Page 1

FC700A

Fire detection system

Planning

Fire & Security Products

Siemens Building Technologies

Page 2

Liefermöglichkeiten und technische Änderungen vorbehalten.

Data and design subject to change without notice. / Supply subject to availability.

Sous réserve de modifications techniques et de la disponibilité.

© 2004 Copyright by

Siemens Building Technologies AG

Wir behalten uns alle Rechte an diesem Dokument und an dem in ihm dargestellten Gegenstand vor. Der Empfänger anerkennt diese

Rechte und wird dieses Dokument nicht ohne unsere vorgängige schriftliche Ermächtigung ganz oder teilweise Dritten zugänglich machen

oder außerhalb des Zweckes verwenden, zu dem es ihm übergeben worden ist.

We reserve all rights in this document and in the subject thereof. By acceptance of the document the recipient acknowledges these rights

and undertakes not to publish the document nor the subject thereof in full or in part, nor to make them available to any third party without our

prior express written authorization, nor to use it for any purpose other than for which it was delivered to him.

Nous nous réservons tous les droits sur ce document, ainsi que sur l'objet y figurant. La partie recevant ce document reconnaît ces droits et

elle s'engage à ne pas le rendre accessible à des tiers, même partiellement, sans notre autorisation écrite préalable et à ne pas l'employer

à des fins autres que celles pour lesquelles il lui a été remis.

Page 3

1 About this document ..............................................................................6

2 Safety regulations...................................................................................8

2.1 Signal words and symbols ........................................................................8

2.1.1 Signal words and their meaning................................................................8

2.1.2 Symbols and their meaning ......................................................................8

2.1.3 Classification and meaning of additional symbols ....................................9

2.2 Safety-relevant working instructions .........................................................9

3 Main features.........................................................................................11

4 Technical data FC700A.........................................................................12

5 Logical and physical structure............................................................13

6 Bus systems..........................................................................................14

6.1 Bus overview...........................................................................................15

6.2 Modifying the impedance of the various C-Bus cables...........................15

6.2.1 Diagram...................................................................................................16

7 C-Bus stations.......................................................................................17

7.1 Station .....................................................................................................17

7.2 Types of stations.....................................................................................17

7.3 Hardware.................................................................................................17

7.4 Visualizer for Windows remote operation software (not available yet)...18

7.5 Logical AREAS........................................................................................19

8 Limitations of C-Bus participants .......................................................20

8.1 Main CPU limits.......................................................................................20

8.1.1 Maximum number of devices ..................................................................20

8.1.2 Limits in the logical structure...................................................................20

8.1.3 Maximum number of criteria in zones control 4 and 6............................20

8.1.4 Maximum number of ZONE time channel...............................................20

8.1.5 Maximum number of I-Bus-modules.......................................................21

8.1.6 Limits of 5V supply..................................................................................21

8.2 Control terminal limits (FC/FT)................................................................21

8.2.1 Limitation of visible texts on a FC700A...................................................21

8.2.2 Limitation of visible texts on a FT700A ...................................................21

8.3 Gateway limits (FG) ................................................................................22

9 Specify hardware required...................................................................23

10 Control unit FC700A .............................................................................24

10.1 Configuration...........................................................................................24

10.2 Block diagram .........................................................................................25

10.3 Modules...................................................................................................25

11 Auxiliary power supply.........................................................................26

11.1 Configuration...........................................................................................26

11.2 Block diagram .........................................................................................26

11.3 Modules...................................................................................................26

12 Control terminal B3Q700 (FC/FT) ........................................................27

12.1 Features .................................................................................................. 27

12.2 Options....................................................................................................27

12.2.1 Plexiglas door to B3Q700 (FC/FT)..........................................................27

12.2.2 Place of the E3I020 RS232 module (FT)................................................28

12.2.3 Place of the E3I040 LON interface (FT) .................................................28

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

3

Page 4

12.3 Installation possibilities (FT)....................................................................29

12.4 Block diagram .........................................................................................29

12.5 Connection lines between control unit and external operating units ......30

12.6 Power supply (24V).................................................................................30

12.7 Modules...................................................................................................31

13 Range of cabinets H23 / H26 / H28 ......................................................32

13.1 Recessed mounting H23G230 and H28G200 ........................................33

13.2 Modules...................................................................................................33

14 19” accessories.....................................................................................34

14.1 Modules...................................................................................................34

15 Line modules .........................................................................................35

15.1 Overview .................................................................................................35

15.2 Modules...................................................................................................35

15.3 Detection line "addressable" SynoLOOP................................................36

15.4 Detection line "collective" SynoLINE600/-Ex ..........................................37

16 Connection factors, line resistances and capacitances...................38

16.1 Terminology and abbreviations...............................................................38

16.2 Collective detection line ..........................................................................38

16.3 Addressable detection line......................................................................38

16.4 Line resistance and capacitance.............................................................39

17 Control modules....................................................................................40

17.1 Application of control modules ................................................................40

17.1.1 Overview of the available modules with control outputs.........................40

17.2 Means of linking ......................................................................................40

17.3 Control outputs station type FC700A ......................................................41

17.4 Control outputs remote station type FT700A ..........................................41

17.5 Modules...................................................................................................41

17.6 CPU-overlapping controls .......................................................................42

17.7 Mimic Display panel outputs ...................................................................43

17.8 Modules...................................................................................................43

17.9 Relay outputs ..........................................................................................44

17.10 Modules...................................................................................................44

18 LON-Bus devices ..................................................................................45

18.1 Features ..................................................................................................45

18.2 LON-Bus as stub line ..............................................................................45

18.3 LON-Bus as free topology.......................................................................46

18.4 LON/Mimic Display p.c.b K3I050 ............................................................46

18.5 LON I/O card K3I110...............................................................................46

18.6 Indicator devices B3Q580 and B3Q590/595...........................................47

18.7 Modules...................................................................................................47

19 Gateway..................................................................................................48

19.1 Main features ..........................................................................................48

19.2 Application...............................................................................................48

19.3 Modules...................................................................................................49

20 Remote transmission............................................................................50

21 Printer interface.....................................................................................51

4

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 5

21.1 Features .................................................................................................. 51

21.2 Application variant FT .............................................................................51

21.3 Application variant FC.............................................................................51

21.4 Modules...................................................................................................51

22 Power supply.........................................................................................52

22.1 Concept...................................................................................................52

22.2 Special functions.....................................................................................52

22.3 Application...............................................................................................52

22.4 Power supply for the control unit.............................................................52

22.5 Auxiliary power supply ............................................................................52

22.6 Modules...................................................................................................53

22.7 Operation with power supply from control unit........................................53

22.8 Power supply for remote transmission equipment and accessories.......53

23 Emergency power supply ....................................................................54

23.1 Specifying battery capacity .....................................................................54

23.1.1 Battery rated capacity .............................................................................54

23.1.2 Ageing of battery.....................................................................................54

23.1.3 Calculation ..............................................................................................54

23.2 Capacity values for standard configurations...........................................54

23.3 Quiescent current table...........................................................................55

24 Alarm concept .......................................................................................56

24.1 Cerberus Alarm Concept (CAC) .............................................................56

24.2 Principle of the Cerberus alarm concept.................................................56

24.3 Determine the alarm organization...........................................................57

24.4 Organization of system operation ...........................................................57

25 Commissioning .....................................................................................58

26 Parameterization, Flash programming ...............................................59

26.1 Functions.................................................................................................59

26.2 Modules...................................................................................................59

27 FC700A modules in alphabetical order ..............................................60

28 Spare parts ............................................................................................62

29 Configuration sheets ............................................................................63

29.1 List of configuration sheets .....................................................................63

30 Control unit FC700A .............................................................................64

31 Auxiliary power supply.........................................................................65

32 Control terminal FT700A ......................................................................66

33 Display & operating terminals .............................................................67

34 Externally placed modules...................................................................68

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

5

Page 6

About this document

1 About this document

Purpose

This document describes the project planning of the hardware modules of the control unit FC700A. The consistent adherence to these instructions is a prerequisite

for a safe application.

Scope

This document contains information of all FC700A components, including part

numbers for ordering.

Target group

This product documentation and the work instructions are aimed at the following

persons, who have a particular function and have the corresponding training and

qualification.

