Page 1

SIMATIC NET

S7-CPs for Industrial Ethernet

Manual Part B3L

CP 343-1 Lean

6GK7 343−1CX10−0XE0 as of hardware version 2, as of firmware version V2.0

for SIMATIC S7−300 / C7−300

LED displays

Release 03/2007

C79000-G8976-C198-04

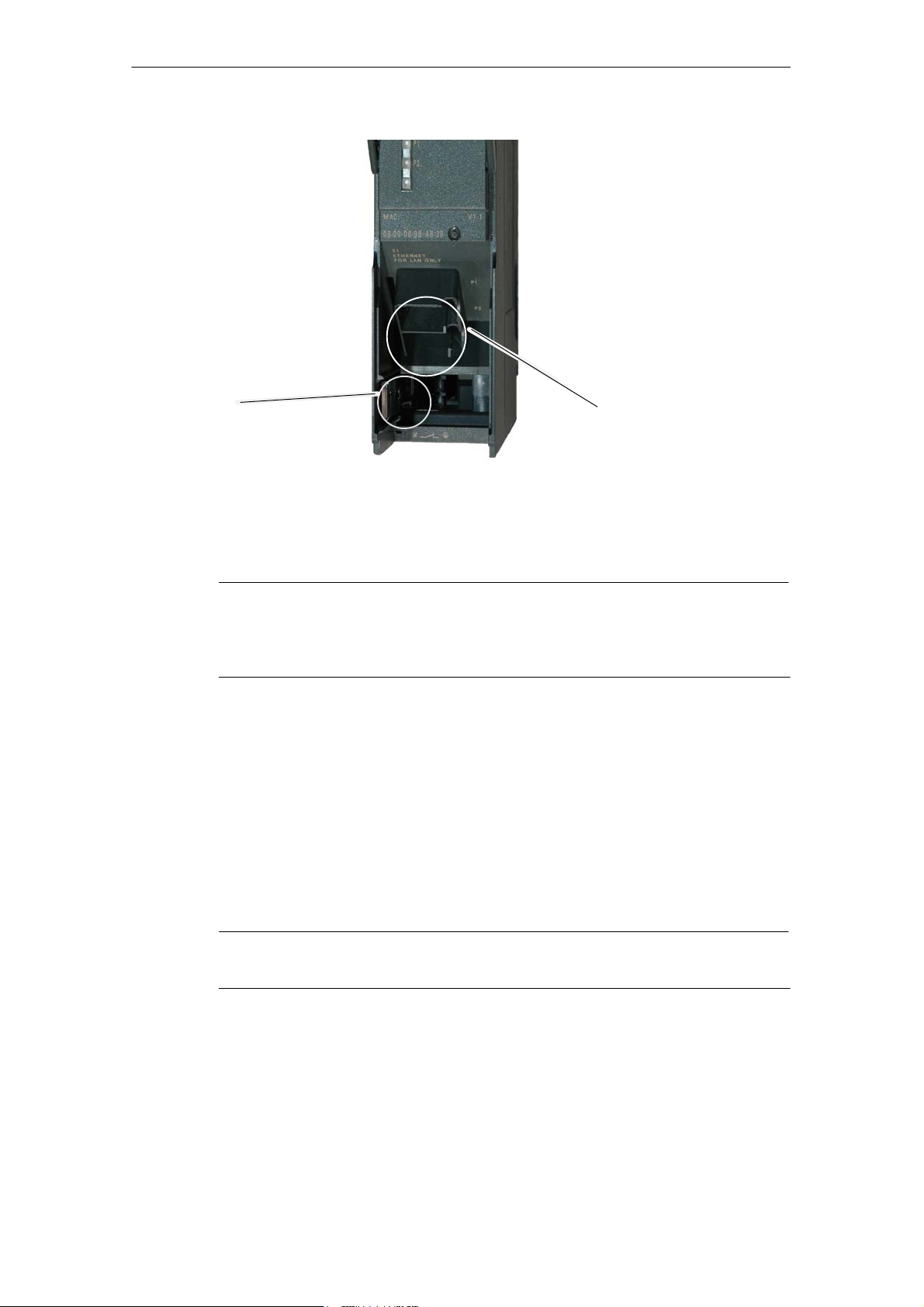

TP port:

2 x 8−pin RJ−45 socket

(beneath the front panel)

X = Placeholder for hardware

version

Page 2

Notes on the Product

Notes on the Product

Product Names

This description contains information on the following product

S CP 343−1 Lean

Order number 6GK7 343−1CX10−0XE0

as of hardware version 2 and firmware version V2.0

for SIMATIC S7−300 / C7−300

Note

In this document, the term CP is used instead of the full product name.

Printed Product Information Supplied with the Product

Note

All the notices in the Product Information Bulletin shipped with this device must

be adhered to.

Compatibility with the Previous Version

Note

Due to the increased functionality and restrictions, pay particular attention to

the notes in Chapter 8 of this manual.

Address label: Unique MAC address preset for the CP

The CP ships with a factory-set MAC address.

To ensure a unique address assignment, we recommend that you use this factory

set MAC address when configuring the module!

B3L−2

-

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 3

Contents

Contents − Part A

Ethernet CPs − General information see general part. . . . . . . . . . . . . . . . . . .

Note

Please remember that Part A of the device manual also belongs to the description

of the CP. Among other things, it contains explanations of the safety notices and

general information that applies to all S7 CPs for Industrial Ethernet.

You will find the references in this Part B of the manual /.../ in the Appendix of the

general Part A of the manual.

The following version of the manual Part A of the manual belongs to this version of

Part B: Release 01/2007

Contents

You can download the general Part from the Internet:

http://www4.ad.siemens.de/view/cs/en/8777865

Contents − Part B3L

1 Properties / Services B3L−5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Requirements for Use B3L−8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Installation and Commissioning B3L−11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Procedure / Steps B3L−11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Displays B3L−14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Performance Data B3L−17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Number of Possible Connections over Ethernet B3L−17. . . . . . . . . . . . . . . . . . .

5.2 Characteristic Data for S7 Communication B3L−17. . . . . . . . . . . . . . . . . . . . . . .

5.3 Characteristics of the SEND/RECEIVE Interface B3L−18. . . . . . . . . . . . . . . . .

5.4 Characteristic Data for PROFINET IO B3L−19. . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Configuring and Programming the CP as a PROFINET IO Device B3L−20. . . . . . . . . .

6.1 Overview of the Preparatory Steps B3L−20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Principle of Data Exchange over PROFINET IO B3L−21. . . . . . . . . . . . . . . . . .

6.3 Configuration B3L−22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Installing the CP and Specifying it as PROFINET IO Device B3L−22. . . . . . . .

6.3.2 Assigning the PROFINET IO Device to a PROFINET IO Controller B3L−24. .

6.4 Programming B3L−27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 Interface for Programming on the PROFINET IO Device B3L−27. . . . . . . . . . .

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−3

Page 4

Contents

6.4.2 Initialization and Configuration B3L−28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Example of Configuration and Programming B3L−30. . . . . . . . . . . . . . . . . . . . .

7 Web Diagnostics B3L−33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Requirements and Use B3L−33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Diagnostics Pages of the CP B3L−34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Start Page B3L−35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Identification B3L−36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 Rack Configuration B3L−37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.4 Diagnostic Buffer B3L−39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.5 Industrial Ethernet B3L−40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.6 PROFINET IO B3L−42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Compatibility with Predecessor Products B3L−44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Extended Functionality B3L−44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Replacing Older Modules / Replacing Faulty Modules B3L−44. . . . . . . . . . . . .

9 Further Notes on Operation B3L−46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Memory Reset B3L−46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Working with Fast Ethernet − automatic switchover B3L−47. . . . . . . . . . . . . . .

9.3 SNMP Agent B3L−49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 Possible Security Gaps on Standard IT Interfaces / Preventing

Illegal Access B3L−50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 Influence of MPI on Connections via Industrial Ethernet B3L−50. . . . . . . . . . .

9.6 Special Features of IP Configuration B3L−51. . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7 Reserved Port Numbers B3L−51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8 Restart after Detection of a Duplicate IP Address in the Network B3L−52. . . .

9.9 Obtaining the IP Address over DHCP − CP STOP on Expiry of

the Lease B3L−52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.10 Other information available about the CP B3L−52. . . . . . . . . . . . . . . . . . . . . . . .

10 How to Load New Firmware B3L−53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 Technical Specifications B3L−54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B3L−4

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 5

1 Properties / Services

Application

The CP 343−1 Lean communications processor is designed for operation in a

SIMATIC S7-300 programmable logic controller. It allows attachment of the

S7−300 to Industrial Ethernet and supports PROFINET IO.

A 2-port switch with autocrossing, autonegotiation and autosensing was integrated

in the CP for simple integration in a line or for attaching a further Ethernet device.

Services

The CP supports the following communication services:

S PROFINET IO device

Integration of the SIMATIC S7−300 programmable controller over the CP as

intelligent PROFINET IO device.

1 Properties / Services

S S7 communication and PG/OP communication

− PG functions (including routing)

− Operator control and monitoring functions (HMI)

− Server for data exchange on S7 connections configured at one end only

without communication blocks on the S7-300 / C7-300 station

S S5 compatible communication with

− SEND/RECEIVE interface over ISO-on-TCP, TCP and UDP connections

− Multicast over UDP connection

The multicast mode is made possible by selecting a suitable IP address

when configuring connections.

− FETCH/WRITE services (server; corresponding to S5 protocol) via

ISO-on-TCP connections and TCP connections;

The addressing mode can be configured for FETCH/WRITE access as the

S7 or S5 addressing mode.

− LOCK/UNLOCK with FETCH/WRITE services;

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−5

Page 6

1 Properties / Services

S Time-of-day synchronization over Industrial Ethernet using the following

configurable modes:

− SIMATIC mode

The CP receives MMS time frames and synchronizes its local time and the

time of the CPU (accuracy approx. +/− 1 second);

or

− NTP mode (NTP: Network Time Protocol)

The CP sends time-of-day queries at regular intervals to an NTP server and

synchronizes its local time of day and the time of the CPU (accuracy approx.

+/− 1 second).

S Time of day for the diagnostic buffer

If a time master exists (using the NTP or SIMATIC mode), the time for the

CP-internal diagnostic buffer is synchronized over the LAN (accuracy approx.

+/− 10 ms)

S Addressing using a factory-set MAC address

The CP can be reached over the default MAC address to allow an IP address to

be assigned.

S SNMP Agent

The CP supports data queries over SNMP in version V1 (Simple Network

Management Protocol) according to the MIB II and LLDP MIB standard.

You will find more information on MIB in the manual “Commissioning PC

Stations” on the SIMATIC NET Manual Collection or at the following

SIMATIC NET Internet page:

http://support.automation.siemens.com/WW/view/en/15177711

S IP configuration

You can configure how and with which method the CP is assigned the IP

address, the subnet mask and the address of a default router.

It is also possible, as an alternative, to assign the connection configuration to

the CP using STEP 7 or using a block interface in the user program (FB55:

IP_CONFIG) (see /Part A/).

S Web diagnostics

With the aid of Web diagnostics, you can read out the diagnostic data from a

station connected over the CP to a PG/PC with an Internet browser.

