Page 1

A6V10334410_h_en_--

Building Technologies

2015

FDA241, FDA221

Aspirating Smoke Detector

Technical Manual

-09-29 Control Products and Systems

Page 2

Legal notice

2

Legal notice

Technical specifications and availability subject to change without notice.

© Siemens Switzerland Ltd, 2011

Transmittal, reproduction, dissemination and/or editing of this document as well as

utilization of its contents and communication thereof to others without express

authorization are prohibited. Offenders will be held liable for payment of damages.

All rights created by patent grant or registration of a utility model or design patent

are reserved.

Issued by:

Siemens Switzerland Ltd.

Building Technologies Division

International Headquarters

Gubelstrasse 22

CH-6301 Zug

Tel. +41 41 724-2424

www.siemens.com/buildingtechnologies

Edition: 2015-09-29

Document ID: A6V10334410_h_en_--

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 3

3

Table of contents

1 About this document ......................................................................................7

1.1 App l icabl e document s .......................................................................................9

1.2 Downl oad center ...............................................................................................9

1.3 Techn ical ter ms ..............................................................................................10

1.4 Revision history ..............................................................................................11

2 Safety ............................................................................................................13

2.1 Safety instructions ..........................................................................................13

2.2 Safety regu lations for the method of operation ................................................14

2.3 Standards and direct i ves complied with ..........................................................16

2.4 Release Notes ................................................................................................16

3 Structure and function .................................................................................17

3.1 Overview ........................................................................................................17

3.1.1 Details for orderi ng...........................................................................20

3.1.2 Product version ES ..........................................................................21

3.2 Setup..............................................................................................................22

3.2.1 Front indicator ..................................................................................24

3.2.2 Int er nal indicator ..............................................................................28

3.2.3 Interface card ...................................................................................29

3.2.4 External power unit and batteries .....................................................31

3.3 Pipe system ....................................................................................................32

3.3.1 Water trap in the pi pe system ...........................................................33

3.4 Parameter settings..........................................................................................34

3.5 Function .........................................................................................................34

3.5.1 Function during operat ion on detec tor line ........................................34

3.5.1.1 Danger levels ...................................................................................35

3.5.1.2 Interface to service devices ..............................................................35

3.5.1.3 Test m ode........................................................................................36

3.5.1.4 Renov ation mode .............................................................................36

3.5.1.5 Line separ ator ..................................................................................36

3.5.1.6 Line tester FDUL221 ........................................................................36

3.5.2 Standalone oper ation .......................................................................37

3.6 Accessories ....................................................................................................37

3.6.1 Communication transponder FDCC221S..........................................37

3.6.2 Power supply kit A (70 W) FP120-Z1................................................37

3.6.3 Battery FA2003-A1 (12 V, 7 Ah, VdS) ..............................................38

3.6.4 Battery FA2004-A1 (12 V, 12 Ah, VdS).............................................38

3.6.5 Battery FA2005-A1 (12 V, 17 Ah, VdS).............................................38

4 Planning ........................................................................................................39

4.1 Compatibility ...................................................................................................39

4.2 Operating modes ............................................................................................39

4.2.1 Parameter Sets ................................................................................40

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 4

4

4.3 Power supply .................................................................................................. 41

4.4 Determining the batteries ................................................................................ 42

4.5 Limit s to planning............................................................................................ 43

4.6 Environmental influences ................................................................................ 44

4.7 Blowing-out unit .............................................................................................. 44

5 Mounting / Installation .................................................................................. 45

5.1 Prep arat or y work ............................................................................................ 45

5.1.1 Opening and clos ing the housing cover

when the power supply is switched off.............................................. 45

5.1.2 Opening and clos ing the housing cover

when the power supply is switched on.............................................. 46

5.1.3 Removing and installing the ho usi n g co v er

when the power supply is switched off.............................................. 48

5.1.4 Removing and installing the housing cover

when the power supply is switched on.............................................. 51

5.1.5 Installation position and space requir ements .................................... 55

5.2 Mounting ........................................................................................................ 58

5.2.1 Ad apting the front indicator to the installation pos i tion ...................... 58

5.2.2 Fastening on a level substructure ..................................................... 59

5.2.3 Connecti ng the pipe s ys tem to the aspir ating smok e detector........... 61

5.2.3.1 Return lin e ....................................................................................... 61

5.2.4 Installi ng communication transponder FDCC2 21S............................ 62

5.3 Installation ...................................................................................................... 64

5.3.1 Connecting the external power unit .................................................. 64

5.3.2 'Smoke 4…20 mA' analog output ..................................................... 66

5.3.3 Configurable 'GPI' input ................................................................... 68

5.3.4 'Purge' relay output for blowing out (with FDA241 only) .................... 68

5.3.5 'Dust' relay output for dust value (with FDA241 only) ........................ 69

5.3.6 'Faul t' relay output for er r or messages.............................................. 69

5.3.7 'Inspect' relay output for early warning (FDA241 only) ...................... 69

5.3.8 'PreAlarm ' relay output for pre-alarm ................................................ 70

5.3.9 'Fire 1' rel ay output for fire al ar m 1 ................................................... 70

5.3.10 'Fire 2' rel ay output for fire al ar m 2 ................................................... 70

5.3.11 Connecti ng to th e detec tor line with the FD CC221S ......................... 71

5.3.12 Connecti on to input/ output module ................................................... 72

6 Configuration ................................................................................................ 77

7 Commissioning............................................................................................. 79

7.1 Oper ation on addressed detec tor line (FDnet/C-NET) ..................................... 79

7.2 Standalone application ................................................................................... 82

7.3 Function al test ing of the syst em ...................................................................... 83

7.3.1 Function al test ing of the syst em with an add r essed detec tor line

(FDnet/C-NET) ................................................................................ 83

7.3.2 Function al test ing of the syst em with the stand alone op tion .............. 84

7.4 Testing the ind i cation of fault s on the front indi cator/ inter nal indic ator.............. 86

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 5

5

7.5 Testing the airflow...........................................................................................87

7.6 Testing the response time ...............................................................................88

7.7 Checking and testing the power supply units ...................................................89

7.8 LE D and buzzer test .......................................................................................89

7.9 Normalization .................................................................................................90

8 Maintenance / Repair ....................................................................................93

8.1 Visual inspect ion .............................................................................................93

8.2 Checking the pi pe sy s tem ...............................................................................93

8.3 Status quer ies with servic e devic es .................................................................93

8.3.1 Communi cation with the aspirating smoke detector ..........................94

8.4 Resetting status displays and relay outputs (standalone option) ......................96

8.5 Perfo r mance check .........................................................................................97

8.6 Cleaning .........................................................................................................97

8.7 Carrying out water trap maintenance...............................................................97

8.8 Maintenance and cleaning i ntervals ................................................................99

8.9 Event memory .............................................................................................. 100

8.10 Modification memory ..................................................................................... 100

8.11 Faults ........................................................................................................... 101

8.11.1 Table of fau lts ................................................................................ 102

8.11.2 Fault an alysis ................................................................................. 104

9 Specifications ............................................................................................. 105

9.1 Techn ical d ata for FDA241, F DA 221 ............................................................. 105

9.2 Dimensions................................................................................................... 108

9.3 Environmental compatibility and disposal ...................................................... 108

10 Annex .......................................................................................................... 109

10.1 Fault in dication ............................................................................................. 109

Index ..................................................................................................................... 110

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 6

6

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 7

About this document

1

Applicable documents

7

Target group

Activity

Qualification

1 About this document

Goal and purpose

This document contains all the information you'll need about the following

aspirating smoke detectors:

FDA241

FDA221

Following the instructions consistently will ensure that the product can be used

safely and without any problems.

Intended use

Aspirating smoke detectors FDA241 and FDA221 may only be used for fire

detection and fire control purposes.

Target groups

The information in this document is intended for the following target groups:

Product Manager Is responsible for information passing

between the manufacturer and regional

company.

Coordinates the flow of information

between the individual groups of people

involved in a project.

Project Manager Coordinates the deployment of all

persons and resources involved in the

project according to schedule.

Provides the information required to run

the project.

Project engineer Sets parameters for product depending

on specific national and/or customer

requirements.

Checks operability and approves the

product for commissioning at the place

of installation.

Is responsible for trouble-shooting.

Installation personnel Assembles and installs the product

components at the place of installation.

Carries out a performance check

following installation.

Commissioning personnel Configure the product at the place of

installation according to customerspecific requirements.

Check the product operability and

release the product for use by the

operator.

Searches for and corrects malfunctions.

Maintenance personnel Carries out all maintenance work.

Checks that the products are in perfect

working order.

Searches for and corrects malfunctions.

Has obtained suitable specialist training

for the function and for the products.

Has attended the training courses for

Product Managers.

Has obtained suitable specialist training

for the function and for the products.

Has attended the training courses for

Project Managers.

Has obtained suitable specialist training

for the function and for the products.

