Siemens FDCIO223, FDCH221 Installation Manual

Building Technologies

009124 Fire Safety & Security Products

FDCIO223 FDCH221

en Input/output module (Transponder) Housing

de Ein-/Ausgabebaustein (Transponder) Gehäuse

fr Interface d'entrées/sorties (transpondeur) Boîtier

es Módulo de entrada/salida (transpondedor) Carcasa

it Modulo in/out digitali (Transponder) Contenitore

en Installation

de Montage

fr Montage

es Montaje

it Montaggio

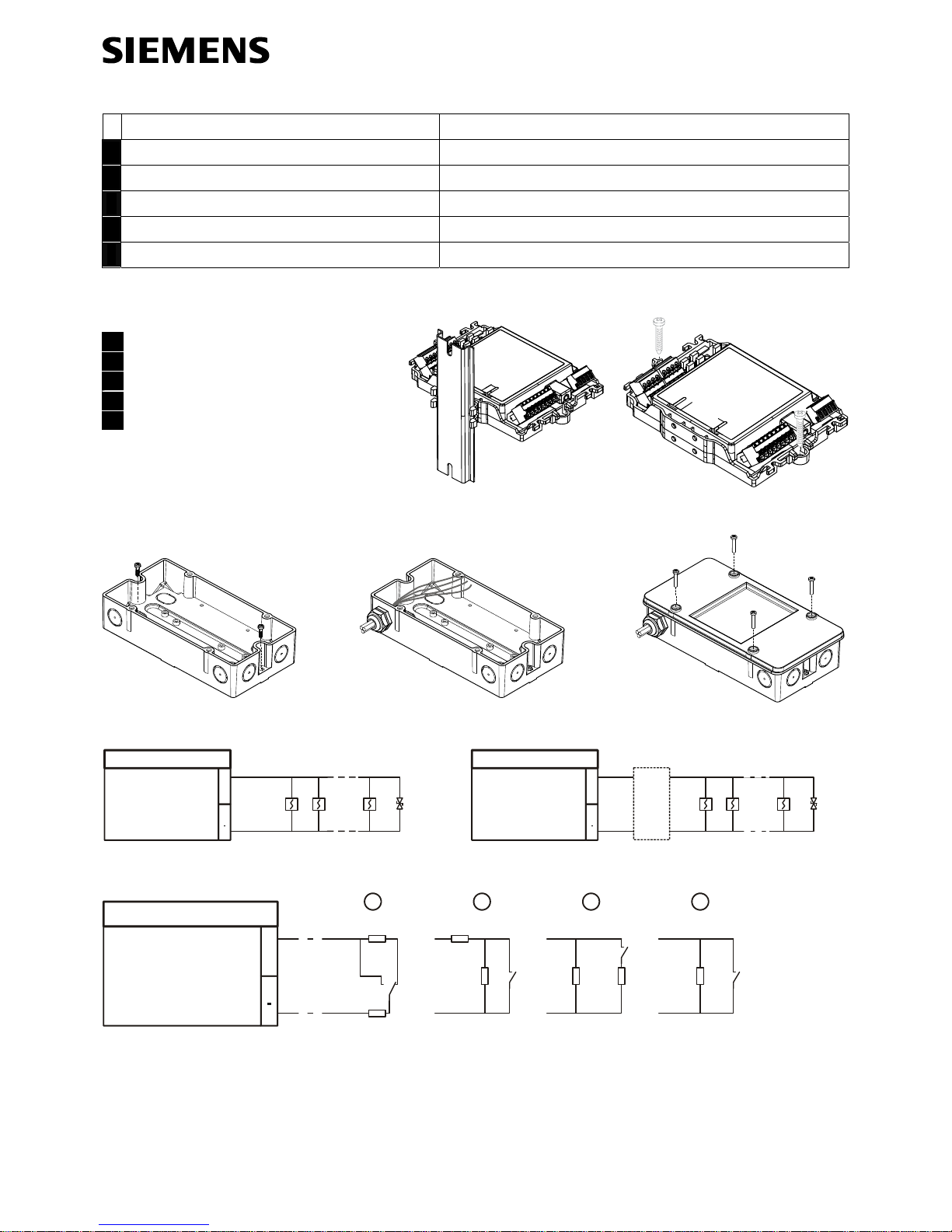

Fig. 1 Fig. 2

Fig. 3 Fig. 4

Fig. 5

+

I/O

FDCIO223

EOL

+

I/O

FDCIO223

SB3

EOL22 (ex)

