Page 1

Global Air Duct Monitoring Housing

Installat ion Instructions

Model FDBZ492-PR

INTRODUCTION Model FDBZ492-PR from Siemens Industry, Inc., is a RoHS

compliant air duct monitoring housing containing sampling

tubes. When used with a Siemens conventional smoke detector,

smoke and combustion products are detected for shutdown of

the duct system and/or operation of supplementary equipment

as provided by the system control panel. The duct unit supports

two sets of Form C alarm contacts, one Form A alarm contact

and one Form C trouble contact. The trouble contact supervises

the presence of the input power, removal of the detector cover

and the removal of the smoke detector head.

TECHNICAL DATA AIR DUCT CONDITIONS

Temperature Range:

With PE-11, 8854, PE-11C: 0

O

C (32OF) - 38OC (100OF)

With OP121: 0

O

C (32OF) - 49OC (120OF)

Altitude Range:

No altitude limitations

Relative Humidity:

Up to 95% RH (non-condensing/non-freezing)

Air Duct Velocity Range:

100-4000 ft/min

Sampling and Exhaust Tube Pressure Differential Range:

Greater than 0.01 and less than 1.2 inches of water column

These airThese air

These airThese air

These air

duct det duct det

duct det duct det

duct det

ectors are designed forectors are designed for

ectors are designed forectors are designed for

ectors are designed for

det det

det det

det

ectect

ectect

ect

ion andion and

ion andion and

ion and

control of products of combustcontrol of products of combust

control of products of combustcontrol of products of combust

control of products of combust

ion in a duct syion in a duct sy

ion in a duct syion in a duct sy

ion in a duct sy

stst

stst

st

em.em.

em.em.

em.

They areThey are

They areThey are

They are

not to be used as a substnot to be used as a subst

not to be used as a substnot to be used as a subst

not to be used as a subst

itit

itit

it

utut

utut

ut

ion forion for

ion forion for

ion for

open area prot open area prot

open area prot open area prot

open area prot

ectect

ectect

ect

ion.ion.

ion.ion.

ion.

DO NODO NO

DO NODO NO

DO NO

T USE air

T USE air

T USE airT USE air

T USE air

duct det duct det

duct det duct det

duct det

ectors with ectors with

ectors with ectors with

ectors with

Alarm Alarm

Alarm Alarm

Alarm

VV

VV

V

erificaterificat

erificaterificat

erificat

ion.ion.

ion.ion.

ion.

ASSEMBLY This detector has a cover tamper (removal) switch. Care should

be taken when installing the cover. Squarely place the cover on

the unit to aviod possible damage to the switch.

DO NODO NO

DO NODO NO

DO NO

T SLIDE COT SLIDE CO

T SLIDE COT SLIDE CO

T SLIDE CO

VER INVER IN

VER INVER IN

VER IN

TT

TT

T

O POSITION.O POSITION.

O POSITION.O POSITION.

O POSITION.

Siemens Siemens

Siemens Siemens

Siemens

IndustryIndustry

IndustryIndustry

Industry

,,

,,

,

Inc. Inc.

Inc. Inc.

Inc.

Building Building

Building Building

Building

TT

TT

T

ecec

ecec

ec

hnologies Dihnologies Di

hnologies Dihnologies Di

hnologies Di

visionvision

visionvision

vision

P/N A6V10330327_a_en

Page 2

P/N A6V10330327_a_en

Siemens Industry, Inc.

Building Technologies Division

2

APPLICATION The FDBZ492-PR duct smoke detectors provide early detection

of smoke and products of combustion present in air moving

through an HVAC duct supply, return, or both. These devices are

designed to prevent the recirculation of smoke in areas by the

air handling system’s fans and blowers and may be used with

fire alarm systems that shut down complete air handling system

in the event of smoke detection.

FF

FF

F

oror

oror

or

the cor the cor

the cor the cor

the cor

rect instrect inst

rect instrect inst

rect inst

allatallat

allatallat

allat

ion of a duct smokion of a duct smok

ion of a duct smokion of a duct smok

ion of a duct smok

e unit please refere unit please refer

e unit please refere unit please refer

e unit please refer

to NFPto NFP

to NFPto NFP

to NFP

A 72 (NatA 72 (Nat

A 72 (NatA 72 (Nat

A 72 (Nat

ional Fire ional Fire

ional Fire ional Fire

ional Fire

Alarm Code),Alarm Code),

Alarm Code),Alarm Code),

Alarm Code),

NFP NFP

NFP NFP

NFP

A 90A (StA 90A (St

A 90A (StA 90A (St

A 90A (St

andardandard

andardandard

andard

forfor

forfor

for

Inst Inst

Inst Inst

Inst

allatallat

allatallat

allat

ion of ion of

ion of ion of

ion of

AirAir

AirAir

Air

Condit Condit

Condit Condit

Condit

ioning and

ioning and

ioning and ioning and

ioning and

VV

VV

V

entent

entent

ent

ilatilat

ilatilat

ilat

ion Sion S

ion Sion S

ion S

yy

yy

y

stst

stst

st

ems),ems),

ems),ems),

ems),

and NFPand NFP

and NFPand NFP

and NFP

A 92A (RA 92A (R

A 92A (RA 92A (R

A 92A (R

ecommended Pecommended P

ecommended Pecommended P

ecommended P

ractract

ractract

ract

ice forice for

ice forice for

ice for

Smok Smok

Smok Smok

Smok

e Controle Control

e Controle Control

e Control

SS

SS

S

yy

yy

y

stst

stst

st

ems).ems).

ems).ems).

ems).