Has attended the training courses for

Product Engineer.

Has received specialist training in the

area of building installation technology

or electrical installations.

Has obtained suitable specialist training

for the function and for the products.

Has attended the training courses for

commissioning personnel.

Has obtained suitable specialist training

for the function and for the products.

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 8

1

About this document

Applicable documents

8

Source language and reference document

ID code

Examples

on symbols and for identification between steps

The 'i' symbol identifies supplementary information and tips for an easier way of

The source/original language of this document is German (de).

The reference version of this document is the international version in English.

The international version is not localized.

Document identification

The document ID is structured as follows:

ID_ModificationIndex_Language_COUNTRY

-- = multilingual or international

A6V10215123_a_de_DE

A6V10215123_a_en_-A6V10315123_a_--_--

Date format

The date format in the document corresponds to the recommendation of

international standard ISO 8601 (format YYYY-MM-DD).

Conventions for text marking

Markups

Special markups are shown in this document as follows:

⊳ Requirement for a behavior instruction

1.

2.

– Version, option, or detailed information for a behavior instruction

⇨ Intermediate result of a behavior instruction

⇨ End result of a behavior instruction

Numbered lists and behavior instructions with an operation

Behavior instruction with at least two operation sequences

sequence

[➙ X] Reference to a page number

'Text' Quotation, reproduced identically

<Key> Identification of keys

> In addition to relati

in a sequence, e.g., 'Menu bar' > 'Help' > 'Help topics'

↑ Text Identification of a glossary entry

Supplementary information and tips

working.

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 9

About this document

1

Applicable documents

9

1.1 Applicable documents

Document ID

Title

You will also find information about search variants and links to mobile

001508 Guidelines Connection factors, line resistances and

capacitances for fire detection systems collective, AnalogPLUS,

interactive, FDnet

007023 Technical manual Input module, input/output module FDCI222,

FDCIO222, FDCIO224

007227 Technical manual Detector exchanger and tester FDUD292

008250 Technical Manual Line tester FDUL221

008331 List of compatibility (for 'Sinteso™' product line)

009052 FS20 Fire detection system - Commissioning, Maintenance,

Troubleshooting

009078 FS20 Fire detection system - Configuration

009718 Technical Manual Intelligent detector tester FDUD293

A6V10210416 FS720 Fire detection system - Commissioning, Maintenance,

Troubleshooting

A6V10210424 FS720 Fire detection system - Configuration

A6V10229261 List of compatibility (for 'Cerberus™ PRO' product line)

A6V10331032 Data sheet Aspirating Smoke Detectors FDA221, FDA241

A6V10332759 Installation, Operation Manual, Configuration 'ASD

Configuration Tool FXS2051'

A6V10334435 Planning, Installation ASD Pipe system

A6V10340094 User Manual 'ASD Asyst Tool FXS2055'

A6V10344957 Installation Manual for 'FXS2055 ASD Asyst Tool'

A6V10345654 Installiotion, Mounting Aspirating Smoke Detectors FDA241,

FDA221

A6V10348930 Driver Installer and Uninstaller for TUSB3410 based devices

A6V10367668 Open-Source Software (OSS) Licenses ASD

A6V10387338 Open-Source Software (OSS) Licenses ASD

A6V10388922 Open-Source Software (OSS) Licenses TUSB3410

A6V10393194 Technical manual Power supply kit A 70 W FP120-Z1

A6V10448753 Data sheet Remote test system for aspirating smoke detectors

(ASD)

1.2 Download center

You can download various types of documents, such as data sheets, installation

instructions, and license texts via the following Internet address:

http://siemens.com/bt/download

Enter the document ID in the 'Find by keyword' input box.

applications (apps) for various systems on the home page.

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 10

1

About this document

Technical terms

10

1.3 Technical terms

Term

Explanation

P

ABS Acrylonitrile-butadiene-styrene (plastic)

ASD Aspirating smoke detector

FDnet/C-NET Addressed detector line

GPI General Purpose Input, connection for an external switch

MC link Maintenance and commissioning link

n.c. normally closed (standard state of connection is closed)

n.o. normally open (standard state of connection is open)

PC Personal computer

PC Polycarbonate (plastic)

PSU

SRC1 Optical detection channel in the FDnet/C-NET

SRC3 Channel for monitoring the airflow in the FDnet/C-NET

ower supply unit

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 11

About this document

1

Revision history

11

1.4 Revision history

The first edition of a language version or a country variant may, for example, be

Modification index

Edition date

Brief description

New firmware version 3.10 taken into account

New chapters:

Amended chapters:

The language versions and country variants produced by a local company have

me modification index as the corresponding reference document. They are

The reference document's version applies to all languages into which the reference

document is translated.

version 'd' instead of 'a' if the reference document is already this version.

The table below shows this document's revision history:

h 2015-09-29

'Connection to input/output module'

'About this document' ('Intended use' section added); 'Applicable documents';

'Operation on addressed detector line' ('Selection of settings' > 'Smoke alarm

delay time'); 'Testing the airflow' ('Large deviations in the airflow'); 'Power supply';

'Normalization'; 'Table of faults'; ' 'Dust' relay output for dust value (FDA241 only)';

'Technical data FDA241, FDA221'

g 2015-03-03 Data sheet 'Remote test system for aspirating smoke detectors' added in

'Applicable documents' chapter. 'Technical data FDA241, FDA221' chapter

amended and supplemented. Power supply kit FP120-Z1 added. Battery FA2003A1 added. Detector can also be installed horizontally. Editorial changes

f 2014-06-25 Data sheet updated in 'Applicable documents' chapter.

Editorial changes

New chapter with reference to download center added

e 2013-07-02 Change of function when opening housing cover.

d 2012-11-02 Planning limits adapted. Additional references to license document and

commissioning on the detector line. Information added about commissioning and

maintenance. Change to date format in line with ISO 8601 specifications

(yyyy-mm-dd format).

c 2012-03 Document adapted to the following type designation: communication transponder

FDCC221S. Additional information on blowing-out unit. Technical data and

mounting notes added. Additional notes on test mode and about commissioning

on the detector line.

b 2011-12 Revised version

a 2011-10 First edition

the sa

not however included in the table below.

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 12

1

About this document

Revision history

12

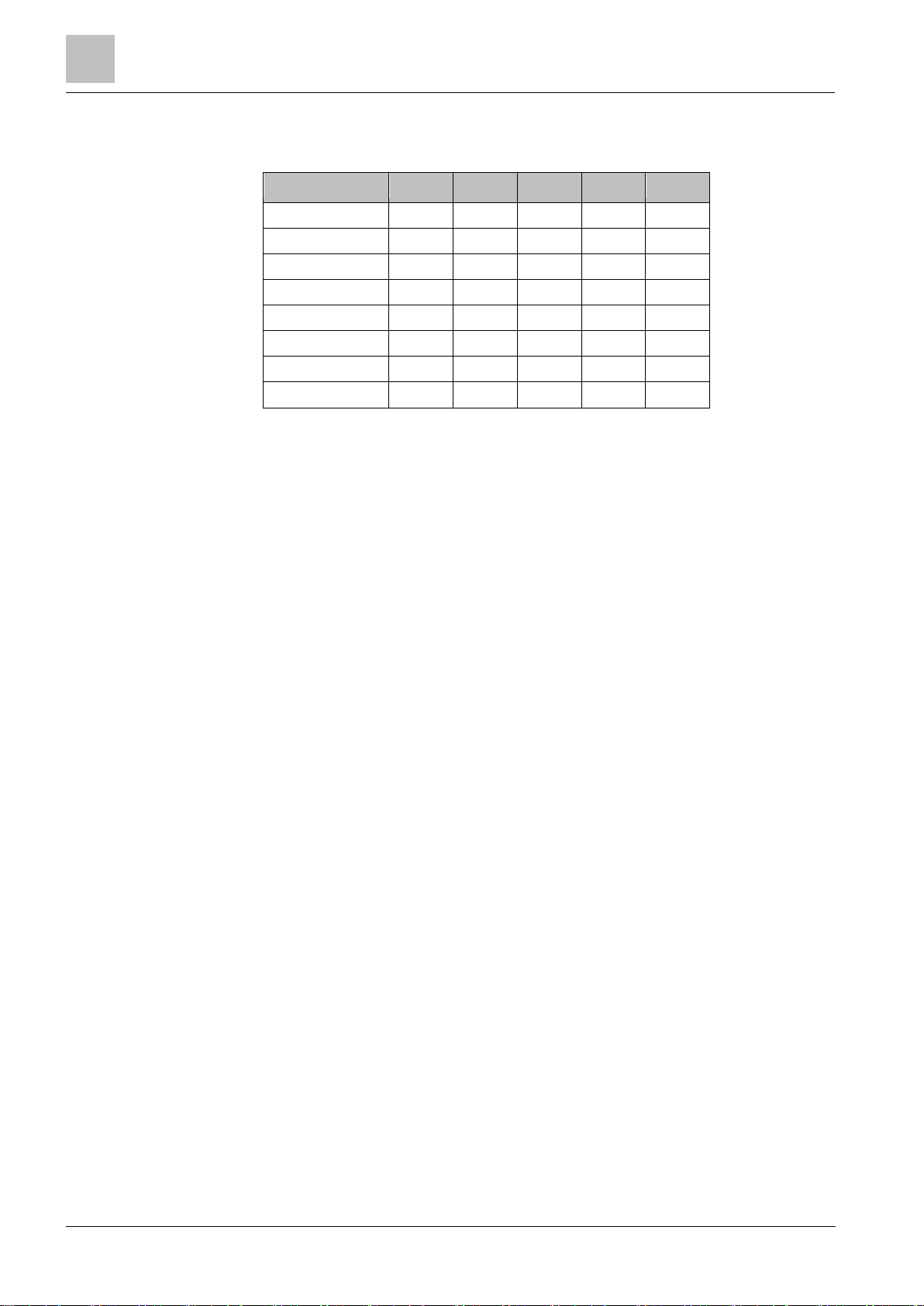

The table below shows the published language versions and country variants with

Modification index

en_--

de_--

fr_--

it_--

es_--

the corresponding modification index:

