Page 1

Siemens - Electrogeräte GmbH

Carl-Wery-Straß e 34

81739 München

Cod. 9000432107 A

This cooktop is for use with Natural Gas and propane gas

ER926SB90A

ER626PB90A

ER326AB90A

ER326BB90A

Page 2

Content

Safety considerations . . . . . . . . . . . . . . . . 5

For your safety . . . . . . . . . . . . . . . . . . . . . . . 5

What to do if you smell gas . . . . . . . . . . . . . . 5

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . 8

Statutory requirements . . . . . . . . . . . . . . . . . . 8

Preparing to install . . . . . . . . . . . . . . . . . . . . . . . 8

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation of cooktop into the kitchen bench . 11

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Conversion from Nat. Gas to Propane Gas . . . 14

To change injectors . . . . . . . . . . . . . . . . . . . . 14

Changing the nozzles of the large, medium

and small buners on the cooktop

Changing double-flame burner tips. . . . . . . . . 15

Changing the outer flame nozzle . . . . . . . . . 16

Changing the inner flame nozzle . . . . . . . . . 17

Adjustment of the taps . . . . . . . . . . . . . . . . . 17

Operating instructions. . . . . . . . . . . . . . . . 17

Burner locations . . . . . . . . . . . . . . . . . . . . . . . . 19

The gas burners. Operation . . . . . . . . . . . . . . . 19

Switching on automatically . . . . . . . . . . . . . . . 20

Safety system . . . . . . . . . . . . . . . . . . . . . . . . . 21

Switching off a burner . . . . . . . . . . . . . . . . . . . 21

Power levels . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Suitable pans . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Additional wok pan support . . . . . . . . . . . . . . 23

Additional coffee maker support. . . . . . . . . . . 23

Cooking recommendation . . . . . . . . . . . . . . . . 24

Precautions for use. . . . . . . . . . . . . . . . . . . . . . 25

Cleaning and maintenance . . . . . . . . . . . . . . 26

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Unsuitable products . . . . . . . . . . . . . . . . . . 26

Maintenance . . . . . . . . . . . . . . . . . . . . . . . 26

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . 15

3

Page 3

Dear customer,

Congratulations on your choice and thank you for purchasing one of our appliances. This

practical, modern and functional appliance is manufactured using materials of the highest

quality which are subject to strict quality control checks throughout the entire manufacturing

process. The appliance is meticulously tested to ensure that it meets your demands and

produces perfect cooking results.

Do not remove the appliance from its protective packaging until it is installed in the unit.

Please read these instructions carefully before proceeding to install and use the appliance.

The information contained in these instructions is essential for the correct operation of the

appliance and, more importantly, for your safety.

The packaging of your appliance has been manufactured using only the materials which are

strictly necessary to guarantee efficient protection during transport.

These materials are 100% recyclable, thus reducing the environmental impact. You can also

contribute to caring for the environment, by following the advice below:

- dispose of the packaging in the appropriate recycling bin

- before you get rid of an old appliance, make sure you disable it. Contact your local authority

to find out the address of your nearest recycling centre to dispose of your appliance

- do not pour used oil down the sink. Collect it in a sealed container and take it to an

appropriate collection point or, failing that, place it in the rubbish bin (it will end up in a

controlled dump; this is probably not the best option, but it will avoid contaminating ground

water)

IMPORTANT:

In the unlikely event that the appliance should be damaged or not meet your expectations

in terms of quality, please inform us as soon as possible. For the warranty to be valid, the

appliance must not have been tampered with, or used inappropriately.

4

Page 4

Safety considerations

For your safety

What to do if you

smell gas

Warnings

If the information in this manual is not followed exactly, a

fire or explosion may result causing property damage,

personal injury or death.

Do not store articles on or against this appliance.

Do not store flammable material near this appliance.

Do not spray aerosols in the vicinity of this appliance

while it is in operation.

Do not try to light the appliance.

Do not touch any electrical switch; do not use any phone

in your building.

Inmediately call your gas supplier from a neighbour’s

phone. Follow the gas supplier’s instructions.

If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by an

authorised person.

Do not allow the flame to extend beyond the edge of the

cooking utensil. This instruction is based on safety

considerations.

Do not forget that the unit becomes hot when in use.

Common sense is important. Just because the flame is

out, does not mean parts cannot still be hot.

This appliance shall not be used for space heating. This

instruction is based on safety considerations.

Be sure to disconnect the electrical supply before

disassembly of the appliance.

Keep the appliance area clear and free from combustible

materials, gasoline and other flammable vapours and

liquids.

This appliance must be installed in a position with the

proper level of ventilation. Do not obstruct the flow of

combustion and ventilation air.

Cabinets installed above the gas cooktop must have a

minimum clearance of 650 mm (24”).

The gas pressure regulator supplied with the appliance

must be installed in line with the gas pipe. (N.G. only).

5

Page 5

For pressure testing in excess of 3.5 kPa (1/2 psig) the

appliance and its individual shutoff valve must be

disconnected from the gas supply piping system.

Important. When using a very large pot, leave a gap of at

least 50 mm (2”) to avoid damaging any parts in bench

top wood, plastic or other non-heat resistant materials.

Never leave oil or hot fat unattended.

The surfaces on heating and cooking appliances get hot

when in use. Be careful. Keep children away from the

appliance.

Only use your appliance for the preparation of food and

never for room-heating purposes.

This appliance leaves the factory set for the gas supply

indicated on the data label. Call the Service Centre if it

needs to be altered.

