Page 1

Building Technologies

Fire Safety & Security Products

FC18 Controller

Operating manual

Page 2

Operating Manual of FC18 Controller

Page: 1/63

TABLE OF CONTENTS

CHAPTER 1 SYSTEM OVERVIEW ················································································································ 3

1. FEATURES ······································································································································· 3

2. TECHNICAL DATA ····························································································································· 4

3. DIMENSIONS···································································································································· 5

4. COMPATIBLE EQUIPMENT LIST ··········································································································· 5

5. SYSTEM STRUCTURE ······················································································································· 6

CHAPTER 2 INSTALLATION ······················································································································· 8

1. INSTALLATION ·································································································································· 8

2. CONNECTION DIAGRAM ···················································································································· 9

3. DIP-SWITCH ··································································································································· 10

4. Power Supply ··································································································································· 11

CHAPTER 3 OPERATION ·························································································································· 13

1. INTERFACE ···································································································································· 13

2. LCD WINDOW································································································································· 16

3. USER LEVEL ·································································································································· 18

4.1 Login ········································································································································· 19

4.2 Logout ········································································································································ 19

5. STATUS TYPES ······························································································································· 20

6. FIRE ALARM EVENT HANDLING········································································································· 22

7. TROUBLE EVENT HANDLING ············································································································ 23

8. SUPERVISION EVENT HANDLING ······································································································ 24

9. ACTIVATION/CONFIRMATION EVENT HANDLING ·················································································· 25

10. REAL-TIME QUERY ························································································································· 26

11. HOW TO QUERY EQUIPMENT PROPERTY··························································································· 27

12. HOW TO QUERY HISTORY················································································································ 28

13. HOW TO DISABLE/ENABLE ··············································································································· 29

14. HOW TO ACTIVATE/DEACTIVATE THE CONTROLLER ············································································ 30

15. HOW TO TEST/WALK-TEST ··············································································································· 31

16. HOW TO LOCATE/STOP LOCATING ···································································································· 32

17. HOW TO ADJUST BUZZER LEVEL ······································································································ 33

18. HOW TO SET LOGIN TIME ················································································································ 34

19. HOW TO SET WALK-TEST TIME ········································································································· 35

20. HOW TO SET LCD CLOSING TIME ······································································································ 36

21. HOW TO SET TIME ·························································································································· 37

22. HOW TO CHECK SYSTEM ················································································································ 38

23. HOW TO SAVE CONFIGURE ·············································································································· 39

24. HOW TO EDIT PARAMETER ·············································································································· 40

25. HOW TO CREATE/VIEW LOGIC ·········································································································· 41

26. HOW TO EDIT/DELETE LOGIC ··········································································································· 42

27. HOW TO ASSIGN GROUP/ FRT ·········································································································· 43

28. HOW TO GET HELP ························································································································· 44

29. HOW TO OPERATE INTERLOCKING PANEL ························································································· 45

30. HOW TO OPEN/CLOSE A PRINTER ····································································································· 46

Page 3

Operating Manual of FC18 Controller

Page: 2/63

31. HOW TO REPLACE DEVICE ·············································································································· 48

32. HOW TO UPGRADE TO FC1840 ········································································································· 49

33. HOW TO CHANGE LANGUAGE ·········································································································· 50

34. HOW TO QUERY THE INFORMATION OF OTHER EVENTS ······································································ 51

CHAPTER 4 MAINTENANCE ······················································································································ 52

1. DAILY EXAMINATION ······················································································································· 52

2. EMERGENCY AND TROUBLE HANDLING ···························································································· 52

APPEN DIX 1 P A RA METE R LIST ··················································································································· 54

APPEN DIX 2 OPERABLE ITE M LIST ·············································································································· 57

APPEN DIX 3 EQUIP MENT GROUP ING T ABLE ································································································· 59

APPEN D IX 4 RULE S F OR LOGIC EXPR ES SION ······························································································ 60

APPEN DIX 5 INPU T METH OD ······················································································································ 62

APPENDIX 6 “STICKER METHOD”EASY FOR COM MISS IONIN G ····································································· 63

Page 4

Operating Manual of FC18 Controller

Page: 3/63

CHAPTER 1 SYSTEM OVERVIEW

There are three types of FC18 series controllers:

- FC1820 fire alarm controller (interlocking)

- FC1840 fire alarm controller (interlocking)

- FC1840C fire alarm controller (no interlocking panel, no printer)

1. FEATURES

- Fulfill Chinese Standard of GB4717-2005 and GB16806-2006.

- Multi-language operation menu designed with windows style for fast and easy operation.

- Shortcut key (right key) for popping out operation items of equipment/event.

- Large memory space for up to 10000 history records, first in first out order, all events can be recorded

during operation period.

- LCD backlight Auto-off mode. When no operation or event to display within preset time, LCD backlight

will be automatically turn off. When there are events / operations, LCD will light up automatically to

display events and/or interlocking devices.

- 2 channels of programmable input/output (Output: 40mA@24VDC, it can be programmed as general

alarm output or general trouble output; Input: dry contact).

- 1 channel of NAC for audible and visible devices (max. 0.5A @24VDC).

- 8 channels of interlocking functions for automatic control and manual operations of control equipments.

- Efficient group programming according to different using.

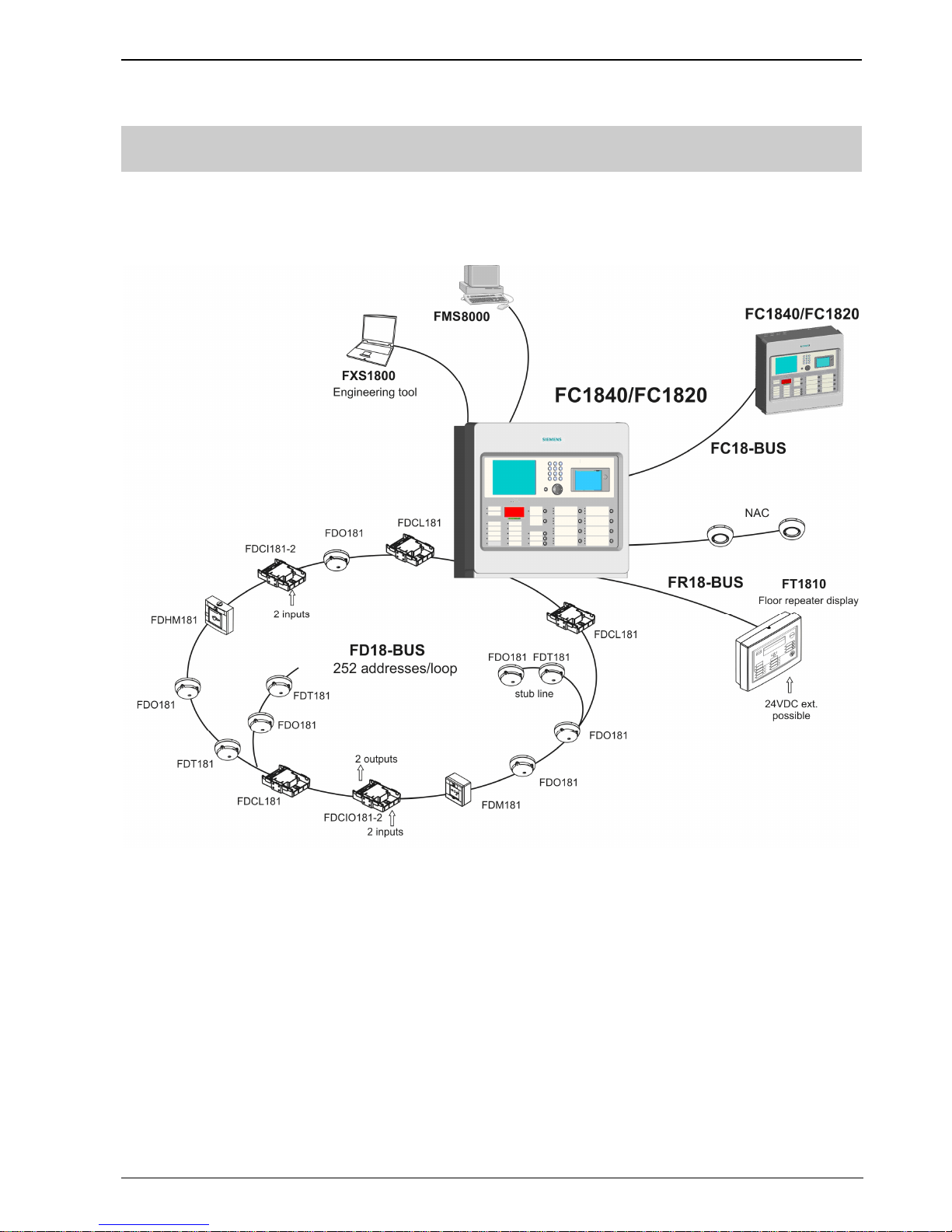

- FC1820 controller can connect up to 252 points, FC1840(C) controller can connect up to 504 points.

- Network bus (FC18-BUS), the max. distance is 1000m (the twist wiring capacity is 1.0 to 1.5 mm

2

). Up to

32 controllers can be networked together with FC1820 and FC1840(C).

- FRT bus (FR18-BUS), the max. distance is 1000m (the twist wiring capacity is 1.0 to 1.5 mm

2

). Up to 32

floor repeater displays can be networked.

- Detection bus (FD18-BUS), 2-wire polarity-free, the max. distance for line resistance is 4000m, the max.

distance for line capacitance is 5000m. (the twist wiring capacity is 1.0 to 1.5 mm2)

- Three user levels for different operation authority. Each user level is accessed by a pre-defined and

changeable password.

- Convenient pluggable terminals with clear marks for field wiring.

- Auto-mapping function to support on commissioning task.

- Detection algorithm can be adjusted from controller according to different environment, to provide high

reliability of alarm and reduce false alarm.

- Programming can be done either directly on controller or through computer.

- “Sticker Method” easy for commissioning on site.