B3L−6

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 7

1 Properties / Services

Configuration

It is possible to download the configuration data to the CP over MPI or

LAN/Industrial Ethernet. You require STEP 7 with NCM S7 for Industrial Ethernet

(NCM IE) with the following version:

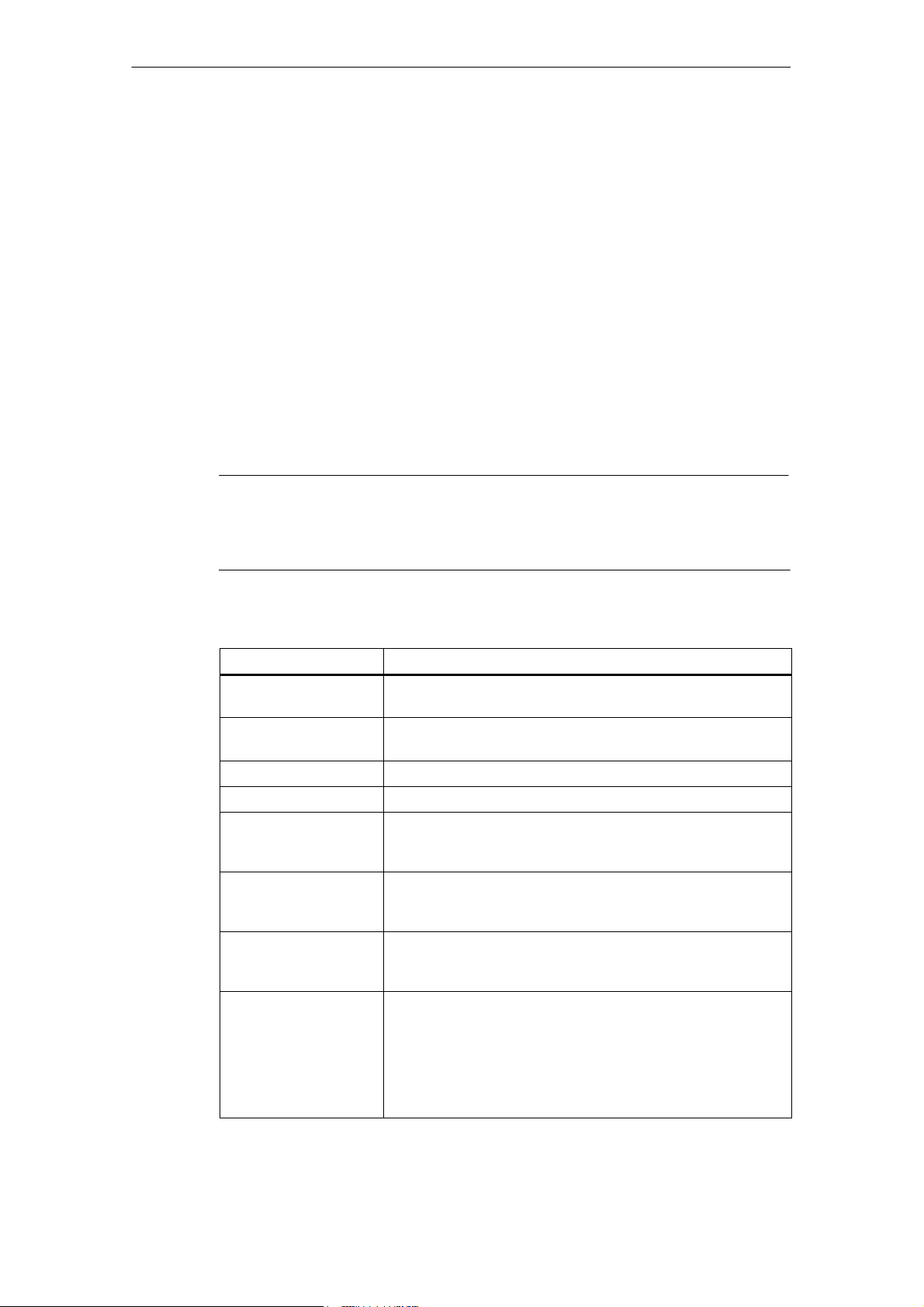

Table 1-1

Version STEP 7 / NCM IE Functions of the CP

V5.2 or higher The range of functions of the CP 343−1 Lean (CX00) can be

configured.

V5.4 or higher Requirement for configuring the full functionality of the

CP 343−1 Lean (CX10 with firmware V1.0) including PROFINET

IO.

V5.4 Service Pack 2 *) Requirement for configuring the full functionality of the

CP 343−1 Lean (CX10 with firmware V2.0) including Web

diagnostics.

*) To use the CP with V5.4 Service Pack 1, you will need to install Hotfix 2, the corresponding hardware

update and a block setup. You will find more information at the following Internet page:

http://www4.ad.siemens.de/WW/news/en/24463868

Programming − Using Blocks

For some communications services, there are pre-programmed blocks (FCs/FBs)

available as the interface in your STEP 7 user program.

You will find a detailed description of these blocks in the NCM S7 for Ethernet

manuals.

Notice

We recommend that you always use the latest block versions for all module types.

You will find information on the latest block version and links to download the

current blocks in our Customer Support area on the Internet:

http://www4.ad.siemens.de/WW/news/en/8797900

If you are using older block types, this recommendation only applies if you also

have the latest firmware version.

You will find further information and Internet addresses in the Preface of the

General Part of this manual.

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−7

Page 8

2 Requirements for Use

2 Requirements for Use

General Operation

The CP can be operated in the following device families:

S S7−300 stations with the CPU types

− Standard

− Compact

− Modular

S C7 control systems in C7 packaging system

The following tables show the devices with which the CP can be operated with this

range of functions:

Notice

The tables list the CPUs and devices approved at the time of printing this manual.

S7-300 CPUs or C7 or C7 control systems approved later and not listed in the

table also support the range of functions described here.