h X X X X X

g X X X X X

f – X – – –

e X X X X X

d X X – – –

c - X – – –

b - X – – –

a X X – – –

X = published

– = no publication with this modification index

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 13

Safety

2

Safety instructions

13

risks of injury

Signal word

Danger level

DANGER

will result directly in death or

serious injury

WARNING

may result in death or serious

injury

CAUTION

slight to

moderately serious injury

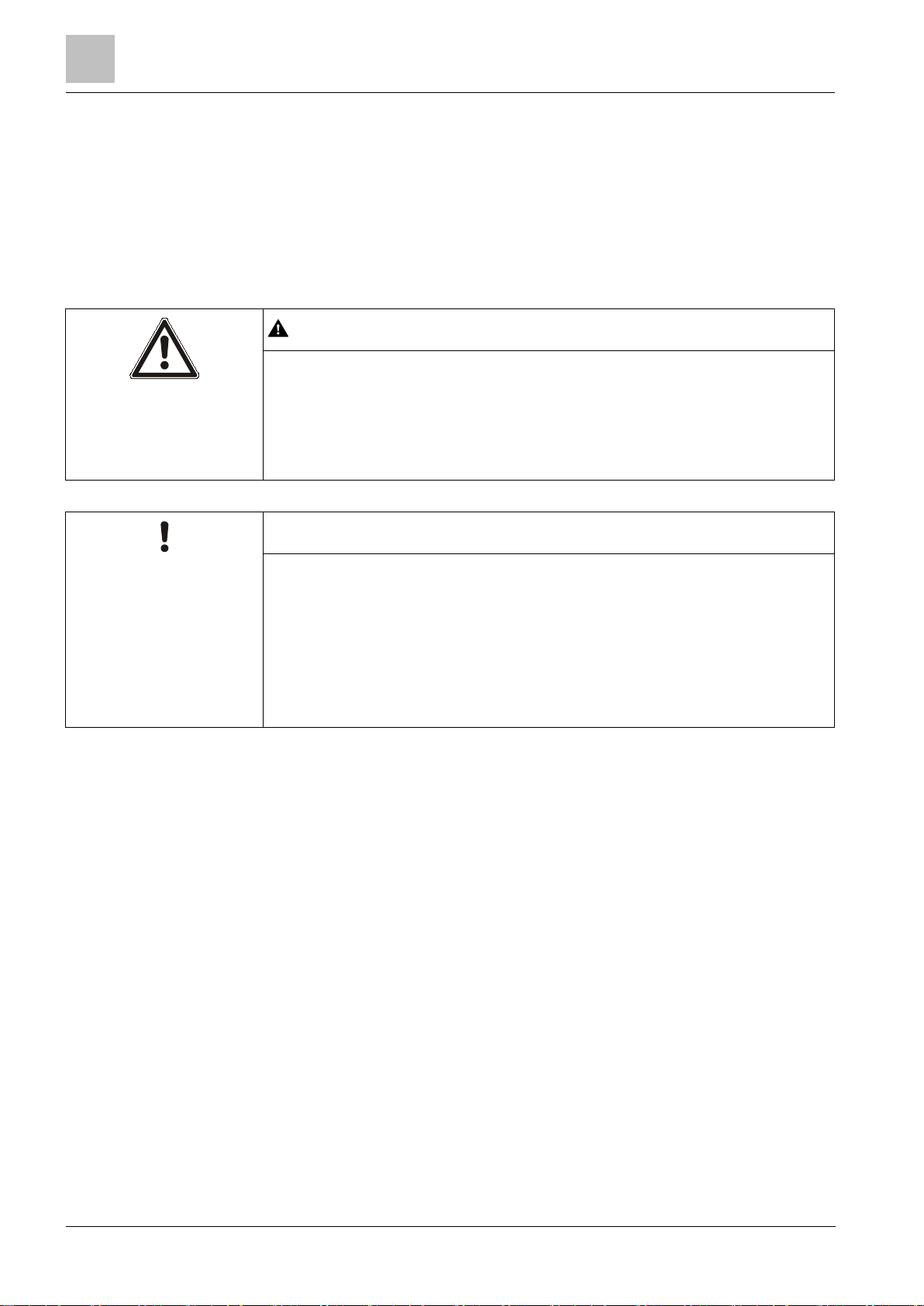

2 Safety

2.1 Safety instructions

The safety notices must be observed in order to protect people and property.

The safety notices in this document contain the following elements:

Symbol for danger

Signal word

Nature and origin of the danger

Consequences if the danger occurs

Measures or prohibitions for danger avoidance

Symbol for danger

This is the symbol for danger. It warns of

Follow all measures identified by this symbol to avoid injury or death.

Additional danger symbols

These symbols indicate general dangers, the type of danger or possible

consequences, measures and prohibitions, examples of which are shown in the

following table:

General danger

Explosive atmosphere

.

NOTICE

Voltage/electric shock

Battery

Laser light

Heat

Signal word

The signal word classifies the danger as defined in the following table:

DANGER identifies a dangerous situation, which

if you do not avoid this situation.

WARNING identifies a dangerous situation, which

if you do not avoid this situation.

CAUTION identifies a dangerous situation, which could result in

if you do not avoid this situation.

NOTICE

identifies possible damage to property that may result from non-

observance.

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 14

2

Safety

Safety regulations for the method of operation

14

How risk of injury is presented

WARNING

Nature and origin of the danger

● Measures / prohibitions for danger avoidance

NOTICE

Nature and origin of the danger

● Measures / prohibitions for danger avoidance

WARNING

Electrical voltage

regulations.

Information about the risk of injury is shown as follows:

Consequences if the danger occurs

How possible damage to property is presented

Information about possible damage to property is shown as follows:

Consequences if the danger occurs

2.2 Safety regulations for the method of operation

National standards, regulations and legislation

Siemens products are developed and produced in compliance with the relevant

European and international safety standards. Should additional national or local

safety standards or legislation concerning the planning, mounting, installation,

operation or disposal of the product apply at the place of operation, then these

must also be taken into account together with the safety regulations in the product

documentation.

Electrical installations

Electric shock

● Work on electrical installations may only be carried out by qualified

electricians or by instructed persons working under the guidance and

supervision of a qualified electrician, in accordance with the electrotechnical

Wherever possible disconnect products from the power supply when carrying

out commissioning, maintenance or repair work on them.

Lock volt-free areas to prevent them being switched back on again by mistake.

Label the connection terminals with external external voltage using a

'DANGER External voltage' sign.

Route mains connections to products separately and fuse them with their own,

clearly marked fuse.

Fit an easily accessible disconnecting device in accordance with IEC 60950-1

outside the installation.

Produce earthing as stated in local safety regulations.

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 15

Safety

2

Safety regulations for the method of operation

15

Mounting, installation, commissioning and maintenance

If you require tools such as a ladder, these must be safe and must be intended

for the work in hand.

When starting the fire control panel ensure that unstable conditions cannot

arise.

Ensure that all points listed in the 'Testing the product operability' section below

are observed.

You may only set controls to normal function when the product operability has

been completely tested and the system has been handed over to the customer.

Testing the product operability

Prevent the remote transmission from triggering erroneously.

If testing building installations or activating devices from third-party companies,

you must collaborate with the people appointed.

The activation of fire control installations for test purposes must not cause

injury to anyone or damage to the building installations. The following

instructions must be observed:

– Use the correct potential for activation; this is generally the potential of the

building installation.

– Only check controls up to the interface (relay with blocking option).

– Make sure that only the controls to be tested are activated.

Inform people before testing the alarm devices and allow for possible panic

responses.

Inform people about any noise or mist which may be produced.