Page 5

Operating Manual of FC18 Controller

Page: 4/63

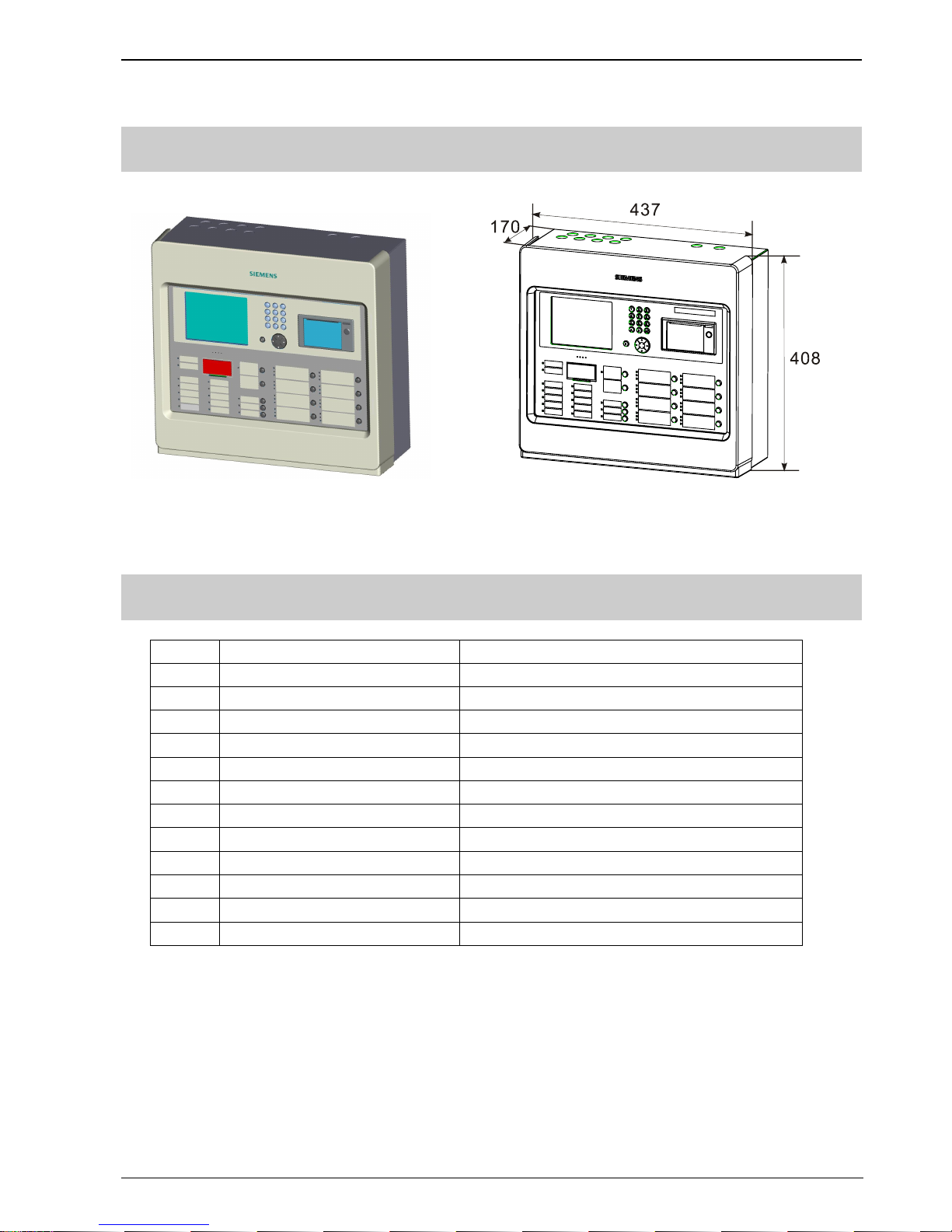

2. TECHNICAL DATA

Item Parameter

FC1820 FC1840 FC1840C

No. of line modules 1 2 2

No. of points 252 504 504

LCD screen

320×240 pixels,backlit

No. of programmable input/output on mainboard 2

No. of zone of interlocking panel 8 0

No. of NAC (0.5mA @24VDC) 1

Max. history records 10000

Max. distance between controllers within FC18-BUS 1,000 m

Max. No. of controllers connected within FC18-BUS 32

Max. distance between a controller and a FRT within FR18-BUS 1,000 m

Max. No of FRT connected to a controller 32

Auto-mapping function Operation from terminal

Battery(not included) Depends on local regulation

Communication interface Special converter module

Input voltage 220 V@1.5 A, 110V@3 A

220 V / 50 Hz, 110V / 60 Hz

Power supply capacity 5 A@24 VDC

External power output 1 A@24 VDC

Size (mm) 437×408×197

Weight (without battery) 10.35 Kg

Power fuse 1.5 A

Battery fuse 5.0 A

Operating temperature

0 ~ +40 ℃

Storage temperature

–10 ~ +50 ℃

Relative humidity

≤95%(40±2 ℃)

Protection category IP30

Environment requirement Indoor / Clean

Page 6

Operating Manual of FC18 Controller

Page: 5/63

3. DIMENSIONS

Fig. 1-1 FC18 Appearance Fig. 1-2 FC18 Dimensions (mm)

4. COMPATIBLE LIST

No. Type Description

1. FDT181 Addressable heat detector

2. FDO181 Addressable smoke detector

3. FDM181 Addressable manual call point

4. FDCI181-2 Addressable input module

5. FDCIO181-2 Addressable input/output module

6. FDCI181-1 Addressable input module

7. FDCIO181-1 Addressable input/output module

8. FT1810 Addressable floor repeater display

9. FDCL181 Isolator

10. FT1811 Addressable mimic drive

11. FTM1811 Addressable mimic display board

12. FDCAI181 Addressable alarm indicator

Page 7

Operating Manual of FC18 Controller

Page: 6/63

5. SYSTEM STRUCTURE

- Up to 32 FC1820/40(C) controllers can be networked together. Any controller can be set as master

controller to supervise devices connected with its slave controller and its own.

Fig. 1-3 System structure

Page 8

Operating Manual of FC18 Controller

Page: 7/63

Fig. 1-4 Internal structure

Po

wer supply

Terminal board

B

attery

Line card 2

Line card 1

LED screen

Keyboard 2

Interlocking panel

Pinter

Keyboard 1

Main board

CPU board

Page 9

Operating Manual of FC18 Controller

Page: 8/63

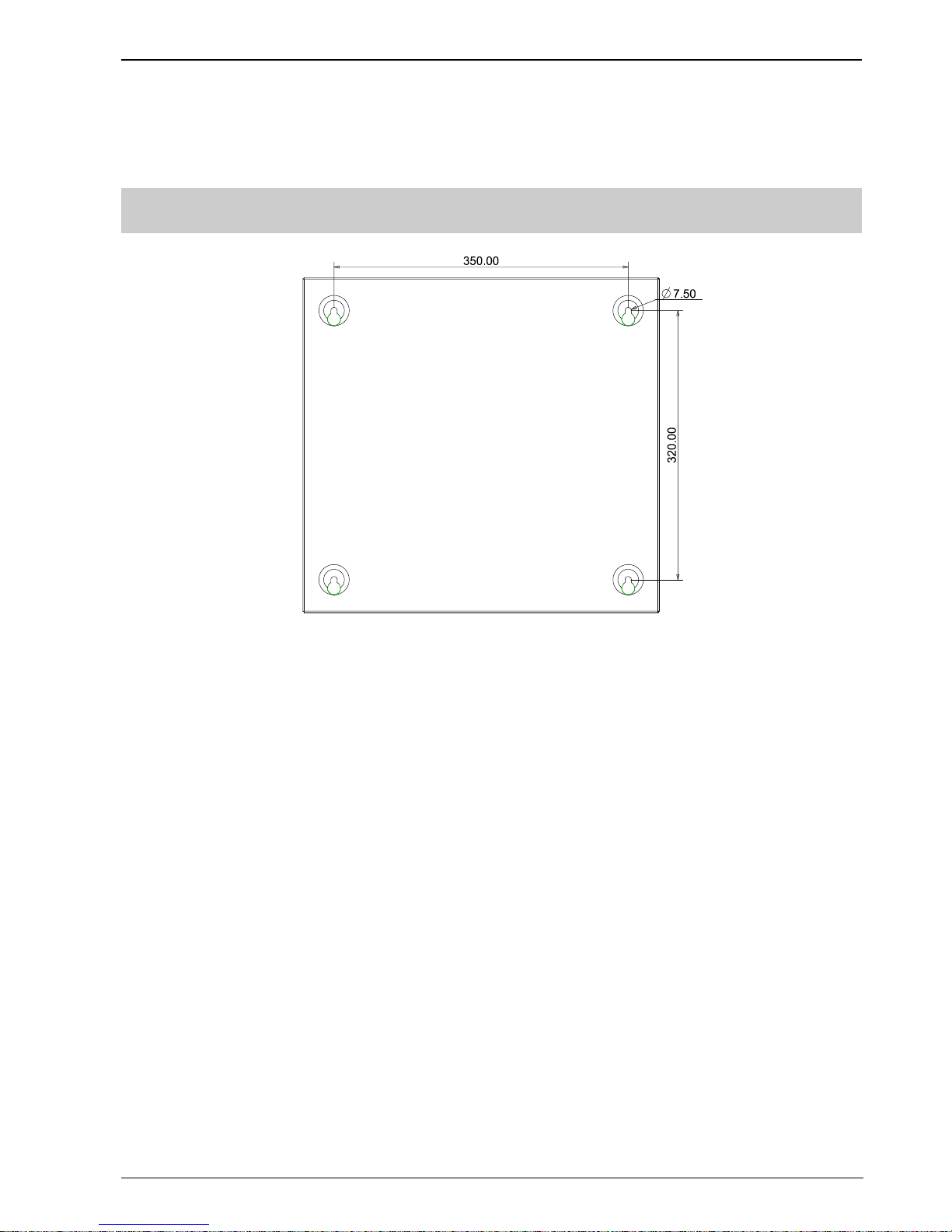

CHAPTER 2 INSTALLATION

1. INSTALLATION

Fig. 2-1 Dimensions (mm)

Installation must comply with the local regulation!

1. Ensure the wall is dry, clean, flat and firm in which the controller is installed.

2. Chose a proper installation location to make sure the front door can be opened smoothly.

3. Mark the drillings for 4 installation holes on the wall. (Fig. 2-1)

4. Drill the holes, put expansion bolts in and insert the M6 screws.

5. Break the cable entries on the controller.

6. Hang the controller over those screws.

7. Insert cables into the controller.

8. Open the front panel and tighten the screws to fix the controller on the wall.

9. Connect cables to the terminals according to Fig. 2-2, 2-3, 2-4, 2-5, 2-6, 2-7, 2-8.

10. Install and secure the batteries properly.

11. Close the front panel. Lock it with special tools and store the tools in safe place.

Page 10

Operating Manual of FC18 Controller

Page: 9/63

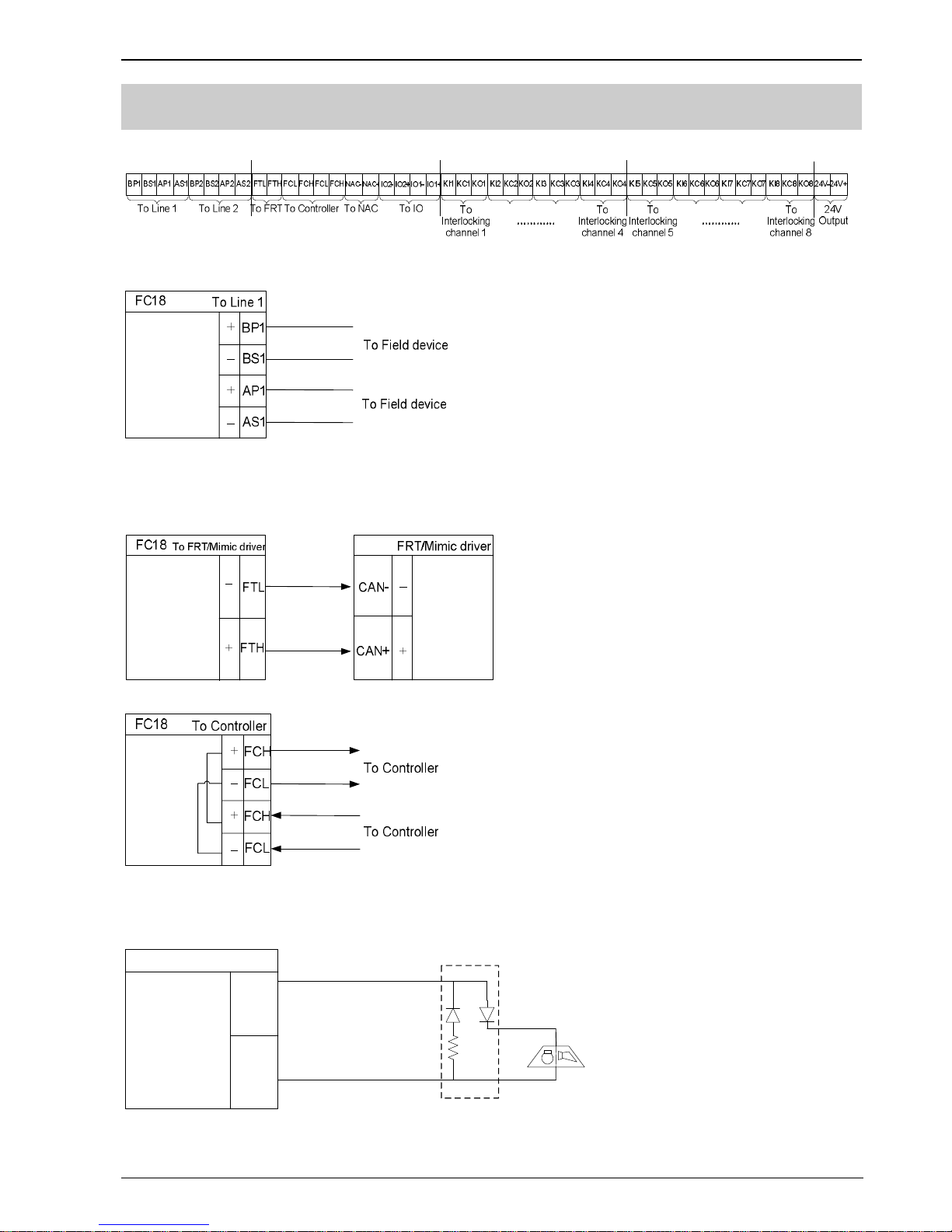

2. CONNECTION DIAGRAM

Fig. 2-2 Terminal line

Note: In loop mode, wires from BP1 must end at AP1; wires from BS1 must end at AS1. The connection of field

devices (except FDCL181 isolator) is polarity free.