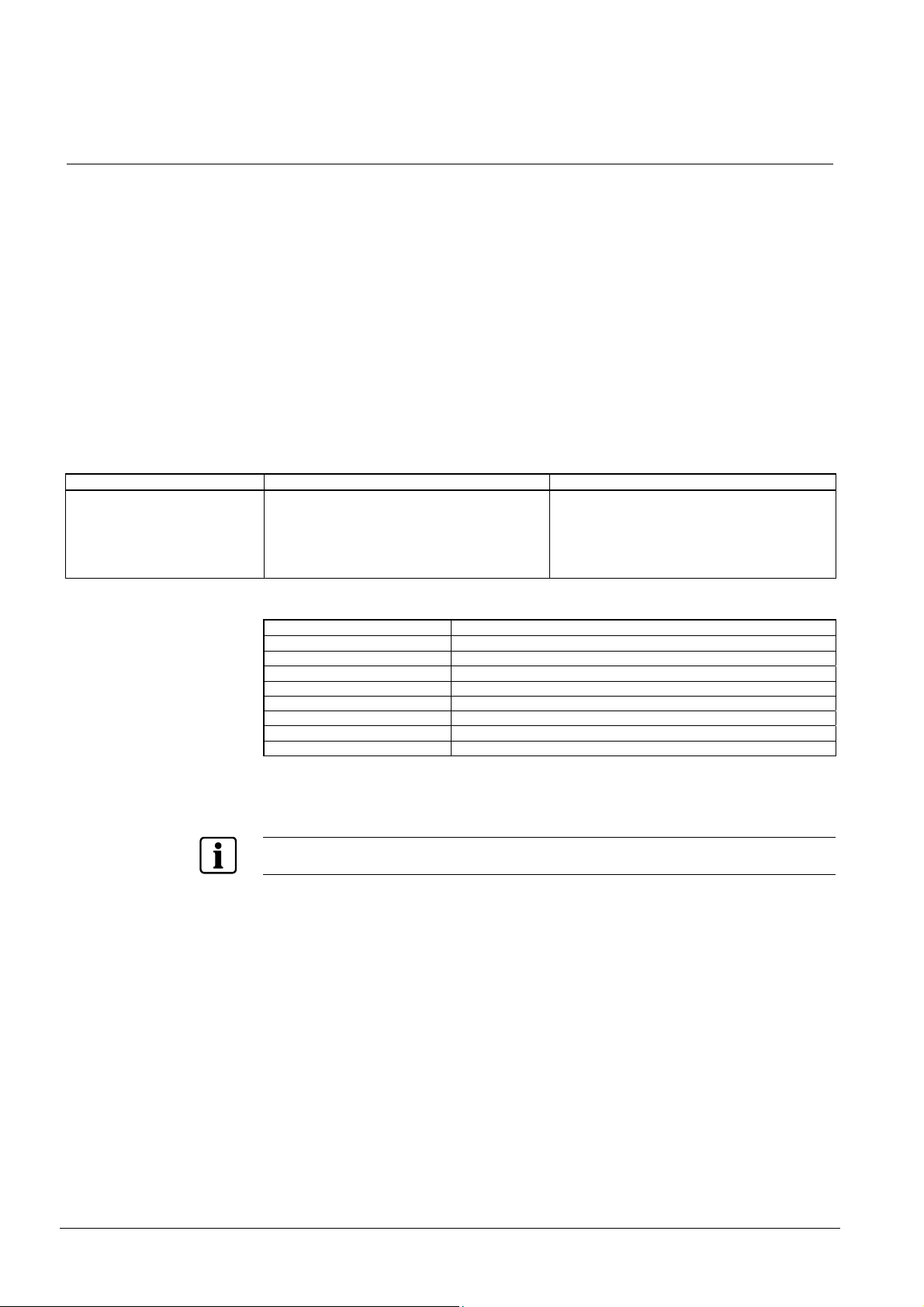

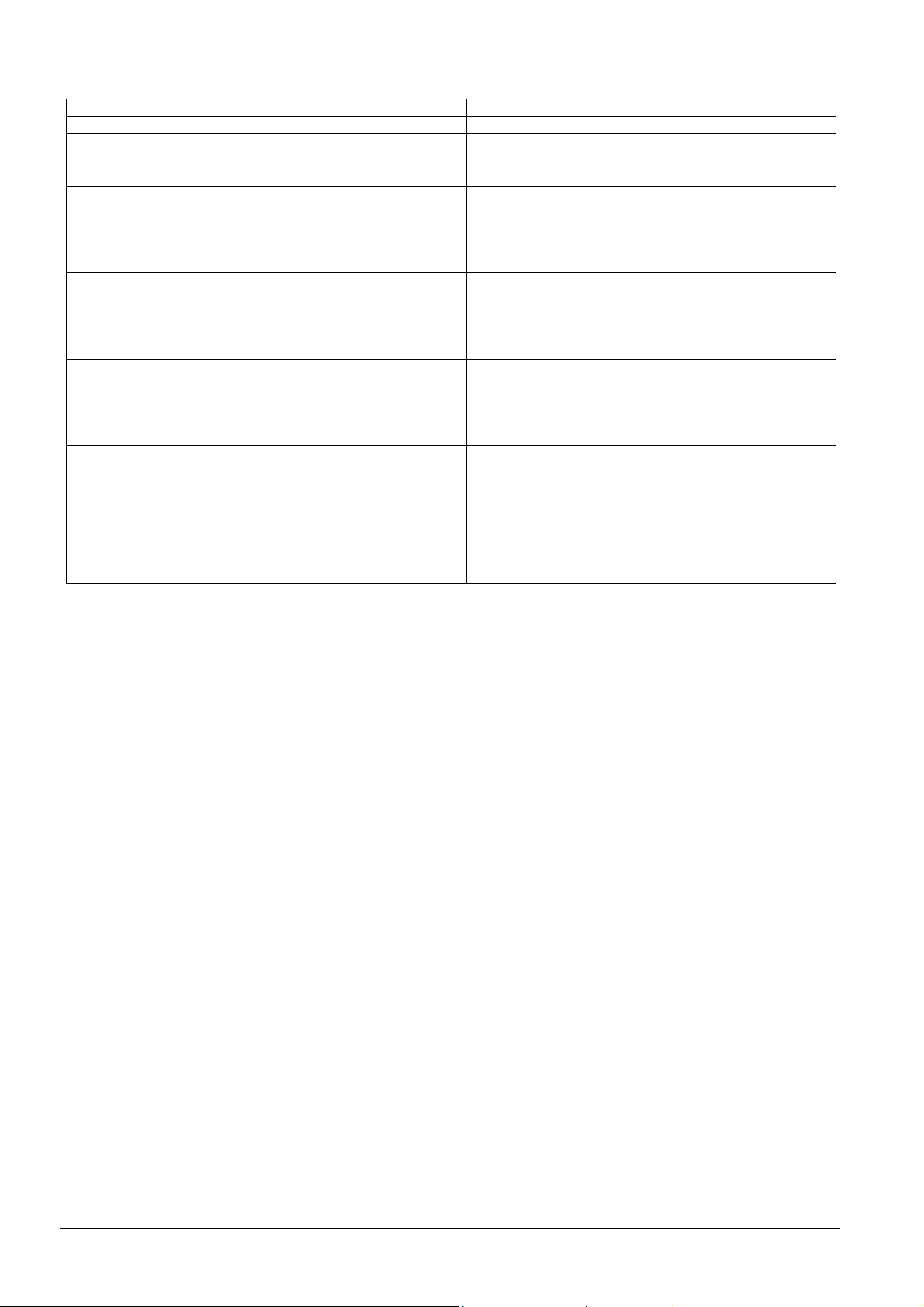

Group of persons Activity Qualification

Project Manager The project manager is responsible for the local

project management. He co-ordinates the schedules of all groups of people working on a project

as well as resources. He also continuously obtains the technical information required for project

realization.

He has had the technical training appropriate to

his function and the size of a project or the product line used in the project and has attended the

training courses for project managers at the supplier’s works.

Reference documents

Information in Document

007831 Hardware description

007827 Installation housing H26... /H28...

007832 Visualizer Customizing / End user (not yet available)

007835 Operating instructions

007828 Installation / Hardware Commissioning

007833 Maintenance instructions

007894 Templates for inscription stripes

007895 Operating platform for Tools

Work and operational safety

Before personnel begin work on the system they must have read and understood the related operating

instructions, in particular chapter 2 ”Safety regulations”.

Disregard of the safety regulations

Before they are delivered, products are tested to ensure they function correctly

when used properly. Siemens disclaims all liability for damage or injuries caused

by the incorrect application of the instructions or disregard of warnings of danger

contained in the documentation. This applies in particular to:

– Personal injuries or damage caused by improper use and incorrect use;

– Personal injuries or damage caused by disregarding safety instructions in the

documentation or on the product;

– Personal injuries or damage caused by poor maintenance or a lack of mainte-

nance.

6

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 7

About this document

Conventions

(...) Additional information

..) Notes

’’......’’ / ’.....’ Definitions of designations

-> Details see page ...., chapter or document .....

Configuration sheets to fill out

Document identification

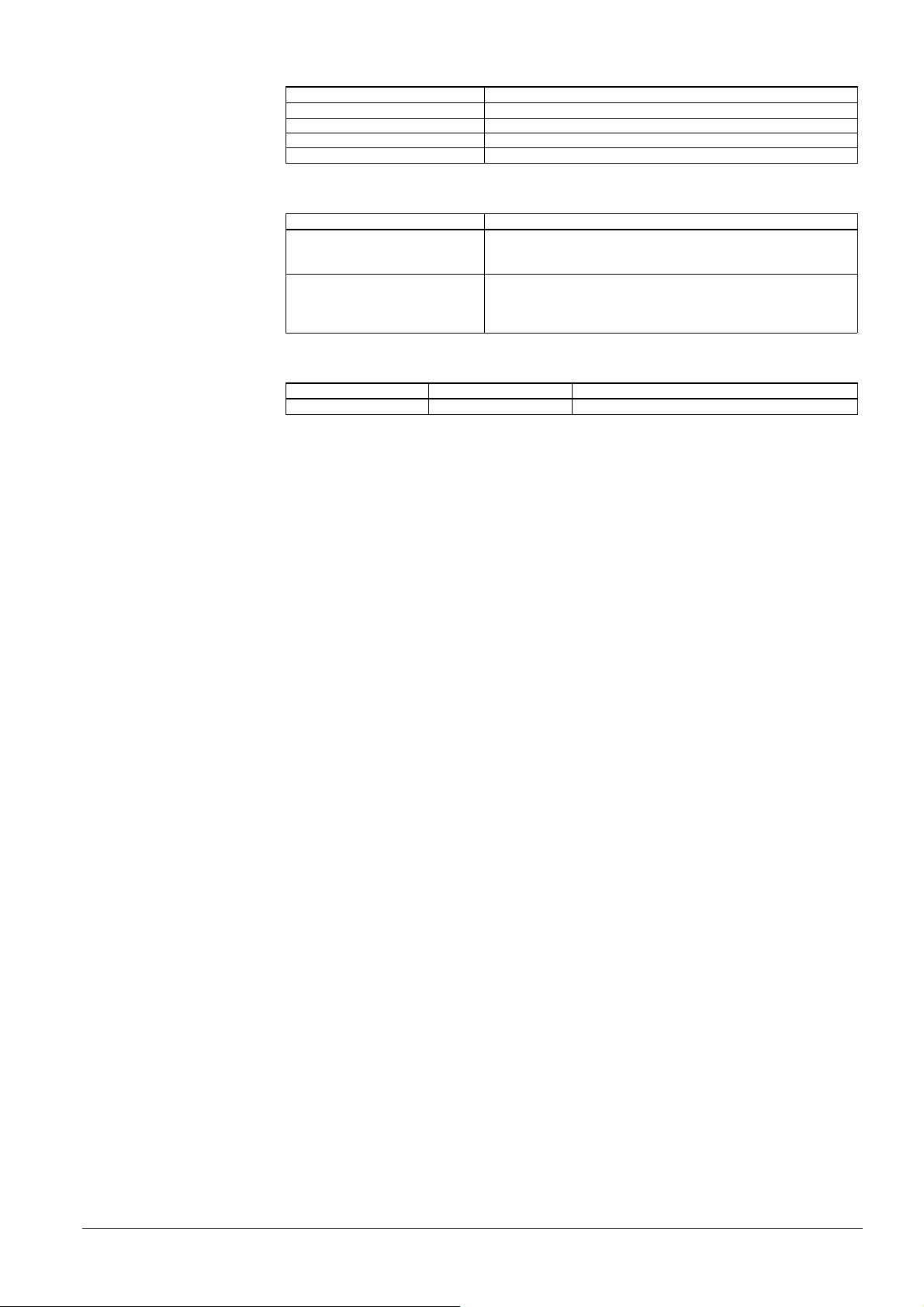

Place Signification

Title page – System names

Last page

bottom left

bottom right

– Product type

– Document purpose

– The document number consists of: Language, number, index

– Version date

– Manual

– Register

Modification index

Version Date Brief description

007836_a_en_-- 03. 2004 First edition

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

7

Page 8

Safety regulations

2 Safety regulations

This chapter describes the danger levels and the relevant safety regulations applicable for the use of our products. Please read the work instructions as well as the

chapter ”About this document” thoroughly before beginning any work.

2.1 Signal words and symbols

2.1.1 Signal words and their meaning

The danger level that is, the severity and probability of danger are indicated by the

signal words listed below. Non-observance may lead to the consequences indicated:

DANGER

Imminent danger!

May cause serious bodily injury or danger to life!

WARNING

Dangerous situation!

May cause serious bodily injury or danger to life!

CAUTION

Possibly dangerous situation!

May cause light injuries!

NOTE

Possibly harmful situation!

May cause damage to the product or to objects in the immediate vicinity of the

product!

2.1.2 Symbols and their meaning

The symbols listed below indicate the nature and origin of the danger.

Signal word General danger

Signal word Electrical voltage

Example for a danger warning

DANGER

External voltage

Disconnect the module from power supply.

8

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 9

2.1.3 Classification and meaning of additional symbols

Tips and information

Refers to extremely important or critical decisions to be taken into account before continuing the work.

2.2 Safety-relevant working instructions

Country-specific standards

The products are developed and produced in compliance with the relevant international and European safety standards. Should additional country-specific, local

safety standards or regulations concerning project planning, assembly, installation,

operation and disposal of the product apply in the place of operation, then these

standards or regulations must also be taken into account in addition to the safety

regulations mentioned in the product documentation.

Safety regulations

DANGER

Work on electrical

installations

Any work on electrical installations may only be carried out by qualified electricians or instructed persons working under the guidance and supervision of a

qualified electrician, in accordance with the electro technical regulations.

Electrical installations

Control units must be disconnected from the power supply during commissioning

or maintenance work.

Terminals with an external voltage supply must be provided with a sign ”DAN-

GER - External voltage”.

Mains leads to the control unit must be installed separately and provided with a

clearly marked fuse.

Earthing must be carried out in compliance with local safety regulations.

When work is carried out in explosion-hazardous areas, the appropriate safety

precautions must be taken.

Assembly, installation, commissioning and inspection work

If any tools or accessories such as ladders are required, safe and suitable de-

vices must be used.

Prevention of spurious tripping of the remote transmission must be assured.

Always inform the fire brigade before testing the remote transmission.

The activation of fire control installations for test purposes must not cause dam-

age to the system or parts thereof.

Fire control installations must only be activated after the test has been com-

pleted and the system has been handed over to the customer.

Third party systems or devices must only be activated in the presence of the re-

sponsible person.

When work on management stations and system terminals are performed, the

safety regulations of the connected sub-systems must be observed. This especially applies when switching-off system components.

In the case of extinguishing systems, always use the ”General installation in-

structions” as a guideline. This guideline is available on request.

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

9

Page 10

Safety regulations

Testing the product operability

Evacuate and cordon off extinguishing sector.

Inform people about the possibility of occurring fog and noise.

Inform people before testing of alarm devices; take the possibility of panic reac-

tions into account.

Inform the alarm and fault receiving stations connected to the system before

running the tests.

Modifications to the system design and the product

Modifications to a system or to individual products may cause faults or malfunctioning.

Please request written approval from us, and the relevant authorities concerning intended system modifications and system extensions.

Modules and spare parts

Locally procured modules and spare parts must comply with the technical speci-

fications laid down by the manufacturer. This compliance is always ensured for

original spare parts supplied by us.

Only use fuses with the specific fuse characteristics.

Wrong battery types and improper battery exchange may introduce the danger

of explosion. Only use the specified battery type or an equivalent battery type

recommended by the manufacturer.

Batteries require environmentally safe disposal. They must be handed in at the

local collecting points.

Please take into account that the extinguishing agent cylinders are pressurized

and must be exchanged in compliance with the local safety regulations.

10

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 11

3 Main features

Fire detection system for modular configuration

Up to 1000 detectors per FC700A possible

For the processing of addressable and conventional detectors

Logical and physical structure totally separated

Control console as main CPU

Interfaces for VdS peripheral equipment, printer, host systems

Different types of input and output modules

Special Mimic Display terminal activating module

Multidetector logic

Up to 16 free selectable type of stations per C-Bus

Comfortable operation with soft keys and large LC display

Up to 64 independent logical AREAS (Organization levels)

Single-AREA or multi-AREA operation

Event memory with sub-menu / search functions

Integrated real time clock with auxiliary battery

Automatic summer/winter time switchover

Integrated emergency operation function

Flexible detector parameters setting via maintenance PC

Connectible detector systems

Synova™ 300/600, Special detectors

SynoLOOP

Stations

Control terminal / Main-CPU ‘FC700A’

B3Q700

Main features

Control terminal ‘FT700A’

B3Q700

CPU

SynoLINE300

SynoLINE600 / SynoLINE600-Ex

Special detectors

E

-

A

1

0

1

1

O

D

e

p

y

S

N

T

E

®

M

s

E

u

I

r

e

S

b

r

e

C

x

E

E

x

i

b

I

I

C

T

4

P

T

B

N

r

.

