Page 1

Fire Control Panel

FC121-ZA / FC122-ZA / FC123-ZA / FC124-ZA

Technical Manual

A6V10393190_h_en_-2019-09-01

Smart Infrastructure

Page 2

Legal notice

Technical specifications and availability subject to change without notice.

© 2014 Copyright by Siemens Switzerland Ltd.

Transmittal, reproduction, dissemination and/or editing of this document as well as

utilization of its contents and communication thereof to others without express

authorization are prohibited. Offenders will be held liable for payment of damages. All

rights created by patent grant or registration of a utility model or design patent are

reserved.

Issued by:

Siemens Switzerland Ltd

Smart Infrastructure

Global Headquarters

Theilerstrasse 1a

CH-6300 Zug

+41 58 724 2424

www.siemens.com/buildingtechnologies

Edition: 2019-09-01

Document ID: A6V10393190_h_en_--

2

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 3

Table of contents

1 About this document.................................................................................. 7

2 Safety regulations .................................................................................... 10

3 System description .................................................................................. 13

3.1 System overview ................................................................................................... 13

3.2 Features ............................................................................................................... 13

3.3 Technical data....................................................................................................... 14

3.3.1 Electrical data ....................................................................................................... 14

3.3.2 Mechanical data .................................................................................................... 15

3.3.3 Environmental conditions ...................................................................................... 16

3.4 Standard and options EN 54.................................................................................. 17

4 Installation ................................................................................................ 18

4.1 Power supply – mains voltage connection ............................................................. 18

4.2 Instruction ............................................................................................................. 20

4.2.1 Connection overview ............................................................................................. 21

4.3 Zone modes .......................................................................................................... 22

4.3.1 Standard ............................................................................................................... 22

4.3.2 Mixed .................................................................................................................... 23

4.3.3 GB continuity ........................................................................................................ 24

4.3.4 Short = alarm ........................................................................................................ 25

4.4 Outputs ................................................................................................................. 26

4.4.1 Mainboard (OUT1 / OUT2) .................................................................................... 26

4.4.2 Output card (OUTA / OUTB).................................................................................. 26

4.4.3 Relay .................................................................................................................... 28

4.4.4 Dialer connection .................................................................................................. 29

4.5 Input ..................................................................................................................... 30

4.6 Accessories .......................................................................................................... 31

4.6.1 Key switch set ....................................................................................................... 31

4.6.2 Output card ........................................................................................................... 32

4.6.3 EVAC module (NL) ................................................................................................ 33

4.6.4 Zone indication field .............................................................................................. 34

4.7 Initial start-up ........................................................................................................ 35

4.7.1 Prepare the panel.................................................................................................. 35

4.7.2 Pre configuration ................................................................................................... 36

5 Function overview .................................................................................... 37

5.1 Operating functions ............................................................................................... 37

5.2 Access levels ........................................................................................................ 37

5.3 LED indication ....................................................................................................... 38

5.4 Buttons ................................................................................................................. 39

5.5 Display .................................................................................................................. 40

5.6 Password entry ..................................................................................................... 40

6 Operation .................................................................................................. 41

6.1 General fire alarm procedure ................................................................................. 41

6.1.1 Procedure without Alarm verification...................................................................... 42

6.1.2 Alarm Verification Concept (AVC) .......................................................................... 43

6.1.3 Procedure with Alarm Verification .......................................................................... 44

6.2 Fault procedure ..................................................................................................... 45

6.3 Access level 1 ....................................................................................................... 46

6.3.1 Actual events ........................................................................................................ 46

6.3.2 Login ..................................................................................................................... 47

6.3.3 Alarm counter........................................................................................................ 47

6.4 Access level 2 ....................................................................................................... 48

6.4.1 Manned / unmanned ............................................................................................. 48

6.4.2 Silence / resound .................................................................................................. 48

6.4.3 LED, display and buzzer test ................................................................................. 48

6.4.4 Display history log ................................................................................................. 49

6.4.5 Logout................................................................................................................... 49

6.4.6 Set date and time .................................................................................................. 50

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

3

Page 4

6.4.7 Enable / disable zone ............................................................................................ 51

6.4.8 Enable test mode .................................................................................................. 52

6.4.9 Enable / disable outputs ........................................................................................ 53

6.4.10 Panel information .................................................................................................. 54

6.4.11 Service information ............................................................................................... 54

7 Programming ............................................................................................ 55

7.1 Configure .............................................................................................................. 55

7.1.1 Zone ..................................................................................................................... 55

7.1.2 Output ................................................................................................................... 56

7.1.3 Input ..................................................................................................................... 57

7.1.4 Accessories .......................................................................................................... 58

7.2 Global ................................................................................................................... 59

7.2.1 Country settings .................................................................................................... 59

7.2.2 Language .............................................................................................................. 59

7.2.3 Change password ................................................................................................. 59

7.2.4 User interface........................................................................................................ 60

7.2.5 Zone options ......................................................................................................... 60

7.2.6 Output options....................................................................................................... 60

7.2.7 Mains power ......................................................................................................... 60

7.2.8 Set date and time .................................................................................................. 61

7.2.9 Summer / winter time ............................................................................................ 61

7.2.10 Manned / unmanned ............................................................................................. 61

7.2.11 Service information ............................................................................................... 61

7.2.12 Buzzer .................................................................................................................. 61

7.2.13 Calibrate line ......................................................................................................... 61

7.2.14 Delete history log .................................................................................................. 62

7.3 Logout................................................................................................................... 62

7.4 Reset alarm counter .............................................................................................. 63

7.5 Customer text........................................................................................................ 64

7.5.1 Button function ...................................................................................................... 64

7.5.2 Text entry .............................................................................................................. 65

8 Tool function ............................................................................................ 66

8.1 Set up communication ........................................................................................... 66

8.1.1 Tool installation ..................................................................................................... 66

8.1.2 Tool settings ......................................................................................................... 67

8.2 Transfer history log data to PC .............................................................................. 68

8.3 Save configuration file ........................................................................................... 69

8.4 Restore configuration file ....................................................................................... 70

8.5 Download firmware ............................................................................................... 71

9 Commissioning ........................................................................................ 73

10 Maintenance ............................................................................................. 74

10.1 Preparatory work ................................................................................................... 74

10.2 Function test ......................................................................................................... 74

10.3 Device Test ........................................................................................................... 75

10.4 Completion work ................................................................................................... 75

11 Battery capacity........................................................................................ 76

11.1 FC121-ZA calculation ............................................................................................ 76

11.2 FC122-ZA calculation ............................................................................................ 76

11.3 FC123-ZA calculation ............................................................................................ 78

11.4 FC124-ZA calculation ............................................................................................ 79

12 Trouble shooting ...................................................................................... 80

12.1 LED indication ....................................................................................................... 80

12.2 System.................................................................................................................. 81

12.3 Accessories .......................................................................................................... 81

12.4 Factory reset ......................................................................................................... 82

13 Components and spare parts .................................................................. 83

14 Disposal and environmental protection.................................................. 84

Appendix A: Site configuration, Factory Setting.............................................. 85

4

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 5

Appendix B: Switch mains to AC 115 V ............................................................ 87

Appendix C: History log ..................................................................................... 88

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

5

Page 6

6

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 7

1 About this document

Goal and purpose

The information provided in this manual is a summary of the key procedures and

functions required to assemble, install, operate, commission and repair the system.

It is intended to provide experienced and qualified personnel a guide on the required

processes.

Scope

The technical manual applies to the Cerberus FIT fire control panel FC12x series.