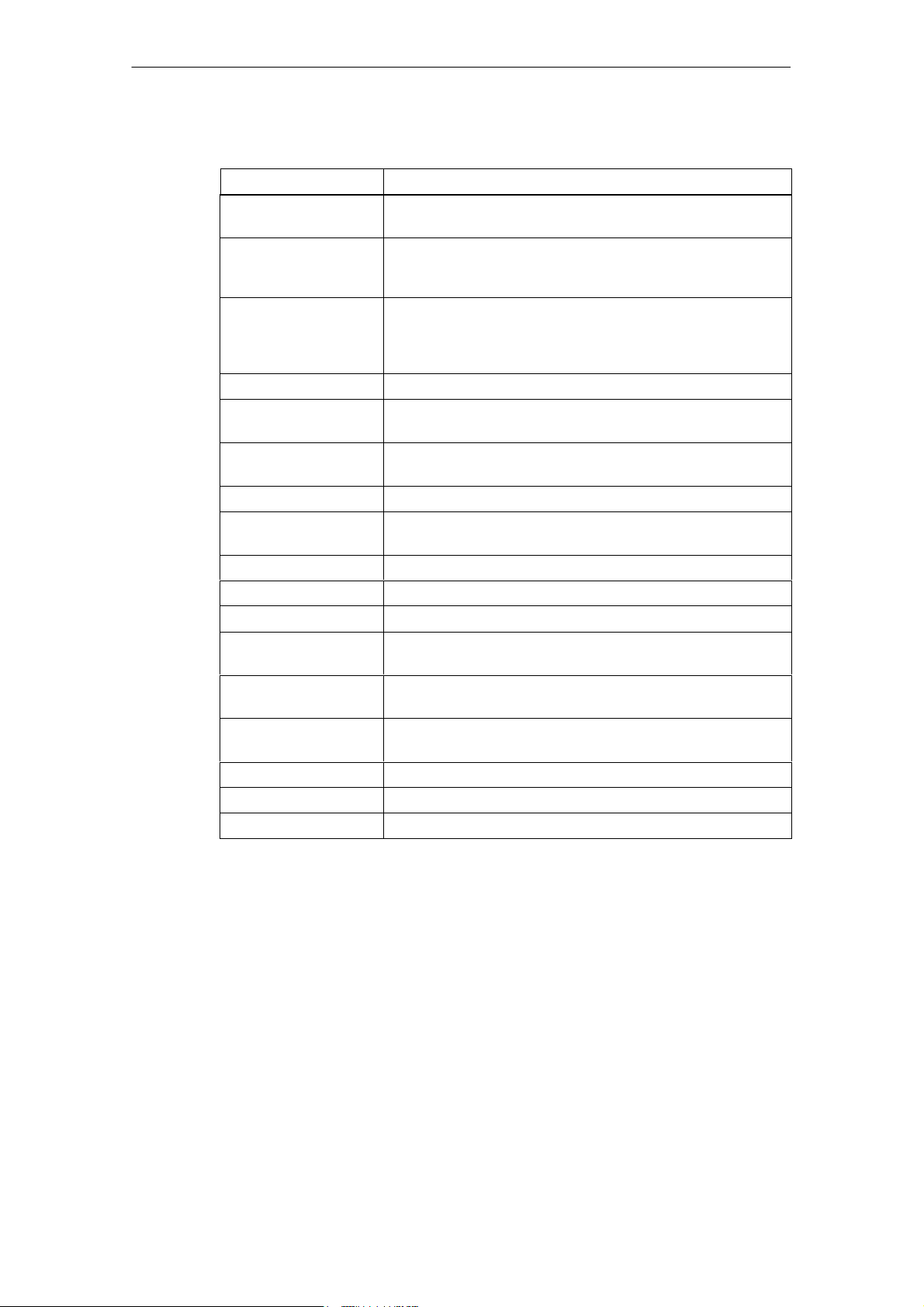

Table 2-1 Use of the CP with S7−300

CPU

CPU 312 6ES7 312−1AD10−0AB0

6ES7 312−1AE13−0AB0

CPU 312C 6ES7 312−5BD01−0AB0

6ES7 312−5BE03−0AB0

CPU 312 IFM 6ES7 312−5AC02−0AB0

CPU 313 6ES7 313−1AD03−0AB0

CPU 313C 6ES7 313−5BE00−0AB0

6ES7 313−5BE01−0AB0

6ES7 313−5BF03−0AB0

CPU 313C−2 DP 6ES7 313−6CE00−0AB0

6ES7 313−6CE01−0AB0

6ES7 313−6CF03−0AB0

CPU 313C−2 PtP 6ES7 313−6BE00−0AB0

6ES7 313−6BE01−0AB0

6ES7 313−6BF03−0AB0

CPU 314 6ES7 314−6AE01−0AB0

6ES7 314−6AE02−0AB0

6ES7 314−6AE03−0AB0

6ES7 314−6AE04−0AB0

6ES7 314−1AF10−0AB0

6ES7 314−1AF11−0AB0

6ES7 314−1AG13−0AB0

Order Number

B3L−8

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 9

Table 2-1 Use of the CP with S7−300

CPU Order Number

CPU 314 IFM 6ES7 314−5AE03−0AB0

6ES7 314−5AE10−0AB0

CPU 314C−2 DP 6ES7 314−6CF00−0AB0

6ES7 314−6CF02−0AB0

6ES7 314−6CG03−0AB0

CPU 314C−2 PtP 6ES7 314−6BF00−0AB0

6ES7 314−6BF01−0AB0

6ES7 314−6BF02−0AB0

6ES7 314−6BG03−0AB0

CPU 315 6ES7 315−1AF03−0AB0

CPU 315−2 DP 6ES7 315−2AF03−0AB0

6ES7 315−2AG10−0AB0

CPU 315−2 PN/DP 6ES7 315−2EG10−0AB0

6ES7 315−2EH13−0AB0

CPU 315F−2 DP 6ES7 315−6FF01−0AB0

CPU 315F−2 PN/DP 6ES7 315−2FH10−0AB0

6ES7 315−2FH13−0AB0

2 Requirements for Use

CPU 316 6ES7 316−1AG00−0AB0

CPU 316−2 DP 6ES7 316−2AG00−0AB0

CPU 317−2 DP 6ES7 317−2AJ10−0AB0

CPU 317−2 PN/DP 6ES7 317−2EJ10−0AB0

6ES7 317−2EK13−0AB0

CPU 317F−2 DP 6ES7 317−6FF00−0AB0

6ES7 317−6FF03−0AB0

CPU 317F−2 PN/DP 6ES7 317−2FJ10−0AB0

6ES7 317−2FK13−0AB0

CPU 318−2 6ES7 318−2AJ00−0AB0

CPU 319−3 PN/DP 6ES7 318−3EL00−0AB0

CPU 614 6ES7 614−1AH03−0AB3

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−9

Page 10

2 Requirements for Use

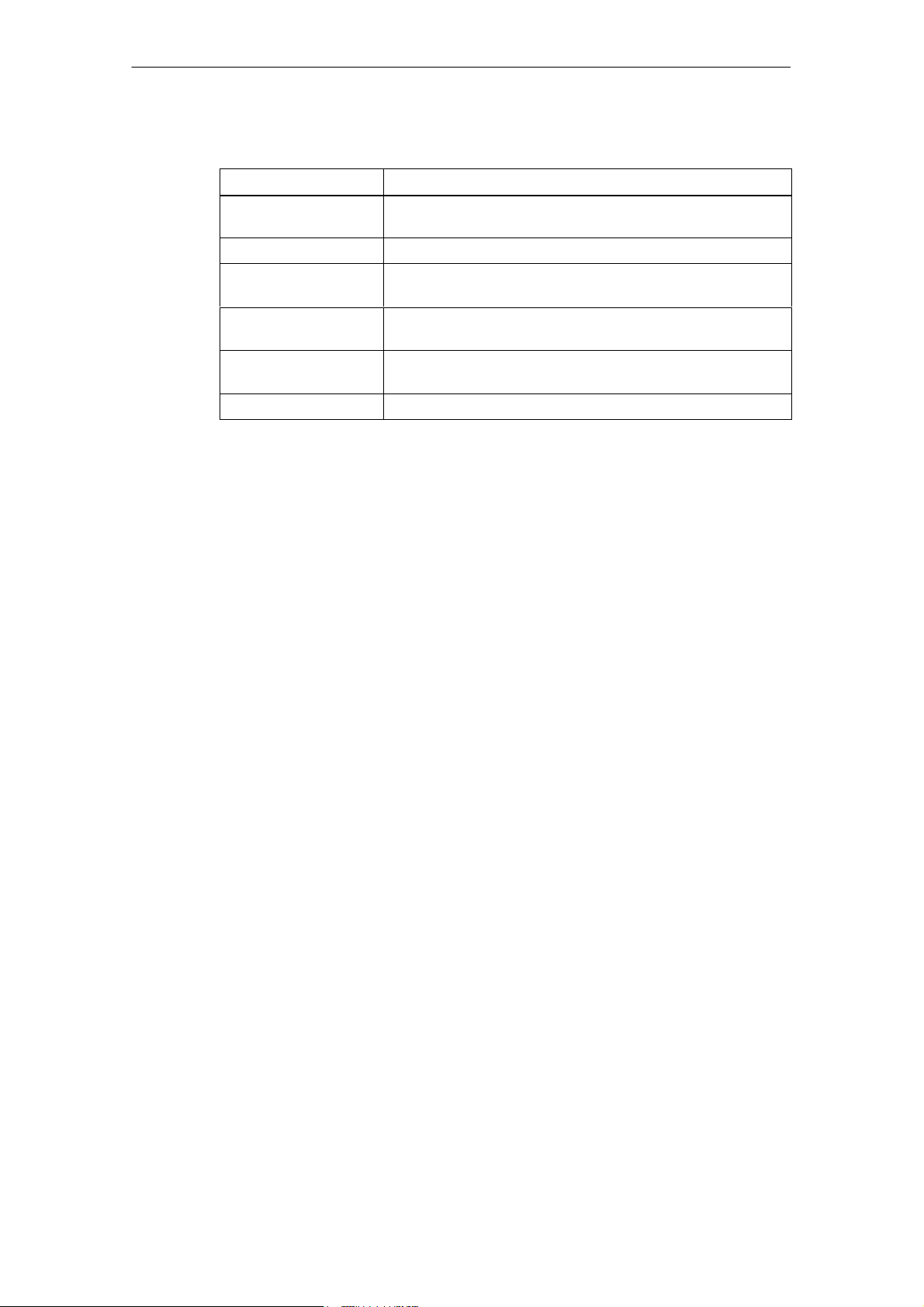

Table 2-2 Use of the CP in C7 Control Systems

C7

C7−613 6ES7 613−1CA01−0AE03

6ES7 613−1CA02−0AE3

C7−633 DP 6ES7 633−2BF02−0AE03

C7−635 Keys 6ES7 635−2EC01−0AE3

6ES7 635−2EC02−0AE3

C7−635 Touch 6ES7 635−2EB01−0AE03

6ES7 635−2EB02−0AE3

C7−636 Keys 6ES7 636−2EC00−0AE03

6ES7 636−2EC00−0AE3

C7−636 Touch 6ES7 636−2EB00−0AE3

Order Number

B3L−10

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 11

3 Installation and Commissioning

3 Installation and Commissioning

3.1 Procedure / Steps

Step Explanation / Meaning

1. Install the CP on the S7 standard rail.

2. Establish the connection via the enclosed bus

connector to the backplane bus.

Note

The CP cannot be used in an extension rack that is connected via the IM 365! Reason: The required

communication bus is not connected to the extension rack via the IM 365.

3. Connect the CP to the power supply. Follow the steps as described in detail in /1/ when

Slots 4 to 11 are permitted for the CP in racks 0 to 3

(connected by IM 360/361).

Proceed as in the sections dealing with setup and

wiring, described in detail in /1/.

wiring between the power supply and the CPU.

Notes

S The CPU, CP and IM (if one exists) must be connected to the same power supply.

S Only wire up the S7-300 / C7-300 with the power switched off!

4. Attach the CP to Industrial Ethernet.

5. The remaining steps in commissioning involve

downloading the configuration data.

To download the configuration, you can connect

the PG as follows:

S via MPI

S via Industrial Ethernet

For further details, refer to the general Part A of

this manual:

− addressing the first time (IP address

assignment / node initialization);

− downloading the defined configuration

The PG/PC requires a LAN attachment, for

example via a CP 1613 or CP 1411 and must have

the necessary software (for example the S7-1613

package or SOFTNET IE). The TCP/IP protocol

must be installed. The protocol used must then be

applied to the S7ONLINE access point.

6. User diagnostics for commissioning and to

analyze problems.

The following options are available:

S The LED displays on the CP

S Hardware diagnostics and troubleshooting with

STEP 7

S Communication diagnostics with STEP 7 / NCM

Diagnostics

S Standard information using HW Config

S Web diagnostics

S If applicable, evaluation of the alarm block

FB54 in the user program

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−11

Page 12

3 Installation and Commissioning

Slider for setting

the chassis

ground contact

Figure 3-1 Connectors of a CP 343−1 Lean with the Front Panel Open

Ground/Chassis Ground Concept

Notice

Please note the instructions regarding the grounding and chassis ground concept

in the SIMATIC S7 installation guides; see “SIMATIC S7 Programmable Controller

S7−300 − Installation and Hardware: Installation Manual” /1/.

Behind the hinged panel on the left of the device, you will see a slider with which

you can connect or disconnect the chassis ground of the 24 V power supply with

reference ground.

S Slider pushed in: chassis and reference ground connected (note: the slider

must be felt to lock in place).

S Slider pulled out: No connection between chassis and reference ground.

Attachment to Industrial

Ethernet:

2 x 8-pin RJ-45 jack

B3L−12

When shipped: Slider pushed in

Use a screwdriver to set the slider.

Note

An Ethernet cable can also be inserted and removed with the power supply on.

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 13

3 Installation and Commissioning

Note

The hinged front panel must be kept closed during operation.

The module must be installed so that its upper and lower ventilation slits are not

covered, allowing adequate ventilation.

Warning

!

When used under hazardous conditions (zone 2), the devices must be installed in

an enclosure.

To comply with ATEX100a (EN 60079−15), this enclosure must meet the

requirements of at least IP54 in compliance with EN 60529.

WARNING − EXPLOSION HAZARD: DO NOT DISCONNECT EQUIPMENT

WHEN A FLAMMABLE OR COMBUSTIBLE ATMOSPHERE IS PRESENT.

Warning

!

The device is designed for operation with safety extra-low voltage (SELV). This

means that only safety extra-low voltages (SELV) complying with

IEC950/EN60950/ VDE0805 may be connected to the power supply terminals.

The power unit for supplying the device must comply with NEC Class 2 as

described by the National Electrical Code(r) (ANSI/NFPA 70).

The power of all connected power units in total must correspond to a limited power

source (LPS).

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−13

Page 14

4 Displays

4 Displays

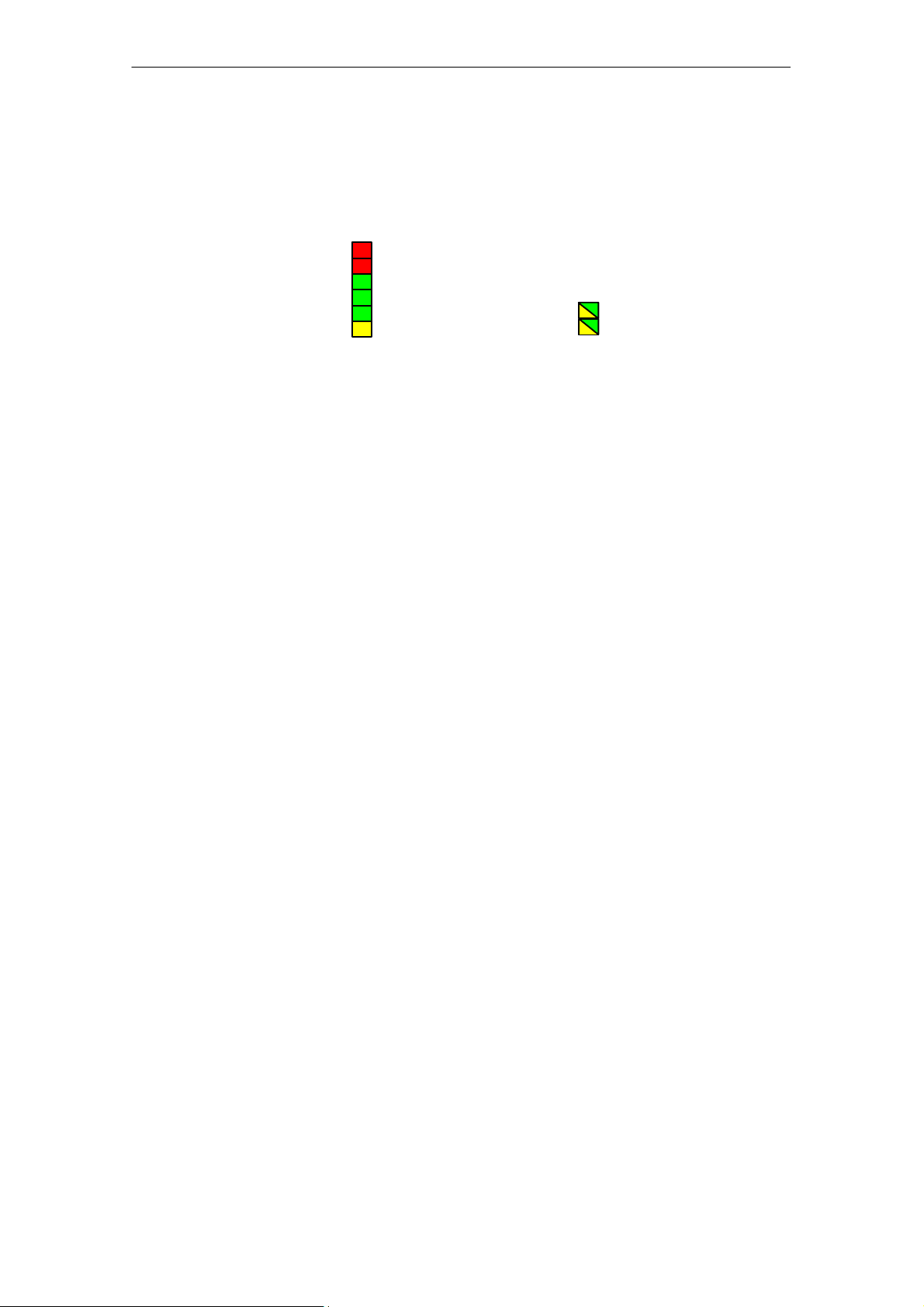

The display on the front panel consists of 8 LEDs that indicate the operating mode

and the communication status.