Before testing the remote transmission, inform the corresponding alarm and

fault signal receiving stations.

Modifications to the system design and the products

Modifications to the system and to individual products may lead to faults,

malfunctioning and safety risks. Written confirmation must be obtained from

Siemens and the corresponding safety bodies for modifications or additions.

Modules and spare parts

Components and spare parts must comply with the technical specifications

defined by Siemens. Only use products specified or recommended by

Siemens.

Only use fuses with the specified fuse characteristics.

Wrong battery types and improper battery changing lead to a risk of explosion.

Only use the same battery type or an equivalent battery type recommended by

Siemens.

Batteries must be disposed of in an environmentally friendly manner. Observe

national guidelines and regulations.

Disregard of the safety regulations

Before they are delivered, Siemens products are tested to ensure they function

correctly when used properly. Siemens disclaims all liability for damage or injuries

caused by the incorrect application of the instructions or the disregard of danger

warnings contained in the documentation. This applies in particular to the following

damage:

Personal injuries or damage to property caused by improper use and incorrect

application

Personal injuries or damage to property caused by disregarding safety

instructions in the documentation or on the product

Personal injury or damage to property caused by poor maintenance or lack of

maintenance

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 16

2

Safety

Standards and directives complied with

16

2.3 Standards and directives complied with

WARNING

Limited or non-existent fire detection

detection installation.

NOTICE

Incorrect planning and/or configuration

Additional expense resulting from necessary new planning and/or configuration.

detection installation.

A list of the standards and directives complied with is available from your Siemens

contact.

2.4 Release Notes

Limitations to the configuration or use of devices in a fire detection installation with

a particular firmware version are possible.

Personal injury and damage to property in the event of a fire.

● Read the 'Release Notes' before you plan and/or configure a fire detection

installation.

● Read the 'Release Notes' before you carry out a firmware update to a fire

Important standards and specifications are not satisfied.

Fire detection installation is not accepted for commissioning.

● Read the 'Release Notes' before you plan and/or configure a fire detection

installation.

● Read the 'Release Notes' before you carry out a firmware update to a fire

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 17

Structure and function

3

Overview

17

3 Structure and function

3.1 Overview

Aspirating smoke detectors are used for early detection of smoke-generating fires

in rooms and equipment. They are especially suited to applications in which point

detectors are pushed to their limits, cannot be used or can only be used with

restrictions.

The aspirating smoke detector continually takes air from the monitored room using

a connected pipe system with defined aspirating holes. The air is supplied to the

detection chamber and is analyzed for smoke particles using the detector installed

there. The sensitivity of the detector can be adjusted.

The position and size of the aspirating holes are calculated with the 'FXS2055 ASD

Asyst Tool' software. The calculation ensures that the air passes from the

aspirating hole to the detector in the time specified and with the required calculated

sensitivity.

Examples of application

Cavities such as false ceilings or false floors

Rooms with polluted air, in which the pollution has impaired the performance of

optical point detectors

Clean rooms

Rooms the height of which is greater than that permitted for point detectors

Rooms with electromagnetic fields which influence the function of point

detectors

Large rooms up to 800 m²

Separate monitoring of control cabinets and electronics cabinets

Data centers

Telecommunication centers

Mounting lines

Cable tunnels

Conveyor belts

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 18

3

Structure and function

Overview

18

The aspirating smoke detector can be operated on an FDnet/C-NET detector line.

1

7

2

3

4

4

56

8

4

8

8

8

When the aspirating smoke detector is operated on a FDnet/C-NET detector line,

For this purpose, communication transponder FDCC221S is also required:

Aspirating smoke detector on addressed detector line

1

Aspirating smoke detector with

communication transponder FDCC221S

2 External power unit with batte ry 6 Fire control panel FC20xx /FC72x

3 Blowin g-out unit (optional) 7 FDnet/C-NET detector line

4 Pipe system 8 FDnet/C-NET peripheral device

the relay outputs are inactive.

5 Return line (optional)

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 19

Structure and function

3

Overview

19

Alternatively, various external devices can be connected to the aspirating smoke

1

7

2

3

4

4

5

6

4

8

9

10

detector in standalone operation [➙ 37]:

Aspirating smoke detector in standalone operation

1 Aspirating s moke det ector 6

2 External power unit with batte ry 7 External control/indicator (optional)

3 Blow ing-out un it (optional)

4 Pipe system

5 Return line (optional)

PC with 'FXS2051 ASD Configuration

Tool' software

8 External button (optional)

9

External acoust ic signa l equipment

(optional)

10

External optical signa l equipment

(optional)

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 20

3

Structure and function

Overview

20

Properties

Type

Order no.

Designation

Patented technology

Can be used with Siemens FDnet/C-NET loop (with optional FDCC221S

installed)

Extended optical detection thanks to dual wavelengths (blue and infrared)

Configuration via USB or FDCC221S (option)

'Out-of-the-box' installation and commissioning

Early detection of a wider spectrum of particle sizes in the air

Software 'FXS2055 ASD Asyst Tool' and pipe configuration supported

Programmable alarm thresholds

Unique dust-resistant detection chamber

Intuitive front indicator for airflow and smoke value

Normalization of the smoke value

Normalization of the airflow

Access to service functions

Different event protocols

Offline/online configuration supported

FDA241, monitoring area of up to 800 m²

FDA221, monitoring area of up to 500 m²

4…20 mA output

Cleaning function (with FDA241 only)

Firmware can be updated locally

3.1.1 Details for ordering

FDA241 S54333-F17-A1 Aspirating smoke detector (8H)

FDA221 S54333-F15-A1 Aspirating smoke detector (5S)

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 21

Structure and function

3

Overview

21

3.1.2 Product version ES

ES

ES

04

Depending on the product and various approvals, the product labels may differ in

The product version ES provides the technical status of a device in terms of

software and hardware. The product version is provided as a two-digit number.

You will find the details of your device's product version:

On the packaging label

On the product label or the type plate

Product version on the packaging label

Details of the product version can be found directly on the packaging label in the

barcode:

Example of a packaging label with details of the product version

Product version on the product label and the type plate

Details of the product version can be found after the device order number:

Example of a product label with details of the product version

terms of the information type and layout.

Look for your device's order number on the product label.

You will find the product version after the order number.