Do not tamper inside the appliance. If necessary, call

your local Service Centre.

Overheated fat or oil can easily catch fire. Never leave the

appliance unattended when cooking food with fat or oil,

e.g. chips.

Never pour water on burning fat or oil. DANGER OF

BURNS! Cover the receptacle to smother the flames and

turn the cooktop off.

In the event of a fault, cut the gas and electricity supplies

to the appliance. Call our Service Centre to repair the

fault.

Do not use unstable or uneven-based receptacles on

cooking plates or burners. They may accidentally tip over.

If a gas supply knob/valve jams, do not force it. Call your

official Service Centre immediately for them to repair or

replace it.

The illustrations used in this booklet are only intended as

a guide.

If your cooktop is supplied with a glass cover, do not

subject it to excessive force. If the glass should become

detached from the cooktop, call the Service Centre

immediately for them to repair or replace it.

While using your gas should avoid draughts and

spillages of cold liquids. As these may cause the glass to

break.

Grids become very hot during use. When operating the

appliance control knobs, take care not to make contact

with the grids.

Do not use this appliance neither in marine craft nor in

caravans.

6

Page 6

Important: Do not cover up the slots at the rear of the

cooktop and observe the minimum insertion gap.

DANGER, COMBUSTION MAY BE AFFECTED.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction

concerning use of the appliance by a person responsible

for their safety.

Make sure you keep these instructions for use and

assembly in a safe place, so that you can hand them on

with the appliance if it ever changes owner.

Note: To avoid jeopardising the electrical safety of the

appliance, it is forbidden to use high-pressure or steam

jet cleaning devices.

SHOULD THE RELEVANT CONDITIONS NOT BE

PROPERLY SATISFIED, THE INSTALLER, AND NOT THE

MANUFACTURER, SHALL HELD LIABLE.

7

Page 7

Installation

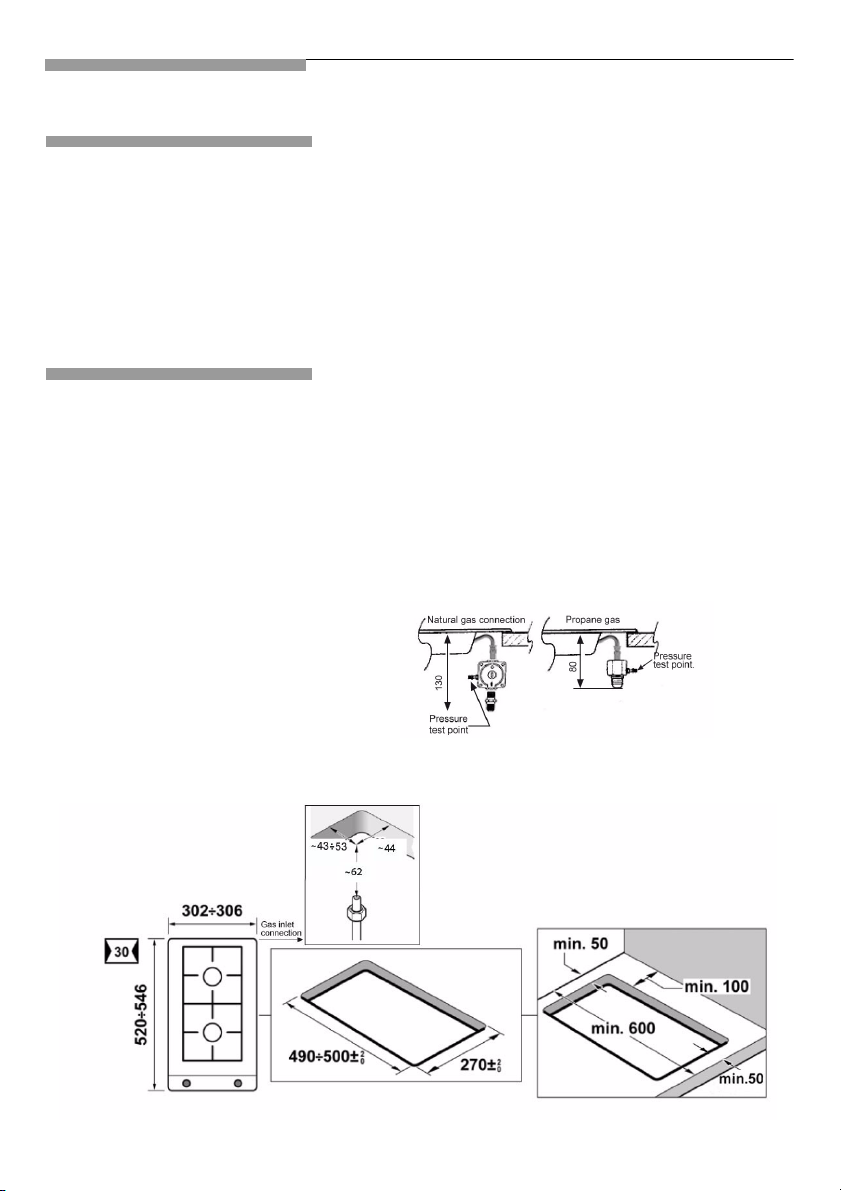

Fig. 1a

Statutory

requirements

Preparing to install

This installation must conform with the following:

Ø Manufacturer’s Installation instructions

Ø Local Gas Fitting Regulations

Ø Municipal Building Codes,

Ø Refer to AS/NZS 5601.1 for Gas Installations.