This unit is not intended for open area protection nor should it

be used for early warning detection or to replace a regular fire

detection system.

OPERATION When the Model FDBZ492-PR is operating, a sample of air is

drawn from the duct and passed through the sampling chamber by

means of the input sampling tube. The air sample passes through

the smoke detector mounted in the duct housing and is exhausted

back into the duct through the outlet tube.

• The FDBZ492-PR supports two sets of Form C alarm

contacts, one Form A alarm contact and one Form C trouble

contact. The trouble contact supervises the presence of the

input power, removal of the detector cover and the removal

of the smoke detector head.

• The FDBZ492-PR contains a green power on LED, red alarm

LED and yellow trouble LED which are visible through the

housing cover.

• The trouble LED is activated when either the housing cover

or smoke detector is removed from the unit.

• When the trouble LED is activated, the power LED turns off.

• A reset/test switch is located on the housing cover and is

used to reset the unit after an alarm and the smoke

condition is cleared. When not in alarm, the reset/test

switch can be used to test that the unit will operate

properly when an alarm condition exists.

The trouble contacts will not operate in the event of a smoke alarm.

The FDBZ492-PR duct detector will operate from various input

voltage sources; namely 24VAC, 24VDC, 115VAC and 230VAC.

Page 3

Siemens Industry, Inc.

Building Technologies Division

3 P/N A6V10330327_a_en

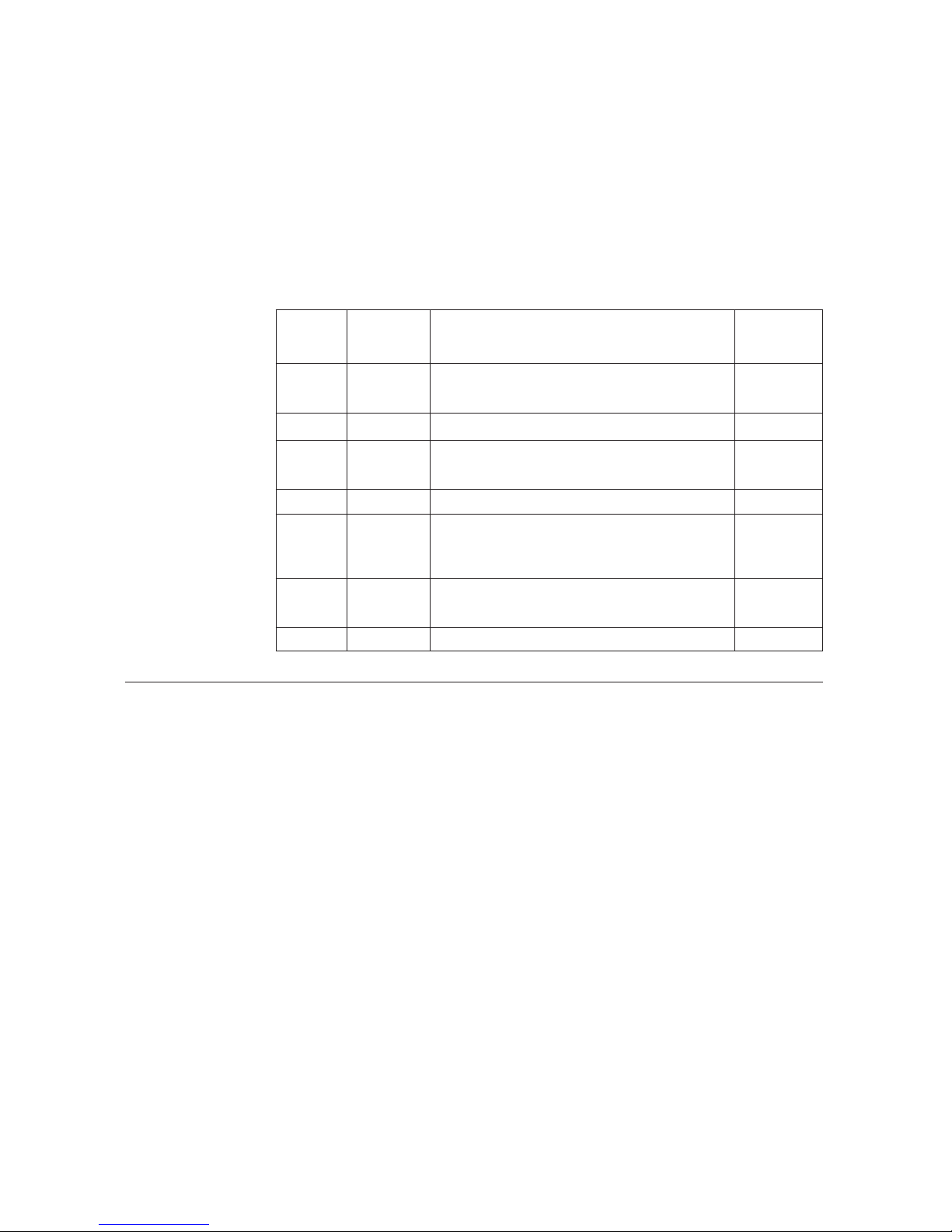

Detector LED The FDBZ492-PR contains an LED indicator (located on the

smoke detector) capable of flashing either one of three distinct

colors: green, yellow, or red. During each flash interval, the

microprocessor based detector checks the following:

• for smoke in its sensing chamber

• that its critical smoke sensing electronics are operating.