WINDOWS based

Configuration software

FG700A

Gateway

SWE700A

11

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 12

Technical data FC700A

4 Technical data FC700A

Operating voltage 115 / 230VAC ±15% 50... 60Hz

Power consumption 40... 220VA (per converter B2F020)

Battery operation in the event of mains failure

- Standard operating period

- Optional

Environmental conditions

Temperature during operation

Storage

Humidity

IP protection category (EN 60529 / IEC 529)

- Control unit

- Remote control terminal

Dimensions

- Control unit cabinet

- Separate control terminal in cabinet H26G220

H28G200

Colors

- Control unit cabinet

- Operating unit front terminal B3Q700

- Control terminal cabinet H26G220

H28G200

H28T110/120

12...24h

Up to 72h (see chapter 23)

0°C... +40°C

-20°C... +60°C

Max. 95%, no condensation

Complies with class 3K5 according to IEC 721–3–3

IP50

IP52 H26G220 cabinet

IP40 H28G200 cabinet

W = 520mm, H = 602mm, D = 100mm / 155mm

W = 366mm, H = 219mm, D = 76mm

W = 520mm, H = 300mm, D = 70mm

RAL 7035 light grey

Dark grey like Pantone 431C, Pantone 429C grey

Pantone 421 grey

RAL 7035 light grey

1E110 dark grey

12

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 13

5 Logical and physical structure

r

r

g

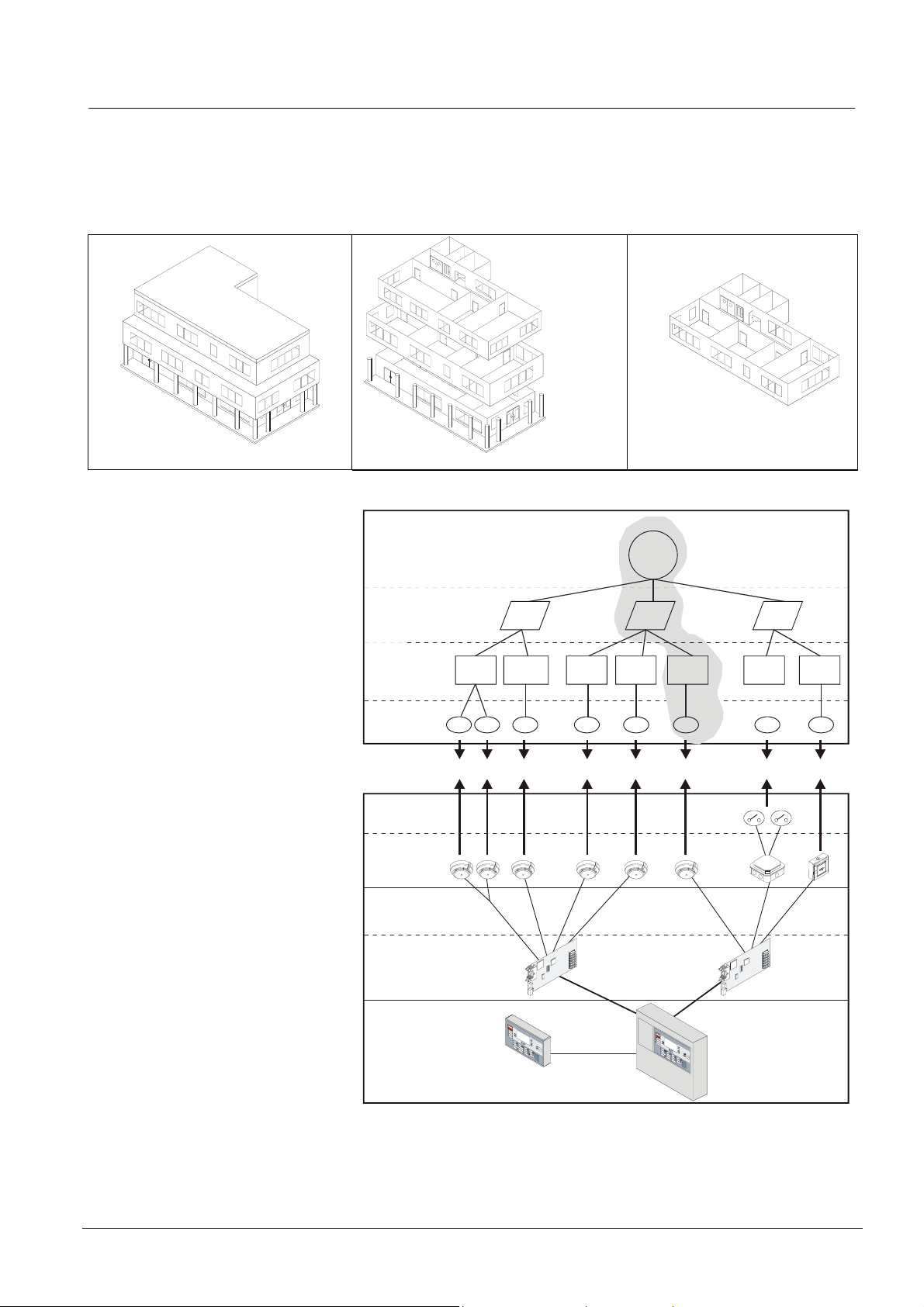

In the FC700A fire detection system, the logical structure is completely separated

from the physical structure. This enables the greatest possible flexibility. Display

and control terminal are based on the geographical and organizational aspects and

are independent of the actual hardware installation of the detector network.

Geographical features (-> building structure)

Logical and physical structure

Main building (Area)

Logical structure

The logical structure is a configuration of the

geographical features of a system. It can be

modified easily to the building structure, room

utilization etc.

Within the same control unit the logical structure is independent of the wiring of the detector network.

Linking

The lowest levels of both structures are linked

to each other. It is determined which physical

devices (e.g. detectors) are in which logical or

geographical location.

Physical structure

The physical structure is a configuration of the

hardware. It results from the hardware installation. The number of used levels is depending on the type of hardware.

Area

Section

Zone

Element

Level 2

Level 1

Device

Level 2

Level 1

Function unit

Station

st

floor (Section)

1

Ware

house

Line 1

Control terminal ‘FT’

2nd floor

1st floor

ground floo

logical structure

Ground

floor

Reception

Line 2

Room

Line 3

C-Bus

physical structure

Room 101

building

Room

102

103

Linkin

Line 4

Line modules E3M111

I-Bus

Main

1st

floor

Room 102

Room 103

Room 104 (Zone)

Room

104

SynoLOOP

Control unit ‘FC’

Room 104

Canteen

2nd

floor

1st floo

EDP

room

13

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 14

Bus systems

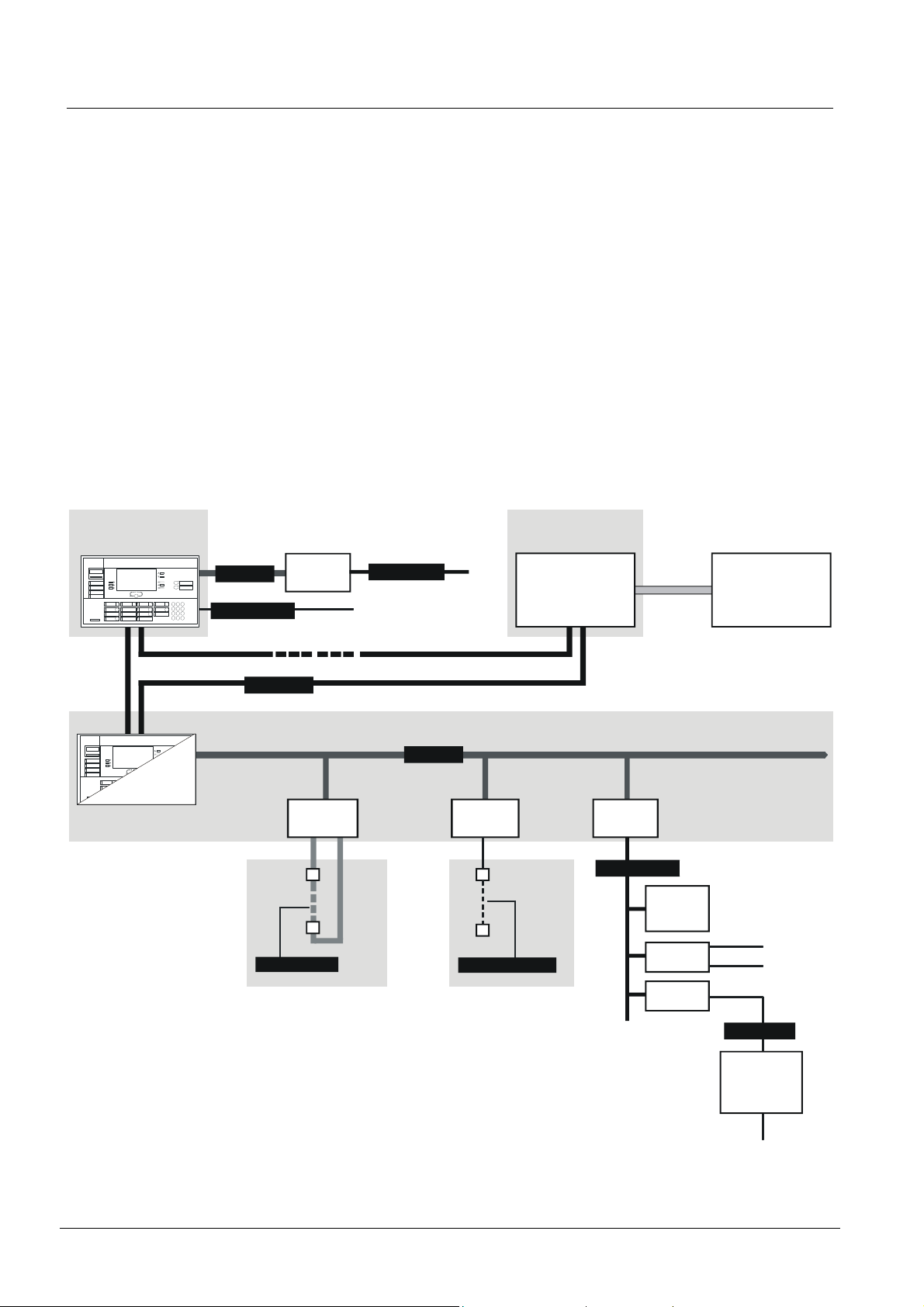

6 Bus systems

In the FC700A fire detection system there are 5 communication levels:

I-Bus

Internal data bus between individual modules in the control unit (line modules,

control modules etc.)

C-Bus

Local data bus between control unit(s), control terminal(s) and Gateway(s)

