Page 1

SITRANS F

Coriolis Flowmeters

MASS 2100 & FC300 (FCT030)

These Operating Instructions apply to Siemens

products

Introduction

1

Operating Instructions

Safety notes

Description

Installing/mounting

Connecting

Commissioning

Operating MASS 2100/

FC300 with FCT030

Functions

2

3

4

5

6

7

8

Service and maintenance

Diagnosing and

troubleshooting

Technical data

Dimension drawings

Technical reference

Default settings

Certificates and support

9

10

11

12

A

B

C

06/2017

A5E39789040-AA

HMI menu structure

D

Page 2

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E39789040

Ⓟ 10/2017 Subject to change

Copyright © Siemens AG 2017.

All rights reserved

Page 3

Table of contents

1 Introduction.................................................................................................................................................11

1.1 Document history...................................................................................................................11

1.2 Product compatibility..............................................................................................................12

1.3 Device documentation package.............................................................................................12

1.4 Items supplied........................................................................................................................13

1.5 Checking the consignment.....................................................................................................15

1.6 Security information...............................................................................................................15

1.7 Transportation and storage....................................................................................................16

2 Safety notes................................................................................................................................................17

2.1 Preconditions for safe use......................................................................................................17

2.2 Laws and directives................................................................................................................17

2.2.1 FCC Conformity.....................................................................................................................18

2.2.2 Conformity with European directives......................................................................................18

2.3 Requirements for special applications...................................................................................19

2.4 Use in hazardous areas.........................................................................................................20

2.4.1 Qualified personnel for hazardous area applications.............................................................20

2.4.2 Use in hazardous areas.........................................................................................................20

2.4.3 Loss of safety of device with type of protection "Intrinsic safety Ex i"....................................20

2.4.4 Installation in hazardous areas..............................................................................................21

2.4.5 Special conditions for safe use..............................................................................................23

2.4.6 Maximum temperature specifications for Ex use...................................................................24

3 Description..................................................................................................................................................27

3.1 Overview................................................................................................................................27

3.2 System configuration..............................................................................................................27

3.3 Design....................................................................................................................................28

3.3.1 Applications............................................................................................................................28

3.3.2 Versions.................................................................................................................................29

3.4 Features.................................................................................................................................32

3.5 Applications............................................................................................................................34

3.6 Approvals...............................................................................................................................34

3.7 Theory of operation................................................................................................................34

4 Installing/mounting......................................................................................................................................37

4.1 Basic safety notes..................................................................................................................37

4.1.1 Installation location requirements...........................................................................................39

4.1.2 Proper mounting.....................................................................................................................40

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 3

Page 4

Table of contents

4.2 Installation instructions...........................................................................................................40

4.2.1 Sensor installation..................................................................................................................40

4.2.1.1 Determining a location ..........................................................................................................40

4.2.1.2 Orientation of the sensor........................................................................................................41

4.2.1.3 Mounting the sensor...............................................................................................................45

4.2.1.4 Hydrostatic testing..................................................................................................................47

4.2.1.5 Process pipe connection........................................................................................................48

4.2.1.6 Mounting a pressure guard....................................................................................................48

4.2.2 Transmitter installation...........................................................................................................50

4.2.2.1 Remote transmitter mounting.................................................................................................51

4.2.2.2 Turning the local display........................................................................................................53

4.2.2.3 Wall mount housing transmitter..............................................................................................54

4.3 Disassembly...........................................................................................................................56

5 Connecting.................................................................................................................................................57

5.1 Basic safety notes..................................................................................................................57

5.1.1 Energized devices..................................................................................................................61

5.1.2 Safety notes for connecting....................................................................................................61

5.1.3 Lack of equipotential bonding................................................................................................62

5.2 Connecting MASS 2100/FC300.............................................................................................62

5.2.1 Cable requirements................................................................................................................63

5.2.2 Connection safety information................................................................................................63

5.2.3 Connecting the multiple plug to the sensor............................................................................64

5.2.4 Transmitter power supply and I/Os connection......................................................................64

5.2.4.1 Step 1: Connecting the DSL and the transmitter....................................................................64

5.2.4.2 Step 2: Preparing for the transmitter connections..................................................................68

5.2.4.3 Connecting the Current HART, CH1......................................................................................70

5.2.4.4 Connecting the Modbus (CH1)...............................................................................................73

5.2.4.5 Connecting the Profibus (CH1)..............................................................................................74

5.2.4.6 Step 3: Connecting the power supply....................................................................................75

5.2.4.7 Connecting the power supply (with DSL)...............................................................................76

5.2.4.8 Step 4b: Connecting the inputs and outputs (channels 2 to 4)..............................................78

5.2.4.9 Step 5: Finishing the transmitter connection..........................................................................81

5.2.5 Ready for commissioning.......................................................................................................82

5.3 Wiring information..................................................................................................................82

5.3.1 Wiring in hazardous areas.....................................................................................................82

5.3.2 Signal wiring...........................................................................................................................82

5.3.3 Wiring.....................................................................................................................................83

5.4 Device nameplates.................................................................................................................84

5.4.1 Transmitter identification nameplate......................................................................................85

5.4.2 Sensor identification nameplate FC300.................................................................................89

6 Commissioning...........................................................................................................................................91

6.1 Basic safety notes..................................................................................................................91

6.1.1 Warnings................................................................................................................................93

6.2 General requirements............................................................................................................93

6.3 Local commissioning..............................................................................................................93

6.3.1 Power-up................................................................................................................................93

6.3.2 Local display..........................................................................................................................93

MASS 2100 & FC300 (FCT030)

4 Operating Instructions, 06/2017, A5E39789040-AA

Page 5

Table of contents

6.3.3 Initial startup...........................................................................................................................94

6.3.4 Commissioning via HMI.........................................................................................................95

6.3.4.1 Wizard introduction................................................................................................................95

6.3.4.2 Quick Commissioning wizard (menu item 1.1).......................................................................96

6.3.4.3 Zero point adjustment............................................................................................................97

6.3.4.4 Zero Point Adjustment wizard (menu item 1.2)......................................................................99

6.3.4.5 Wizards................................................................................................................................100

6.4 Commissioning with PDM....................................................................................................110

6.4.1 Operating via SIMATIC PDM...............................................................................................110

7 Operating MASS 2100/FC300 with FCT030............................................................................................111

7.1 Chapter overview Operating................................................................................................111

7.2 Operating instructions..........................................................................................................111

7.2.1 Local display (HMI)..............................................................................................................111

7.2.1.1 Display view structure..........................................................................................................113

7.2.1.2 Access control......................................................................................................................117

7.2.1.3 Operation view.....................................................................................................................118

7.2.1.4 Measurement views.............................................................................................................119

7.2.1.5 Operating views...................................................................................................................122

7.2.1.6 Alarm views..........................................................................................................................123

7.2.1.7 Diagnostic views..................................................................................................................125

7.2.1.8 Fixed display texts................................................................................................................126

7.2.1.9 Navigation view....................................................................................................................127

7.2.1.10 Parameter view....................................................................................................................129

8 Functions..................................................................................................................................................135

8.1 Process values.....................................................................................................................135

8.2 Zero point adjustment..........................................................................................................138

8.3 Low flow cut-off....................................................................................................................140

8.4 Empty tube monitoring.........................................................................................................140

8.5 Process noise damping........................................................................................................141

