data is plugged in. 2)

• LINK is to run with data from the C-

PLUG instead of with the internal

data.

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

The power for the LINK must be turned

off and on again.

The LINK starts up with the configuration data on the C-PLUG.

The configuration data in the internal

memory is deleted.

The LINK runs with the configuration

data adopted from the C-PLUG. 1)

39

Page 40

Installation, connecting up, commissioning

Status / procedure

Response when adopting data / actions

Result after startup

data in the internal memory is deleted.

1)

2)

3)

Only possible when using as "Gateway in standard mode".

Backing up configuration data of the LINK

3.5 C-PLUG

• Internal memory with configuration

data

• C-PLUG is plugged in.

• Configuration data is to be adopted

on the C-PLUG from internal

memory.

• Internal memory with configuration

data

• C-PLUG with valid but incorrect

configuration data is plugged in accidentally.

• Both sets of configuration data

(internal memory and C-PLUG)

should be retained, LINK should

continue to run with internal configuration data.

• Internal memory with configuration

data

• C-PLUG with valid but incorrect

configuration data is plugged in accidentally.

• Both sets of configuration data

(internal memory and C-PLUG)

should be retained, LINK should

continue to run with internal configuration data.

The following situations are possible:

• The C-PLUG has data written to it:

Format the C-PLUG using special

diagnostics. The data on the CPLUG is deleted.

The LINK then restarts.

• The C-PLUG is brand new (without

device ID):

Turn the power supply for the LINK

off and on again.

When the LINK starts up, the configuration data is loaded on the C-PLUG from

the internal memory. The configuration

Back up the configuration data of the

internal memory with STEP 7 STEP 7

(with "Upload from device"). 3)

Turn off the power to the LINK and

remove the incorrectly inserted CPLUG.

Turn on the power to the LINK and

download the configuration data

backed up in STEP 7 to the LINK.

The power to the LINK must be

switched off.

Remove the incorrectly inserted CPLUG.

Insert a C-PLUG without a device ID

(e.g. brand new).

Switch on the power of the LINK.

The data previously stored in the inter-

nal memory is transferred to the new CPLUG.

The LINK runs with the configuration

data transferred to the C-PLUG from

the internal memory.

1)

The LINK continues to run with the

internal configuration data.

The LINK continues to run with the

original internal configuration data,

which is now located on the new CPLUG.

The incorrectly inserted C-PLUG still

has its original data.

When used as a PROFINET IO device: Only the PROFINET device name and the I&M data are stored retentively on the

C-PLUG. Configuration data is transferred from the PROFINET IO controller at each new startup and entered in the

temporary memory.

If the C-PLUG for the LINK does not contain valid configuration data, the device does not start up. In this case, use the

diagnostics of STEP 7 for further clarification and possibly to format the C-PLUG.

If the C-PLUG has not been written to (factory status), when the device starts up all

configuration data of the LINK is automatically backed up.

Changes to the configuration during operation are also backed up on the C-PLUG.

IE/PB LINK PN IO

40 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 41

Installation, connecting up, commissioning

Replacing a device

C-PLUG formatting

Note

Using the C-PLUG of a LINK with firmware version < V3.0

If you use a C

V3.0, the

C

PLUG must be

reformatted.

Diagnostics

3.5 C-PLUG

A basic device with an inserted C-PLUG uses the configuration data of the inserted C-PLUG

when it starts up unless the internal memory is full. This is, however, only possible when the

data from a compatible device type was written to the C-PLUG.

Saving the configuration data on the C-PLUG makes it simple to replace the LINK. If a LINK

needs to be replaced, the C-PLUG is simply taken from the replaced LINK and inserted in

the replacement device. After it starts up the first time, the replacement automatically has the

same configuration data as the replaced device.

-PLUG that has already been used in a LINK with firmware version <

-PLUG can only be read. To have configuration data transferred to it, this C-

Use only a C-PLUG that is formatted for the IE/PB LINK PN IO.

A C-PLUG that has already been used in a different device type and that was formatted for

this device type must first be formatted for the LINK. After formatting, all data areas are

deleted on the C-PLUG and the LINK restarts.

The configuration data is adopted only after reloading or after turning on the power supply

again.

To format use STEP 7 special diagnostics > Operating mode > C-PLUG. For more detailed

information, refer to the online help in the topic "General Diagnostics Functions - C-PLUG

Diagnostics Object".

Malfunctions are signaled using diagnostics mechanisms of the device (LEDs "ER" and

"MT"):

● Inserting a C-PLUG that contains the configuration data of an incompatible device type.