Target groups

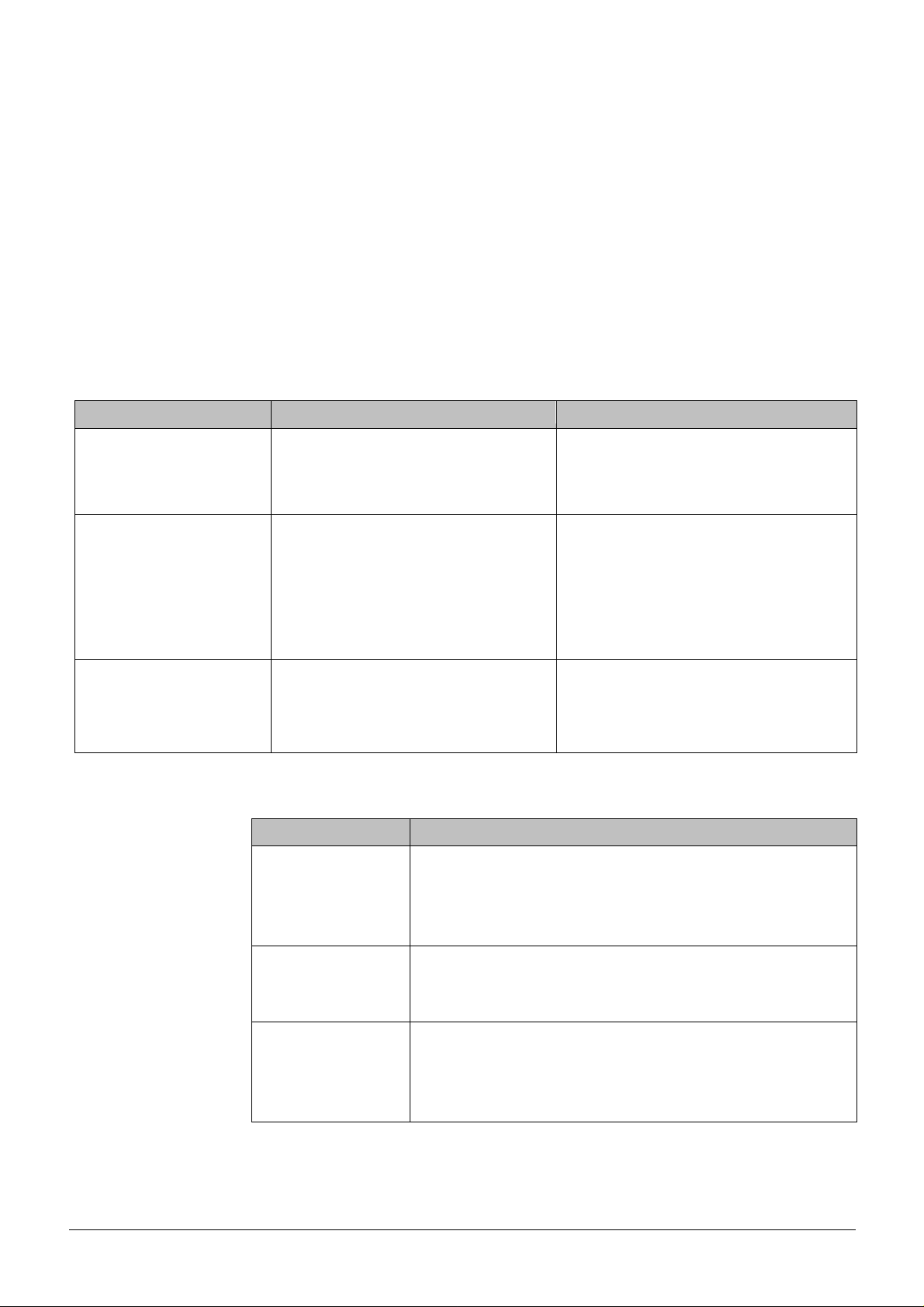

The information in this document is intended for the following target groups:

Target group Activity Qualification

Installation personnel

Commissioning personnel

Maintenance personnel

Assembles and installs the product

components at the place of installation.

Carries out a performance check

following installation.

Configures the product at the place of

installation according to customerspecific requirements.

Checks the product operability and

releases the product for use by the

operator.

Searches for and corrects malfunctions.

Carries out all maintenance work.

Checks that the products are in perfect

working order.

Searches for and corrects malfunctions.

Document identification

Position Information

Title page

Footers

Last page

Product picture

Product type

Product designation

Document type

Pages

Document ID

Edition date

Document ID

Edition date

Manual

Register

Has received specialist training in the

area of building installation technology or

electrical installations.

Has obtained suitable specialist training

for the function and for the products.

Has attended the training courses for

commissioning personnel.

Has obtained suitable specialist training

for the function and for the products.

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

7

Page 8

Reference document and source language

l The source language of this document is English (en)

l The reference version of this document is the international version in English. The

international version is not localized.

The reference document has the following designation:

ID_x_en_-x = version, en = English, -- = international

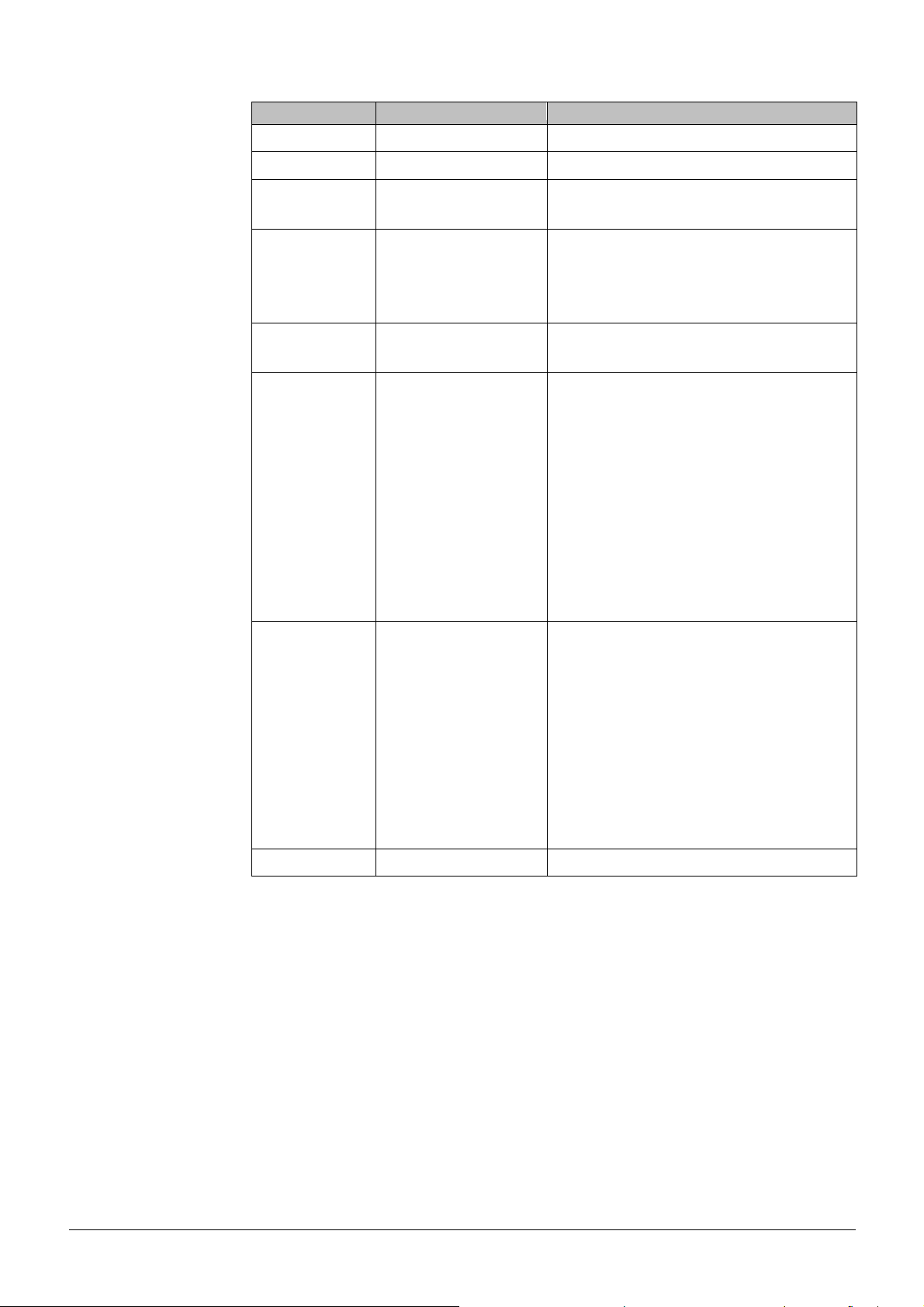

Applicable documents

The list below is used as a reference for the fire control panel FC12x and as a

supplement to this document.

Number Name

A6V10393192

A6V10393169

A6V10393171

A6V10371354

'List of compatibility for FC12x'

Installation of FC121-ZA / FC122-ZA

Installation of FC123-ZA / FC124-ZA

Data sheet of FC12x

Abbreviations

Abbreviations Explication

AVC

EOL

MCP

PSU

Alarm verification concept

End of line

Manual call point

Power supply unit

8

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 9

Modification history

Version

Edition date

Brief description

h 2019-09-01 - Chapter '8.1.1 Tool installation'

g 2018-10-30 - Updated the company address

f 2015-09-09 - Screenshot in appendix A replaced with

language dependent screenshot.

e 2015-07-07 - Chapter '4.3.4 Short = Alarm' updated

- Chapter '10.3 Device test': Information

about the detector test in collective

mode added

d 2015-02-12 - Chapter '3.3.1 Electrical data'

- Chapter '7.2.10 Manned / unmanned'

c 2014-05-28 - Chapter '1 About this document':

Information about reference document

and source language added

- Chapter '3.3.1 Electrical data': Values for

Line resistance / capacitance changed

- Chapters '11.3 FC123-ZA calculation'

and '11.4 FC124-ZA calculation': Value

of threshold for requirement of external

power supply changed from 1200 mA to

1000 mA

- Editorial changes made

b 2014-04-15 - On Page 11, Change color of

housing&cover ('grey, ~RAL 7035' to

'grey ~RAL-Design 000 50 00')

- On Page 12/50/55, Change device

coincidence inhibit time (10→15)

- On Page 18, Change mixed zone

drawing (delete diode)

- Change 'Line resistance / capacitance'

- Add warning for ‘Short=alarm’ zone

function

a 2014-02-19 First version

Smart Infrastructure A6V10393190_h_en_--

9

2019-09-01

Page 10

2 Safety regulations

Signal words

The signal word classifies the danger as defined in the following table:

Signal word Danger level

DANGER DANGER identifies a dangerous situation, which will result

directly in death or serious injury if you do not avoid this

situation.