8.6 Inputs and outputs................................................................................................................143

8.6.1 Current output......................................................................................................................143

8.6.2 Pulse output.........................................................................................................................149

8.6.3 Frequency output.................................................................................................................150

8.6.4 Redundancy mode (frequency)............................................................................................151

8.6.4.1 Redundancy mode...............................................................................................................151

8.6.5 Digital output........................................................................................................................153

8.6.6 Input.....................................................................................................................................153

8.7 Totalizers..............................................................................................................................154

8.8 Dosing..................................................................................................................................155

8.8.1 Dosing control configuration.................................................................................................156

8.8.2 Valve control configuration...................................................................................................157

8.8.3 Dosing operation..................................................................................................................162

8.8.4 Fault handling.......................................................................................................................163

8.9 Audit trail logging..................................................................................................................163

8.10 Diagnostic log.......................................................................................................................163

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 5

Page 6

Table of contents

8.11 Custom unit..........................................................................................................................164

8.12 SensorFlash.........................................................................................................................164

8.13 Datalogging on sensorFlash................................................................................................165

8.14 Process peak values on sensorFlash..................................................................................165

8.15 Simulation............................................................................................................................165

8.16 Maintenance.........................................................................................................................166

9 Service and maintenance.........................................................................................................................167

9.1 Basic safety notes................................................................................................................167

9.2 Recalibration........................................................................................................................168

9.3 Cleaning...............................................................................................................................169

9.4 Maintenance and repair work ..............................................................................................169

9.4.1 Service information..............................................................................................................171

9.5 Replacing the device............................................................................................................172

9.6 Return procedure.................................................................................................................172

9.7 Disposal...............................................................................................................................173

9.8 Spare parts/Accessories......................................................................................................173

9.8.1 Ordering of spare parts........................................................................................................173

9.8.2 Ex approved products..........................................................................................................173

9.8.3 Replaceable components.....................................................................................................174

9.8.4 Field Enclosure Spareparts..................................................................................................182

10 Diagnosing and troubleshooting...............................................................................................................185

10.1 Device status symbols.........................................................................................................185

10.1.1 Device status icons..............................................................................................................185

10.2 Fault codes and corrective actions.......................................................................................188

10.2.1 Sensor diagnostic events.....................................................................................................189

10.2.2 Transmitter diagnostic events..............................................................................................194

10.3 Operation troubleshooting....................................................................................................208

10.3.1 How do I copy application setup from one device to another?.............................................208

10.3.2 Troubleshooting sensor-related problems............................................................................209

10.3.3 How do I update the firmware?............................................................................................213

10.4 Diagnosing with PDM...........................................................................................................213

11 Technical data..........................................................................................................................................215

11.1 Power...................................................................................................................................215

11.2 Performance.........................................................................................................................215

11.3 Interface...............................................................................................................................218

11.3.1 Modbus interface..................................................................................................................218

11.3.2 HART interface.....................................................................................................................218

11.4 Inputs...................................................................................................................................219

11.4.1 Digital input..........................................................................................................................219

11.4.2 Process variables.................................................................................................................219

MASS 2100 & FC300 (FCT030)

6 Operating Instructions, 06/2017, A5E39789040-AA

Page 7

Table of contents

11.4.3 Input.....................................................................................................................................219

11.5 Outputs.................................................................................................................................220

11.5.1 Current output......................................................................................................................222

11.5.2 Pulse output.........................................................................................................................227

11.5.3 Frequency output.................................................................................................................228

11.5.4 Digital output........................................................................................................................229

11.5.5 Redundancy mode...............................................................................................................229

11.6 Construction.........................................................................................................................230

11.6.1 Local display (HMI)..............................................................................................................233

11.6.2 Cables and cable entries......................................................................................................233

11.7 Operating conditions............................................................................................................234

11.7.1 Rated operating conditions..................................................................................................234

11.8 Process................................................................................................................................235

11.8.1 Pressure drop curves...........................................................................................................235

11.8.2 Pressure drop.......................................................................................................................236

11.8.3 FC300 DN4..........................................................................................................................236

11.8.4 MASS2100 Di3, Di6 & Di15.................................................................................................237

11.9 Bus communication..............................................................................................................238

11.10 Approvals.............................................................................................................................239

11.11 SensorFlash.........................................................................................................................240

11.12 PED......................................................................................................................................241

11.13 Pressure - temperature ratings............................................................................................245

11.13.1 Pressure - temperature ratings (stainless steel sensors).....................................................246

11.13.2 Pressure - temperature ratings (Hastelloy sensors).............................................................248

12 Dimension drawings.................................................................................................................................249

12.1 Sensor dimensions...............................................................................................................249

12.2 MASS2100 DI3, DI6 & DI15.................................................................................................254

12.3 Transmitter dimensions........................................................................................................256

12.4 Mounting bracket..................................................................................................................257

A Technical reference..................................................................................................................................259

A.1 Sensor dimension dependent default settings.....................................................................259

A.1.1 Sensor dimension dependent default settings (Inputs/Outputs)..........................................269

B Default settings.........................................................................................................................................271

B.1 Sensor..................................................................................................................................271

B.2 Process Values....................................................................................................................273

B.3 Standard volume flow...........................................................................................................276

B.4 Totalizer...............................................................................................................................284

B.5 Inputs and outputs................................................................................................................291

B.6 Dosing..................................................................................................................................377

B.7 Date and time.......................................................................................................................403

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 7

Page 8

Table of contents

B.8 Local display........................................................................................................................404

B.9 Maintenance and diagnostics...............................................................................................422

B.10 Audit Trail.............................................................................................................................465

B.11 Resets..................................................................................................................................466

B.12 Firmware update..................................................................................................................466

B.13 Communication....................................................................................................................466

B.14 Security................................................................................................................................476

B.15 Language.............................................................................................................................477

C Certificates and support............................................................................................................................479

C.1 Technical support.................................................................................................................479

C.2 QR code label......................................................................................................................479

C.3 Certificates...........................................................................................................................480

D HMI menu structure..................................................................................................................................481

D.1 Main menu...........................................................................................................................481

D.2 Menu item 2.1: Sensor.........................................................................................................483

D.3 Menu item 2.2: Process values............................................................................................484

D.4 Menu item 2.3: Totalizer.......................................................................................................487

D.5 Menu item 2.4: Inputs and outputs.......................................................................................488

D.6 Menu item 2.5: Dosing.........................................................................................................495

D.7 Menu item 2.7: Date and time..............................................................................................500

D.8 Menu item 2.8: Local display................................................................................................501

D.9 Menu item 3.1: Identification................................................................................................503

D.10 Menu item 3.2: Diagnostic events........................................................................................504

D.11 Menu item 3.3: Maintenance................................................................................................505

D.12 Menu item 3.4: Diagnostics..................................................................................................505

D.13 Menu item 3.5: Peak values.................................................................................................507

D.14 Menu item 3.6: Characteristics.............................................................................................507

D.15 Menu item 3.7: SensorFlash................................................................................................508

D.16 Menu item 3.8: Simulation....................................................................................................510

D.17 Menu item 3.9: Audit trail.....................................................................................................511

D.18 Menu item 3.10: Self test.....................................................................................................511

D.19 Menu item 3.11: Resets.......................................................................................................512

D.20 Menu item 3.12: Firmware update.......................................................................................512

D.21 Menu item 4: Communication..............................................................................................512

D.22 Menu item 5: Security..........................................................................................................514

MASS 2100 & FC300 (FCT030)

8 Operating Instructions, 06/2017, A5E39789040-AA

Page 9

Table of contents

Index.........................................................................................................................................................515

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 9

Page 10

Table of contents

MASS 2100 & FC300 (FCT030)

10 Operating Instructions, 06/2017, A5E39789040-AA

Page 11

Introduction

Note

This manual applies to the Coriolis flowmeter SITRANS FC MASS 2100 / FC300 with

transmitter FCT030, from firmware xx

This document are standard delivered in electronic media with the device. Latest version can

be downloaded at www.siemens.com (http://support.automation.siemens.com/WW/view/en/

60666565/134200)

These instructions contain all information required to commission and use the device. Read

the instructions carefully prior to installation and commissioning. In order to use the device

correctly, first review its principle of operation.