Ø S.A.A. Wiring Code

Ø Local Electrical Regulations

Ø Any other statutory regulations

Refer to AS/NZS 5601.1 for piping size details. These

built-in cooktops are intended to be inserted in a

benchtop cutout.

Do not stick the cooktop onto the worktop with silicone.

Only an officially authorised technician should connect

the appliance.

Before you begin, turn off the gas and electricity supply.

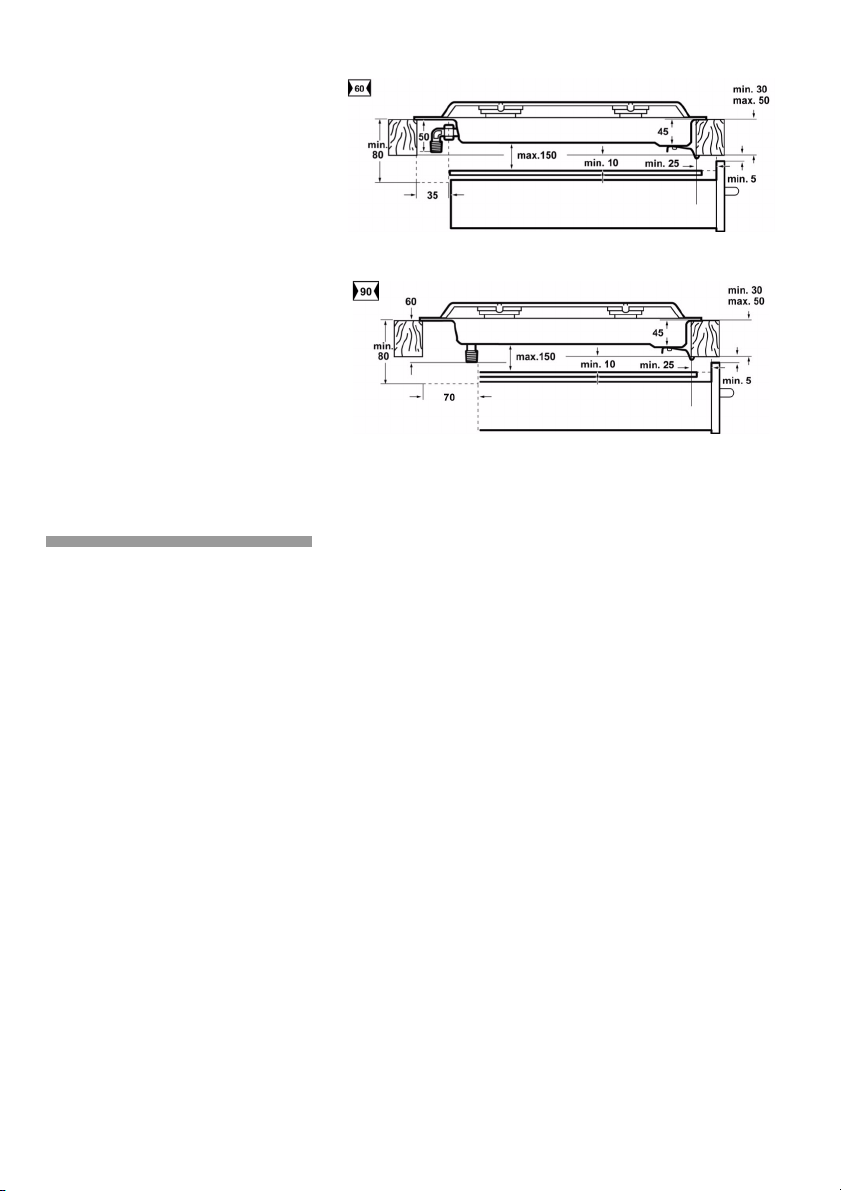

Installation dimensions are shown in Fig.1a/1b/1c.

8

Page 8

Fig. 1b

Fig. 1c

Before connecting the unit, check whether the local

9

Page 9

connection conditions (type of gas) are compatible with

Fig. 2a

the unit’s setting. Observe any special conditions

imposed by local suppliers (utilities). The specifications

of this cooktop are stated on the data label located on the

bottom of the cooktop base.

A duplicate data label is supplied for adhesion to an

accessible location near the hotplate if the data label on

the base of the hotplate cannot be accessed when the

hotplate is installed.