Based on the results of these checks, the LED indicator flashes

as follows:

rotceteD

hsalF

roloCnoitidnoC

hsalF

lavretnI

)sdnoceS(

11-EP

4588

C11-EP

neerG.noitarepoyrosivrepuslamroN7

121POnee

rG.noitarepoyrosivrepuslamroN01

11-EP

4588

C11-EP

wolleY

siro)riaperrogninaelc(ecivresseriuqerrotceteD

.snoit

acificepslatnemnorivnestidnoyebgnitarepo

03-7

121POwolleY.tnemecalpersdeendnaelbuortnisirotceteD5

11-EP

4588

C11-EP

121PO

deRmralA½2

11-EP

4588

C11-EP

sehsalFoN.riaperseriuqerroderewoptonsirotceteD__

121POsehsalFoNroderewop

tonsirotceteDdedeensitnemecalper.__

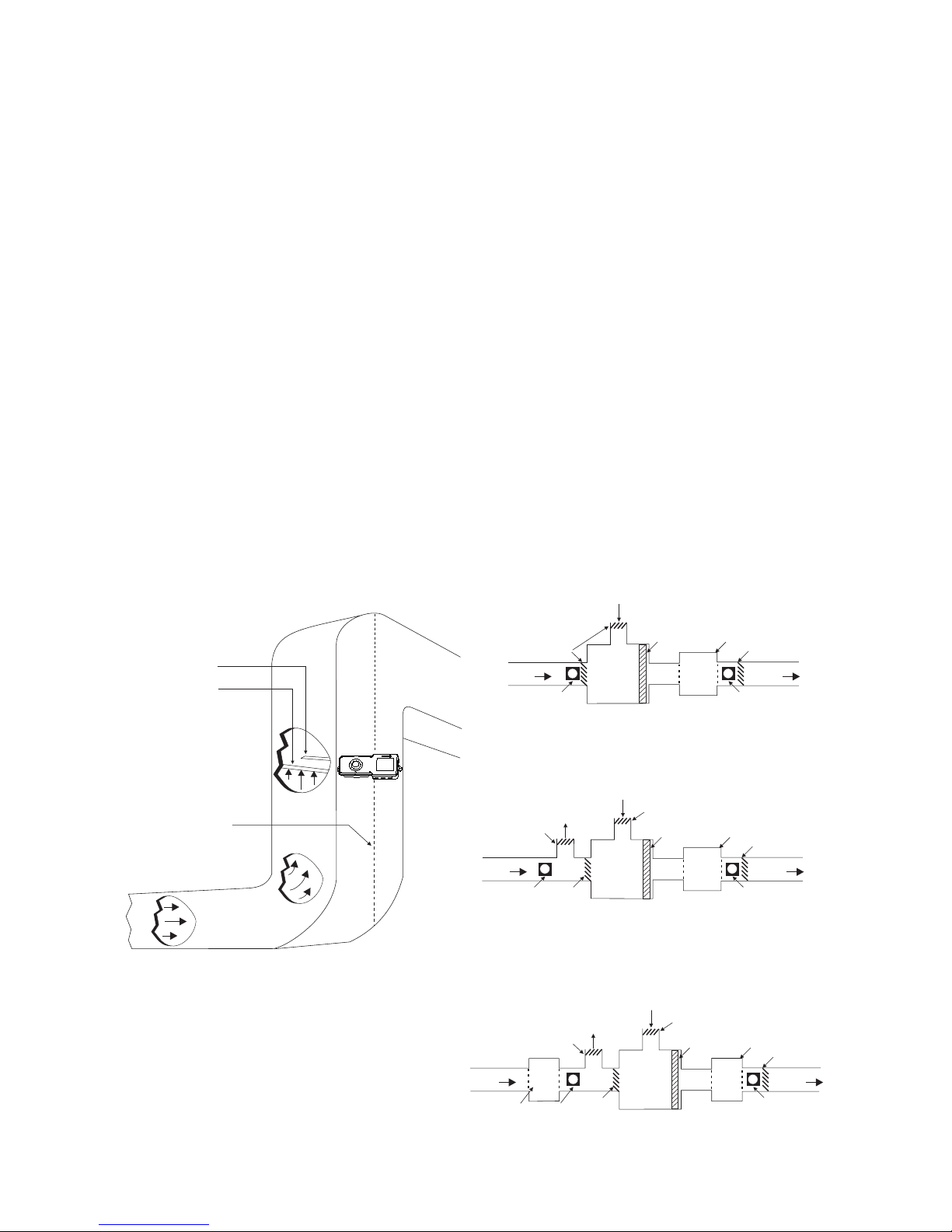

MOUNTING THE AIR DUCT HOUSING

Location on Duct System

This guideline contains general information on duct smoke

detector installation, but does not preclude the NFPA documents listed. Siemens Industry, Inc. assumes no responsibility

for improperly installed duct detectors. To determine the correct

installation position for an FDBZ492-PR duct smoke detector, the

following factors must be considered.