The instructions are aimed at persons mechanically installing the device, connecting it

electronically, configuring the parameters and commissioning it, as well as service and

maintenance engineers.

1.1 Document history

1

The following table shows major changes in the documentation compared to the previous

edition.

Edition Remarks EDD version FW revision

02/2017

● First edition

Use the device to measure process medium in accordance with the information in the

Operating Instructions.

Note

Use in a domestic environment

This Class A Group 1 equipment is intended for use in industrial areas.

In a domestic environment this device may cause radio interference.

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 11

Page 12

Introduction

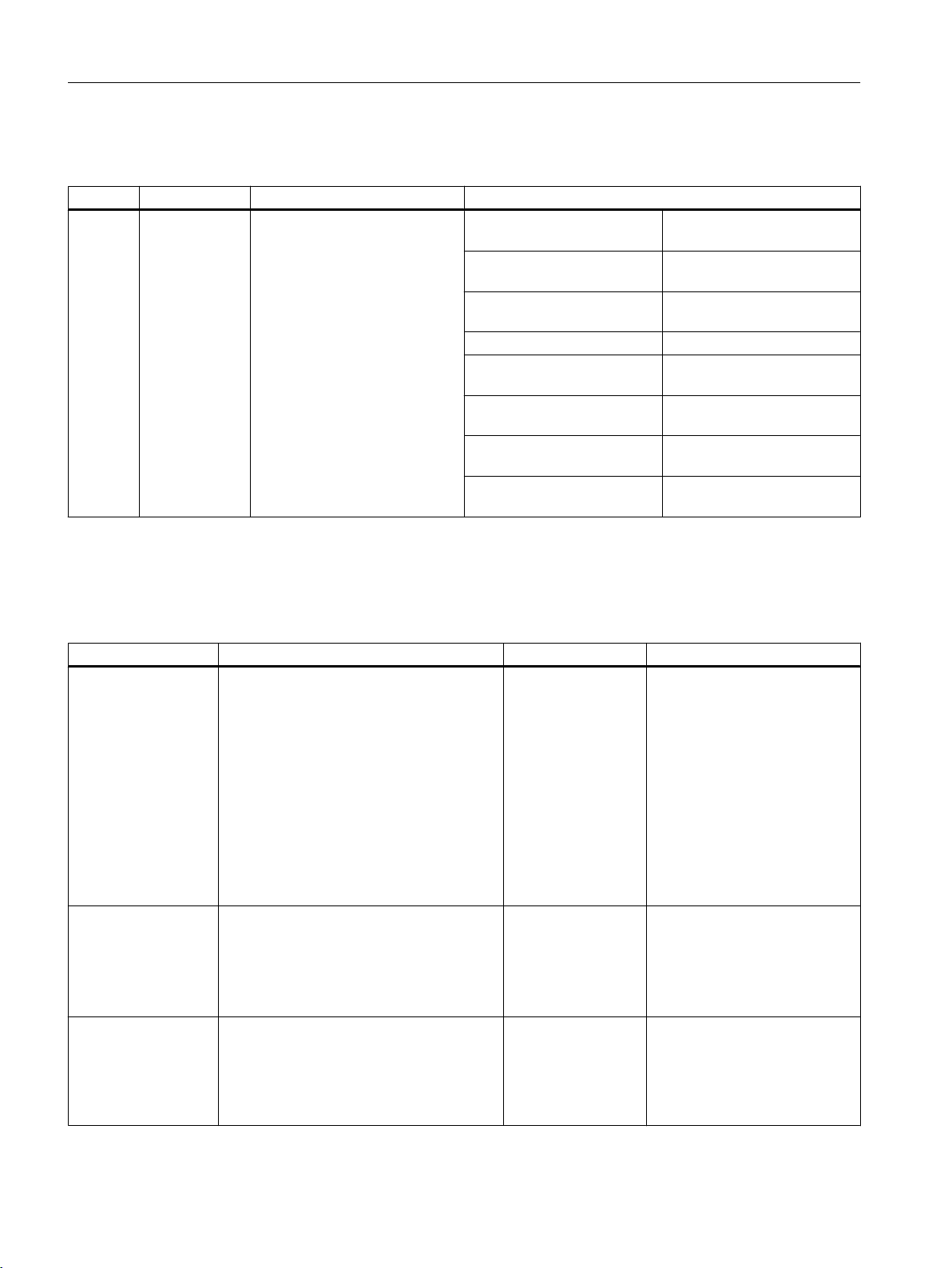

1.3 Device documentation package

1.2 Product compatibility

Edition Remarks Product compatibility Compatibility of device integration package

06/2017 First revision HW revision 03

Compact FW revision 4.xx.xx-xx

Remote FW revision 4.xx.xx-xx

Service channel: SIMATIC

V8.2 Service Pack 1 or later

Modbus: SIMATIC V8.2 Serv‐

ice Pack 1 or later

HART: SIMATIC V8.2 Serv‐

ice Pack 1 or later

HART: SITRANS DTM V4.1 5.00.xx-xx

HART: AMS Device manager

V12

PROFIBUS: SIMATIC V8.2

Service Pack 1 or later

PROFIBUS: AMS Device

manager V12

PROFIBUS : SITRANS DTM

V4.1

5.00.xx-xx

5.00.xx-xx

5.00.xx-xx

5.00.xx-xx

1.00.xx-xx

1.00.xx-xx

1.00.xx-xx

1.3 Device documentation package

The user documentation package for this product includes the following documents

Document Purpose Intended users Availability

Operating Instruc‐

tions

Compact Operating

Instructions - Ex

Functions Manual Contains

Contains all information needed to

● check and identify the delivered

package

● install and electrically connect the

product

● commission the product, (setting

parameters via HMI menu)

● operate and maintain the device on a

daily basis

● troubleshoot and remedy minor

operation interruptions

Contains all information needed to

● satisfy the Special conditions for

installation of Ex-certified products

● descriptions of all functions that can be

accessed via the local display (HMI)

● guide to setting parameters to obtain

optimum operation of the device

Instrument techni‐

cians, plant opera‐

tors

Instrument techni‐

cians, plant opera‐

tors with special

training in systems

for hazardous

areas.

