Page 1

SITRANS F

Coriolis Flowmeters

FCT030 HART (From firmware 4.0)

Introduction

HART Communication

Interface

1

2

Function Manual

Commissioning

HART commands

Specification

Definitions

3

4

5

A

06/2018

A5E39931617-AB

Page 2

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Siemens products

Note the following:

WARNING

Siemens products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and

maintenance are required to ensure that the products operate safely and without any problems. The permissible

ambient conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Siemens AG. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Siemens AG

Division Process Industries and Drives

Postfach 48 48

90026 NÜRNBERG

GERMANY

Document order number: A5E39931617

Ⓟ 05/2018 Subject to change

Copyright © Siemens AG 2018.

All rights reserved

Page 3

Table of contents

1 Introduction...................................................................................................................................................5

1.1 Purpose of this documentation.................................................................................................5

1.2 Document history.....................................................................................................................5

1.3 Product compatibility................................................................................................................6

2 HART Communication Interface...................................................................................................................7

2.1 HART Communication Interface..............................................................................................7

2.2 Connecting the Current HART, CH1......................................................................................10

3 Commissioning...........................................................................................................................................13

3.1 General requirements............................................................................................................13

3.2 Operating via SIMATIC PDM.................................................................................................13

3.3 Functions in SIMATIC PDM...................................................................................................13

3.4 Commissioning steps.............................................................................................................13

3.5 Initial Setup............................................................................................................................14

3.6 Adding device to communication network..............................................................................15

3.7 Configuring a new device.......................................................................................................18

3.8 Wizard - Quick Start via PDM................................................................................................18

3.9 Wizard - Zero Point adjustment..............................................................................................27

3.10 Changing parameter settings using SIMATIC PDM...............................................................28

3.11 Parameters accessed via drop-down menus.........................................................................29

4 HART commands.......................................................................................................................................33

4.1 Device Variables....................................................................................................................33

4.2 Universal commands..............................................................................................................34

4.3 Common practice commands................................................................................................36

4.4 Burst Mode.............................................................................................................................37

4.4.1 Catch Device Variable............................................................................................................37

4.5 Device-specific commands....................................................................................................37

4.5.1 Command #130: Read. User Login........................................................................................37

4.5.2 Command #131: Read, Current HART Access Level............................................................38

4.5.3 Command # 140: Read Parameter(s)....................................................................................39

4.5.4 Command # 141: Write Parameter(s)....................................................................................40

4.5.5 Command # 142: Write Parameter(s)....................................................................................41

4.5.6 Command # 143: Write Parameter(s)....................................................................................42

4.5.7 Command # 144: Read Device Variable Information.............................................................43

4.5.8 Command # 145: Read Unit Related Parameter(s)...............................................................45

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 3

Page 4

Table of contents

4.5.9 Command # 146: Write Unit Related Parameter(s)...............................................................46

4.6 Supported Engineering Units.................................................................................................47

4.7 HART specific information table.............................................................................................50

4.8 Example using HART command............................................................................................54

4.8.1 Reset totalizer 1.....................................................................................................................54

5 Specification...............................................................................................................................................57

A Definitions...................................................................................................................................................59

Index...........................................................................................................................................................63

FCT030 HART (From firmware 4.0)

4 Function Manual, 06/2018, A5E39931617-AB

Page 5

Introduction

1.1 Purpose of this documentation

This manual contains all information needed to integrate the process instruments into a

communications network. The manual is aimed at control system designers, system

integrators, instrument engineers.

In order to operate safety and for more detailed information you need the product specific

manual. Available for download from Flow documentation (http://www.siemens.com/

flowdocumentation).

This manual applies to the SITRANS FCT030 transmitter HART version only. The FCT030

transmitter can be used in combination with the following sensors:

Mass 2100

FC300

FCS400 and FCS300

In order to operate a Coriolis flow meter, you also need Operating Instructions. See Flow

documentation (http://www.siemens.com/flowdocumentation)

1

1.2 Document history

The following table shows major changes in the documentation compared to the previous

edition.

The most important changes in the documentation when compared with the respective

previous edition are given in the following table.

Edition Note

06/2018 Second edition

06/2017 First edition

Use the device to measure process medium in accordance with the information in the

Operating Instructions.

Note

Use in a domestic environment

This Class A Group 1 equipment is intended for use in industrial areas.

In a domestic environment this device may cause radio interference.

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 5

Page 6

Introduction

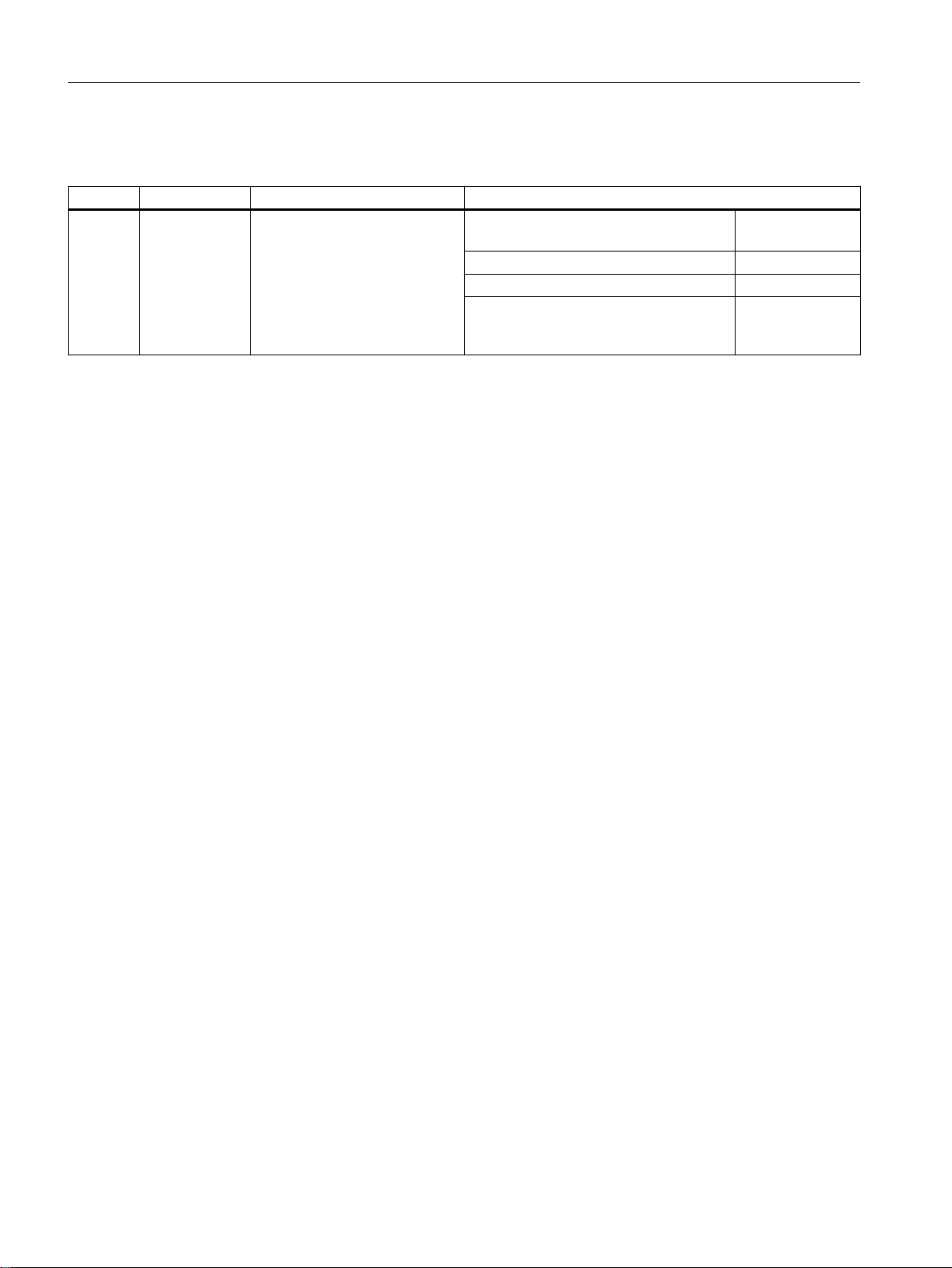

1.3 Product compatibility

1.3 Product compatibility

Edition Remarks Product compatibility Compatibility of device integration package