Front panel:

The LEDs have the following meaning:

S SF: Group error

S BF: Bus fault PROFINET IO

S DCV5: DC 5 V power supply via the backplane bus (green = OK)

S RX/TX: Acyclic data exchange, for example Send/Receive

(not relevant for PROFINET IO data)

S RUN: RUN mode

S STOP: STOP mode

S P1 / P2: Link status of Ethernet port 1 / port 2

SF

BF

DC5V

RX/TX

RUN

STOP

P1

P2

B3L−14

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 15

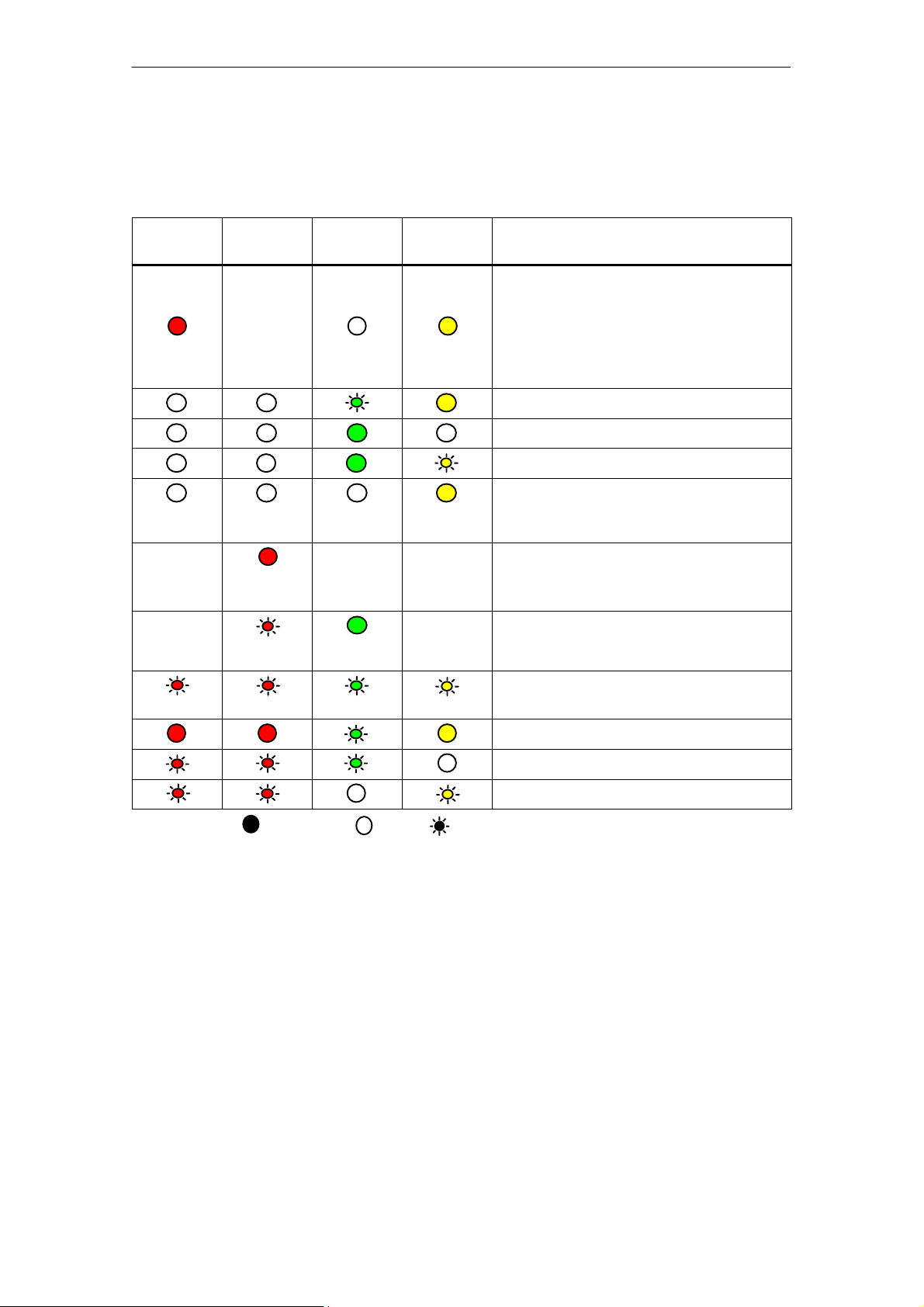

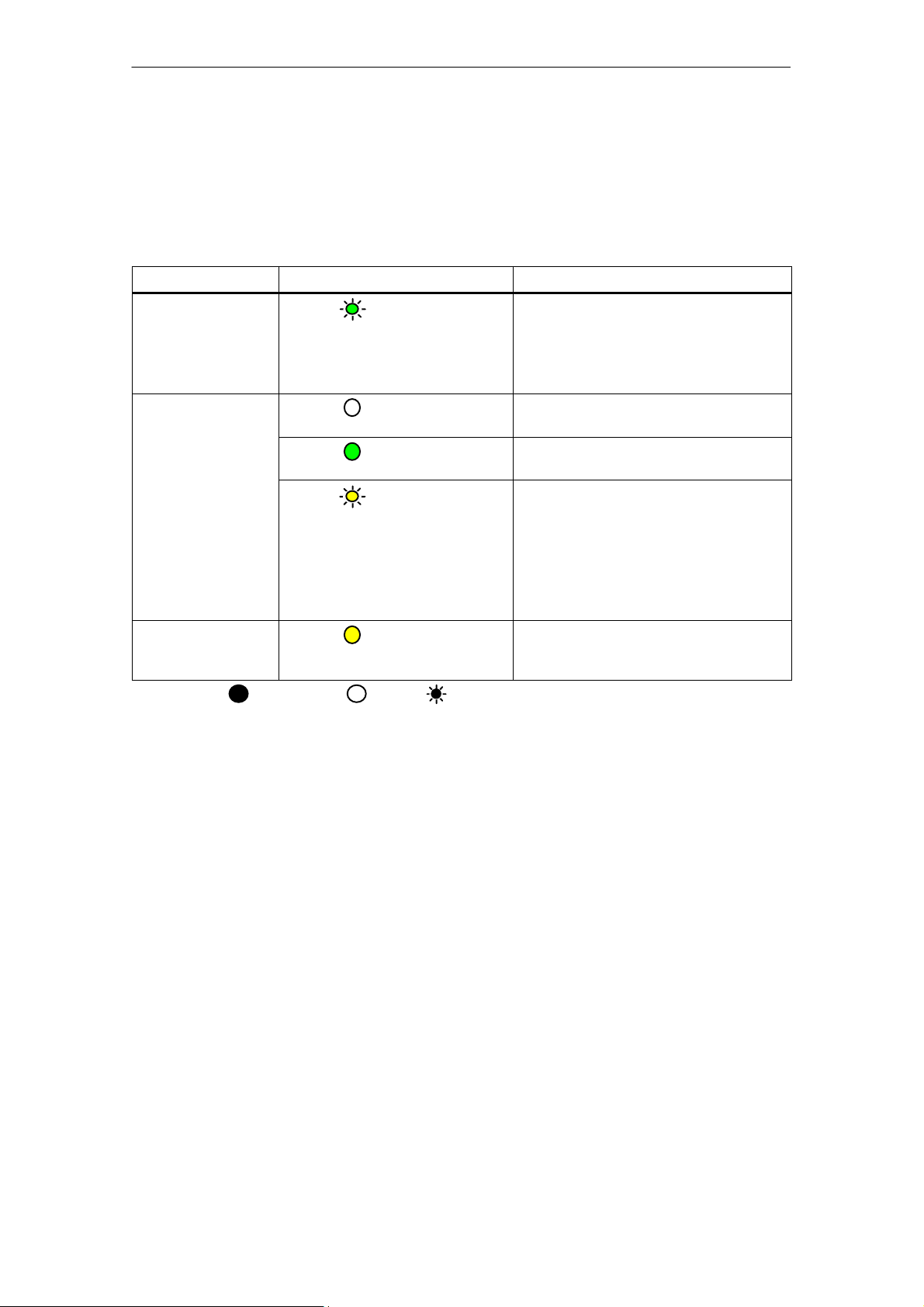

LEDs for displaying the mode

The different combinations of the LEDs on the front panel indicate the status:

4 Displays

SF(red) BF (red) RUN

(green)

STOP

(yellow)

CP Operating Mode

S Starting up after power “ON”

or

−

− − − S No LAN cable plugged in

S Stopped (STOP) with errors

In this state, the CPU or intelligent

modules in the rack remain accessible

using PG functions.

Starting up (STOP->RUN)

Running (RUN)

Stopping (RUN->STOP)

Stopped (STOP)

In the STOP mode configuring and performing

diagnostics on the CP remain possible.

or

S Duplicate IP address detected

−

−

− The CP is configured as a PROFINET IO

device; there is no data exchange with the

PROFINET IO controller

Module fault / system error

Downloading firmware.

Firmware was successfully downloaded.

Firmware could not be downloaded.

Legend: (colored) on off (colored) flashing “−” any

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−15

Page 16

4 Displays

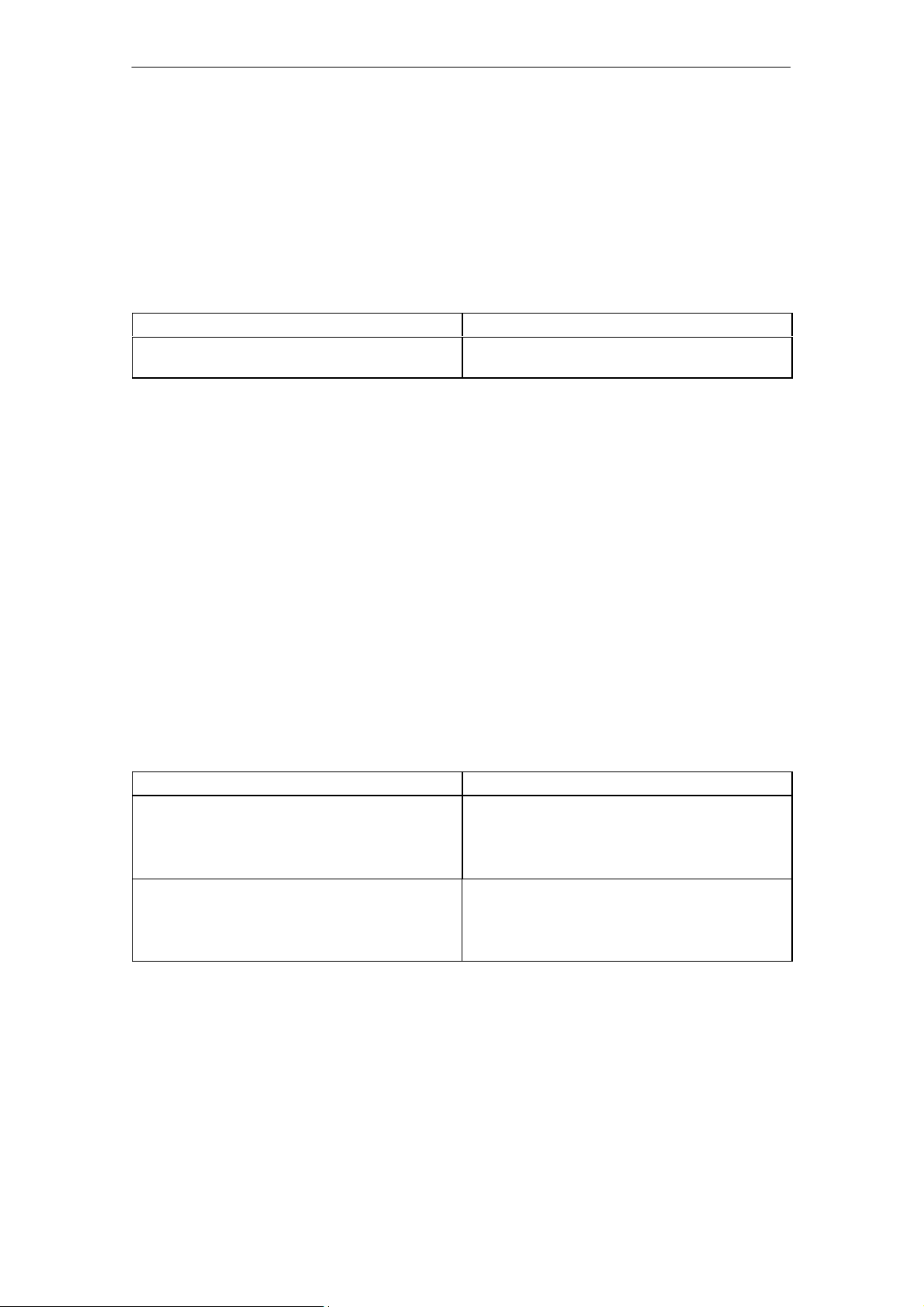

LEDs for displaying the CP communication status

In addition to the LEDs that signal the CP state, the following LEDs provide

information about the status of the CP interface to Industrial Ethernet.

Table 4-1

LED

RX/TX (green) The CP is sending/receiving over Industrial

P1 / P2

(green / yellow)

P1 / P2

(green / yellow)

Legend: (colored) on off (colored) flashing “−” any

Display Meaning

Ethernet

Note:

Sending / receiving over PROFINET IO is

not signaled here.