Instrument techni‐

cians, plant opera‐

tors

● Available for download from

homepage

● Hardcopy can be purchased

via PIA Life Cycle Portal

(only English and German

versions)

● On documentation disk

● Available for download from

homepage

● Hardcopy can be ordered

via PIA Life Cycle Portal

● Available for download from

homepage

MASS 2100 & FC300 (FCT030)

12 Operating Instructions, 06/2017, A5E39789040-AA

Page 13

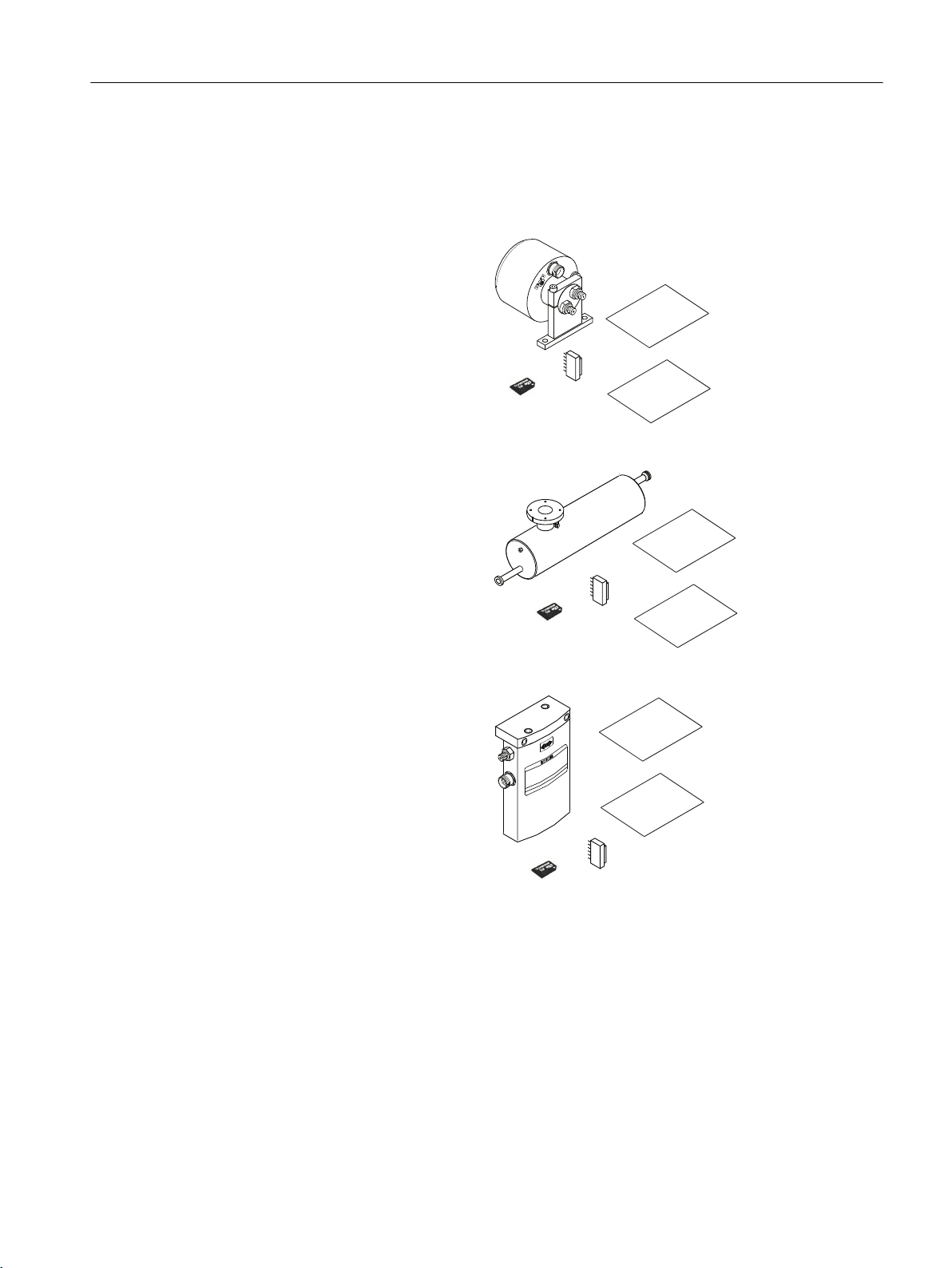

1.4 Items supplied

Safety N

ote

C

al.

rep.

Safety N

ote

C

al.

rep.

Safety N

ote

C

al.

rep.

Flowsensors

● MASS 2100 DI 1.0, DI 1.5, DI 2.1

● Sensorprom or SensorFlash

● Calibration report

● Calibration certificate

● MASS 2100 DI 3, DI 6, DI 15

● Sensorprom or SensorFlash

● Calibration report

● Calibration certificate

Introduction

1.4 Items supplied

● FC300 DN 4

● Sensorprom or SensorFlash

● Calibration report

● Calibration certificate

Flow transmitters:

● FCT010

● FCT030

● SIFLOW

● Calibration report

● Calibration certificate

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 13

Page 14

Safety N

ote

C

al.

rep.

Safety N

ote

C

al.

rep.

Safety N

ote

C

al.

rep.