06/2017 First revision HW revision 03

Compact FW revision 4.xx.xx-xx

Remote FW revision 4.xx.xx-xx

HART: SIMATIC V8.2 Service Pack 1 or

later

HART: SITRANS DTM V4.1 5.00.xx-xx

HART: AMS Device manager V12 5.00.xx-xx

Defice integration package for Field De‐

vice Communicator (Handheld FC375/

FC475 V3.8)

5.00.xx-xx

5.00.xx-xx

FCT030 HART (From firmware 4.0)

6 Function Manual, 06/2018, A5E39931617-AB

Page 7

HART Communication Interface

2))

21

+$57

DGGUHVV

2.1 HART Communication Interface

System communication

Table 2-1 HART protocol identification data

Manufacturer ID 42 (2A Hex) Manufacturer ID parameter

Device type 34 (22 Hex) Device type parameter

HART protocol revision 7.5 HART protocol revision parameter

Device revision 5 Device revision parameter

Note: Version numbers and other references shown above are typical or example values.

Device description files

Available EDD drivers:

● SIMATIC PDM

2

● FDT/DTM

● AMS suite

● 375 Field Communicator

The drivers can be downloaded here:

Download EDD Files (http://www.siemens.com/flowdocumentation)

Configuration of the HART polling address

The HART address can be set either via hardware (DIP switch) or via software (HMI or

SIMATIC PDM).

The DIP switch is located on the transmitter cassette.

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 7

Figure 2-1 HART slave address switch

Page 8

HART Communication Interface

2.1 HART Communication Interface

● Configuration via DIP switch (HW polling address)

Set 1 to 15 on the DIP switch if you wish to set a fixed (hardware-defined) HART polling

address (SW polling address will be ignored). The configured HW polling address can be

read via HMI in menu item 4.2.

● Configuration via HMI or SIMATIC PDM (SW polling address)

Disable the HW polling address by setting all switches to "OFF" on the HART DIP switch.

The device starts up with default slave address = 0. The SW polling address can be changed

to a value between 0 and 63 via HMI (menu item 4.1) or SIMATIC PDM

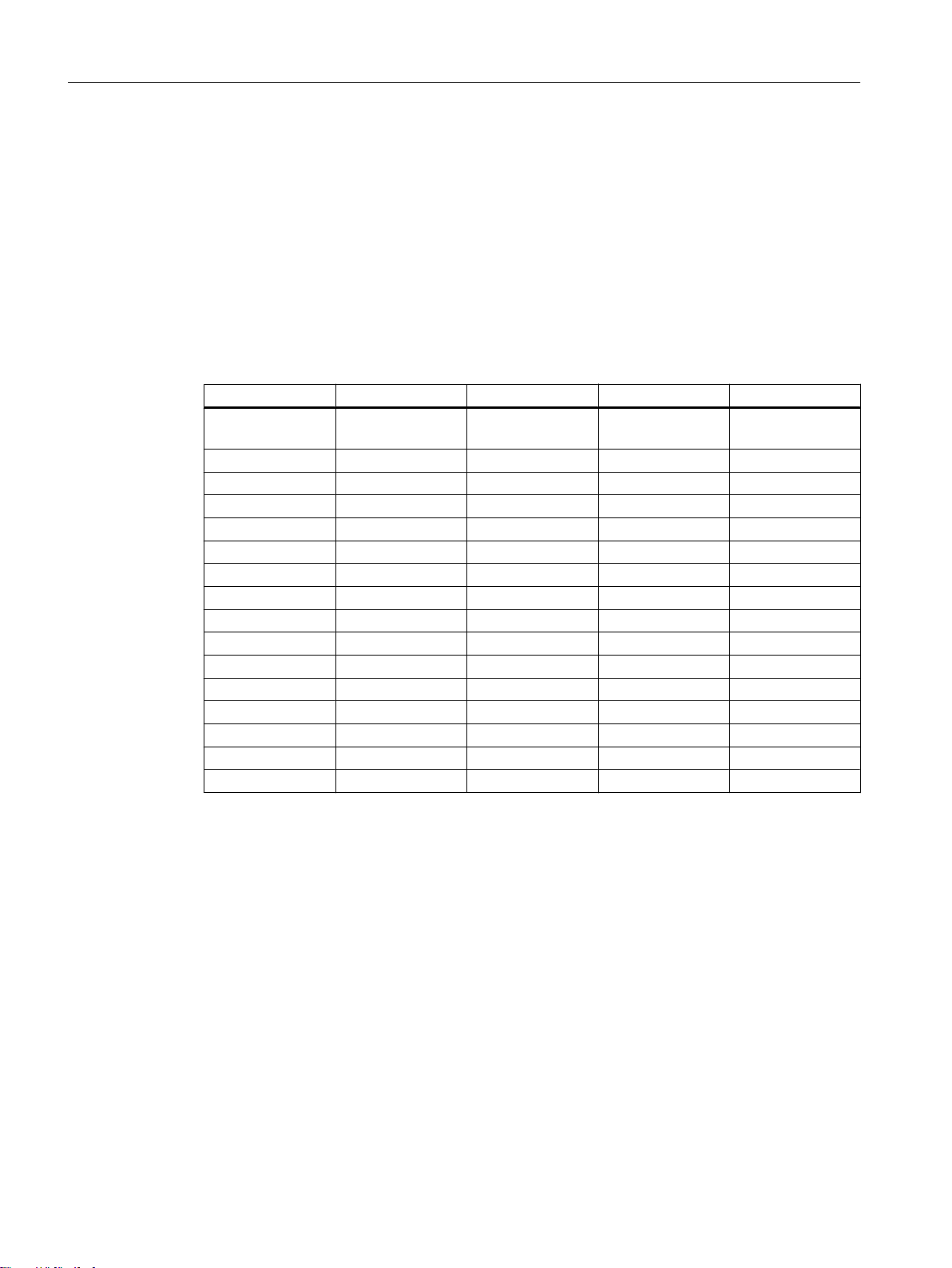

DIP switch configuration

Table 2-2 HW polling address

Address Switch 1 Switch 2 Switch 3 Switch 4

"SW polling ad‐

dress"

1 On Off Off Off

2 Off On Off Off

3 On On Off Off

4 Off Off On Off

5 On Off On Off

6 Off On On Off

7 On On On Off

8 Off Off Off On

9 On Off Off On

10 Off On Off On

11 On On Off On

12 Off Off On On

13 On Off On On

14 Off On On On

15 On On On On

Off Off Off Off

Mapping of measured process variables

The assignment of the measured process values to HART device variables (PV - primary

variable; SV - secondary variable; TV - tertiary variable; and QV - quaternary variable) can be

modified and assigned as desired via local user interface or via HART interface using SIMATIC

PDM.

