Page 1

Factory Automation

Svibanj 2020.

siemens.com/simatic© Siemens 2020

Page 2

Razvojni alat, softver

Page 3

Unrestricted © Siemens 2020

May 2020Page 3

Energy Management

Diagnostics

Safety integrated

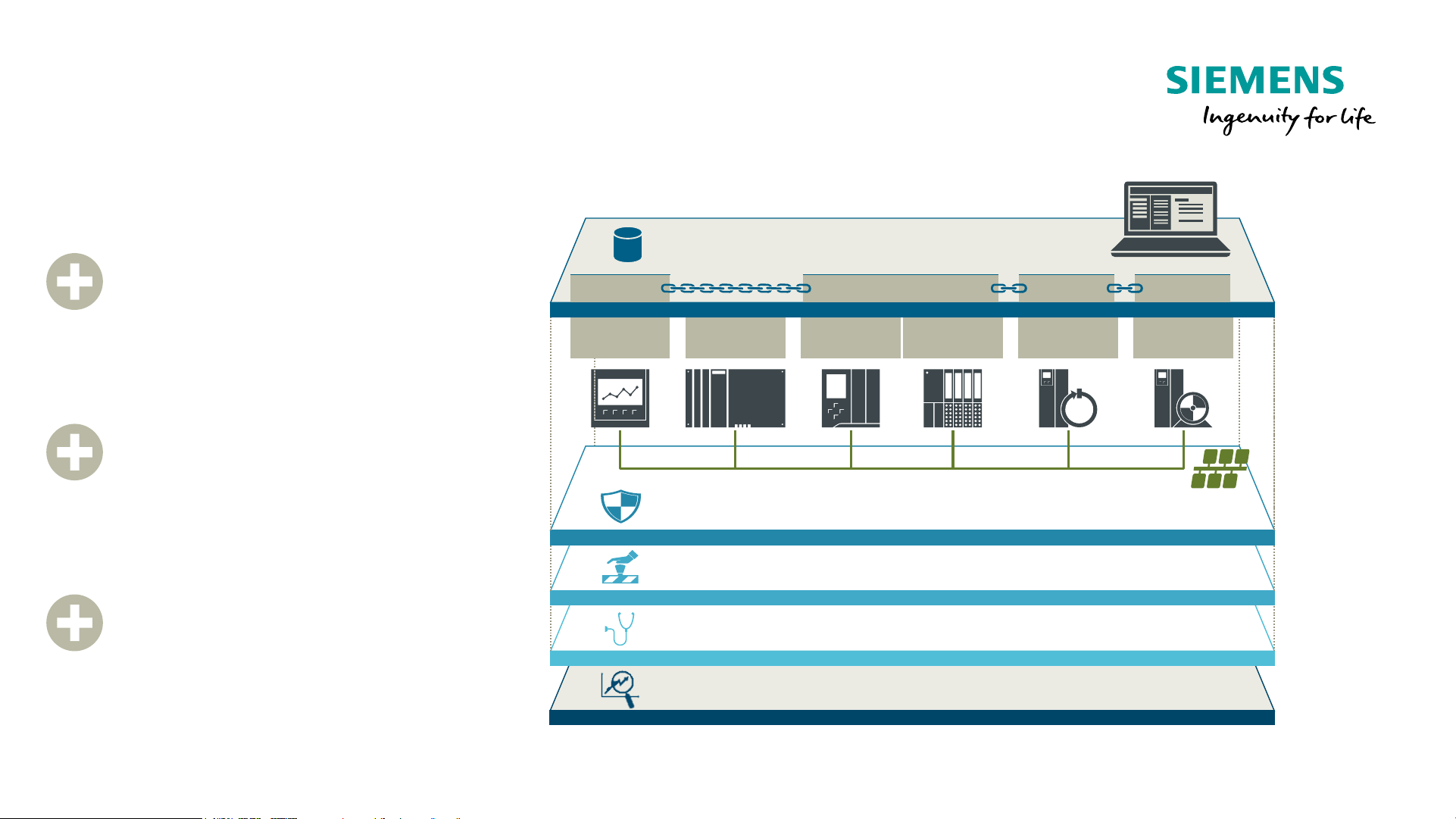

Totally Integrated Automation Portal (TIA Portal)

One for all…

Security integrated

HMI Controller

Distributed

I/O

Motion

Control

DrivesIPC

PROFINET

Totally Integrated Automation Portal

Common data management

WinCC STEP 7 SCOUT Startdrive

One common database

Consistent and unified

operator concept

Common, central

services

Page 4

Unrestricted © Siemens 2020

May 2020Page 4

TIA Portal V16

Your gateway to automation in the Digital Enterprise

Digital Workflow with TIA Portal

NEW

Feature / Function Feature / Function

TIA Portal Openness

• Support of Software Units

• PLC Online Fingerprint

• Support of SINAMICS DCC

TIA Add-Ins

• Extension of the TIA Portal functionality

with the help of the Openness API

Version Control Interface (VCI)

• Interface to external versioning systems

(GIT, SVN, TFS)

• Export/import of software objects via the TIA

Portal interface

Project Trace

• Coordination of traces in multiple devices

(multiple CPUs, different device types)

• Representation in a common diagram

• Alternative trigger sources

TIA Portal Test Suite

• Automated creation and review of

programming guidelines

• Creation and execution of application tests

with S7-PLCSIM Adv

Support for new HW functions

• S7-1200 OPC Server

• S7-1500 - R/H, Web Server invation,

IP forwarding, Drive controller

• WinCC Unified panels

NEW

SIOS dodatne informacije: link

Page 5

Unrestricted © Siemens 2020

May 2020Page 5

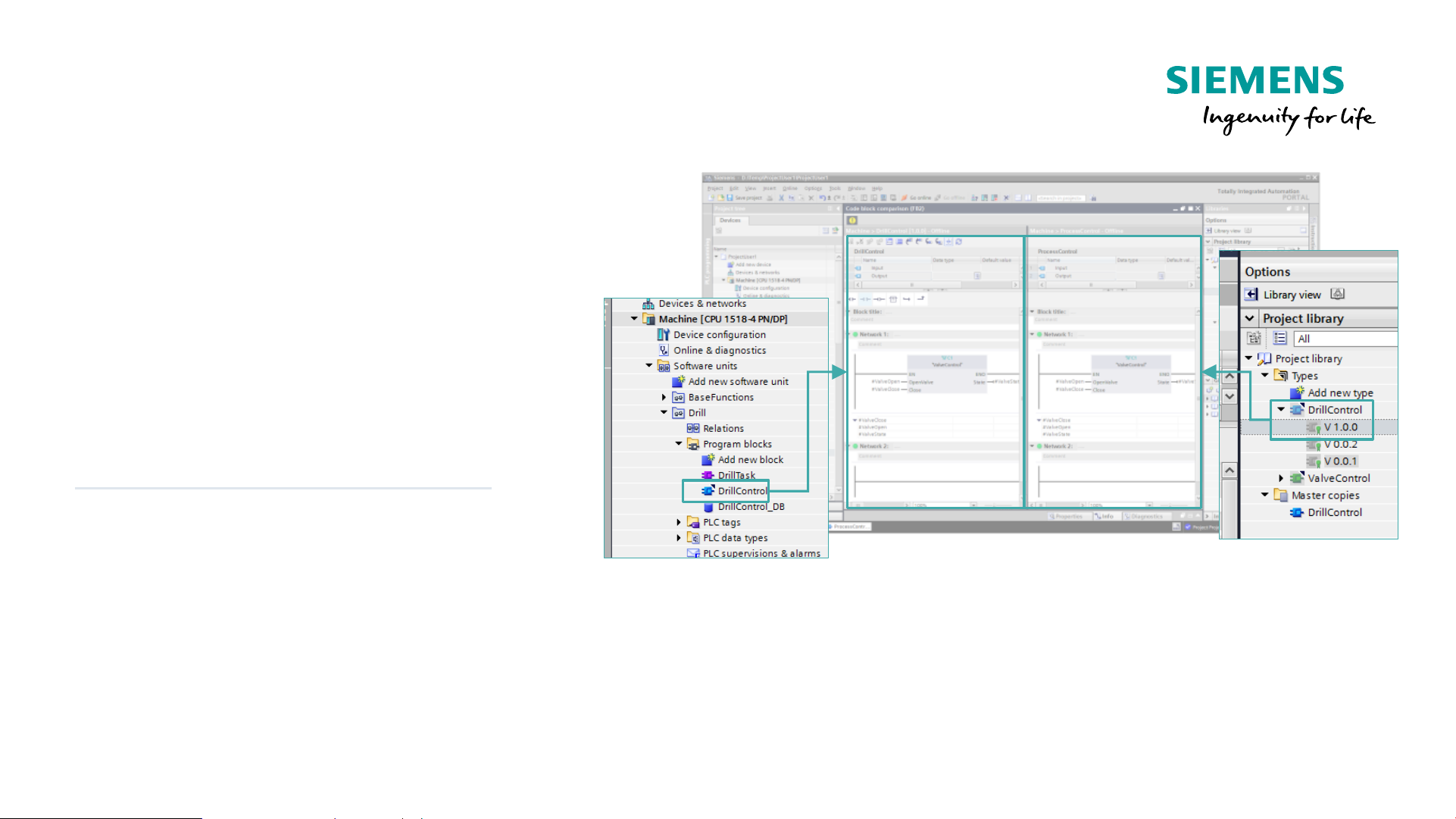

STEP 7 - Innovations

Detailed block compare for project library

Benefit

• Easier handling of blocks in libraries

• Better usability for tracking changes

between type versions

Function

• Detailed block compare for blocks

from a project and

• Mastercopies(project or global library)

• Single versions of Types (from project

or global library)

• Via Quick Compare or High-Level

Compare Editor

• Detailed block compare between library

blocks (e.g. V1.0 vs V2.0)

