Page 1

FDCL221

Line separator

Technical manual

Building Technologies

Fire Safety & Security Products

Page 2

Technical specifications and availability subject to change without notice.

© 2004-2009 Copyright Siemens Building Technologies, Inc.

We reserve all rights in this document and in the subject thereof. By acceptance of the document the recipient acknowledges these rights

and undertakes not to publish the document nor the subject thereof in full or in part, nor to make them available to any third party without our

prior express written authorization, nor to use it for any purpose other than for which it was delivered to him.

Page 3

Table of contents

About this document ....................................................................................5

1

2 Safety..............................................................................................................8

2.1 Safety notices.................................................................................................. 8

2.2 Safety regulations for the method of operation .............................................10

2.3 Standards and directives complied with........................................................12

2.4 Release Notes...............................................................................................12

3 Structure and function................................................................................13

3.1 Overview .......................................................................................................13

3.1.1 Details for ordering ........................................................................14

3.2 Setup .............................................................................................................14

3.2.1 Indication elements........................................................................14

3.3 Function.........................................................................................................15

3.4 Accessories ...................................................................................................16

3.4.1 Top hat rail TS35 ...........................................................................16

3.4.2 Connection terminal DBZ1190-AB.................................................16

3.4.3 Micro terminal DBZ1190-AA ..........................................................16

4 Planning .......................................................................................................17

4.1 Compatibility.................................................................................................. 18

4.2 Fields of application ......................................................................................18

4.3 Positioning.....................................................................................................19

4.4 Environmental influences ..............................................................................19

5 Mounting / Installation ................................................................................20

5.1 Assembly.......................................................................................................20

5.2 Electrical connection .....................................................................................22

5.2.1 Wiring.............................................................................................23

5.2.2 Shielded cable ...............................................................................24

6 Commissioning ...........................................................................................25

7 Maintenance and troubleshooting.............................................................26

8 Specifications ..............................................................................................27

8.1 Technical data...............................................................................................27

8.2 Dimensions....................................................................................................28

8.3 Environmental compatibility ..........................................................................28

9 Index .............................................................................................................29

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

3

Page 4

4

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 5

1 About this document

Goal and purpose

This document contains all information on the line separator module FDCL221.

Consistent compliance with the instructions guarantees correct and safe use.

Target groups

The information in this document is intended for the following target groups:

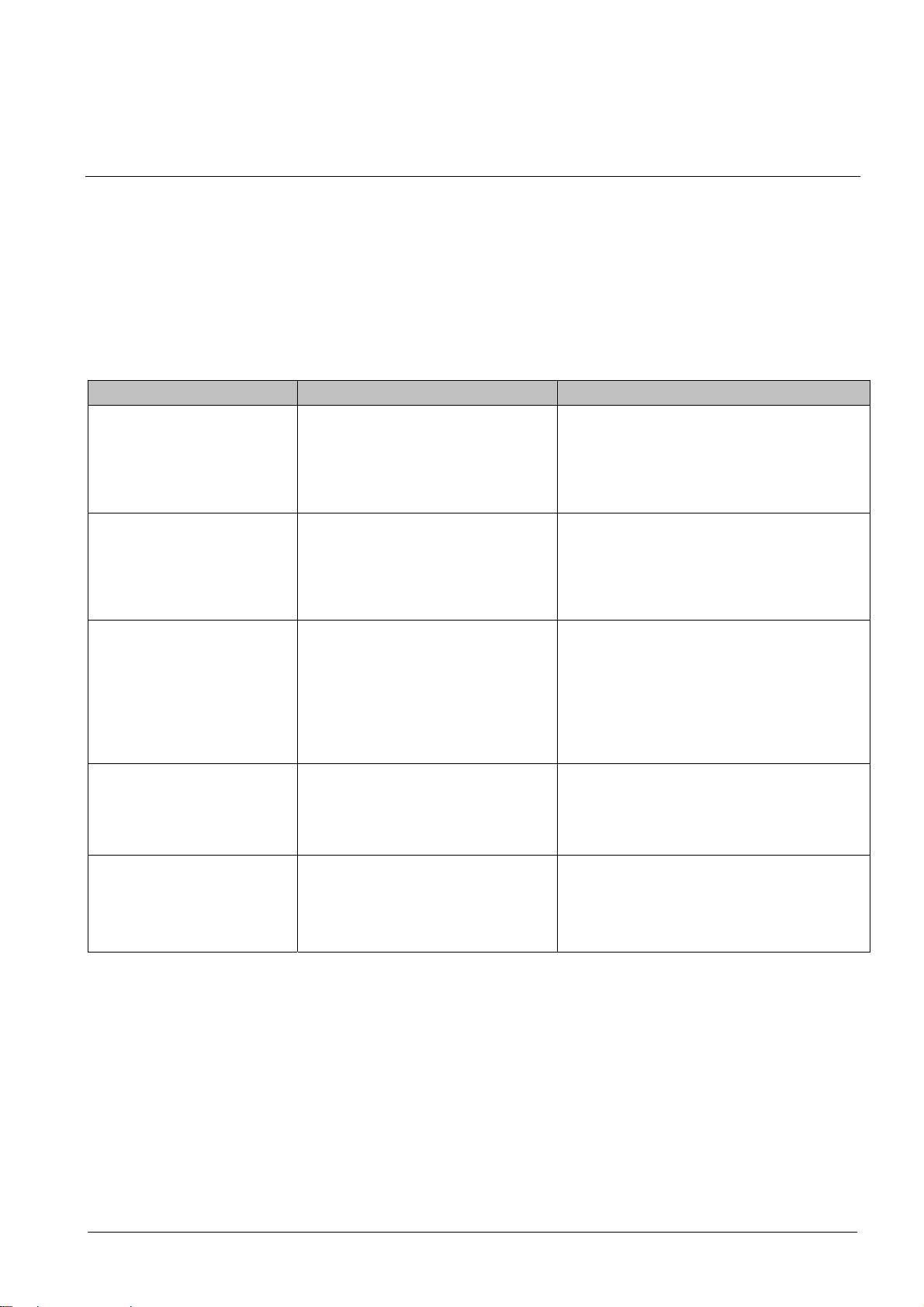

Target group Activity Qualification

Product Manager z Is responsible for information

passing between the manufacturer

and regional company.

z Coordinates the flow of information

between the individual groups of

people involved in a project.

Project Manager z Coordinates the deployment of all

persons and resources involved in

the project according to the

schedule.

z Provides the information required to

run the project.

Project Engineer z Parameterizes the product

according to country-specific and

customer-specific requirements.

z Checks operability and releases the

product for commissioning at the

place of installation.

z Searches for and corrects

malfunctions.

Installation personnel z Assembles and installs the product

components at the place of

installation.

z Carries out a performance check

following installation.

Maintenance personnel z Carries out all maintenance work.

z Checks that the products are in

perfect working order.

z Searches for and corrects

malfunctions.

z Has obtained suitable specialist training for

the function and for the products.

z Has attended the training courses for

Product Managers.

z Has obtained suitable specialist training for

the function and for the products.

z Has attended the training courses for Project

Managers.

z Has obtained suitable specialist training for

the function and for the products.

z Has attended the training courses for Project

Engineers.

z Has received specialist training in the area of

building installation technology or electrical

installations.

z Has obtained suitable specialist training for

the function and for the products.

About this document

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

5

Page 6

About this document

Document identification

Position Information

Title page z Product type

z Product designation

z Document type

Last page, bottom left z Document ID

ID_ModificationIndex_Language_COUNTRY

z Edition date

Last page, bottom right z Manual

z Register

Conventions for text marking

Markups

Special markups are shown in this document as follows:

⊳ Requirement for a behavior instruction

⇨ Intermediate result of a behavior instruction

⇨ End result of a behavior instruction

'Text' Quotation, reproduced identically

<Key> Identification of keys

Supplementary information

i

The

symbol identifies supplementary information such as a tip for an easier

way of working.