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 22

3

Structure and function

Setup

22

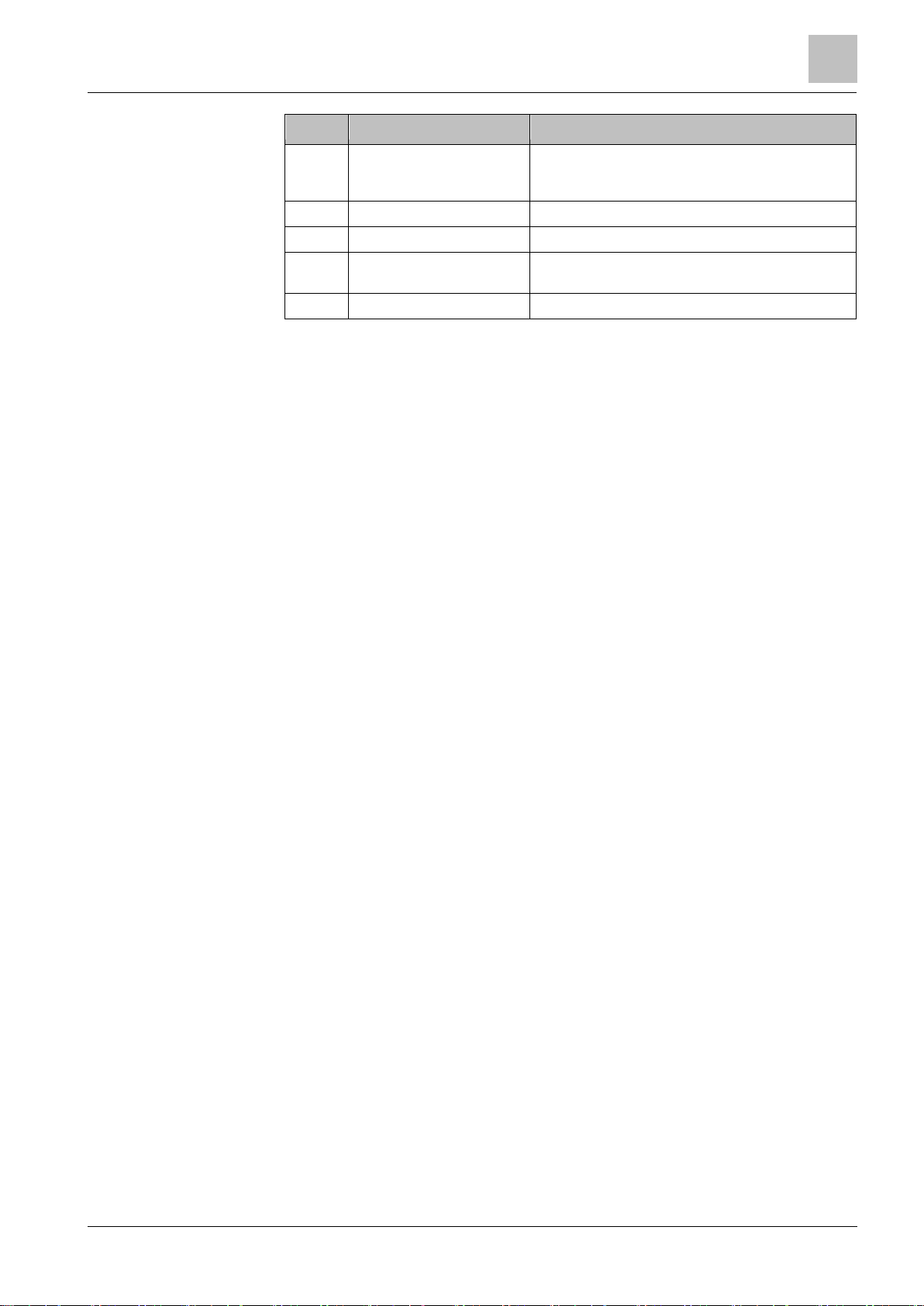

3.2 Setup

Position

Part

Function

Components

Overview

1 Housing cover -

2 Front indicator Operating indicators and fault indicators,

connected to the interface card by a cable

3 Opening Cable entry

4 Back box Wall mounting with screws

5 Interface card Connections to external devices and signal

equipment. Depending on the version of the

aspirating smoke detector, not all connections are

available. If the aspirating smoke detector is

operated on a FDnet/C-NET detector line, certain

outputs are not active. See the chapter 'Function

[➙ 34]'.

6 Air inlet Pipe system connection

7 Detection chamber Smoke sensor with flow monitoring

8 Internal indicator Alarm indicator, activate normalization

9 Aspiration unit Fan for aspirating the air.

10 Type plate Relevant identification and detector data

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 23

Structure and function

3

Setup

23

Position

Part

Function

11 Mini USB connection for

PC

Interface for configuring the aspirating smoke

detector using the 'FXS2051 ASD Configuration

Tool' software

12 Air outlet Air outlet in the room or return line connection

13 Cables Connection to the front indicator

14 Contact pins Connection for communication transponder

FDCC221S

15 Buzzer Signal tone output

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 24

3

Structure and function

Setup

24

3.2.1 Front indicator

The front indicator can be rotated 180° in the housing cover if necessary. See

The front indicator on the housing cover provides a quick overview of the aspirating

smoke detector's current status using LED indicators. The buzzer can be switched

off and a function test for LEDs and buzzers activated using a button.

Front indicator FDA241

Front indicator FDA221

'Adapting the front indicator to the installation position [➙ 58]'.

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 25

Structure and function

3

Setup

25

Display

Designation

Function

Operating indication The green LED lights up permanently:

When the power supply is con nected

1

Blowin g-out indicator

The yellow LED lights up permanently:

When the blowing-out process is activated

The yellow LED flashes:

Once the blowing-out process has been act ivated until the normal operating status

is achieved (lasts up to 2 minutes)

Indication of faults The yellow LED flashes:

When there is a technical fa ult

Airflow indicator The current airf low is indicated by an LED in the airflow indicator (b ar graph ind icator).

When the housing cover is opened

a) LED yellow

b) LED green

If a yellow LED lights up, the airflow has increased.

As the deviation increases, the light moves upwards.

If the topmost LED flashes, the airf low has exceeded the upper limit an d the a larm de lay

time has expired.

Example: There may be a leak in the pipe system.

One of the green LEDs lights up.

The airflow is normal.

c) LED yellow

If a yellow LED lights up, the airflow is too low.

As the deviation increases, the indicator moves downwards.

If the bottommost LED flashes, the airflow has fallen below the lower limit and the alarm

delay time has expired.

Example: Some of the as pirating holes in the pipe sy stem may be blocked.

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 26

3

Structure and function

Setup

26

Alarming indicator

Number of LEDs lighting up and their meaning

The aspirating smoke detector's current alarm status is ind icated by LEDs in the s moke indicator

(bar grap h indicator).

Yellow LED

Green LED

Smoke indicator

Alarm level

1

Alarm level

Inspect

1…5 'Smoke low'

6…9 ' Inspect'

10…12 'Prealarm'

13…14 'Fire 1'

15 'Fire 2'

The green LED lights up if the level of smoke is minimal.

At the same time, the bottommost 1 to 5 yellow LEDs may indicate minor dev iations.

The red LED lights up at the 'I nspect' alarm lev e l.

At the same time, the bottommost 6 to 9 yellow LEDs light up.

Red LED

Red LED

Red LED

Red LED

Alarm level

Prealarm

Alarm level

Fire 1

Ala rm le vel

Fire 2

The red LED lights up at the 'Prealarm' alarm level.

At the same time, the bottommost 10 to 12 yellow LEDs light up.

The red LED lights up at the ' Fire 1' a lar m level.

At the same time, the bottommost 13 to 14 yellow LEDs light up.

The red LED lights up at the ' Fire 2' a lar m leve l.

At the same time, the 15 yellow LEDs light up.

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 27

Structure and function

3

Setup

27

Button

Actio n

Consequence

LED status

Meaning

Press the button br ief ly The buzzer sw itches off

Press and hold the button

A signal test/fault analysis is activated.

(approx. 5 s)

When the housing cover is open , the button takes on the function of the reset button and the alarm

outputs are deactivated. See t he chapter 'Int ernal indicato r [➙ 28]'.

Press the button briefly The buzzer sw itche s off.

The relay outputs are deactivated.

The 4…20 mA analog out put re mains on fault.

Dust indicato r 1 Flashing becomes more frequent as the dust d ensity increases.

Off Normal operation

Slow flashing Low dust v alue

Fast flashing Medium dust va lue

Permanently on High dust value

1

FDA241 only

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 28

3

Structure and function

Setup

28

3.2.2 Internal indicator

Indication

Designation

Function

Button

Designation

Function

The 'Normalize Flow' and 'Normalize Smoke' buttons can only be actuated using

When the housing cover [➙ 46] is open, the internal indicator is accessible. The

internal indicator performs the following functions:

Status display for airflow, smoke value, and alarm using 3 LEDs

Activate or stop normalization of the airflow using a button

Activate or stop normalization of the smoke value using a button

Reset self-retaining status displays and relay outputs using a button

Internal indicator

Flow ok The green LED flashes when the airflow is normal.

Smoke ok The green LED flashes when the smoke value is low.

Alarm The red LED flashes during an alarm.

Normalize Flow Button for activating or stopping normalization of the

Normalize Smoke Button for activating or stopping normalization of the

airflow.

smoke value.

Reset Button for resetting the self-retaining status displays

and relay outputs. The current detector status is

reset.

a suitable, thin tool, e.g. a pen or a paper clip.