Page 6

Unrestricted © Siemens 2020

May 2020Page 6

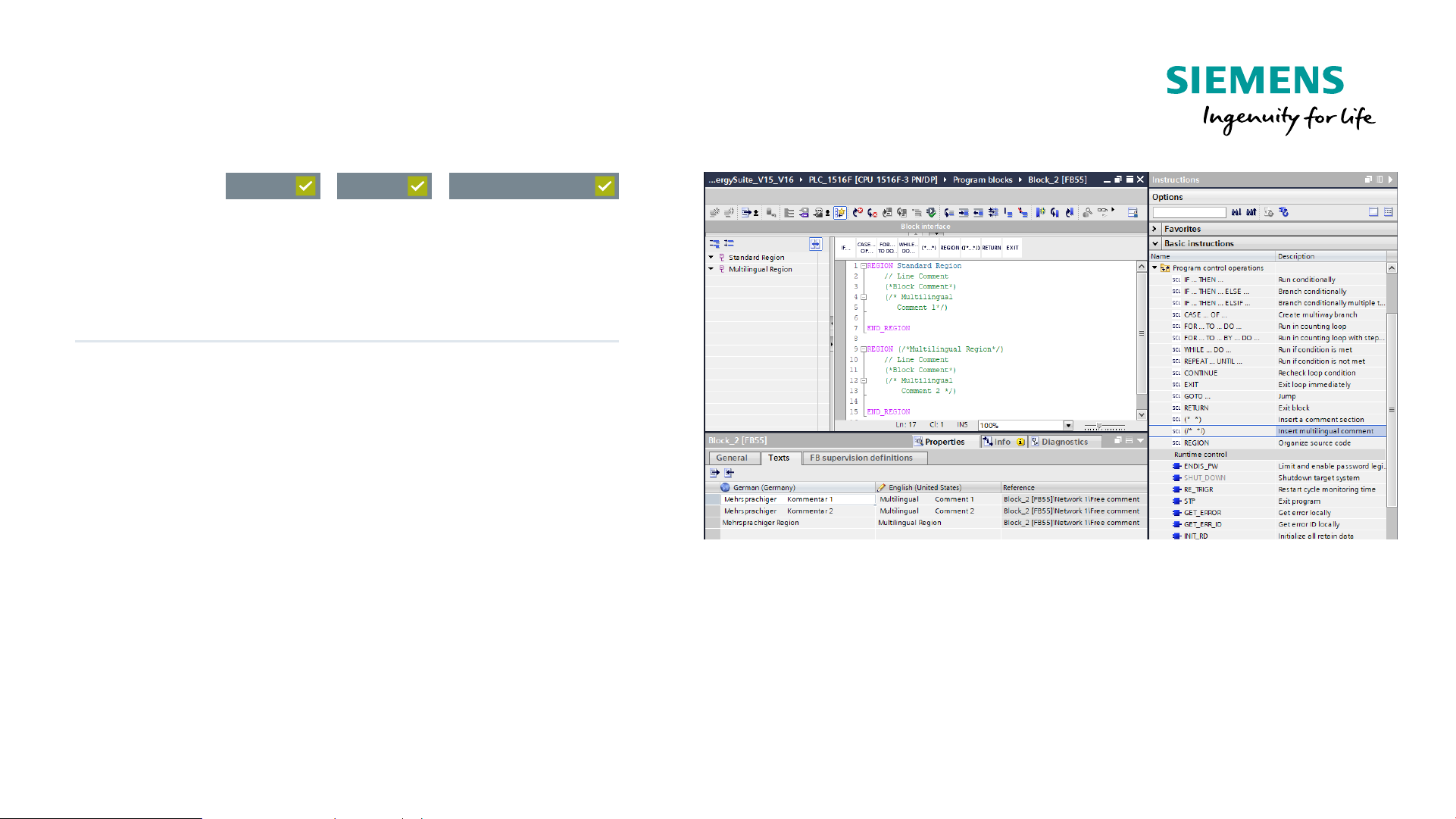

STEP 7 - Innovations

Multilingual comments in SCL programs

Advantage of the function

The code implementation can be commented in

different languages. This enables the use and

maintenance of complex algorithms at distributed

production sites worldwide.

Function

The syntax (/* ... */) enables the entry of

multilingual comments and regions

in SCL blocks.

S7-1200S7-1500 S7-300/400/WinAC

Page 7

Unrestricted © Siemens 2020

May 2020Page 7

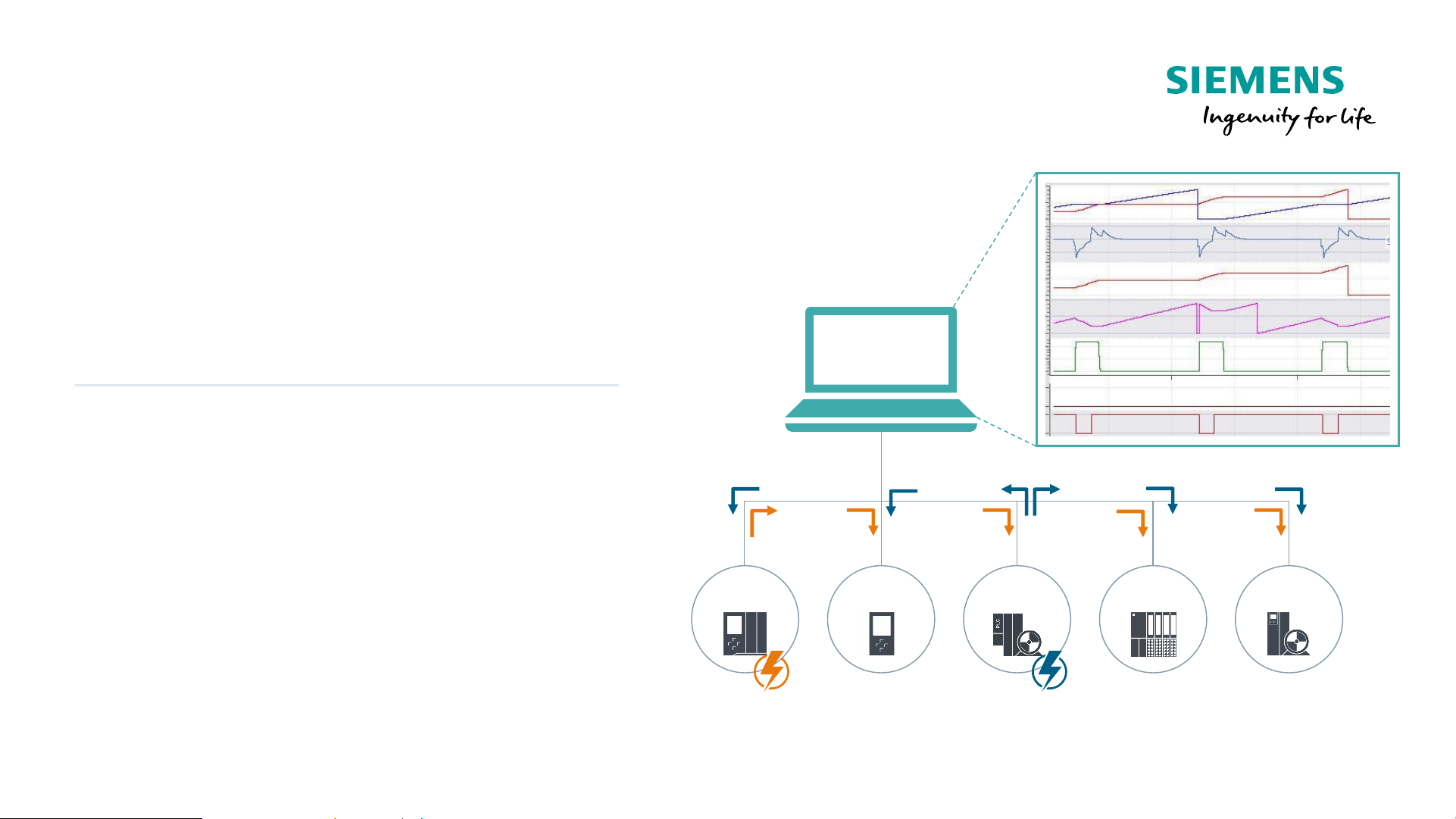

STEP 7 - Innovations

Project Trace

S7-1500 S7-1500T Drive

1

Trigger-1 Trigger-2

S7-1500

Drive Contr.

ET 200SP

CPU

Function

• Coordination of traces in several devices

• Supports multiple CPUs

• Supports a wide range of device types

• Display in a common diagram

• Alternative trigger sources possible

Benefits

• Cross-device troubleshooting

• Extensive trigger options

• Simple combination of

related traces

Page 8

Unrestricted © Siemens 2020

May 2020Page 8

System functions

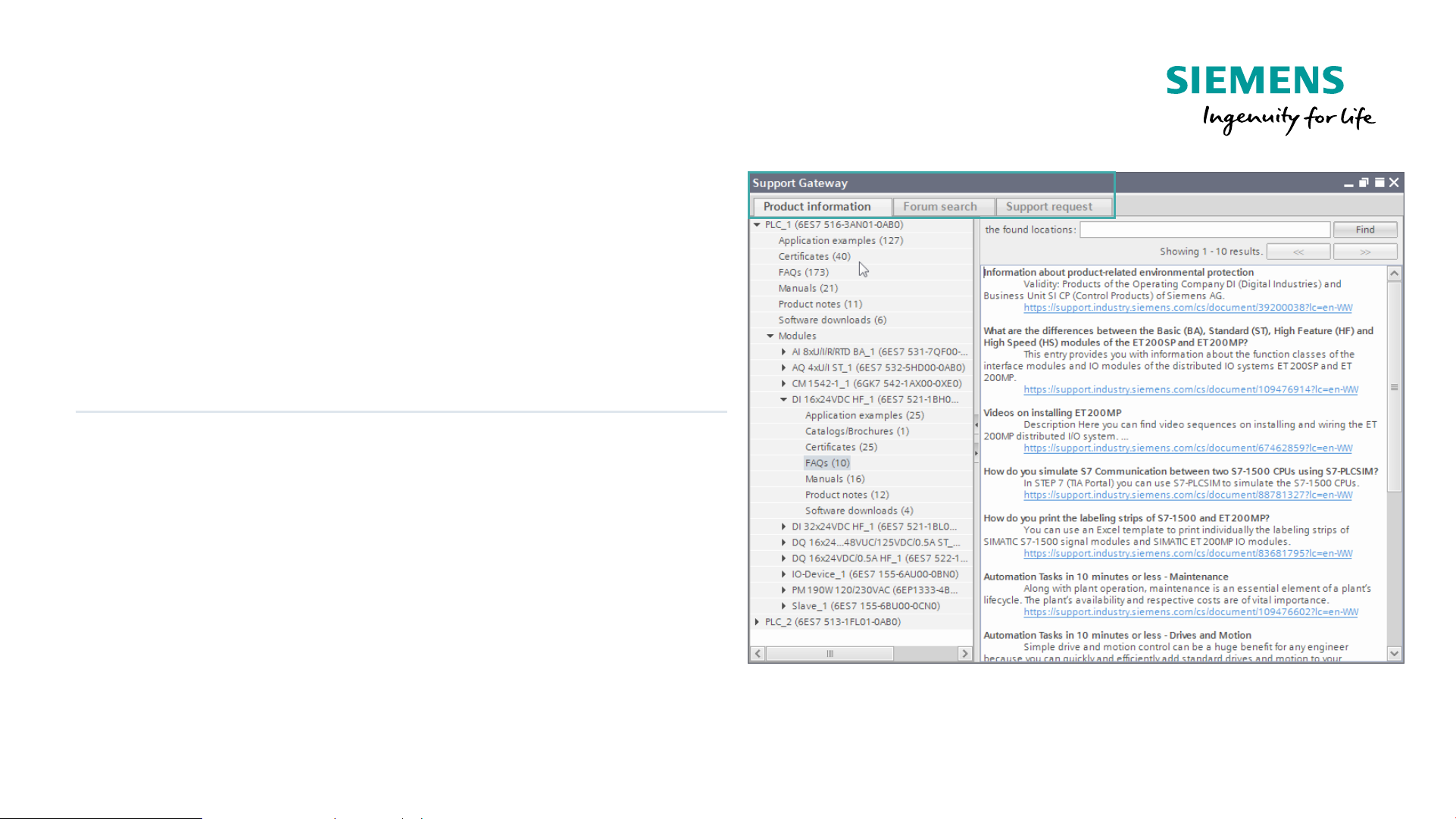

TIA Portal Support Gateway

Overview

• The TIA Portal Support Gateway is the integrated connection

of the Siemens Industry Online Support pages to the TIA Portal

• The Support Gateway includes the following functions:

• Forum search

• Product search

• Generation of support request file

Benefits

• Seamless integration of SIOS added value functions into the TIA

Portal

• Know-how management without change of media

• Simple and fast forum search

• Pre-filtered product search based on the components contained in

the TIA Portal

• Generation of a support request file with the most important

computer and TIA Portal data

Page 9

Unrestricted © Siemens 2020

May 2020Page 9

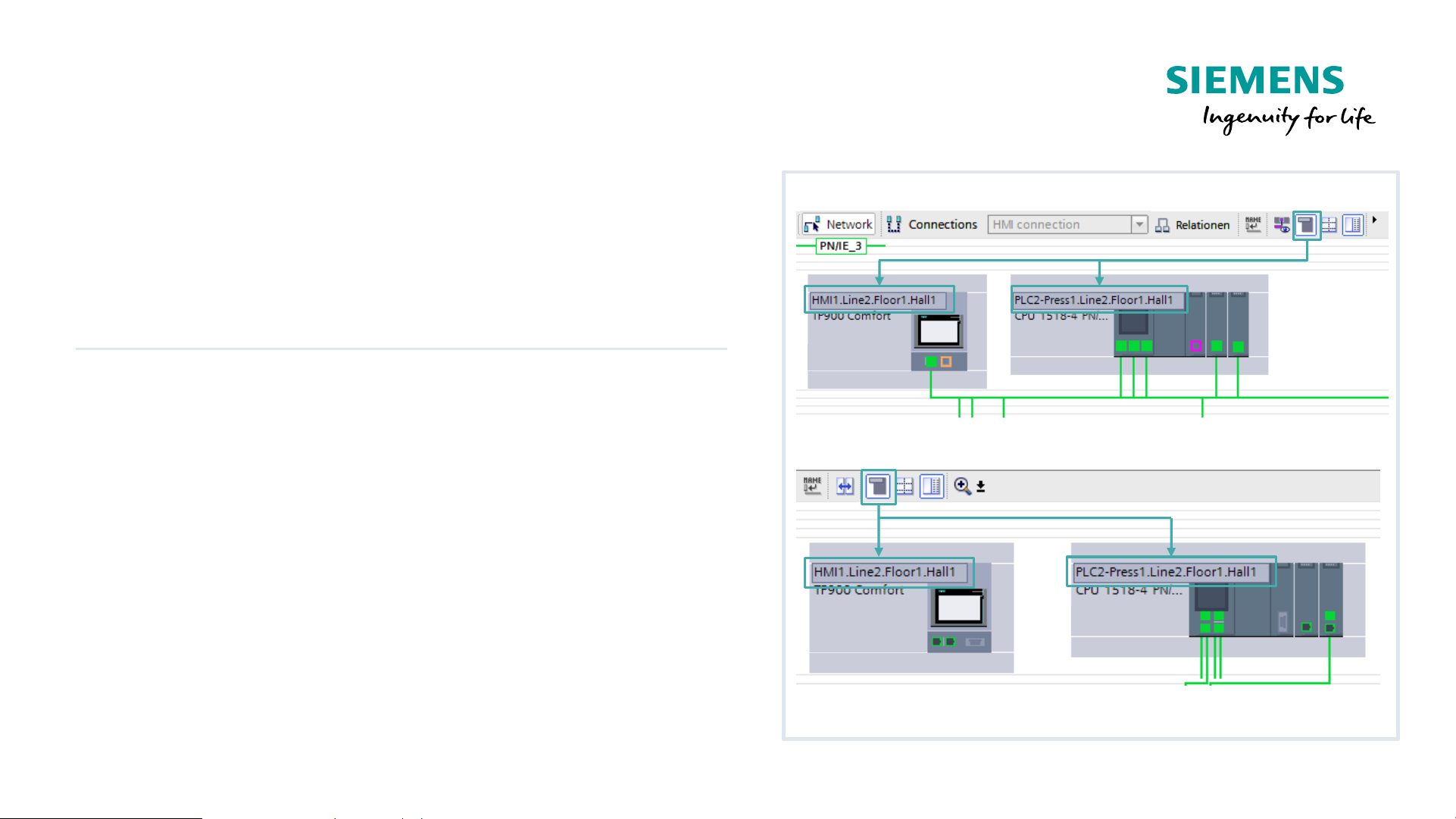

Hardware configuration

Improvement of display of the device name

in network and topology view

Function

• Device name can be displayed in network view and topology

view.

Advantage

• The clarity and orientation of projects with long device names is

facilitated.

Page 10

Unrestricted © Siemens 2020

May 2020Page 10

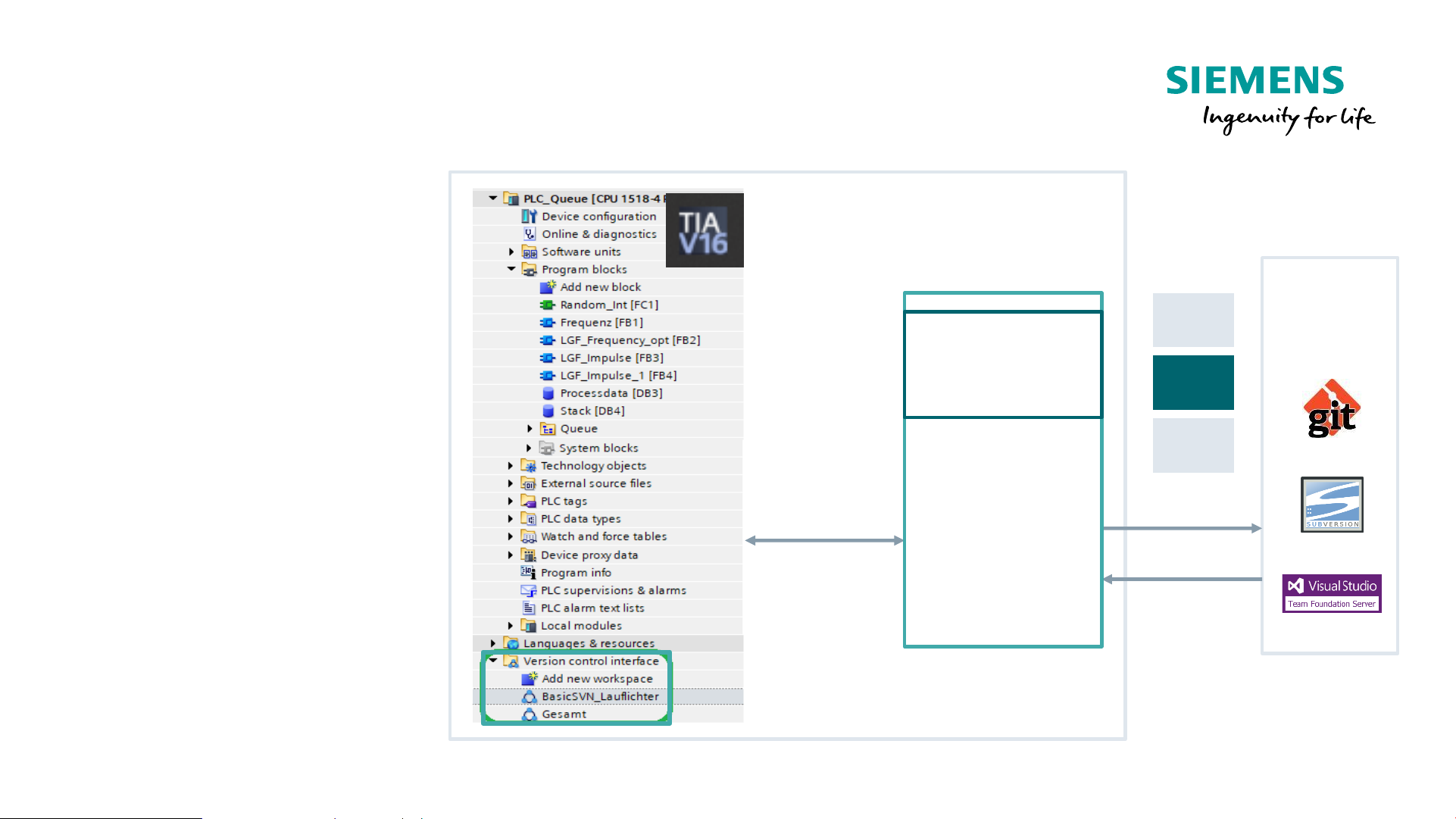

System functions

VCI – Interface for external version management

Functionality

Ex-/Import of program objects

• Blocks

• User data types

• Tagtables

Compare

• Objectstatus (equal/unequal)

• Detailed Block compare

Interfaces for

• External compare tool

• Userscripts

Openness Interface

• API with VCI operations

• Without User-Interface

Source

Control

System

(Repository)

Transfer

via Openness

Check-In

Check-Out

Git

Adapter

TFS

Adapter

SVN

Adapter

1

1 Samplescripts available

Workspace

Copy of SCL/XML

files to Filesystem

Version Control

Interface

Preparation of

versionable objects

Page 11

Unrestricted © Siemens 2020

May 2020Page 11

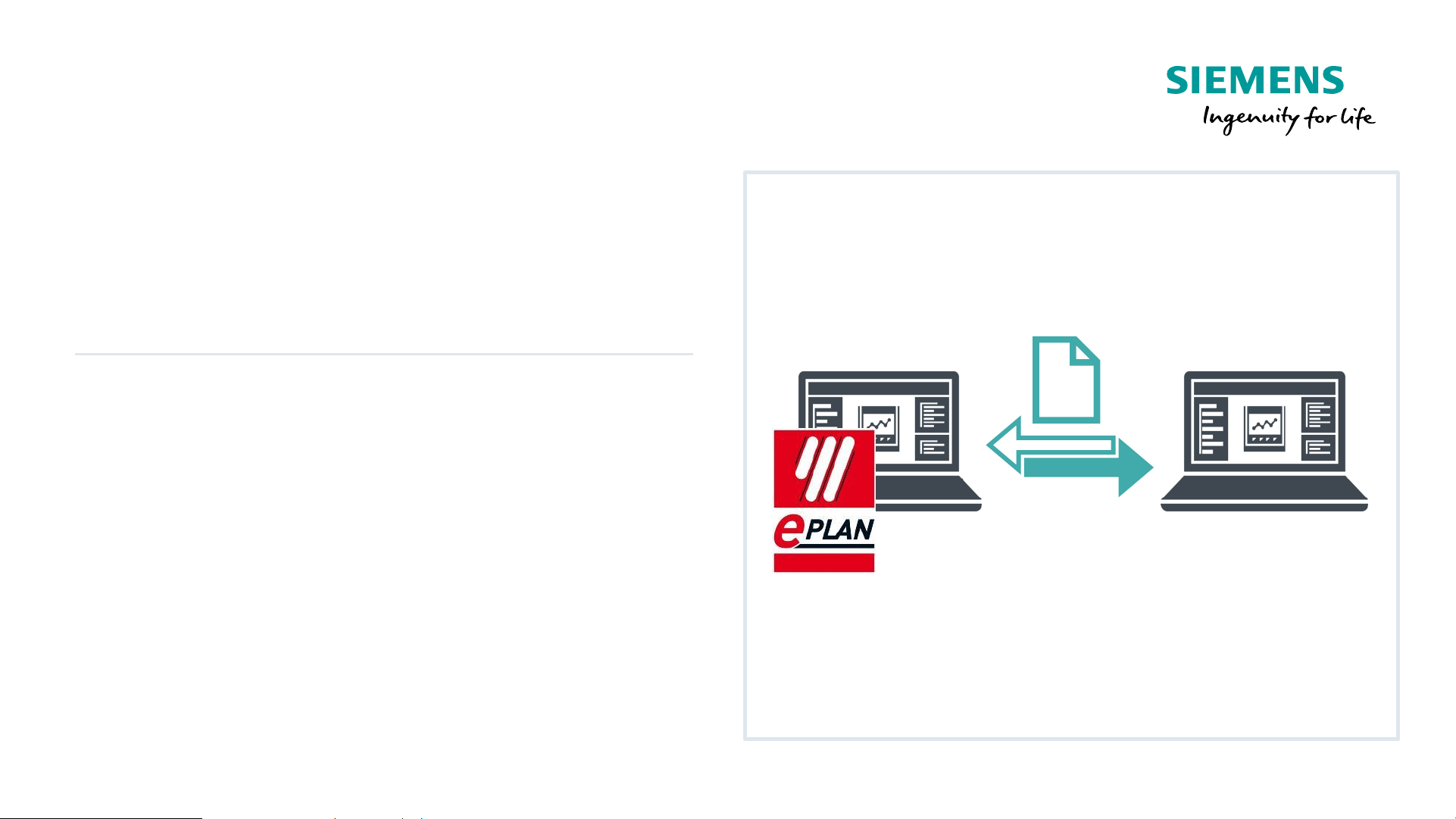

System functions

CAx export/import

TIA Portal V16

ECAD

AML

Extension of the CAx export and import

• Support of the AR APC V1.1

• Use of objects from TIA Portal libraries

• Support of BaseUnits for ET200SP modules (except Safety

modules)