WARNING WARNING identifies a dangerous situation, which may result in

death or serious injury if you do not avoid this situation.

CAUTION CAUTION identifies a dangerous situation, which could result

in slight to moderately serious injury if you do not avoid this

situation.

NOTICE NOTICE identifies possible damage to property that may result

from non-observance.

Symbols

The symbols listed below indicate the nature and origin of the danger.

General danger

Electrical voltage

How risk of injury is presented

Information about the risk of injury is shown as follows:

WARNING

Nature and origin of the danger

Consequences if the danger occurs

● Measures / prohibitions for danger avoidance

How possible damage to property is presented

Information about possible damage to property is shown as follows:

NOTICE

Nature and origin of the danger

Consequences if the danger occurs

● Measures / prohibitions for danger avoidance

10

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 11

Safety–relevant instructions

National standards, regulations and legislation

Siemens products are developed and produced in compliance with the relevant

European and international safety standards. Should additional national or local safety

standards or legislation concerning the planning, assembly, installation, operation or

disposal of the product apply at the place of operation, then these must also be taken

into account together with the safety regulations in the product documentation.

Electrical installations

WARNING

Electrical voltage

Electric shock

Work on electrical installations may only be carried out by qualified electricians or by

instructed persons working under the guidance and supervision of a qualified

electrician, in accordance with the electro technical regulations.

l Wherever possible disconnect products from the power supply when carrying out

commissioning, maintenance or repair work.

l Lock volt-free areas to prevent them from being switched back on again by mistake.

l Label the connection terminals with external voltage using a 'DANGER External

voltage' sign.

l Route mains connections to products separately and fuse them with their own,

clearly marked fuse.

l Fit an easily accessible disconnecting device in accordance with IEC 60950-1

outside the installation.

l Produce earthing as stated in local safety regulations.

Assembly, installation, commissioning and maintenance

l The panel is designed for operation in a closed room, please note the

environmental conditions in this technical manual.

l Please check the country specific regulations and guidelines during installation and

programming of the fire control panel.

l Only operate the fire control panel with housing closed due to the danger of an

electric shock.

l If you require tools such as a ladder, these must be safe and must be intended for

the work in hand.

l When starting the fire control panel ensure that unstable conditions cannot arise.

l Ensure that all points listed in the 'Testing the product operability' section below are

observed.

l You may only set controls to normal function when the product operability has been

completely tested and the system has been handed over to the customer.

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

11

Page 12

Testing the product operability

l Prevent the remote transmission from triggering erroneously.

l If testing building installations or activating devices from third-party companies, you

must consult with the appointed people.

l The activation of fire control installations for test purposes must not cause injury to

anyone or damage to the building installations. The following instructions must be

observed:

– Use the correct potential for activation; this is generally the potential of the

building installation.

l Inform people before testing the alarm control devices and allow for possible panic

responses.

l Inform people about any noise or mist which may be produced.

l Before testing the remote transmission, notify the appropriate alarm and fault signal

receiving stations.

Modifications to the system layout and products

Modifications to the system and to individual products may result in faults, malfunctioning

and safety risks. Written confirmation must be obtained from Siemens and the

corresponding safety bodies for modifications or additions.

Modules and spare parts

l Components and spare parts must comply with the technical specifications defined

by Siemens. Only use products specified or recommended by Siemens.

l Only use fuses with the specified fuse characteristics.

l Wrong battery types and improper battery changing lead to a risk of explosion. Only

use the same battery type or an equivalent battery type recommended by Siemens

(refer to Chapter 13).

l Batteries must be disposed of in an environmentally friendly manner. Observe all

national guidelines and regulations.

Disregarding safety regulations

Before they are delivered, Siemens products are tested to ensure they function correctly

when used properly. Siemens disclaims all liability for damage or injuries caused by the

incorrect application of the instructions or the disregard of danger warnings contained in

the documentation. This applies in particular to the following damage or injury:

l Personal injuries or damage to property caused by improper use and incorrect

application.

l Personal injuries or damage to property caused by disregarding safety instructions

in the documentation or on the product.

l Personal injury or damage to property caused by poor maintenance or lack of

maintenance.

Disclaimer

We have checked that the content of this document matches the hardware and software

described. Despite this, we cannot rule out deviations and therefore assume no liability

for them matching completely. The details in this document are checked regularly and

any corrections needed included in subsequent editions.

We are grateful for any suggestions for improvement.

12

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 13

3 System description

s

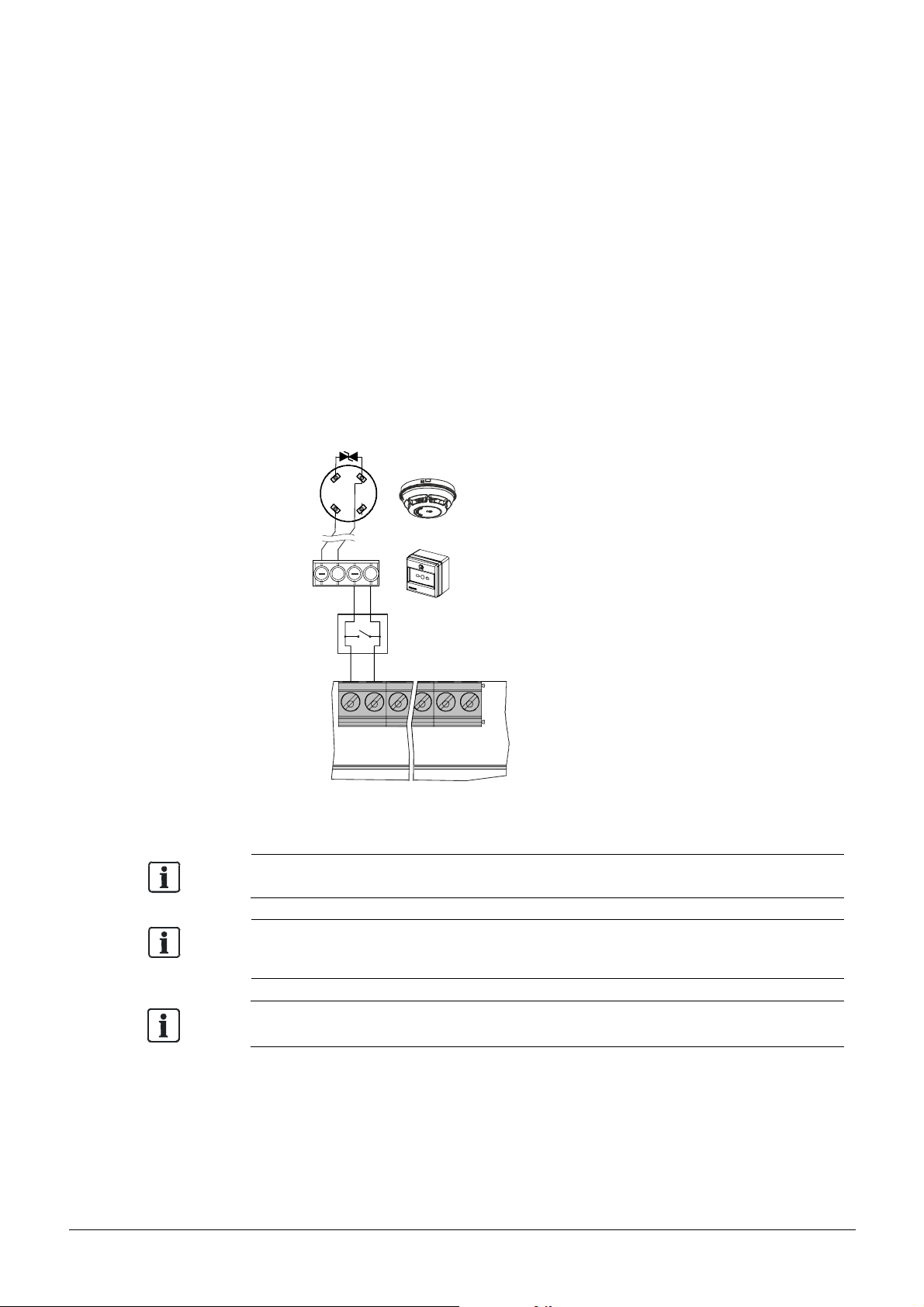

3.1 System overview

The conventional fire control system comprises all the components required for

detection, evaluation and alarming in the event of fire.

The integrated operating unit processes signals from conventional and collective

detectors. See list of compatibility A6V10393192.

The panel FC12x is self-contained with integral power supply and simple to operate,

offering exceptional flexibility and comprehensive features.