SynoLOOP and SynoLINE600

Local detector bus; connects the detectors to the control unit

LON-Bus

Local data bus for floor repeater panels, mimic display converter and LON I/O

card

Data Bus

Local data bus for parallel indicator panel, synoptic panel or relay

Control terminal

FT700A

CPU

B3Q700

I-Bus

Databus

C-Bus

SynoLOOP

E3I040

E3M111

LON-Bus

I-Bus

Line modules

E3M080

SynoLINE600

Gateway

FG700A

E3H020

E3I040

LON-Bus

RS232

Building

management

system

ISO1745 Protocol

Control unit FC700A

B3Q580/

B3Q590/

B3Q595

K3I110

In-/Outputs

K3I050

Databus

B3R051

or

K3R072/

K3G060

14

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 15

Bus systems

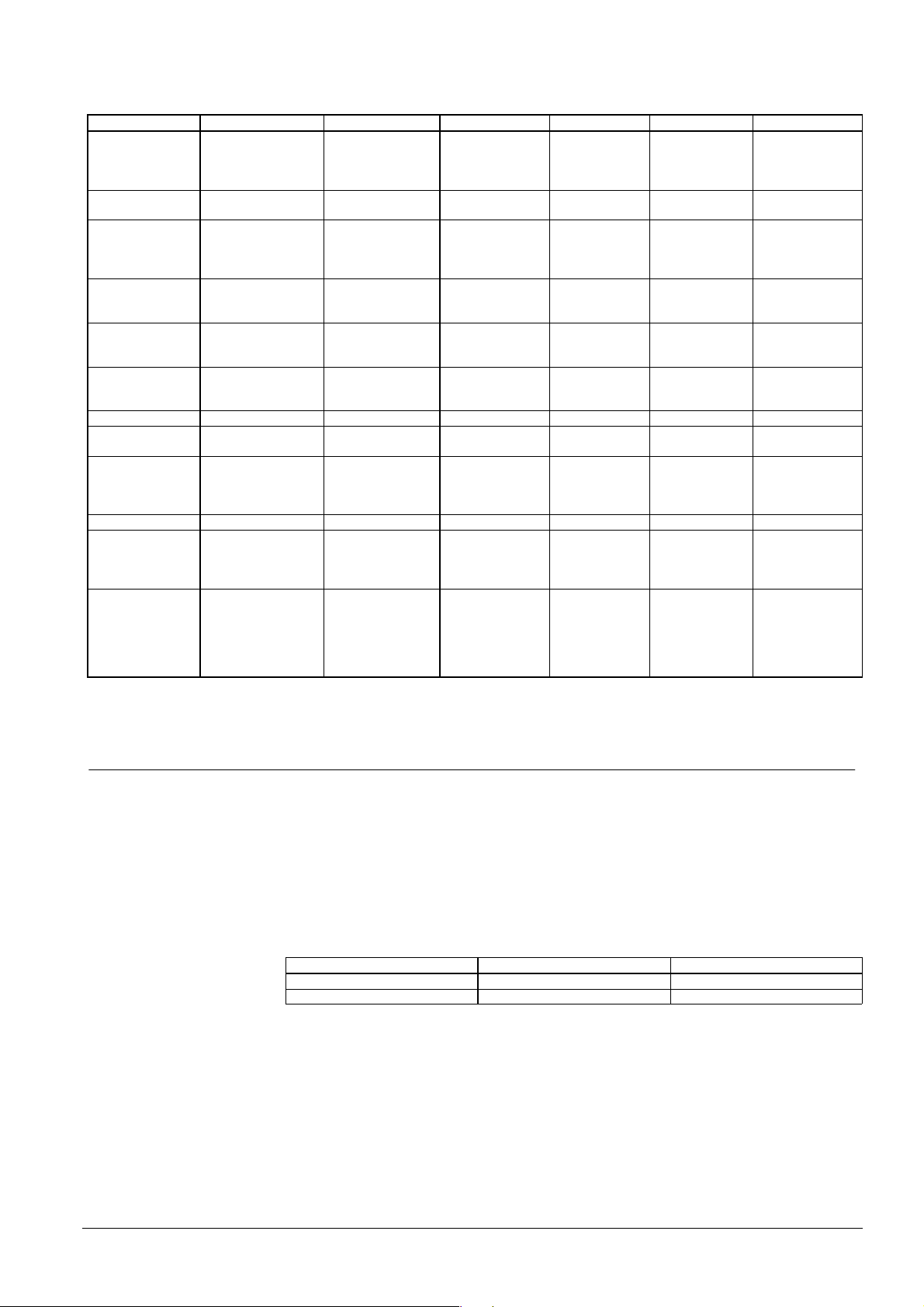

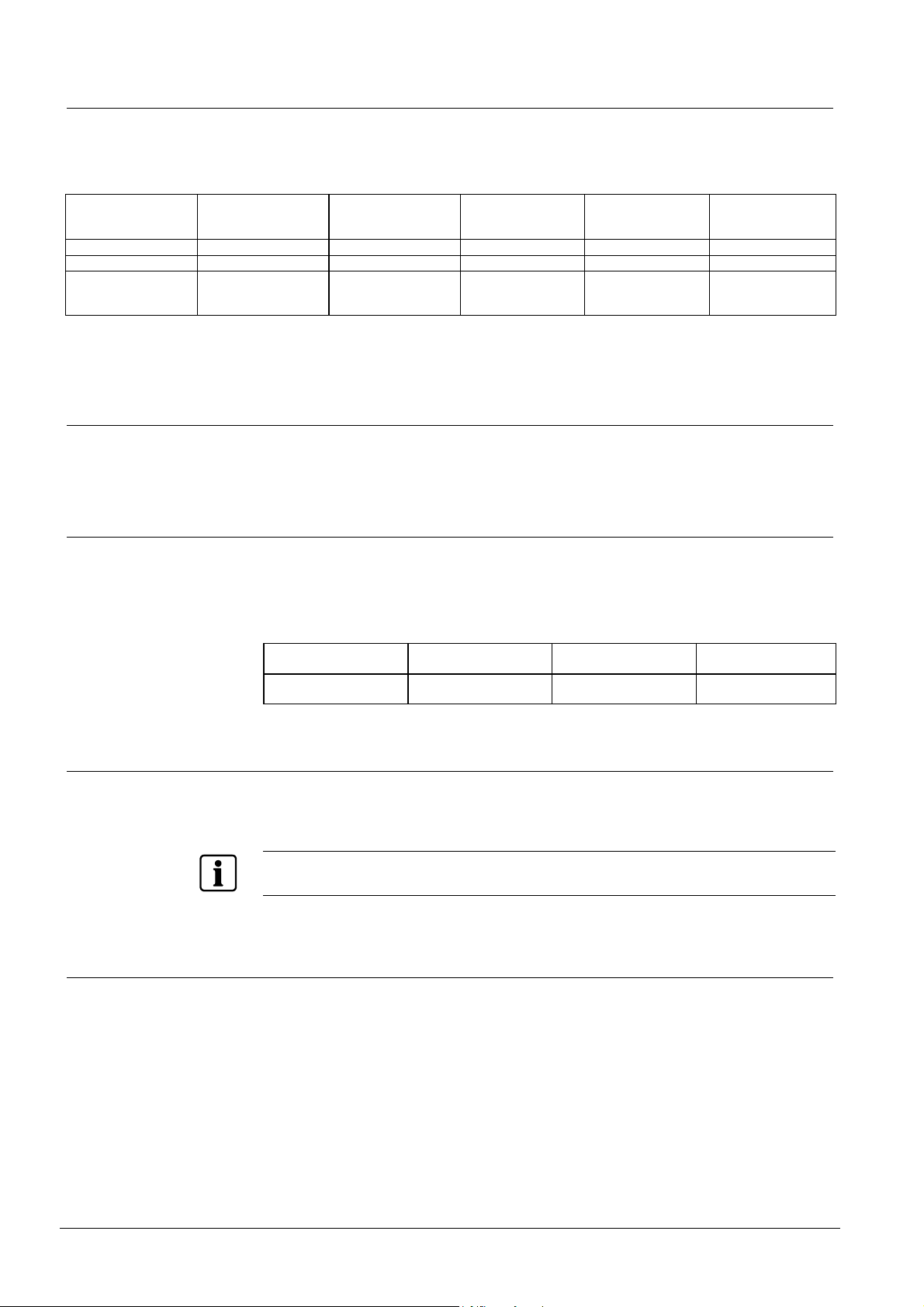

6.1 Bus overview

Features C-Bus I-Bus SynoLOOP SynoLINE600 LON-Bus Data Bus

Field of application

Speed of transmission

Length of line

Number of users

connected or

addresses

Number of wires 2

Type of cable

Loop line

T-branch

Short-circuit proof Yes

Network structure

Scanning

Principle

Local system bus Inside control unit

57kBaud 1000kBaud 2 messages/sec

Max. 1000m

(G51 ∅ 0,8: 1400m)

… 16

C-Bus devices

(+3 wires for emer-

gency operation)

Twisted 1) Flat cable

✔

– – – –

Each user connected with line

separator

Master/master Master/slave Master/slave Master/slave Master/slave Master/slave

Event-controlled,

presence monitoring

Serial Bus

- Cerberus protocol

- Collision detection

- Manchester coding

For addressable

detectors

Max. 3m (only

inside cabinet)

… 16

I-Bus modules

26 2 2 2

–

–

Cyclic,

Event controlled

C-Bus

- Cerberus protocol

- SPI/Motorola

Max. 150Ω/300nF

See chapter 16

… 128

D-Bus devices

Twisted

(Un-twisted per-

missible)

✔

Yes

Each user connected with line

separator

Cyclic

- typ. all 64s

- Interrupt on

alarm

Sensor/actor-Bus

- Cerberus protocol 'K31'

- Serial 8bit

- Start-up: daisychain

For collective

detectors

(Direct current

signal)

Max.

150/250Ω/4µF

See chapter 16

1 address

(Max. 25 detec-

tors)

Twisted

(Un-twisted

permissible)

– – –

No No Yes

–

Conventional

- Current gain

principle

- Voltage levels

Local data bus

for floor indicator

panels

78kBaud SPI-Bus 2KHz

Max. 500m as

free topology

Max. 1000m as

stub line

… 32

LON-Bus de-

vices

Twisted Twisted

✔

(See chapter 18)

Event-controlled,

presence moni-

toring

(All 60s)

Network

- Echelon Chip

(LON protocol)

- Cerberus

specific telegram

1 Calibrated according to cable impedance: 50Ω (MICC) / 110Ω (G51, ø

0.8mm, not shielded)

Local data bus

parallel ind.

panel, synoptic

panel or relay

Max. 1000m

… 24

Max. 8 addresses

6

(+3 wires supply)

–

Cyclic

- typ. all 250ms

Serial bus

- Cerberus protocol

6.2 Modifying the impedance of the various C-Bus cables

C-Bus standard cables have a characteristic impedance of 110Ω. The driver and

end-of-line resistors are soldered to solder lugs and can be adapted accordingly

with other characteristic impedances (see diagram chapter 6.2.1).

1. Explanation

A cable must be terminated with resistors. The resistance value must correspond

to the impedance of the cable. Each C-Bus user has four end-of-line resistors

(Ri). In addition two driver resistors (Rd) are integrated on the p.c.b. In order that

the resistors can be exchanged easily they are all soldered to solder lugs.

C-Bus p.c.b. Ri Rd

B3Q700 R31 ... R34 R49, R50

E3H020 R173, R174, R177, R178 R180, R183

The driver resistors specify the current on the C-Bus. In order that the signal on the

C-Bus always has the same amplitude (1.35Vpp), the following correlation is valid:

Rd = Ri x 3,65 (45Ω < Ri < 200Ω)

15

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 16

Bus systems

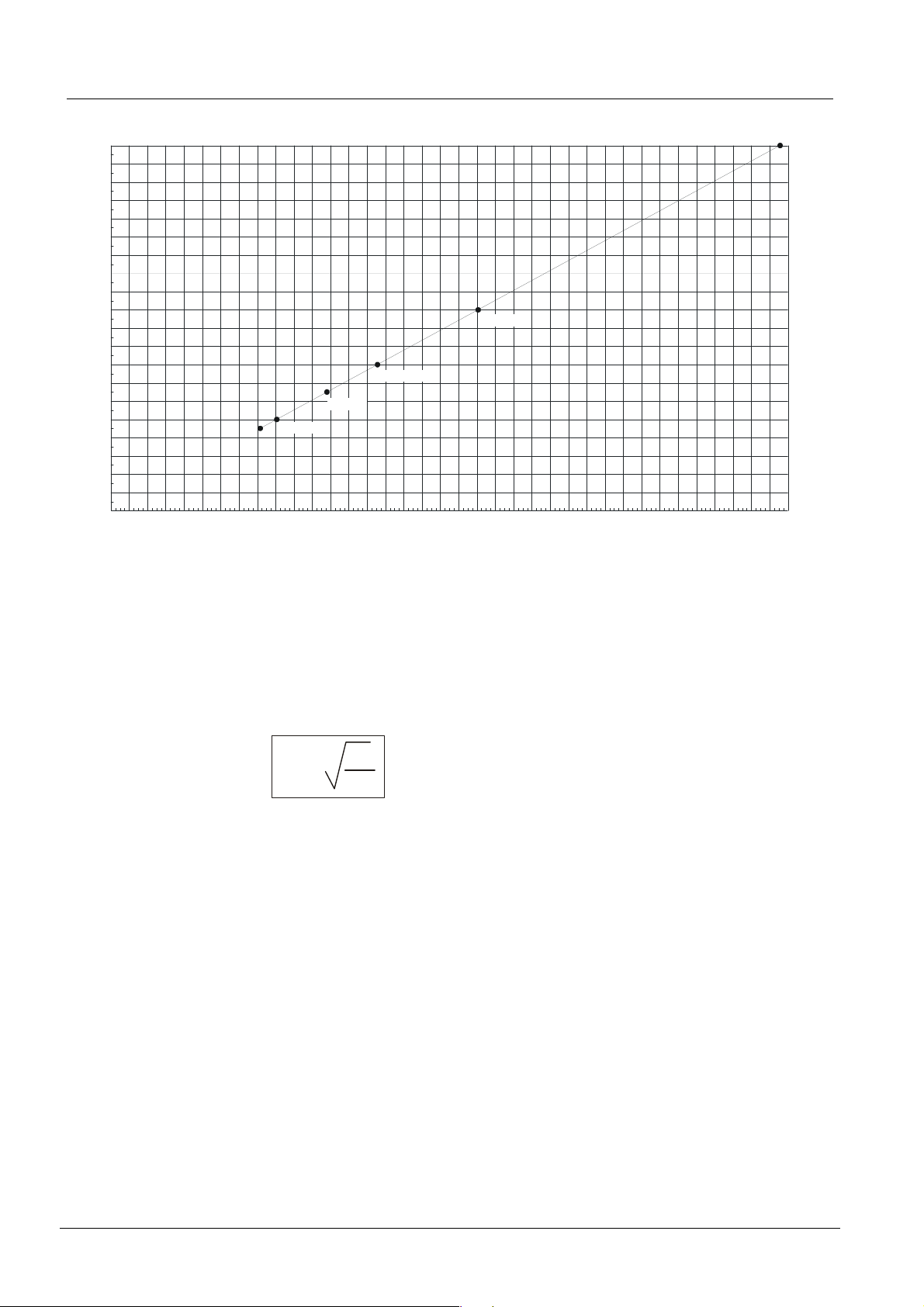

6.2.1 Diagram

Ri [Ohm]

200

190

180

170

160

150

140

130

120

110

100

90

80

70

60

50

40

30

20

10

0

0

20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440

Standard

Lifeline

Radox

MICC

460 480 500 520 540 560 580 600 620 640 660 680 700 720 740

Rd [Ohm]

2. Procedure

Request characteristic impedance of the cable from manufacturer (45Ω ... 200Ω)

Select the value of the Ri the same as the value of the cable characteristic im-

pedance and insert the four end-of-line resistors on the p.c.b.