Fig. 2-3 Line card connection diagram (the same for Line 2)

Fig. 2-4 FRT/Mimic driver connection diagram

Note: Ensure positive and negative connections are properly in place; FC18-BUS is polarity sensitive.

Connect a 120Ω resistor as monitoring resistor. It must be connected to the end of the line. ( It can be set by

the two-digit Dip-switch on the main board, see “Dip-switch connection configuration” )

Fig. 2-5 Network connection diagram

Visible and

audible device

FC18

To NAC

NAC+

NAC-

Red

Black

Orange

Black

20K

resistor

NAC-EOL-FC18

Fig. 2-6 NAC connection diagram

Page 11

Operating Manual of FC18 Controller

Page: 10/63

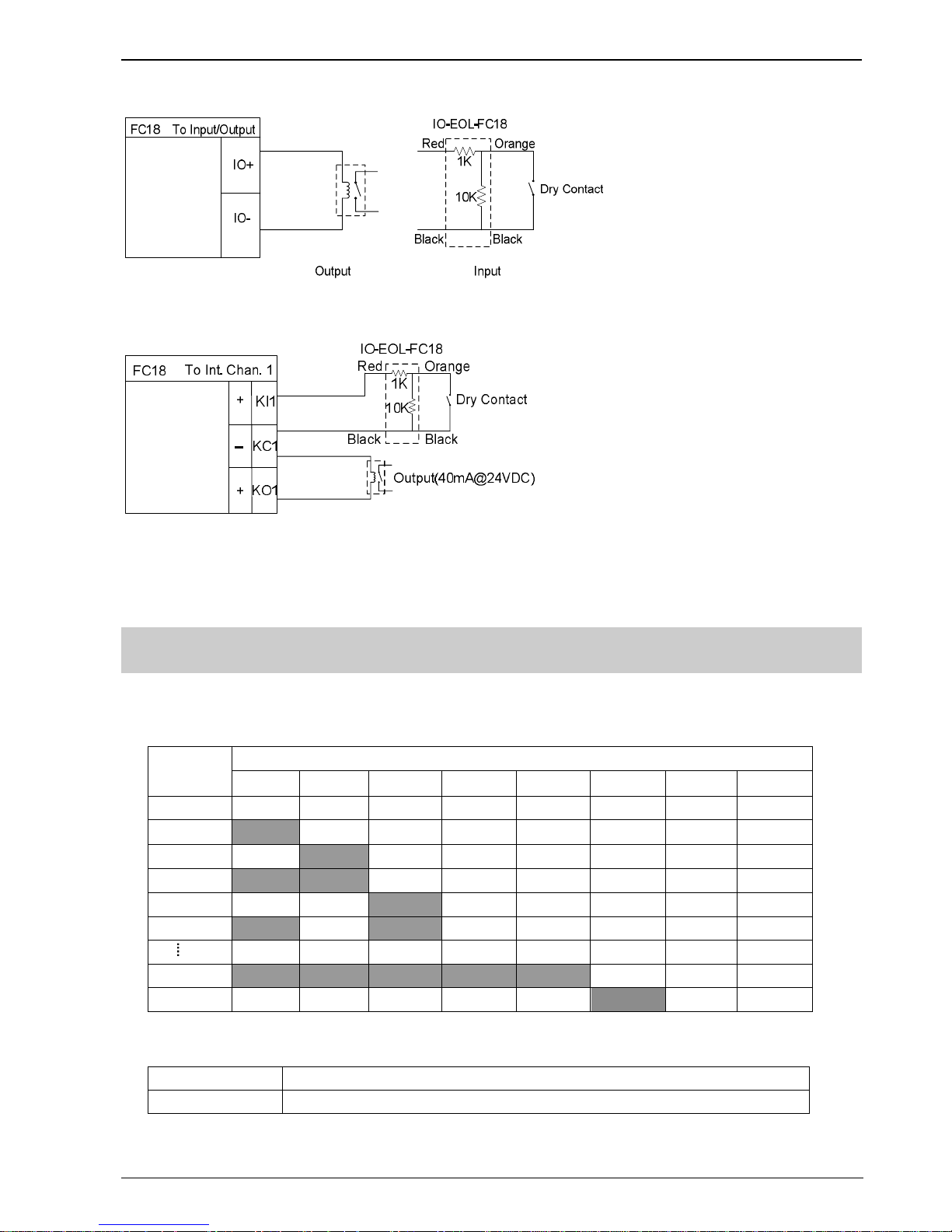

Fig. 2-7 Main board input/output connection diagram

Fig. 2-8 Interlocking panel connection diagram (the same for other channels)

Note: the load range of each output is 24VDC, 600Ω – 1.2kΩ

3. DIP-SWITCH

Each controller/interlocking panel has an eight-digit Dip-switch for address setting. Each Dip-switch can set address

1-32 within its first 6 digits.

FC18-BUS

address

DIP switches

1 2 3 4 5 6 7 8

Idle Off Off Off Off Off Off Off Off

1

On

Off Off Off Off Off Off Off

2 Off

On

Off Off Off Off Off Off

3

On On

Off Off Off Off Off Off

4 Off Off

On

Off Off Off Off Off

5

On

Off

On

Off Off Off Off Off

31

On On On On On

Off Off Off

32 Off Off Off Off Off

On

Off Off

The controller has a two-digit Dip-switch for setting terminal resistor of FC18-BUS or FR18-BUS.

1

On:FC18-BUS terminal selected; Off:not selected

2

On:FR18-BUS terminal selected; Off:not selected

Page 12

Operating Manual of FC18 Controller

Page: 11/63

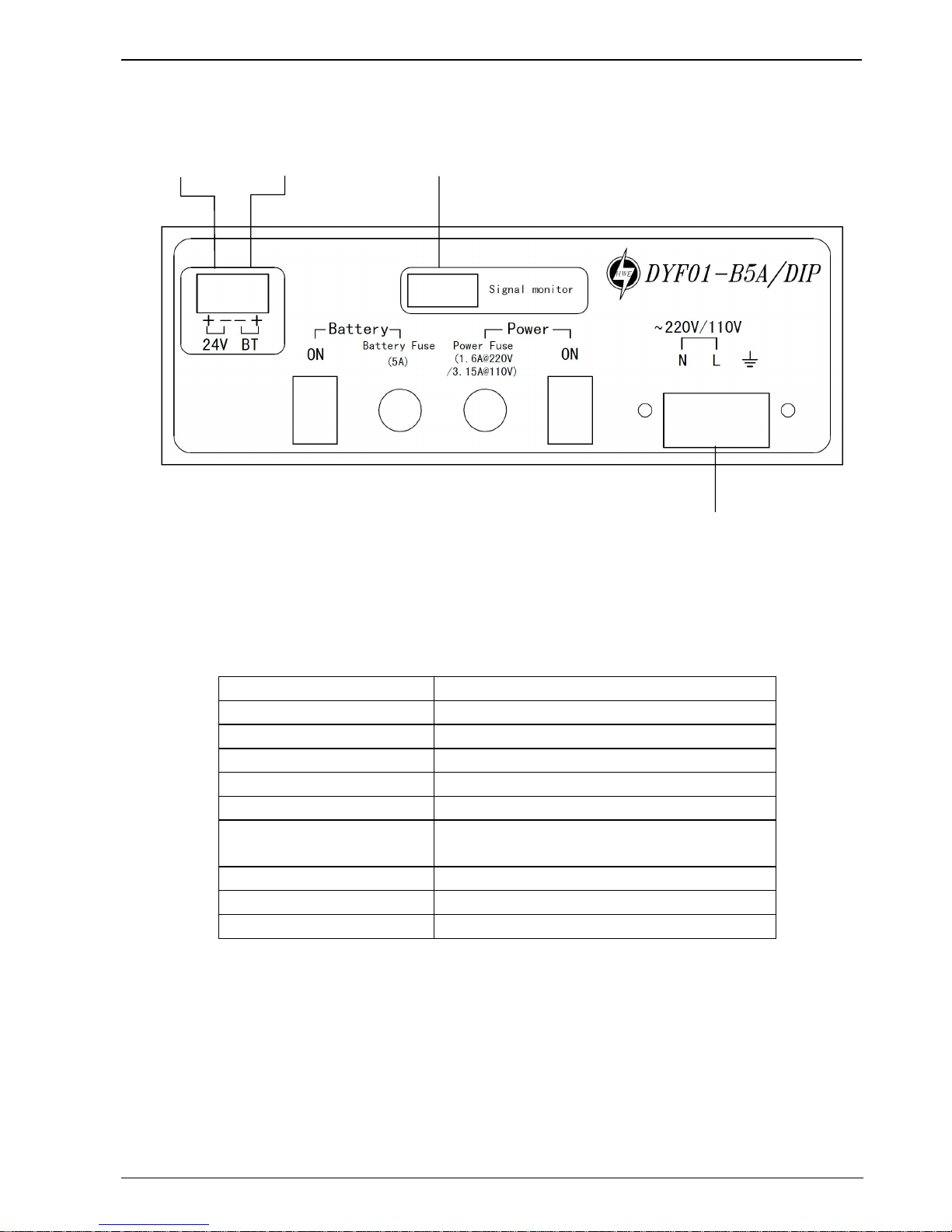

4. Power Supply

- Stable and reliable DC output

- Auto switch between main power and battery

- Alternative AC power switch

- Charge and protect battery

- Monitor main power, battery, trouble status

- Auto recoverable current protection circuit for overload and short circuit

Fig. 2-9 AC Input Switch

Switch between 220VAC

and 110VAC

Page 13

Operating Manual of FC18 Controller

Page: 12/63

Fig. 2-10 Wire connection

Specification of power supply

Input voltage 110/220 VAC

Input frequency 60/50 Hz

Output voltage 24 VDC

Output current 5A

AC fuse capacity 110VAC: 3.15A 220VAC:1.6A

DC fuse capacity 5A

Operating temperature 0 ~ +40℃

when it is over 40℃, output power will reduce half

Storage temperature -20 ~ +60℃

Humidity ≤95% (40±2℃)

Size 220*136*70 mm

Connect external AC input

Connect to

battery

Connect to port

” PS” on main unit

Connect to port “Pwr

Status” on main unit

Page 14

Operating Manual of FC18 Controller

Page: 13/63

CHAPTER 3 OPERATION

1. INTERFACE

Fig. 3-1 Operation panel

① LCD

The LCD backlight automatically turns off within the preset time in the idle mode; the preset time can be adjusted in

the parameter setting. Press any key will turn on the LCD again.

② Printer

There are two indicators and two buttons on the printer panel. Indicator: the green LED indicates power-up state while

the red LED for operation state (on: online; off: offline). Button: SEL (set online/offline), LF (line feed).

③ Key board

¹ Press number keys to enter numbers and characters.

¹ C: Press “C” to cancel or return to the previous menu; Press “OK” to confirm or enter the menu.

¹ : Menu button, press “ ” to show menu.

¹ Press “↓”/“↑” to move the cursor.

¹ Press “←” to delete the previous input.

¹ Press “→” as shortcut key to show the function menu. The operation items of the selected equipment are listed

in the menu according to operator’s user level.

④ Indicators and operation keys

¹ Alarm: Off when there is no fire; On when fire detected; Off again when all alarms are cleared and "reset" is

pressed.

¹ Supervision: On when supervision signal is detected; Off when the event disappears and “reset” is pressed.

Page 15

Operating Manual of FC18 Controller

Page: 14/63

¹ System trouble: On when system hardware/software is faulty.

¹ Trouble: On when trouble occurs; Off when trouble is resolved.

¹ Activation: On when some equipment (such as output module or main board output port) is activated; Off when

activation signal disappears and “reset” is pressed.

¹ Confirmation: On when controller receives confirmation signal; Off when the signal disappears.

¹ NAC trouble: On when trouble occurs on NAC line; Off when trouble disappears.

¹ Main Power: On when main power supply is working; Off when the AC supply is disconnected.

¹ Battery: On when backup batteries are working; Off when the Main power are working and the backup batteries

are not working.

¹ Disable: On when some equipment is disable; Off when no equipment is disable; Flashing when system is in

startup status.