Detector line series-110

Manual call point line

Mixed line

Intrinsically safe detectors

3.2 Features

System

l Stand-alone fire control panel

l Switch mains to AC 115V (FC123-ZA / FC124-ZA only)

l Monitored detector and sounder lines

l Collective and conventional devices can be combined within the same zone

l Display with 7 lines, max. 20 characters per line

l Country specific settings

l Multilingual variants

l Up to 1000 events can be stored in history log with stamped date and time

l Alarm counter for up to 9999 alarms

l One man walk test

TM

Cerberus

FC120

okC

230 V output

Sounder control

Fire output

Dialer outputs

Optional hardware

l Output cards

l Zone indication module (FC123-ZA / FC124-ZA only)

l EVAC module

l Key switch set

Periphery

l Compatible with 110-series / SynoLINE300

l Compatible with DS11 / SynoLINE600

l Mixed lines with detectors and MCPs

Programmable parameters

l Individual customer text for each zone

l Automatic summer / winter time change

l Alarm Verification Concept (AVC)

l Cross zoning (Zone coincidence)

l Detector coincidence for false alarm suppression

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

13

Page 14

3.3 Technical data

1

You will find information on approvals, CE marking, and the relevant EU directives for

this device (these devices) in the following document(s); see 'Applicable documents'

chapter:

· Document A6V10371354

FC121-ZA FC122-ZA FC123-ZA FC124-ZA

Zones

Number of zones 2 4 8 12

Number of detectors per zone Up to 32 Up to 32

Inputs

Number of inputs 2 3

Outputs

Number of monitored outputs

- Mainboard 2 2

- Output cards (Optional) 2

Number of relay outputs

- Mainboard 1 1

- Output cards (Optional) 2

Number of optional output cards 1

Alarm counter

History log

9999 alarms 9999 alarms

1000 events 1000 events

3.3.1 Electrical data

FC121-ZA FC122-ZA FC123-ZA FC124-ZA

Zone

Operating voltage

- Standard zone

- GB continuity zone

Line resistance / capacitance

Collective & Conventional

device

- GB continuity

- Mixed zone

Used Conventional device

- Standard

- Short=alarm

Collective & Conventional

device

- Standard

- Short=alarm zone

DC 16.5…19 V

DC 21…28.6 V

≤50 Ω / ≤1 μF

≤50 Ω / ≤1 μF

≤100 Ω / ≤1 μF

≤100 Ω / ≤1 μF

≤80 Ω / ≤1 μF

≤80 Ω / ≤1 μF

1,2,4,6

1,2,4,6

1,2,4,5

1,4

1,2,3,4,5,6

1,3,4

4 6

4

2

DC 16.5…19 V

DC 21…28.6 V

≤50 Ω / ≤1 μF

≤50 Ω / ≤1 μF

≤100 Ω / ≤1 μF

1,2,4,6

1,2,4,6

1,2,4,5

≤100 Ω / ≤1 μF

≤80 Ω / ≤1 μF

≤80 Ω / ≤1 μF

1,2,3,4,5,6

1,3,4

6

3

1,4

Detector 110-series;2 Detector FDOOT241-X, OOH740, FDF221-9, FDF241-9, FDL241-9;

3

Detectors series DS11, Synova Series 600C;4Synova Series 300C;5Conventional MCP;6Collective MCP

Alarm trigger Z-Diode 5.6 V or resistor 410…820 Ω Z-Diode 5.6 V or resistor 410…820 Ω

14

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 15

FC121-ZA FC122-ZA FC123-ZA FC124-ZA

EOL element

- Standard zone

- Short=alarm

- Mixed zone

- GB continuity zone

18V TVS

18V TVS

18V TVS

10 μF capacitor

18V TVS

18V TVS

18V TVS

10 μF capacitor

Monitored output mainboard

Voltage / Current (max.) 24 V / 0.5 A 24 V / 1.0 A

EOL element Diode (1N4007) Diode (1N4007)

Relay output mainboard 1.0 A @ DC 30 V

AUX. power output (max.) DC 24 V / 200 mA

1.0 A @ DC 30 V

DC 24 V / 500 mA

Power supply

Mains voltage AC 196…253 V AC 196…253 V

or

AC 97…127 V

Mains fuse F1 AC 250 V @ 1.6 AT

AC 250 V @ 2.5 AT

AC 115 V @ 2.5 AT

Power consumption 25 W 70 W

Max. nominal output current with

battery charging, I

max a

Max. nominal output current

without battery charging, I

Min. output current I

max b

min

max. 0.3 A max. 0.9 A

max. 0.9 A max. 2.5 A

0.1 A 0.1 A

System supply voltage DC 21…28.6 V DC 21…28.6 V

Mains failure delay 0…30 min. / default 5 min. 0…30 min. / default 5 min.

Battery low discharge cut off DC 20.5 V…DC 21 V DC 20.5 V…DC 21 V

Temperature compensation Yes Yes

Battery

Operation time Up to 72 h Up to 72 h

Battery size 2 x 12 V, 4.5 Ah / 7 Ah, lead acid

2 x 12 V, 7 Ah / 12 Ah / 17 Ah, lead

acid

Voltage DC 21…28.6 V DC 21…28.6 V

Load resistance R

imax

max. 2.5 Ω max. 1.0 Ω

3.3.2 Mechanical data

FC121-ZA FC122-ZA FC123-ZA FC124-ZA

Terminals 0.2...2.5 mm

Dimensions (W x H x D) 360 x 310 x 85 mm 430 x 399 x 124 mm

Weight 2.0 kg without batteries 4.5 kg without batteries

Color

- Housing, Cover

grey, ~RAL-Design 000 50 00

2

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

15

Page 16

3.3.3 Environmental conditions

FC121-ZA FC122-ZA

Operating temperature

-5…+40 °C

Storage temperature -20…+60 °C

Humidity (no condensation

≤95 % rel.

permitted)

Protection category IP30

FC123-ZA FC124-ZA

-5…+40 °C

-20…+60 °C

≤95 % rel.

IP30

16

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 17

3.4 Standard and options EN 54

EN 54-2 Definitions

The fire control panel is designed to comply with the requirements of EN 54 part 2 / 4.

The EN 54-2 options are fulfilled if the following

configurations are used.

Installation Configuration / Operation Chapter

7.8

7.9.1

7.9.2

7.10.1

7.11.1

7.11.2

7.12.1

7.12.2

Output to fire alarm device

EN 54-1 / C

Output to fire alarm routing equipment

EN 54-1 / E

Alarm confirmation input from fire

alarm routing equipment

Outputs to fire protection equipment

EN 54-1 / G

Delays to outputs V1 / V2 timer for

alarm organization

Switch on /off delays to outputs, V1 /

V2 timer for alarm organization

Dependencies on more than one

alarm signal.

Type A dependency from the same

detector, or another in the same zone

Dependencies on more than one

alarm signal

Type B dependency cross zoning

Monitored output

e.g. OUT 1

Monitored output

e.g. OUT 2

Input

Monitored output

e.g. OUT 4

Sounder control

7.1.2

6.4.2

7.2.6

Alarm dialer 7.1.2

7.2.4

Dialer device confirmation

signal; LED fire brigade

activated via input

7.1.3

7.2.4

Fire output 7.1.2

Alarm Verification Concept;

Manned / unmanned

6.1.3

7.2.10

Button 'Manned/unmanned' 6.4.1

7.2.10

Detector coincidence inhibit

time 15 - 60 sec.

7.1.1

7.2.5

Reset of the first alarm after

90 sec.

Zone coincidence

7.1.1

(= cross zoning)

7.13

Alarm counter

(option with requirement)

8.8

Output to fault warning routing

equipment

8.9

Output to fault warning routing

equipment according EN 54-1 / J

10

Test condition

(option with requirements)

EN 54-13 Definitions

5.3.4.2

Open and short circuit on a

transmission path

Alarm counter 6.3.3

7.4

Relay output

Fault dialer 7.1.2

e.g. OUT 3

Monitored output

Fault dialer 7.1.2

e.g. OUT 4

Test zone 6.4.8

The EN 54-13 standard is achieved, if the following

system functions are fulfilled:

Installation Chapter

Zone mode 'standard' 7.1.1

Outputs card supervised

Card 1, OUT A / B: 4 / 5

4.4.2

7.1.2

Card 2, OUT A / B: 8 / 9

Card 3, OUT A / B: 12 / 13

Fault dialer

4.4.4

Card 1, OUT A: 4

Card 2, OUT A: 8

Card 3, OUT A: 12

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

17

Page 18

4 Installation

241

3

4.1 Power supply – mains voltage connection

WARNING

Electrical voltage

Electric shock

l Before connecting the mains cable, make sure that the cable is current-free.

l Ensure that the mains is secured against inadvertently being switched on.

3

1

2

4

FC121-ZA / FC122-ZA FC123-ZA / FC124-ZA

Explanation

1. Mains supply

2. Boundary of mains zone

3. Safety zone (no high-voltage power permitted)

4. Signal and control lines

l The cables must be inserted from above. Use only the provided cable openings.

l The mains lead must be placed along the left side of the housing (observe

boundary of mains zone).

l Signal and control lines must only be fed into the housing on the right from

above or from the rear.

l Batteries must be installed so that they cannot leak.

l Open cable entries must be closed completely.

18

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 19

To avoid the risk of a connected wire become loose and can come in contact with the

5 mm

5 mm

966

9

6

mains terminal, a single wire must not be so long that it can come into contact with the

mains terminal or tie at least two such wires together so that the free end of a single

wire cannot reach the mains terminal!

10

7

8

5

FC123-ZA / FC124-ZA

fixing mains wire

7

Strip the insulation from the

wire

FC121-ZA / FC122-ZA secure wires

6

7

10

FC123-ZA / FC124-ZA secure wires

Explanation

5. Fixing cables and removing the outside isolation.

6. Lay the mains cable along the left side and signal and control lines to the right

side of the housing.