FCT030 HART (From firmware 4.0)

8 Function Manual, 06/2018, A5E39931617-AB

Page 9

HART Communication Interface

2.1 HART Communication Interface

PV: The process value assigned to current output 1 (HMI menu item 2.4.1.1) is automatically

assigned to PV.

● Measured values for PV

– Mass flow

– Volume flow

– Density

– Process media temperature

– Standard volume flow

– Fraction flow Media A (mass or volume flow)

– Fraction flow Media B (mass or volume flow)

– Fraction A %

– Fraction B %

– Frame Temperature

SV, TV, QV: Freely selectable (HMI menu item 4.6) from the list below.

● Measured values for SV, TV and QV

– Massflow

– Volumeflow

– Density

– Process media temperature

– Standard volumeflow

– Fraction A massflow

– Fraction A volumeflow

– Fraction B massflow

– Fraction B volumeflow

– Fraction A %

– Fraction B %

– Frame temperature

– Totalized batch amount

– Totalized value of totalizers 1, 2 or 3

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 9

Page 10

HART Communication Interface

2.2 Connecting the Current HART, CH1

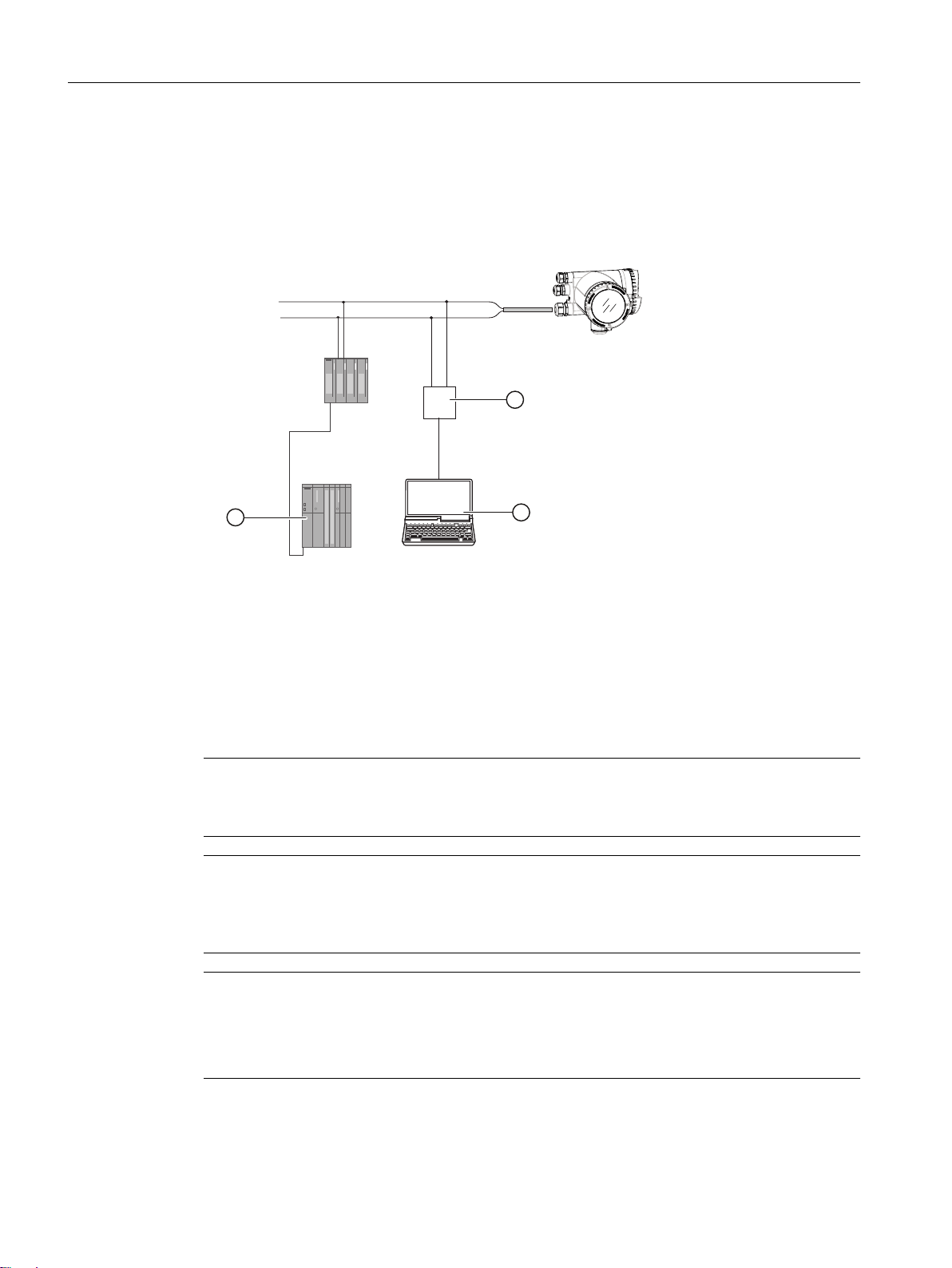

Communication is via the HART protocol, using:

● HART Communicator (load 230 to 500 Ω)

● PC with HART modem, on which appropriate software is installed, for example

SIMATIC PDM (load 230 to 500 Ω)

● Control system which can communicate via the HART protocol, for example SIMATIC PCS7

① SIMATIC PLC system with HART interface

② HART modem

③ PC with SIMATIC PDM or similar application

Figure 2-2 Possible system configurations

2.2 Connecting the Current HART, CH1

Note

4 to 20 mA output

It is not required to use shielded cables for the pure 4 to 20 mA current output.

Note

HART communication

It is recommended by the FieldComm Group (FCG) to use shielded cables for the HART

communication.

Note

Passive channels only

Channel 1 power supply must be separated from that for channels 2 to 4.

Signal return (or common) can be joined.

FCT030 HART (From firmware 4.0)