¹ Test: On when some equipment is at test/walk-test mode; Off when no equipment is being tested.

¹ NAC disable: On when NAC line is disable; Off when it’s enable.

¹ Auto: Only level 2&3 users can access. At auto mode all interlocking equipments can be activated automatically

by controller according to interlocking expressions. Manual operations have high priority at auto mode.

¹ Manual: Only level 2&3 can access. At manual mode all interlocking equipments can only be activated manually.

¹ Acknowledge/Silence: Only level 2&3 users can access. Press “Acknowledge/Silence” to turn off the buzzer

(except when battery is under voltage).

- Flashing when there are events and “Acknowledge/Silence” is not pressed. OR when there are

events and “Acknowledge/Silence” is pressed while new event occurs.

- Off when there are events and “Acknowledge/Silence” is pressed, OR when there are no events.

Sound elimination in a network,

- Press “Acknowledge/Silence” on master controller: internal sounder will turn off for both master and

slaves, also indicator will turn off.

- Press “Acknowledge/Silence” on slaves controller: internal sounder will turn off slave itself, indicator

will turn off, but master remains unaffected.

¹ NAC activation: Only level 2&3 users can access. When fire is detected, NAC is activated and the LED is on.

Press “NAC activation” to deactivate NAC devices and the LED is off. Press it again, NAC device is

activated again and the LED is on. So on and so forth.

- “NAC activation” is used to activate/deactivate NAC devices.

- NAC device can be disabled through the menu.

- NAC device can not be activated neither the alarm nor the key when NAC device is disable.

- When NAC device is activated, it can be disable. But when it is enable again, its status will be normal

(no matter there is fire alarm or not).

- The LED status is consistent with NAC device status (no matter there is fire alarm or not). That

means when NAC device is activated, the LED is on; when NAC device is deactivated, the LED is

off.

¹ Reset: Only level 2&3 users can access. It is used to reset the system to normal status. Any event can be reset

by pressing this key no matter it’s silence or not. It’s different to reset fire alarm events from resetting

other events in a network.

- Non-fire alarm events:

If master is reset, events in both master and salves are reset.

If a slave is reset, events in the slave are reset, and the same events in master are also reset.

- Fire alarm event:

If master is reset, events in both master and salves are reset.

If a slave is reset, events in the slave are reset while the same events in master will not reset

Page 16

Operating Manual of FC18 Controller

Page: 15/63

until master is reset.

⑤ Interlocking panel

The interlocking panel has 8 output channels. Each channel has indicators to indicate trouble, activation and

confirmation status. Each channel can be controlled manually with Activation/Deactivation button. Only level 2&3 user

can access. Press the button to activate it and press it again to deactivate it, so on and so forth.

¹ Trouble: On when there is trouble; Off when trouble is solved.

¹ Activation: On when output channel is activated; Flashing when there's no confirmation; Off when the output

channel resume normal.

¹ Confirmation: On when confirmation is received; Off when confirmation signal disappears.

Note: FC1840C doesn’t have interlocking panel and printer.

Page 17

Operating Manual of FC18 Controller

Page: 16/63

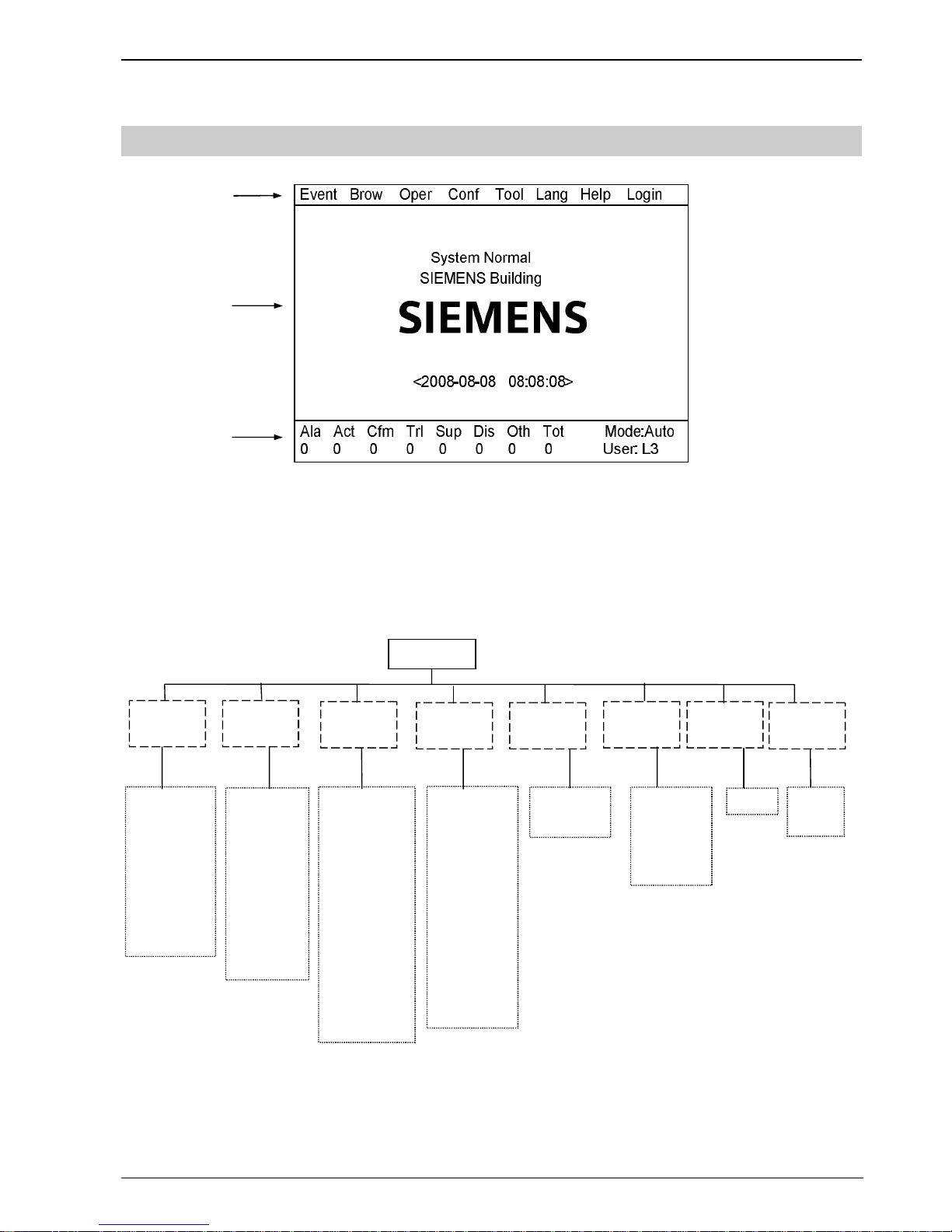

2. LCD WINDOW

FC18 controller has 3 windows which are menu window (1), browser window (2) and statistics window (3).

① Menu window:

¹ Display different operation menus according to different user levels. Items for Level 3 are shown as follows.

Fig. 3-2 Display screen

③①②

Main menu

Operate

—Alarm & active

—Trouble

—Supervision

—Disable

—Test

—Walk-test

—Locat e

—Disable

—Enable

—Open

—Close

—Activate

—Deactivate

—Test

—Walk-test

—Restore

—Locat e

—Stop locating

—Edit parameter

—Save configure

—Assign group

—Assign FRT

—Equipment

repl acement

—Create logic.

—View logic

—Edit logic

—Delet e logic

—English

—Taiwan

—HongKong

—Portugal

—About

BrowseEvent

Tool

Help

Configure Login

—All

—Unconfigure

—Unknown

—Inconsistent

—Exchange

—History

—Property

—Others

—Login

—Logout

Lang

—Set time

—Check

system

Page 18

Operating Manual of FC18 Controller

Page: 17/63

② Browser window:

¹ Display real-time events: fire alarm, activation & confirmation, trouble, supervision, disable, test and walk-test.

¹ Display node tree.

¹ Priority of display: fire alarm→ activation & confirmation→ supervision→ disable→ trouble→ test/walk-test→ normal.

③ Statistics window:

¹ Display total number of real-time events including fire alarm, activation, confirmation, trouble, supervision and disable.

¹ Display the level of the present user as well as the system mode.

¹ icon is displayed when system clock is wrong, possible reason is : the button battery on main board is used or

clock chip can not work normally.

Page 19

Operating Manual of FC18 Controller

Page: 18/63

3. USER LEVEL

l FC18 has 3 user levels. User level is displayed at the lower right corner of the screen (Fig. 3-2)

l Users of different levels have their own matching privileges and interfaces.