7. Fix the mains wire with cable ties.

8. Insulate the mains, signal and control lines wires as needed and connect it to

the terminals according to the pin assignment specified in chapter 4. Use mains

cable with cross section of 3*1.5 mm2up to 3*2.5 mm2.

9. Fix the signal and control lines with cable ties.

10. Shield connection terminal.

19

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 20

4.2 Instruction

ADB

Follow the instructions and consider the power calculation.

WARNING

Voltage

Electric shock

Assembly and installation work may only be undertaken by qualified staff and when

the system is de-energized.

NOTICE

Electrostatics

Damage to electronics

Suitable protective measures must be taken when working with electronics modules.

Steps:

1) Remove the cover.

2) Define the mounting location.

3) Mark position of mounting holes (A).

4) Cut out the cable entries (B) and cover all open entries with cable glands (C) (not

included).

5) Optional: Mount accessories (D). See chapter 4.6.

6) Install chassis on the wall / screws (∅ min. 5 mm) and plastic dowels are not

included.

7) Switch off the mains supply and connect the power cable.

8) Connect signal and control lines of installed field device (zones, outputs and

inputs).

9) Initial start-up, see chapter 4.7.

L

N

N

C

FC121-ZA / FC122-ZA FC123-ZA / FC124-ZA

20

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 21

4.2.1 Connection overview

4

-

7

1

2

-

1

5

8

-

1

1

COM

–

EOL

EOL

EOL

*

Monitored

Relay

Class change sig.

Relay

Fire output (C)

Fire output (D)

Supervised

Sounder

control (A)

Sounder

control (B)

R

External PSU fault

The graphic below shows the default configuration of the panel.

Available zones, outputs and inputs are considered in the chapter 3.3.

EOL

–

+

EOL

–

+

+

+

EOL

+

+

+

–

–

+

EOL

6

b

1

1

a

5

6

1

b

1

a

5

–

AUX 24V ZONE1 ZONE2 ZONE n INPUT OUT1 OUT2

–

+

+

Standard zone

Example FC124-ZA

+

+ n

OUT3

NO

Aux 24 V / 0.5 A

eset

Sounder control

Alarm Dialer

Fault dialer (#)

(#) 'Fault dialer' contact is open as long as the panel is in fault condition.

Provided EOL elements:

Picture EOL element Function

Transzorb diode (18 V TVS)

EOL element for all zones except

GB continuity

Capacitor 10 μF EOL element for GB continuity

Diode 1N4007

Smart Infrastructure A6V10393190_h_en_--

EOL element for monitored and

supervised outputs

2019-09-01

21

Page 22

4.3 Zone modes

+++

+

–

+

AUX 24V

. . . . . .

1

a

1

b

1

a

1

b

EOL

1

a

1

b

EOL

+

+

EOL

4.3.1 Standard

The Standard line supports collective and conventional devices within the same zone.

Technical:

- Each line must be terminated with EOL element Transzorb diode (18 V TVS).

- Max. 32 devices on each line

Programming:

- Configure g Zone g Zone 1 – n g Mode g Standard

6

5

6

5

6

5

–

ZONE1

–

+

–

+

+

ZONE n

Zone mode 'Standard' complies with EN 54-2 and EN 54-13.

22

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 23

4.3.2 Mixed

.

The mixed line allows a mixture of detectors and manual call points within the same

zone. Moreover it can distinguish between direct and delayed alarming.

Technical:

- Siemens detectors 110-series or detectors with an alarm resistor are required for

delayed alarming (AVC, V1 / V2).

- MCPs require a Z-diode for direct alarming (AVC).

- Max. 32 devices on each line.

- Each line must be terminated with EOL element Transzorb diode (18 V TVS).

Programming:

- Configure g Zone g Zone 1 – n g Mode g Mixed MCP & det.

- Configure g Zone g Zone 1 – n g AVC g Via AVC timer MCP direct

Zone mode 'Mixed' does NOT comply with EN 54-13.

Behavior of MCP in zone coincidence with function 'direct alarming' is not supported

23

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 24

4.3.3 GB continuity

EOL

The GB continuity line allows a mixture of MCPs and detectors within the same zone.

In addition this mode supports a reliable operation, even though one or more detectors

are removed from its base. The CIE detect the removed detector and report a zone fault.

Technical:

- Special detector bases equipped with a diode (1N5819):

DB110D part number S54372-F6-A1 or DB110RD part number S54372-F8-A1

- MCPs require a Z-diode for direct alarming (AVC).

- Siemens detectors 110-series or detectors with an alarm resistor are required for

delayed alarming (AVC, V1 / V2).

- Each line must be terminated with EOL element Capacitor 10 µF.

- Limitation: Max. 18 detectors per line is allowed due to voltage drop on the detector

base.

- MCPs have no limitation and can be installed to reach the maximum of 32 devices.

Programming:

- Configure g Zone g Zone 1 – n g Mode g GB continuity

- Configure g Zone g Zone 1 – n g AVC g Via AVC timer MCP direct

6

1

b

1

5

ZONE1

a

+

+

–

+

NOTICE

See details of the specification in chapter 3.3.1.

Zone mode ‘GB continuity’ does NOT comply with EN 54-13.

Behavior of MCP in zone coincidence with function 'direct alarming' is not supported.

24

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 25

4.3.4 Short = alarm

Even if a zone

is switched off, a short

is evaluated as an alarm.

ZONE1

. . . . . .

EOL

This line supports a mixture of detectors and MCPs within the same zone.

In addition, this line supports devices with a closed contact for alarm.

Only automatic fire detectors can be switched off. Manual call points with the alarm

criterion 'Short = Alarm' are always switched on and cannot be switched off.

Technical:

- Short in the line is detected as an alarm and not as a fault.

- Max.32 devices on each line.

- Each line must be terminated with EOL element Transzorb diode (18 V TVS).

- Does not fulfill EN 54-2.

Programming:

- Configure g Zone g Zone 1-n g Mode g Short = alarm

6

b

1

a

1

5

+

+

–

–

+

+

–

+

ZONE n

Zone mode 'Short = alarm' does NOT comply with EN 54-2 and EN 54-13.

Special detectors FDOOT241-9, OOH740, FDF221-9, FDF241-9, FDL241-9 NOT

compatible with the zone mode 'Short = alarm'.

Smart Infrastructure A6V10393190_h_en_--

25

2019-09-01

Page 26

4.4 Outputs

OUTA

OUTB

OUTC

OUTD

EOL

EOL

COM

COM

Outputs are used to transmit system status information. As a result three different types

are available: Monitored, Supervised and Relay.

–

+

–

OUT1

Monitored

+

–

+

OUT2

COM NO

OUT3

Relay

–

Monitored or

Supervised

Mainboard

4.4.1 Mainboard (OUT1 / OUT2)

Functionality 'Monitored line':

The panel monitors the line in terms of open and short circuits from the panel to the

EOL element.

Application:

Sounder controls, fire outputs and dialer

Technical:

- Max. current

FC121-ZA and FC122-ZA à 24 V / 0.5 A

FC123-ZA and FC124-ZA à 24 V / 1 A

- Each line must be terminated with EOL element (Diode 1N4007)

- Supervised functionality: Not available

–

+

+

NONC

NONC

Relay

Output card

Programming:

- Configure g Output g Output 1 – n g Mode g Sounder control

4.4.2 Output card (OUTA / OUTB)

The output can be either programmed as 'Monitored' or 'Supervised'.

Functionality 'Monitored line':

The panel monitors the line in terms of open and short circuits from the panel to the

EOL element.

Application:

Sounder controls, fire outputs and dialer

Technical:

- Max. current 24 V / 1 A

- Each line must be terminated with EOL element (Diode 1N4007)

Programming:

- Configure g Output g Output 4 – n g Mode g Sounder control

26

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 27

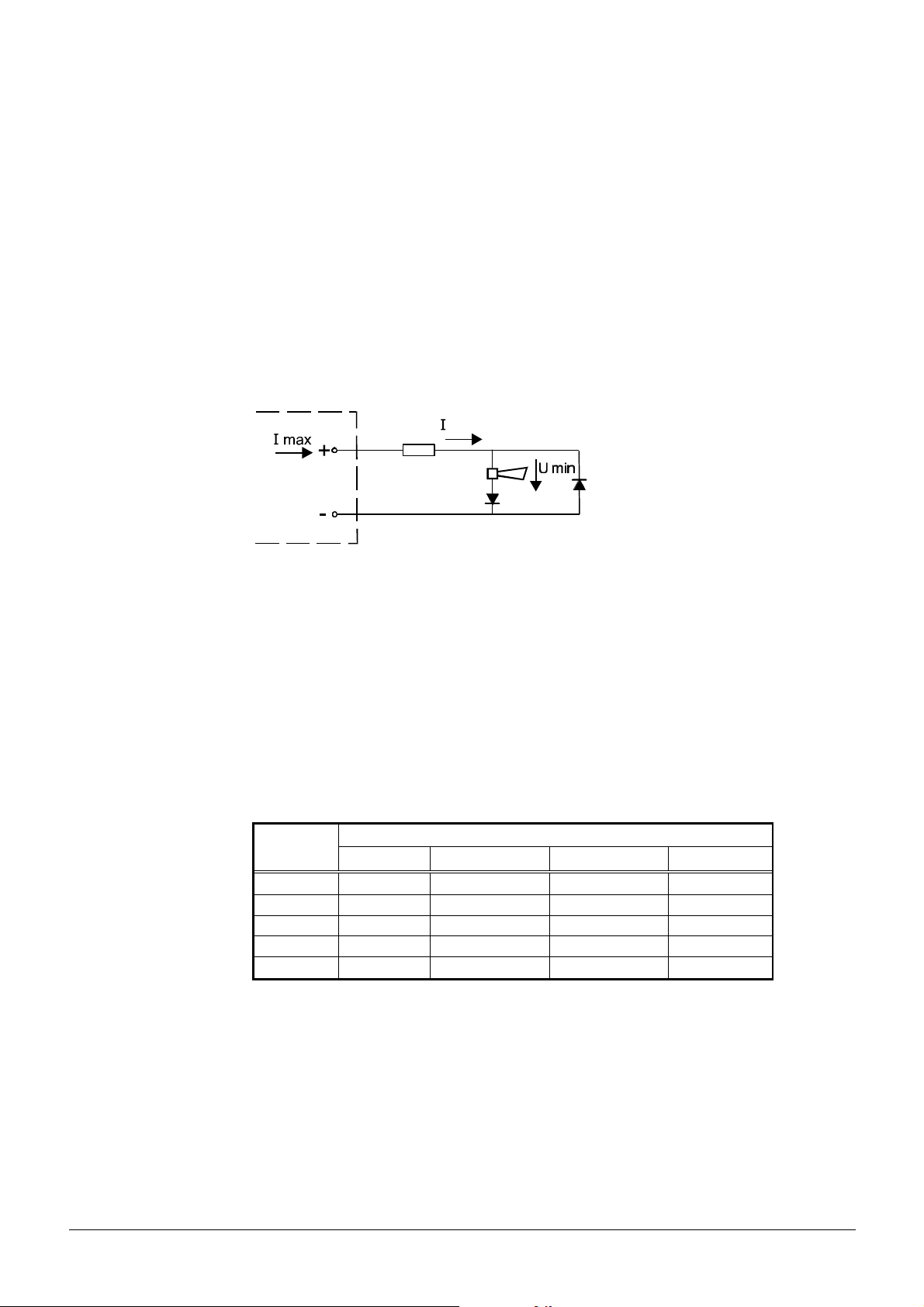

Functionality 'Supervised line':

max

min

min

min

min

OUT A

The panel monitors the line in terms of open and short circuits from the panel to the

EOL element.

In addition to the line monitoring, the panel will recognize a change of line resistance.

Due to aging or other circumstances (creeping effect), the transition resistance on

contacts may increase, which in turn leads to voltage drop.

In order to detect the creeping effect (supervision), the line must be calibrated during the

commissioning process. A line fault is indicated if the resistance is higher than 35 Ω.

Checking the line resistance depending on the required current

It is calculated that the supply of the connected devices is met.

The picture shows the dependence of the line resistance (R Line) in relation to the device

voltage (U

) and the available output current (I

min

) and the minimum required current of

max

the connected devices (I Load).

R Line

Load

EOL

Procedure for determining the maximum available device current (I Load):

1) Determine the line resistance R Line.

Programming: see chapter 7.2.1 (Calibration)

Configure à Output à Output 4 – n à Calibrate line

2) Detecting the voltage U

according to the device datasheet.

min

3) Verification: Are all parameters satisfied for the correct operations?

Table 1 can be used for this check, here are maximum values shown.

Details are individual to calculate.

Table 1

R Line

U

I

= 9 V U

= 14.5 V U

= 16.8 V U

= 18 V

1 A 0 ~ 7 Ω 0 ~ 3.5 Ω 0 ~ 2 Ω 0 ~ 1 Ω

0.5 A 0 ~ 14.5 Ω 0 ~ 7.5 Ω 0 ~ 4.5 Ω 0 ~ 3 Ω

0.3 A 0 ~ 25 Ω 0 ~ 13 Ω 0 ~ 8 Ω 0 ~ 5.5 Ω

0.1 A 0 ~ 35 Ω 0 ~ 35 Ω 0 ~ 26 Ω 0 ~ 18.5 Ω

0.05 A 0 ~ 35 Ω 0 ~ 35 Ω 0 ~ 35 Ω 0 ~ 35 Ω

Counteractive measures: Reduction of I Load or of R Line.

Functionality 'Supervised line for fault dialer and relay':

The line is supervised, from the terminal including the activated relay in the fault dialer, in

terms of open and short circuit. In addition to the line supervising, the panel will recognize

a change of line resistance. Due to aging or other circumstances (creeping effect), the

transition resistance on contacts may increase, which in turn leads to voltage drop.

27

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 28

In order to detect the creeping effect (supervision), the line must be calibrated during the

commissioning process. A line fault is indicated if the resistance is higher than calibrated.

The range of the line resistance including the relay is between 200-1000 Ω.

Application:

With EOL diode: Sounder controls, fire outputs and alarm dialer.

With monitored relay for fault dialer: Only OUT A is specified to supervise the device

relay, see details in chapter 4.4.4.

Technical:

- Max. current 24 V / 1 A

- Line resistance max. 35 Ω

- Each line must be terminated with EOL element (Diode 1N4007)

Programming:

- Configure g Output g Output 4 – n g Mode g e.g. Sounder control

- Configure g Output g Output 4 – n g Supervision EN 54-13

- Configure g Output g Output 4 – n g Calibrate line

4.4.3 Relay

Relay outputs are used for controls without line monitoring.

Application:

LED indication on a remote terminal

Technical:

- Max. current 30 V / 1 A

Programming:

- Configure g Output g Output 6 – n g Mode g Fire output

28

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 29

4.4.4 Dialer connection

O

U

T

3

C

O

M

N

O

+

+

_

X

.

2

4

+

+

_

O

U

T

A

+

_

C

O

M

N

O

+

200 1000

Ω ~ Ω

FC12x

Dialer

FC12x

Dialer

The FC12x fire control panel provides 'monitored' and 'supervised' dialer connections:

Application 1

- 'Alarm dialer' output (OUT2) monitors the line to the dialer.

- 'Fault dialer' output (OUT3) has no line monitoring to the dialer.

(Does not fulfill chapter 8.9 in EN 54-2)

Programming:

- Configure g Outputs g Output 2 g Alarm dialer g

Activation condition 'General Alarm'

- Configure g Outputs g Output 3 g Fault dialer g Activation condition 'Any fault'

Application 2

- 'Alarm dialer' output (OUTB) supervises the line to the dialer.

- 'Fault dialer' output (OUTA) supervises the line and the build in relay of the dialer.

The relay takes over EOL element functionality, if the resistance is between 2001000 Ω.

Programming:

- Configure g Outputs g Output 5 g Alarm dialer g

Supervision EN 54-13 / Calibrate line / Activation condition 'General Alarm'

- Configure g Outputs g Output 4 g Fault dialer g

Supervision EN 54-13 / Calibrate line / Activation condition 'Any fault'

_

X.24

+

INPUT 1*

_

+

AU

INPUT 1*

_

_

+

(1)

OU

OUT2

_

+

Application 1 Application 2

(1) Dialer device confirmation signal

As an option, the panel can receive the dialer activation if desired.

The output 'fault dialer' is closed (Inverse function) in quiescent mode.

In case of fault, the output opens.

_

T B

+

29

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 30

4.5 Input

INPUT

The programmable input function allows control of the panel by a third-party system.

Programming:

- Configure g Input g Input 1-n g Mode g e. g. Class change signal

–

+

AUX 24V

Third-party system

1 2 3

30

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 31

4.6 Accessories

X40

X10

X30

X20

X50

X10

X40

X30

X20

Connect the accessories as shown.

FC121-ZA / FC122-ZA

Terminals Accessories

X50 not used

X40

FTO1201-H1 EVAC Module (NL 2&4 Z)

FTO1203-H1 EVAC Module (NL 8&12 Z)

FTO1202-Z1 Zone ind. field 12x2LED

X30 FCA1203-Z1 Output card 2M 2R

X20 FCA1206-Z1 Key switch set (Nordic SE)

X10 FDUZ221 MCL-USB adapter

FDUZ227 MCL-USB adapter (radio)

4.6.1 Key switch set

The key switch set is available for the following panels.

FC121-ZA FC122-ZA FC123-ZA FC124-ZA

FCA1206-Z1

FC123-ZA / FC124-ZA

þ þ þ þ

FCA1206-Z1

Example FC124-ZA

Function:

The key switch enables 'access level 2' (see chapter 6.4) without password.

Programming:

- No programming is required.

31

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 32

4.6.2 Output card

2

EOL

EOL

Earth con

n

ection

(only used for FCA1203

-

Z1)

The output card is available for the following panels.

Output card Mounting slot FC121-ZA FC122-ZA FC123-ZA FC124-ZA

FCA1203-Z1

Example FC124-ZA

①

þ þ þ þ

② þ þ

③

þ

FCA1203-Z1

1

3

FC121-ZA / FC122-ZA

Function:

Each output card provides four outputs and one power input 24 V for external powering

of the outputs A and B. Check power calculation in chapter 11 whether you have to

power those outputs internally or externally.