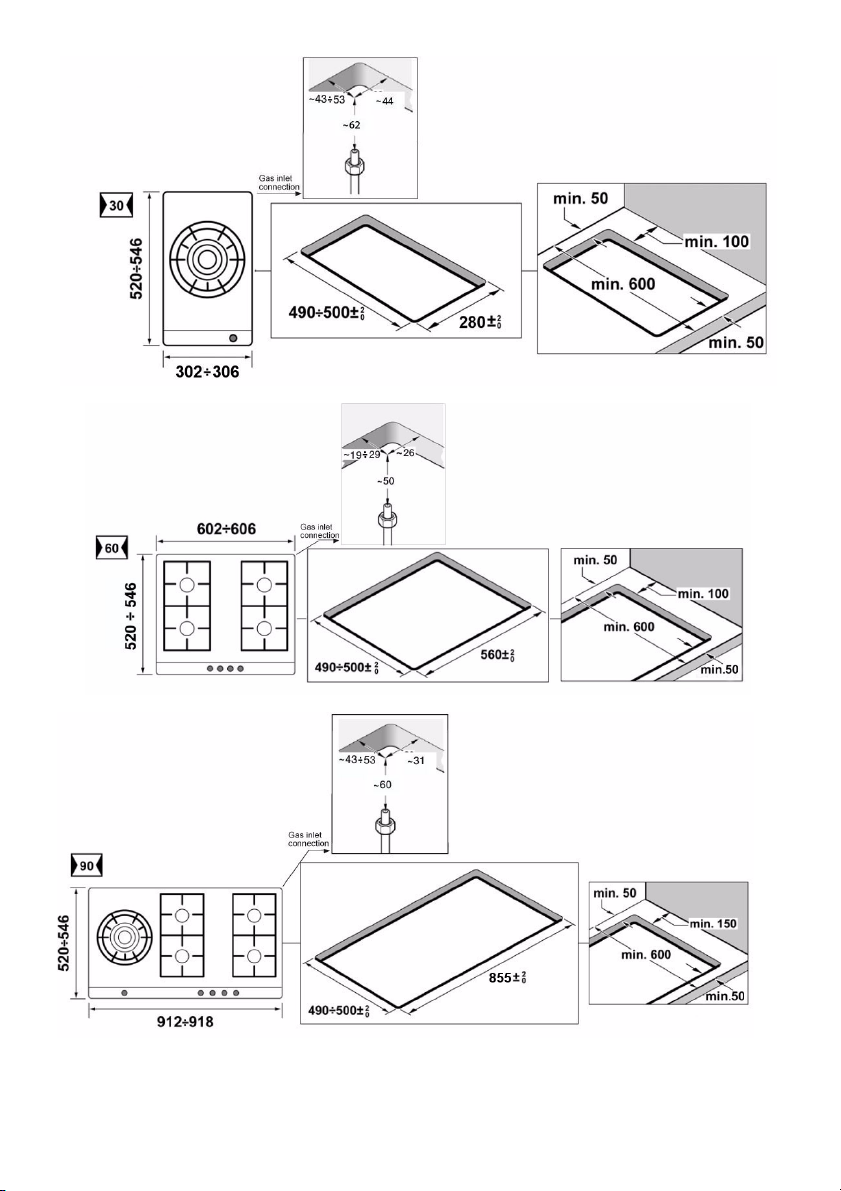

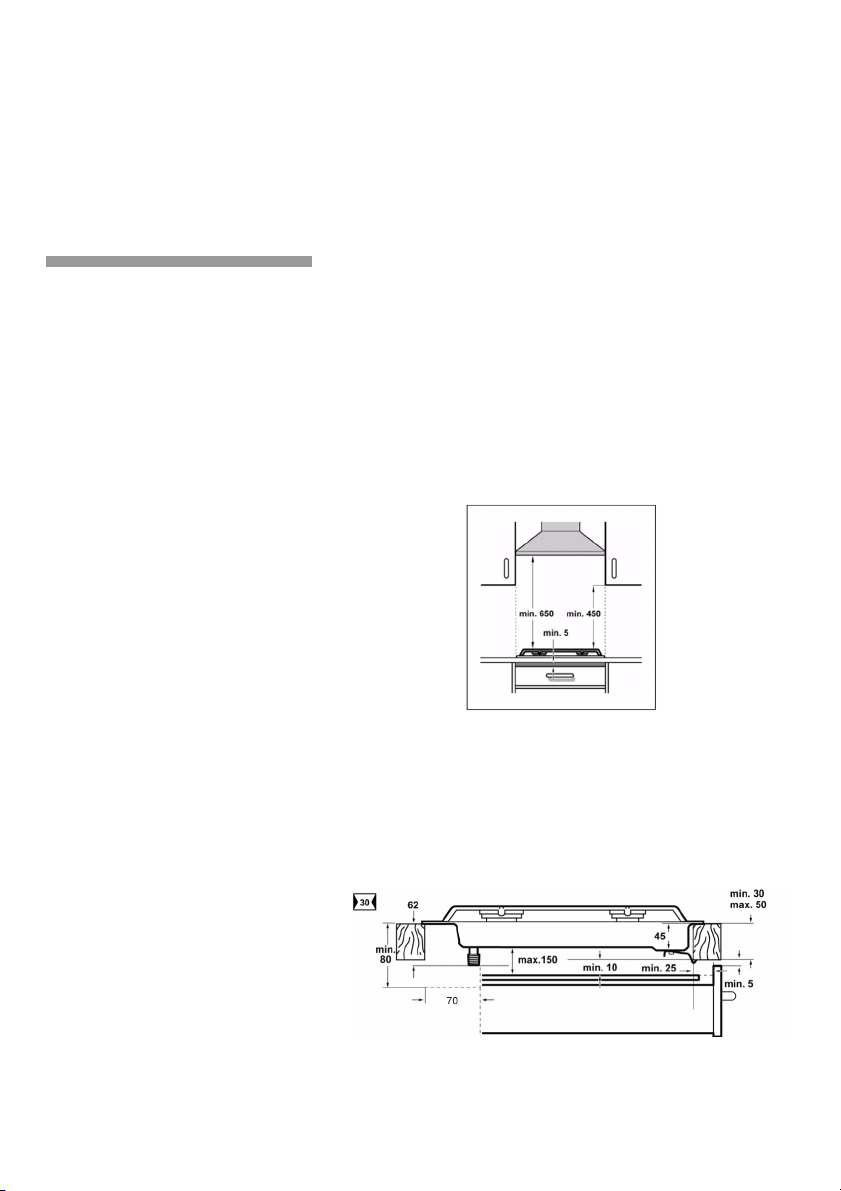

Clearances

A range hood fitted above the top must be installed

according to the installation instructions for the range

hood. A minimum distance of 650 mm is required for a

range hood and 750 mm for an exhaust fan.