1) A uniform non-turbulent (laminar) airflow between 100 ft/

min. to 5,000 ft/min. must be present in the HVAC duct. To

determine duct velocities, examine the engineering

specifications that define the expected velocities or use an

Alnor model 6000AP velocity meter (or equivalent).

2) To minimize the impact of air turbulence and stratification

on performance, a duct smoke detector should be located

as far as possible downstream from any obstruction (i.e.

deflector plates, elbows, dampers, etc.). In all situations,

Page 4

P/N A6V10330327_a_en

Siemens Industry, Inc.

Building Technologies Division

4

confirmation of velocity and pressure differential within

specifications is required.

The pressure differential between the input sampling (high

pressure) tube and outlet (low pressure) tube for the

FDBZ492-PR smoke duct detector should be greater than

0.01 inches of water and less than 1.2 inches of water.

3) Identify a code compliant location (supply or return side, or

both) for the installation of the duct unit that will permit

easy access for viewing and serviceability.

4) When installing on the return side, install duct units prior to

the air being exhausted from the building or diluted with

outside “fresh” air.

5) When installing duct smoke units downstream of filters,

fires occurring in the filters will be detected, but if the filters

become blocked, insufficient air flow through the duct unit

will prevent the correct operation of the duct detector. Duct

units installed in the supply air side may monitor upstream

equipment and/or filters.

Figure 2

Recommended Locations in Duct Systems

RETURN

AIR

SUPPLY

AIR

AIR DUCT

HOUSING

AIR DUCT

HOUSING

DAMPER

BLOWER

FILTER

PLENUM

FRESH AIR INTAKE

DAMPER

TYPE A: CLOSED SYSTEM - NO EXHAUST

D D

TYPE B: PROVISION FOR EXHAUSTING

SOME PERCENTAGE OF RETURN AIR

RETURN

AIR

SUPPLY

AIR

AIR DUCT

HOUSING

AIR DUCT

HOUSING

DAMPER

DAMPER

BLOWER

FILTER

PLENUM

FRESH AIR INTAKE

DAMPER

D D

EXHAUST AIR

OUTPUT

DAMPER

TYPE C: RETURN AIR UNDER POSITIVE PRESSURE

FROM SEPARATE BLOWER

EXHAUST AIR

OUTPUT

DAMPER

RETURN

AIR

SUPPLY

AIR

AIR DUCT

HOUSING

RETURN AIR

BLOWER

AIR DUCT

HOUSING

DAMPER

DAMPER

BLOWER

FILTER

PLENUM

FRESH AIR INTAKE

DAMPER

D D

Figure 1

Typical Mounting of Duct Housing

OUTLET

TUBE

INPUT

SAMPLING

TUBE

CENTER

LINE

OF DUCT

C

L

Page 5

Siemens Industry, Inc.

Building Technologies Division

5 P/N A6V10330327_a_en

6) Where possible, install duct detectors upstream of air

humidifiers and downstream of dehumidifiers.

7) To prevent false alarms, the duct detector should not be

mounted in areas of extreme high or low temperatures, in

areas where high humidity exists, or in areas where the

duct may contain gases or excessive dust.

Duct Preparation The FDBZ492-PR Housings come with an installation kit that

contains the following items:

• Short return (outlet) tube

• Input sampling tube stopper

• Two #12 x

3

/4” sheet metal screws

• Mounting template (packaged separately)

Remove mounting template. Remove paper backing from the

mounting template and affix it to the duct at the desired

location. Using the template as a guide, drill (2) mounting holes,

3/32" (2.5mm) for the #12 X

3

/4” sheet metal screws packaged in

the installation kit. Drill or punch (2) 1¼” (32mm) holes for input

sampling and outlet tubes, using the template as a guide. Clean

all holes.

Sampling Tube Installation

The FDBZ492-PR duct smoke detectors use a specially notched

sampling tube, which may be ordered separately in one of four

standard lengths.

ST-10 For duct widths of 6" to 1.0’

ST-25 For duct widths of 1.0’ to 3.0’

ST-50 For duct widths of 3.0’ to 5.0 (requires support)

ST-100* For duct widths of 5.0’ to 10.0’ (requires support)

*

This model is supplied as two 5 ft. sections with a coupling.

Assembly is required for installation.

EacEac

EacEac

Eac

h model is manufacth model is manufact

h model is manufacth model is manufact

h model is manufact

ured with a difured with a dif

ured with a difured with a dif

ured with a dif

ferent numberferent number

ferent numberferent number

ferent number

and and

and and

and

sizsiz

sizsiz

siz

e of sampling holes.e of sampling holes.

e of sampling holes.e of sampling holes.

e of sampling holes.

Only the specific t Only the specific t

Only the specific t Only the specific t

Only the specific t

ube must be usedube must be used

ube must be usedube must be used

ube must be used

for the specified duct width.for the specified duct width.

for the specified duct width.for the specified duct width.

for the specified duct width.

Standard sampling tubes are steel tubes with air intake holes

drilled the entire length of the tube. These tubes can be cut to

length and must span at least 80% the width of the duct.

Sampling tubes over 3.0’ must be supported on the opposite

side of the duct. To ensure the correct operation, the red stopper

(stopper in installation kit) must be inserted in the end of the air

input sampling tube. If the input tube protrudes through the

opposite side of the duct, the opening around the tube must be

Page 6

P/N A6V10330327_a_en

Siemens Industry, Inc.