Insert two driver resistors Rd = Ri x 3.65 on the p.c.b.

Each C-Bus user must be adapted

If only the inductance and the capacitance are known for a cable, the impedance

can be calculated with the aid of the following formula:

Zc: Cable impedance [Ω]

Lc: Cable inductance [µH]

Cc: Cable capacitance [µF]

Zc =

Lc

Cc

3. Mixing of different types of cable

In a C-Bus loop (or stub line) only one type of cable may be used.

4. Operation as a stub line

If the C-Bus is operated as a stub line, two end-of-line resistors (values as for Ri)

must be inserted externally at both ends of the line (default 110Ω). In the choice of

other cables the above rules apply (the Ri are in this case the external end-of-line

resistors).

For further information, see document 007831

16

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 17

7 C-Bus stations

r

The C-Bus network contains max. 16 stations (user connected)

– Within the limits stated below (FC, FT, FG) are any stations in any arrangement

possible

– Max. 64 AREAS

Control terminal

C-Bus Network

- max. 16 Stations

- 3 different types of stations

- loop line max. 1400m with G51 ø 0.8mm

FT700A

(max.15)

Building mangement system

ISO1745 Protocol

FG700A

(max.15)

Gateway

C-Bus

C-Bus stations

Control terminal

Main-CPU

FC700A

(max.16)

7.1 Station

– Function unit within C-Bus network

– Several stations are be located in geographically dispersed cabinets

7.2 Types of stations

Differentiated by function and represented by a certain module

Certain modules can be used for different types of stations

Types of stations available:

– FC700A Combination of main CPU and operating unit

– FT700A Control terminal

– FG700A Gateway (e.g. conversion of C-Bus Protocol -> ISO1745)

7.3 Hardware

Type of station Module

FC700A B3Q700

FT700A B3Q700

FG700A E3H020

I-Bus

Line

modules

’Main CPU’

Control

modules

Detecto

Function

✔ ✔

–

Function

’Operation’

✔

–

Function

’Gateway’

–

✔

17

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 18

C-Bus stations

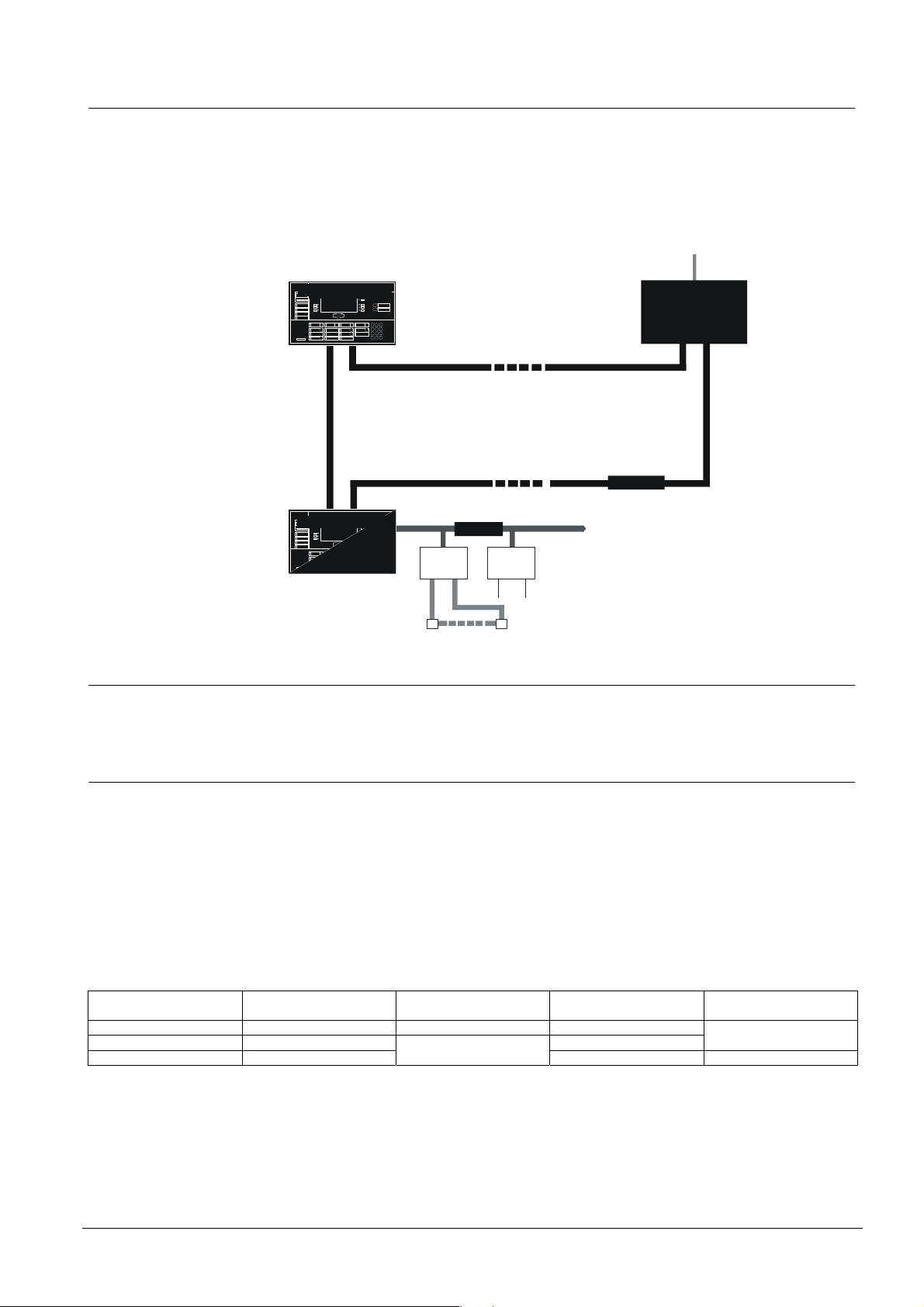

7.4 Visualizer for Windows remote operation software (not available yet)

– Operating platform requirements in detail see document 007895

– For details see document ……. (not available yet)

max. length of line

C-BUS

FC/FT

FC/FT

E3I020

E3I020

E3I020

B3D021

E3I020

dependent on

type of modem

Modem

Tel.

Modem

(RS232) ....15m

Standard PC with keyboard, software

’Visualizer for Windows’,

Tel .

Modem

e.g. Service Notebook, software

’Visualizer for Windows’,

SWE700A for Windows

Dedicated line

temporary public

telephone line

temporary public

telephone line

Modem

Tel .

Modem

Tel .

Modem

Visualizer

Remote Operation

(temporary)

18

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 19

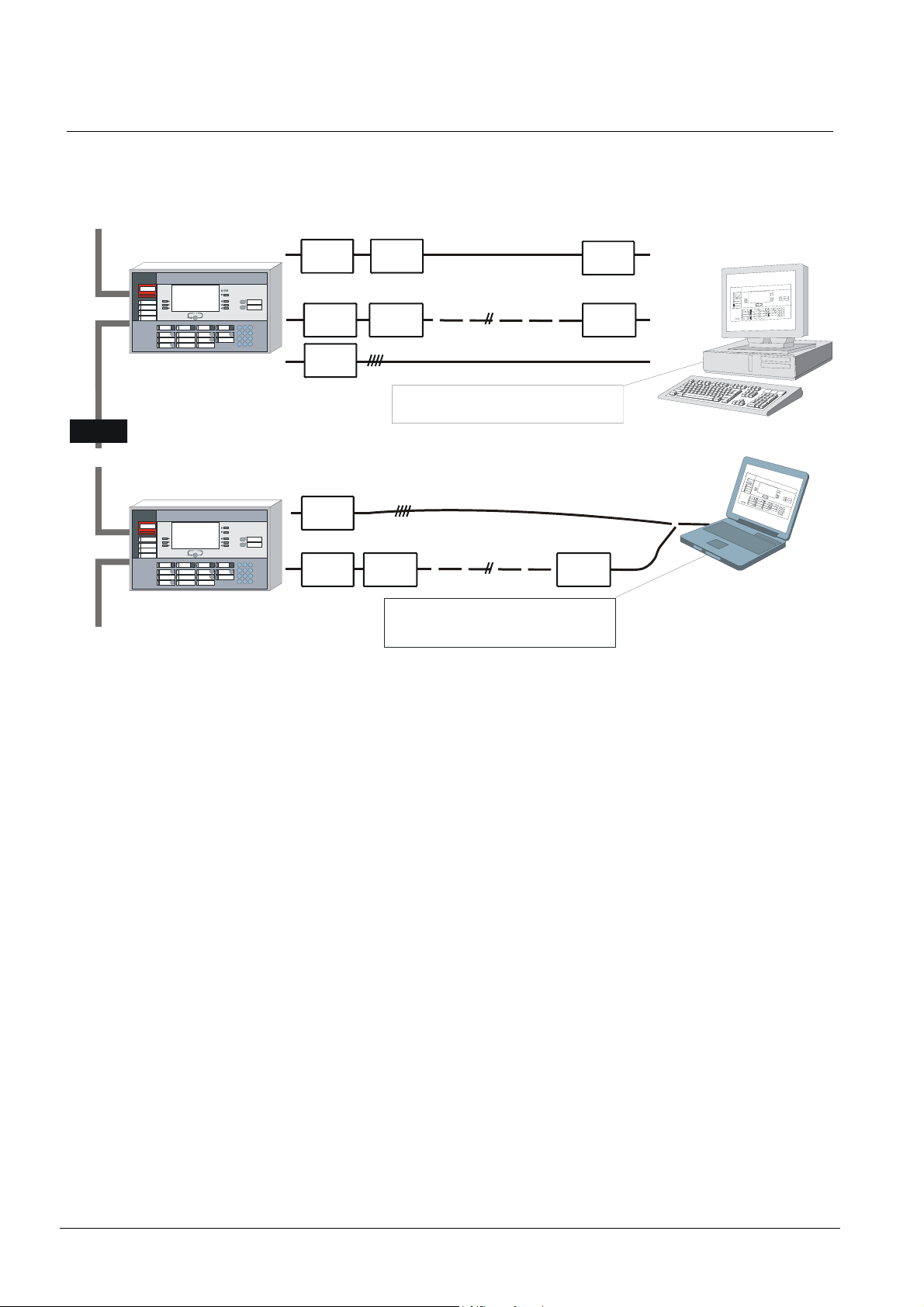

7.5 Logical AREAS

A

FC FC FC FC

C-Bus stations

1 2

AREA

34

5 6

78

FC FC

– Within one main CPU (FC) max. 4 AREAS can be configured

– CPUs cannot link up with AREAS of other CPUs

– CPU overlapping controls are possible

– Control terminals (FT) can be freely allocated to AREAS as required

– Visibilities on gateways (FG) shall be set per station only, not per AREA!

.. ..

All AREAS control terminal

.. ..

61 62

63 64

REA

FGFG

19

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 20

Limitations of C-Bus participants

8 Limitations of C-Bus participants

This chapter describes the quantitative limits of the FC700A station.

The selection of the station type depends on the requirements. The following variants are available:

Station type Modules

FC700A B3Q700 CIY00760 4x512Kx8Bit – –

FT700A B3Q700 CTY00760 4x512Kx8Bit – –

FG700A E3H020 – –

Flash ROM

(2x1024Kx8Bit)

'Program file'

8.1 Main CPU limits

8.1.1 Maximum number of devices

1000 devices (with AMPK=1) per FC700A.

SRAM

Soldered

EPROM set RAM set

CKQ007.60

(2x512Kx8Bit)

2 x Z3S070

(2x512Kx8Bit)

(Assembly ex works)

8.1.2 Limits in the logical structure

The limits in the logical structure are given by the node-type, by the highest possible CSX number and the maximum amount of display-digits. These limits are given

by the system and are independent of the memory capacity.