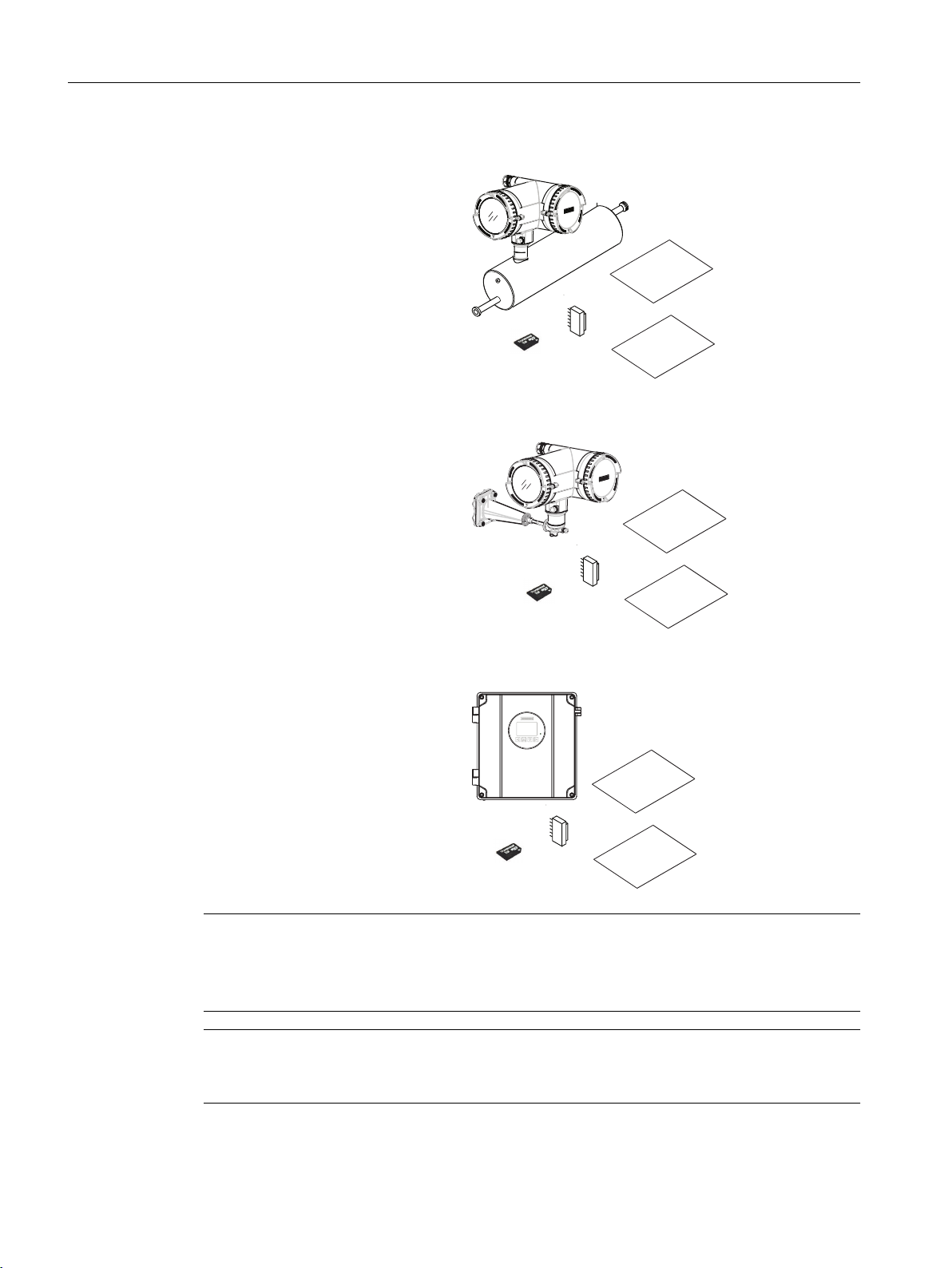

Introduction

1.4 Items supplied

Compact systems

● Packet of cable glands

● Calibration report

● Calibration certificate

● SensorFlash

(installed in FCT030 transmiiter)

Remote system

● Remote field mount

● Packet of cable glands

● Calibration report

● Calibration certificate

● Remote wall mount

● Packet of cable glands

● Calibration report

● Calibration certificate

Note

Supplementary information

Supplementary product and production specific certificates are included on the SensorFlash®

SD card in the transmitter socket.

Note

Scope of delivery may vary, depending on version and add-ons. Make sure the scope of

delivery and the information on the nameplate correspond to your order and the delivery note.

MASS 2100 & FC300 (FCT030)

14 Operating Instructions, 06/2017, A5E39789040-AA

Page 15

1.5 Checking the consignment

1. Check the packaging and the delivered items for visible damage.

2. Report any claims for damages immediately to the shipping company.

3. Retain damaged parts for clarification.

4. Check the scope of delivery by comparing your order to the shipping documents for

correctness and completeness.

WARNING

Using a damaged or incomplete device

Risk of explosion in hazardous areas.

● Do not use damaged or incomplete devices.

1.6 Security information

Siemens provides products and solutions with industrial security functions that support the

secure operation of plants, systems, machines, and networks.

Introduction

1.6 Security information

In order to protect plants, systems, machines and networks against cyber threats, it is

necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial

security concept. Siemens’ products and solutions only form one element of such a concept.

Customer is responsible to prevent unauthorized access to its plants, systems, machines and

networks. Systems, machines and components should only be connected to the enterprise

network or the internet if and to the extent necessary and with appropriate security measures

(e.g. use of firewalls and network segmentation) in place.

Additionally, Siemens’ guidance on appropriate security measures should be taken into

account. For more information about industrial security, please visit:

http://www.siemens.com/industrialsecurity.

Siemens’ products and solutions undergo continuous development to make them more secure.

Siemens strongly recommends to apply product updates as soon as available and to always

use the latest product versions. Use of product versions that are no longer supported, and

failure to apply latest updates may increase customer’s exposure to cyber threats.

To stay informed about product updates, subscribe to the Siemens Industrial Security RSS

Feed under

http://www.siemens.com/industrialsecurity.

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 15

Page 16

Introduction

1.7 Transportation and storage

1.7 Transportation and storage

To guarantee sufficient protection during transport and storage, observe the following:

● Keep the original packaging for subsequent transportation.

● Devices/replacement parts should be returned in their original packaging.

● If the original packaging is no longer available, ensure that all shipments are properly

packaged to provide sufficient protection during transport. Siemens cannot assume liability

for any costs associated with transportation damages.

NOTICE

Insufficient protection during storage

The packaging only provides limited protection against moisture and infiltration.

● Provide additional packaging as necessary.

Special conditions for storage and transportation of the device are listed in Technical data

(Page 215).

The contents of this manual shall not become part of or modify any prior or existing agreement,

commitment or legal relationship. The sales contract contains all obligations on the part of

Siemens as well as the complete and solely applicable warranty conditions. Any statements

regarding device versions described in the manual do not create new warranties or modify the

existing warranty.

The content reflects the technical status at the time of publishing. Siemens reserves the right

to make technical changes in the course of further development.

MASS 2100 & FC300 (FCT030)

16 Operating Instructions, 06/2017, A5E39789040-AA

Page 17

Safety notes

2.1 Preconditions for safe use

This device left the factory in good working condition. In order to maintain this status and to

ensure safe operation of the device, observe these instructions and all the specifications

relevant to safety.

Observe the information and symbols on the device. Do not remove any information or symbols

from the device. Always keep the information and symbols in a completely legible state.

Symbol Explanation

Consult operating instructions

Use the device only for flow measurement in accordance with this operating instruction and

observe the technical data.

WARNING

2

Improper device modifications

Risk to personnel, system and environment can result from modifications to the device,

particularly in hazardous areas.

● Only carry out modifications that are described in the instructions for the device. Failure

to observe this requirement cancels the manufacturer's warranty and the product

approvals.

Note

Functional safety applications (SIL)

If the device is used in a functional safety application, refer to the functional safety manual.

2.2 Laws and directives

Observe the safety rules, provisions and laws applicable in your country during connection,

assembly and operation. These include, for example:

● National Electrical Code (NEC - NFPA 70) (USA)

● Canadian Electrical Code (CEC) (Canada)

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 17

Page 18

Safety notes

2.2 Laws and directives

Further provisions for hazardous area applications are for example:

● IEC 60079-14 (international)

● EN 60079-14 (EC)

2.2.1 FCC Conformity

US Installations only: Federal Communications Commission (FCC) rules

WARNING

Improper device modifications

Danger to personnel, system and environment can result from improper modifications to the

device.

● Changes or modifications not expressly approved by Siemens could void the user’s

authority to operate the equipment.

Note

● This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment.

● This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the operating instructions, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference to radio communications, in which case the user will be required to

correct the interference at his own expense.

2.2.2 Conformity with European directives

The CE marking on the device symbolizes the conformity with the following European

directives:

Electromagnetic

compatibility EMC

2014/30/EU

Low voltage direc‐

tive LVD

2014/35/EU

18 Operating Instructions, 06/2017, A5E39789040-AA

Directive of the European Parliament and of the Council on the harmoni‐

sation of the laws of the Member States relating to electromagnetic com‐

patibility

Directive of the European Parliament and of the Council on the harmoni‐

sation of the laws of the Member States relating to the making available

on the market of electrical equipment designed for use within certain volt‐

age limits

MASS 2100 & FC300 (FCT030)

Page 19

Safety notes

2.3 Requirements for special applications

Atmosphère explosi‐

ble ATEX

2014/34/EU

Pressure equipment

directive PED

2014/68/EU

The applicable directives can be found in the EC conformity declaration of the specific device.