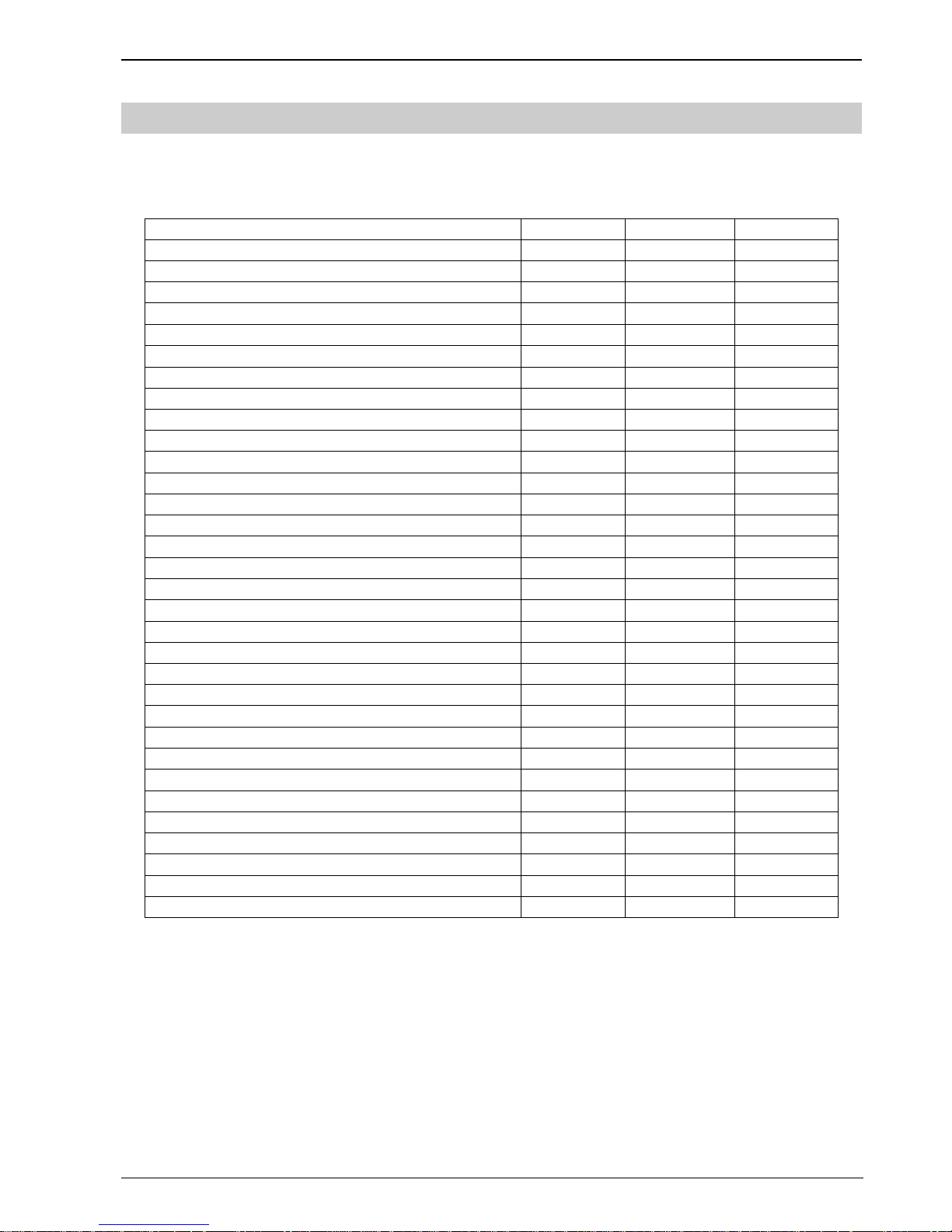

Table 3-1 user privilege list

It em Level 1 Level 2 Level 3

Login √

Logout √ √

Real-time event query √ √ √

History query √ √ √

Property query √ √ √

Disable/Enable devices √ √

Activation/Deactivation devices √ √

Test √ √

Walk-test √ √

Restore √ √

Locate √ √

Stop locating √ √

Login time setting √

Buzzer level setting √

LCD closing time setting √

System time setting √

Auto/manual mode setting √ √

Edit parameter √

Create logic √

Delete logic √

Edit logic √

View logic √

Print events √ √ √

Save configure √

Operate interlocking panel √ √

System check √

Acknowledge/Silence √ √

NAC √ √

Group assignment √

FRT assignment √

Change language √

Reset √ √

Page 20

Operating Manual of FC18 Controller

Page: 19/63

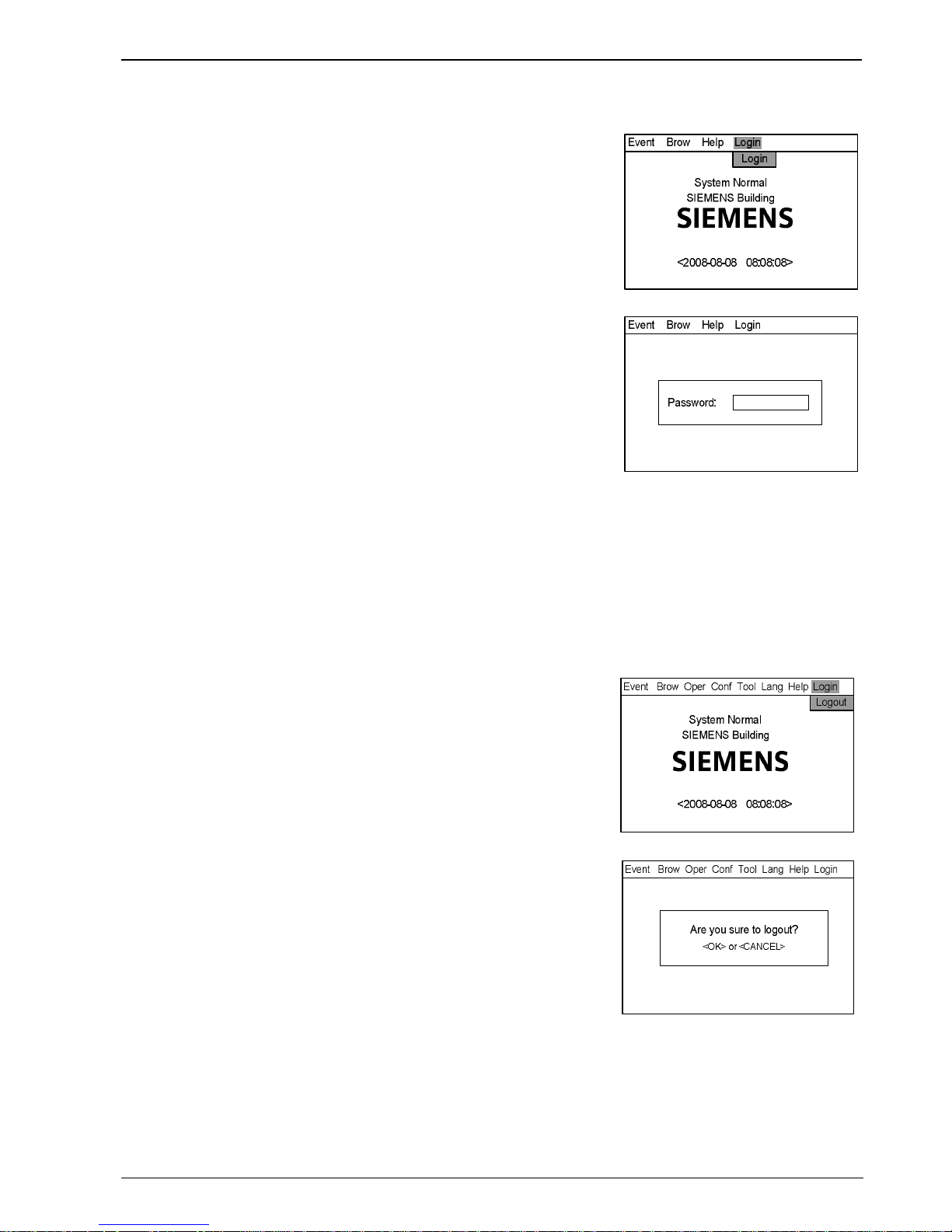

3.1 Login

1. Press “Menu” to browse the main menu.

Display main menu.

2. Press”→” to select “Login”, and then press “OK”.

Password entry window pops out.

3. Enter the password for Level2/3 and press “OK”.

Login as a Level 2/3 user if the password entered is correct.

(Press “←” to delete previous input.)

Note:

Default password for Level 2 is 1234, for Level 3 is 4321. Default password

can be changed by FXS1800 software tool.

System logout automatically after 3 times of invalid entries.

Fig. 3-3

Fig. 3-4

3.2 Logout

There are two ways to logout:

l System logout automatically: System autom atically logs out to Level 1 if no operations during a preset login time. (System

login time can be set by modifying station parameters.)

l Use the menu to logout:

1. Press “Menu” to browse the main menu.

Display event menu.

2. Press”→” to select “Login”, and then press “OK”.

Logout window pops out.

3. Press “OK” to return back to Level 1 interface; press “C” to cancel the logout

operation.

Note:

Users can directly login Level 2/3 interface under Level 1 interface; Users

need to return back to Level 1 interface before logging in Level 2 from Level

3 interface, also same from Level 2 to Level 3.

Fig. 3-5

Fig. 3-6

Page 21

Operating Manual of FC18 Controller

Page: 20/63

4. STATUS TYPES

FC18 controller contains 8 status types: normal, fire alarm/activation, trouble, supervision, disable, test/walk-test and locate.

Normal:

l Main power supply indicator on

l Auto/Manual indicator on

l No events taken place such as fire alarm/activation, trouble, supervision,

disable, test, walk-test etc.

l LCD shown as the figure

The screen shall show “System Normal” and project name.

SIEMENS

<2008-08-08 08:08:08>

System Normal

SIEMENS Building

Event Brow Help Login

Fig. 4-1

Fire alarm status:

l Fire alarm indicator on

l LCD shown as the figure

l Acknowledge/Silence indicator flashing

l NAC activation indicator on

l Buzzer ringing

l NAC device activated

0001 Auto Alarm 2008-08-08 10:10:10

Room 1001, Building 1 / 01.005.001

Alarm & Active

0002 Auto Alarm 2008-08-08 10:10:11

Room 1008, Building 1 / 01. 005.008

0001 Active 2008-08-08 10:10:11

Output 1 / 01.005.008

Fig. 4-2

Trouble status:

l Trouble indicator on

l LCD shown as the figure

l Acknowledge/Silence indicator flashing

l Buzzer ringing

0002 COMM trouble 2008-08-08 10:10:10

Interlocking Line / 01.005

Trouble

0001 Other 2008-08-08 10:10:08

Room 1008, Building 1 / 01. 001.291

Fig. 4-3

Supervision status:

l Supervision indicator on

l LCD shown as the figure

l Acknowledge/Silence indicator flashing

l Buzzer ringing

Supervision

0001 Supervision 2008-08-08 10:10:15

Supervision 1 / 01.005.010

Fig. 4-4

Page 22

Operating Manual of FC18 Controller

Page: 21/63

Activation status:

l Activation indicator on (flashing when there is no confirmation)

l LCD shown as the figure

l Acknowledge/Silence indicator flashing

l Buzzer ringing

Activation

0001 Activation 2008-08- 08 10:10:13

Output 1 / 01.005.008

Fig. 4-5

Confirmation status:

l Confirmation indicator on

l LCD shown as the figure

l Acknowledge/Silence indicator flashing

l Buzzer ringing

Confirmation

0001 Confirmation 2008-08-08 10:10:11

Output 1 / 01.005.008

Fig. 4-6

Disable status:

l Disable indicator on

l LCD shown as the figure

0002 Disable 2008-08-08 10:10:10

Room 1001, Building 1 / 01.005.001

Disable

0001 Disable 2008-08-08 10:08:10

Room 1008, Building 1 / 01. 001.291

Fig. 4-7

Test/Walk-t est stat us:

l Test indicator on

l LCD shown as the figure

Test

0001 Test 2008-08-08 10:10:11

Room 1008, Building 1 / 01.0 05.008

Fig. 4-8

Locate status:

l No indication

l No interface, it only can be found in equipment properties.

Page 23

Operating Manual of FC18 Controller

Page: 22/63

5. FIRE ALARM EVENT HANDLING

Fire alarm status:

l Fire alarm indicator turns on

l Fire event with customer information shown in the LCD as the figure

l Acknowledge/Silence indicator flashing

l NAC activation indicator turns on

l Buzzer turns on

l NAC devices activated

How to handle:

1. Press Acknowledge/Silence to silence the buzzer:

l Under Level 1 interface, a login interface pops out automatically. Enter

Level 2/3 password and press “OK” to return back to fire alarm window

then press “Acknowledge/Silence”. Now,

- Buzzer is mute

- The Acknowledge/Silence indicator turns off

- NAC devices still in activation status

l Under Level 2/3 interface,

- Buzzer is mute

- The Acknowledge/Silence indicator turns off

- NAC devices still in activation status

2. Press “NAC Activation” to deactivate NAC devices and the indicator turns

off. Press it again to reactivate NAC devices and the indicator turns on. So

on and so forth.

3. Find out fire location from LCD.

4. Go to the site to investigate the situation.

5. Call the firemen immediately if it’s an emergency. If it’s controllable, press

“Reset” after handling the fire to remove the fire alarm event and the fire

alarm indicator turns off.

Handling mu lti-fire alarm:

- Information of multi-fire alarm is displayed.

- The cursor stays on the first alarm. Other alarms are displayed

repeatedly in a reverse order.

- Browsing each item by pressing ”↓” / ”↑“

Note: The re are 2 kin ds of fire al arms nam ely “auto alarm” an d “manual

alarm”.

Fig. 5-1fire alarm interface

Page 24

Operating Manual of FC18 Controller

Page: 23/63

6. TROUBLE EVENT HANDLING

Trouble status:

l Trouble indicator turns on

l Trouble events are shown on the LCD as the figure

l Acknowledge/Silence indicator flashing

l Buzzer turns on

How to handle:

1. Press “Acknowledge/Silence” to silence the buzzer:

l Under Level 1 interface, a login interface pops out automatically. Enter

Level 2/3 password and press “OK” to return back to fire alarm window

then press “Acknowledge/Silence”. Now,

- Buzzer is mute.

- The Acknowledge/Silence indicator turns off.

l Under Level 2/3 interface,

- Buzzer is mute

- The Acknowledge/Silence indicator turns off.

2. Find out the trouble location from LCD.

3. Go to the site to trouble-shoot.

4. The trouble indicator turns off when problems are solved. If you cannot solve

the problem, please call local Siemens service center.

Note:

When a trouble occurs together with another event of higher priority, trouble

event cannot be displayed automatically. Enter the trouble window manually

(see “real-time query” function) to handle trouble.

CPU trouble:

When application software in trouble or CPU hardware trouble occurs,

system trouble indicator turns on. In such case, system cannot operate

normally and no key is available. Now you should disconnect the power

supply and contact with Siemens service center.

Fig. 6-1

Page 25

Operating Manual of FC18 Controller

Page: 24/63

7. SUPERVISION EVENT HANDLING

Supervision status:

l Supervision indicator on

l Supervision events are shown on the LCD as the figure

l Acknowledge/Silence indicator flashing

l Buzzer turns on

How to handle:

1. Press “Acknowledge/Silence” to silence the buzzer:

l Under Level 1 interface, a login interface pops out automatically. Enter

Level 2/3 password and press “OK” to return back to fire alarm window

then press “Acknowledge/Silence”. Now,

- Buzzer is mute.

- The Acknowledge/Silence indicator turns off.

l Under Level 2/3 interface,

- Buzzer is mute

- The Acknowledge/Silence indicator turns off.

2. Find out the supervision location from LCD.

3. Go to the site to handle it if necessary.

4. The supervision event will disappear when supervision signal disappears.

Press “Reset” to turn off the supervision indicator and the controller return to

normal.