Port has no connection to

Industrial Ethernet.

green Existing connection over port to

Industrial Ethernet (LINK status).

green /

yellow

yellow Continuous data transfer at the port over

LED flashes yellow (constant light green):

Port sending/receiving over

Industrial Ethernet or PROFINET IO.

Note:

All received / sent frames are signaled for

each specific port including those simply

forwarded by the switch.

Industrial Ethernet (for example

PROFINET IO).

B3L−16

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 17

5 Performance Data

5 Performance Data

5.1 Number of Possible Connections over Ethernet

Table 5-1

Characteristic Explanation / Values

Permitted number of simultaneous connections in

total over Industrial Ethernet

Example of Maximum Load

You can operate:

4 S7 connections

4 ISO-on-TCP connections

2 TCP connections

2 UDP connections

12 maximum

Also:

S Further TCP connections for Web diagnostics

S 1 PROFINET connection to a PROFINET IO controller

5.2 Characteristic Data for S7 Communication

Table 5-2

Characteristic Explanation / Values

Number of connections for S7 communication on

Industrial Ethernet for

S Operator control and monitoring functions (HMI)

S S7 connections configured at one end

LAN interface − data record length per protocol unit

S sending

S receiving

4 maximum

(the number depends on the CPU type being used.

Please refer to /1/ for the values for your CPU.)

240 bytes / PDU

240 bytes / PDU

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−17

Page 18

5 Performance Data

5.3 Characteristics of the SEND/RECEIVE Interface

Table 5-3

Characteristic Explanation / Values

Number of ISO-on-TCP connections + TCP

connections + UDP connections in total

Max. data length for blocks AG_SEND (V4.0 and

higher) and AG_RECV (V4.0 and higher)

Restrictions for UDP

S Transfer is not confirmed The transmission of UDP frames is unconfirmed, in

8 maximum

Notes:

S All UDP connections are also possible in the

multicast mode

S Free UDP connections are supported by the

CP.

AG_SEND and AG_RECV allow the transfer of

data fields of between 1 and 240 bytes.

S 1 to 8192 bytes for ISO-on-TCP, TCP;

S 1 to 2048 bytes for UDP

other words the loss of messages is not detected

or displayed by the send blocks (AG_SEND).

S Data field length The maximum length of the data fields is 2048

bytes.

S No reception of UDP broadcast To avoid communication overload resulting from a

high broadcast load, the CP does not permit

reception of UDP broadcast.

Execution Times of the FCs AG_SEND / AG_RECV

To calculate the CPU cycle times (OB1) with SEND/RECEIVE connections, the

execution time for the FCs (FC AG_SEND, FC AG_RECV) required for processing

on the S7−300 / C7−300 CPU is the decisive factor.

Table 5-4

Component

Execution time on the CPU

315−2 DP

(6ES7 315−2EG10−0AB0)

Execution time on the CPU

317−2 PN/DP

(6ES7 317−2EJ10−0AB0)

per AG_SEND block call:

S <1 ms at <= 240 bytes

per AG_SEND block call:

S <0.8 ms at <= 240 bytes

Explanation / Values

per AG_RECV block call:

S <1 ms at <= 240 bytes

per AG_RECV block call:

S <0.8 ms at <= 240 bytes

B3L−18

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 19

5.4 Characteristic Data for PROFINET IO

CP as PROFINET IO device

The CP supports the following maximum configuration as a PROFINET IO device:

Table 5-5

5 Performance Data

Characteristic

Size of the input area of the PROFINET IO device 512 bytes max.

Size of the output area of the PROFINET IO device 512 bytes max.

Size of the IO data area per submodule in a PROFINET IO device

S Inputs

S Outputs

Size of the consistency area for a submodule 240 bytes

Maximum number of submodules 32

Explanation / Values

240 bytes

240 bytes

Execution times of the FCs PNIO_SEND / PNIO_RECV

The calculation of the reaction times with PROFINET IO is determined by the

execution time of the function blocks required on the S7-300 CPU (PNIO_SEND,

PNIO_RECV).

Table 5-6

Component

Execution time on the CPU

315−2DP

(6ES7 315−2EG10−0AB0)

Execution time on the CPU

317−2PN/DP

(6ES7 317−2EJ10−0AB0)

per PNIO_SEND block call:

S < 1 ms at 240 bytes

per PNIO_SEND block call:

S < 0.8 ms at 240 bytes

Explanation / Values

per PNIO_RECV block call:

S < 1 ms at 240 bytes

per PNIO_RECV block call:

S < 0.8 ms at 240 bytes

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−19

Page 20

6 Configuring and Programming the CP as a PROFINET IO Device

6 Configuring and Programming the CP as a

PROFINET IO Device

“Intelligent” PROFINET IO Device

A CP 343−1 Lean can be configured so that the SIMATIC 300 station can be

addressed as a PROFINET IO device. Due to the programmability of SIMATIC 300

stations, they are also known as “intelligent” PROFINET IO devices because:

Process data can be processed before it is forwarded to the PROFINET IO

controller or after it has been received from it and output to the process I/O.

In the following sections, the name “PROFINET IO device” also refers to the CP

located in the S7 station and configured as a PROFINET IO device.

6.1 Overview of the Preparatory Steps

The following steps are necessary to operate the SIMATIC 300 station with the

CP as a PROFINET IO device:

Configuration Programming

Configure the CP as PROFINET IO device for

data exchange over PROFINET IO. See Section

6.3

Commission and test the PROFINET

IO controller and PROFINET IO

device

Communication diagnostics (for example

if problems occur during communication)

Write the user program for the PROFINET IO

device SIMATIC S7 and download it to the

SIMATIC S7 CPU. See Section 6.4

Commissioning

B3L−20

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 21

6 Configuring and Programming the CP as a PROFINET IO Device

6.2 Principle of Data Exchange over PROFINET IO

Data Exchange between controller and CP as PROFINET IO device

Data exchange between a PROFINET IO controller and PROFINET IO device

involves the following procedure:

S On the PROFINET IO controller

Data exchange is initiated by the PROFINET IO controller that writes output

data to the configured output area (O addresses) and fetches input data from

the configured input area (I addresses).

S On the PROFINET IO device

Data is processed by the CP in the PROFINET IO device on the interface to the

PROFINET IO controller.

Communication within the PROFINET IO device involves calling the FCs

PNIO_RECV and PNIO_SEND in the user program of the CPU.

PROFINET IO device

CPU

STEP 7

user program

PROFINET IO

Process

outputs

Process

inputs

Figure 6-1 Interaction between PROFINET IO Device and PROFINET IO controller

data areas (DB,

bit memory)

PNIO_RECV

PNIO_SEND

CP

database

CP

Receive

Send

PROFINET IO

Configured

O addresses

Configured

I addresses

Note

In the CPU of the device, the IO data areas for input data and output data are

transferred as an entire area to or from one of the data areas (DB, bit memory)

including any gaps.

PROFINET

IO controller

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−21

Page 22

6 Configuring and Programming the CP as a PROFINET IO Device

6.3 Configuration

Configuring the CP as a PROFINET IO device involves the two following activities

in STEP 7:

1. The CP is inserted in a SIMATIC 300 station in HW Config and enabled for

PROFINET IO device mode in the properties dialog.

2. The CP is assigned to a PROFINET IO controller as a PROFINET IO device in

HW Config.

Notice

These two configuration steps can be taken independently in HW Config. In both

steps, make sure that the configured device name for the PROFINET IO device

matches exactly.

6.3.1 Installing the CP and Specifying it as PROFINET IO Device

Follow the steps below in STEP 7 / HW Config:

1. Take the required CP from the hardware catalog and insert the module in the

SIMATIC 300 station.

Figure 6-2 Inserting the CP in a SIMATIC Station in HW Config

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

B3L−22

Release 03/2007

C79000-G8976-C198-04

Page 23

6 Configuring and Programming the CP as a PROFINET IO Device

2. Check and, if necessary, correct the IP address in the “Properties Ethernet”

dialog.

Notice

The IP address of the PROFINET IO device and the IP address of the

PROFINET IO controller must be located in the same IP subnet.

3. Complete the “Properties Ethernet” dialog with OK.

4. Open the properties dialog of the CP.

5. Assign a unique name to the CP as PROFINET node in the “PROFINET” tab.

This name may only be assigned once in the PROFINET IO line.

6. Select the option “Enable PROFINET IO device operation”.

Figure 6-3 Setting the Device Name and the PROFINET IO Device Mode

7. Download the configuration data to the SIMATIC 300 station.

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−23

Page 24

6 Configuring and Programming the CP as a PROFINET IO Device

6.3.2 Assigning the PROFINET IO Device to a PROFINET IO Controller

PROFINET IO Controller

This section describes the configuration of PROFINET IO controllers with STEP 7.

This includes:

S Stations of the type SIMATIC 300 and SIMATIC 400

− CPU with integrated PROFINET IO controller (for example CPU 317−2

PN/DP).

− CPU with external PROFINET IO controller (for example CP 343−1).

S SIMATIC PC station

− For example with CP 1616

If you do not configure your system with STEP 7, you will need to use the GSDML

file of the CP to configure the CP in your configuration system (download address

see Section 9.10)

When configuring the PROFINET IO device (see Section 6.3.1), the selected

PROFINET IO controller is unimportant.

Requirements for Configuration in STEP 7

There must be a SIMATIC station in the STEP 7 project in which a module (CPU

or CP) supports operation as PROFINET IO controller.

Notice

The IP address of the PROFINET IO device and the IP address of the PROFINET

IO controller must be located in the same IP subnet.

Step 1: Configuring the PROFINET IO controller

With some PROFINET IO controller types, STEP 7 automatically creates a

PROFINET IO system as soon as you insert the module, otherwise you may need

to add a PROFINET IO system. Drag the required IO devices from the hardware

catalog to this PROFINET IO system.

Configure a PROFINET IO controller as follows:

1. Open the hardware configuration of the station you want as PROFINET IO

controller in HW Config.

B3L−24

2. If no PROFINET IO system exists, select the PROFINET IO controller (for

example CP 343−1 EX30/GX21, CP 443−1 EX41, CPU 317−2 PN/DP) and

insert a PROFINET IO system (menu “Insert” "“PROFINET IO System”).

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 25

6 Configuring and Programming the CP as a PROFINET IO Device

Result:

You will see the connector symbol for the PROFINET IO system beside the

PROFINET IO controller.

Step 2: Configuring the PROFINET IO device on the PROFINET IO controller

1. Open the hardware catalog and select a version of the CP V2.0 or higher as the

PROFINET IO device from the folder “PROFINET IO” "“I/O”

"

“SIMATIC S7−CP” "“CP 343−1 Lean”.

2. Connect the CP with the PROFINET IO system (drag and drop).

3. Add input and output modules with the required I/O data length (1 to max. 240

bytes) to the PROFINET IO device.

The following screenshot shows the configuration table of the PROFINET IO

controller with an S7−400 station as PROFINET IO controller. The PROFINET IO

device shown here, for example, has three modules for process inputs (I address)

and process outputs (O address).

Figure 6-4 SIMATIC Station with PROFINET IO System with the CP as Device with Input (DI) and

Output Modules (DO)

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−25

Page 26

6 Configuring and Programming the CP as a PROFINET IO Device

Step 3: Configuring the properties of the CP as PROFINET IO device

Continue configuration in HW Config as follows:

1. Open the properties dialog of the PROFINET IO device that you inserted in the

PROFINET IO system.

2. In the “General” tab, assign the same device name that you selected in Section

6.3.1.

B3L−26

Figure 6-5 Properties Dialog of the Device: Assigning the Device Name

3. Deselect the “Assign IP address by IO controller” option.

This step is a recommendation!

By deactivating this option, the IP address you assigned when you installed the

CP in the SIMATIC 300 station (see Section 6.3.1) comes into effect on the

PROFINET IO device. Otherwise the IP address you selected there will be

overwritten by an IP address assigned by the PROFINET IO controller. If it is

overwritten, any configured connections (S7, ISO-on-TCP, TCP) will no longer

be established.

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 27

6 Configuring and Programming the CP as a PROFINET IO Device

No further parameter assignment of the modules is necessary.

Note

By selecting suitable network components and setting the network properties

(Section 9.2) make sure that in PROFINET IO mode, the PROFINET line can be

operated without exception at 100 Mbps full duplex.