10 Function Manual, 06/2018, A5E39931617-AB

Page 11

5

4

5

6

,VLJQDO

U

0

)&

Ca+

Cp-

C

8

LQW

+

-

,VLJQDO

8

H[W

8

Ca+

+

-

Cp-

)&

C

HART Communication Interface

2.2 Connecting the Current HART, CH1

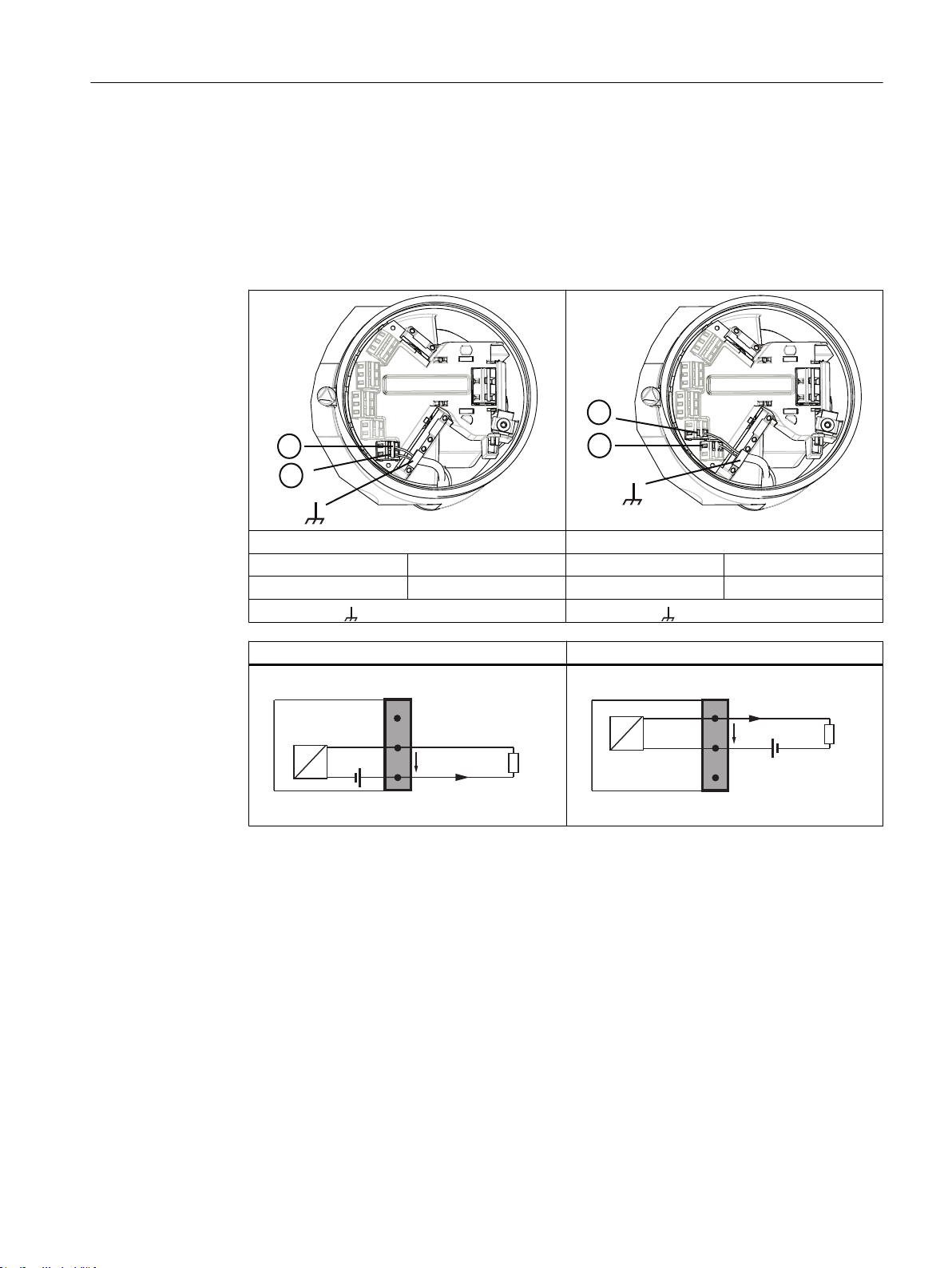

1. Remove cap and ferrule from cable gland and slide onto cable.

2. Push cable through open gland and cable path.

3. Restore ferrule and tighten cap to lightly hold cable in place.

4. Signal cable screen is folded back over outer sheath and grounded beneath cable clamp.

5. Connect wires to terminals using wiring tool, field mount transmitter

Active current output Passive current output

⑤ C ⑥ Cp-

④ Ca+ ⑤ C

Functional Earth Functional Earth

Active current output Passive current output

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 11

Page 12

)

)

HART Communication Interface

2.2 Connecting the Current HART, CH1

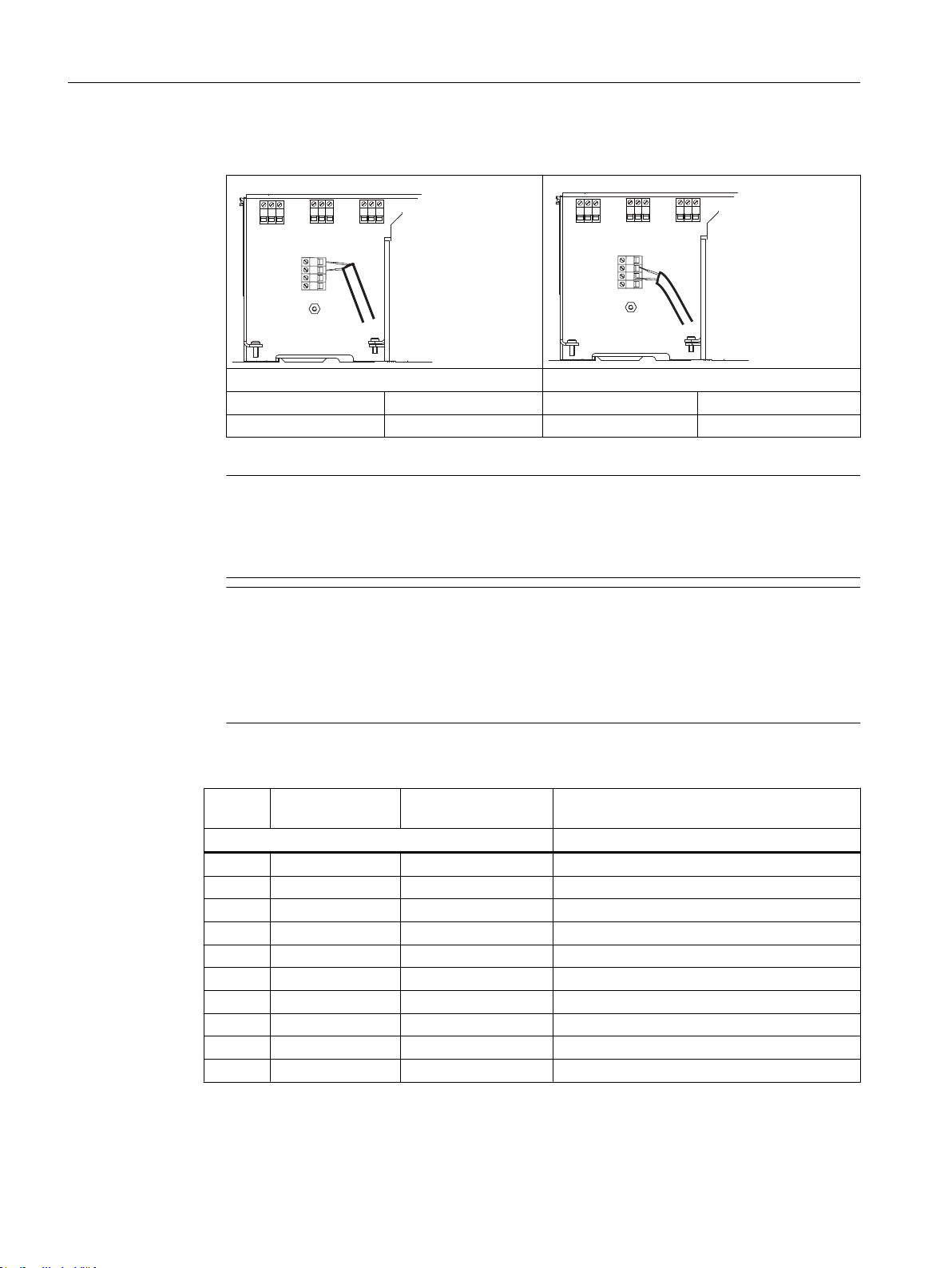

6. Connect wires to terminals, wall mount transmitter.

Active current output Passive current output

5 Ca+ 6 Cp4 C 5 C

7. Tighten cable gland.

Note

For Ex versions active or passive current output is preselected at ordering and cannot be

changed.

Non-Ex versions can be connected as either active or passive.