Note:

When a supervision event occurs together with another event of higher

priority, supervision event cannot be displayed automatically. Enter the

supervision window manually (see “real-time query” function) to handle it.

Fig.7-1

Page 26

Operating Manual of FC18 Controller

Page: 25/63

8. ACTIVATION/CONFIRMATION EVENT HANDLING

Activation status:

l Activation indicator on (flashing if there is no confirmation)

l Confirmation indicator on (only if there is confirmation signal)

l Activation events are shown on the LCD as the figure

l Acknowledge/Silence indicator flashing

l Buzzer turns on

How to handle:

1. Press Acknowledge/Silence to silence the buzzer:

l Under Level 1 interface, a login interface pops out automatically. Enter

Level 2/3 password and press “OK” to return back to fire alarm window

then press “Acknowledge/Silence”. Now,

- Buzzer is mute.

- The Acknowledge/Silence indicator turns off.

l Under Level 2/3 interface,

- Buzzer is mute

- The Acknowledge/Silence indicator turns off.

2. Find out the activation/confirmation location from LCD.

3. Go to the site to handle it if necessary.

4. Confirmation indicator turns off when confirmation signal disappears. When

activation signal disappears, press “Reset” to turn off the activation indicator

and the controller return to normal.

Note:

- When an activation/confirmation event occurs together with another

event of higher priority, activation/confirmation event cannot be

displayed automatically. Enter the activation/confirmation window

manually (see “real-tim e query” function) to handle it.

- Press “←” to switch between fire alarm window and activation window.

Fig.8-1activation interface

Page 27

Operating Manual of FC18 Controller

Page: 26/63

9. REAL-TIME QUERY

FC18 fire alarm controller (interlocking) contains ten types of real-time events:

Table 3-2

T ypes of real-time events Priority

Fire alarm/activation 1

Supervision 2

Disable 3

Trouble 4

Test 5

Walk-test 5

Locate 5

Unconfigure equipment 6

Unknown equipment 7

Inconsistent equipment 8

Exchange equipment 9

Unconfigure equipment: Equipments not on the engineering document list.

Unknown equipment: Equipments not listed by Table 1-2.

Inconsistent equipment: The type of installed equipment on site is inconsistent with engineering document.

Exchange equipment: Dirty smoke detector.

Steps:

1. Press “Menu” to browse the main menu. (Fig. 9-1)

Main menu displayed.

2. Press “↓” to select an event type to query then press “OK”.

All the events meeting the requirements will be displayed in the window. Use

“↓” /”↑” to browse items.

When an event is selected, press “→” to pop out a shortcut menu (Fig. 9-2). All

operable items will be listed according to user’s level. Use “↓” / “↑” to select

an operation then press “OK” to take the operation.

Note:

- “0001”: Order of an event

- “COMM trouble”: Type of an event

- “2008-08-08 10:10:10”: Date and time when an event takes place

- “Interlocking line / 01.0005”: Text message and equipment address of an

event

- “Interlocking group”: text message of the group which this interlocking

equipment belongs to. (If the equipment does not belong to any group,

only text message of the event and equipment address are displayed.)

SIEMENS

<2008-08-08 08:08:08>

System Normal

SIEMENS Building

Event Brow Help Login

Alarm & active

Trouble

Supervision

Disable

Test

Walk-Test

Locate

Alarm & active

Fig. 9-1

0002 COMM trouble 2008-08-08 10:10: 10

Interlocking Line / 01.005

Trouble

0001 Other 2008-08-08 10:10:08

Room 1008, Building 1 / 01.001.291

Property

History

Disable

Test

Property

Fig. 9-2

Page 28

Operating Manual of FC18 Controller

Page: 27/63

10. HOW TO QUERY EQUIPMENT PROPERTY

Steps:

1. Select a station, a line or a point and press “→” to pop out a shortcut menu

(Fig. 10-1), then select “Property” and press “OK” to pop out a property

window. (Fig. 10-2)

2. Press “C” to quit equipment property query.

0002 COMM trouble 2008-08-08 10:10:10

Interlocking Line / 01.005

Trouble

0001 Other 2008-08-08 10:10:08

Room 1008, Building 1 / 01. 001.291

Property

History

Property

Fig.10-1

Station ID: 1

Line ID: 1

Point ID: 3

Text: Room 1008, Building 1

Type: Heat detectot

Status: Normal

Property

Fig.10-2

Page 29

Operating Manual of FC18 Controller

Page: 28/63

11. HOW TO QUERY HISTORY

FC18 fire alarm controller (interlocking) contains 11 types of history records which are fire alarm, trouble, supervision,

activation/confirmation, disable, test and walk-test, unconfigure equipment, unknown equipment, inconsistent equipment,

exchange equipment. The first six types support advanced query.

Steps:

1. Select a station, a line or a point and press “→” to pop out a shortcut menu,

and then press “↓” to “History” (Fig. 11-1). Press “OK” to pop out the

record window. All the history records will be displayed. (Fig. 11-2)

Note:

If a system is selected, all the history records of all the stations, lines and

points belonging to this system are displayed.

If a station is selected, all the history records of this station and the line and

equipment which belongs to this station will be displayed.

If a line is selected, all the history records of this line will be displayed.

If a point is selected, all the history records of this point will be displayed.

2. Press “Menu” to pop out the record menu, select “Advanced Query”

(Fig.11-3), then press “OK” to pop out advanced query window (Fig.11-4).

3. Select a type and input query time period then press “OK”. All the events

meet the requirements will be displayed in the window. Use “↓” /”↑” to

browse items then press “Menu”:

Select “Print” to print all the history records displayed.

Select “Quit” to return back to initial interface.

Note:

Use “↓” / “↑” to switch active window.

Use “→” to activate the dropdown menu of types.

Use “←” to clear wrong input.

Date format:YYYY-MM-DD; time format: HH-MM-SS.

0002 COMM trouble 2008-08-08 10:10: 10

Interlocking Line / 01.005

Trouble

0001 Other 2008-08-08 10:10:08

Room 1008, Building 1 / 01.001.291

Property

History

History

Fig.11-1

+ 001 Disable 01.005.001

Room 1001, Building 1

2008-08-08 10:10:10

Record

+ 002 Disable 01.001.291

Room 1008, Building 1

2008-08-08 10:11:10

Fig.11-2

+ 001 Disable 01.005.001

1号楼1001室

2008-08-08 10:10:10

Record

+ 002 Disable 01.001.291

Room 1008, Building 1

2008-08-08 10:11:10

Print

Quit

Advanced Query

Fig.11-3

+ 001 Disable 01.005.001

Room 1001, Building 1

2008-08-08 10:10:10

Record

+ 002 Disable 01.001.291

Room 1008, Building 1

2008-08-08 10:11:10

Advanced Query: Type

Start Time End Time

All

2008-08-08

08:08:08

2008-08-09

10:10:10

Fig.11-4

Page 30

Operating Manual of FC18 Controller

Page: 29/63

12. HOW TO DISABLE/ENABLE

Function: The controller should be disabled when the house is being decorated

or there are equipment damages or failure. It should be resumed to

normal state as soon as the decorating work or equipment repair is

finished.

Note: Disabled equipment cannot send any message to controller.

Equipment cannot be disabled when being replaced.

Steps to disable:

1. Press “Menu” to browse the main menu (Fig.12-1).

Main menu displayed.

2. Press “→” to select “Brow” submenu (Fig. 12-2). Press “↓” to select the

item which contains the equipment to be disabled, and then press “OK”.

Now the equipment will be displayed directly in the window.

If you don’t know which type the equipment to be disabled belongs to,

please select “All equipments”, then press “OK” to display the tree (Fig.

12-3). Search down level by level through stations, lines and points until

you find the equipment you are looking for.

3. Press “→” to pop out the shortcut menu (Fig.12-4). Use “↓” to select

“Disable” and press “OK” to disable the selected equipment.

Steps to enable (two ways):

The first way: the same as the steps to disable. The only difference is that select

“Enable” instead of “Disable” in step 3.

The second way: it’s easier to find the disable equipment through real-time

disable query (see real-time query). Press “→” to pop out the shortcut

menu (Fig. 12-5) and press “↓” to select “Enable”, then press “OK” to

enable the selected equipment.

Disable indicator goes off when all the disable equipments are enabled.

Fig.12-1

Fig.12-2

Fig.12-3

Fig.12-4

Fig.12-5

Page 31

Operating Manual of FC18 Controller

Page: 30/63

13. HOW TO ACTIVAT E/DEACT IVATE THE CONTROLLER

Function: Through controller, manually activation/deactivation mainboard

output, output module, interlocking panel output and NAC devices etc.

Steps to activation:

1. Press “Menu” to browse the main menu (Fig. 13-1).

Main menu displayed.

2. Press “→” to select “Brow” submenu (Fig. 13-2). Press “↓” to select “All”,

then press “OK” to display the tree diagram (Fig. 13-3). Search down level

by level through stations, lines and points until you find the equipment you

are looking for.

3. Press “→” to pop out a shortcut menu (Fig.13-4). Use “↓” to select

“Activate” and press “OK” to activate the selected equipment.

4. Press “Acknowledge/Silence” to silence the buzzer and to turn off the

flashing “Acknowledge/Silence” indicator.

Steps to deactivate (two ways):

The first way: the same as the first 2 steps to activation. The only difference is

that select “Deactivate” instead of “Activate” in step 3.

The second way: It’s easier to find the activated equipment through real-time

activation query (see real-time query). Press “ →” to pop out a shortcut

menu (Fig. 13-5) and press “↓” to select “Deactivate”, then press “OK”

to deactivate the selected equipment.

Activation indicator turns off when all the activated equipments are

deactivated.

Fig.13-1

Fig.13-2

All

NAC

SIEMENS Buidling

Building 1 Controller

Power Monitor Line

Onboard I/O

Main Board I/O 2

Main Board I/O 1

P2 Line

Fig.13-3

All

NAC

SIEMENS Buidling

Building 1 Controller

Power Monitor Line

Onboard I/O

Main Board I/O 2

Main Board I/O 1

P2 Line

Property

History

Activate

Disable

Edit Parameter

Activate

Fiig.13-4

Fig.13

-

5

Page 32

Operating Manual of FC18 Controller

Page: 31/63

14. HOW TO TEST/WALK-TEST

Function: To test whether the alarm device is in normal status. Under

test/walk-test mode, an alarm will be triggered when there is an alarm

event while the interlocking equipment will not be activated. Make sure the

controller is back to normal after the test.

Difference between test and walk-test:

Test: Fire alarms cannot reset automatically under test mode. Controller

need to be resumed back to normal status by manual reset.

Walk-test: Controller can resume back to normal status automatically after

the preset walk-test time (which can be set by editing the

controller parameters).

Steps to tes t/w alk-test:

1. Press “Menu” to browse the main menu (Fig. 14-1).

Main menu displayed.

2. Press “→” to select “Brow” submenu (Fig. 14-2). Press “↓” to select “All”,

then press “OK” to display the tree diagram (Fig. 14-3). Search down level

by level through stations, lines and points until you find the equipment you

are looking for.

3. Press “→” to pop out the shortcut menu (Fig.14-4). Use “↓” to select

“Test/Walk-Test” and press “OK” to test the selected equipment.

How to restore to normal: two ways

The first way: the same as the first 2 steps to conduct a test/walk-test. The only

difference is that select “Restore” instead of “Test/Walk-Test” in step 3.

The second way: It’s easier to find the tested equipment through real-time

test/walk-test query (see real-time query). Press “→” to pop out the

shortcut menu (Fig. 14-5) and press “↓” to select “Restore”, then press

“OK” to restore the selected equipm ent.

Test/walk-test indicator turns off when all the tested equipments are

restored to normal.

Fig.14-1

Fig.14-2

Fig.14-3

Fig.14-4

Fig.14-5

Page 33

Operating Manual of FC18 Controller

Page: 32/63

15. HOW TO LOCATE/STOP LOCAT ING

Function: To locate equipment.

Steps to locate:

1. Press “Menu” to browse the main menu (Fig. 15-1)

Main menu displayed.

2. Press “→” to select “Brow” submenu (Fig. 15-2). Press “↓” to select “All”,

then press “OK” to display the tree diagram (Fig. 15-3). Search down level

by level through stations, lines and points until you find the equipment you

are looking for.

3. Press “→” to pop out the shortcut menu (Fig.15-4). Use “↓” to select

“Locate” and press “OK” to locate the selected equipment. Now the test

indicator is flashing.