Note

CE declaration

The CE declaration certificate is available on the SensorFlash SD card delivered with the

device.

Directive of the European Parliament and the Council on the harmonisa‐

tion of the laws of the Member States relating to equipment and protective

systems intended for use in potentially explosive atmospheres

Directive of the European Parliament and of the Council on the approxi‐

mation of the laws of the Member States concerning pressure equipment

2.3 Requirements for special applications

Due to the large number of possible applications, each detail of the described device versions

for each possible scenario during commissioning, operation, maintenance or operation in

systems cannot be considered in the instructions. If you need additional information not

covered by these instructions, contact your local Siemens office or company representative.

Note

Operation under special ambient conditions

We highly recommend that you contact your Siemens representative or our application

department before you operate the device under special ambient conditions as can be

encountered in nuclear power plants or when the device is used for research and development

purposes.

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 19

Page 20

Safety notes

2.4 Use in hazardous areas

2.4 Use in hazardous areas

2.4.1 Qualified personnel for hazardous area applications

Qualified personnel for hazardous area applications

Persons who install, connect, commission, operate, and service the device in a hazardous

area must have the following specific qualifications:

● They are authorized, trained or instructed in operating and maintaining devices and systems

according to the safety regulations for electrical circuits, high pressures, aggressive, and

hazardous media.

● They are authorized, trained, or instructed in carrying out work on electrical circuits for

hazardous systems.

● They are trained or instructed in maintenance and use of appropriate safety equipment

according to the pertinent safety regulations.

2.4.2 Use in hazardous areas

WARNING

Use in hazardous areas

Risk of explosion.

● Only use equipment that is approved for use in the intended hazardous area and labelled

accordingly.

2.4.3 Loss of safety of device with type of protection "Intrinsic safety Ex i"

WARNING

Loss of safety of device with type of protection "Intrinsic safety Ex i"

If the device has already been operated in non-intrinsically safe circuits or the electrical

specifications have not been observed, the safety of the device is no longer ensured for use

in hazardous areas. There is a risk of explosion.

● Connect the device with type of protection "Intrinsic safety" solely to an intrinsically safe

circuit.

● Observe the specifications for the electrical data on the certificate and/or in Technical

data (Page 215).

MASS 2100 & FC300 (FCT030)

20 Operating Instructions, 06/2017, A5E39789040-AA

Page 21

2.4.4 Installation in hazardous areas

WARNING

Equipment used in hazardous locations

Equipment used in hazardous locations must be Ex-approved for the region of installation

and marked accordingly. It is required that the special conditions for safe use provided in the

manual and in the Ex certificate are followed!

Hazardous area approvals

The device is approved for use in hazardous area and has the approvals listed below. Special

conditions for safe installation and operation specified by each approval authority are included

in the relevant certificate.

ATEX:

Safety notes

2.4 Use in hazardous areas

IECEx:

EAC Ex

CSA:

FCT030 field mount transmitter (can be installed in Zone 1 for gas and Zone 21 for dust):

Certificate: SIRA 11ATEX1342X

II 2(1) GD

Ex db eb [ia Ga] IIC T6 Gb Ta = -40°C to +60°C

Ex tb [ia Da] IIIC T85°C Db

FCT030 field mount transmitter (can be installed in Zone 1 for gas and Zone 21 for dust):

Certificate: IECEx SIR 11.0150X

Ex db eb ia [ia Ga] IIC T6 Gb Ta = -40°C to +60°C.

Ex tb [ia Da] IIIC T85°C Db

FCT030 field mount transmitter / -40°C ≤ Tamb ≤ +60°C

1Ex db eb ia [ia Ga] IIC T6 Gb

Ex tb [ia Da] IIIC T85°C Db

Ex Canada:

FCT030 field mount transmitter (can be installed in Zone 1 for gas and Zone 21 for dust):

Certificate: cCSAus 2508628

Ex db eb ia [ia Ga] IIC T6 Gb

Ex tb [ia Da] IIIC T85°C Db

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 21

Page 22

Safety notes

2.4 Use in hazardous areas

For US:

FCT030 field mount transmitter (can be installed in Zone 1 for gas and Zone 21 for dust) and

Class I +II+III Group A, B, C, D, E, F:

Certificate: cCSAus 2508628

Class I, II, III Division 1 Gp A, B, C, D, E, F, G

Class I Zone 1: AEx db eb ia [ia Ga] IIC T6 Gb

Class II Zone 21: AEx tb [ia Da] IIIC T85°C Db

Installation variations

Note

Requirements for safe installation

● Standard remote installation with FCT030 because the connection is certified Intrinsically

Safe. however flameproof seals and conduit (for IS cable) can be used.

● Requirement for IS circuit is that the maximum input voltage Vi to DSL is 20 VDC, Ii is

maximum 484 mA, Pi < 2.3 W

FC300

ATEX Certificate : DEMKO 05 ATEX 138072X.

Sitrans FC300 can be used in zone 0.

Ex ia IIC T6…T3 Ga

IECEx Certificate: IECEx ULD 17.0030

Sitrans FC300 can be used in zone 0.

Ex ia IIC T6…T3 Ga

Canada Certificate. UL E232147

Sitrans FC300 can be used in zone 0 and Class I Division 1.

Class I Div. 1 Grp. A, B, C, D.

Ex ia IIC T6…T3 IIC Ga

US Certifikate. UL E232147

Sitrans FC300 can be used in zone 0 and Class I Division 1.

Class I Div. 1 Grp. A, B, C, D

AEx ia IIC T6…T3 IIC Ga

MASS 2100 & FC300 (FCT030)

22 Operating Instructions, 06/2017, A5E39789040-AA

Page 23

MASS 2100

Safety notes

2.4 Use in hazardous areas

ATEX Certificate : DEMKO 03 ATEX 135252X

Sitrans FC MASS 2100 can be used in zone 0, 20

Ex ia IIC T6…T3 Ga

Ex ia IIIC T135°C…T180°C Da

IECEx Certificate : IECEx ULD 17.0029

Sitrans FC MASS 2100 can be used in zone 0, 20

Ex ia IIC T6…T3 Ga

Ex ia IIIC T135°C…T180°C Da

Canada Certificate. UL E232147

Sitrans FC MASS 2100 can be used in zone 0, 20 and Class I+II+III Division 1. Grp. A,B,C,D,

E, F, G

Class I+II+III Division 1. Grp. A,B,C,D, E, F, G.

Ex ia IIC T6…T3 Ga

Ex ia IIIC T135°C…T180°C Da

US Certifikate: UL E232147

Sitrans FC MASS 2100 can be used in zone 0 and Class I Division 1.

Class I+II+III Division 1. Grp. A,B,C,D, E, F, G.

AEx ia IIC T6…T3 Ga

AEx ia IIIC T135°C…T180°C Da

2.4.5 Special conditions for safe use

Special conditions for safe use

In general, it is required that:

● The transmitter electronic compartment shall not be opened when energized and when an

explosive gas or dust atmosphere may be present.

● The terminal compartment may be opened when an explosive gas or dust atmosphere may

be present at any time. Access power terminals by lifting the cover only when de-energized.

● Appropriate cable connectors are used.

● Substitution of components may impair Intrinsic Safety.

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 23

Page 24

Safety notes

2.4 Use in hazardous areas

● Sensor and transmitter are connected to the potential equalization throughout the

hazardous area.