6.4 Programming

By programming, you specify the sequence of the user program for the CPU and

therefore also access to the I/O data.

To write and read process data, use the FCs PNIO_SEND (FC11) or PNIO_RECV

(FC12) from the SIMATIC NET block library in your user program.

How to use the existing functions (FCs) in your user program for PROFINET IO

device mode is described in the following sections of this chapter.

You will find an example matching the configuration described in the previous

chapter in Section 6.5.

6.4.1 Interface for Programming on the PROFINET IO Device

FCs

Two functions (FCs) are available for data exchange using the STEP 7 user

program:

S PNIO_SEND (FC11)

This FC reads the preprocessed process inputs of the CPU and transfers them

to the PROFINET IO controller (configured I addresses).

The preprocessed process inputs are available in a DB or bit memory area.

S PNIO_RECV (FC12)

The block accepts the data transferred by the PROFINET IO controller

(configured O addresses) and writes it to the data areas of the CPU reserved

for process outputs.

You will find the precise syntax of the FCs and the meaning of the block

parameters in the chapter on FCs in the general part of the manual or in the online

help for the block library in STEP 7.

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−27

Page 28

6 Configuring and Programming the CP as a PROFINET IO Device

Data consistency

The length information in the block call must be identical to the total length of the

input or output data configured for this PROFINET IO device.

The entire input or output data area of the PROFINET IO controller is transferred

in its entirety between the CP and CPU and is therefore consistent.

Note: Remember, however, that in terms of the “IO user data” within a PROFINET

IO system, only the data consistency of individual IO slots can be guaranteed. This

applies regardless of whether consistent data transfer between the CPU and CP is

guaranteed for the blocks described here.

6.4.2 Initialization and Configuration

Initialization

As a PROFINET IO device, the CP requires the following information in the user

program for configuration by the PROFINET IO controller at every startup:

S Length of the input data (when FC11 is called)

S Length of the output data (when FC12 is called)

When the connection is established between the PROFINET IO controller and the

PROFINET IO devices of a PROFINET IO line, the entire length of the input and

output data is checked. The PROFINET IO controller compares the configured

entire length of the input and output data with the LEN parameter of FC11 and

FC12 in the user program of the device for every PROFINET IO device.

If the length information for the input and output data does not match, the block is

terminated with an error.

During this initialization phase, the two blocks must be called until FC11 signals

DONE=1 and FC12 signals NDR=1.

Notice

Remember that the successful configuration by the PROFINET IO controller is

only possible after local initialization by the FC calls PN IO_SEND (FC11) for the

input data and PN IO_RECV (FC12) for the output data.

B3L−28

Note

During initialization, the data of PNIO_SEND (FC11) is not evaluated and the data

of PNIO_RECV (FC12) is initialized with default values.

FC11 and FC12 transfer valid data only following the subsequent calls.

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 29

6 Configuring and Programming the CP as a PROFINET IO Device

Reasons for reinitialization

The PROFINET IO device requests reinitialization by the user program in the

following situations:

S The length information of the input and output areas in the FCs does not match

the information configured for this PROFINET IO device on the PROFINET IO

system. A change in the length in the FC calls in the user program counts as a

configuration change.

S The CPU or CP changes to STOP mode.

S The watchdog time was exceeded (see below).

S Following a connection abort between the PROFINET IO controller and

PROFINET IO device (for example because the PROFINET IO controller was

turned off).

Watchdog

FC11 and FC12 each have their own watchdog. Depending on the average CPU

cycle time, the connection to the PROFINET IO controller is terminated if one of

the two blocks is no longer called following the initialization phase.

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−29

Page 30

6 Configuring and Programming the CP as a PROFINET IO Device

6.5 Example of Configuration and Programming

The configured input/output modules must be accessed in the user program of the

PROFINET IO device using FCs. The FCs provide the process data preprocessed

in the user program of the PROFINET IO device on the interface to the PROFINET

IO controller (PNIO_SEND) or fetch the data provided by the PROFINET IO

controller for further processing in the user program of the PROFINET IO device

(PNIO_RECV).

The following example shows the configuration in HW Config and excerpts of the

user program of the CPU.

I addresses and O addresses configured on the PROFINET IO controller

The schematic shows the CP configured as a PROFINET IO device in the

PROFINET IO system with three modules for process inputs and process outputs.

S Input area:

− Length: 20 bytes

− available in DB10

− transferred with FC11 PNIO_SEND

Figure 6-6 Configuration of a PROFINET IO device in HW Config

S Output area:

− Length: 7 bytes

− available in DB11

− transferred with FC12 PNIO_RECV

PNIO_RECV

PNIO_SEND

B3L−30

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 31

6 Configuring and Programming the CP as a PROFINET IO Device

Transfer the process inputs (DB10) to the I addresses with PNIO_SEND

For the configured I addresses, you will need to make data areas available on the

PROFINET IO device, for example in a DB (in this example in a DB10) that

contains not only the process data but also the data areas for the IOCS status

information.

Figure 6-7 Data Structure for PNIO_SEND in the PROFINET IO Device

The call interface PNIO_SEND in the user program

STL Explanation

call fc 11

CPLADDR:= W#16#0100

LEN := 20

IOCS := P#DB10.DBX20.0 BYTE 3

DONE := M 70.0

ERROR := M 70.1

STATUS := MW 72

CHECK_IOCS := M 70.2

SEND := P#DB10.DBX0.0 BYTE 20

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

//PNIO_SEND block call

//(transfer inputs to IO controller)

//Module address from hardware configuration

//No. of log. I addressesto transfer. in bytes

//Per send data byte, one bit status in DB10

//Address for return parameter DONE

//Address for return parameter ERROR

//Address for return parameter STATUS

//Address for return parameter CHECK_IOCS

//Data area to be transferred from DB10

//(20 bytes)

B3L−31

Page 32

6 Configuring and Programming the CP as a PROFINET IO Device

Transfer the O addresses to the process outputs (DB11) with PNIO_RECV

For the configured O addresses, you will need to make data areas available on the

PROFINET IO device, for example in a DB (in this example in a DB11) that

contains not only the process data but also the data areas for the IOPS status

information.

Figure 6-8 Data Structure for PNIO_RECV in the PROFINET IO Device

The call interface PNIO_RECV in the user program

STL Explanation

call fc 12

CPLADDR:= W#16#0100

LEN := 7

IOPS := P#DB11.DBX7.0 BYTE 1

NDR := M 74.0

ERROR := M 74.1

STATUS := MW 76

CHECK_IOPS := M74.2

RECV := P#DB11.DBX0.0 BYTE 7

ADD_INFO:= MW 26

//PNIO_RECV block call

//(read outputs from IO controller)

//Module address from hardware configuration

//No. of log. O addresses to transfer in bytes

//Per receive data byte one status bit in DB11

//Address for return parameter NDR

//Address for return parameter ERROR

//Address for return parameter STATUS

//Address for return parameter CHECK_IOPS

//Received data in DB11 (7 bytes)

//Diagnostic information

B3L−32

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 33

7 Web Diagnostics

With Web diagnostics, the CP provides you with the option of calling up the most

important settings of a connected station and the status of their network

connections and communication partners from an HTTP client on a PG/PC. You

can also query the diagnostic buffer entries of the modules of the rack in which the

CP is located.

Using Web diagnostics, you can only read the data of the connected station.

7.1 Requirements and Use

Settings for Access to Diagnostic Data

Check the following settings that are necessary for access to the diagnostic data:

7 Web Diagnostics

S To load diagnostic data, Java Script must be enabled in the Internet browser.

S The browser must support frames.

S Cookies must be accepted.

S The browser should be set so that it downloads the current data from the server

automatically each time it accesses a page.

In Internet Explorer, you will find these settings in the “Tools” menu "“Internet

Options” "“General” tab "“Temporary Internet Files” group box " “Settings”

button.

S When using a firewall on your PG/PC, the following port must be enabled for

Web diagnostics: “http port 80/TCP”

Note

Station or device names configured in STEP 7 with special characters (for

example umlauts ä, ü etc.) may possibly be incorrectly interpreted in Web

diagnostics.

Starting and Working with Web Diagnostics

Follow the steps outlined below to start Web diagnostics:

1. Connect your PC with the LAN to which the CP is connected.

2. Start the Internet browser and enter the following address in the address line of

your Internet browser:

http:\\<IP address of the CP>

Web diagnostics opens with the “Start Page”.

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−33

Page 34

7 Web Diagnostics

3. Select the display language you require from the “Language” drop-down list box

at the top right. The following languages are available:

S English

S Deutsch

S Français

S Español

S Italiano

4. You open the other pages using the navigation panel to the left of the window.

7.2 Diagnostics Pages of the CP

Layout of the Diagnostics Pages

The title bar of the Web diagnostics page displays the STEP 7 station name of the

S7 station in which the CP is located.

Below the title bar of the start page, you can see the CP type (here:

CP 343−1 CX10).

Above the navigation panel to the left, you can see the module type (here:

“SIMATIC S7 CP”).

B3L−34

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 35

7.2.1 Start Page

This page displays general device data and the status of the connected CP.

7 Web Diagnostics

Parameter Function

General

Station name Configured name of the station in which the CP is installed.

Module name Configured name of the module

Module type Name of the module type

Status

Operating mode Current mode of the CP:

S Starting

S RUN (CP in productive mode)

S Stopping

S STOP

S Stopped with error

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−35

Page 36

7 Web Diagnostics

7.2.2 Identification

Here, you can see a variety of information on the CP for identification and

maintenance.

Parameter Function

Identification

Plant designation 1)Plant designation of the CP if this was configured.

Location identifier 1)Location identifier of the CP if this was configured.

Serial number Serial number of the CP

Order number Order number of the CP

Version

Hardware Hardware version of the module

Firmware Version of the stored firmware

1)

A CP acting as PROFINET IO device can be informed of the plant designation

and location identifier by the PROFINET IO controller using the “write data

record” function. This is done using the maintenance data record “IM1” with

index AFF1H.

The “write data record” function is explained in detail in the general part A of the

manual in the description of the FCs for PROFINET IO.

B3L−36

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 37

7.2.3 Rack Configuration

The slots of the station and general data along with the status of the devices is

displayed here.

7 Web Diagnostics

Parameter Function

Rack Configuration (rack name)

Slot Slot of the individual modules in the rack

Status Status display of the relevant module:

S Green (OK, module in operation)

S Red (a problem has occurred)

S Yellow (module changed to STOP)

The last column “LED Status” contains more information.

Module name Name of the module configured in HW Config

Order number Order number of the module

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−37

Page 38

7 Web Diagnostics

Parameter Function

Version Firmware version of the module

LED Status LED display of the module:

S Gray (inactive LED, the LED is off)

S Colored (active LED, the LED is lit)

The number of type of the LEDs depends on the particular module type. You will

find an explanation of the significance of the LEDs in the documentation for the

particular module.

B3L−38

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 39

7 Web Diagnostics

7.2.4 Diagnostic Buffer

This table lists all the events in the chronological order in which they were

received. The latest entry is at the start and the oldest entry at the end of the table.

By clicking on the various tabs above the table, you can select the individual

modules in the rack.

Parameter Function

Events

Number Consecutive number of the entry

Time Time of the entry

Note

If the module has synchronized itself with a time server, the current time is

displayed. Otherwise the time since the last restart is displayed.

Date Date of the entry if the module is synchronized. Otherwise the default time of the

module (01.01.1994) or the day of the last restart is displayed.

Event Displays the diagnostic buffer entry (entries only in English)

Details: “no. of the event”

Event ID Event ID of the diagnostic buffer entry

Text of the event entry

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−39

Page 40

7 Web Diagnostics

7.2.5 Industrial Ethernet

“Parameters” Tab

This page shows you the various parameters of the MAC address, the IP address

and the LAN attachments.

Parameter Function

Network attachment

MAC address

(active)

Active MAC address of the CP

MAC address

(factory setting)

Device name Device name configured in STEP 7 (properties dialog, “PROFINET” tab)

IP parameters

IP address IP address of the CP

Subnet mask Configured subnet mask

Default router IP address of a configured router

IP settings How the IP address is assigned (for example, STEP 7, DHCP ...)