Building Technologies Division

6

sealed. For custom duct widths, always use the next longest

standard size and cut down to the exact requirement.

Once the airflow direction has been determined (refer to Figure

3), insert the input and outlet tubes into the duct housing.

1. Remove the cover from the housing.

2. Loosen the screw and rotate the tube retainer until the

input tube is inserted and oriented properly. Ensure that the

notched end of the tube is inside the housing and that the

air input sampling tube is positioned so that the input holes

are directly facing the airflow.

3. Once the tube is installed, rotate the retainer back into

place and tighten screw.

4. Install the outlet tube in the remaining position. Once the

tube is installed, rotate the retainer back into place and

tighten screw.

Mounting After securing the input and outlet tubes to the duct smoke unit,

(or initially placing the tubes through the 1¼” holes drilled or

punched in the HVAC duct to accept the input and outlet tubes

and then attaching them to the duct unit), hold the duct unit

assembly in position and use (2) # 12 X

3

/4” sheet metal screws

(packaged in the installation kit) to secure the duct smoke

detector to the HVAC duct sheet metal.

INPUT

TUBE HOLES

FACE AIR FLOW

INSERT RED STOPPER

THIS END OF INPUT

TUBE

OUTLET

TUBE INSTALLED

DOWNSTREAM OF AIRFLOW

DO NOT INSERT RED STOPPER

AIR FLOW DIRECTION

DUCT WIDTH

TUBE SUPPORT ONLY FOR DUCTS GREATER THAN 3 FEET WIDE

NOTE: Mountings shown

are typical. Detectors can

be installed side, bottom

or top of duct as long as

proper tube operation and

flow/pressure performance

is maintained.

Figure 3

Sampling Tube Orientation

Page 7

Siemens Industry, Inc.

Building Technologies Division

7 P/N A6V10330327_a_en

Air Duct Sampling Tube Pressure Measurement

The Model PDM-3 Pressure Differential Measuring device

should be used to ensure that the sampling tube pressure

differential is within the specified limits. The differential pressure

between the two tubes should be greater than 0.01 inches of

water and less than 1.2 inches of water. Qualified personnel

should take measurements in accordance with the PDM-3

instructions, P/N 315-085535.

WIRING Conduit Knockouts

To remove plastic knockout, first cut the plastic tab on the

specific knockout. Refer to Figure 4 to locate the tab. Then,

using a screw driver placed at the tab location, tap with a

hammer until the knockout breaks out. Clean the hole before

installing conduit.

3/4” KNOCKOUTS

1/2” KNOCKOUT

PLASTIC

TAB

Figure 4

Removing the Knockouts

Wiring FDBZ492-PR terminal wiring connections are shown in Figure 5.

Note any limitations on the number of detectors and restrictions on

the use of remote devices permitted for each circuit.

Do not use looped wire underDo not use looped wire under

Do not use looped wire underDo not use looped wire under

Do not use looped wire under

t t

t t

t

erminals.erminals.

erminals.erminals.

erminals.

Break wire run to Break wire run to

Break wire run to Break wire run to

Break wire run to

propro

propro

pro

vide forvide for

vide forvide for

vide for

proper proper

proper proper

proper

supervision of connect supervision of connect

supervision of connect supervision of connect

supervision of connect

ions.ions.

ions.ions.

ions.

With detector head removed, connect one of the appropriate

dedicated power sources to the applicable terminals (Refer to

Figure 5). Replace detector head and depress the cover removal

switch (SW1) on the PCB assembly and the unit will be energized. The green power LED will be illuminated, and when

pressing the test/reset button (SW2) on the PCB assembly, the

red alarm LED will be illuminated. This test confirms the correct

basic operation of the duct smoke unit, excluding the detector

head (see functional testing).

Wire the FDBZ492-PR as a stand alone unit as shown in Figure 6.

Wire the FDBZ492-PR as part of a FACP as shown in Figure 7.

Wire the FDBZ492-PR accessories as shown in Figures 7 and 8.

Page 8

P/N A6V10330327_a_en

Siemens Industry, Inc.