Any adjoining wall surface situated within 200 mm from

the edge of any hob burner must be a suitable noncombustible material for a height of 150 mm for the

entire length of the hob. Any combustible construction

above the hotplate must be at least 650 mm above the

top of the burner and no construction shall be within

450 mm above the top of the burner.

A minimum depth of 50 mm from the top of the worktop

surface must be provided for the appliance.

If the base of the hotplate can be touched, a protecting

shield must be fitted. This shield must be at least 10 mm

from the lo we st part of t he hotplate a nd must be cap able

of withstanding the appliance temperatures. Minimum

thickness of benchtop is 30 mm. See Fig. 2a/2b/2c.

10

Page 10

If an oven is positioned below the cooktop the barrier

Fig. 2b

Fig. 2c

does not need to be fitted, but a space of 35 mm must

be maintained between the underside of the cooktop and

the top of the oven.

Installation of cooktop

into the kitchen bench

Installation procedure:

Side clearances: If the distance measured from the

periphery of the nearest burner to any vertical surface is

less than 200 mm, the surface shall be protected in

accordance with clauses 6.10.1.2 of AS/NZS 5601.1

1. For cutout dimensions and clearances refer Fig.1.

2. The clips and the adhesive seal (underside of the

cooktop) are factory-fitted: do not under any

circumstances remove them. The seal ensures that the

entire work surface will be watertight, and prevents water

seepage. In order to fit the appliance into the kitchen unit,

first place the cooktop in the correct position then loosen

each of the clips so that they all turn freely (it is not

necessary to completely undo them).

Insert and centre the cooktop.

Press the sides of the cooktop until it is supported around

its entire perimeter.

11

Page 11

Turn the clips and tighten them fully. Fig. 3a.

Fig. 3a

Fig. 4

Connection

Electrical An electrical 10 amp socket needs to be within 1 m of the

hotplate to allow electrical connection. The socket must

remain accessible after installation of the appliance.

Important note:

This appliance is connected to the mains (240 VAC) by

means of the connecting lead which must be fixed to the

kitc he n unit to p reve nt i t fro m c o ming in t o con ta c t wit h h o t

parts of the cooktop (or an oven installed underneath)

and remain accessible after installation of the cooktop.

When making this connection make sure that the lead

cannot come into contact with hot parts of the cooktop.

Important: This appliance must be earthed. When

connecting the cooktop ensure that the earth wire is

connected first and that all wires are connected to the

correct terminals. Fig. 4.

Gas

12

During the planning stage, consider the position of supply

connections.

The cooktop must be connected to the gas supply with

upstream connection of an isolation valve in accordance

with the respectively valid regulations. We recommend

that the isolation valve be fitted prior to the cooktop to

enable isolation of cooktop from gas supply. The valve

must be easily accessible at all times.

Page 12

To find out the factory set gas type, see bottom of

Fig. 5 Fig. 6

cooktop next to gas connection.

Remove plastic cap from gas supply line prior to

installation.

Fit regulator (N.G.) or a test point (Propane gas) directly

to the R 1/2’’ connection as per Fig. 5. and Fig. 6.

Direction of gas flow is indicated on the rear of the

regulator.

For position of the inlet connection refer Fig.1.

Use pipe compound or thread sealant, properly theaded

pipes and careful assembly procedure so that there is no

cross threading, etc., which might cause damage or

leakage.

Make sure that all connections peformed are free of

leakage.

The manufacturer does not accept any liability for

leakage on connections performed by the installer or if

the L-tube is moved or twisted.

There are two ways to carry out the connection to the

main gas line:

A. The hotplate can be connected with rigid pipe as

specified in AS/NZS 5601.1

B. Flexible Hose: If installing with a hose assembly, install

with a hose assembly that complies with AS/NZS 1869

(AGA Approved), 10 mm ID, class Bor D, no more than

1,2 m long and in accordance with AS/NZS 5601.1.

Ensure that the hose does not contact the hot surfaces of

the hotplate, oven, dishwasher or any other appliance

that may be installed underneath or next to the hotplate.

The hose should not be subjected to abrasion, kinking or

permanent deformation and should be able to be

inspected along its entire length with the cooktop in the

installed position. Unions compatible with the hose

fittings must be used and all connections tested for gas

leaks.

The supply connection point shall be accessible with the

appliance installed.

13

Page 13

WARNING: Ensure that the hose assembly is restrained

from accidental contact with the flue outlet of an

underbench oven.

Before Leaving- Check all connections for gas leaks with

soap and water. DO NOT use a naked flame for detecting

leaks. Ignite all burners both individually and concurrently

to ensure correct operation of gas valves, burners and

ignition. Turn gas taps to low flame position and observe

stability of the flame for each burner individually and all

together. Adhere the duplicate data plate to an

accessible location near the hotplate. When satisfied with

the hotplate, please instruct the user on the correct

method of operation. In case the appliance fails to

operate correctly after all checks have been carried out,

refer to the authorised service provider in your area.

It should be expressly noted that we cannot accept any

liability for direct or indirect damage caused by wrong

connection, leakage or improper installation. When being

repaired, the appliance must always be disconnected

from the mains supply; if required, notify our customer

service.

Converting the

cooktop from Nat.

Gas to Propane Gas

To change injectors All work involved in installation, setting and adaptation to

a different gas type must be carried out by authorised

personnel from our Service Centre and must comply with

current regulations and the conditions laid down by the

local gas company.