Internal:

By default, output A and B are supplied by the internal PSU.

External:

Connect the wires from an external PSU to the terminal '24V In'.

The output card switches automatically from internal to external supply.

Programming:

- Output cards are automatically enabled if plugged in before initial start-up.

Output:

The output numbers include a reference to the respective output cards:

Mounting

slot

Outputs for programming

A B C D

① 4 5 6 7

② 8 9 10 11

32

Smart Infrastructure A6V10393190_h_en_--

③ 12 13 14 15

2019-09-01

Page 33

4.6.3 EVAC module (NL)

FTO1203-H1

The EVAC module is available for the following panels.

EVAC Module (NL) FC121-ZA FC122-ZA FC123-ZA FC124-ZA

FTO1201-H1

FTO1203-H1

FC121-ZA / FC122-ZA

Function:

The EVAC module NL provides the Dutch special function.

All sounder controls are changed to EVAC sounder NL.

Mounting module before initial start-up:

- If the module is connected before the initial start-up, the NL presetting and language

is pre-selected automatically.

- The functionality and EVAC sounder NL are available if the pre-selected setting is used.

þ þ

þ þ

FTO1201-H1

FC123-ZA / FC124-ZA

Mounting module after initial start-up:

- Enable the EVAC module in the programming.

- Change all programmed sounder outputs to EVAC sounder NL.

Programming: Configure g Accessory g EVAC module

Configure g Output g Output n g Mode g EVAC Sounder NL

Operating:

All programmed outputs to 'EVAC Sounder NL' are activated by pressing the start

button twice.

1

3

4

2

No. Description Status Function

1 LED: EVAC zone active ON Evacuation is activated.

2 LED: EVAC fault Flashing Fault on the EVAC sounder lines(s) has occurred.

3 Button: START Press twice to start the evacuation.

4 Button: STOP Press twice to stop the evacuation.

33

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 34

4.6.4 Zone indication field

The zone ind. field FTO1202-Z1 as shown in the graphic below.

FC121-ZA FC122-ZA FC123-ZA FC124-ZA

FTO1202-Z1

þ þ

Example FC124-ZA

Function:

The zone ind. field shows the actual status of each zone.

- LEDs are fixed assigned and cannot be changed.

Programming:

FTO1202-Z1

- No programming is needed.

1

2

3

No. Description Status Function

1 Zone alarm

(Red)

2 Zone fault

(Yellow)

ON The zone is in alarm state.

Flashing The zone is in first alarm state.

ON The zone is disabled.

Flashing Zone is in fault.

3 Inscribable fields Inscription of zone number and customer text.

34

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 35

4.7 Initial start-up

The initial start-up is required with every new installation.

4.7.1 Prepare the panel

Make sure that the installation instructions, steps 1-8 are fulfilled (chapter 4.2)

and all accessories are connected (chapter 4.6).

1) Switch on the mains supply.

N

2) Connect the battery.

L

Red (+)

Black (-)

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

35

Page 36

4.7.2 Pre configuration

ok

ok

p

q

After the panel is powered up, the following display is shown.

Country settings

Presetting t Factory setting u

Language t English u

Country settings

Presetting t Factory setting u

Language t English u

Country settings

Presetting < UK >

Panel

Language < English >

will restart!

p

t

t

u

q

p

u

t

Change country setting by the navigation key

<u>.

Move to the second line with <q> and

u

select the appropriate Language with <u>.

q

Confirm the entry by the <ok> button.

The panel will restart with the country specific

presetting.

Set date & time

01.01.2000 00:00

Set date & time

22.12.2012 08:08

p

t

u

p

Change the first value ‘day’ with <p> / <q>

t

u

and move to the next with <u> and so on.

q

q

Confirm the entry by the <ok> button.

The system is now ready for individual

programming (see chapter 7).

Relevant to NL with EVAC module only:

If the EVAC module is mounted, the country setting is automatically selected by the

system.

36

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 37

5 Function overview

5.1 Operating functions

The operating functions are related to the following topics.

Alarm Disable / Enable System test

- Acknowledge

- Reset

- Silence sounder

- Manned / unmanned

- Cancel alarm delay

5.2 Access levels

The FC12x provides four different access levels.

Access

level

1 No need End user to view pending events.

2 5555

3 6666 Commissioning personnel:

Password Function

or

key switch

- Zone

- Sounder control

- Fire output

- Alarm dialer

- Fault dialer

Instructed and authorized end user:

- Switch on / off zones and outputs.

- Automatic logout after 2 minutes of no operation.

- Password is not necessary if a key switch is used.

- System programming.

- Automatic logout after 10 minutes of no operation.

- The basic function of panel will not continue.

- Mode walk test with

sounder activation for

1 second

- LED test

4 6666

and front

cover open

6669 - Reset alarm counter.

Smart Infrastructure A6V10393190_h_en_--

Commissioning personnel:

- Save and restore site configuration.

- Upload history log.

- Update firmware.

2019-09-01

37

Page 38

5.3 LED indication

put

The following LED indications are available:

1

2

3

4

5

6

q

7

No. Description Colour Status Function

1 Alarm Red ON The fire control panel is in 'Alarm' condition.

2 Acknowledge Yellow Slow Indicates where action is expected.

3 More alarm Red Slow More than two zones have triggered a fire alarm.

4 Reset Yellow Slow Indicates the action in case of an alarm or fault.

5 Fire brigade Red ON Depending on the programming mode.

6 System on Green ON The system is in operation.

7 General fault Yellow ON Indicates any fault in the system.

8 System fault Yellow ON Indicates CPU failure.

9 Sounder fault Yellow ON Sounder lines are disabled.

10 Alarm dialer fault Yellow ON Alarm dialer output is disabled.

8

9 10

Option 1: Call the fire brigade, panel is in alarm mode.

Option 2: Call the fire brigade, output Alarm dialer is active.

Option 3: Fire brigade is called.

Slow Sounder line is in fault state.

Slow Alarm dialer output is in fault state.

11 12

13 14 15

11 Test condition Yellow ON At least one zone is in test state.

12 Isolation Yellow ON At least one zone or output is disabled.

13 Manned / Unmanned Yellow ON Manned operation (AVC).

OFF Unmanned operation (AVC).

Fast 2 Hz Reaction time V1 is running (AVC).

Slow 1 Hz Investigation time V2 is running (AVC).

14 Resound Red ON Sounder lines are activated.

15 Silence Yellow ON Sounder lines are silenced.

38

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 39

5.4 Buttons

▲►▼

◄

The following buttons are available:

11

10

9

8

7

6

5

1 432

No. Description Function

1 MORE ALARM Move to the next 'fire alarm'.

2 RESET Reset the fire control panel to quiescent condition.

· Starts the investigation time V2 (AVC).

3 ACKNOWLEDGE

· Silence the buzzer until a new alarm event occurs.

· Silence the sounder until a new event occurs (if programmed).

4 SILENCE BUZZER Silence the buzzer until a new event (alarm, alert or fault) occurs.

5 SILENCE

RESOUND

· Silence the sounder control(s) in the event of alarm.

· Manually re-activate the sounder control(s) during alarming.

· If programmed, activation of all sounder control(s)

(activation mode only in quiescent condition).

MANNED /

6

UNMANNED

· Switch between manned / unmanned.

· Cancel the alarm delay V1 / V2 when V1 / V2 is running.

7 LAMP TEST Activate all LEDs, the buzzer and the display on the PMI.

8 CANCEL Move one step back without saving the change.

9 OK Confirm the selected value.

10 MENU Enter the main menu.

· Select the menu or change the time: <p> and <q>.

11 NAVIGATION

· Change the selection: <t> and <u>.

· Change to the next level or select value in the checkbox: <u>.

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

39

Page 40

5.5 Display

ok

????

The display is divided into 4 sections.

1

Menu 2:00

Actual events u ▲

Enable / disable u

2

History log u

Set date & time u

Login u

Logout u ▼

1: Title

This line displays the main menu.

2: Window

This window displays the sub menus and its parameters.

3: AVC timer or access level

- Countdown of the AVC timer V1 and V2

- Indication of the access level

4: Scrollbar

Scrollbar is provided if more information is visible in a second window.

5.6 Password entry

3

4

How to get access to the fire control panel.

Login 1

1 2 3

4 5 6

7 8 9

0

Access levels according to chapter 5.2.

l Select the 1st number of the password by

the navigation button and confirm with <ok>.

p

ut

q

l Repeat until the last '?' is replaced.

l If the password is correct, the respective

access level is granted.

40

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 41

6 Operation

6.1 General fire alarm procedure

In case of a fire alarm, the following indication is shown on the panel:

· The fire alarm is indicated by the LEDs (1).

· The first and last alarm zone are displayed (8).

· Further fire alarms are indicated by the flashing LED (2). In order to move to the

next alarm event, press the button (4).

· The internal panel buzzer indicates a fire condition acoustically. As an option,

the buzzer can be silenced by pressing the button (7). A new alarm event will

reactivate the buzzer again.

· Output alarm dialer is activated when LED (3) is ON. (Call the fire brigade.)

· Programmed system outputs, including connected audible and visual

notification appliances, get activated.