Supplementary information is labeled using the 'i' symbol.

Reference documents

Document ID Title

008025 Installation of FDCL221 line separator

008331 'List of compatibility'

A6V10229261 'List of compatibility' (for 'Cerberus PRO' product line)

6

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 7

About this document

Technical terms

Term Explanation

FDnet/C-NET Addressed detector line

Collective detector line Non-addressed detector line

LED Light-emitting diode

Loop Detector line loop line

PC Polycarbonate (plastic)

Sub-stub Detector line on a FDnet/C-NET loop only connected on one

side

History of changes

Document ID Edition date Brief description

007063_e_en_-- 06.2009 Editorial revision of entire document

007063_d_en_-- 09.2007 Technical data:

New line separator parameters

Changed air humidity

Standard EN 54-17

Approval LPCB 126ae/01

007063_c_en_-- 09.2006 Zug address;

Technical data revised

Connections with 2.8 x 0.8 mm flat

connector sleeves

007063_b_en_-- 01.2005 Name of division

007063_a_en_-- 03.2004 First edition

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

7

Page 8

Safety

2 Safety

2.1 Safety notices

The safety notices must be observed in order to protect people and property.

The safety notices in this document contain the following elements:

z Symbol for danger

z Signal word

z Nature and origin of the danger

z Consequences if the danger occurs

z Measures or prohibitions for danger avoidance

Symbol for danger

This is the symbol for danger. It warns of risks of injury.

Follow all measures identified by this symbol to avoid injury or death.

Additional danger symbols

These symbols indicate general dangers, the type of danger or possible

consequences, measures and prohibitions, examples of which are shown in the

following table:

General danger

Voltage/electric shock

Battery

Explosive atmosphere

Laser light

Heat

8

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 9

Safety

Signal word

The signal word classifies the danger as defined in the following table:

Signal word Danger level

DANGER DANGER identifies a dangerous situation, which will result

directly in death or serious injury if you do not avoid this

situation.

WARNING WARNING identifies a dangerous situation, which may result

in death or serious injury if you do not avoid this situation.

CAUTION CAUTION identifies a dangerous situation, which could result

in slight to moderately serious injury if you do not avoid this

situation.

NOTICE

NOTICE

identifies possible damage to property that may

result from non-observance.

How risk of injury of presented

Information about the risk of injury is shown as follows:

WARNING

Nature and origin of the danger

Consequences if the danger occurs

z Measures / prohibitions for danger avoidance

How possible damage to property is presented

Information about possible damage to property is shown as follows:

NOTICE

Nature and origin of the danger

Consequences if the danger occurs

z Measures / prohibitions for danger avoidance

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

9

Page 10

Safety

2.2 Safety regulations for the method of operation

National standards, regulations and legislation

Siemens products are developed and produced in compliance with the relevant

European and international safety standards. Should additional national or local

safety standards or legislation concerning the planning, assembly, installation,

operation or disposal of the product apply at the place of operation, then these

must also be taken into account together with the safety regulations in the product

documentation.

Electrical installations

WARNING

Electrical voltage

Electric shock

z Work on electrical installations may only be carried out by qualified

electricians or by instructed persons working under the guidance and

supervision of a qualified electrician, in accordance with the electrotechnical

regulations.

z Wherever possible disconnect products from the power supply when carrying

out commissioning, maintenance or repair work on them.

z Lock volt-free areas to prevent them being switched back on again by mistake.

z Label the connection terminals with external external voltage using a

'DANGER External voltage' sign.

z Route mains connections to products separately and fuse them with their own,

clearly marked fuse.

z Fit an easily accessible disconnecting device in accordance with IEC 60950-1

outside of installation.

z Produce earthing as stated in local safety regulations.