Advantages of the function

• Due to the extension, the relevant data is retained in round-trip

scenarios and saves manual post-configuration

• The use of references to library objects (master copies) enables

the integration of pre-configured hardware components

Page 12

Unrestricted © Siemens 2020

May 2020Page 12

Virtual commissioning of automation solutions

Using the TIA and Digital Enterprise Suite to simulate,

validate, and optimize controllers and machines

Feature/ Function Benefit

Virtual Controller SIMATIC

S7-PLCSIM Advanced V3.0

• extended hardware support: S7-1500 MFP

incl. ODK

• PLCSIM Advanced API improvements:

browse for available runtimes in the

network

• no changes of the STEP 7 program / HW

configuration necessary to use the

functionalities of the S7-1500 MFP-CPU

• Better and simpler applicability in complex

scenarios

Simulation platform SIMIT V10.1

• Functional Mockup Unit (FMU)

• Functional Mockup Interface (FMI)

• Integration of manufacturer-independent

standardized behavior models e.g. from

AMESIM or Matlab in SIMIT

• Standardized interface for the data

exchange of different simulation software

(via FMU)

NEW

NEW

Page 13

Unrestricted © Siemens 2020

May 2020Page 13

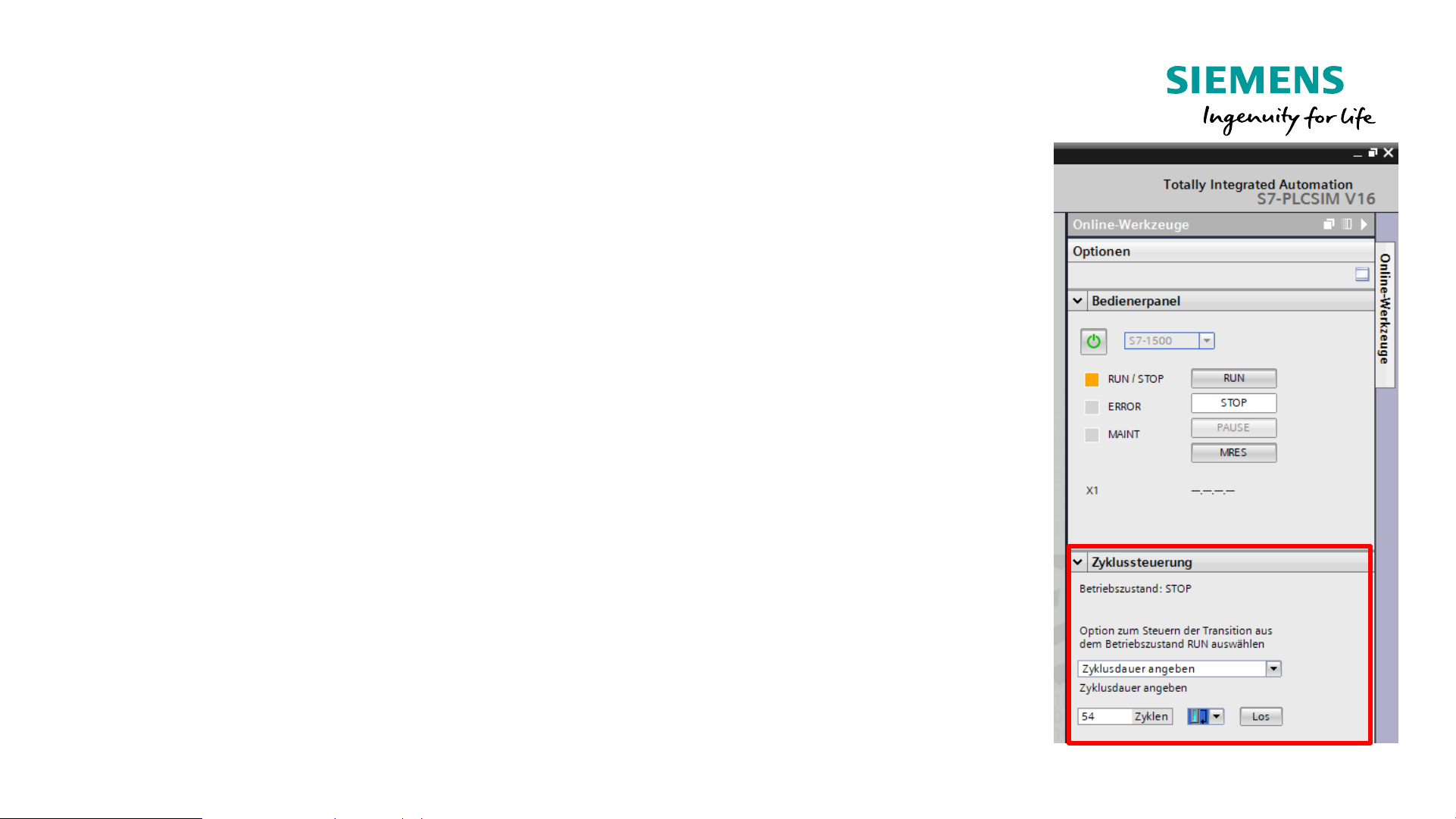

New functions in S7-PLCSIM V16

Cycle control

Function

In order to improve the applicability of PLCSIM while testing the PLC

programs, the functionality has been extended to include “Cycle control”.

In the options below the operator panels the following modes can be set via the new section "Scan

Control".

Pause allows the cycle to stop

• For analyzing process values at a selectable time

Specify simulation duration (image)

• Observing the program behavior in slow motion. At least one cycle is always running through

• The following can be set: number of cycles or running time in ms./ sec./ min.

Pause after execution of the startup OB

• To analyze and verify the OB startup behavior, the program is stopped after its execution

Page 14

Unrestricted © Siemens 2020

May 2020Page 14

System functions

Project upgrade

TIA Portal V16 TIA Portal >V13 TIA Portal V13 SP1/SP2

Side-by-side installation of V13 SP1/SP2 up to V16 allows access to all project versions.

The V16 license can be used for all available versions from V11.