Note

Load

Signal output: < 500 Ω at 14 to 24 VDC (active), 14 to 30 VDC (passive)

Relay output: 30 VAC/VDC, 100 mA

Passive signal input: 15 to 30 VDC, 2 to 15 mA

Table 2-3 HW polling address

Load [Ω] Voltage (active

Ex) [V]

Measurered

100 3 3 17.7

200 5.9 5.9 19.6

500 11.4 14.9 21.0

1000 14.8 19.2 21.6

2000 17.4 20.1 21.9

5000 19.4 20.4 22.2

10000 20.3 21 22.3

20000 20 20.4 22.4

50000 20.4 20.6 22.5

100000 20.6 20.7 22.6

Voltage (active non

Ex) [V]

24 V DC Voltage supply (passive) [V] Ex and

Non Ex

FCT030 HART (From firmware 4.0)

12 Function Manual, 06/2018, A5E39931617-AB

Page 13

Commissioning

3.1 General requirements

Before commissioning it must be checked that:

● The device has been installed and connected in accordance with the guidelines provided

in the Operating Instruction for FCT030 transmitter

3.2 Operating via SIMATIC PDM

SIMATIC PDM is a software package used to commission and maintain process devices.

See also

www.siemens.com/simatic-pdm. (www.siemens.com/simatic-pdm.)

3

3.3 Functions in SIMATIC PDM

SIMATIC PDM monitors the process values, alarms and status signals of the device. It allows

you to display, compare, adjust, verify, and simulate process device data; also to set schedules

for calibration and maintenance.

3.4 Commissioning steps

In the following it is described how to commission the device with SIMATIC PDM.

The steps are divided into the following sections:

1. Initial Setup (Page 14)

2. Adding device to communication network (Page 15)

3. Wizard - Quick Start via PDM (Page 18)

4. Wizard - Zero Point adjustment (Page 27)

5. Configuring a new device (Page 18)

6. I/O configuration

7. Summary

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 13

Page 14

Commissioning

3.5 Initial Setup

3.5 Initial Setup

To ensure that SIMATIC PDM connects properly, please complete the two processes outlined

below:

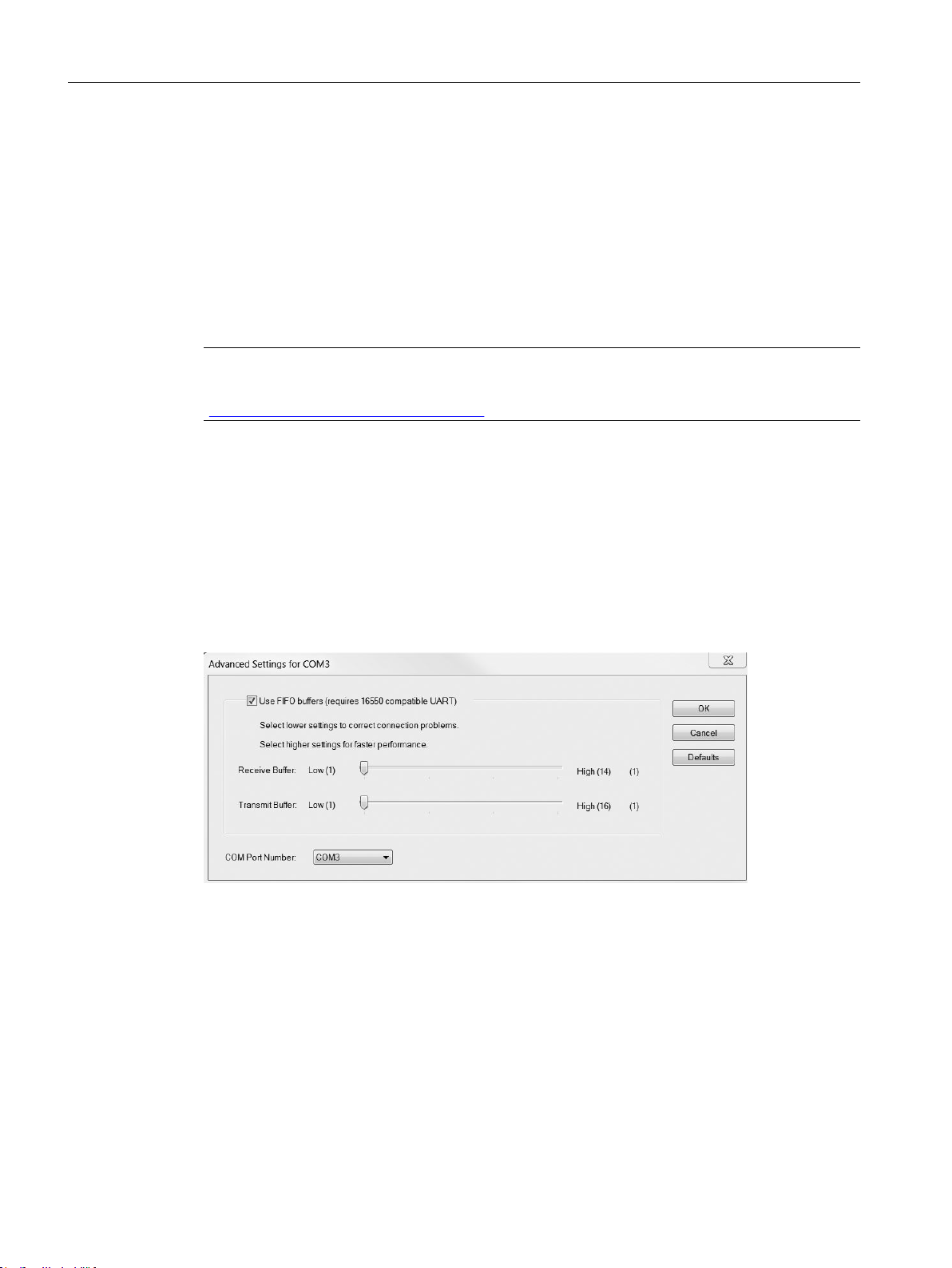

1. Deactivating buffers

2. Updating the Electronic Device Description (EDD)

Deactivating buffers for RS 485 COM port

This deactivation is required to align SIMATIC PDM for Windows® operating systems.

Note

Support for Windows operating systems can be found here: support.automation.siemens.com

(http://support.automation.siemens.com)

1. Click Start → Control Panel to begin configuration.

2. Click on Hardware and Sound and then on Device Manager.

3. Open Ports folder and double-click the COM Port used by the system to open the

Communications Port Properties window.