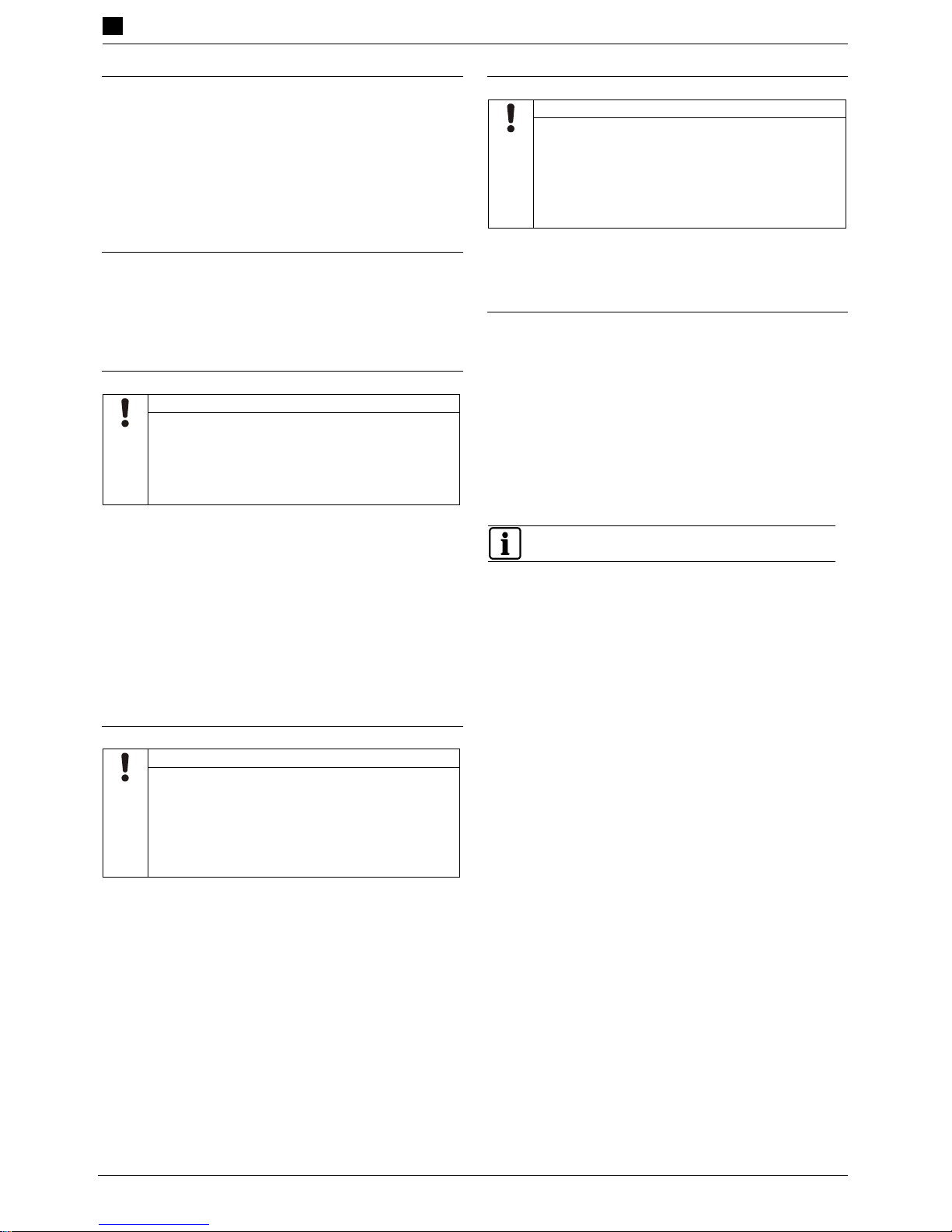

Fig. 6 Fig. 7

+

I/O

FDCIO223

2k7

560

3k3 680

560

2k7

3k3

1 2 3 4

Fig. 8

2

Building Technologies 009124_d_--_-Fire Safety & Security Products 12.2009

24 V

0 V

0 V

3 V

RL = 30 ... 3k3

I/O

FDCIO223

+

2 AT

10 V

0 V

3k3

I/O

FDCIO223

24 V

0 V

+

2 AT

Fig. 9 Fig. 10

Fig. 11

en Legend es Leyenda

Fig. 6 Detector line Fig. 6 Línea de detectores

Fig. 7 Detector line with safety barrier (Ex Zone 1+2) Fig. 7 Línea de detectores con barrera de seguridad (zona Ex