● EN/IEC 60079-14 is considered for installation in hazardous areas.

Further information and instructions including approval-specific special conditions for safe use

in Ex applications can be found in the certificates on the accompanying literature CD and at

the product web page (www.siemens.com/FC430).

WARNING

Laying of cables

Explosion hazard

Cable for use in hazardous areas must satisfy the requirements for having a proof voltage of

at least 500 V AC applied between the conductor/ground, conductor/shield and shield/ground.

Connect the devices that are operated in hazardous areas as per the stipulations applicable

in the country of operation.

WARNING

Field wiring installation

Ensure that the national requirements of the country in which the devices are installed are

met.

2.4.6 Maximum temperature specifications for Ex use

MASS2100 remote sensor

Temperature classification with and without dust is related to the process temperature and

ambient temperature as listed below.

The maximum allowable process fluid temperatures with respect to temperature class for the

device when used with potentially explosive gases.

Max media temperature [°C] versus temperature classification (T-ambient: -20 to +50 °C)

Maximum Process Temperature per Temperature Class (°C)

Di1/1.5/2.1/3 Di6 Di15

T6 75 46 38

T5 100 100 100

T4 135 135 135

T3 180 180 180

Additionally, the maximum surface temperature of the overall device shall be:

● For dust application, maximum surface temperature = 135°C

● For media temperature above 135°C surface temperature = media temperature

MASS 2100 & FC300 (FCT030)

24 Operating Instructions, 06/2017, A5E39789040-AA

Page 25

For MASS 2100 compact with either FCT010 or FCT030

Safety notes

2.4 Use in hazardous areas

Ambient

Temperature

50°C 75 46 38 100 130 130

45°C 80 51 43 100 135 160

40°C 85 56 48 100 135 180

35°C 85 61 53 100 135 180

30°C 85 66 58 100 135 180

Maximum Process Temperature per Temperature Class (°C)

Di3 Di6 Di15

T6 T6 T6 T5 T4 T3

● For dust application, maximum surface temperature = 135°C

● For media temperature above 135°C surface temperature = media temperature

FC300

T3 for liquid temperatures from 135°C to 180°C.

T4 for liquid temperatures lower than 135°C.

T5 for liquid temperatures lower than 100°C.

T6 for liquid temperatures up to 65°C.

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 25

Page 26

Safety notes

2.4 Use in hazardous areas

MASS 2100 & FC300 (FCT030)

26 Operating Instructions, 06/2017, A5E39789040-AA

Page 27

Description

3.1 Overview

SITRANS Coriolis flow meter systems consist of a transmitter and a sensor. The following

table lists the available combinations of transmitters and sensors.

Transmitter Sensor type

FCT030 MASS 2100

3.2 System configuration

3

FC300

The flowmeter can be used in a number of system configurations:

● as a field mounted transmitter and display supplied only with the necessary auxiliary power

● as part of a complex system environment, for example SIMATIC S7

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 27

Page 28

Description

3.3 Design

3.3 Design

3.3.1 Applications

Measurement of liquids and gases

SITRANS F C Coriolis mass flowmeters are designed for measurement of a variety of liquids

and gases. The flowmeters are multi-parameter devices offering accurate measurement of

massflow, volumeflow, density, temperature and, depending on product variants, fraction,

including industry-specific fractions.

Main applications

The main applications of the Coriolis flowmeter can be found in all industries, such as:

● Chemical & Pharma: detergents, bulk chemicals, acids, alkalis, pharmaceuticals, blood

products, vaccines, insulin production

● Food & Beverage: dairy products, beer, wine, soft drinks, °Brix/°Plato, fruit juices and pulps,

bottling, CO2 dosing, CIP/SIP-liquids, mixture recipe control

● Automotive: fuel injection nozzle & pump testing, filling of AC units, engine consumption,

paint robots

● Oil & Gas: filling of gas bottles, furnace control, test separators, bore-hole plasticizer dosing,

water-cut metering

● Water & Waste Water: dosing of chemicals for water treatment

MASS 2100 & FC300 (FCT030)

28 Operating Instructions, 06/2017, A5E39789040-AA

Page 29

3.3.2 Versions

Versions

The SITRANS FC flowmeters uses the Coriolis principle to measure flow and is available in a

remote and a compact version.

● Compact version: The MASS2100 is a single mechanical unit where the transmitter is

directly mounted on the sensor.

● Remote version: The MASS2100 sensor unit is remotely connected to a SITRANS FCT

transmitter. Directly mounted on the sensor, its Digital Sensor Link (DSL) performs the

signal processing of all measured signals in the sensor. The 4-wire connection between

the transmitter and the sensor provides power and high-integrity digital communication

between the DSL and the transmitter.

Description

3.3 Design

Sensor design

Figure 3-1 Compact version

Figure 3-2 Remote version - M12 connection

All primary process measurement of massflow, volumeflow, density and process temperature

are made in the DSL/sensor front end.

The sensor comprises one single continuous bended tube, with no internal welds. The sensor

is available in an intrinsically safe (IS) design for hazardous area installations.

The sensors are available in AISI 316L stainless steel and Hastelloy C22. The enclosure is

made of AISI 316L stainless steel.

The sensor enclosure can be equipped with a pressure guard or flushed with dry inert gas at

the threaded ports for non-hazardous applications only.

In the remote configuration, the sensor front end (DSL) is available in an aluminum enclosure

with an ingress protection grade of IP67/NEMA 4X. For communication and power supply a 4-

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 29

Page 30

Description

3.3 Design

Sensor overview

wire connection can be made via M12 plug and socket or cable gland/conduit entry for cable

termination.

① Earthing terminal

② Sensor enclosure

③ Plug and threaded port for e.g. pressure guard

Figure 3-3 Overview, remote and compact configuration

Transmitter design

The transmitter reads the primary values from the sensor and calculates derived values. It

provides up to four configurable I/Os. On channel 1, HART communication, PROFIBUS DP,

PROFIBUS PA or Modbus RTU RS485 is possible. On channel 2,3,4 each I/O can be

individually configured. A local display (human machine interface - HMI) is available, which

consists of a display and four buttons for user interaction. The transmitter adds functionalities

such as Standard volume flow, fractions, totalizers, dosing, access control, diagnostics,

configuration and logging.

The transmitter has a modular design with discrete, replaceable electronic modules and

connection boards to maintain separation between functions and facilitate field service. All

modules are fully traceable and their provenance is included in the transmitter setup.

30 Operating Instructions, 06/2017, A5E39789040-AA

MASS 2100 & FC300 (FCT030)

Page 31

Transmitter exploded view

D

E

D

/

E

Description

3.3 Design

① Display cover ⑫ Transmitter housing

② Local display (HMI) ⑬ Terminal space

③ Connector for HMI ⑭ Power supply terminal protection cover

④ SD card (SensorFlash) ⑮ Lid for terminal connections

⑤ DIP switch (for custody transfer) ⑯ Wiring tool

⑥ DIP switch (for HART and Modbus) ⑰ I/O cassette (optional)

⑦ HMI port ⑱ I/O configuration keys (optional)

⑧ USB service port ⑲a M12 socket

⑨ Transmitter cassette ⑲b Terminal housing

⑩ Heatsink cover for power supply module ⑳a Sensor module (compact version)

⑪ Cable entry ⑳b Barrier module (remote version)

Figure 3-4 Transmitter exploded view

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 31

Page 32

Description

3.4 Features

3.4 Features

● The device can be used as HART slave in operation on SIEMENS SIMATIC S7/PCS7 or

third party automation systems

● Available in compact and remote design

● Full graphical local display (HMI)

● SensorFlash (SD card) for memory backup and documentation storage (certificates etc.)