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 29

Structure and function

3

Setup

29

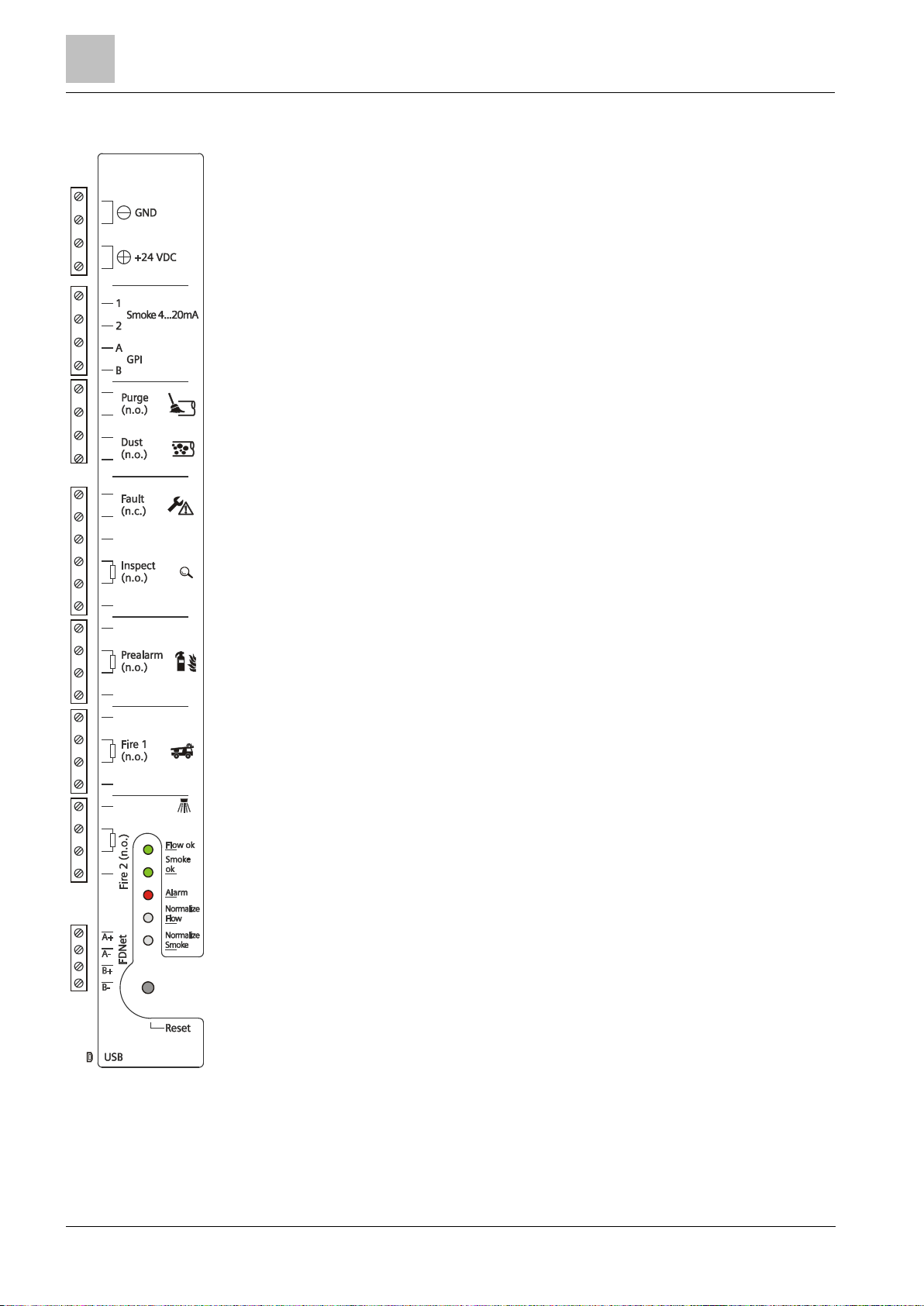

3.2.3 Interface card

The interface card in the back box is accessible once the housing cover has been

removed.

You can do the following on the interface card:

Establish the cable connection to the front display in the housing cover

Connect the external power supply for the aspirating smoke detector

Control various external functions via relays

Install communication transponder FDCC221S (accessory)

Establish a connection to a PC using the mini USB interface

The graphic below provides an overview of the connections together with the

associated symbols and labels.

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 30

3

Structure and function

Setup

30

The connection terminals are combined in functional units.

'Smoke 4…20 mA'

'GPI'

'Purge'

'Dust

'Fault'

'Inspect'

'Prealarm'

'Fire 1'

'Fire 2'

'FDNet

'USB'

Power supply

You will find details on page [➙ 64].

analog output. You will find details on p age [➙ 66].

Configurable

You will find details on page [➙ 68].

relay output f or blowing out (with FDA24 1 only)

You will find details on page [➙ 68].

' relay output for dust value (with FDA24 1 only). You w ill find details on page [➙ 69].

relay output for error messages. You will find details on page [➙ 69].

relay output for Ins pect (with FDA241 only)

You will find details on page [➙ 69].

You will find details on page [➙ 70].

relay output for Fire 1

You will find details on page [➙ 70].

relay output for Fire 2

You will find details on page [➙ 70].

' relay connection w ith FDCC 221S (optional)

You will find details on page [➙ 66].

Mini USB port for connecting to a PC

You will find details on page [➙ 94].

input

relay output f or Prealarm

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

See also

Communication transponder FDCC221S [➙ 37]

External power unit and batteries [➙ 31]

Removing and installing the housing cover when the power

supply is switched on [➙ 51]

Page 31

Structure and function

3

Setup

31

3.2.4 External power unit and batteries

Company

Type

VdS

For battery type

External power unit

The aspirating smoke detector must be supplied with electricity by an external

power unit. The power unit must satisfy the following requirements:

Version according to EN 54-4

Output voltage: DC 24 V

Output current: 250 mA

The power unit must be connected to the aspirating smoke detector with as

short a cable as possible.

Suitable power unit:

Siemens FP120-Z1 G214130 2x FA2003-A1 (12 V, 7 Ah)

Or

2x FA2004-A1 (12 V, 12 Ah)

Or

You will find more information on the power supply kit FP120-Z1 in

document A6V10393194. See the 'Applicable documents [➙ 9]' chapter.

2x FA2005-A1 (12 V, 17 Ah)

Batteries

If the power supply via the external power unit fails, the power supply of the

aspirating smoke detector must be guaranteed using batteries.

If the aspirating smoke detector is in standalone operation: Observe local

regulations for the minimum detector operation period for power supply failure.

The capacity of the batteries must be selected according to the local

regulations.

If the aspirating smoke detector is being operated on a FDnet/C-NET detector

line: The capacity of the batteries must match the runtime of the connected fire

detection installation if the power supply fails. Observe local regulations for the

fire detection installation.

The batteries are charged using the external power unit. The charging current

for the batteries depends on the battery capacity. You should therefore select

your external power unit to match the batteries' capacity.

See also

Determining the batteries [➙ 42]

Battery FA2003-A1 (12 V, 7 Ah, VdS) [➙ 38]

Battery FA2004-A1 (12 V, 12 Ah, VdS) [➙ 38]

Battery FA2005-A1 (12 V, 17 Ah, VdS) [➙ 38]

Power supply kit A (70 W) FP120-Z1 [➙ 37]

Power supply [➙ 41]

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 32

3

Structure and function

Pipe system

32

3.3 Pipe system

3

6

4

3

2

5

2

4

1

The pipe system must be designed according to the calculation with the 'FXS2055

ASD Asyst Tool' software.

The components used for the pipe system must satisfy the requirements according

to document A6V10334435. See 'Applicable documents [➙ 9]'.

Example pipe system for air aspiration

Pipe system

1 Monitored room 4 Aspirating smoke detector

2 Pipes and fittings 5 Outlet line as retu rn line (optional)

3 Hose 6 Outlet line (optional)

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 33

Structure and function

3

Pipe system

33

3.3.1 Water trap in the pipe system

The condensation water that has been collected must not enter the airflow and

In the case of highly variable ambient conditions where there is a risk of

condensation water forming in the pipe system, a water trap must be used. The

water trap collects the condensation water. The condensation water must be

drained via a drain hole in the water trap.

must be drained in good time.

Installation site requirements

It must be easy to read the level of water in the water trap.

It must be possible to access the water trap when full for the purpose of

emptying it.

The water trap must be installed at a horizontal point within the pipe system

that is as low as possible. It must not be possible for water to accumulate at

any other point.

Example of how to arrange a water trap

→ → Airf low

1

Aspirating smoke detector with front

indicator that is rotate d by 180°

2

T-fitting for connecting the water trap at a

low horizontal point within the pipe system

3

Distance betwee n manifold and surface of

the water > 300 mm

See also

Adapting the front indicator to the installation position [➙ 58]

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

4 Valve for draining cond ensation wate r

5 Outlet open ing

6 Condensat ion water

Page 34

3

Structure and function

Parameter settings

34

3.4 Parameter settings

Relay output

Operation on FDnet/C-NET

detector line

Standalone operation

The information in this chapter only applies to applications in which a

communication transponder FDCC221S (accessory) is installed in the aspirating

smoke detector and the aspirating smoke detector is connected to a compatible

Parameter sets can be used to select the sensitivity with a view to optimizing the

aspirating smoke detector for the current application. You will find information

about selection and application in the chapter 'Operating modes [➙ 39]'.

3.5 Function

The aspirating smoke detector can be used on a FDnet/C-NET detector line or in

standalone operation.

Comparison of the operating types

When operating on a FDnet/C-NET detector line, configuration takes place

using the software for the fire control panel.

– For fire control panels FC20xx: 'SintesoWorks'

– For fire control panels FC72x: 'Cerberus-Engineering-Tool'

In standalone operation: Configuration with the 'FXS2051 ASD Configuration

Tool' software

Controlling the relay outputs on the interface cards

The table below provides an overview of the controlled relay outputs when the

aspirating smoke detector is being operated on an FDnet/C-NET detector line and

in standalone operation:

Purge X X

Dust – X

Fault X X

Infoalarm – X

Prealarm – X

Fire1 – X

Fire2 – X

X = control of relay output

– = no control of relay output

3.5.1 Function during operation on detector line

fire control panel via the FDnet/C-NET.

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 35

Structure and function

3

Function

35

3.5.1.1 Danger levels

The evaluation of the danger level and the decisions to be taken (e.g. activation of

The aspirating smoke detector can transmit the following danger levels to the fire

control panel:

Symbol

Danger level _ 1 1 2 3 3

Designation _ Inspect Prealarm Fire 1 Fire 2

Configuration in the

fire detection

installation

Meaning No danger Possible danger Warning Alarm Alarm and extinguishing

Comment Normal Check situation Possible

_ Sensor 1 Sensor 2

Alarm level: Fire 2

Fire The highest danger level 3 has been

danger

reached and the conditions for

activating extinguishing are satisfied.