Request change-over injectors from our customer service

deparment (refer injector chart below for sizes).

Natural Gas Propane Gas

Burner Hourly Gas

Small 4,80 97 3,50 53

Medium 8,10 130 6,00 70

Large 11,60 157 8,50 83

wok (inner)

wok (outer) 215 115

distanze

“Z’’

Consumption

(MJ)

22,00

Injector

mark

65

11 12

Hourly Gas

Consumption

(MJ)

20

Injector

mark

(mm)

47

14

Before conversion the cooktop must be disconnected

from the electricity and gas valves must be turned to the

OFF position.

Page 14

Changing the nozzles

Fig. 7

Fig. 8

Fig. 9bFig. 9a Fig. 9c

Fig. 10

of the large, medium

and small burners on

the cooktop

- Remove the pan supports, burner covers and

diffusers.Fig. 7

- Change the nozzles using the spanner provided by our

Service Centre (code 424699), taking special care to

ensure that the nozzle does not fall when it is removed

from the burner or when fitted. Fig. 8.

Ensure that it is completely tightened in order to

guarantee the seal. Primary air adjustment is not

necessary with these burners.

Note: it is not necessary to adjust the primary air control

on these burners.

Changing doubleflame burner tips

The glass panel and frame are fixed to the rest of the

cooktop using a clip mounting system. The following

steps must be taken to remove the glass panel and

frame:

- Remove all the burner covers and pan supports. Fig. 9a.

- Release the front clip fixing the appliance to the kitchen

unit by removing the screw. Fig. 9b.

- Loosen the screws on the burners, Fig. 9c, and remove

the control knobs from their respective housings.

Use the disassembly lever 483196 available from our

Service Centre. To release the front clips, apply the lever

in the area shown in figures 10 according to the cooktop

model.

15

Page 15

Never use the lever on glass edges which have no trim or

Fig. 10a

Fig. 11

frame!

- To release the rear clips, carefully raise the entire glass

panel and frame, as in Fig.10a.

Changing the outer flame nozzle (Fig. 11)

- Loosen the clamp screw to release the bushing by

moving it backwards to access the main nozzle easily.

Fig. a1.

- Remove the outer flame nozzle by turning it towards the

left. Fig. a2-a3.

- Screw in the new outer flame nozzle. Fig. a3-a4.

- Adjust the distance of the airflow adjusting bushing L2

according to the value -Z-. Fig. a5.

- Tighten the clamp screw. Fig. a6.

16

Page 16

Changing the inner flame

Fig. 12

Fig. 13

nozzle (fig. 12)

- Unscrew the part M3 from the threaded part M2; to do

this, hold the threaded part in the opposite direction.

- Remove the pipe from the part M2. Fig. b2.

- Disassemble the assembly of parts M2 and M4 from

part M1. Fig. b3-b4.

- Remove the inner flame nozzle M4 from part M2.

Fig. b5-b6.

- Screw in the new inner flame nozzle M4. Fig. b6-b7.

Adjustment of the

taps

Refit all the components, proceeding in the reverse order to

removal.

Set the control knobs to minimum.

Remove the control knobs from the taps. Fig. 13.

It has a flexible rubber valve reinforcing ring. Simply press

on this seal with the tip of a screwdriver to allow access

to the tap adjusting screw.

17

Page 17

Never remove the valve reinforcing ring.

Fig. 14

If the by-pass screw cannot be accessed, disassemble

the glass panel and frame described in: Changing the

nozzles for double-flame burners. Fig. 9.

Adjust the minimum ring setting by turning the by-pass

screw using a flat head screwdriver.

To adjust the minimum flame for N.G. replace the control

knob onto the spindle, light the gas and turn the control

knob to the small flame position. Screw the adjustment

screw anti-clockwise to estabilish a minimum stable

flame position. The flame should remain alight and not

burn back to the injector when the valve is turned

quickcly from ‘Full On’ to the “Minimum flame” position

and back a few times. To adjust the minimum flame

position for ULPG the screw must be fully tightened down

clockwise.

Refit the control knobs.

Never remove the tap spindle. In the event of a

malfunction, change the whole tap.Fig. 14.

Warning! After finishing, the sticker indicating the new type

of gas must be placed close to the specifications plate.

18

Page 18

Operating instructions

Control knob

Pan support

Burner (up

to 1.9 kW)

Burner (up

to 2.8 kW)

Control knob

Double flame

burner (up to

6kW)

Pan

support

Pan support

Burner (up

to 1.9 kW)

Burner (up

to 1.1 kW)

Control knob

Burner (up

to 2.8 kW)

Burner (up

to 1.9 kW)

Pan support

Burner (up

to 2.8 kW)

Control knob

Burner (up

to 1.1 kW)

Burner (up

to 1.9 kW)

Burner (up

to 1.9 kW)

Double flame burner

(up to 6 kW)

Burner locations

The gas burners

Operation

There are indications to show which burner each control

knob operates. Fig. 15.

It is essential to ensure that all the burner parts and pan

supports are correctly installed for the appliance to work

correctly. Fig.16-17-18-19-20-21.

19

Page 19

Fig. 15 Fig. 16

Fig. 17

Fig. 18

Fig. 19

Fig. 20

Fig. 21

Switching on automatically

20

If your cooktop can be switched on automatically (ignition

sparkers):

1. Press the chosen burner control knob and turn it

anticlockwise to the maximum power setting.

While the control knob is still pressed down, sparks are

produced on all burners. The flame ignites (it is no longer

necessary to press down the control knob).