● One current output a standard

– Channel 1: Current output with HART, Modbus, Profibus

The available process values for Channel 1 are restricted to those which are safety

certified: Massflow, Volumeflow and Density. For access to other process values,

including Process Temperature, an extra channel is required at ordering.

● Three optional input/output channels:

– Channel 2: Signal output; can be parameterized for:

Current output (0/4-20 mA)

Pulse output

Frequency output

One on/off valve output

Two on/off valves output

Alarm, status, flow direction

– Channels 3 and 4: Signal output (as channel 2)

Pulse or frequency redundancy mode ((only channel 3 linked to channel 2 with 90° or

180° redundancy))

– Channels 3 and 4: Relay output; can be parameterized as:

One on/off valve output

Two on/off valves output

Alarm, status, flow direction

– Channels 3 and 4: Signal input; can be parameterized as:

Dosing control

Totalizer control (resetting of totalizers)

Zero adjustment

Setting or freezing a frequency at the digital outputs if these are set to 'Frequency'

● Current, frequency, and pulse outputs with configurable fail safe mode

● High immunity against process noise

● Fast response to step changes in flow

● High update rate (100 Hz) on all process values

MASS 2100 & FC300 (FCT030)

32 Operating Instructions, 06/2017, A5E39789040-AA

Page 33

● Measurement of process values:

– Mass flow

– Volume flow

– Standard volume flow (including normalized gas flows)

– Density

– Process media temperature

– Fraction A (mass flow or volume flow)

– Fraction B (mass flow or volume flow)

– Fraction A %

– Fraction B %

● Configurable upper and lower alarms and warning limits for all process values

● Independent low flow cut-off settings for mass flow and volume flow

● Automatic zero-point adjustment (initiated by host system)

● Process noise damping using digital signal processing (DSP).

Description

3.4 Features

● Three totalizers for summation of massflow, volumeflow and corrected volumeflow,

depending on setting, of:

– Mass flow measurement

– Volume flow measurement

– Fraction A and B measurement (mass flow or volume flow)

– Corrected volumeflow

● Empty pipe monitoring

● Simulation of process values:

– Mass flow

– Volume flow

– Standard volume flow

– Density

– Process media temperature

– Fraction A %

– Fraction B %

– Sensor frame temperature

● Simulation of all outputs

● Simulation and suppression of alarms

● Comprehensive diagnostics (NAMUR or Siemens standard) for troubleshooting and sensor

checking

● Firmware update

● Use in hazardous locations according to specification

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 33

Page 34

Description

3.7 Theory of operation

3.5 Applications

Measurement of liquids and gases

SITRANS F C Coriolis mass flowmeters are designed for measurement of a variety of liquids

and gases. The flowmeters are multi-parameter devices offering accurate measurement of

massflow, volumeflow, density, temperature and, depending on product variants, fraction,

including industry-specific fractions.

Main applications

The main applications of the Coriolis flowmeter can be found in all industries, such as:

● Chemical & Pharma: detergents, bulk chemicals, acids, alkalis, pharmaceuticals, blood

products, vaccines, insulin production

● Food & Beverage: dairy products, beer, wine, soft drinks, °Brix/°Plato, fruit juices and pulps,

bottling, CO2 dosing, CIP/SIP-liquids, mixture recipe control

● Automotive: fuel injection nozzle & pump testing, filling of AC units, engine consumption,

paint robots

● Oil & Gas: filling of gas bottles, furnace control, test separators, bore-hole plasticizer dosing,

water-cut metering

● Water & Waste Water: dosing of chemicals for water treatment

3.6 Approvals

Note

For further details see Approvals (Page 239).

The device is available with approvals for general purpose and for hazardous areas. In all

cases, check the nameplate on your device, and confirm the approval rating.

3.7 Theory of operation

The Coriolis principle of measurement

The flow measurement is based on the Coriolis law of motion. Particles moving in a rotating /

oscillating system will resist imposed oscillations in a manner consistent with their mass and

velocity (momentum). Oscillation produced by a Coriolis flowmeter where the process media

is accelerated around bends results in phase distortions of the measuring tubes.

The SITRANS F C sensors are energized by an electromagnetic (voice coil) driver circuit which

oscillates the pipes at their resonant frequency. Two pickups are placed symmetrically on either

side of the driver to provide position signals for digital processing.

MASS 2100 & FC300 (FCT030)

34 Operating Instructions, 06/2017, A5E39789040-AA

Page 35

)UHTXHQF\'HQVLW\

à

7LPH0$66IORZ

à

3LFNXS3LFNXS

Description

3.7 Theory of operation

When the media flows through the sensor, Coriolis force will act on the measuring tubes and

cause deflection which can be measured as a phase shift between Pickup 1 and Pickup 2.

The phase shift is proportional to the mass flowrate.

The frequency (or period) of the vibration is a direct function of the process media density.

The frequency and amplitude of the driver is regulated to ensure a stable output from the 2

pickups. The temperature of the sensor tubes is measured to provide accurate compensation

for changes in the material stiffness. As a result the process media temperature is also

accurately measured.

The flow proportional phase signal from the pickups, the temperature measurement and the

driver frequency enable calculation and reporting of mass, density, volume, and temperature.

Digital signal processing (DSP)

The analog to digital conversion takes place in an ultra low noise sigma delta converter with

high signal resolution. With fast digital signal processing massflow and density values are

calculated using a patented DFT technology (Discrete Fourier Transformation). The

combination of this patented DFT technology and the fast DSP enables short response time

(< 10 ms) to changes in the measured values.

The built-in noise filter is configurable and can be used for improving the performance of the

flowmeter, in case the installation and application conditions are not ideal. Typical process

noise such as gas bubbles (two-phase-flow) can be reduced through the filter functions.

MASS 2100 & FC300 (FCT030)

Operating Instructions, 06/2017, A5E39789040-AA 35

Page 36

Description

3.7 Theory of operation

MASS 2100 & FC300 (FCT030)

36 Operating Instructions, 06/2017, A5E39789040-AA

Page 37

Installing/mounting

4.1 Basic safety notes

CAUTION

Hot surfaces resulting from hot process media

Risk of burns resulting from surface temperatures above 70 °C (155 °F).

● Take appropriate protective measures, for example contact protection.

● Make sure that protective measures do not cause the maximum permissible ambient

temperature to be exceeded. Refer to the information in Technical data (Page 215).

WARNING

Wetted parts unsuitable for the process media

Risk of injury or damage to device.

Hot, toxic and corrosive media could be released if the process medium is unsuitable for the

wetted parts.

● Ensure that the material of the device parts wetted by the process medium is suitable for

the medium. Refer to the information in Technical data (Page 215).

4

Note

Material compatibility

Siemens can provide you with support concerning selection of sensor components wetted by

process media. However, you are responsible for the selection of components. Siemens

accepts no liability for faults or failures resulting from incompatible materials.

WARNING

Unsuitable connecting parts

Risk of injury or poisoning.

In case of improper mounting hot, toxic and corrosive process media could be released at

the connections.