● General malfunctions of the C-PLUG

● Duplicate database

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

41

Page 42

Installation, connecting up, commissioning

3.6

Commissioning and startup of the LINK

Requirements for commissioning

Startup behavior of the LINK

Commissioning the LINK

LINK in standard mode

LINK al PROFINET IO proxy

3.6 Commissioning and startup of the LINK

Prior to commissioning the LINK, make sure that the following conditions are met:

● The system is completely installed.

● The communications partners are reachable.

● The STEP 7 configuration data is complete.

● When using a C-PLUG: The C-PLUG is plugged in.

● The PG or engineering station with the STEP 7 configuration data is connected to the

LINK.

See section PG/PC connector (Page 37) for information on this.

Commission the LINK by first turning on the power supply. During startup the LINK behaves

as follows:

● When starting up the first time (brand new) the LINK searches for the configuration data

in the internal memory.

The LINK changes to STOP and shows the LED pattern "Reset to factory settings", see

also section LED displays of the LINK (Page 21)

● When starting up after a phase of operation the LINK searches for the configuration data

either on the C-PLUG (if plugged in) or in the internal memory.

For information on the startup with C-PLUG refer to the section C-PLUG (Page 38).

After startup the subsequent procedure depends on the required mode.

After startup - depending on the mode of the LINK - follow the steps below:

You have the following options:

● Optional: Assign or change the IP address

● Download the configuration data

In this mode. the following first step is necessary:

● Assign the LINK the PROFINET device name

Following this you can take the following steps:

● Optional: Assign or change the IP address

● Download the configuration data

IE/PB LINK PN IO

42 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 43

Installation, connecting up, commissioning

Information on commissioning

Commissioning when using bus adapters

3.6 Commissioning and startup of the LINK

Depending on the configuration tool you are using, you will find information on

commissioning in the following sections:

● STEP 7 V5

– LINK as PROFINET IO device

See section Commissioning the LINK as a PROFINET IO device (Page 53).

– LINK as gateway in standard mode

See section Commissioning the LINK as a gateway (Page 55).

● STEP 7 Professional

– LINK as PROFINET IO device

See section Commissioning the LINK as a PROFINET IO device (Page 60).

– LINK as gateway in standard mode

See section Commissioning the LINK in standard mode (Page 61).

For information on saving the configuration data when turning off the power supply and when

changing from RUN to STOP, see section Changing from RUN to STOP (Page 44).

If you use bus adapters instead of the Ethernet interface, follow the steps below during

commissioning:

1. First download the configuration data.

2. Then turn off the power.

3. Now plug in the bus adapter connected to the network.

4. Turn on the power.

Only now is the interface X3 of the bus adapter active and the ports X1P1R / X1P2R of

the integrated Ethernet interface are deactivated.

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

43

Page 44

Installation, connecting up, commissioning

3.7

Changing from RUN to STOP

STOP → RUN

RUN → STOP

Power ON → OFF → ON

Note

Configuration data when turning off the power

• LINK as PROFINET IO device

vely by the LINK. After cycling power on the LINK, all the configuration data except

During startup the configuration data is once again downloaded from the PROFINET IO

• LINK in standard mode

tained after turning off the power and when the power is turned on the

LINK starts up as configured.

3.7 Changing from RUN to STOP

In the standard mode of the LINK you can change the operating mode of the LINK between

RUN and STOP with STEP 7.

The LINK loads configured and/or downloaded data into the work memory and then changes

to RUN mode.

With a transition phase (LED pattern "Stopping (RUN → STOP)", the LINK changes to STOP

mode.

● Established routed S7 connections are not terminated.

● The following functions are disabled:

– PROFINET IO

– Time-of-day synchronization

● The following functions remain enabled:

– Downloading the configuration data and diagnostics of the LINK

– Routing function

Configuration data loaded during startup is not stored retentively.

The configuration data downloaded from the PROFINET IO controller is not stored

retenti

for the device name is deleted.

controller.

All stored data is re

System connections for configuration, diagnostics and PG channel routing still exist.

IE/PB LINK PN IO

44 Operating Instructions, 11/2017, C79000-G8976-C393-02

Page 45

4

4.1

Security recommendations

General

Physical access

Network attachment

Keep to the following security recommendations to prevent unauthorized access to the

system.

● You should make regular checks to make sure that the device meets these

recommendations and other internal security guidelines if applicable.

● Evaluate your plant as a whole in terms of security. Use a cell protection concept with

suitable products.

● Do not connect the device directly to the Internet. Operate the device within a protected

network area.

● Keep the firmware up to date. Check regularly for security updates of the firmware and

● Check regularly for new features on the Siemens Internet pages.

Restrict physical access to the device to qualified personnel.

use them.