1

If danger level 1 is frequently transmitted, check whether another sensitivity

setting is more suitable.

remote transmission) are configured in the fire detection system.

3.5.1.2 Interface to service devices

A port with the MC link (maintenance and commissioning link) is installed on

communication transponder FDCC221S.

Using this interface, it is possible to read data from the device with the 'FDUD292

detector exchanger and tester' or the 'FDUD293 intelligent detector tester'.

You will find more information in documents 007227 and 009718.

See also

Applicable documents [➙ 9]

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 36

3

Structure and function

Function

36

3.5.1.3 Test mode

For testing purposes the aspirating smoke detectors can be set to test mode. Test

mode does the following:

The relays are deactivated.

The buzzer is operated at a lower sound level.

The green operating indicator flashes.

No changes are made to the sensitivity.

Electronic testing:

The aspirating smoke detectors can be tested on FC20xx/FC72x fire control panels

(market package MP5.0/IP5 or higher) using detector exchanger and tester

FDUD292 or intelligent detector tester FDUD293.

You will find more information in documents 007227 and 009718.

See also

Applicable documents [➙ 9]

3.5.1.4 Renovation mode

When operating the point detectors on the FDnet/C-NET, individual detectors can

be set specifically to renovation mode on the fire control panel.

Select renovation mode if major work is being carried out in the room and large

volumes of dust or aerosols are being produced.

In renovation mode, the detector is operated with the least sensitive parameter set

(no. 10).

See also

Parameter Sets [➙ 40]

3.5.1.5 Line separator

Line separators are electronic switches which isolate the defective part in case of a

short-circuit on the FDnet/C-NET detector line. The rest of the detector line remains

serviceable. On a loop line all FDnet/C-NET devices remain fully functional after a

simple error.

The function of the line separator is integrated in communication transponder

FDCC221S.

See also

Communication transponder FDCC221S [➙ 37]

3.5.1.6 Line tester FDUL221

The line tester FDUL221 detects aspirating smoke detectors on the FDnet/C-NET

detector line.

You will find more information in document 008250.

See also

Applicable documents [➙ 9]

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 37

Structure and function

3

Accessories

37

3.5.2 Standalone operation

A fire control panel is not essential to operate the aspirating smoke detector.

Various functions can be directly controlled by the aspirating smoke detector. In the

case of standalone operation, communication transponder FDCC221S must not be

installed.

In standalone operation, the aspirating smoke detector is configured using a PC

with the 'FXS2051 ASD Configuration Tool' software.

3.6 Accessories

3.6.1 Communication transponder FDCC221S

For connecting the aspirating smoke detector to

FDnet/C-NET

Integrated 'line separator' function

Additional MC line interface (port)

Tool-free installation on an intended PCB slot

Supplied with:

– 2 spacer bolts

– 4-pin terminal

– ID adhesive label

Compatible with:

– Aspirating smoke detector FDA241

– Aspirating smoke detector FDA221

Order no.: S24218-A201-A2

See also

Installing communication transponder FDCC221S [➙ 62]

3.6.2 Power supply kit A (70 W) FP120-Z1

For converting the mains voltage into system

voltage

For charging connected batteries

For supplying devices according to EN 54-4

Choice of input voltage between AC 115 V or

AC 230 V

Compatible with:

– Battery FA2003-A1

– Battery FA2004-A1

– Battery FA2005-A1

For details, see document A6V10393194

See also

External power unit and batteries [➙ 31]

Order no.: S4400-S122-A1

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 38

3

Structure and function

Accessories

38

3.6.3 Battery FA2003-A1 (12 V, 7 Ah, VdS)

For supplying fire control panels and aspirating

smoke detectors with power

Compatible with:

– Fire control panels for the 'Sinteso' and

'Cerberus PRO' product lines

– External power units for the aspirating smoke

detectors FDA241 and FDA221

VdS approval: G103032

Order no.: A5Q00019353

See also

Determining the batteries [➙ 42]

3.6.4 Battery FA2004-A1 (12 V, 12 Ah, VdS)

For supplying fire control panels and aspirating

smoke detectors with power

Compatible with:

– Fire control panels for the 'Sinteso' and

'Cerberus PRO' product lines

– External power units for the aspirating smoke

detectors FDA241 and FDA221

VdS approval: G103034

Order no.: A5Q00019354

See also

Determining the batteries [➙ 42]

3.6.5 Battery FA2005-A1 (12 V, 17 Ah, VdS)

For supplying fire control panels and aspirating

smoke detectors with power

Compatible with:

– Fire control panels for the 'Sinteso' and

'Cerberus PRO' product lines

– External power units for the aspirating smoke

detectors FDA241 and FDA221

VdS approval: G103035

Order no.: A5Q00019677

See also

Determining the batteries [➙ 42]

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 39

Planning

4

Compatibility

39

Detector line

Fire control panel

FC20xx

FC72x

SIGMASYS

AlgoRex

FDnet

C-NET

4 Planning

4.1 Compatibility

Compatible with fire control panels that support the FDnet/C-NET detector line.

You will find detailed information in the 'List of compatibility'.

The table below shows the compatibility of the aspirating smoke detectors and

installed communication transponder FDCC221S with various fire control panels:

X – – –

– X – –

X = compatible

– = not compatible

Please also observe the documentation for your fire detection system.

See also

Applicable documents [➙ 9]

4.2 Operating modes

Three different modes can be set.

'Automatic: switches between blue and blue-red based on ratio'

This mode is suitable for standard use. The sensitivity to small smoke particles is

high and dust suppression is normal. The particle size is taken into account. This

reduces the likelihood of a false alarm.

'Robust'

This mode is suitable for use in dirty rooms where there is a high dust load. The

sensitivity to small smoke particles is lower, but this results in a higher level of dust

suppression. This makes use possible in a dirty environment or in changing

ambient conditions.

'Ultra sense: always blue'

This mode is suitable for use in clean rooms where there is a low dust load. The

sensitivity to small smoke particles is very high and dust suppression is low. As a

result, the detector is very sensitive even to minor changes relating to smoke or

dust in the intake air.

Parameter sets can be used to make further settings with a view to fine-tuning the

product for the installed pipe system. When making your selection, take the

following into account:

Ambient conditions

Place of installation

Usage conditions

Alarm delay

In the FDnet/C-NET, the operating mode and parameter sets can be configured

from the fire control panel.

To determine suitable parameters, use the recommendations from the

'FXS2055 A6V10340094' software.

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 40

4

Planning

Operating modes

40

4.2.1 Parameter Sets

Set

No.

Sensitivity [%/m]

Comment

Inspect

Prealarm

Fire 1

Fire 2

Set no.

Sensitivity [%/m]

Comment

Prealarm

Fire 1

Fire 2

The following information applies to the 'Automatic: switches between blue and

blue-red based on ratio' mode.

FDA241

0 0.07 0.10 0.15 20 default

1 0.03 0.04 0.05 2 -

2 0.03 0.045 0.06 2.5 -

3 0.04 0.055 0.07 3 -

4 0.05 0.075 0.10 4 -

5 0.07 0.10 0.15 5 -

6 0.08 0.14 0.20 6 -

7 0.18 0.28 0.40 8 -

8 0.30 0.50 0.70 10 -

9 0.40 0.70 1.00 15 -

10 0.80 1.40 2.00 20 -

FDA221

0 0.50 0.70 20 default

6 0.14 0.20 6 -

7 0.28 0.40 8 -

8 0.50 0.70 10 -

9 0.70 1.00 15 -

10 1.40 2.00 20 -

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 41

Planning

4

Power supply

41

4.3 Power supply

The normal status and the alarm status must be taken into account when

dimensioning the power supply. When the normal status applies, the power supply

must provide the quiescent current for the smoke aspiration systems and ensure

that the emergency batteries are charged in accordance with VDE 0883, Part 1.

When the alarm status applies, additional power is required. Take this into account

when dimensioning the batteries. The batteries must be designed to support a

bridging time of 24 hours in the normal status and 1 hour in the alarm status.

You will find details of the aspirating smoke detector's current consumption in

chapter 'Technical data for FDA241, FDA221 [➙ 105]'.

Line calculation

The maximum length of the line is calculated on the basis of the permissible

voltage drop on the supply line. The permissible voltage drop is the difference

between the final voltage of the batteries (21.5 V) and the lower operating voltage

limit of the smoke aspiration systems.

L

= Maximum length of line in [m]

max

∆U = Max. voltage drop on supply line

A

= Wire cross-section in [mm²]

I

= Maximum current of all aspirating smoke detectors in alarm status in [A]

alarm

Ƴ = Specific resistance: Cu = 0.0175 Ω mm²/m

To ensure the housing remains properly sealed, select the relevant grommet for

the cable concerned.