1+2)

Fig. 8 Contact inputs

1 … 3 = monitoring for short-circuit and open line

4 = monitoring for open line

Fig. 8 Entradas de contacto:

1 … 3 = Monitorización en cuanto a cortocircuito y circuito

abierto

4 = Monitorización en cuanto a circuito abierto

Fig. 9 Control output with equality polarity monitoring Fig. 9 Línea de mando con monitorización de la misma polaridad

Fig. 10 Control output with reversed polarity monitoring Fig. 10 Línea de mando con monitorización de polaridad inversa

de Legende it Leggenda

Fig. 6 Melderlinie Fig. 6 Linea di rivelatori

Fig. 7 Melderlinie mit Sicherheitsbarriere (Ex-Zone 1+2) Fig. 7 Linea di rivelatori con barriera di sicurezza (zona Ex 1+2)

Fig. 8 Kontakteingänge:

1 … 3 = Überwachung auf Kurzschluss und Unterbruch

4 = Überwachung auf Unterbruch

Fig. 8 Ingressi contatti:

1 … 3 = monitoraggio per cortocircuiti e interruzioni

4 = monitoraggio per interruzione

Fig. 9 Steuerlinie mit gleichgepolter Überwachung Fig. 9 Linea di pilotaggio con monitoraggio dotato di polarità

uguale

Fig. 10 Steuerlinie mit gegenpoliger Überwachung Fig. 10 Linea di pilotaggio con monitoraggio dotato di polarità

opposta

fr Légende

Fig. 6 Ligne de détection

Fig. 7 Ligne de détection avec barrière à sécurité intrinsèque

(zone Ex 1+2)

Fig. 8 Entrées de contact :

1 à 3 = contrôle de court-circuit et d'interruption

4 = contrôle d'interruption

Fig. 9 Ligne de commande avec surveillance homopolaire

Fig. 10 Ligne de commande avec surveillance de pôles

opposés

3

Building Technologies 009124_d_--_-Fire Safety & Security Products 12.2009

en Installation

Intended use

The in/output module is operated on the FDnet/C-NET. It

has two inputs/outputs. These can be wired as follows:

– Collective detector lines

– Control lines

– Contact input

An optional housing is available to protect against

environmental influences such as wet or damp.

Installing the in/output module

The in/output module can be installed as follows:

– In the housing FDCH221 (Fig. 5)

– On a top hat rail (Fig. 1)

– On an even surface (Fig. 2)

Installation in housing

NOTICE

Module use in a damp, wet or dusty

environment

Damage to module from dust or jet of water

In damp, wet or dusty environments, fit the

module in a housing FDCH221.

1. Open the housing (Fig. 5).

2. Determine the cable entries in the housing and break

these open.

3. Use two screws to fit the housing on a plane surface

(Fig. 3).

4. Secure the M20 x 1.5 cable glands on the housing and

guide in the cables (Fig. 4).

5. Use two M3 x 12 screws to fit the module in the housing

(Fig. 2).

6. Close the housing with the screws provided (Fig. 5).

Procedure with installation on a top hat rail

NOTICE

High temperatures in the module's

environment

Module overheating and damage

A minimum clearance of 1 cm must be

observed between two modules or between

the module and any other boundary.

1. Place two mounting feet in the in/output module.

2. Press the in/output module with the mounting feet

against the top hat rail until it engages (Fig. 1).

Procedure with installation on an even surface

NOTICE

High temperatures in the module's

environment

Module overheating and damage

A minimum clearance of 1 cm must be

observed between two modules or between

the module and any other boundary.

1. Fix the in/output module with two screws on an even

surface (Fig. 2).

Electric connection

1. Connect the cables to the terminals according to the

connection diagram (Fig. 11). Connect only one wire

per terminal.

2. Every control line must be protected with a separate

fuse, with a rating of max. 1.5 or 2 AT.

3. Connect the monitoring resistors or line terminators

(EOL). These must be connected to the end of the line

(Fig. 6 … 10).

4. Connect the cables to the module with cable ties (max.

width 2.6 mm).

For additional information please refer to doc. no. 009122

Loading...

Loading...