2. Turn the control knob to the required setting.

If it does not come on, turn the control knob to the off

setting and repeat the steps above. This time, press and

hold the control knob for longer (up to 10 seconds).

Warning! If after 15 seconds the flame does not ignite,

switch off the burner and open a nearby window or door.

Wait at least one minute before trying to switch the burner

on.

Page 20

Safety system Depending on the model, your cooktop may have a

Thermocouple

Ignition sparker

Fig. 22

safety system (thermocouple) that prevents the flow of

gas if the burners accidentally switch off. To ensure that

this device is active, switch on the burner as usual and,

without releasing the control knob, press and hold it

down firmly for 4 seconds after lighting the flame. Fig. 22.

Switching off a burner Turn the corresponding control knob clockwise to the 0

setting.

Power levels The progressive control knobs can be used to control the

power needed, from minimum to maximum power.

Setting

Large flame

Economy

flame

For double-flame burners, the inner and outer flames

can be controlled separately.

The available power levels are as follows:

Ú

™

š

Control off

Maximum capacity

or aperture and

electricity on

Minimum capacity

or aperture

Inner and outer flame on full power.

Outer flame on minimum, inner flame on full power.

Inner flame on full power.

Inner flame on minimum power.

21

Page 21

Warnings It is normal to hear a slight whistling noise while the

burner is operating.

When it is first used, it is normal for the burner to give off

odours; this does not pose any risk and does not indicate

a malfunction; they will disappear in time.

A few seconds after switching off the burner, it will make

a sound (thud). This is not a fault - this means that the

safety device is no longer operating.

Keep the burner as clean as possible. If the ignition

sparkers are dirty they will not light properly. Clean them

periodically using a small non-wire brush. Bear in mind

that the ignition sparkers must not suffer any serious

impacts.

An orange-coloured flame is normal. This is caused by

the presence of dust in the atmosphere, spilt liquids, etc.

The kitchen will become hot and humid when this gas

appliance is used.

You must therefore ensure that the kitchen is well

ventilated:

either keep the natural ventilation apertures open, or

install a ventilation system (extractor hood).

If using the appliance intensively for prolonged periods,

you may require additional ventilation (e.g. by opening a

window) or more effective ventilation (e.g. by increasing

the cooktop's ventilation, if possible).

If the burner flames are accidentally blown out, switch off

the burner operating control knob and do not try to relight

it for at least one minute.

22

Use “Large flame” setting to bring the pan to the boil,

then adjust the flame between “Large flame” and

“Economy flame” to maintain the required pan

temperature.

Important:

The use of a cooktop leads to the production of heat and

moisture in the kitchen. For this reason make sure that

the room is properly ventilated. Keep natural ventilation

openings, such as windows, open or provide a

mechanical ventilation device (e.g. a range hood or

overhead exhaust fan). An orangy flame is normal and

simply indicates the presence of salt in the atmosphere

(from cooking). If the flame has yellow patches, this is not

a fault (of any kind).

Page 22

Suitable pans

Fig. 24

Fig. 25

The chart below gives the correct pan usage for each burner

Burner Recomended pan

diameter

Medium burner 140-200 mm 140 mm

Large burner 220-260 mm 220 mm

Wok burners ≥220 mm

Small burner 120-160 mm 120 mm

Minimum pan

diameter

Accessories

Additional wok pan support

Additional coffee maker support

Depending on the model, the cooktop may include the

following accessories. These are also available from the

Service Centre.

Only for use on the double flame burner with pans which are

more than 26 cm in diameter (roasting dishes, earthenware

pots, etc.) and with pans with a concave base. Fig. 24.

Only for use on the small burner with pans which are no

more than 12 cm in diameter. Fig. 25.

23

Page 23

Cooking

recommendation

Very high, high Medium Low

Wok burner Boiling, grilling,

browning and

Asian food (wok).

Large burner Steaks, omelettes,

frying.

Medium burner Steaming potatoes,

fresh vegetables,

stews, pasta.

Small burner Casseroles, rice

pudding and

caramels.

Do not place anything, eg. flame tamer,

asbestos mat, between pan and pan support as

serious damage to the appliance may result.

Do not remove the pan support and enclose the

burner with a wok stand as this will concentrate

and deflect heat onto the hotplate.

Reheating and keeping things hot:

cooked and pre-cooked dishes.

Rice, white sauce

and ragout.

Reheating, keeping things hot and

making tasty casseroles.

Defrosting and

slow cooking:

vegetables, fruits

and frozen

products.

Steaming and

vegetables.

Melting:

butter, chocolate

and jelly.

24

Do not use large pots or heavy weights which

can bend the pan support or deflect flame onto

the hotplate.

Page 24

Precautions for use

The following advice is intended to help you save energy

and prevent pan damage:

Use pans which are the right size for each burner.

Do not use small pans on large burners. The flame

should not touch the sides of the pan.

Do not use damaged pans, which do not sit evenly on

the cooktop. Pans may tip over.

Only use pans with a thick, flat base.

Do not cook without using a lid and make sure the lid is

properly fitted to avoid wasting energy.

Always place the pan right over the burner, not to one

side. Otherwise it could tip over.

Do not place large pans on the burners near the control

knobs. These may be damaged by the very high

temperatures.

Place the pans on the pan supports, never directly on

the burner.

Pans should be placed on the cooktop carefully.

Do not strike the cooktop and do not place excessive

weight on it.

Make sure that the pan supports and burner covers are

correctly positioned before using the appliance.