Physical properties

Port number Number of the LAN port of the CP: 1, 2

Link status Status of the LAN port:

MAC address set in the factory

S OK

S no link

Setting Display of the individual network settings configured in STEP 7:

S Configured

S automatic (automatic setting / autonegotiation)

Mode Displays the current network properties (transmission rate and direction). Possible

values:

S 10 Mbps half duplex

S 10 Mbps full duplex

S 100 Mbps half duplex

S 100 Mbps full duplex

B3L−40

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 41

7 Web Diagnostics

“Statistics” Tab

This page displays information on sent and received frames since the last module

restart.

Parameter Function

Data packets sent

Number of error-free frames sent, number of unicast, multicast and broadcast frames and the frames

canceled due to a collision

Received data packets

Number of error-free received frames, received unicast, multicast and broadcast frames, frames rejected

due to checksum or alignment errors and frames rejected due to a lack of resources

“TCP Connections” Tab

This page informs you about existing TCP connections.

Parameter Function

Number Consecutive number of the TCP connection

Local IP address IP address of the CP

Partner IP address Partner IP address

Local port Number of the port used for the TCP connection

Partner port Number of the port on the partner used for the TCP connection

Status Connection status of the TCP connection, for example:

S LISTEN (waiting for connection)

S ESTABLISHED (existing connection)

S TIME WAIT (wait state prior to connection termination) and

S other interim statuses such as SYN SENT, SYN RECV, CLOSING etc.)

“UDP Connections” Tab

This page informs you about existing UDP connections.

Parameter Function

Number Consecutive number of the UDP connection

Local IP address IP address of the CP

Partner IP address Partner IP address

local port Number of the port used for the UDP connection

Partner port Number of the port on the partner used for the UDP connection

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−41

Page 42

7 Web Diagnostics

7.2.6 PROFINET IO

This page provides you with information on the most important parameters of the

PROFINET IO configuration.

Parameters of a PROFINET IO Device

Parameter Function

PROFINET IO Configuration

Mode PROFINET IO mode of the CP (here: PROFINET IO device):

S PROFINET IO controller

S PROFINET IO device

S No PROFINET IO configuration

Device name Device name

IP address IP address of the device

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

B3L−42

Release 03/2007

C79000-G8976-C198-04

Page 43

Parameter Function

Status Status of the device:

S OK

(problem-free operation)

S No connection to PROFINET IO controller

(connection disrupted or broken down)

S PROFINET IO blocks are not called correctly

(the blocks are not called or not correctly called)

Assigned PNIO controller

Device name Device name of the assigned controller

IP address IP address of the controller

7 Web Diagnostics

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−43

Page 44

8 Compatibility with Predecessor Products

8 Compatibility with Predecessor Products

8.1 Extended Functionality

New: Enhanced functions compared with module 6GK7 343−1CX10−0XE0 with

firmware version V1.0

The following properties, services and functions are new:

S Web diagnostics

S New GSDML file

8.2 Replacing Older Modules / Replacing Faulty Modules

Use as a Replacement:

The CP 343−1 Lean with order number 6GK7 343−1CX10−0XE0 (firmware version

2.0) described here can be used as a replacement for the following predecessor

products:

S CP 343−1 Lean (6GK7 343−1CX00−0XE0)

If you replace a CP 343−1 Lean (CX00) module with a CP 343−1 Lean (CX10)

and have STEP 7 version < V5.4, all the previous functions of the module

remain available. Any port settings relating to Ethernet are adopted for port 1.

The additional second RJ−45 port is also available in the “Automatic setting”

mode.

S CP 343−1 Lean (6GK7 343−1CX10−0XE0, firmware version 1.0)

All previous functions remain available. They are supplemented by the functions

of Web diagnostics.

Notice

For new user programs, please make sure that you always use the latest block

versions. You will find information on the latest block version and links to download

the current blocks on the Internet:

B3L−44

http://www4.ad.siemens.de/WW/news/en/8797900

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 45

Module Replacement

When replacing an older module with the module described here, keep to the steps

outlined below:

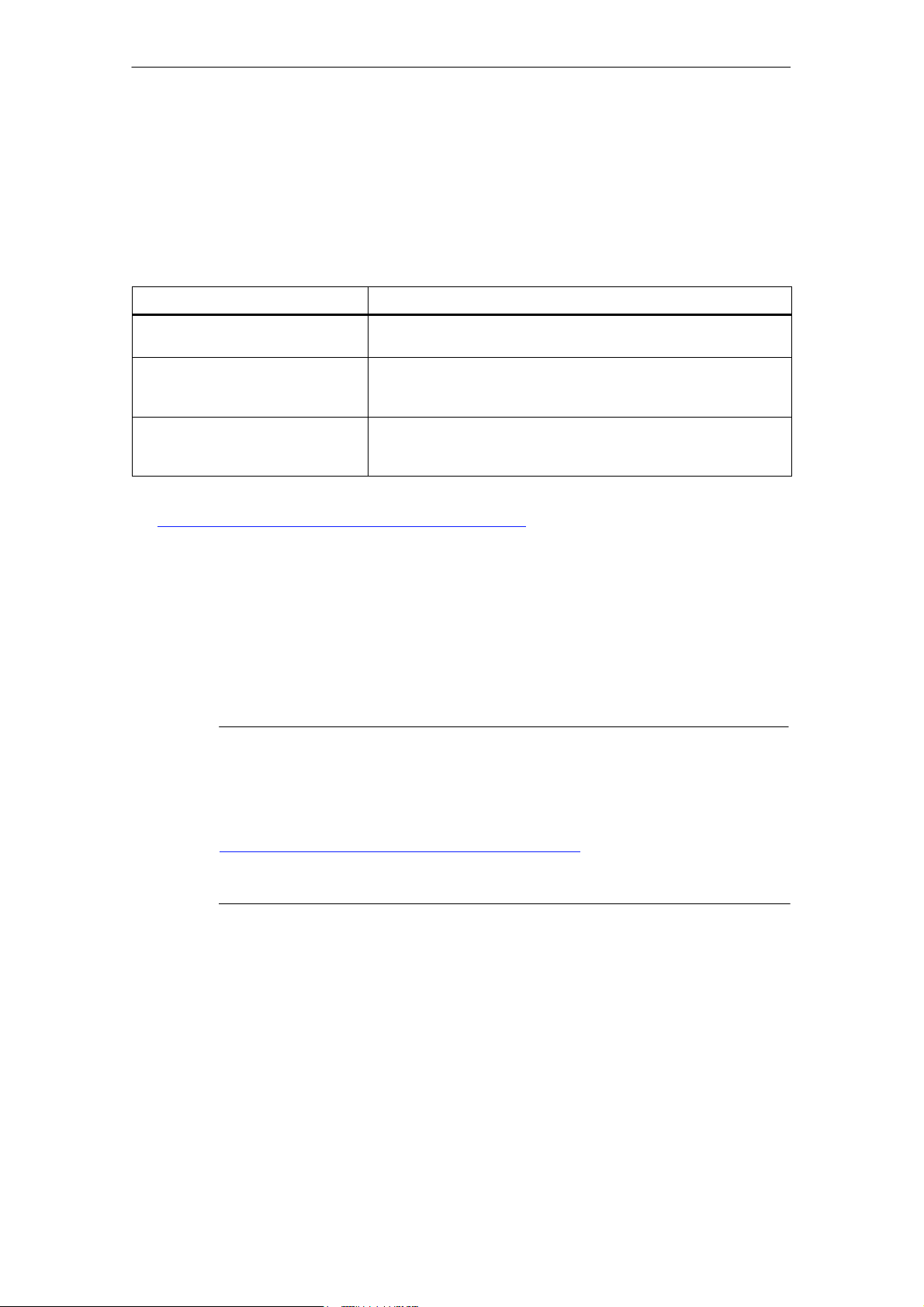

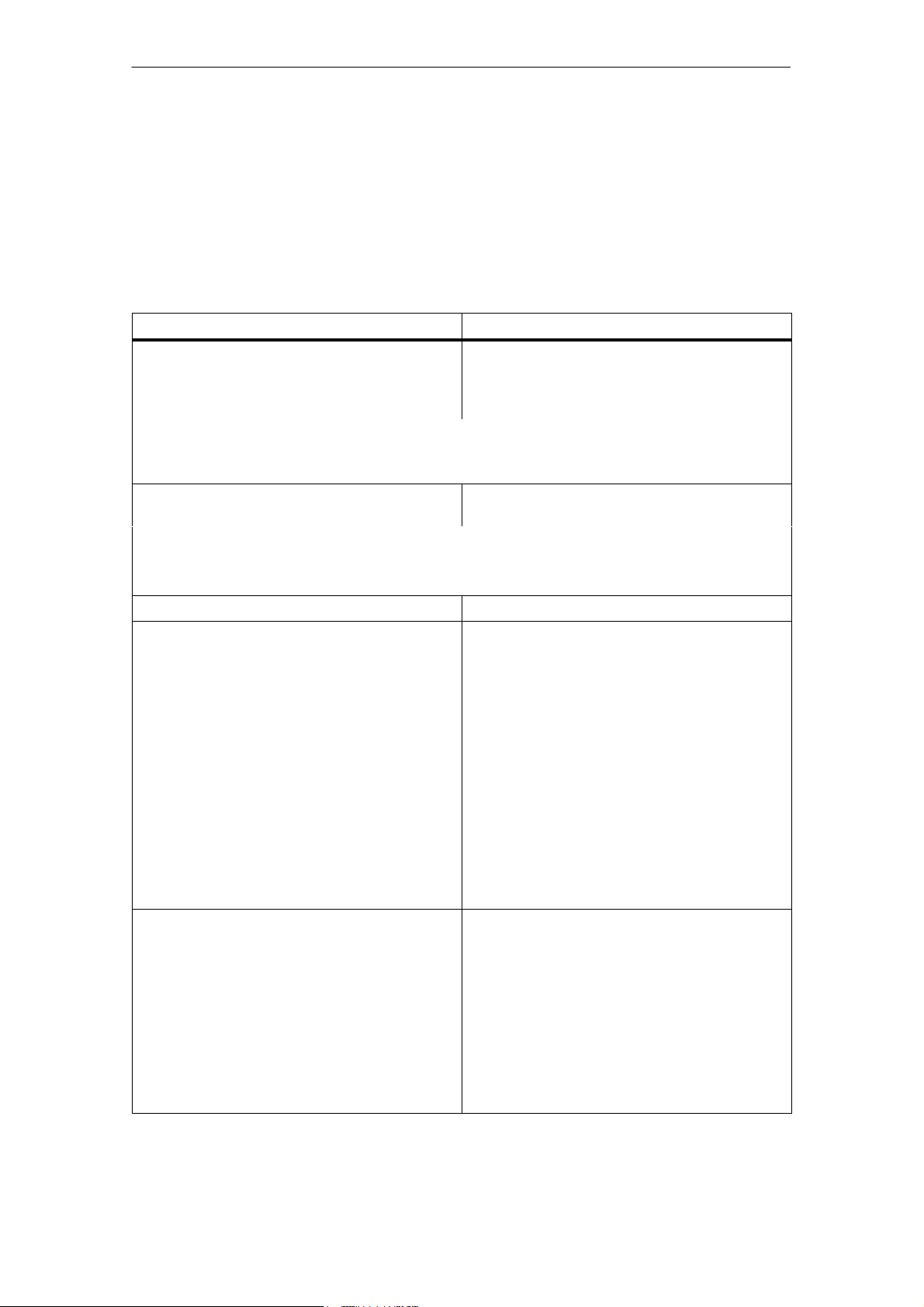

Table 8-1

8 Compatibility with Predecessor Products

Originally configured module

6GK7 343−1CX00−0XE0 Case a: Configuration unchanged

If you do not have any new requirements compared with the previous

CP (for example, PROFINET IO mode), no modification of the project

engineering is necessary.

Case b: Adapted project engineering data

If you want to use the extended functionality of the new CP, follow the

steps below:

1. In STEP 7 / HW Config, replace the previously configured CP

Lean with the new module from the hardware catalog.

2. Extend your configuration to match your requirements, for

example, by enabling the CP for PROFINET IO device mode.

3. Save, compile and download the configuration data to the CPU

again.

Configuration Steps

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−45

Page 46

9 Further Notes on Operation

9 Further Notes on Operation

9.1 Memory Reset

Available Functions

The CP has a two-level function available for resetting memory:

S Clear / reset

Following this memory reset, the CP retains the preset MAC address and the

retentive parameters. The CP is therefore immediately ready for downloads

using the IP address.