4. Select the Port Settings tab and click the Advanced button.

5. If the Use FIFO buffers check box is deselected, click to select.

6. Set Receiver Buffer and Transmitter Buffer to Low (1).

Figure 3-1 COM Port Setting

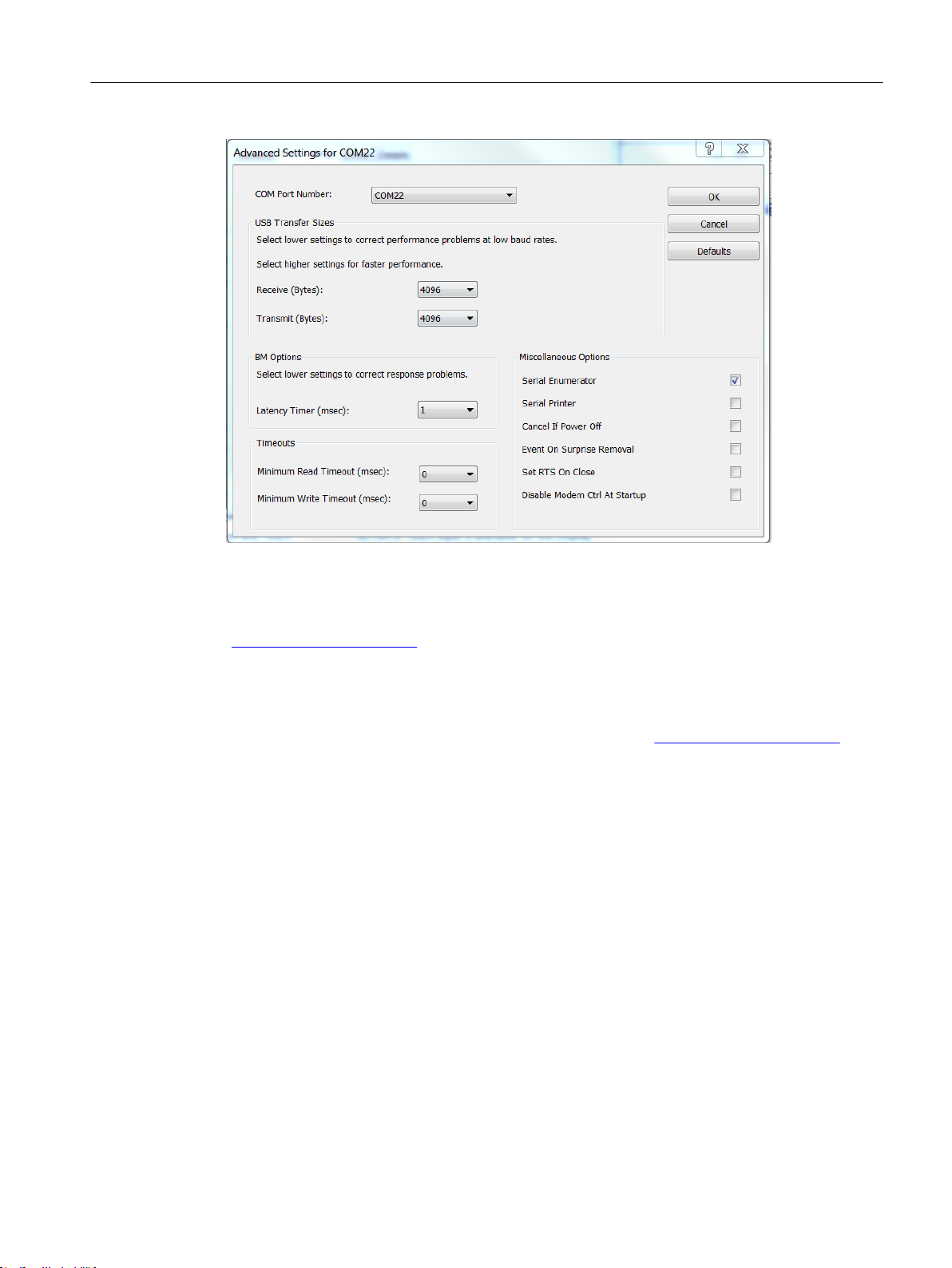

For serial adapters it can be required to change the Latency Timer (msec) to 1

FCT030 HART (From firmware 4.0)

14 Function Manual, 06/2018, A5E39931617-AB

Page 15

Commissioning

3.6 Adding device to communication network

See also

Updating the Electronic Device Description (EDD)

You can locate the EDD in the SIMATIC PDM Device Library under Devices → HART → Sensors

→ Flow → Coriolis → Siemens AG → SITRANS FC430. Check the product page of our website

(www.siemens.com/FC430) under Support > Software downloads, to make sure you have the

latest version of SIMATIC PDM, the most recent Service Pack (SP) and the most recent hot

fix (HF).

Installing a new EDD:

1. Download the EDD from the product page of our website (www.siemens.com/FC430) and

save the files to your computer.

2. Launch the SIMATIC PDM Device Integration Manager, browse to the EDD file and select

it.

3. Select the check boxes for the devices whose device descriptions are to be integrated. The

check box is automatically selected for devices that have not been integrated or have been

integrated with an older version. You can work with a split device list window.

4. Select Catalog → Integration. The device descriptions are transferred to the PC.

Commissioning steps (Page 13)

Wizard - Quick Start via PDM (Page 18)

3.6 Adding device to communication network

Before setting the parameters, it is necessary to configure the FC430 project in PDM.

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 15

Page 16

Commissioning

3.6 Adding device to communication network

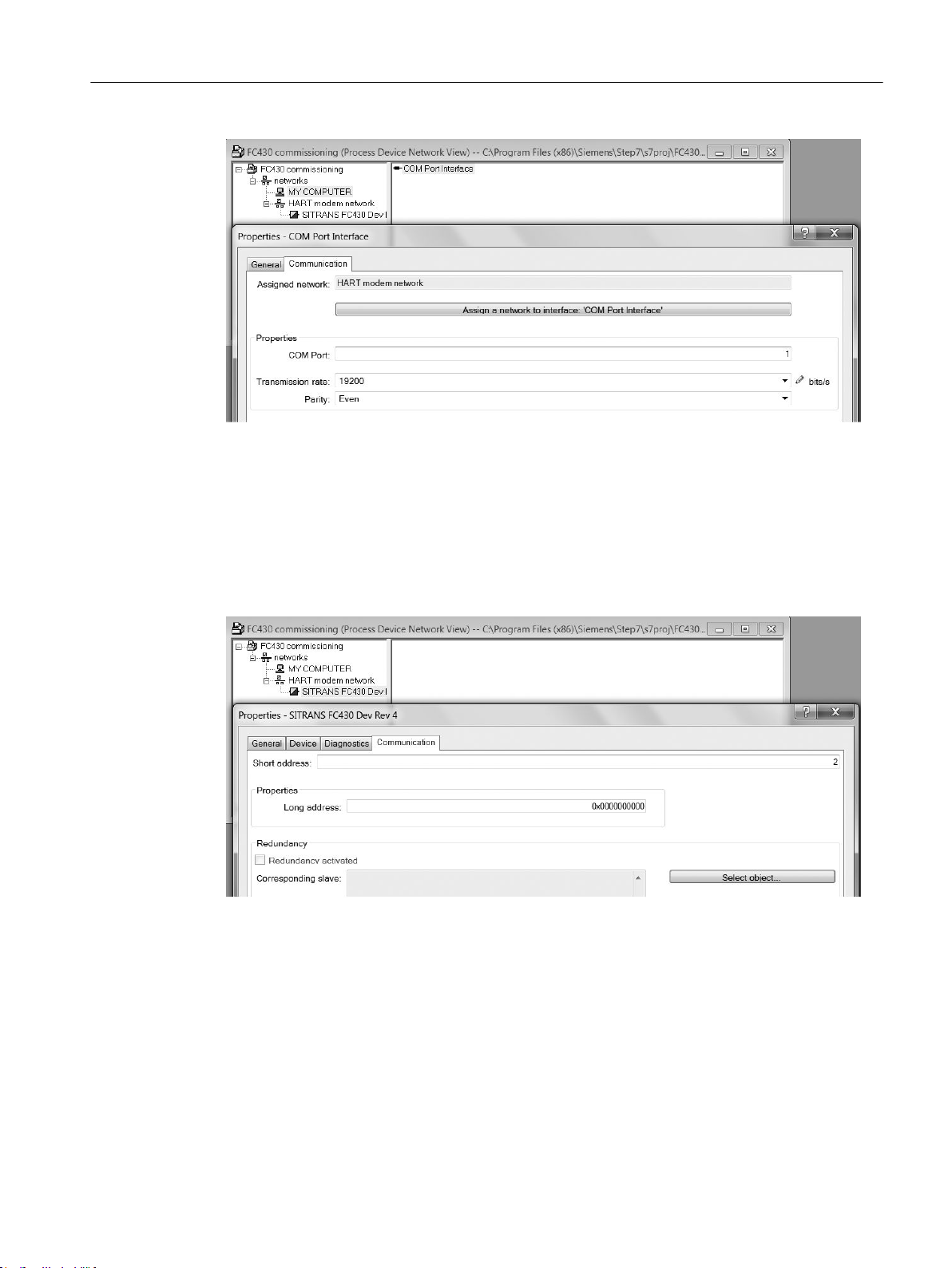

1. Add the device to SIMATIC HART network:

– Select File → New. Type in a project name, for example FC430 commissioning.