Table 'Limits of the logical structure'

Maximum rating

AREAS per STATION

... 4 …255 …255 …99

Maximum rating

SECTIONS per AREA

Maximum rating

ZONES per SECTION

8.1.3 Maximum number of criteria in zones control 4 and 6

The maximum number of control zones with 16 criteria is limited by 200.

To optimize the performance of your system minimize the number of CPU-overlapping controls as

much as possible.

A maximum of 40 CPU-overlapping controls (zone control 6) are admissible per C-Bus.

8.1.4 Maximum number of ZONE time channel

Max. 16 ZONES time channel are permitted per station.

Maximum rating

ELEMENTS per ZONE

International 5: …255

20

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 21

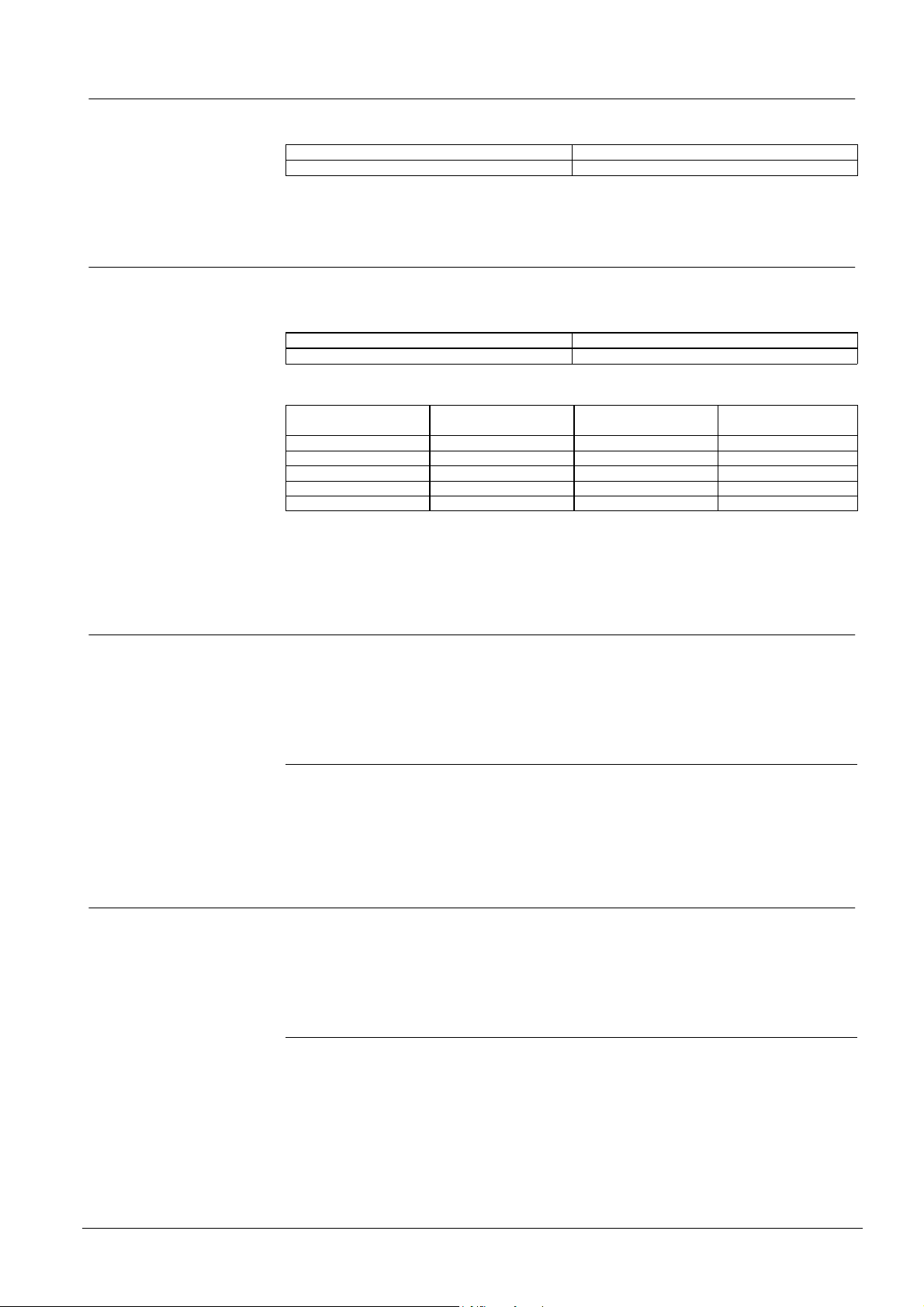

8.1.5 Maximum number of I-Bus-modules

Table 'Maximum number of I-Bus-modules'

Station type FC700A

I-Bus modules ... 16 1) ... 8 2) 3)

1) Limited by software

2) Value based on experience (depends on cabinet size and/or 5V current consumption)

3) Battery charging unit E3C011 counts as one I-Bus module

8.1.6 Limits of 5V supply

All I-Bus modules are supplied with 24V and 5V. The available current for the 5V,

supplied from main CPU is limited:

'Main CPU' Available current

B3Q700 / E3C011 250mA

Table '5V-Current consumption of I-Bus modules'

I-Bus module

E3M080 55mA E3G060 10mA

E3M111 25mA E3G070 10mA

E3L020 10mA E3C011 12mA

E3L030 35mA E3I020* 100mA

E3G050 8mA E3I040 70mA

* Not an I-Bus module, but supplied via the 'Main CPU'

Current consumption

from 'Main CPU'

Limitations of C-Bus participants

I-Bus module

Current consumption

from 'Main CPU'

8.2 Control terminal limits (FC/FT)

8.2.1 Limitation of visible texts on a FC700A

The number of texts of other stations (i.e. AREAS) that can be displayed on one

control terminal is limited by 14'000 texts.

To evaluate how many control panels FC700A can be displayed to one FC700A,

the following calculation must be used:

Twice the number of visible sections (worst case 1000)

+ The number of visible ZONES (worst case 1000)

+ The number of visible ELEMENTS with element text (worst case 1000)

= Number of texts per FC/FT (worst case 4000)

Example (worst case)

14'000 : 4000 (e.g.) = 3 fully configured FC can be displayed to one FC

8.2.2 Limitation of visible texts on a FT700A

The number of texts of other stations (FC700A) that can be displayed on one control terminal is limited by 14'000 texts.

To evaluate how many control panels FC700A can be displayed to one FT700A,

the following calculation must be used:

Twice the number of visible sections (worst case 1000)

+ The number of visible ZONES (worst case 1000)

+ The number of visible ELEMENTS with element text (worst case 1000)

= Number of texts per FC/FT (worst case 4000)

Example (worst case)

30'000 : 4000 (e.g.) = 7 fully configured FC can be displayed to one FT

21

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 22

Limitations of C-Bus participants

8.3 Gateway limits (FG)

Via one gateway a maximum of 8 C-Bus stations (FC700A) can be addressed.

If more than 8 C-Bus stations (FC700A) are present, they must be split up on two

gateways.

Also for special applications, more than two gateways can be configured.

Visibilities of C-Bus stations (FC700A) on gateways must be set station wise, not

area wise!

22

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 23

9 Specify hardware required

In order to be able to specify the hardware required, system key data must be

specified according the following procedure:

1. Specify number and type of detection lines

Dependent on:

– Detector series

– Number of detectors, input and output modules

– Building structure

2. Specify number and type of fire control installations

Dependent on:

– The fire protection installations to be activated

– Location of the contacts (centralized or decentralized)

– Individual types of contact (250VAC/10A or 30VDC/1A)

3. Specify number of operating units

Dependent on:

– Operating concept

– Parallel indicator panels, fire department control panels

4. Specify Accessories required

Dependent on:

– Printer interface and printer

– Remote transmission equipment

– Gateway, etc.

5. Specify emergency power supply battery capacity

Dependent on:

– Total quiescent current

– Required emergency current operating period (according to country)

– Type of remote transmission

6. Provide configuration sheet/sheets (see chapter 29)

Dependent on:

– Select sheets corresponding to the configuration

– Complete everything

Specify hardware required

23

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 24

Control unit FC700A

V

X1X

10 Control unit FC700A

10.1 Configuration

Pre-assembled compact control unit

E3G070 and E3M111 are pre-wired on terminal block 'X1'

Place for additional terminal block 'X2', modules, relay and batteries

Batteries as required either 2x 12V/15Ah or 2x12V/27Ah

Control terminal built into front terminal (also serves as main CPU)

Installation of parallel indicator panel B3R051 possible

Door right hinged, can be locked with 2 Allen screws

520

602

147

155 incl. projecting door hinges

Module chassis

view 'Modules'

EMC Precaution:

Slot rows with

E3C011 module

is not be allowed

with E3I040 module

46

E3H020 and

E3L030 requires

2 module spaces

E3H020

+ 2 x Z1K030

E3L030

+ 2 x Z1K or Z3I

E3....

Z1K or Z3I

E3....

Z1K or Z3I

View A

27

37

47

57

E3I020

E3M111

E3....

E3....

Z1K or Z3I

28

E3C011

Z1K030

38

E3G070

Z3I1050

48

E3....

Z1K or Z3I

5856

E3....

Z3I470

Z3I1050

Z1K or Z3I

Z1K or Z3I

21

B2F020

AC/DC converter

31

(Akku 12V)

AX1201

or

AX1210

51

(Akku 12V)

AX1201

or

AX1210

Converter 115/230VAC

-> 29.6VDC/6A

Cabinet front view

23

Mains

terminals

Z3B171

1

Z3B171

10

Battery charging module

Module chassis

view ‘Terminals’

FC700A-1

AB

Control module ‘universal’

Line module ‘SynoLOOP’

Terminal block ‘X1’ with

2x20 terminals in two levels

pre-mounted and pre-wired

recommended space

allocation

Z3I1060

2

Z3I1060

iew B

Control terminal

Cover plate

Z1K030

connection direct

Z3I1050

connection via terminal

block ‘X2’

24

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 25

10.2 Block diagram

B3Q700 ‘FT’

(additional operating facilities)

Control unit FC700A

RT = Remote transmission

Batteries

AX12..

1........7

Z3B171

I-Bus

E3L030

FSK

FBF HM

VdS peripheral

equipment

E3M111

1..........4 1.............8

SynoLOOP

E3M080

SynoLINE600

E3G...

E3L...

Basic equipment

Option

E3I040

LON-Bus

LON synoptic converter

LON I/O card

Floor repeater terminal

B3Q580/

FC700A

K3I050

K3I110

B3Q59x

24V

E3I020

RS232

1

Printer

C-Bus

2

B3Q700

‘FC’

24V

Mains

1..2

E3C011

24V

E3G070

24V

RT

250VDC / 10A

Fire control

installation

B2F020

5V

B3R051

10.3 Modules

Component Order-No. Description Notes

Control unit

FC700A-1 A5Q00004734 Control unit pre-assembled Including B3Q700, H23B010, B2F020, E3C011,

Control terminal, Parallel indicator panel

B3Q700 A5Q00004719 Control terminal

B3R051 490513 Parallel indicator panel

LON-Bus devices

E3I040 499310 LON interface

K3I050 496766 LON/Mimic Display converter

K3I110 528854 LON I/O card

B3Q580 496177 Floor repeater panel

B3Q590 496180 Floor repeater panel with control functions

B3Q595 534110 Floor repeater panel with control functions

Line modules

E3M111 511531 Line module SynoLOOP

E3M080 460268 Line module SynoLINE600/-Ex

Control modules

E3G050 460255 Control module 'Contacts'

E3G060 542539 Control module 'monitored'

E3G070 546661 Control module 'universal'

E3L020 546645 Control module 'Driver'

Z3B171 484383 Relay module

Interfaces

E3H020 460475 Gateway module Details see chapter 19

E3I020 460239 RS232 module Details see chapter 12 and 21

E3L030 475994 Control module VdS

Power supply

AX1201 225487 Battery 12V/27Ah

AX1210 475570 Battery 12V/15Ah

Accessories

Z3I1060 A5Q00004722 Terminal block, 2x20 terminals in two levels For additional modules

Z3I1050 A5Q00004717 Connection cable 19 conductors For connection via terminal 'X2'

Z1K030 484231 Terminal block with p.c.b. Chassis To direct connection

Z3I380 475567 Cable set I-Bus long To connect modules at the bottom with modules

Z3I470, E3G070, Z3I380, 2x Z3I1050, 1x Z3I1060

pre-wired

Details see chapter 12

Details see chapter 18

Details see chapter 15

Details see chapter 17

at the top

25

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 26

Auxiliary power supply

11 Auxiliary power supply

11.1 Configuration

Module chassis

view 'Modules'

27

28

37

38

E3C011

Z3I470

47

46

56

57

View A

48

58

31

B2F020

51

Cabinet front view

AX1201

or

AX1210

AX1201

or

AX1210

23

Mains

terminals

H38G310

A

absolutely essential

B2F020

Converter 115/230VAC

-> 29.6VDC/6A

Z3I470

Cable set, terminal strip

with card holder

AX1201 / AX1210

Batteries

E3C011

Battery charging module

11.2 Block diagram

* TF = Temperature sensor for battery temperature monitoring

Mains

B2F020

Extension

TF*

H38G310

Batteries

AX12..