V13 SP1 project

Project upgrade to V16Project upgrade to V13 SP1

≤V13 project

V16 project>V13 project

Page 15

Unrestricted © Siemens 2020

May 2020Page 15

System functions

Spare parts compatibility S7-1500 and ET 200 CPUs –

FW 2.8 with older TIA Portal versions

TIA Portal V16 TIA Portal V12/V13/V14/V15/V15.1

Full spare part functionality: Online support: ID 109744163

New functions can be used with TIA

Portal V16 and firmware V2.8

Firmware V2.8

V15/V15.1

project with

FW 2.5/FW 2.6

Firmware V2.8

V14/V14 SP1

project with

FW 2.0/2.1

Firmware V2.8

V12

project

with FW 1.0/1.1

Firmware V2.8

V13/V13 SP1

project with FW

1.5/1.6/1.7/1.8

Firmware V2.8

V16 project

with FW 2.8

Page 16

Unrestricted © Siemens 2020

May 2020Page 16

TIA Portal V16

Your gateway to automation in the Digital Enterprise

NEW

Feature / Function Benefit

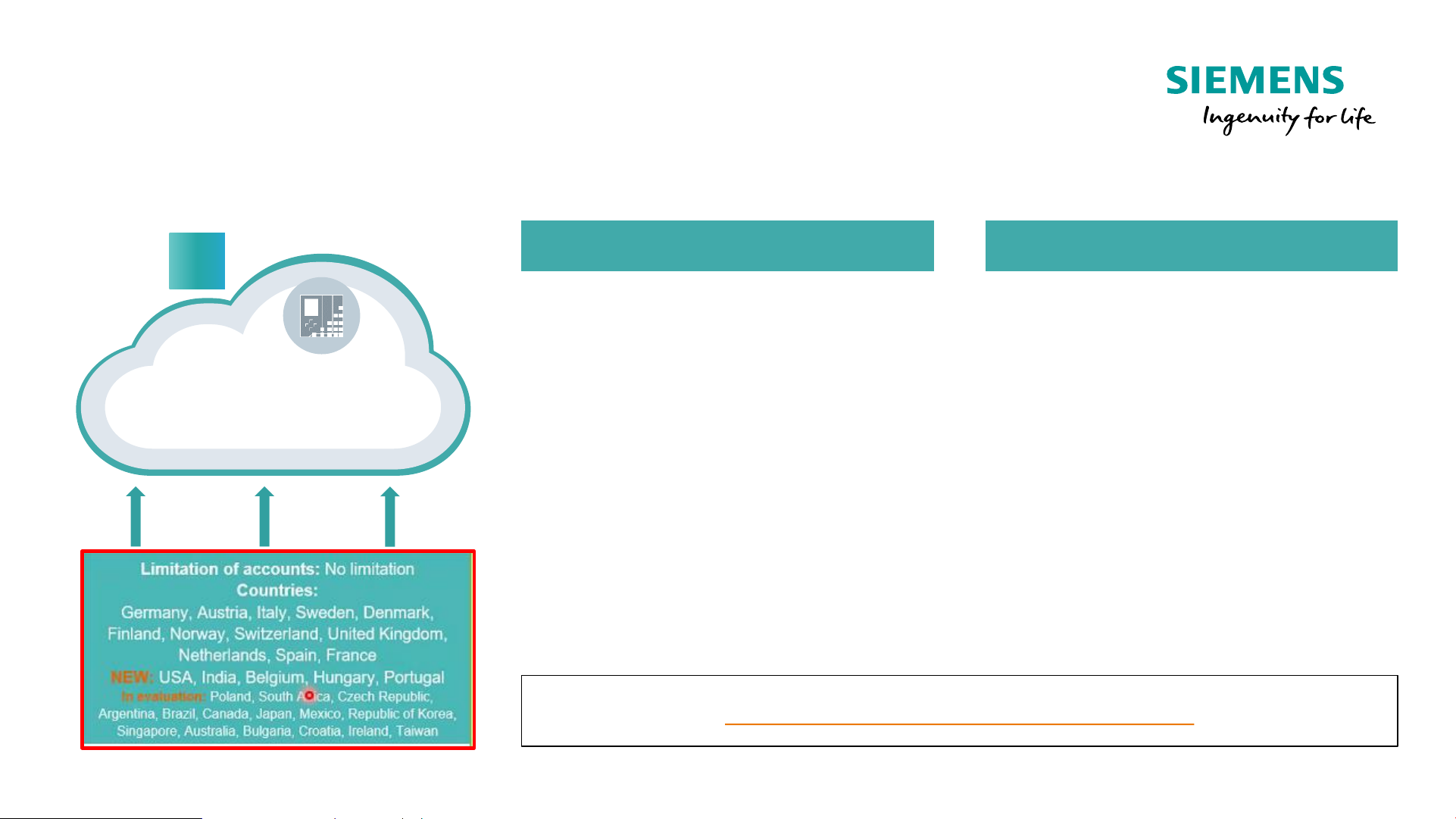

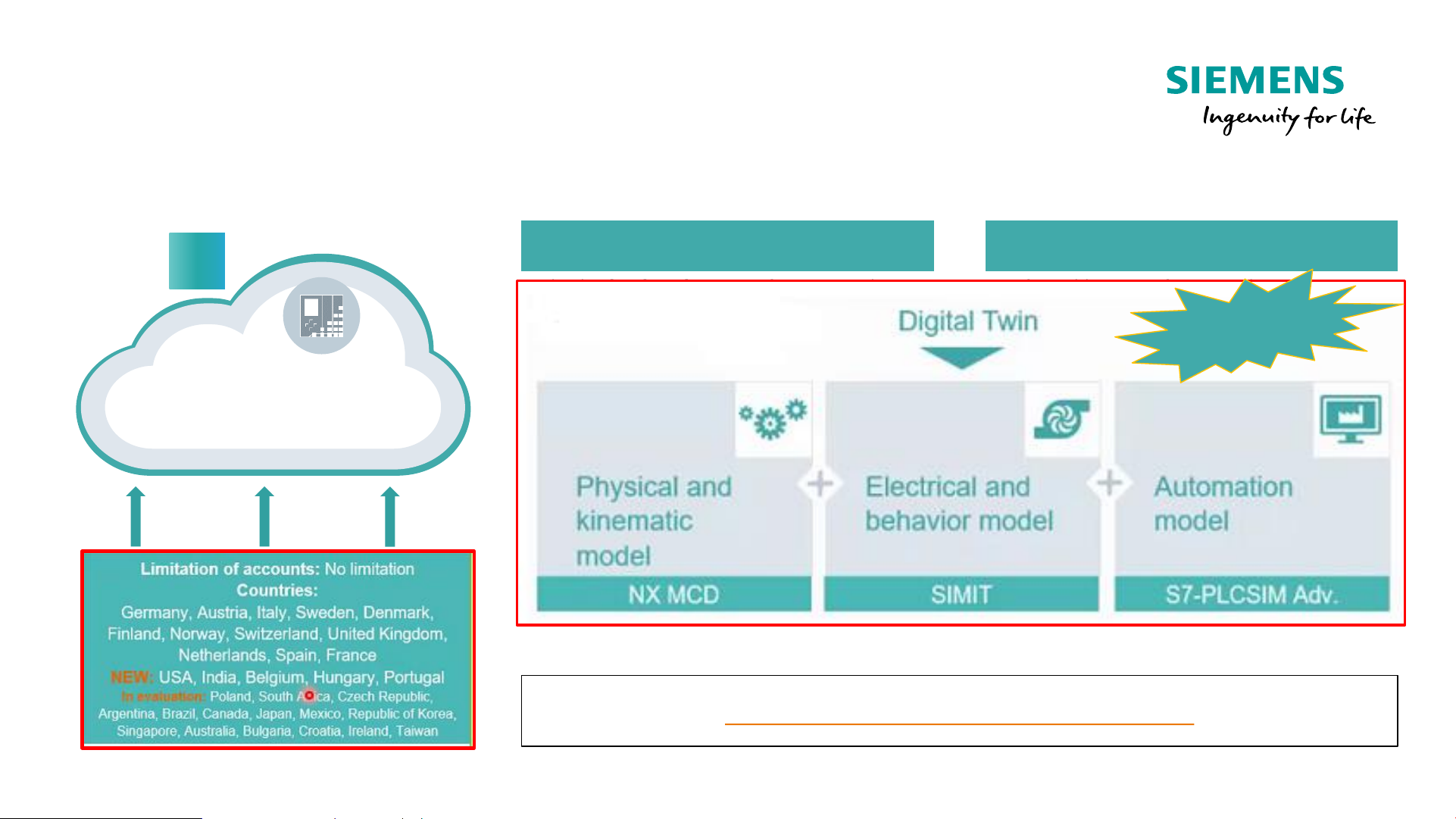

Simple cloud environment for TIA Portal

Engineering

• fast ad-hoc use of TIA Portal

• Simplified trial use of TIA Portal and TIA

Portal options

Simple test environment for TIA Portal

usecases in the cloud

• Simplified test environment with high

performance

• simulation capability with

S7-PLCSIM Advanced

web-based access to TIA Portal engineering

in the cloud

• No installation effort at all

• Flexible application possibilities on any PC

and tablet hardware

• Very low hardware requirements

Cloud-based FileShare for

TIA Portal projects

• Easy management with centralized data

storage of

TIA Portal projects

TIA Portal + SIMATIC Tools

• Step 7 Prof. / WinCC Adv. / Safety Adv.

• Startdrive Adv. / SINAMICS DCC

• S7-PLCSIM Adv. / Energy Suite / SiVArc

• Sinetplan / Proneta / SAT

TIA Portal Cloud as 21-day free TRIAL

New

www.siemens.com/simulation-cloud

Page 17

Unrestricted © Siemens 2020

May 2020Page 17

TIA Portal V16

Your gateway to automation in the Digital Enterprise

NEW

Feature / Function Benefit

Simple cloud environment for TIA Portal

Engineering

• fast ad-hoc use of TIA Portal

• Simplified trial use of TIA Portal and TIA

Portal options

Simple test environment for TIA Portal

usecases in the cloud

• Simplified test environment with high

performance

• simulation capability with

S7-PLCSIM Advanced

web-based access to TIA Portal engineering

in the cloud

• No installation effort at all

• Flexible application possibilities on any PC

and tablet hardware

• Very low hardware requirements

Cloud-based FileShare for

TIA Portal projects

• Easy management with centralized data

storage of

TIA Portal projects

TIA Portal + SIMATIC Tools

• Step 7 Prof. / WinCC Adv. / Safety Adv.

• Startdrive Adv. / SINAMICS DCC

• S7-PLCSIM Adv. / Energy Suite / SiVArc

• Sinetplan / Proneta / SAT

TIA Portal Cloud as 21-day free TRIAL

New

www.siemens.com/simulation-cloud

NAJAVA

Page 18

Unrestricted © Siemens 2020

May 2020Page 18

TIA Portal V16 u vrijeme COVID-19

„Home-Office ponuda” do 31.7.2020.

Svjedoci smo da je u ovim izazovnim vremenima vrlo važna fleksibilnost i mogućnost rada

neovisno o lokaciji. Kako bismo omogućili rad izvan firme, pripremili smo posebnu ponudu koja

će našim korisnicima omogućiti korištenje najnovijeg TIA PORTALA V16.

Trajanje licenci vremenski je ograničeno do 31.12.2020.

U promotivni paket uključene su TIA Portal floating licence:

• STEP 7 Professional V16

• WinCC Advanced V16 i WinCC Unified V16 (10K PT)

• STEP 7 Safety Advanced V16

Kataloški broj za naručivanje: 6ES7822-1AE06-0YS0

>> Narudžbe su moguće do 31.7.2020.

>> Kataloška cijena: 25 €

>> Isporuka isključivo putem standardnog Online Software Delivery (OSD) procesa.

Page 19

PLC oprema

Page 20

Unrestricted © Siemens 2020

May 2020Page 20

SIMATIC – pregled aktualne PLC opreme

Složenost aplikacije

Modularni, kompaktni PLC

primjeren za jednostavnije

aplikacije.

SIMATIC S7-200

RANIJE ............................................................................................… DANAS

SIMATIC S7-300

SIMATIC S7-400

S7-1500

FW 2.8

S7-1200

FW 4.4.

Modularni PLC sa

mnoštvom mogućnosti i

opcija za srednje zahtjevne

aplikacije.

Modularni PLC za

najzahtjevnije aplikacije i

procesnu industriju.

Discontinued

10/2017

PHASE

OUT

2023.

Logo! 8.3

Page 21

Unrestricted © Siemens 2020

May 2020Page 21

ET200M

ET200S

ET200MP

ET200SP

SIMATIC – pregled distribuirane periferije ET200

PHASE OUT

10/2020.

PHASE OUT

2023.

Page 22

HW inovacije

Page 23

Unrestricted © Siemens 2020

May 2020Page 23

Innovation Basic Controller SIMATIC S7-1200

New Firmware 4.4 – enhanced connectivity

NEW

Page 24

Unrestricted © Siemens 2020

May 2020Page 24

Companion

Specification

Browsing SubscriptionRead/Write

OPC UA

S7-1200 V4.4 - Functional scope

Asynchronous

data access

Information

modeling

Browsing of

CPU data

Load reduction for HMI /

monitoring applications

S7-1200 exceptions

in the 1st version

• No registered read/write

• No structured

data types and arrays

• No methods

• No alarms

and conditions

Client ClientClientClient

Server Server

DB

Server

DB

Server

Browse request

Browse response

R/W request

R/W response

Publishing

Sampling

Page 25

Unrestricted © Siemens 2020

May 2020Page 25

Hardware configuration

S7-1200 V4.4 – E-mail encryption with TMAIL_C – optionally

with attachment

Encrypted e-mail communication with TMAIL_C

via internal CPU interfaces

Requirements

• TIA Portal V16, CPU FW V4.4 and

TMAIL_C block version V6.0

Procedure

1. Import of certificate from the e-mail provider to the TIA

Portal

2. Programming with TMAIL_C and reference to imported

certificate (assignment of certificate to the CPU)

3. Program download with TMAIL_C and referenced

certificate for encrypted communication

4. Sending of an encrypted e-mail with fault/diagnostics

information to service staff/center; display on PC, tablet or

smart watch

5. Optional: Sending of data log, recipes or user files

1 Certificate import

3

2

4

4

Page 26

Unrestricted © Siemens 2020

May 2020Page 26

Hardware configuration

S7-1200 V4.4 – DNS name resolution for OUC

Open user communication

with DNS name resolution

• CPUs query IP addresses from one another on the DNS

server

• DNS server configuration in the CPU properties

Benefits

• Clear configuration thanks to name-based addressing

• No IP addresses needed for configuration of Open User

Communication

OUC independent of IP address

PLC 1

IP: 192.168.0.10

DNS: 192.168.0.1

PLC 2

IP: 146.254.222.212

DNS server

IP: 192.168.0.1

Entries

PLC2: 146.254.222.212

PLC1.local: 192.168.0.10

DNS query: PLC2

DNS answer: 146.254.222.212

Page 27

Unrestricted © Siemens 2020

May 2020Page 27

Hardware configuration

S7-1200 – DC signal modules with 16 digital outputs sinking

2 additional 16-channel DC output modules

sinking

Sourcing/PNP Sinking/NPN

SM 1222 DC DQ16xDC

6ES7222-1BH32-0XB0

SM 1222 DC DQ16xDC SINK

6ES7222-1BH32-1XB0

SM 1223 DC/DC DI 16xDC/

DQ 16xDC

6ES7223-1BL32-0XB0

SM 1223 DC/DC DI 16xDC/

DQ 16xDC SINK

6ES7223-1BL32-1XB0

New

Page 28

Unrestricted © Siemens 2020

May 2020Page 28

SIMATIC S7-1500

Page 29

Unrestricted © Siemens 2020

May 2020Page 29

System functions

New product features for SIMATIC S7-1500 and

ET 200 CPUs – Enhanced environmental conditions

Planning

• Adjustment in stages

• -25°C for CPUs

• I/O modules down to -30°C in some cases

Examples of possible applications

• Outdoor plants

• AGV (deep-freeze) cold storage facilities

• Tunnel construction

• Cranes

• Shipbuilding

• …

Additional benefits of SIPLUS versions

• -40°C to +70°C

• Condensation, 100% rel. humidity and icing allowed

• Higher resistance to harmful gases and salt mist

• Railway standards

Previous

standard

0°C

60 °C

SIPLUS Extreme

-40°C

70 °C

New

standard

1

-25°C

60 °C

1) Please observe the information in the manual with regard to condensation

Page 30

Unrestricted © Siemens 2020

May 2020Page 30

System functions

New features for the SIMATIC S7-1500 system and

ET 200SP CPUs – Enhanced environmental conditions

Extended installation altitude

• Adjustment in stages

• Permissible installation altitude depends on the

module

• Information about the possible installation altitude can

be found in the technical specifications

or in the system manual

2,000 m

2,000 m + x

Possible applications

• Cable railways

• Wind farms

• Automobile (e.g. Mexico)