· The flashing acknowledge LED (5) indicates the possible action to acknowledge

by pressing the button (6).

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

41

Page 42

6.1.1 Procedure without Alarm verification

The Alarm dialer is activated in the event of a fire alarm.

Fire alarm 1

Zone 1 1/1

Meeting room 1

MAJOR INCIDENT: A real fire emergency

Fire alarm 1

Zone 1 1/1

Meeting room 1

MINOR INCIDENT: No fire alarm

Press the <ACKNOWLEDGE> button.

If the alarm event is acknowledged, the panel

turns off the panel buzzer.

è Access level 2 password is required.

Optional: Silence the sounder lines by pressing

<RESOUND / SILENCE> button.

Check if the fire brigade called.

Normal Operation

Siemens FC12X

22.12.2012 08:08

1

Reset the system to quiescent mode by pressing

<RESET> button.

è Access level 2 password is required.

Inform the fire brigade about the actual situation.

Notice

The fire alarm reoccurs if any device remains in fire condition.

42

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 43

6.1.2 Alarm Verification Concept (AVC)

Unmanned

State

'ALERT

”

unmanned:

unmanned:

The graphic below illustrates the difference between the AVC and the DIRECT alarm

procedure. The AVC concept takes the interaction of personnel into consideration.

AVC DIRECT

Manned

· Buzzer activated

· Sounder output activated if programmed

· Reaction time 'V1” has started

No

Yes

Fire?

Manned/

V1 time out

State 'ALARM'

· Buzzer (re-)activated

· Sounder output (re-)activated

Manned operation

Manned operation enables the responsible personnel to examine the fire alarm before

initiating the intervention force. This may avoid hassles in case of false alarms.

Reaction time (V1)

In case of a fire incident, the responsible personnel must confirm the alert at the fire

control panel by pressing the acknowledge button (ACK).

Investigation time V2 starts if activated. If nobody confirms the alert state, the V1 timer

expires and the panel automatically goes to 'ALARM' state.

In the event of a major incident (emergency), the nearest ‘Manual call point’

or <Manned/Unmanned> button must be pressed to turn the fire control panel into

'ALARM' state. (1function depends on programming)

Ack:

No

Yes à V2 start

No

Fire?

Reset: Manned/

V2 time out

Yes

· Fire output activated

· Alarm dialer activated (Intervention)

1

Investigation time (V2)

During the investigation time V2 the operating personnel may examine the location of

fire:

In the event of a major incident (emergency), the nearest ‘Manual call point’

2

or <Manned/Unmanned> button must be pressed to turn the fire control panel into

'ALARM' state. (2function depends on programming)

The panel goes to 'ALARM' state if the investigation is not confirmed within time V2.

The operator may reset the panel in the case of a minor incident or false alarm.

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

43

Page 44

6.1.3 Procedure with Alarm Verification

In the event of a fire alarm, the reaction timer V1 gets started.

Fire alarm 2:00

Zone 1 1/1

Meeting room 1

Fire alarm 3:00

Zone 1 1/1

Meeting room 1

Action is requested

During the investigation time, examine the location of the fire and decide whether it is

a MAJOR INCIDENT or MINOR INCIDENT.

MAJOR INCIDENT: A real fire emergency

V1

V2

Press the <ACKNOWLEDGE> button to confirm

the attendance. If the alarm event is

acknowledged, the buzzer turns off.

è Access level 2 password is required.

The investigation timer V2 is started.

Optional:

Silence the sounder by pressing <RESOUND /

SILENCE> button.

Fire alarm 2:00

Zone 1 1/1

Meeting room 1

MINOR INCIDENT: No fire alarm

Normal Operation

Siemens FC12X

22.12.2012 08:08

Notice

The fire alarm reoccurs if any device remains in fire condition.

Cancel the investigation time by pressing the

<MANNED / UNMANNED> button.

è Access level 2 password is required.

Reset the system to normal operation by pressing

<RESET> button.

è Access level 2 password is required.

44

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 45

6.2 Fault procedure

A list of possible '

Faults

' can be found in

chapter

12

.

In the event of a fault, the panel displays the fault.

As an option, programmed outputs can be activated (e.g. fault dialer).

Fault 1

Battery 1/2

Zone 1 2/2

Action is requested.

Solve the cause of the fault.

Press the <SILENCE BUZZER> button.

Buzzer is turned off.

Normal Operation

Siemens FC12X

22.12.2012 08:08

Acknowledge and reset the system to normal

operation by pressing the <ACKNOWLEDGE>

and <RESET> button.

è Access level 2 password is required.

Notice

The fault reoccurs if acknowledged but not resolved.

Smart Infrastructure A6V10393190_h_en_--

45

2019-09-01

Page 46

6.3 Access level 1

C

ok

p

ok

tpq

t

Operation is available without password.

6.3.1 Actual events

The actual events will display all pending events.

Menu 1

Actual events u

Login u

Alarm counter 0001

Actual events 1

Fire alarm u 0

Fault u 2

Isolation u 0

Test u 0

Information u 0

Push button <MENU>.

u

Select ‘Actual events’ with navigation button and

confirm with <ok>.

t

u

The left picture shows the 5 entry points.

Select one event type and confirm with <ok>.

q

Fault 1

Battery 1/2

Output 1 2/2

①

p

t

u

q

The details are visible with the number of events

indicated for the category.

e.g. two events exist in this category.

Go back to the main menu with <C>.

46

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 47

6.3.2 Login

C

ok

**

??

ok

t

The panel is protected against unauthorized user operation.

Therefore enter the password or turn the key switch (optional).

Menu 1

Actual events u

Login u

Alarm counter 0001

Push button <MENU>.

p

t

u

q

Select ‘Login’ and confirm with <ok>.

Login 1(#)

1 2 3

4 5 6

7 8 9

0

6.3.3 Alarm counter

The alarm counter counts all fire alarms.

Menu 1

Actual events u

Login u

Alarm counter 0001

l Select the digit using the navigation button

p

ut

q

and confirm it with <ok>.

l The ‘?’ is replaced by ‘*’ with every entered

digit.

l Press <C> to cancel the input.

(#) shows the actual access level.

t

Push button <MENU>.

The number of counted alarms is shown.

Exit with <C>.

47

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 48

6.4 Access level 2

Operation is available with password or key switch.

6.4.1 Manned / unmanned

In case of attendance switch the fire control panel to manned operation.

Information 2

Manned operation 1/1

Manned mode

activated

6.4.2 Silence / resound

Sounders are activated in the event of a fire alarm.

Press the <MANNNED / UNMANNED> button to

toggle.

Manned mode – LED ON

Unmanned mode – LED OFF

Press the <SILENCE / RESOUND> button to

silence the sounders.

It is possible to reactivate the sounders in the

event of a fire alarm at any time.

Every new alarm event will reactivate the

sounders again, if programmed.

Optional: The sounders can be activated at any

time 'Toggle function' (no alarm event is required)

if programmed.

6.4.3 LED, display and buzzer test

Test the panel indication.

Press the button <LAMP TEST> and all LEDs, the

display and the internal buzzer are activated for a

period of 5 seconds.

48

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 49

6.4.4 Display history log

ok

tpq

C

p

ok

p

Logout

u

t

All events such as alarm(s), fault(s), isolation(s), input(s) and output(s) activation are

stored in a history log.

Menu 2

Actual events u

Enable / disable u

History log u

Set date & time u

Login u

History log 2

Fault 1/2

Set date & time

10.08.2012 12:18

Push button <MENU>.

t

u

q

Select ‘History log’ and confirm with <ok>.

All events are visible.

t

u

q

Fast scrolling is possible by holding <p> / <q>

navigation button.

6.4.5 Logout

Manual logout to access level 1.

Panel automatically logs out if no action is taken within 2 minutes.

Menu 2

Actual events u

Enable / disable u

History log u

Set date & time u

Login u

Logout u

Successful

Go back to the main menu with <C>.

t

u

1

Push button <MENU>.

Select ‘Logout’ and confirm with <ok>.

The panel is logged out successfully to previous

access level.

49

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 50

6.4.6 Set date and time

ok

qut

ok

t

p

q

Push button <MENU>.

Menu 2

Actual events u

Enable / disable u

History log u

Set date & time u

Login u

Logout u

Set date & time

01.01.2000 00:00

Set date & time

22.12.2012 08:08

p

t

t

u

q

p

u

Select ‘Set date & time’ and confirm with <ok>.

Change the first value with <p> / <q> and

move to the next with <u> and so on.

Confirm with <ok>.

50

Smart Infrastructure A6V10393190_h_en_--

2019-09-01

Page 51

6.4.7 Enable / disable zone

C

Zone

6tOn

u

ok

p

Zone

6tOn

u

ok

p

ok

Each zone can be isolated individually.

Menu 2

Actual eventsu

Enable / disable u

History log u

Set date & time u

Login u

Logout u

Enable / disable 2

Zone u

Sounder t On u

outputs

Fault t On u

dialer

Enable / disable 2

Zone 1 t On u

Zone 2 t Off u

Zone 3 t Off u

Zone 4 t On u

Zone 5 t On u

t

p

t

t

t

u

q

u

q

p

u

t

q

q

Push button <MENU>.