FC700A

TF*

Basic emergency

power supply

Batteries

AX12..

Mains

B2F020

E3C011

Battery charging unit

Cascading

E3C011

Monitoring via HW monitoring path

Details see document 007831, chapter 'Cascading principle'

To activate the supervision path of the E3C011, the device "Fu supply ext. supply

supervision" must be created in the tool SWE700A.

11.3 Modules

Component Order-No. Description Notes

H38G310 484930 Housing set Door without cut-out

B2F020 470588 Converter 115/230VAC -> 29,6VDC 6A

E3C011 505479 Battery charging unit

Z3I470 484341 Cable set with card holder

AX1201 225487 Battery 12V / 27Ah Capacity based battery make 'ALARMCOM' (FIAMM)

AX1210 475570 Battery 12V / 15Ah

26

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 27

12 Control terminal B3Q700 (FC/FT)

12.1 Features

Double-sized (240x128 dots), backlit LC-Display for most intuitive and user-

friendly operation

Context- and system state adjusted operation functions via soft keys

Functionally grouped, ergonomically operating and indicating elements

Detailed event information like event type and location, intervention instruction

texts, system operating conditions etc.

Integrated emergency operation function

Insertable inscription strips in various languages

Access to system functions via four different operating levels depending on user

profile

Configurable for single or multi AREA operation

Access authorisation via password or key switch

Options

– Lockable Plexiglas door H26T030

– RS232 module E3I020

– LON interface E3I040 for LON devices (floor control terminals etc.)

– Parallel indicator panel B3R051

Control terminal B3Q700 (FC/FT)

12.2 Options

12.2.1 Plexiglas door to B3Q700 (FC/FT)

Z3S200

for the locking of doors and/or

access authorization for operation

H26T030

Plexiglas door

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

27

Page 28

Control terminal B3Q700 (FC/FT)

12.2.2 Place of the E3I020 RS232 module (FT)

B3Q700

Use flat cable F20A020

12.2.3 Place of the E3I040 LON interface (FT)

RS232 module E3I020 is mounted at the rear of the

control terminal ‘FT’ by means of accessories Z1B020

-> Details see document 007827

Supplied with Z1B020:

Plug-in terminal 12 cont.

Installation material

Protective cover

H28T110

B3Q700

H28G200

LON interface E3I040 connected at the I-Bus of a

remote control terminal 'FT', only mounted in the

housing H28G200

-> Details see document 007827

Supplied with Z1B070:

- Mounting bracket with card holder and

terminal block numbering in red

- I-Bus flat and supply cable

28

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 29

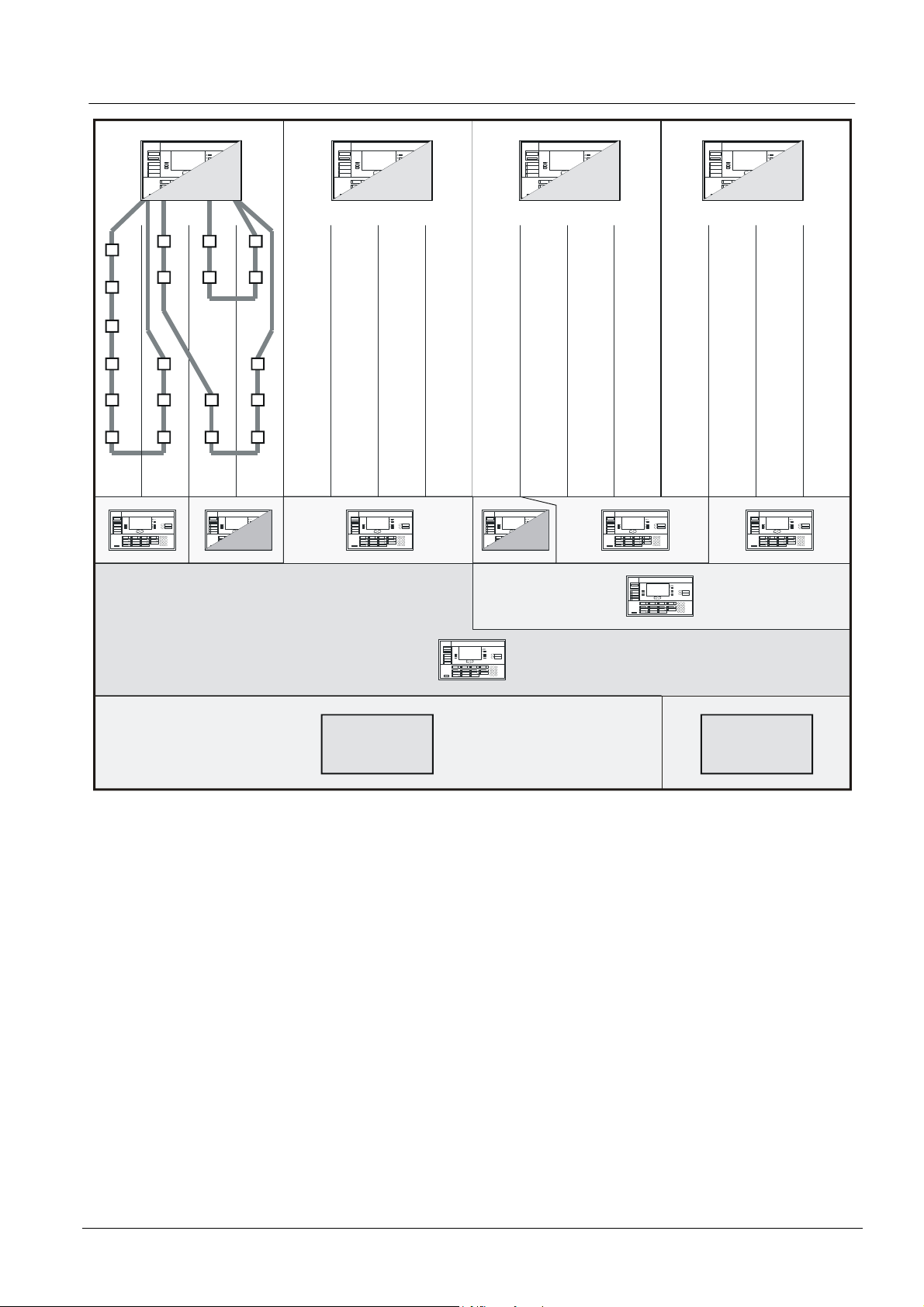

12.3 Installation possibilities (FT)

B3R051

B3Q700

H23G230

19“ cabinet

H26G220

Dimensions

B = 520

H = 300

T = 70

Dimensions

Built into H23/H26 cabinets Built into H28 cabinet

H23 cabinet

B = 125

H = 219

T = 76

Dimensions

H26 cabinet

B = 366

H = 219

T = 76

Built into 19“ cabinet

G2A130

H28T110

By choice

B3R051

H23B020

H23B020+E3I040

Control terminal B3Q700 (FC/FT)

H28G200

B3Q700

H28T120

B3Q700

G2A140

By choice

B3R051

H23B020

12.4 Block diagram

FC, FT, FG

FC/FT

E3I020

RS232

1

Printer

C-Bus

2

B2F020

I-Bus

F12A100

– B3R051

– Can be installed separately, however at max. 1000m

– Max. 24 units, however max. 8 addresses

– Free allocation of the LEDs (programming according to application)

– Line and equipment not monitored

4xB3R051

Mains

E3C011

Batteries

AX12..

B3R051B3R051 B3R051B3R051

F12A100 F12A100/470

LON-Bus

E3I040

24V Supply line

Databus

max.

1000m

separately connected

parallel indicator

Activation of Mimic Display, see chapter

'Mimic Display panel outputs'

Parallel branching permissible

Basic equipment

Option

29

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 30

Control terminal B3Q700 (FC/FT)

12.5 Connection lines between control unit and external operating

units

Control terminal FT700A

Options

B3R051 (Parallel indicator panel)

E3I040 (LON module)

Printer

Loop C-Bus

Control unit FC700A

2…11

leads

max. 1000m per loop with ∅0,6mm G51 (incl. return line)

max. 1400m per loop with ∅0,8mm G51 (incl. return line)

When planning a system the following condition must be complied with:

At least one operating unit must comply with standard EN54, i.e. it must be

equipped with emergency operation and emergency power supply.

Control terminal

FT700A

EN54 requirements:

Communication as loop line -> design C-Bus as a loop line

Operating units also with emergency operation -> 3 additional wires

Second de-coupled 24V supply -> 3 additional wires or autonomous power

supply

The number of wires in the connection cable depends on the application and the

distances between the stations:

Application C-Bus 24V supply

24V supply from

control unit

EN54 complied with

24V supply from

control unit without

emergency operation

and emergency

power supply

✔

(2 wires)

✔

(2 wires)

✔

(3 wires)

✔

(3 wires)

Emergency power

supply

✔

(3 wires)

Note:

– Emergency operation circuit required including between CPUs or for a sepa-

rately connected Gateway

– Emergency operation circuit and emergency supply are not designed as a loop

line

– Emergency supply via separate cable or C-Bus feedback

Emergency opera-

tion circuit

✔

(3 wires)

5

Number of wires

11

12.6 Power supply (24V)

Operating unit B3Q700 is designed for the voltage range 18...45VDC

The maximum current at 24V is 400mA

Max. Length of line (approximate):

– For cables ø 0.8mm -> 180m

– For cable cross-section 1mm

The current consumption for the options (parallel indicator panel, LON-module)

must be taken into account separately

30

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

2

-> 360m

Page 31

Control terminal B3Q700 (FC/FT)

12.7 Modules

Component Order-No. Description Notes

B3Q700 A5Q00004719 Control terminal FT700A Operating unit

CTY00760 (OSS) Flash program file For control terminal

CIY00760 (OSS) Flash program file For control unit

FCA725 A5Q00004833 Inscription set 'Spanish'

FCA775 A5Q00004834 Inscription set 'Italian'

FCA785 A5Q00004835 Inscription set 'polish'

H26T030 570530 Plexiglas door Incl. mounting accessories

Z3S200 570349 Key switch module (KABA) For operating access

B3R051 490513 Parallel indicator panel '2x24 LEDs'

E3I020 460239 RS232 module For the connection of a printer -> see chapter 21

Z1B020 475907 Mounting accessories for E3I020 Essential when mounting E3I020 on the rear terminal of

F20A020 476317 Flat cable micro 20 conductors 0.165m Link between E3I020 -> B3Q700, if E3I020 on the rear of

E3I040 499310 LON interface Converter between I-Bus and LON-Bus

Z1B070 A5Q00001720 Mounting accessory for E3I040 Essential when mounting E3I040 in housing H28G200

Z3I481 491185 Cable set for control terminal FT700A in

Cabinets H23/H26/H28 for details referring cabinets -> see chapter 13

H28G200

B3Q700 (FT)

B3Q700 (FT)

Comprising -> Terminal block with made-to measure

cable, cleat and cable clips

-> Details see document 007827

31

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 32

Range of cabinets H23 / H26 / H28

13 Range of cabinets H23 / H26 / H28

H23G230

Dimensions 125x219x76mm

Material Plastic

Colour Pantone 421 grey

Protection category IP40

H26G220

Dimensions 366x219x76mm

Material Plastic

Colour Pantone 421 grey

Protection category IP40

H28G200

Housing with lock (DOM)

Dimensions 520x300x70mm

Material Steel sheet

Colour housing RAL7035 light grey

Protection category IP30

H28G200

Front can not be pivoted

Front can not be pivoted

Details of the cabinets -> see document 007827

H28T110

H28T120

H28T110

Door with cut-out for control terminal and parallel indicator panel

B3R051 or cover plate H23B020

Colour door RAL7035 dark grey

Protection category IP30

H28T120

Door with cut-out for 4 parallel indicator panel B3R051

Colour door RAL7035 dark grey

Protection category IP30

Doors are hinged at left!