The retentive parameters include:

− IP address, subnet mask and, if applicable, router address

− LAN settings

S Resetting to factory settings

After this memory reset, the CP retains only the factory-set MAC address (as

shipped).

Note

Using the functions described here to reset the memory, you do not modify the

configuration data on the CPU!

If you subsequently upload the configuration data from the CPU to a PG you will

always obtain the configuration data that were previously on the CP (with

parameters, connections, IP address).

How to Use the Function

You can start the memory reset functions in STEP 7.

S Clear / reset

In STEP 7 / /HW Config with PLC " Clear/Reset

or

B3L−46

In STEP 7 / NCM Diagnostics with Operating Mode " Clear/Reset Module

S Factory defaults reset

In STEP 7 / NCM Diagnostics with Operating Mode " Reset to Factory

Defaults

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 47

9 Further Notes on Operation

Behavior after Memory Reset

The CPU in the S7 station does not recognize that the CP memory was reset. The

CP therefore changes to the “stopped with error” state (see Chapter 4).

The configuration data must then be reloaded.

You can initiate this loading by turning the power off and on again.

9.2 Working with Fast Ethernet − automatic switchover

How Automatic Switchover of the Network Settings Works

The CP has two 10/100 Mbps half/full duplex ports with autosensing and

autonegotiation of the network settings. After turning on the CP, these functions

work as explained below:

S The CP attempts to detect the transmission rate (10/100 Mbps) being used by

S If detection is possible, the CP attempts to negotiate a full duplex with the

S If no negotiation is possible, the CP uses the previously detected transmission

Duration of the procedure: up to 2 seconds

You set the network properties of the CP in STEP 7 in the properties dialog of the

CP, “Port Parameters” tab.

Autocrossing

The automatic setting also includes an “autocrossing” mechanism. With

autocrossing, you can connect network components and end devices using either

crossover or straight−through cables.

the partner.

If no connection is established between partners in PROFINET IO mode, you

should check whether the devices involved are set to “automatic setting” or

100 Mbps full duplex.

partner.

rate and half duplex.

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−47

Page 48

9 Further Notes on Operation

Automatic Setting or Individual Network Settings

As default, the CP is configured for automatic detection (autosensing). As soon as

you define a configuration manually when configuring the CP with

STEP 7/HW Config (in the properties dialog of the CP − “Port Parameters” tab),

the automatic negotiation of the network settings (autonegotiation) is no longer in

effect. If, on the other hand, the communication partner works with autonegotiation,

no communication will be established.

Only use manual configuration when the communication partner works with the

same manually set configuration.

Notice

When operating with PROFINET IO, a transmission rate of 100 Mbps full duplex is

necessary.

Further Notes:

S Autocrossing

If you disable the “automatic setting” option in the “Port Parameters” tab,

autocrossing is also disabled; which cable you can then use depends on the

role of the CP (network component or end device).

S 10/100 Mbps network components without “Autonegotiation”

If you use 10/100 Mbps network components that do not support

“Autonegotiation”, you may have to set the mode manually during CP

configuration using STEP 7 / HW Config (in the properties dialog of the CP). As

default, the CP is configured for automatic detection.

S Forcing a specific network setting instead of “Autonegotiation”

If your application requires a fixed network setting instead of “Autonegotiation”,

both partner devices must have the same setting.

S No reaction to Autonegotiation query with manual configuration

Remember that if you configure the CP manually, it will not react to an

autonegotiation query! As a result, a connected partner will not be able to make

the required network setting and communication will not be established.

Example:

If, for example, the CP is set to “100 Mbps − full duplex”, a CP connected as

partner will set “100 Mbps − half duplex”. Reason: Due to the fixed setting, no

autonegotiation response is possible; the connected partner recognizes the 100

Mbps with autosensing but nevertheless remains in half duplex.

B3L−48

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 49

9 Further Notes on Operation

S Recommendation: Change “individual network settings” only over MPI.

If you modify the LAN settings in the properties dialog of the CP in the “Port

Parameters” tab, these changes will be adopted by the CP and activated when

the configuration data is downloaded to the CP.

We therefore recommend that you download configuration data to the S7

station over an MPI connection if you change this setting.

If you download the configuration data over the LAN interface, depending on

the selected setting, it is possible that the current download will not be

completed due to the changes to the configuration taking immediate effect.

STEP 7 / NCM Diagnostics and Web diagnostics display the network setting

You will find information on the network settings currently being used in NCM

Diagnostics in the “Industrial Ethernet” diagnostic object in the “Network

Attachment” section or in Web diagnostics on the “Industrial Ethernet” page in the

“Parameters” tab.

9.3 SNMP Agent

SNMP (Simple Network Management Protocol)

The CP supports data queries over SNMP in version 1.

SNMP is protocol language for managing networks. To transmit data, SNMP uses

the connectionless UDP protocol.

The information on the properties of SNMP−compliant devices is entered in MIB

files (MIB = Managed Information Base). For more detailed information on working

with MIB files, refer to the documentation of the SNMP client you are using

(example of an SNMP client: SNMP OPC Server from SIMATIC NET).

Supported MIB Objects

The CP supports all MIB objects according to the MIB standard MIB II (RFC 1213)

and LLDP MIB.

Exceptions / restrictions:

S Write access is permitted only for the following MIB objects:

sysContact, sysLocation and sysName;

For security reasons, only read access is permitted for all other MIB objects.

S Traps are not supported by the CP.

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−49

Page 50

9 Further Notes on Operation

Access Permissions using Community Name

The CP uses the following community names for assigning permissions:

S For read access: “public”

S for read and write access: “private”

(note the use of lower−case letters!)

9.4 Possible Security Gaps on Standard IT Interfaces / Preventing Illegal Access

With various SIMATIC NET components, such as OSMs/ESMs, a wide range of

parameter assignment and diagnostic functions (for example, Web servers,

network management) are available over open protocols and interfaces. The

possibility of unauthorized misuse of these open protocols and interfaces by third

parties, for example to manipulate data, cannot be entirely excluded.

When using the functions listed above and these open interfaces and protocols (for

example, SNMP, HTTP), you should take suitable security measures to prevent

unauthorized access to the components and the network particularly from within

the WAN/Internet.

Notice

We expressly point out that automation networks must be isolated from the rest of

the company network by suitable gateways (for example using tried and tested

firewall systems). We do not accept any liability whatsoever, whatever the legal

justification, for damage resulting from non−adherence to this notice.

If you have questions on the use of firewall systems and IT security, please contact

your local Siemens office or representative. You will find the address in the

SIMATIC catalog IK PI or on the Internet at

http://www.automation.siemens.com/net > Contact & Partners > Local

Partners.

9.5 Influence of MPI on Connections via Industrial Ethernet

If a station on MPI is added or removed, for example because a service PG has

been connected or disconnected, it is possible that active communication

connections on the communications bus are aborted. This has the following effects

on the communication connections on Industrial Ethernet:

B3L−50

S All S7 connections are temporarily aborted.

This does not apply when using CPUs with a separate K bus (for example, the

CPU 318−2, CPU 317−2 PN/DP, CPU 319−3 PN/DP).

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 51

9 Further Notes on Operation

S The connections on which a job on the communication bus with a data length >

240 bytes is being processed are aborted temporarily.

S FETCH/WRITE connections are temporarily aborted.

On the FC interface in the user program, the condition codes made up of the

DONE, ERROR and STATUS parameters must be evaluated in FC11 / FC12.

9.6 Special Features of IP Configuration

Configured S7 connections cannot be operated if the IP address is assigned

over DHCP

Notice

If you obtain the IP address over DHCP, any S7 connections you may have

configured will not work. Reason: The configured IP address is replaced by the

address obtained over DHCP during operation.

9.7 Reserved Port Numbers

The following local port numbers are reserved; You should not use these for other

purposes in the connection configuration.

Table 9-1 Reserved Port Numbers

Protocol

TCP 20, 21 FTP

TCP 25 SMTP

TCP 80 HTTP

TCP 102 RFC1006

TCP 135 RPC−DCOM

UDP 161 SNMP_REQUEST

UDP 34964 PN IO

UDP 65532 NTP

UDP 65533 NTP

UDP 65534 NTP

UDP 65535 NTP

Port number Service

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−51

Page 52

9 Further Notes on Operation

9.8 Restart after Detection of a Duplicate IP Address in the Network

To save you time-consuming troubleshooting in the network, the CP detects double

addressing in the network.

When you eliminate the cause by removing the device with the same IP address or

changing its address, you must then restart the CP.

9.9 Obtaining the IP Address over DHCP − CP STOP on

Expiry of the Lease

If you have configured “Obtain IP address from a DHCP server”, when the CP

starts up, it is assigned a valid IP address by the DHCP server for a restricted time

(period of the lease).

When the lease expires the reaction of the CP is as follows:

The CP changes to STOP and loses the previously assigned IP address if the

DHCP server does not assign a new IP address on expiry of the lease. All

communication connections are terminated.

9.10 Other information available about the CP

FAQ

You will find detailed information (FAQs) on using the CP described here on the

Internet under the following entry number:

http://www4.ad.siemens.de/WW/news/en/10806025 > “FAQ” tab

GSDML file

You will find the GSDML file for the CP described here on the Internet under the

following entry ID:

http://support.automation.siemens.com/WW/view/en/19698639/133100

B3L−52

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

Page 53

10 How to Load New Firmware

Requirements

You download new firmware to a SIMATIC NET CP using the firmware loader

shipped with STEP 7 / NCM S7.

Requirements for Downloading

S To download firmware, you require an Industrial Ethernet CP module in the

PG/PC (for example, CP 1613) or a normal Ethernet module with the “Softnet”

software package.

S The S7-ONLINE interface must be set to the “ISO − Industrial Ethernet”

protocol. It is not possible to download using TCP/IP (and therefore not to other

networks).

How to Download New Firmware

10 How to Load New Firmware

You always start the download using the active MAC address of the CP!

LEDs to Indicate the CP Mode

The different combinations of the LEDs on the front panel indicate the status:

Table 10-1

SF

(red)

Legend: (colored) on off (colored) flashing “−” any

BF

(red)

RUN

(green)

STOP

(yellow)

What to do if a Download is Interrupted

Disturbances or collisions on the network can lead to packets being lost. In such

cases, this can lead to an interruption of the firmware download. The firmware

loader then signals a timeout or negative response from the module being loaded.

CP Operating Mode

Downloading firmware.

Firmware was successfully downloaded.

Firmware could not be downloaded.

In this case, turn the station off and on again and repeat the download.

CP 343-1 Lean for Industrial Ethernet / Manual Part B3L

Release 03/2007

C79000-G8976-C198-04

B3L−53

Page 54

11 Technical Specifications

11 Technical Specifications

Transmission rate 10 Mbps and 100 Mbps

Interfaces

Connection to Ethernet 2 x RJ−45 jack

Power supply DC +24 V (permitted range: +20.4 V through +28.8

V)

Current consumption

S from backplane bus

S from external 24 V DC

Power loss approx. 5.8 W

Permitted ambient conditions

S Operating temperature

S Transportation/storage

temperature

S Relative humidity max.

S Altitude

Design

S Module format

Compact module S7-300; single width

S Dimensions (W x H x D) in mm

S Weight approx.

200 mA maximum

TP: approx. 0.2 A maximum

0 °C to +60 °C

−40 °C to +70 °C

95% at +25 °C

up to 2000 m above sea level

40 x 125 x 120

220 g

Table 11-1 Description of the Approvals

c−UL−us

c−UL−us for hazardous locations UL 1604, UL 2279PT.15

FM FM 3611

C−TICK AS/NZS 2064 (Class A).

CE EN 61000−6−2, EN 61000−6−4 (replaces EN

ATEX Zone 2 EN60079−15

Temperature code “T..” and maximum ambient temperature “Ta:..” as listed on the type plate

UL 508

CSA C22.2 No. 142

CL. 1, Div. 2 GP.A.B.C.D T..

CL. 1, Zone 2, GP. IIC, T..

CL. 1, Zone 2, AEx nC IIC T..

CL. 1, Div. 2 GP.A.B.C.D T..

CL. 1, Zone 2, GP.IIC. T..