Steps to stop locating:

The same as the first 2 steps to conduct a remote test. The only difference

is that select “Stop locating” instead of “Locate” in step 3. Then press "OK"

to reset the selected equipment and turn off the flashing indicator.

Fig.15-1

Fig.15-2

Fig.15-3

Fig.15-4

Page 34

Operating Manual of FC18 Controller

Page: 33/63

16. HOW TO ADJUST BUZZER LEVEL

Function: Turn up or down the buzzer between level 0-7. Level 0 is mute mode.

Steps:

1. Press “Menu” to browse the main menu (Fig. 16-1)

Main menu displayed.

2. Press “→” to select “Brow” submenu (Fig. 16-2). Select "All" and then press

“OK”. Now the tree diagram will be displayed in the window (Fig.16-3).

3. Use "↓" / "↑" to select the controller you are looking for.

4. Press “→” to pop out the shortcut menu (Fig.16-4). Use “↓” to select “Edit

Parameter” and press “OK” to enter the parameter editing interface

(Fig.16-5).

5. Press "↓" to select "Buzzer Level" window. Press "←" to delete the

previous number and enter the expected one.

6. After the change, press "Menu" and press "↓" to select "Confirm", then

press "OK" to save the change and quit. A dialog box will pop out to remind

you to save the change (Fig. 22-3). Press "OK" to save the change

permanently or press "C" to save the change temporarily. (The change will

be lost if the system is restarted.)

Select "Cancel" and press”OK” if you don't want to save the change.

Note:

·The saved changes take effect immediately.

·These operations can only be applied to the selected controller.

Fig.16-1

Fig.16-2

Fig.16-3

Fig.16-4

Fig.16-5

Page 35

Operating Manual of FC18 Controller

Page: 34/63

17. HOW TO SET LO GIN TIME

Function: Under 2/3 level, if there is no operation in preset login time, controller

will autom atically log out to 1level. Setting range: 1-60 minutes.

Steps:

1. Press “Menu” to browse the main menu (Fig. 17-1)

Main menu displayed.

2. Press “→” to select “Browse” submenu (Fig. 17-2). Select "All" and then

press “OK”. Now the tree diagram will be displayed in the window

(Fig.17-3).

3. Use "↓" / "↑" to select the controller you are looking for.

4. Press “→” to pop out the shortcut menu (Fig.17-4). Use “↓” to select “Edit

Parameter” and press “OK” to enter the parameter editing interface

(Fig.17-5).

5. Press "↓" to select "Login Time" window. Press "←" to delete the previous

number and enter the expected one.

6. After the change, press "Menu" and press "↓" to select "Confirm", then

press "OK" to save the change and quit. A dialog box will pop out to remind

you to save the change (Fig. 22-3). Press "OK" to save the change

permanently or press "C" to save the change temporarily. (The change will

be lost if the system is restarted.)

Select "Cancel" and press”OK” if you don't want to save the change.

Note: The saved changes take effect immediately.

These operations can only be applied to the selected controller.

Fig.17-1

Fig.17-2

Fig.17-3

Fig.17-4

Fig.17

-

5

Page 36

Operating Manual of FC18 Controller

Page: 35/63

18. HOW TO SET WALK-TEST TIME

Function: Controller being tested will restore to normal status automatically after

the preset walk-test time. Setting range: 1-60 min.

Steps:

1. Press “Menu” to browse the main menu (Fig. 18-1)

Main menu displayed.

2. Press “→” to select “Brow” submenu (Fig. 18-2). Select "All" and then press

“OK”. Now the tree diagram will be displayed in the window (Fig.17-3).

3. Use "↓" / "↑" to select the controller you are looking for.

4. Press “→” to pop out the shortcut menu (Fig.18-4). Use “↓” to select “Edit

Parameter” and press “OK” to enter the parameter editing interface

(Fig.18-5).

5. Press "↓" to select "Walk-Test" window. Press "←" to delete the previous

number and enter the expected one.

6. After the change, press "Menu" and press "↓" to select "Confirm", then

press "OK" to save the change and quit. A dialog box will pop out to remind

you to save the change (Fig. 22-3). Press "OK" to save the change

permanently or press "C" to save the change temporarily. (The change will

be lost if the system is restarted.)

Select "Cancel" and press”OK” if you don't want to save the change.

Note: The saved changes take effect immediately.

These operations can only be applied to the selected controller.

Fig.18-1

Fig.18-2

Fig.18-3

Fig.18-4

Fig.18

-

5

Page 37

Operating Manual of FC18 Controller

Page: 36/63

19. HOW TO SET LCD CLOSING TIME

Function: LCD turns off its back light if there is no operation or event during the

preset LCD closing time. Press any key to turn on the back light. Setting

range: 1-60 min.

Steps:

1. Press “Menu” to browse the main menu (Fig. 19-1)

Main menu displayed.

2. Press “→” to select “Browse” submenu (Fig. 19-2). Select "All" and then

press “OK”. Now the tree diagram will be displayed in the window

(Fig.19-3).

3. Use "↓" / "↑" to select the controller you are looking for.

4. Press “→” to pop out the shortcut menu (Fig.19-4). Use “↓” to select “Edit

Parameter” and press “OK” to enter the parameter editing interface

(Fig.19-5).

5. Press "↓" to select "LCD closing time" window. Press "←" to delete the

previous number and enter the expected one.

6. After the change, press "Menu" and press "↓" to select "Confirm", then

press "OK" to save the change and quit. A dialog box will pop out to remind

you to save the change (Fig. 22-3). Press "OK" to save the change

permanently or press "C" to save the change temporarily. (The change will

be lost if the system is restarted.)

Select "Cancel" and press”OK” if you don't want to save the change.

Note: The saved changes take effect immediately.

These operations can only be applied to the selected controller.

Fig.19-1

Fig.19-2

Fig.19-3

Fig.19-4

Fig.19

-

5

Page 38

Operating Manual of FC18 Controller

Page: 37/63

20. HOW TO SET TIME

Function: To set system time.

Steps:

1. Press “Menu” to browse the main menu (Fig. 20-1)

Main menu displayed.

2. Press “→” to pop out the "Tool" submenu (Fig.20-2). Select “Set Time" and

press “OK” to enter the time setting interface (Fig.20-3).

3. Press "←" to delete the previous number and enter the exact time and date

then press "OK". The change will take effect immediately.

Note: A master controller can be set as a time-based controller by FXS1800

engineering tool. The time-based controller synchronizes other slave

controller every one hour. Salve controller can not be synchronized

when system rest art.

Fig.20-1

Fig.20-2

Fig.20-3

Page 39

Operating Manual of FC18 Controller

Page: 38/63

21. HOW TO CHECK SYSTEM

Function: To check whether the LCD, indicators, printer and the buzzer are in

normal state.

Steps:

1. Press “Menu” to browse the main menu (Fig. 21-1)

Main menu displayed.

2. Press “→” to pop out the "Tool" submenu (Fig.21-2). Press "↓" to select

“Check System" and press “OK” to display the checking system window

(Fig.21-3). Press "OK" to examine the system.

- LCD: Flash in white and black once for each. It's normal if there is no

blank spot.

- Indicator: All indicators flashing. Any indicator not flashing is broken.

- Buzzer: Rings in 4 different sounds. The sound system is abnormal if

there is sound missed.

- Printer: Print "successful test!" automatically. It's broken if it fails to print

them.

3. After finishing checking system, it will return to the original interface.

Fig.21-1

Fig.21-2

Fig.21-3

Page 40

Operating Manual of FC18 Controller

Page: 39/63

22. HOW TO SAVE CONFIGURE

Function: Save changes permanently, otherwise the changes will be lost when

the system is restarted.

Steps:

1. Press “Menu” to browse the main menu (Fig. 22-1)

Main menu displayed.

2. Press “→” to pop out the "Conf" submenu (Fig.22-2). Press "↓" to select

“Save Configure" and press “OK” to display the configuration saving

window (Fig.22-3). Press "OK" to save the changes.

3. It will return to the original interface after the changes are saved.

Fig.22-1

Fig.22-2

Fig.22-3

Page 41

Operating Manual of FC18 Controller

Page: 40/63

23. HOW TO EDIT PARAMETER

Function: To modify parameters in system. See Appendix table 1 for details.

Steps:

1. Press “Menu” to browse the main menu (Fig. 23-1)

Main menu displayed.

2. Press “→” to select “Brow” submenu (Fig. 23-2). Press “↓” to select the

item which contains the equipment whose parameters need to be modified,

and then press “OK”. Now the equipment will be displayed derectly in the

window.

If you don’t know which type the equipment belongs to, please select “All”,

then press “OK” to display the tree diagram (Fig. 23-3). Search down level

by level through stops, loops and points until you find the equipment you

are looking for.

3. Press “→” to pop out a shortcut menu (Fig.23-4). Use “↓” to select “Edit

Parameters” and press “OK” to enter the parameter modify interface

(Fig.23-5).

4. Operations to modify:

- Press “↓”/” ↑” to switch between windows.

- If it is numerical value type of item, press “←” to delete the previous

number and then enter the expected one.

- If it is a pull-down menu, press "→" to pop out the pull-down menu,

and then press “↓” to choose, then press “OK” to confirm.

5. After the modification, press "Menu" and press "↓" to select "Confirm",

then press "OK" to save the change and quit. A dialog box will pop out to

remind you to save the change (Fig. 16-6). Press "OK" to save the change

for permanence or press "C" to save the change temporarily. (The change

will be lost if the system is restarted.)

Select "Cancel" and press”OK” if you don't want to save the change.

Note: The saved changes take effect immediately.

These operations can only be applied to the selected controller.

Fig.23-1

Fig.23-2

Fig.23-3

Fig.23-4

Fig.23

-

5

Page 42

Operating Manual of FC18 Controller

Page: 41/63

24. HOW TO CREAT E/VIEW LOGIC

Function: To create/view logic among detection group, supervision group and

control output group.

Steps:

1. Press “Menu” to browse the main menu (Fig. 24-1)

Main menu displayed.

2. Press “→” to select “Brow” submenu (Fig. 24-2). Select "All" and then press

“OK”. Now the tree diagram will be displayed in the window (Fig.24-3).

Press “↓”/” ↑” to find out the group for which you want to build a interlock.

3. Press “→” to pop out the shortcut menu (Fig.24-3). Use “↓” to select

“Create Logic” and press “OK” to enter the logic interface (Fig.24-4). The

address of the group chosen is shown in the editing window automatically.

Users can input an interlocking expression according to "Rules for editing

interlocking" (see Appendix table 4).

4. After modification/entering, press “Menu” (Figure 24-5), select “Confirm”,

and then press “OK” to begin system compiling. If successful, it will display

“Logic relations compiled successfully”. If not successful, display will

indicate error information. If you don’t want to save this change, select

“Cancel”, and press “OK” to quit.

5. After the change, press "Menu" and press "↓" to select "Confirm", then

press "OK" to save the change and quit. A dialog box will pop out to remind

you to save the change (Fig. 22-3). Press "OK" to save the change for

permanence or press "C" to save the change temporarily. (The change will

be lost if the system is restarted.)

Select "cancel" and press “OK” if you don't want to save the change.

Note: The saved changes take effect immediately.

These operations can only be applied to the selected controller.

"0" can be neglected in expressions because the system will add it

automatically.

6. Select "View Logic" in step 3 to enter the view window which includes all

the logical expressions of the selected group. You cannot edit interlock in

the view window. Press "C" to quit after the view.

Note: These operations can be applied to both host machine and slaves.

Fig.24-1

Fig.24-2

Fig.24-3

Fig.24-4

Fig.24-5

Page 43

Operating Manual of FC18 Controller

Page: 42/63

25. HOW TO EDIT/DELETE LOGIC

Function: To modify or delete logic.

Steps:

1. Press “Menu” to browse the main menu (Fig. 25-1)

Main menu displayed.

2. Press “→” to select “Browse” submenu (Fig. 25-2). Select "All" and then

press “OK”. Now the tree diagram will be displayed in the window

(Fig.25-3). Press “↓”/” ↑” to find out the expression to be modified.

3. Press “→” to pop out the shortcut menu (Fig.25-3). Use “↓” to select

“Edit Logic” and press “OK” to enter the logic interface (Fig.25-4). Then

users can edit the selected expression.