– Go to View and select Process Device Network view.

– Right-click on the typed in Project name and select Insert New Object → Networks.

– Right-click on Networks and Insert New Object → Communication Network.

– Click on Assign Device Type and select HART Modem Network. Click OK two times. Your

PC is now added to the HART Modem Network.

– Right-click on HART Modem Network and select Insert New Object → Object.

– Click on Assign Device Type, and select Devices → HART → Sensors → Flow → Coriolis →

SIEMENS AG → SITRANS FC430 Click OK two times.

Figure 3-2 Assigning a HART modem network

2. Set up the communication parameters for SIMATIC HART modem network:

– Select Networks → My computer, right-click on COM Port Interface and select Object

Properties.

– Select the Communication tab and configure the communication parameters.

FCT030 HART (From firmware 4.0)

16 Function Manual, 06/2018, A5E39931617-AB

Page 17

Figure 3-3 HART modem properties

– Click OK.

3. Set up the HART address:

– Select HART modem network.

Commissioning

3.6 Adding device to communication network

– Right-click on the object name SITRANS FC430 and select Object Properties.

– Select the Communication tab and configure the HART address.

Figure 3-4 Set the HART address

– Click OK.

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 17

Page 18

Commissioning

3.8 Wizard - Quick Start via PDM

3.7 Configuring a new device

Note

Clicking on "Cancel" during an upload from device to SIMATIC PDM will result in some

parameters NOT being updated.

1. Check that you have the most recent EDD, and if necessary update it, see "Updating the

Electronic Device Description (EDD)" in Initial Setup (Page 14).

2. Launch SIMATIC Manager.

3. Right-click on SITRANS FC430 and select Open Object to open SIMATIC PDM.

4. Click on the device and select Upload to the PG/PC to upload the configuration from he

device.

3.8 Wizard - Quick Start via PDM

The graphic Quick Start Wizard provides an easy 7-step procedure that configures the device

for a simple application.

Please consult the SIMATIC PDM operating instructions or online help for details on using

SIMATIC PDM.

Access level control

Some parameters are protected against changes by access level control. To gain access,

select Access Management from the device menu, select User or Expert mode and enter the

PIN code.

● User

Allows configuration and service of all parameters except calibration parameters. Default PIN

code is 2457.

● Expert

Allows configuration and service of all parameters including flow and density adjustment

parameters. Default PIN code is 2834.

Quick start

Note

● The Quick Start wizard settings are inter-related and changes apply only after you click on

● Do not use the Quick Start Wizard to modify individual parameters.

● Click on "Back" to return and revise settings or "Cancel" to exit the Quick Start.

"Apply" at the wizard to transfer settings to save settings offline and transfer them to the

device.

FCT030 HART (From firmware 4.0)

18 Function Manual, 06/2018, A5E39931617-AB

Page 19

Commissioning

3.8 Wizard - Quick Start via PDM

Launch SIMATIC PDM, open the menu "Device – Wizard - Quick Start", and follow steps.

Figure 3-5 Wizard Quick Start

Step 1 - Identification

Note

The layout of the dialog boxes shown may vary according to the resolution setting for your

computer monitor. The recommended resolution is 1280 x 960.

1. The parameter settings are read from device automatically so the Quick Start wizard starts

with the values stored in device.

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 19

Page 20

Commissioning

3.8 Wizard - Quick Start via PDM

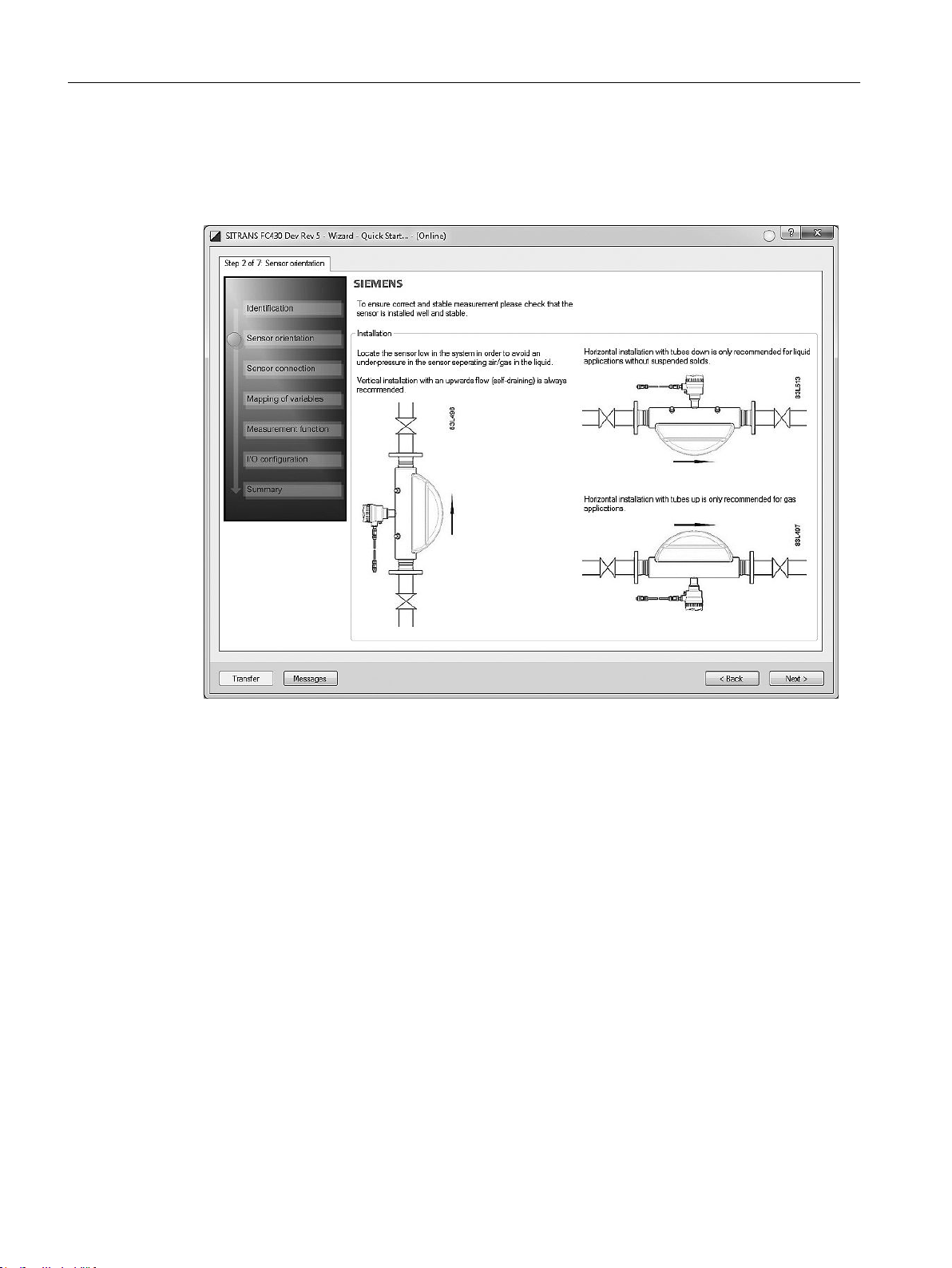

Step 2 - Sensor orientation

Step 2 shows an overview of the various recommended installation orientations depending on

the application.