Assembly, installation, commissioning and maintenance

z If you require tools such as a ladder, these must be safe and must be intended

for the work in hand.

z When starting the fire control panel ensure that unstable conditions cannot

arise.

z Ensure that all points listed in the 'Testing the product operability' section below

are observed.

z You may only set controls to normal function when the product operability has

been completely tested and the system has been handed over to the customer.

10

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 11

Safety

Testing the product operability

z Prevent the remote transmission from triggering erroneously.

z If testing building installations or activating devices from third-party companies,

you must collaborate with the people appointed.

z The activation of fire control installations for test purposes must not cause

injury to anyone or damage to the building installations. The following

instructions must be observed:

‒ Use the correct potential for activation; this is generally the potential of the

building installation.

‒ Only check controls up to the interface (relay with blocking option).

‒ Make sure that only the controls to be tested are activated.

z Inform people before testing the alarming control devices and allow for possible

panic responses.

z Inform people about any noise or mist which may be produced.

z Before testing the remote transmission, inform the corresponding alarm and

fault signal receiving stations.

Modifications to the system layout and products

Modifications to the system and to individual products may lead to faults,

malfunctioning and safety risks. Written confirmation must be obtained from

Siemens and the corresponding safety bodies for modifications or additions.

Components and spare parts

z Components and spare parts must comply with the technical specifications

defined by Siemens. Only use products specified or recommended by

Siemens.

z Only use fuses with the specified fuse characteristics.

z Wrong battery types and improper battery changing lead to a risk of explosion.

Only use the same battery type or an equivalent battery type recommended by

Siemens.

z Batteries must be disposed of in an environmentally friendly manner. Observe

national guidelines and regulations.

Disregard of the safety regulations

Before they are delivered, Siemens products are tested to ensure they function

correctly when used properly. Siemens disclaims all liability for damage or injuries

caused by the incorrect application of the instructions or the disregard of danger

warnings contained in the documentation. This applies in particular to the following

damage:

z Personal injuries or damage to property caused by improper use and incorrect

application

z Personal injuries or damage to property caused by disregarding safety

instructions in the documentation or on the product

z Personal injury or damage to property caused by poor maintenance or lack of

maintenance

11

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 12

Safety

Disclaimer

We have checked that the content of this document matches the hardware and

software described. Despite this, we cannot rule out deviations and cannot

therefore assume liability for them matching completely. The details in this

document are checked regularly and any corrections needed included in

subsequent editions.

2.3 Standards and directives complied with

We are grateful for any suggestions for improvement.

A list of the standards and directives complied with is available from your Siemens

contact.

2.4 Release Notes

Limitations to the configuration or use of devices in a fire detection installation with

a particular firmware version are possible.

WARNING

Limited or non-existent fire detection

Personal injury and damage to property in the event of a fire.

z Read the 'Release Notes' before you plan and/or configure a fire detection

installation.

z Read the 'Release Notes' before you carry out a firmware update to a fire

detection installation.

NOTICE

Incorrect planning and/or configuration

Important standards and specifications are not satisfied.

Fire detection installation is not accepted for commissioning.

Additional expense resulting from necessary new planning and/or configuration.

z Read the 'Release Notes' before you plan and/or configure a fire detection

installation.

z Read the 'Release Notes' before you carry out a firmware update to a fire

detection installation.

12

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 13

3 Structure and function

3.1 Overview

Structure and function

FDCL221 line separator

The FDCL221 line separator can detect and disconnect short-circuits in the

FDnet/C-NET.

Properties

z Compatible with FS20/FS720 fire detection system

z Communication via the detector line

z Individual addressing of line separators for easy location identification

z Protects the FDnet/C-NET from short-circuits when sub-stubs are connected

z Status indicator (LED) for the line separator

z Different types of installation

z Maintenance-free

Applications

z Line separators are interconnected to ensure that several sub-stub lines do not

fail in the event of a short-circuit.

z Modernization of collective detector lines on the addressed FDnet/C-NET

system.