Building Technologies Division

8

FAN SUPPLY SOURCE

NC*

NO*

COM*

ALARM RELAY

*See Figure 5 for

terminal block

connections

Figure 5

Wiring the FDBZ492-PR

TB7

TB8

25

24

23

21 22

TB10

TB9

987321654

19

20

18

17

16

15

14

13

12

1110

Figure 6

Stand Alone Wiring the FDBZ492-PR

GNIRIWRP-294ZBDF

LANIMRET

NEERCSKLIS

GNIKRAM

NOITCNUFNOITCENNOC

9BT

1

1YALERMRALA

CNdetcetedekomsnehwdenepO-tcatnocCN-yaler1mralA

2MOCtcatnocMOC-yaler1mralA

3ONdetcetedekomsne

hwdesolC-tcatnocON-yaler1mralA

4

2YALERMRALA

CNdetcetedekomsnehwdenepO-tcatnocCN-yaler2mralA

5MOCtcatnocMOC-

yaler2mralA

6ONdetcetedekomsnehwdesolC-tcatnocON-yaler2mralA

7

ELBUORT

CNedomybdnatslamronnidesolC-tcatnocCN

-yalerelbuorT

8MOCtcatnocMOC-yalerelbuorT

9ONedomybdnatslamronninepO-tcatnocON-yalerelbuorT

01BT

01

/TCENNOCRE

TNI

ETOMER

SEIROSSECCA

TNC-LTRtsetotCDV42ylppA-mralatseT

11+BT elbuortstcetedtinunehwCDV42+-setomerroftuptuo

elbuorttnerrucwoL

21-LTR/-CdnuorG

31+LTR/+CtuptuoCDV42

411LAdetcetedekomsnehwCDV42+-tuptuomralatnerruchgiH

51+LA

detcetedekomsnehwCDV42+-setomerroftuptuomralatnerrucwoL

61+PdevomerrevocrodaehnehwtuC-setomerottuorewoP

7

1+R/TteserrotsetotCDV42ylppA-tupniteseR/tseT

81+CtuptuoCDV42

91

PCAF

MOCtcatnocMOC-yaleRlenaPlortnoCmralAeriF

0

2ON edomybdnatslamronninepO-tcatnocON-yaleRlenaPlortnoCmralAeriF

8BT

12

REWOPTUPNI

CD/CA42evitisopCDV42rotoH

CAV42-tupnirewoP

22O/NevitagenCDV42rolartueNCAV42-tupnirewoP

7BT

32N lartueNCA-tupnirewoP

42511toHCAV511-tupnire

woP

52032toHCAV032-tupnirewoP

Page 9

Siemens Industry, Inc.

Building Technologies Division

9 P/N A6V10330327_a_en

Figure 7

Wiring the FDBZ492-PR to a Fire Alarm Control Panel

Figure 8

FDBZ492-PR Remote Accessory Wiring

FDBZ492-PR

UL Listed

Conventional

Fire Alarm

Control Panel

FDBZ492-PR

N.C. TROUBLE

CONTACT

N.C. TROUBLE

CONTACT

N.O. ALARM

CONTACT

N.O. ALARM

CONTACT

SAMPLE CONTROL PANEL WIRING - STYLE D / CLASS A IDC )*

(Supervised - A fault condition will not inhibit an alarm response

*See Figure 5 for terminal block connections

FDBZ492-PR

UL Listed

Conventional

Fire Alarm

Control Panel

FDBZ492-PR

N.C. TROUBLE

CONTACT

N.C. TROUBLE

CONTACT

N.O. ALARM

CONTACT

N.O. ALARM

CONTACT

SAMPLE CONTROL PANEL WIRING - STYLE B / CLASS B IDC

(Supervised - A fault condition will not inhibit an alarm response)*

*See Figure 5 for terminal block connections

EOL

End

of

Line

for

Specific

FACP

FDBZ492-PR*

FDBZ492-RTL

C-/RTL-

GREEN/

RED

LED

RTL-CNT

C+/RTL+

KEY

SWITCH

(NORMAL/TEST)

5

6

1b

*

See Figure 5 for

terminal block

connections

AL1

AL1

FACP

NO

FACP

NO

C

-

C-

C+

C+

FACP

COM

FACP

COM

+

-

+

-

FDBZ492-PR

#1

FDBZ492-PR

#X

All alarm relays operate with single alarm.

Individual horn/strobe units operate on

alarmed detector only. 30 detectors max.

FDBZ492-PR#1FDBZ492-PR

#X

T/R+

T/R+

C+

C+

Common test/reset. 30 detectors max.

(Use normally open test/reset switch.)

TEST/RESET

SWITCH

FDBZ492-PR

#1

FDBZ492-PR

#X

AL1

AL1

C

+

C

+

All alarm relays operate with

single alarm. 30 detectors max.

A common power supply must be used for all

interconnected detectors.

INTERCONNECTION WIRING FOR COMMON FUNCTIONS*

*See Figure 5 for terminal block connections

AL1

AL1

C

-

C

-

C

+

C

+

+

-

+

-

FDBZ492-PR

#1

FDBZ492-PR

#X

All alarm relays operate with single

alarm. All horn/strobe units operate

as well. 10 detectors max.

Page 10

P/N A6V10330327_a_en

Siemens Industry, Inc.

Building Technologies Division

10

In the event of a fire alarm, certain equipment may be required

to be shut down. For example, shut down may be achieved by

interrupting the fan supply source to that particular piece of

equipment when wired as indicated in Figure 6.

Installation Of Smoke Detectors

To Install:

• Remove cover by loosening the four screws. Take off the

cover and set it aside.

• Align detector with base and insert detector.

• Rotate detector

clockwise while gently pressing on it until

the detector drops fully into base.

• Then rotate the detector clockwise until it stops and snaps

in place.

• Replace cover and tighten the four screws.

To Remove:

• Rotate the detector counterclockwise until stop is reached.

• Pull detector out of base.

TESTING Only qualified service personnel should test these units. To

assure proper operation of the detector and control panel, both

the Sensitivity and the Functional tests should be conducted.

The minimum test schedule may be found in the current edition

of NFPA 72 for installations in the U.S

Sensitivity Test The detectors monitor their smoke sensitivity automatically and

require no test equipment. A green flash of the detector LED or

in the FDBZ492-RTL Remote Accessory indicates that the

smoke sensitivity is within its listed limits.