32

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 33

Range of cabinets H23 / H26 / H28

13.1 Recessed mounting H23G230 and H28G200

H23U220

H23G230

H23G230

H23Z230

H23U230

H23Z230

UPR28

H28Z010

H28G200

Details of the cabinets -> see document 007827

13.2 Modules

Component Order-No. Description Notes

H23G230 475091 Plastic cabinet For additional indicators and operating units

H26G220 462800 Plastic cabinet For remote control terminal B3Q700 (FT)

H28G200 409944 Cabinet (without door) For various applications

H28T110 474982 Cabinet door for B3Q700 (FT) / B3R051

H28T120 474995 Cabinet door for 4 B3R051 Parallel indicator

H23B020 476278 Cover plate For H28T110/120

H28Z010 410593 UP frame set For recessed mounting of cabinet H28G200

H23U220 379126 Recess box to B3R051 For recessed mounting of cabinet H23G230

H23U230 532879 Recess box to B3Q580/590/595 For recessed mounting of cabinet H23G230

H23Z230 532882 Cover frame to B3Q580/590/595/B3R051 For recessed mounting of cabinet H23G230

UPR28 430434 Recess box For 1 H28G200 cabinet (poss. required)

panel

33

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 34

19” accessories

14 19” accessories

Application of 3rd party cabinets

G2A130

G2A140

19”

Z2G030

6HU

14.1 Modules

Component Order-No. Description Notes

Z2G030 378198 Hinge 19"/6HE Consisting of hinge and spacer profile

G2A130 475088 Adapter plate 19"/6HE For control terminal B3Q700 (FT)

G2A140 484228 Adapter plate 19"/6HE For parallel indicator panel B3R051

34

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 35

15 Line modules

15.1 Overview

E3M111 for addressable detectors SynoLOOP

E3M080 for collective detectors SynoLINE600/-Ex

FC700A

E3M111

Line modules

I-Bus

E3M080

24V

max. 500mA

24V

max. 500mA

1 2......... 8

Detector system SynoLOOP SynoLINE600/-Ex

Number of lines 4 8

Number of addresses 4 x 128 8

Loop line

Stub line

Short-circuit separator In each device -

Special features Separate supply output 24V for

input/output modules

✔

✔ ✔

Line short circuit can be evaluated

as a fault or as an alarm

-

Z3I1050 or

E3M111

Z1K030

E3M080

15.2 Modules

Component Order-No. Description Notes

E3M111 511531 Line module SynoLOOP Addressable

E3M080 460268 Line module SynoLINE600/-Ex Collective

Z3I1050 A5Q00004717 Connection cable 19 conductors For connection via terminal block 'X2'

Z1K030 484231 Terminal block with p.c.b. Chassis For direct connection

35

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 36

Line modules

15.3 Detection line "addressable" SynoLOOP

Number of addresses per line max. 128 with APMK1

All detectors, manual call points and input/output modules with integrated line

separator

Connectable types of detectors and connection see document 007831

4 Loop lines

E3M111

24VDC

AI340

1

2

3

4

24VDC

DBZ1197A

DC1192

SB3

DM1103

DO1101-Ex

DT1101-Ex

DF1101-Ex

SynoLINE600-Ex

collective

max. 25

DM1133/MT320A

CB320A

OH320C

HI32xC

OP320C

SynoLINE300

conventional

max. 32

OP620A

24VDC

HI32xA

DC1192

SynoLINE600

collective

max. 25

24VDC

OP620C

HI62xC

OH320A

DC1192

24VDC

OP320A

DC1192

DLR11 . .

AI300

DLO1191

DF1191/92

ABI322A

EB322A

AB322A

BFST

Some detectors have different loading factors, to evaluate how many special de-

tectors can be connected to one addressable line see chapter 16.3

Control output for 1 external response indicator in each detector base

fixed allocation (output active as

soon as the internal LED is flashing)

Room 101

Room 102

ZONE 7

ZONE 5

Room 103

Room 104

36

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 37

15.4 Detection line "collective" SynoLINE600/-Ex

All detectors on a line have the same collective address (ZONE)

Number of detectors per line max. 25 with KMK1

Line termination depending on application by means of Transzorb or EOL22 (Ex)

Connectable types of detectors and connection see document 007831

8 Stub lines

1

DBZ1197A

DLO1191

DM1103

DF1191/92

HI62xC

OP620C

Line modules

Line termination: Transzorb 20V/EOL22

Line resistance: max.150

Ω

E3M080

2

3

DLR11 . .

SynoLINE600

SynoLINE600-Ex

DM1103

DO1101A-Ex

DT1101xA-Ex

DF1101-Ex

Line termination

EOL22 (Ex)

24VDC

DC1192

SB3

8

OP620C

HI62xC

Some detectors have different loading factors, to evaluate how many special de-

tectors can be connected to one collective line see chapter 16.2.

37

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 38

Connection factors, line resistances and capacitances

16 Connection factors, line resistances and capacitan-

ces

16.1 Terminology and abbreviations

KLK Collective line factor (SynoLINE600)

KMK Load factor for collective / conventional elements (SynoLINE600/300)

APLK addressable line factor (SynoLOOP)

APMK Load factor for addressable elements (SynoLOOP)

16.2 Collective detection line

– The modules E3M080 / DC1192 have the collective line factor KLK 25

– Line resistance max. 250Ω, 150Ω depending on evaluation required (line type 1,

11)

– Line capacitance max. 4µF

The entire line from the control unit to the last detector as well as all response

indicator lines must be included when working out capacitance.

Details see document 007831

The total amount of detectors connected to one collective line should not exceed a loading factor of 25

Element Short designation Load factor KMK

Smoke detector OP620C/OP320C 1

Heat detector HI620C/622C/HI320C/322C 1

Multisensor smoke detector OH320C 1

Smoke detector DO1101-Ex 1,6

Heat detector DT1101-Ex 1

Infrared flame detector DF1101-Ex 6

Infrared flame detector DF1191/92 6

Linear smoke detector DLO1191 25

Manual call point DM1101, DM1103 1

In-/output module DC1192 1

16.3 Addressable detection line

– The line module E3M111 has the addressable line factor APLK 128

– Line resistance see chapter 16.4

– Line capacitance see chapter 16.4

For a description of the E3M111 line module, see document 007831 'Hardware description'.

The total amount of detectors connected to one addressable line should not

exceed a loading factor of 128

Element Short designation Load factor APMK

Smoke detector OP620A, OP320A 1

Heat detector HI620A/622A, HI320A/322A 1

Multisensor smoke detector OH620A, OH320A 1

Infrared flame detector DF1191/92 5

Manual call point MT320A, DM1133 1

Input module EB322A 1

Output module AB322A 2

In-/output module ABI322A 2

In-/output module DC1192, CB320A 3

Do not install lines longer than 2000m

38

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 39

Connection factors, line resistances and capacitances

16.4 Line resistance and capacitance

– The max. line resistance of the entire detector loop respectively from the detec-

tor furthest away to each of the two control unit connections must not exceed

150Ω .

– The entire line from the control unit to the equipment connected and back again

to the control unit as well as response indicator lines must be included when

working out capacitance.

max. C

E3M111

24VDC

max. R

EB322A

DC1192

CB320A

DC1192

24VDC

DC1192

24VDC

Max. Resistance 150Ω (max. R)

Max. Capacitance 300nF (max. C) -> max. 600nF with max. 50Ω line resistance

24VDC

DC1192

ABI322A

AB322A

39

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 40

Control modules

A

17 Control modules

17.1 Application of control modules

Activation of fire control installations (shutting-down ventilation, closing fire

dampers etc.)

Activation and monitoring of alarm device

Activation and monitoring of remote transmission equipment

Activation of Mimic Display panels

17.1.1 Overview of the available modules with control outputs

Modules Monitored con-

trol lines

For alarm devices

E3G070 2 7 1) 2)

E3L020 16 1)

E3G050 8

E3G060 6 5)

K3R072 48 3)

K3G060 24 NO contact 4)

K3I110 16 NO contact 5)6)

1 Can also be used as control inputs (e.g. 'acknowledgement')

2 These inputs/outputs also serve for the activation of the remote transmission

equipment

3 For activation of Mimic Display panel, connected to the operating terminal

B3Q700 or K3I050 (no I-Bus module) -> Details see chapter 17.7

4 Applicable only with K3R072 -> Details see chapter 17.9

5 Programmable

6 LON-Bus module -> Details see chapter 18.5

Driver outputs

Programmable

Contact outputs

(Volt free)

Programmable

Remote transmis-

sion interface

To remote transmis-

sion equipment

✔

17.2 Means of linking

Any statuses of entry nodes can be linked to control ZONES

Normally, only 1 control ELEMENT is contained in 1 control ZONE (= control

output)

A user text is allocated to each control ZONE

Acquisition level Control level

addressable

collective

Visible statuses:

- active

- switched off

- executed ('Acknowledgem.')

- fault

AREA

SECTION

ZONE

Digital input

‘active’

Operating level

Operatable functions:

- switch on/off

- activate/de

-activate

Statuses:

- alarm

- info

- switched off

- on detector TEST

- fault

- etc.

Control

ZONE

E3G050

K3I110

E3L020

E3G070

E3G060

cknowledgement circuit

not

monitored

monitored

40

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 41

17.3 Control outputs station type FC700A

)

A

30VDC/1A

CPU

Basic equipment

B3Q700

E3G070

24V

FÜ

1...............7

Z3B171

250VAC/10A

Fire control

installations

Driver

dditional control modules according to application

I-Bus

E3L020

Driver Driver

1..........16

Z3B171

250VAC/10A

E3G050

1..........8 1..........6

30VDC/1A

E3I040

Converter

I-Bus/LON

LON-Bus

K3I110

1......16

Control modules

E3G060

max. 24V/2A

(max. 4A/E3G060

Z3I1050

Up to 2 Z3I1050 (with additional

terminal block) can be used other-

E3I040

E3L020

wise Z1K030 must be used.

K3I110

17.4 Control outputs remote station type FT700A

I-Bus

B3Q700

E3I040

converter

I-Bus/LON

LON-Bus

Z1K030

Z3I1050

E3G070

E3G060

E3G050

E3I040

K3I110

1......16

30VDC/1A

Z1B070

K3I110

Details mounting E3I040 see document 007827

17.5 Modules

Component Order-No. Description Notes

E3G070 546661 Control module 'Universal' Included in FC700A-1 package

E3L020 546645 Control module 'Driver' 16 control inputs or outputs

E3G050 460255 Control module 'Contacts' 8 control output contacts

E3G060 542539 Control module 'Monitored' 6 monitored control lines for alarm equipment

K3I110 528812 LON-I/O card 16 programmable in-/outputs

Z3B171 484383 Relay module 1x 250VAC/10A To switch from external voltage

E3I040 499310 LON module Converter between I-Bus and LON-Bus

Z1B070 A5Q00001720 Mounting accessory for E3I040 Essential for mounting E3I040 in housing H28G200

Z3I1050 A5Q00004717 Connection cable 19 conductors 1 of each per E3L020/E3G050/60

Z1K030 484231 Terminal block with p.c.b. Chassis For direct connection

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

41

Page 42

Control modules

17.6 CPU-overlapping controls

CPU

1

all-AREA

FC

single-AREA

FTFT

C-Bus

FC FC FC

CPU CPU CPU

2 3 n

Gateway

FG

A1

A2 A3 A4

= AREA

A5 A6 A7 A8 A9 A10 A11 A12 A.. A.. A.. A..

initiating data point

control ZONE/ELEMENT

control device

Limitation: see chapter 8

must be within the CPU

same

42

Siemens Building Technologies 007836_a_en_--.doc

Fire & Security Products 03.2004

Page 43

17.7 Mimic Display panel outputs

Control modules

B3Q700 (FT)

B3Q700 (FC/FT)

24V

F12A100

or

F12A470

Parallel branching permissible

24V

Z3I530

(Adapter)

max.1000m

(not monitored)

K3R072

Data bus

1

48

Details see document 007831

K3R072:

– Short circuit-protected outputs

– Output for local buzzer and LED operation

– Inputs for button 'buzzer switch-off' und 'lamp test'

– Only suitable for the activation of LEDs

– Outputs can only be allocated the statuses from one logical node

– Max. 24 devices however max. 8 addresses

LED flat cable

cable length 1m, 24 red LEDs

LED flat cable

1

K3R072

48

F50F410

F50F410

LED flat cable

cable length 1m, 24 red LEDs

LED flat cable

Mimic Display panel

F50F410

F50F410

Mimic Display panel

Synoptic display

panel housing

K3R072

K3R072

Z3I520

Short-circuit proof in-/outputs

only for housing application

inside

LED 1....24

wires 49+50 for 'LED operation'

LED 25....48

wires 49+50 unused

Key 'Switch-off buzzer'

Key 'Lamp test'

Buzzer

max. permissible length

B3Q700

of the data bus 1000m

These in-/outputs can be in

parallel with other K3R072

if located in same cabinet

17.8 Modules

Component Order-No. Description Notes

K3R072 528605 Mimic Display activation

Z3I520 484969 Cable set for K3R072 Comprises 12 cables (2-wire with connector, length=0.5m)

F50F410 529141 LED flat cable for K3R072 50-wire, 24 red LEDs, cable length 1m

Z3I530 484972 Adapter To adapt flat cable to terminals

F12A100 495275 Flat cable Micro 12-pin, 0.4m From B3Q700 (FT) to K3R072/B3R051

F12A470 495288 Flat cable Micro 12-pin, 1.5m From B3Q700 (FT) to K3R072/B3R051

43

Siemens Building Technologies 007836_a_en_--.doc