4. After editing, press “menu” (Figure 25-5), choose “Confirm”, and then

press “OK” to begin system compiling. If successful, it will display “Logic

relations compiled successfully”. If not successful, display will indicate

error information. If you don’t want to save this change, select “Cancel”,

and press “OK” to quit.

5. A dialog box will pop out to remind you to save the change (Fig. 22-3)

after you quit the edit window. Press "OK" to save the change

permanently or press "C" to save the change temporarily. (The change

will be lost if the system is restarted.)

6. If you select "Delete Logic" in step 3, the system will pop out a remind

window (Fig.25-5). Press "OK" to delete the interlock or press "C" to give

up.

This operation is temporary. Repeat step 5 to save the change

permanently.

Note: The saved changes take effect immediately.

These operations can only be applied to the selected controller.

"0" can be neglected in expressions because the system will add

it automatically.

Fig.25-1

Fig.25-2

Fig.25-3

Fig.25-4

SIEMENS

<2008-08-08 08:08:08>

Are you sure to delete logic?

<OK> or <CANCEL>

Event Brow Oper Conf Tool Lang Help Login

Fig.25-5

Page 44

Operating Manual of FC18 Controller

Page: 43/63

26. HOW TO ASSIGN GROUP/ FRT

Function: It's more convenient to edit logic with the concept of "Group". There

are four groups in the system: detection group, control output group, supervision

group and FRT group. See Appendix table 3 for details.

Steps:

1. Press “Menu” to browse the main menu (Fig. 26-1)

Main menu displayed.

2. Press “→” to select “Brow” submenu (Fig. 26-2). Select "All" and then press

“OK”. Now the tree diagram will be displayed in the window (Fig.26-3).

Press “↓”/” ↑” to find out the equipment to be assigned to group.

3. Press “→” to pop out a shortcut menu (Fig.26-3). Use “↓” to select “Assign

Group” or "Assign FRT"and press “OK” to enter the grouping interface

(Fig.26-4).

4. Press “→” to popup pull-down menu of groups that can be assigned to,

choose expected group, press “OK”, and system will save and return to the

original window. But the save here is just temporary; if the equipment is

reloaded, changed data will lost. As a result, for long-term storage, please

refer to “how to save configuration”. If you don’t want to save this change,

press “C”.

Note: The saved changes take effect immediately.

These operations can only be applied to the selected controller.

Fig.26-1

Fig.26-2

Fig.26-3

Fig.26-4

Page 45

Operating Manual of FC18 Controller

Page: 44/63

27. HOW TO GET HELP

Function: To show the company name, system edition, product series No,

download time of configuration file and modification time.

Steps:

1. Press “Menu” to browse the main menu (Fig. 27-1)

Main menu displayed.

2. Press “→” to select “Help” submenu (Fig. 27-2). Press "OK" to display the

help information window (Fig.27-3).

3. Press "C" to return to the original window.

Fig.27-1

Fig.27-2

Fig.27-3

Page 46

Operating Manual of FC18 Controller

Page: 45/63

28. HOW TO OPERAT E INTERLOCKING PANEL

Function: The interlocking penal has 8 channels of input/output. Each of them has indicators of trouble, activation and

confirmation to indicate its state, as well as activation/deactivation key for manual control.

Steps:

¹ When the controller is in automatic status, the controller can activate spot equipment through logical relation. The

"activation" indicator is on when activation order is given. The "confirmation" indicator is on when confirmation signal is

received.

¹ When the controller is in manual status, spot equipment can be activated/deactivated manually. "Activation" indicator

is on when "Activation/Deactivation" key is pressed. "Confirmation" indicator is on when confirmation signal is

received. When "Activation/Deactivation" is pressed, "activation" indicator is off and the equipment output stops.

¹ Trouble indicator is on when trouble occurs during examination. It is off when the trouble is solved.

Page 47

Operating Manual of FC18 Controller

Page: 46/63

29. HOW TO OPEN/CLOSE A PRINTER

Function: When the printer is open, it can print real-time events at any time and

print history records if needed (see "History Query"); when it is off, it

cannot print anything.

Steps to open printer:

1. Press “Menu” to browse the main menu (Fig. 29-1)

Main menu displayed.

2. Press “→” to select “Brow” submenu (Fig. 29-2). Select "All" and then press

“OK”. Now the tree diagram will be displayed in the window (Fig.29-3).

Usually printer is under mainboard port.

3. Press “→” to pop out the shortcut menu (Fig.29-4). Use “↓” to select

“Open” and press “OK” to open the printer.

Steps to close p rin ter:

The same as the steps to turn it on. The only difference is to select “Close”

instead of “Open” in step 3 (Fig.29-5). Then press "OK" to close printer.

Note: Open/close a printer is neither an event nor a history record.

Checking system does not change the status of the printer.

Fig.29-1

Fig.29-2

Fig.29-3

Fig29-4

Fig.29-5

Page 48

Operating Manual of FC18 Controller

Page: 47/63

Operations of printer:

There are two indicators and two keys. Indicators are under the transparent key.

Indicator:

Green indicator indicates electrifying state of printer; red indicator indicates

working state of printer (online/offline).

Green

indicator

On Normal power supply

Off No power supply

Red indicator

On Online

Off Offline

Keys:

SEL: Choose online/offline states of printer; LF: Line feed.

Self examination: To check whether:the printer is normal. Operation steps:

- Before electrified, press SEL and then connect 5V power supply, and

printer will print "self-examination".

- When printer is electrified, if indicator is on, press SEL to turn it off (if

indicator is off, this operation is not necessary). Press LF, and press

SEL, then the printer will print self-examination.

Press SEL to stop during self examination if needed.

Change paper roll:

1. As Fig.29-6, press the key to open the front cover.

2. Take out the left paper roll, and install the new one as Fig.29-7.

3. As Figure 29-8, close the front cover.

Note:

When close the front cover, let some of paper leave out of the exit to

make sure the plastic shaft is pressing it tightly.

Make sure heat-sensitive coat of print paper is on the front otherwise

nothing can be printed on the paper.

The printer state can be saved when panel power off.

Fig.29-6

Fig.29-7

Fig.29-8

Page 49

Operating Manual of FC18 Controller

Page: 48/63

30. HOW TO REPLACE DEVICE

Function: To copy the configuration information to the new equipment when the

old one is replaced.

Steps:

1. Press “Menu” to browse the main menu (Fig. 30-1)

Main menu displayed.

2. Press “→” to select “Browse” submenu (Fig. 30-2). Press "↓" to select "

Unconfigure" and then press “OK”. Now the equipments unconfigure will be

displayed in the window (Fig.30-3).

3. Press "↓" to select equipment to configure. Press “→” to pop out the

shortcut menu (Fig.30-4). Use “↓” to select “Equipment Replacement” and

press “OK” to enter the equipment replacement interface.

4. Press “→” to pop out the pull-down menu (Figure 30-5), and all equipments

that can be replaced will be displayed. Press “↓”/” ↑” to choose

equipments that need to be replaced, and press “OK”. System returns to

the original window.

But the save here is just temporary; if the equipment is restarted, the

change will be lost. For long-term storage, please refer to “how to save

configuration”. If you don’t want to save this change, press “Quit” to quit.

Note: The saved change will not take effect until the system is restarted.

Fig.30-1

Fig.30-2

Fig.30-3

Fig.30-4

Fig.30

-

5

Page 50

Operating Manual of FC18 Controller

Page: 49/63

31. HOW TO UPGRADE TO FC1840

Function: The FC18 wall-mounted controller has two types: the FC1820 and the

FC1840. FC1820 can be upgraded to FC 1840 through adding a loop card and

conducting the following operations.

Steps:

1. Press “Menu” to browse the main menu (Fig. 31-1)

Main menu displayed.

2. Press “→” to select “Brow” submenu (Fig. 31-2). Select "All" and then press

“OK”. Now the tree diagram will be displayed in the window (Fig.31-3). Use

"↓" / "↑" to select the host machine.

3. Press “Menu” to browse the main menu then press “→” to select “Oper”

submenu. Select "upgrade to FC1840" (Fig.31-3) then press "OK".

4. System pop out dialog window to ask user whether to upgrade or not

(Fig.31-4). Press "OK" to upgrade to FC1840 or press "C" to give up.

Note:

The saved change will not take effect until the system is reset.

This operation can only be applied to host machine.

This operation can only be applied to FC1820.

FC1840 cannot be degraded to FC1820. If it's needed, it should be

done through PC and downloading configuring files.

System Normal

SIEMENS Building

SIEMENS

<2008-08-08 08:08:08>

System Normal

Event Brow Oper Conf Tool Help Login

SIEMENS Building

Alarm & active

Trouble

Supervision

Disable

Test

Walk-Test

Alarm & active

Fig.31-1

Fig.31-2

Fig.31-3

Fig.31-4

Page 51

Operating Manual of FC18 Controller

Page: 50/63

32. HOW TO CHANGE LANGUAGE

Function: The system provides four kinds of language: English, Taiwan,

Hongkong, and Portuguese. Apply languages as needed.

Steps:

1. Press “Menu” to browse the main menu (Fig. 32-1).

Main menu displayed.

2. Press “→” to select “Lang” submenu (Fig. 32-2). Select a language you

need and press “OK”.

3. The system language is changed.

Note:

The saved change will take effect immediately.

This operation can only be applied to host machine.

Fig.32-1

Fig.32-2

Page 52

Operating Manual of FC18 Controller

Page: 51/63

33. HOW TO QUERY THE INFORMAT ION OF OTHER EVENTS

Function: Other events include: Test, Walktest, Locate, Unconfigure,

Unknown, Inconsistent, and Exchage. Through this function, can

check the qty for each event.

Step:

1. Press “Menu” to browse the main menu (Fig. 33-1).

Main menu displayed.

2. Press “→” to select “Brow” submenu (Fig. 33-2). Press “↓” to select

“Other”, and then press “OK” to display the information (Fig. 33-3).

3. Press "C" to return to the original window.

Fig. 33-1

Fig. 33-2

Fig. 33-3

Page 53

Operating Manual of FC18 Controller

Page: 52/63

CHAPTER 4 MAINTENANCE

1. DA ILY EXAMIN ATION

Operator on duty should examine controllers every day and record status. If there is fire alarm, error or other abnormal status,

please follow “Emergency Failure Guideline”; when controller gets normal again, the event should be recorded.

2. EMERGENCY AND TROUBLE HANDLING

Table 4-1

No. Fai lure phenomenon Cause analysis Solving Method

1.

Failure or damage of

function keys, LED,

LCD, etc.

Error of signal line, power line

Corresponding hardware trouble;

Ensure proper installation of

wiring; Change corresponding

hardware;

2.

No voltage indication of

controller

Whether main and backup power is on;

Whether power lines inside controller is firm

enough

Power trouble;

Ensure proper installation of

the power wiring; Check

power lines

Change power supply;

3.

Controller “black screen”

with voltage

No power supply for LCD or power supply

component of main board failure;

LCD trouble;

Wire connection loosening

Check power lines or change

main board;

Change LCD;

Check the wire connection

4.

No display of controller

System software or engineer software lost;

CPU trouble;

Change corresponding

software;

Change CPU;

5.

No sound

No voltage;

Not enough sound volume;

Beeper trouble;

Change power lines or main

board;

Adjust sound volume of

beeper;

Change beeper;

6.

Control station failure

Engineer software not in line with actual

equipment;

Address not set for main board or not in line

with software address;

Main board failure;

More than 2 controllers check A-BUS

communication and software configuration;

Examine whether A-Bus terminal resistance

connection is reasonable or not;

Change software;

Change configuration;

Change main board;

Examine A-BUS

communication line;

Reasonable connection;

7.

Interlocking panel failure

Engineer software not in line with actual

equipment;

Communication line, power supply trouble;

Address not set for interlocking panel ``or not

in line with software address;

interlocking panel damage;

Examine whether B-Bus terminal resistance

connection is reasonable or not;

Change software;

Correctly connect lines;

Change configuration;

Change interlocking panel;

Reasonable connection;

8.

Main board input/output

failure

Software configuration error;

Main board input/output interface damage;

Change configuration;

Change main board;

9.

Power failure

Engineer software not in line with actual

equipment;

External voltage exceed power requirement;

Battery trouble;

Change software;

Adjust external voltage range;

Change battery;