– Here you will find information on network security:

Link: (http://www.siemens.com/industrialsecurity)

– Here you will find information on Industrial Ethernet security:

Link: (http://w3.siemens.com/mcms/industrial-communication/en/ie/industrial-ethernet-

security/Seiten/industrial-security.aspx)

– You will find an introduction to the topic of industrial security in the following

publication:

Link:

(http://w3app.siemens.com/mcms/infocenter/dokumentencenter/sc/ic/InfocenterLangu

agePacks/Netzwerksicherheit/6ZB5530-1AP010BA4_BR_Netzwerksicherheit_en_112015.pdf)

Do not connect the LINK directly to the Internet. If a connection from the LINK to the Internet

is required, arrange for suitable protection before the LINK, for example a SCALANCE S with

firewall.

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

45

Page 46

Configuration and operation

Protocols

Secure and non-secure protocols

Table: Meaning of the column titles and entries

Protocol / function

Port number (protocol)

Default of the port

Port status

Authentication

Protocol /

function

Port number (protocol)

Default of the port

Port status

Authentication

DHCP

67 (UDP)

Open

Open

No

DCP

93 (UDP)

Open

Open

No

DCE

135 (TCP)

Open

Open

No

HTTP

8080 (TCP)

Open

Open

No

NTP

123 (UDP)

Closed

Open after configuration

No

S7 communication

4.1 Security recommendations

● Only activate protocols that you require to use the system.

● Use secure protocols when access to the device is not prevented by physical protection

measures.

The following table provides you with an overview of the open ports on this device.

●

Protocols that the device supports.

●

Port number assigned to the protocol.

●

– Open

The port is open at the start of the configuration.

– Closed

The port is closed at the start of the configuration.

●

– Open

The port is always open and cannot be closed.

– Open after configuration

The port is open if it has been configured.

– Open (login, when configured)

As default the port is open. After configuring the port, the communications partner

needs to log in.

●

Specifies whether or not the protocol authenticates the communications partner during

access.

IE/PB LINK PN IO

46 Operating Instructions, 11/2017, C79000-G8976-C393-02

102 (TCP) Open Open No

Page 47

Configuration and operation

Protocol /

function

Port number (protocol)

Default of the port

Port status

Authentication

SNMP

161 (UDP)

Open

Open

No

PROFINET

34964 (UDP)

Open

Open

No

4.2

IP configuration

4.2.1

Configuring the IP address

Alternative ways of assigning the address parameters

4.2 IP configuration

You can decide the route and the method with which the IP address of the local interface is

obtained and assigned.

● Set IP address in the project

This is the default setting. You specify the IP address when the device is networked. The

IP address CP is therefore fixed. With this option, you need to configure the

communication connections.

The configuration can be achieved in the following ways:

– PST, see section Assign the address and network parameters with the Primary Setup

Tool (PST) (Page 48).

As an alternative to STEP 7, you can use the PST to assign the address and

PROFINET parameters.

– STEP 7 V5, see section Configuration with STEP 7 V5.5 (Page 51).

– STEP 7 Basic / Professional, see section Configuration with STEP 7 Basic /

Professional (Page 57).

● Obtain IP address from a DHCP server

This is an alternative method if the LINK is operated in standard mode as a gateway.

With this, you specify that the IP address is obtained from a DHCP server when the

device starts up. To do this, the MAC address of the interface or the client ID that can be

entered in the configuration or the PROFINET device name is transferred to the DHCP

server.

You will find further information in the configuration manual for S7 CPs /3/ (Page 90).

IE/PB LINK PN IO

Operating Instructions, 11/2017, C79000-G8976-C393-02

47

Page 48

Configuration and operation

4.2.2

Restart after detection of a duplicate IP address in the network

Behavior when the LINK starts up

4.2.3

Remove retentive storage of the IP address if there are duplicate addresses

4.3

Assign the address and network parameters with the Primary Setup

Tool (PST)

Starting PST and setting the PC access

4.3 Assign the address and network parameters with the Primary Setup Tool (PST)

To save you time-consuming troubleshooting in the network, during startup the LINK detects

double addressing in the network.

If the LINK recognizes double addressing during startup, it changes to the RUN status and

can no longer be reached via the IP parameters. The LEDs "ER" and "R/S" are lit and the

LED "BF PN" flashes.

The IP address and the PROFINET device name of the LINK remain stored retentively:

If, for example during startup, the LINK detects a duplicate address in another network, the

LINK is not connected to the network. The LEDs "ER" and "R/S" are lit and the LED "BF PN"

flashes. The LINK is not reachable via the IP parameters.

To connect the LINK to the network, remove the retentively stored IP address as follows:

Using DCP with the Primary Setup Tool (PST), set the IP address of the LINK to 0.0.0.0

without configuration or set a new address.

This removes the retentively stored IP address of the LINK. The LINK can be connected into

the network.