• Surface mining (e.g. South America)

Benefits

Extended range of applications

Additional benefits of SIPLUS versions

• Portfolio largely released for 5,000 m

• Higher operational temperature at higher altitudes

Page 31

Unrestricted © Siemens 2020

May 2020Page 31

CPU 1515(F) and CPU 1516(F)

Hardware configuration

Improvement of the mechanical ruggedness

S7-1500 CPUs with new mechanical design

• The integration of the display into the CPU results in a

new mechanical design

• Installation dimensions remain identical

• Slight variation regarding connection placement of the

connectors

(PN connector 90° rotated, DP connector)

• RUN/STOP switch is replaced with RUN/STOP buttons

• No more "cancelling" of the RUN/STOP switch

• "STOP ACTIVE" indicates that the CPU was switched to STOP

via the STOP button

• Memory reset/Reset operation: Same as before

• Display can now be read – even when the cover is open

• Mechanical manipulation protection is retained

Spare part functionality

The CPUs are fully "spare part compatible" with previous versions

Page 32

Unrestricted © Siemens 2020

May 2020Page 32

Hardware configuration

S7-1500 based CPUs - IP-Forwarding

IP forwarding in PLC

• PLC can forward received IP frames to directly reachable

IP subnets. IP route table is automatically generated by

the IP configuration of the PLC interfaces

• Optional default IP route if

external IP routers are used

• Additional external router is not needed X

Area of application

• Simplified integration of devices for remote access,

e.g. for diagnostics for remote maintenance or firmware update

• Simple access from control to field level for configuration

and parameter assignment of devices, e.g. via PDM or

Web browser …

Restriction

Additional IP routes cannot be entered in the route table of the

PLC

New

New

Router + VLAN

Device 1

IP: 192.168.1.2/24

Router: 192.168.1.1

Device 2

IP: 192.168.2.2/24

Router: 192.168.2.1

Firewall

P

C

Router

IP: 10.10.0.1/24

X3:10.10.0.1

X2:192.168.2.1

X1:192.168.1.1

PLC – IP route table

Network target Interface

Gateway

0.0.0.0/0 X3: 10.10.0.10 10.10.0.1

192.168.1.0/24 X1:192.168.1.1 –

192.168.2.0/24 X2:192.168.2.1 –

10.10.0.0/24 X3:10.10.0.10 –

Page 33

Unrestricted © Siemens 2020

May 2020Page 33

SIMATIC S7-1500 based CPUs – Web server innovations

New JSON API

Function

• Web server with JSON RPC2.0 as new

"Web data interface" for access

to web server data such as

• Process values (tag values)

• Status and CPU diagnostics data (partly)

• CPU Web server response in JSON format

Advantages of the function

• Future basis for "state of the art" creation of user-defined web

pages

• JSON as web-capable data format for simple linking to web data

consumers, e.g. MES systems, SCADA systems

• JSON as a stable data format for accessing web server data, i.e.

no adjustment of web client code (e.g. JavaScript code) needed

after firmware update

• Spare part compatibility as the new web data interface can be used

in addition to the current options

Process data

System data

Web pages

File system

JSON

NEW

Page 34

Unrestricted © Siemens 2020

May 2020Page 34

SIMATIC ET 200MP – New Products

New products for more flexibility and better scalability

Feature / Function Benefit

AI 8xU/I/R/RTD BA

Cost-effective 8-channel analog input module for measuring

current, voltage, resistance and temperature

(25% less than for ST version)

• Connection of resistance thermometers via 3-wire

connection

• Toolless mounting of the shielding

• Optimized price-performance solution for

price-sensitive measurement applications

• Continuous scalability of the ET 200MP in

terms of cost, functionality and performance

• Time saving for mounting

CM 8xIO-LINK

8 Port IO-Link Master (V1.1)

• Up to 32 Byte In-/Output data per port

• Engineering with the S7-Port Configuration Tool or

directly in the TIA Portal („Autostart-function“)

• Master-Backup via TIA Portal function block

• Space saving in the control cabinet due to

the possibility to connect IO-Link devices

directly and centrally to the S7-1500

• Reduction of engineering and wiring effort

CM 8xIO-LINK

AI 8xU/I/R/RTD BA

Page 35

Unrestricted © Siemens 2020

May 2020Page 35

SIMATIC S7-1500 / ET 200MP – New products

New products & features for better availability and minimum

footprint

Feature / Function Benefit

New modules with high channel density

64-channel digital modules:

• DI 64x24VDC BA (p-/m-reading)

• DQ 64x24VDC/0.3A BA

• DQ 64x24VDC/0.3A SNK BA (m-switching)

• DI 32x24VDC/DQ 32x24VDC/0.3A SNK BA

16-channel analog modules:

• AI 16xU BA

• AI 16xI BA

• Optimized price-performance solution for

price-sensitive applications

• Minimum footprint due to highest possible

channel density

• Time saving for mounting through the tool-

free assembly of shielding and use of TOP

Connect

Active backplane bus / Hot Swapping

By using the active backplane bus for the ET 200MP, hot

swapping (module exchange at RUN of the PLC) is possible

even with multiple modules. Up to 12 S7-1500 / ET 200MP

modules can be plugged in per station.

Highest machine / system availability, since in

the event of failure and replacement of one or

more modules, the PLC and unaffected modules

remain in operation.

High channel modules

NEW

NEW

Active backplane bus

Page 36

Unrestricted © Siemens 2020

May 2020Page 36

SIMATIC Connectivity

TCP

Page 37

Unrestricted © Siemens 2020

May 2020Page 37

Infrastructure/

building

technology

Which networks can SIMATIC S7 communicate with?

Sensor/actuator level

Field level

Control

level

MQTT

OPC UA

Modbus TCP

PROFIBUS

OPC UA

AS-i

Master

SIMATIC S7

controller

IO-Link

Master

IE/Profibus Link

Modbus RTU

M-Bus

SIMATIC

PN/M-Bus LINK

SAE J1939

SIMATIC

PN/J1939 LINK

BACnet

SIMATIC

PN/

BACnet

LINK

DALI

ET 200SP

CM 1xDALI

PROFINET

*) MF: Multifunctionbus

Legend: Link Modules Coupler

Modbus TCP

PROFIBUS

PN/PN

PN/MF*

Sensors, actuators

CAN/-open

ET 200SP

CM CAN

CAN/-open

SIMATIC

PN/CAN LINK

Page 38

Unrestricted © Siemens 2020

May 2020Page 38

SIMATIC ET 200 MultiFieldbus Interfaces for

ET 200MP, ET 200SP, ET 200eco PN, Coupler

BenefitFeature / Function

Additional Information | PROFINET

Products

• ET 200MP IM: IM155-5MF ST

• ET 200SP IM: IM156-6MF HF

• ET 200eco PN “Next generation”*

• PN/MF Coupler

• Functions

• Support for PROFINET, EtherNET/IP and

Modbus TCP

• Simultaneous communication with all protocols

to modules of a station via the same cable (e.g.

Standard I/O via EIP, F-IO via PROFIsafe,

Energy Metering via MTCP)

• Engineering via MFCT Tool

• Support of Shared Device in MultiFieldbus

configurations

(Allocation of a station to several controllers)

• Savings in costs and planning effort when

designing machines/plants, since the same IO

configuration can be used independently of the

overarching controller

• High flexibility due to the possibility of access to

the ET 200 station / modules from several

controllers via shared device

PN/MF Coupler:

• Easy to configure deterministic data exchange,

even across network boundaries, between

SIMATIC and 3rdparty controllers

• Simple integration of SIMATIC controls into

existing machines / plants

Page 39

Unrestricted © Siemens 2020

May 2020Page 39

SIMATIC ET 200SP

innovations

Feature / Function Benefit

SIWAREX TM WP351

New ET 200SP module for fast, precise weighing processes

in confined spaces

(e.g. rotary fillers)

• Legal for trade according OIML R51, R61, R76 & R107

• Easy commissioning and service

via Webserver-Interface

• Cycle times < 1ms

Simple and cost-effective solution for

automated and calibrated weighing applications:

• Saves time during commissioning due to

the simple user interface of the web server

interface

• Saves space in the control cabinet thanks

to the small footprint of the ET 200SP

NEW

SIWAREX

TM WP351

Feature / Function Benefit

CM 1 x CAN

ET 200SP module for integrating CAN/CANopen* nodes into

the automation solution in confined spaces (e.g. for AGVsystems, eCar charging stations, …)

*Implementation acc. to specification "CiA 301"

• Compact and cost-effective solution for the

connection of CAN / CANopen devices

• Time savings in engineering thanks to

simple parameterization possibility in the TIA

Portal

• Saves space in the control cabinet thanks

to the small footprint of the ET 200SP

CM 1 x CAN

NEW

Page 40

Unrestricted © Siemens 2020

May 2020Page 40

SIMATIC ET 200SP for lighting control

Simple integration of lighting controls into the automation

system

Feature / Function Benefit

Upgrade CM PtP for DMX 512

Use of the ET 200SP CM PtP as master module for lighting

control with DMX 512 (Digital MultipleX 512)

• Typical applications: Stage and show lighting, large light

shows, …

Simple and cost-effective integration of

lighting controls into automation:

• Saves space in the control cabinet thanks

to the small footprint of the ET 200SP

• Time savings in engineering due to simple

parameterization and programming in the TIA

Portal

• Saves space and costs for additional control

units

• Scalability of the quantity structure due to

the possibility of inserting several modules per

station

CM 1 x DALI (Digital Addressable Lighting Interface)

ET 200SP DALI Multi-Master module for connecting one

DALI bus (per module) with up to 64 luminaires and 63

sensors

• Control of the connected devices via function blocks

• Integrated power supply up to 160 mA

• Typical applications: tunnels, hall lighting, shipbuilding,

etc.

CM 1 x DALI

NEW

CM PtP

Page 41

Unrestricted © Siemens 2020

May 2020Page 41

Efficient

engineering

Innovative

design

Reliable

diagnostics

Safety

Integrated

Technology

Integrated

Constistent

scalability

SIMATIC ET 200

Portfolio Overview

OUTDOORINDOOR

IP20

IP65/67

SIMATIC ET 200SP

SIMATIC ET 200MP

SIMATIC ET 200AL

SIMATIC ET 200pro

SIMATIC

ET 200eco PN

Ruggedness

Page 42

Unrestricted © Siemens 2020

May 2020Page 42

SIMATIC ET 200pro

Scalable control solutions directly at the machine

SIMATIC CPU 1513pro (F)

Feature / Function Benefit

• Two new SIMATIC CPU 1513pro

controllers in IP65/67 for mounting outside

the control cabinet

• Two (!) independent PROFINET interfaces

with 4 ports

• Programming interface RJ45

• Safety Integrated

• Integrated OPC UA Server/Client

• Integrated Webserver

• Station width up to 1,2m possible

• The performance and functionality of the

S7-1500 for mounting directly on the

machine

• Good price-performance solution

for small

to medium-sized applications

• Easy commissioning and high

transparency due to the possibility of direct

connection of a PG and the diagnostic option

of the web server

• Easy solution for safety requirements up

to SIL3 / PL e via centrally pluggable failsafe I/Os & motor starters

NEW

NEW

Up to 16 modules

max. 1,2 m

Page 43

Unrestricted © Siemens 2020

May 2020Page 43

SIMATIC ET 200eco PN

The next generation of rugged I/O in IP65/67

Feature / Function Benefit

6 new ET 200eco PN modules:

• DI 8X24VDC

• DI 16X24VDC

• DQ 8X24VDC/0,5A

• DQ 8X24VDC/2A

• DIQ 16X24VDC/0,5A/2A

• CM 8x IO-Link + DI 4x24VDC

New features:

• S2-Redundancy

• Shared Device

(Distribution of the outputs of a module to

several controllers)

• MSI / MSO

(Read access to inputs/outputs from up to

4 controllers)

• Clock sync. up to the channel

• High supply current up to 12A

• Single / Double assignment of channels

via parameterization

• Easier mounting & handling due to the

possibility of mounting the modules

directly on the machine outside the control

cabinet

• Less planning effort due to

standardization of the module width

• Cost savings in warehousing by

combining the module portfolio

• Greater machine/plant transparency

through MSI/MSO and detailed

diagnostics

• More flexibility through the

parameterizable channel assignment of

the ports

• Higher machine availability due to the

possibility to operate the modules also in

ring structures

M12, L-coded

(12A / module)

NEW

ET 200eco PN „Next Generation“

Page 44

Unrestricted © Siemens 2020

May 2020Page 44

SIMATIC S7-1500 R/H

TIA Portal

V16

Page 45

Unrestricted © Siemens 2020

May 2020Page 45

SIMATIC S7-1500 Redundant Systems

System overview

High available – S7-1500H

CPU 1517H

via Sync-Module

Yes, ~50 ms switchover time

Consistent concept –

Identical synchronization

process

Scaling of the switching

performance over the available

bandwidth of the

sync connection

CPU type

Synchronization

Hot Standby

I/O systems

Type of connection

Redundant – S7-1500R

CPU 1513R / CPU 1515R

via PROFINET Ring (MRP)

Yes, ~300 ms switchover time

ET 200SP and ET 200MP

Single connection (PN redundancy S2) and switched S1

1)

1) See slide Switched S1 Device

Page 46

Unrestricted © Siemens 2020

May 2020Page 46

SIMATIC S7-1500 Redundant Systems

PLC Hardware

CPU 1513R

-1 PN

6ES7513-1RL00-0AB0

CPU 1515R

-2 PN

6ES7515-2RM00-0AB0

CPU 1517H

-3 PN

6ES7517-3HP00-0AB0

Program /

memory

350 kB code

1,5 MB data

500 kB code

3 MB data

2 MB code

8 MB data

Interfaces

Firmware

V2.8 V2.8 V2.8

X1 X1 X1X2 X2 X3 X4

Short Distance

<= 10m

Long Distance

<= 10km

Fiber Optic Cable

Plastic Glass fiber

Sync module SFP

6ES7960-1CB00-0AA5 6ES7960-1FB00-0AA5

SFP = Small Form-factor Pluggable

X1: PROFINET IO Controller, Supports RT, MRP, Transport Protocol TCP/IP, Open User Communication

X2: PROFINET Basic Services, Transport Protocol TCP/IP, Open User Communication

Page 47

Unrestricted © Siemens 2020

May 2020Page 47

Primary Backup

ET 200SP

ET 200MP

RUN STOP

Primary Backup

ET 200SP

ET 200MP

RUN-Red RUN-Red

V15.1 V16

Benefits:

• No RUN/STOP handling of Backup PLC required

• No SyncUp Phase (with temporary loss of communication)

• User Program is synchronized automatically

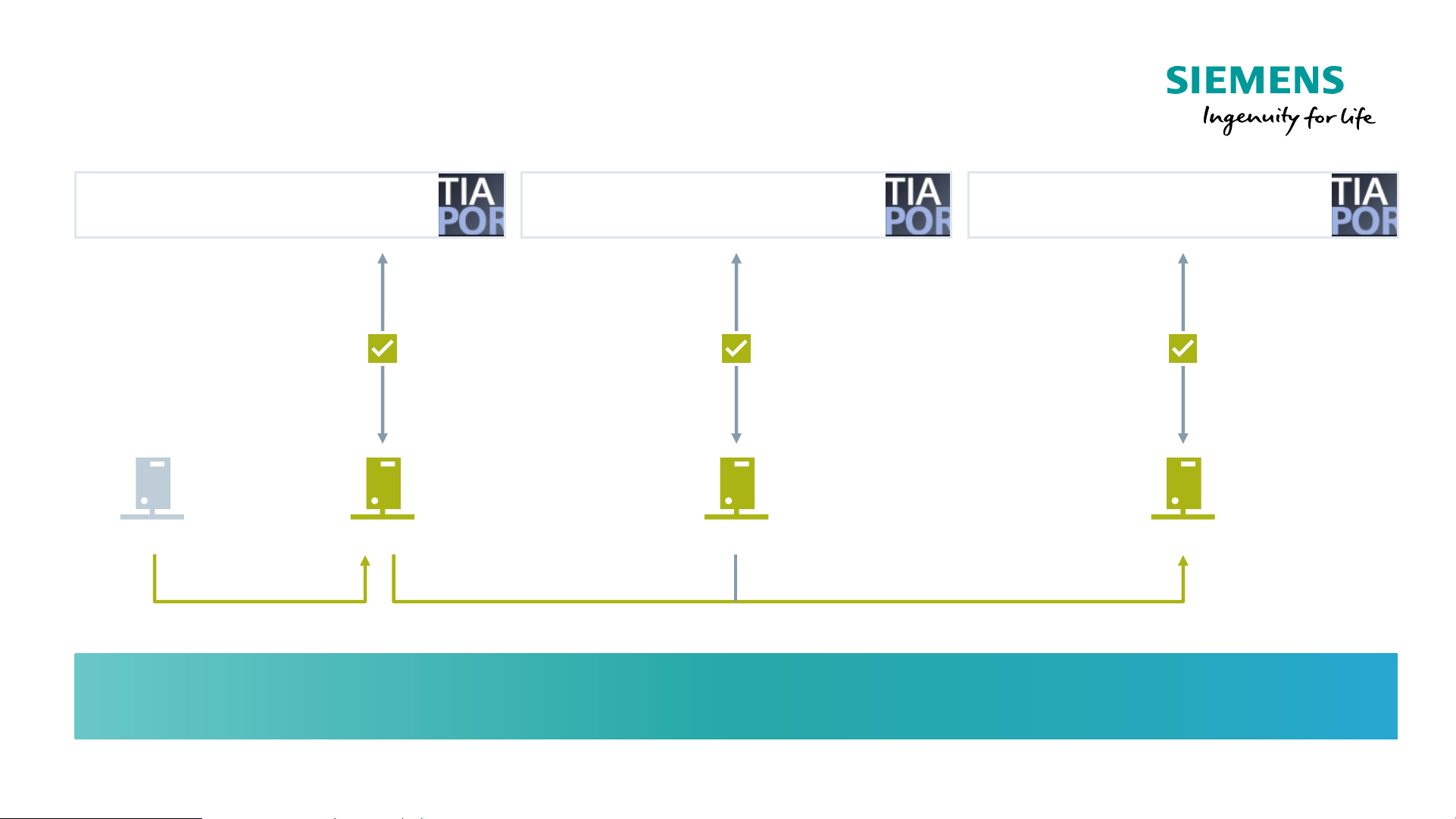

New in V16: Program Download in RUN-Redundant Mode

The Backup-PLC can remain in RUN redundant during download

Page 48

Unrestricted © Siemens 2020

May 2020Page 48

Primary Backup

ET 200SP

ET 200MP

ET 200SP

ET 200MP

S2-Devices

e.g. ET 200pro

e.g. G120D

S1-Devices

Primary

Backup

H-Sync

New

System Behavior when

Primary

-Backup switch occurs

S2

-Devices

(with System Redundancy)

S1

-Devices

(without System Redundancy)

Activation time of device

Very short (50ms +) because backup

communication relation is already established

Some seconds (depended on the device

itself) since device is restarted

Behavior of Outputs

Keeps last valid value during failover

If the device supports the function “Hold

last value”

→ no difference to S2

Otherwise: Outputs switches to “0” during

activation time.

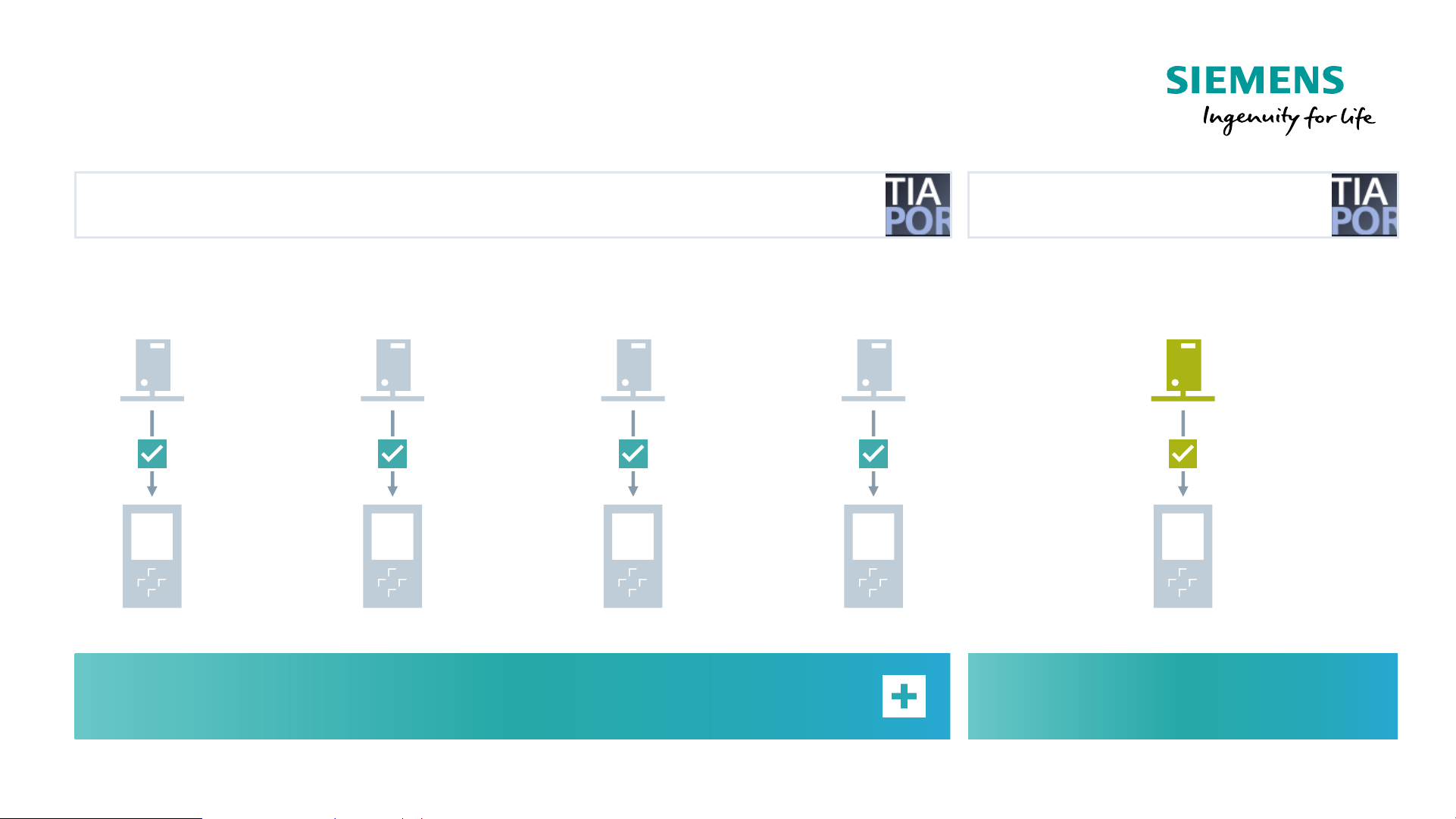

New in V16: Mode „Switched S1 Device“

Also devices without System Redundancy Feature (S1) can be

connected

Page 49

Unrestricted © Siemens 2020

May 2020Page 49

New in V16: Mode „Switched S1 Device“

Comparison with System Redundancy S2

Primary Backup

S2

Primary Backup

S1

Initial Situation

Primary AR

Backup AR

Single AR

Failover R/H

RUN Solo

S2

RUN Solo

S1

Backup AR

X

X

Connection established

RUN Solo

S1

X

X

Single AR

Time

Behavior with

System Redundancy S2

Two AR are established

AR = Application Relation

Only 1 AT to primary

PLC established

Backup AR takes over

S2 Device continues communication

AR to primary PLC gets lost

S1 Device without communication

New AR is created by RUN solo PLC to

S1 device

Behavior with

“Switched S1”

Page 50

Unrestricted © Siemens 2020

May 2020Page 50

Configuration example SIMATIC S7-1500H

CPU1517H

Panel

Switch

PN

PN

CPU 1517H

Primary

CPU 1517H

Backup

PN

MRP-RING

PN

Switch

PN

PN

PC Standard PLC

Panel

PN

PN

PN

PN

PN

PN

FO Sync.