25

Page 25

Cleaning and

maintenance

Cleaning Once the appliance is cool, use a sponge to clean it with

Unsuitable products Never slide pans across the glass surface, as you may

Maintenance Always clean off any liquid as soon as it is spilt: you will

soap and water.

After each use, clean the surface of the respective burner

parts once they have cooled down. If any bits are left

(overcooked food, drops of grease etc.), however few,

they will become stuck to the surface and more difficult

to remove later. The holes and grooves must be clean for

the flame to ignite properly.

The movement of some pans may leave metal residue on

the pan supports.

Clean the burners and pan supports using soapy water

and scrub with a non-wire brush.

If the pan supports are fitted with rubber rests, ensure that

these are also cleaned. The rests may come loose and

the pan support may scratch the cooktop.

Always dry the burners and pan supports completely.

Water droplets or damp patches on the cooktop at the

start of cooking may damage the enamel.

After cleaning and drying the burners, make sure the

burner covers are correctly placed on the burner flame

diffuser.

scratch it. In addition, try not to drop heavy or sharp

objects on the glass. Never strike any part of the cooktop.

Do not use steam cleaners. This could damage the

cooktop.

Never use abrasive products, steel scourers, sharp

implements, knives, etc. to remove bits of hardened food

from the cooktop.

If your cooktop is fitted with a glass or aluminium panel,

never use a knife, scraper or similar to clean the point

where it joins the metal.

Do not use knives, scrapers or similar implements to

clean the point where the glass meets the burner trims,

the metal frames or the glass/aluminium panels, if fitted.

save yourself any unnecessary effort.

Grains of sand that may come from cleaning fruits and

vegetables will scratch the glass surface.

Melted sugar, or foods which contain a lot of sugar which

may have spilt, should be cleaned off the hotplate

immediately, using the glass scraper.

26

Page 26

Service

Sometimes certain faults detected can be easily resolved.

Before calling the Service Centre, bear in mind the

following advice:

Fault Possible cause Solution

The general electrical

system is malfunctioning.

The automatic on

function does not work.

The burner flame is not

uniform.

The flow of gas does not

appear normal or no gas

comes out.

The kitchen smells of

gas.

The safety valves on one

of the burners are not

working.

Defective fuse.

The automatic safety switch or

circuit breaker has tripped.

There may be food or cleaning

products stuck between the

ignition sparkers and the

burners.

The burners are wet.

The burner covers are not

correctly positioned.

The appliance is not earthed, is

not correctly connected or the

earth wire is faulty.

The burner components are not

correctly positioned.

The grooves on the burner are

dirty.

The gas supply is blocked via

intermediary valves.

If the gas is supplied from a

gas cylinder, check that this is

not empty.

A gas tap has been left on.

There may be a leak in the gas

cylinder coupling.

The control knob was not held

down for long enough.

The grooves on the diffuser are

dirty.

Check the fuse in the main fuse

box and change it if it is damaged.

Check the main control panel to

see if the automatic safety switch

or circuit breaker has tripped.

The space between the ignition

sparker and the burner must be

clean.

Dry the burner covers carefully.

Check that the covers are correctly

positioned.

Contact the electrical installer.

Ensure the components are

correctly positioned.

Clean the grooves on the diffuser.

Open all intermediary valves.

Change the gas cylinder.

Turn off the gas taps.

Check that the coupling is sound.

Once the burner is lit, hold the

control knob down a few seconds

longer. Clean the grooves on the

diffuser.

Any of the following are considered to be abnormal

operation and may require servicing:

Yellow tipping of the cooktop burner flame.

Sooting up of cooking utensils.

Burners not lighting properly.

Gas valves, which are difficult to turn in case the

appliance fails to operate correctly, contact the

authorised service provider in your area.

27

Page 27

Wiring diagram

A. Switch

B. Blue wire

C. Brown wire

D. Terminal

E. Ignition module

S

iemens-Electrogeräte Gmb

E-Nr ER926B90A

Gas type

Test point pressure (kPa)

Injectors marks

LH

RHF

RHR

CF

HGC (MJ)

In compliance with AS/NZ 3100 and AS 4551

Preinstalled NG

Made in Spain

CR

H

NG

1,0

65/125

130

157

130

97

54,60

CIF: A-28-893550

FD

LP

2,75

47/115

70

83

70

53

GMK10013

NG

1,0

22

CIF: A-28-893550

FD

LP

2,75

47/115

20

GMK10013

S

iemens-Electrogeräte Gmb

E-Nr ER326AB90A

Gas type

Test point pressure (kPa)

Injectors marks

C

44

HGC (MJ)

In compliance with AS/NZ 3100 and AS 4551

Preinstalled NG

Made in Spain

H

65/215

S

iemens-Electrogeräte Gmb

E-Nr ER326BB90A

Gas type

Test point pressure (kPa)

Injectors marks

F

R

HGC (MJ)

In compliance with AS/NZ 3100 and AS 4551

Preinstalled NG

Made in Spain

H

NG

1,0

130

157

19,70

28

CIF: A-28-893550

FD

LP

2,75

70

83

1

4,50

GMK10014

S

iemens-Electrogeräte Gmb

E-Nr ER626PB90A

Gas type

Test point pressure (kPa)

Injectors marks

LHF

LHR

RHF

RHR

HGC (MJ)

In compliance with AS/NZ 3100 and AS 4551

Preinstalled NG

Made in Spain

H

NG

1,0

130

97

130

1

32,60

57

CIF: A-28-893550

FD

LP

2,75

2

4,00

GMK10014

70

53

70

83

Loading...

Loading...