13

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 14

Structure and function

Assembly

z Installation in intermediate distributor or directly in a fire control panel

z Attachment options:

‒ Directly on a top hat rail TS35

‒ Attachment with a screw or cable tie directly on a wall

3.1.1 Details for ordering

Type Order no. Designation

FDCL221 A5Q00004011 Line separator

See also

Positioning [J 19]

Assembly [J 20]

3.2 Setup

1

View of FDCL221 with open housing

1 Housing cover 4 PCB

2 Yellow LED

3 Housing bottom

2

3

4

5

5 Stranded cable with 2.8 x 0.8 mm flat

connector sleeve

3.2.1 Indication elements

The line separator has a status indicator. The yellow LED flashes if the line

separator is open or in localization mode.

See also

Setup [J 14]

14

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 15

3.3 Function

The FDCL221 line separator is an electronic switch which is inserted in the

FDnet/C-NET.

The function of the line separator in the FDnet/C-NET loop is to connect sub-stub

lines to the FDnet/C-NET and selectively disconnect them in the event of a shortcircuit. In the event of a short-circuit in the FDnet/C-NET, the line separator

disconnects the negative conductor such that the side not affected by the shortcircuit can continue to be operated.

The FDCL221 line separator has 2 x 2 screw terminals for the FDnet/C-NET.

The status of the line separator is indicated by a yellow LED. The LED flashes if

the line separator is open or in localization mode.

The line separator is installed in the intermediate distributor or directly in the fire

control panel.

Structure and function

15

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 16

Structure and function

3.4 Accessories

3.4.1 Top hat rail TS35

z Standard top hat rail for installing devices

z Width: 35 mm

z Length: 122 mm or 288 mm

z Compatible with:

z Order no. (length 122 mm): BPZ:5644780001

z Order no. (length 288 mm): BPZ:5644230001

3.4.2 Connection terminal DBZ1190-AB

– FDCL221 line separator

– Mounting foot FDCM291

3.4.3 Micro terminal DBZ1190-AA

z For connecting cables

z For T-branches of additional cabling for detector

heating units, sounder base, external alarm

indicators, etc.

z For wire diameters of 1 … 2.5 mm

z 3-pin

z Order no.: BPZ:4942340001

z For connecting cables

z For T-branches of additional cabling for detector

2

heating units, sounder base, external alarm

indicators, etc.

z For wire diameters of 0.28 … 0.5 mm

z 4-pin

z Order no.: BPZ:4677080001

2

16

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 17

4 Planning

Unique detector line topology recognition is ensured if at least one device with a

separating function is present between two sub-stub lines. In this case a line

separator.

If several sub-stub lines are to be activated on one FDnet/C-NET loop, failure of

large numbers of devices must be prevented in the event of a line short-circuit. In

this regard the national regulations must be observed. From a FDnet/C-NET

communication point of view, the line separator is a normal line participant which

occupies one bus address and is visible in the line topology.

The following figures show the common variants of a modernized detector line on

which the FDnet/C-NET devices (T) are installed with integrated line separation

function. The outgoing stub lines A to D are connected to the FDCL221 line

separators via terminal blocks or micro terminals (X).

Planning

Housing FDCL221 line separator in intermediate distributors

1 Intermediate distributor C Sub-stub C

2 FDnet/C-NET loop D Sub-stub D

3 FDCL221 line separator T FDnet/C-NET device

A Sub-stub A X Terminal blocks or micro terminals

B Sub-stub B

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

17

Page 18

Planning

Housing FDCL221 line separator in the control panel

1 Control panel C Sub-stub C

2 FDnet/C-NET loop D Sub-stub D

3 FDCL221 line separator T FDnet/C-NET device

A Sub-stub A X Terminal blocks or micro terminals

B Sub-stub B

4.1 Compatibility

Compatible with all control panels that support the FDnet/C-NET detector line.

For details see 'List of compatibility'.

Mixed operation with other devices on the same detector line is possible without

restrictions.

4.2 Fields of application

The line separator is required in a FDnet/C-NET, where several sub-stub lines

converge at one point. This situation mainly occurs when changing from the old

collective systems to the addressed FDnet/C-NET system.