S1S2

S2

S2

S1

S1

Page 51

Unrestricted © Siemens 2020

May 2020Page 51

Network Configuration with S7-1500 R/H

Basic System Configuration

Structure

MRP-Ring must be connected to the X1 - Port

Synchronization over PN-Ring – no device in this segment

S1 Devices should be connected via a switch to the ring

1)

S2 Devices can be integrated into the ring or also separated

with a switch

1

2

3

PNPN

PN

CPU 151xR

Primary

CPU 151xR

Backup

PN

1

2

3

MRP Ring

4

S1

Switch

S2

S2

4

1) Reason: S1 devices do not forward H-sync telegrams during a MRP reconfiguration phase. This would lead to a high PLC cycle time

in the case that segment is interrupted.

See chapter „H-Sync Forwarding“ in the system manual of S7-1500 R/H for details.

Page 52

Unrestricted © Siemens 2020

May 2020Page 52

PROFINET System Redundancy

PROFINET IO Network

S1 Device

S → Single interface

1 → one connection to one PLC

IM IO

PROFINET IO Network

IM IO

S2 Device

S → Single interface

2 → can switch between two connections

PROFINET IO Network

IM IOIM

R1 Device

R → Redundant interface

1 → each interface has one connection to

one PLC

Standard PLC + R/H For R/H PLC Future 1500H release

S1 Mode S2 Mode R1 Mode

PLC

Page 53

Unrestricted © Siemens 2020

May 2020Page 53

Engineered with TIA Portal

SIMATIC Drive Controller

Motion control, technology and

SIMATIC S7-1500 PLC in the drive

Page 54

Unrestricted © Siemens 2020

May 2020Page 54

SIMATIC Drive Controller

The attractive solution, optimized for production machines

Easy handling

▪ Easy scalability: powerful interfaces, uniform

across all performance classes

▪ Central data storage (one SIMATIC Memory

Card) for controller and drive

▪ Less wiring and installation costs

▪ Efficient engineering in the TIA portal with

SIMATIC STEP 7 and SINAMICS Startdrive

Optimized for production machines

▪ Powerful for demanding applications

▪ Well equipped with interfaces, technology I/Os

and memory

▪ Fail-safe CPU and drive-integrated safety

functions for personal and machine safety

▪ High-speed outputs for ultra-short output delay

times and highest switching accuracy, e.g. for

output cams

Ultra-Compact – Ideal for mechanical

engineering

▪ SIMATIC S7-1500 controller, SINAMICS S120

Control Unit and technology I/Os in one spacesaving device

▪ Small compact design

▪ 2 performance classes

▪ CPU 1504D TF

▪ CPU 1507D TF

▪ SINAMICS Integrated,

based on CU320-2

Technology I/Os

S120 Control Unit

S7-1500 TF-CPU

Page 55

Unrestricted © Siemens 2020

May 2020Page 55

8 DI/DQ (PLC I/Os)

→ DI, DQ, Timer DI, Timer DQ, …

(High-Speed outputs)

12 DI, 8 DI/DQ (DRIVE I/Os, usable by PLC)

→ DI, DQ, up to 8 measuring inputs

4 x DRIVE-CLiQ

PN1: PROFINET IO IRT (3 ports / MRPD)

PROFIBUS (Master)

PN2: PROFINET IO RT

PN3: PROFINET (1 Gbit)

Slot for SIMATIC Memory Card

2 x 3 LEDs (3 x PLC / 3 x Drive)

7 segment display (diagnostics)

Function key (diagnostics, …)

PLC switch (RUN / STOP / MRES)

Eyelet for access protection

2 x USB 3.0 (currently without function)

fanless

24 V supply

SIMATIC Drive Controller

HW setup

Page 56

Unrestricted © Siemens 2020

May 2020Page 56

for up to 6

servo drives

Control Unit

SINAMICS

S120 CU320-2

Infeed

Motor

Modules

SIMATIC Drive Controller

Topology

Motors with/without

DRIVE-CLiQinterface

DRIVE-CLiQ

SINAMICS

S120 CU320-2

for up to 6

servo drives

Terminal Modules

Sensor Modules

PROFINET

Industrial Ethernet

1)

Functional subset (no EPOS/DCC/…)

2)

No CX32-2 like SIMOTION D4x5-2

SINAMICS

S210

ET 200MP

ET 200SP

HMI

Controller

SIMATIC

Drive

Controller

A drive-based SIMATIC solution comprises the following components:

• SIMATIC Drive Controller (with integrated SINAMICS S120 drive control, based on CU320-2)

1)

• SINAMICS S120 components (infeed, motor modules, etc.)

• DRIVE-CLiQ communication, Terminal Modules, Sensor Modules, …

For more than 6 servo drives the drive quantity can be expanded,

e. g., via SINAMICS S120 CU320-2, SINAMICS S210, …

2)

Page 57

Unrestricted © Siemens 2020

May 2020Page 57

SIMATIC Drive Controller

CPU Portfolio will be enlarged by the SIMATIC Drive Controller

1 50 MB add. for C/C++ (PLC-RT)+500 MB for C/C++ appl. (RT/appl.) 2 At 4 msServo/IPO cycle time and 35 % CPU load due to Motion Control 3 No further TO´s applicable

4 Resources for Motion Control technology objects: Speed axis = 40 | Positioning axis = 80 | Synchr. Axis = 160 | Output cam= 20 | Output cam track= 160 | Measuring input= 40

5 Resources for Extended Motion Control technology objects: Cams = 2 | Kinematic objects= 30 | Leading axis proxy = 3

Technology CPU Standard

CPU

Open

Controller

Drive Controller CPU

CPU types

1511TF-1PN1515TF-2 PN1516TF-3

PN/DP

1517TF-3

PN/DP

1518F-4

PN/DP (MFP)

1

1515SP PC2

TF PN

1504D TF 1507D TF

Interfaces

Program memory

Data memory

225/225 KB

1 MB

750/750 KB

3 MB

1,5/1,5 MB

5 MB

3/3 MB

8 MB

4/6 MB

20 MB

1

1/1,5 MB

5 MB

2 MB

4 MB

6 MB

20 MB

Bit performance

60 ns 30 ns 10 ns 2 ns 1 ns 10 ns

Scale with motion control performance

Functions

Display, S7-1500 backplane bus SINAMICS S120 Integrated (incl. 12 DI, 8 DI/DQ)

additional PLC technology I/Os (8 DI/DQ)

Positioning axes

▪ Typical

2

▪ Maximum

3

5

10

7

30

55

80

70

128

128

128

30

30

10

30

55

160

Motion Control Resources

4

800 2.400 6.400 10.240 10.240 2.400

2.400 12.800

Extended Motion Control

Resources

5

40 120 192 256 − 120

120 420

PROFINET IO with IRT PROFINET IO with RT PROFINET basic communication (1 Gbit) PROFIBUS

1 2 3

1

1

112 112 112 111

2 3

111

2 3

NEW

112

3

1

1

Page 58

Logo!8

Page 59

Unrestricted © Siemens 2020

May 2020Page 59

LOGO!8.0

• Brži procesor, udvostručenje broja programskih

blokova

• Umrežavanje s drugom SIMATIC opremom

• Novi displej sa 6 redaka po 16 znakova i

3-bojnim pozadinskim osvjetljenjem

• GSM komunikacijski modul

V8.1 & V8.2

• KNX modul za automatizaciju u zgradarstvu

• Podrška za Modbus TCP

• Custom web stranica na integriranom serveru

• LOGO! Web Editor za izradu web stranica.

• Logo Access program za prebacivanje podataka

iz LOGO! Modula u MS office aplikacije.

LOGO!8

„Malen, ali moćan”

Page 60

Unrestricted © Siemens 2020

May 2020Page 60

Innovation LOGO!8.3

IoT and cloud connectivity for everyone

Feature / Function Benefit

Cloud

• Use of LOGO! WebEditor V2.0 project for

cloud data visualization

• Upload LOGO! WebEditor V2.0 into cloud

• Adding additional cloud services

(e.g. alarming)

Usability

• Easy configuration in LOGO! SoftComfort

V8.3

• Security integrated

• LOGO! Web Editor well known by users

Hardware

• Cloud communication and configuration

part of LOGO! Soft Comfort V8.3

integrated in any LOGO! 8.3 base module

• Create/modify visualization every where

and any time

• Flexible user management in the cloud

• Added values and new business models

through additional cloud services

• Secure communication

• Visualization by using the existing LOGO!

WebEditor knowledge

• LOGO! goes IoT with familiar usability

NEW

07/2020

Page 61

Unrestricted © Siemens 2020

May 2020Page 61

Adrian Lucić

Mob: +385 91 6105 128

adrian.lucic@siemens.com

Siemens d.d.

Heinzelova 70a

10000 Zagreb, Hrvatska

Subject to changes and errors. The information given in this document only contains general descriptions and/or performance features which may

not always specifically reflect those described, or which may undergo modification in the course of further development of the products. The

requested performance features are binding only when they are expressly agreed upon in the concluded contract.

All product designations, product names, etc. may contain trademarks or other rights of Siemens AG, its affiliated companies or third parties.

Their unauthorized use may infringe the rights of the respective owner.

Page 62

Unrestricted © Siemens 2020

May 2020Page 62

SIMATIC Controller

Get more Information…

Always up-to-date!

• interesting news from and about AS,

such as product innovations, success

news, best practice information etc.

Newsletter

https://sie.ag/2WMmRCj

Detailed product information and related

subjects!

• Product Websites

• Twitter, Youtube..

Internet

http://www.siemens.com/S7-1200

References Center

From customer to customer!

• Customers gives account to there

experiences using our Products for

their applications

Getting Started

www.siemens.com/automation-tasks

Easy Introduction to the new SIMATIC

controller generation!

• Learn about the new possibilities

and get to know the new

Hardware

even better

https://webservices.siemens.com/referen

zen/#language=en

SIMATIC S7-1200

Page 63

Unrestricted © Siemens 2020

May 2020Page 63

TIA Portal V16

Zanimljivi linkovi

• Digital Training with Highlights of TIA Portal V16

https://support.industry.siemens.com/cs/document/109772991/sitrain%3A-digital-training-with-highlights-of-tia-portalv16?dti=0&lc=en-WW

• TIA Portal Tutorial Centar

https://cache.industry.siemens.com/dl/dl-media/707/106656707/att_961750/v9/106656707_TIA_Portal_-

_Tutorial_Center_web/start.htm#!/en

• Automation Tasks in 10 minutes

https://cache.industry.siemens.com/dl/dlmedia/570/109767570/att_986452/v1/109476605_Automation_Tasks_web/start.htm#!/de

• Basic Process Library

https://support.industry.siemens.com/cs/ww/de/view/109749508

Loading...

Loading...