Functional Test Smoke Testing

Using TG-11 smoke test canister with testing nozzle model

AD-TGN (purchased separately) available from Siemens Industry,

Inc., insert the test gas nozzle into the hole in the red plug in the

unit cover. Press can against cover for about

1

/2 second to

release gas into the chamber.

Do not spraDo not spra

Do not spraDo not spra

Do not spra

y gy g

y gy g

y g

as foras for

as foras for

as for

more than ½ second. more than ½ second.

more than ½ second. more than ½ second.

more than ½ second.

Overuse of t Overuse of t

Overuse of t Overuse of t

Overuse of t

estest

estest

est

gg

gg

g

as maas ma

as maas ma

as ma

y result in dety result in det

y result in dety result in det

y result in det

ectorector

ectorector

ector

cont cont

cont cont

cont

aminataminat

aminataminat

aminat

ion.ion.

ion.ion.

ion.

After 15 to 20 seconds the detector will go into alarm, illuminating the detector LED and causing the duct unit functions to

operate; alarm relays will change state, and the alarm related

remote accessories, if attached, will function.

Page 11

Siemens Industry, Inc.

Building Technologies Division

11 P/N A6V10330327_a_en

If no test gas is available to conduct functional testing, remove

cover and, while holding down the cover removal switch, blow

smoke from a smoldering cotton wick or punk directly at the

head to cause an alarm. The alarm indicator on the detector

should illuminate within one minute.

Refer to the PE-11 Installation Instructions, P/N 315-094198, the

PE-11C Installation Instructions, P/N 315-095626, the 8854

Installation Instructions, P/N 315-094198FA, or the OP121

Installation Instructions, P/N A6V10281367, as applicable, for

additional information on testing these detectors.

MAINTENANCE This unit is equipped with cover removal switch (SW1) that

instantly provides a trouble condition upon removal of the clear

cover. For all testing and inspection with the cover removed, the

cover removal switch (designated as SW1 on PCB) must be

manually depressed to simulate normal operation.

The performance of the air duct detector unit may be adversely

affected by dirt or foreign matter on the sampling tubes or

detector. If the air holes in the input sampling tube become

restricted, the unit cannot receive a proper air sample, and

performance is impaired. It is recommended that the sampling

tubes be checked and cleaned periodically. The detector maintenance program should consist of periodic cleaning of dust from

the detector head by using a vacuum cleaner. For cleaning, refer

to the PE-11 Installation Instructions, P/N 315-094198, the PE-11C

Installation Instructions, P/N 315-095626, or the 8854 Installation

Instructions, P/N 315-094198FA.

UnderUnder

UnderUnder

Under

no circumst no circumst

no circumst no circumst

no circumst

ances is the OP1ances is the OP1

ances is the OP1ances is the OP1

ances is the OP1

21 det21 det

21 det21 det

21 det

ectorector

ectorector

ector

head to be head to be

head to be head to be

head to be

disassembled.disassembled.

disassembled.disassembled.

disassembled.

No repairs or No repairs or

No repairs or No repairs or

No repairs or

cleaning should be at cleaning should be at

cleaning should be at cleaning should be at

cleaning should be at

tt

tt

t

emptempt

emptempt

empt

ed.ed.

ed.ed.

ed.

The cleaning and test program is recommended for 6 month

intervals, or more frequently, if needed, depending on the

individual detector environment. Consult your local code and

AHJ requirements for required maintenance schedules.

UnderUnder

UnderUnder

Under

no circumst no circumst

no circumst no circumst

no circumst

ances is the detances is the det

ances is the detances is the det

ances is the det

ectorector

ectorector

ector

por por

por por

por

tt

tt

t

ion of the PE-1ion of the PE-1

ion of the PE-1ion of the PE-1

ion of the PE-1

11

11

1

,,

,,

,

PE-1PE-1

PE-1PE-1

PE-1

1C or1C or

1C or1C or

1C or

8853 to be disassembled by an 8853 to be disassembled by an

8853 to be disassembled by an 8853 to be disassembled by an

8853 to be disassembled by an

yy

yy

y

one otherone other

one otherone other

one other

than an than an

than an than an

than an

authorizauthoriz

authorizauthoriz

authoriz

ed Siemens Industryed Siemens Industry

ed Siemens Industryed Siemens Industry

ed Siemens Industry

,,

,,

,

Inc. Inc.

Inc. Inc.

Inc.

S S

S S

S

y

y

yy

y

stst

stst

st

ems ems

ems ems

ems

TT

TT

T

ecec

ecec

ec

hnician.hnician.

hnician.hnician.

hnician.

F F

F F

F

oror

oror

or

service,service,

service,service,

service,

cont cont

cont cont

cont

act yact y

act yact y

act y

ourour

ourour

our

nearest authoriz nearest authoriz

nearest authoriz nearest authoriz

nearest authoriz

ed Siemens Industryed Siemens Industry

ed Siemens Industryed Siemens Industry

ed Siemens Industry

,,

,,

,

Inc.Inc.

Inc.Inc.

Inc.

S S

S S

S

ervice Rervice R

ervice Rervice R

ervice R

epresentepresent

epresentepresent

epresent

atat

atat

at

ii

ii

i

ve.ve.

ve.ve.

ve.