See also

Function [J 15]

18

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 19

4.3 Positioning

When renewing collective systems, the line separators are installed at points where

several stub lines converge.

The line separator can usually be housed in an intermediate distributor on different

floors.

If all the stub lines are routed individually to the collective control panel, the line

separator is directly installed in the new fire control panel.

4.4 Environmental influences

If the devices are used in industrial applications, consultation with the project

manager is required, since plastics do not withstand certain environmental

conditions.

The following factors must be taken into consideration:

Planning

z Chemicals

z Temperature

z Moisture

The housing is made from plastic and the printed circuit board is sealed with wax

for increased corrosion protection.

See also

Technical data [J 27]

19

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 20

Mounting / Installation

5 Mounting / Installation

5.1 Assembly

The line separator may be fitted in any position. Ensure that the line separator LED

is visible after installation.

You can fit the FDCL221 line separator in various ways:

z Using a top hat rail TS35

z Using the fastening hole

Installation on top hat rail TS35

1

Line separator installation on a top hat rail

1 Pair of terminal blocks

z Attach the line separator to the top hat rail.

If you are fitting several line separators onto the top hat rail at the same time, we

20

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

would recommend using a pair of terminal blocks (at least 3 sets) after each line

separator. This results in a clear and space-saving form of installation.

The terminal blocks must be ordered by the party responsible for installation.

Page 21

Mounting / Installation

The terminal block may feature the following forms of connection:

z Flat 2.8 x 0.8 mm plug-type connection (preferred choice)

z Screw terminals or spring terminals

z Soldered connections

Installation with mounting hole

1

Mounting hole in FDCL221

1 Mounting hole with Ø 4.4 mm

Use a screw to secure the line separator onto a plane surface or use a cable tie to

secure to a grid.

See also

Top hat rail TS35 [J 16]

21

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 22

Mounting / Installation

5.2 Electrical connection

Note the positive and negative connections.

Only connect one wire per terminal. This is the only way of ensuring a problem-

free connection over the device's entire service life.

The connection diagram shows the electrical connection for the FDCL221 line

separator in the FDnet/C-NET using terminal blocks or micro terminals.

1 1

Linie

2 2

3

FDCL221 connection diagram

3

1 Sub-stub 3 Terminal blocks or micro terminals

2 FDnet/C-NET detector line

See also

Shielded cable [J 24]

22

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 23

5.2.1 Wiring

Mounting / Installation

Z Always insert a line separator before a sub-stub line.

1. Use a terminal to connect the line separator to the FDnet/C-NET. The pigtails

are provided with pressed-on 2.8 x 0.8 mm flat connector sleeves in the

factory. Cut off the flat connector sleeves if you don't need them for the

connection.

2. Use the same terminal to connect a sub-stub line to the FDnet/C-NET. The

following diagram shows one possible installation variant where the individual

components are wired.

Wiring the components of an installation variant

A Sub-stub line A 2 Top hat rail TS35

B Sub-stub line B 3 At least 3 sets of terminal blocks

C Sub-stub line C 4

1 FDnet/C-NET detector line:

To the line module or to the next

FDnet/C-NET device

FDnet/C-NET detector line:

From the line module or from the

FDnet/C-NET device

See also

Planning [J 17]

23

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 24

Mounting / Installation

5.2.2 Shielded cable

Shielded cables must be earthed in stars at one point (e.g. on the control panel).

Cable shieldings must be linked with one another using an insulated micro terminal

or connection terminal. The shielding must not touch any extrinsic earthing

potentials or metal parts in the device.

See also

Micro terminal DBZ1190-AA [J 16]

Connection terminal DBZ1190-AB [J 16]

24

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 25

6 Commissioning

From a FDnet/C-NET communication point of view, the line separator FDCL221 is

a line participant which occupies one bus address and is visible in the line

topology.

Commissioning is not mandatory. The procedure for the control panel depends on

the fire detection installation.