M20 cable grommet: Ø 8…12 mm

M25 cable grommet: Ø 9…14 mm

Also observe the notices in the 'Technical data for FDA241, FDA221 [➙ 105]'

chapter.

Capacity calculation

Use the following formula to calculate the nominal capacity of the batteries:

K

= Nominal capacity of emergency battery in [Ah]

nominal

I

= Quiescent current [A]

quiescent

I

= Maximum current of all aspirating smoke detectors in alarm status in [A]

alarm

n

= Number of aspirating smoke detectors

t

= Required bridging time during operation in [h] (typically 24 h)

1

t

= Required bridging time in the case of an alarm in [h] (typically 1 h)

2

1.25 = The factor of 1.25 ceases to apply with bridging times of more than 24 hours.

See also

External power unit and batteries [➙ 31]

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 42

4

Planning

Determining the batteries

42

4.4 Determining the batteries

WARNING

Switching batteries in parallel

● If you need more power, you must use batteries with a higher capacity.

If the aspirating smoke detector's power supply via the external power unit fails,

power is supplied via batteries.

Determining the required battery type

The battery capacity depends on the following conditions:

Buffer time required

Battery age

Country-specific specifications, as regulated in local regulations or European

provisions

The required battery capacity can be identified using the following calculations:

C

= Battery capacity

Batter y

f

= Factor for the battery age

t

= Buffer time

Standby

I

= Internal current of the power supply unit

PSU

t

= Alarm time

Alarm

To achieve the system voltage of DC 24 V, two batteries must be connected in

series.

The buffer times specified in the table apply in the case of an operating

temperature within the range -5…45 °C.

The batteries are charged using the external power unit. The charging current

for the batteries depends on the battery capacity. You should therefore select

your external power unit to match the batteries' capacity.

Risk of explosion and fire

● Never connect batteries in parallel!

See also

Battery FA2003-A1 (12 V, 7 Ah, VdS) [➙ 38]

Battery FA2004-A1 (12 V, 12 Ah, VdS) [➙ 38]

Battery FA2005-A1 (12 V, 17 Ah, VdS) [➙ 38]

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 43

Planning

4

Limits to planning

43

4.5 Limits to planning

Observe local regulations and specifications for the limits of the detection range of

the aspirating holes. The local regulations and specifications take priority over all

Detector

Sensitivity

[%/m obs]

Monitored

surface

I-topology

Length of pipe

system

Number of

aspirating holes

(Class A)

Detector

Sensitivity

[%/m obs]

Monitored

surface

U-topology

Length of pipe

system

Number of

aspirating holes

Detector

Sensitivity

[%/m obs]

Monitored

surface

Double U-topology

Length of pipe

system

Number of

aspirating holes

Adherence to the planning limits is verified by the 'FXS2055 ASD Asyst Tool'

other information in this document.

The following limits are set for planning the pipe system depending on the

aspirating smoke detector used.

Single pipe

FDA221 0.14…20 ≤500 m2 ≤30 m ≤12

FDA241 0.03…20 ≤800 m2 ≤60 m ≤16

Branched pipes (symmetrical and asymmetrical U-topology)

FDA221 0.14…20 ≤500 m2 ≤2x 25 m ≤24

FDA241 0.03…20 ≤800 m2 ≤2x 60 m ≤34

FDA241 0.03…20 ≤800 m2 ≤4x 30 m ≤34

software.

The maximum number of aspirating holes depends on the sensitivity and

whether it is a question of class A, B, or C. You will find these details in the

'FXS2055 ASD Asyst Tool' software (see also the table above).

In rooms where there is an increased risk (rooms with ventilation systems), the

size of the monitored area drops to 270…540 m² with the FDA241

(170…340 m² with the FDA221).

The maximum monitored area depends on the topology selected and the overall

maximum pipe length.

See also

Technical data for FDA241, FDA221 [➙ 105]

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 44

4

Planning

Environmental influences

44

4.6 Environmental influences

Always ensure that the blowing-out unit used for blowing out is suitable.

If the devices are used in industrial applications, consultation with the project

manager is required, since plastics do not withstand certain environmental

conditions.

The following factors must be taken into consideration:

Chemicals

Temperature

Moisture

Fluctuations in air pressure, e.g. in well aerated rooms

4.7 Blowing-out unit

Deposits at the aspirating holes affect air aspiration and have the potential to

trigger an alarm. The pipe system should be blown out to purge it. To do this,

compressed air is introduced into the pipe system. The compressed air clears

deposits from the aspirating holes and capillary tubes. The aspirating smoke

detector features an output for the purpose of controlling a blowing-out unit.

Find out about any local regulations.

Blowing out unit requirements

The blowing-out unit must be approved in accordance with local regulations.

The aspirating smoke detector must not be subject to pressure.

– No compressed air is permitted to enter the aspirating smoke detector

during blowing out.

– The blowing-out unit must feature suitable valves.

– For blowing out purposes, it must be possible to disconnect the pipe

system from the aspirating smoke detector.

Once blowing out has been performed, it must be possible to reconnect the

pipe system to the aspirating smoke detector.

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 45

Mounting / Installation

5

Preparatory work

45

NOTICE

Electrostatic discharge

Ground yourself immediately before opening the housing, e.g. by touching a

ground point or wearing an anti-static belt.

1 2

5 Mounting / Installation

5.1 Preparatory work

5.1.1 Opening and closing the housing cover when the power

supply is switched off

When the housing cover is open, the mini USB connection and the internal

indicators are accessible.

Damage to electronic components in the aspirating smoke detector

● When working on the open aspirating smoke detector, use anti-static floor

mats and anti-static work surfaces.

●

Opening the housing cover

Opening the housing cover

The housing is free from dust.

1. Remove the two screws on the top of the aspirating smoke detector using a

size 2 Phillips screwdriver (step 1).

2. Slide the housing cover in the direction of the arrow until it snaps into place

(step 2).

The housing cover is open.

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Page 46

5

Mounting / Installation

Preparatory work

46

Closing the housing cover

NOTICE

Electrostatic discharge

Ground yourself immediately before opening the housing, e.g. by touching a

ground point or wearing an anti-static belt.

NOTICE

Accidental triggering of an alarm

Closing the housing cover automatically reactivates the relay outputs and the

4…20 mA analog output switches to normal operation.

The size 2 Phillips screwdriver and the two screws are available.

The power supply is switched off.

1. Slide the housing cover in the opposite direction to the arrow (step 2) until it

reaches the end position at the bottom.

2. NOTICE! Connection cable clamped between the back box and the housing

cover. Damage to the cable! Be aware of the connection cable when closing

the housing cover.

3. Screw the housing cover to the housing base with the two screws. Tighten the

screws by hand (step 1).

The housing cover is closed.

5.1.2 Opening and closing the housing cover when the power

supply is switched on

When the housing cover is open, the mini USB connection and the internal

indicators are accessible.

Damage to electronic components in the aspirating smoke detector

● When working on the open aspirating smoke detector, use anti-static floor

mats and anti-static work surfaces.

●

Triggering a false alarm

● When the housing cover is opened, the buzzer sounds. The relay outputs

remain active and the 4…20 mA analog output has been switched to fault

(0.5 mA).

● If the button is pressed, the buzzer switches off and the relay

outputs are deactivated. The 4…20 mA analog output remains on fault.

●

Building Tec hnologies A6V10334410_h_en_--

Fire Safety 2015 -09-29

Page 47

Mounting / Installation

5

Preparatory work

47

1 2

Opening the housing cover

Opening the housing cover

The housing is free from dust.

1. Remove the two screws on the top of the aspirating smoke detector using a

size 2 Phillips screwdriver (step 1).

2. Slide the housing cover in the direction of the arrow until it snaps into place

(step 2).

The housing cover is open.

Opening of the housing is logged in the modification memory.

The

The relay outputs remain active and the 4…20 mA analog output has been

switched to fault (0.5 mA).

3. Press the button to switch off the buzzer.

The relay outputs are deactivated.

The 4…20 mA analog output remains on fault.

The housing cover is open.

fault indicator flashes and the buzzer is switched on.

Building Tec hnologies A6V10334410_h_en_ --

Fire Safety 2015-09-29

Closing the housing cover

The size 2 Phillips screwdriver and the two screws are available.

1. Slide the housing cover in the opposite direction to the arrow (step 2) until it

reaches the end position at the bottom.

2. NOTICE! Connection cable clamped between the back box and the housing

cover. Damage to the cable! Be aware of the connection cable when closing

the housing cover.

Closing the housing cover automatically reactivates the relay outputs and

the 4…20 mA analog output switches to normal operation.

Closing of the housing is logged in the modification memory.

The fault indicator

3. Screw the housing cover to the housing base with the two screws. Tighten the

screws by hand (step 1).

The housing cover is closed.

goes out and the audio warning is switched off.

Page 48

5

Mounting / Installation

Preparatory work

48

5.1.3 Removing and installing the housing cover when the power

NOTICE