If the fire alarm syIf the fire alarm sy

If the fire alarm syIf the fire alarm sy

If the fire alarm sy

stst

stst

st

em is connectem is connect

em is connectem is connect

em is connect

ed to a central sted to a central st

ed to a central sted to a central st

ed to a central st

atat

atat

at

ion orion or

ion orion or

ion or

fire fire

fire fire

fire

depardepar

depardepar

depar

tment,tment,

tment,tment,

tment,

or or

or or

or

operat operat

operat operat

operat

es extes ext

es extes ext

es ext

ernal devices sucernal devices suc

ernal devices sucernal devices suc

ernal devices suc

h as fans,h as fans,

h as fans,h as fans,

h as fans,

ext ext

ext ext

ext

in-in-

in-in-

in-

guishers,guishers,

guishers,guishers,

guishers,

etc., etc.,

etc., etc.,

etc.,

connect connect

connect connect

connect

ed,ed,

ed,ed,

ed,

not

not

not not

not

ify appropriatify appropriat

ify appropriatify appropriat

ify appropriat

e personnel ande personnel and

e personnel ande personnel and

e personnel and

disconnect the extdisconnect the ext

disconnect the extdisconnect the ext

disconnect the ext

ernal devices unternal devices unt

ernal devices unternal devices unt

ernal devices unt

il all til all t

il all til all t

il all t

ests are completests are complet

ests are completests are complet

ests are complet

ed.ed.

ed.ed.

ed.

AfAf

AfAf

Af

tt

tt

t

erer

erer

er

t t

t t

t

estest

estest

est

ing,ing,

ing,ing,

ing,

reset the sy reset the sy

reset the sy reset the sy

reset the sy

stst

stst

st

em,em,

em,em,

em,

reconnect the devices, reconnect the devices,

reconnect the devices, reconnect the devices,

reconnect the devices,

and not and not

and not and not

and not

ifyify

ifyify

ify

the personnel that the sythe personnel that the sy

the personnel that the sythe personnel that the sy

the personnel that the sy

stst

stst

st

em is operatem is operat

em is operatem is operat

em is operat

ing aging ag

ing aging ag

ing ag

ain.ain.

ain.ain.

ain.

Page 12

REMOTE ACCESSORIES

The accessories available for use with FDBZ492-PR are:

SEIROSSECCAETOMER

TOLIP

DEL

)neerG(

MRALA

DEL

)deR(

ELBUORT

DEL

)wolleY(

NROH

SGNITARLACIRTCELE

LEDOM/REBMUNTRAPNOITPIRCSED

YBDNATSMRALAELBUORT

-72S-91345S

LTR-294ZBDF/1A

detarepo-yek,toliP,mralAetomeR

hctiwSteseR/tseT

••

Am2.0Am2.0Am0

SAGTSETEKOMS

057946-005saGtseTrotceteD11-GT

717946-005tiKelzzoNsaGtseTNGT-DA

DAEHROTCETEDEKOMS

0

51490-005rotceteDekomScirtceleotohP11-EP

036590-005rotceteDekomScirtceleotohPC11-EP

AF051490-005rotceteDekomScirtceleotohP4588

1A-1F-27345SrotceteDekomScirtceleotohP121PO

GNISUOHTHGITRETAW

1A-62B-345STW-294ZBDF

COMPATIBLE CONTROL EQUIPMENT

ROTCETED121PO/4588/C11-/11-EPGNISURP-294ZBDF

tnempiuqEeludoM

reifitnedIytilibitapmoC

/noitallatsnIeludoM

snoitcurtsnIgniriW

)SLX-redniFeriF(4-CDC 8-001430-513N/P

)3METSYS(53-PC 22-209480-513N/P

)QI-LXM,LXM(6B1-

MZC* 9-553590-513N/P

)QI-LXM,LXM(4-MZC 01-628090-513N/P

MZH )109CF,429CF,229CF,5002CF,5202CF,0502CF,052-S

F,SLX-redniFeriF( 6-058430-513N/P

XE-LXS 8-799590-513N/P

)XE-LXS(X4-EZS 8-810690-513N/P

)XE-LXS(XA8-EZS 8

-220690-513N/P

)C052-SF(MZS* 4-C058430-513N/P

)3METSYS(53-UZ 81-222380-513N/P

)0007-CPM/0006-CPM(5078 8-90

3744-513N/P

ELECTRICAL RATINGS

4588DNAC11-EP,11-EP

egatloVCDV72-61

elppiRkaep-ot-kaepV3

tnerruCyrosivrepuS.xamAu011

emiTpu-tratS.xamsdnoces0

5

tnerruCmralAAm05-33

121PO

egatloVCDV72-61

elppiRkaep-ot-kaepV3

tnerruCyrosivrepuS.xamAu011

emiTpu-tratS.xamsdnoces03

tnerruCmralAAm

05-03

Siemens Industry, Inc.

Building Technologies Division

Florham Park, NJ

P/N A6V10330327_a_enSiemens Canada Limited

Building Technologies Division

2 Kenview Boulevard

Brampton, Ontario L6T 5E4 Canada

RP-294ZBDF

TUPNI

TNERRUC

TNERRUCYBDNATS

)lacipyT(

TNERRUCMRALA

)lacipyT(

TNERRUCELBUORT

)lacipyT(

CDV42Am92Am321A

m02

zH06@CAV42Am08Am372Am56

zH06@CAV511Am62Am75Am53

zH06@CAV032Am03Am83Am02

Loading...

Loading...