Commissioning

25

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 26

Maintenance and troubleshooting

7 Maintenance and troubleshooting

The line separator module is maintenance-free. It monitors itself and has to be

replaced if damaged.

26

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 27

8 Specifications

8.1 Technical data

Detector line

Line separator

External alarm indicators Number of external alarm indicators

Connections Detector line:

Ambient conditions

Operating voltage 12 … 33 V DC

Operating current (quiescent) 250 µA

Maximum current connection factor 1

Quiescent current connection factor 1

Address connection factor 1

Separator connection factor 1

Protocol FDnet/C-NET

Compatibility See 'List of compatibility'

Line voltage:

z Nominal 32 V DC (= V

z Minimum 12 V DC (= V

z Maximum 33 V DC (= V

nom

min

max

)

)

)

Voltage at which the separator opens:

z Minimum 7.5 V DC (= V

z Maximum 10.5 V DC (= V

Permanent current when switches are

Max. 0.5 A (= I

SO min

SO max

C max

)

)

)

closed:

Switching current (e.g. in the event of

Max. 1 A (= I

S max

)

a short-circuit)

Leakage current when switches are

Max. 1 mA (= I

L max

)

open:

Serial impedance when switches are

Max. 0.5 Ω (= Z

C max

)

closed:

None

that can be connected

z Design Strands 500 mm long with pressed-on

2.8 x 0.8 mm flat connector sleeves

z Cable cross section 0.5 mm

Operating temperature/permissible

2

-25 … +70 °C

ambient temperature

Storage temperature -30 … +80 °C

Air humidity ≤95 % rel.

Protection categories according to

IP44

EN 60529 / IEC 60529

Specifications

27

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 28

Specifications

Mechanical data

Standards

Dimensions (L x W x H) 47.5 x 44 x 10 mm

Weight 0,04 kg

Material:

z Housing PC

Colour Transparent

Standards EN 54-17

VdS approvals G204030

LPCB approvals 126ae/01

Certificates 0786-CPD-20449

CE conformity mark Yes

Protection categories IEC 60529

QA Standards z Siemens Standard SN 36350

z ISO 9001

z ISO 9004

8.2 Dimensions

44

10

47.5

4

.

4

Dimensions of FDCL221 line separator

1 Pigtail 0.5 mm2, length = 500 mm, with 2.8 x 0.8 mm flat connector sleeve pressed

on in the factory

8.3 Environmental compatibility

z Reusable materials

z Electronic parts and synthetic materials can be easily separated

z Halogen-free synthetic materials, marked by embossed code

z The synthetic materials used do not generate any toxic substances during

combustion.

Larger synthetic parts are marked in accordance with DIN 4840 and ISO/DIS 1469.

The material codes for basic polymers conform to DIN 728 or ISO 043. This makes

separation for recycling possible.

1

28

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 29

9 Index

Index

A

Attachment

Cable tie, 14

Screw, 14

Top hat rail, 14

C

Compatibility, 18

Compatibility with control panels, 18

Control panel

Installation site, 18

E

Electronic switch

Line separator, 13

I

Installation site

Control panel, 18

Intermediate distributor, 17

Intermediate distributor

Installation site, 17

L

LED

Localization mode, 15

Status indicator, 15

Line separator

Electronic switch, 13

List of compatibility, 6, 18

Localization mode

LED, 15

S

Status indicator

LED, 15

Sub-stub

Stub on detector line loop, 13

T

Top hat rail, 14

29

Building Technologies 007063_e_en_--

Fire Safety & Security Products 09.06.2009

Page 30

Issued by

Siemens Switzerland Ltd

Industry Sector

Building Technologies Division

International Headquarters

Gubelstrasse 22

CH-6301 Zug

Tel. +41 41-724 24 24

www.siemens.com/buildingtechnologies

Document ID 007063_e_en_-- Manual FD20/FD720

Edition 09.06.2009 Register 5

Technical specifications and availability subject to change without notice.

© 2004-2009 Copyright Siemens Building Technologies, Inc.

Loading...

Loading...