Figure 3-6 Quick start step 2

FCT030 HART (From firmware 4.0)

20 Function Manual, 06/2018, A5E39931617-AB

Page 21

Step 3 - Sensor connection (remote version only)

Step 3 shows connection of compact and remote systems.

Commissioning

3.8 Wizard - Quick Start via PDM

Figure 3-7 Quick start step 3

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 21

Page 22

Commissioning

3.8 Wizard - Quick Start via PDM

Step 4 - Mapping of variables

Set the process values (PV, SV, TV, and QV) to be used in the HART system integration and

click on "Next".

Figure 3-8 Quick start step 4

FCT030 HART (From firmware 4.0)

22 Function Manual, 06/2018, A5E39931617-AB

Page 23

Step 5 - Measurement conditions

Configure the measurement conditions for the selected process variables. Change "Flow

Direction" if necessary.

Commissioning

3.8 Wizard - Quick Start via PDM

Figure 3-9 Quick start step 5

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 23

Page 24

Commissioning

3.8 Wizard - Quick Start via PDM

Figure 3-10 Filter setting selection

FCT030 HART (From firmware 4.0)

24 Function Manual, 06/2018, A5E39931617-AB

Page 25

Step 6 - I/O configuration

Configure the current output (channel 1). The process value is selected as PV in step 4

"Mapping of variables".

Commissioning

3.8 Wizard - Quick Start via PDM

Figure 3-11 Quick start step 6

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 25

Page 26

Commissioning

3.8 Wizard - Quick Start via PDM

Step 7 - Summary

Check parameter setting in Summary and apply to transfer the settings to the device.

Figure 3-12 Quick start step 7

The settings have been transferred to the device successfully.

FCT030 HART (From firmware 4.0)

26 Function Manual, 06/2018, A5E39931617-AB

Page 27

3.9 Wizard - Zero Point adjustment

Open the menu Device – Wizard - Zero Point Adjustment.

Figure 3-13 Wizard - Zero point adjustment

Select "Auto". Click on "Next".

Commissioning

3.9 Wizard - Zero Point adjustment

Figure 3-14 Zero point adjustment step 1

It is recommended to use the default settings. Change the "Zero Point Adjustments Settings",

if necessary.

Click on "Perform".

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 27

Page 28

Commissioning

3.10 Changing parameter settings using SIMATIC PDM

Figure 3-15 Zero point adjustment step 2

3.10 Changing parameter settings using SIMATIC PDM

Note

For a complete list of parameters upload all parameters from the device first.

Clicking on "Cancel" during an upload from device to SIMATIC PDM will result in some

parameters NOT being updated.

FCT030 HART (From firmware 4.0)

28 Function Manual, 06/2018, A5E39931617-AB

Page 29

Commissioning

3.11 Parameters accessed via drop-down menus

Many parameters are accessed via the online menus in PDM, see "Parameters accessed via

drop-down menus" for the others.

1. Launch SIMATIC PDM, connect to the appropriate device and upload data.

2. Adjust parameter values in the parameter value field then click on "Enter". The status fields

read "Changed".

3. Open the "Device" menu, click on "Download to device", then use "File – Save" to save

settings offline. The status fields are cleared.

Figure 3-16 Changing parameter settings using SIMATIC PDM

3.11 Parameters accessed via drop-down menus

Click on "Device" or "View" to open the associated drop-down menus.

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 29

Page 30

Commissioning

3.11 Parameters accessed via drop-down menus

Device drop-down menus

Figure 3-17 Device drop-down menus

Menu Description

Download to Device Downloads all writable parameters to the device

Upload to PC/PG Uploads all parameters from the device to the parameter

table

Assign address and TAG Assign communication address and TAG name

Value comparison Compare values between device / project

Object properties Properties for device and project

Calibration log Create calibration logs for field devices.

Cange log The change log records which actions have been per‐

formed with SIMATIC PDM on devices

Set the device checked The device can be set to checked / or unchecked

Check configuration Check configuration if it contains errors

Wizard - Quick Start Guide for a quick commissioning

Wizard - Zero Point Adjustment Guide for zero point adjustment (automatic and manual)

D/A Trim Calibration of current output (channel 1)

FCT030 HART (From firmware 4.0)

30 Function Manual, 06/2018, A5E39931617-AB

Page 31

Commissioning

3.11 Parameters accessed via drop-down menus

Menu Description

Totalizer Controlling totalizers 1, 2 and 3

Maintenance Setup of maintenance functions

Enable Alarms Enables individual alarms

Audit Trail Lists parameter changes, FW updates, and alarm history

logs

Simulation Simulation of process values, alarms, and inputs/outputs

(channels 2 to 4)

Loop Test Simulation of current output (channel 1)

Security Possibility to upgrade access level from “restricted” to

“user” or “expert” and to change PIN code for “user” and

"expert" level

Reset Restore order configuration

Device restart

Configuration Flag Reset Commands reset the configuration flag

HART Communication Number of preambles

Trim signal inputs/outputs Calibration of current output (channels 2 to 4)

Dosing Controlling and calibration of dosing

Firmware update This function allows the user to install firmware that has

been placed on the SDcard

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 31

Page 32

Commissioning

3.11 Parameters accessed via drop-down menus

FCT030 HART (From firmware 4.0)

32 Function Manual, 06/2018, A5E39931617-AB

Page 33

HART commands

4.1 Device Variables

All four dynamic variables PV, SV, TV and QV are supported. Except for PV, they can all be

freely mapped to all dynamic device variables. The following table shows the possible

mappings.

Default values:

PV = Mass flow

SV = Volume flow

TV = Density

QV = Media temperature

Table 4-1 Device Variables

4

Device Varia‐

ble Number

0 Mass flow X X X X

1 Volume flow X X X X

2 Density X X X X

3 Fluid Temperature X X X X

4 Standard Volume Flow X X X X

5 Fractional Flow A X X X X

6 Fractional Flow B X X X X

7 Fractional Percentage Flow A X X X X

8 Fractional Percentage Flow B X X X X

9 Reference Density X X X X

10 Electronics Temperature TRN X X X X

11 Totalized Value 1 X X X

12 Totalized Value 2 X X X

13 Totalized Value 3 X X X

14 Frame Temperature X X X X

15 Totalized batch amount X X X

Device Variable Name PV SV TV QV

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 33

Page 34

HART commands

4.2 Universal commands

4.2 Universal commands

The device supports the following universal commands:

Table 4-2 Universal commands

Com‐

mand

num‐

ber

0 Read Unique Identifier 254, device_type, request_pream‐

1 Read Primary Variable PV.DEVICE_VARIABLE.DIGI‐

2 Read Loop Current And Percent Of Range PV.DAQ.ANALOG_VALUE,

3 Read Dynamic Variables And Loop Current PV.DAQ.ANALOG_VALUE,

6 Write Polling Address polling_address, loop_cur‐

7 Read loop configuration polling_address, loop_cur‐

8 Read Dynamic Variable Classification PV.DEVICE_VARIABLE.CLASSI‐

9 Read Device Variable With Status Read

Function Parameters

bles, universal_revision, transmit‐

ter_revision, software_revision,

hardware_revision <0xf8>, physi‐

cal_signaling_code <0x07>, de‐

vice_flags, device_id, re‐

sponse_preambles,

max_num_device_variables, con‐

fig_change_counter, exten‐

ded_fld_device_status, manufac‐

turer_id, private_label_distributor,

device_profile

TAL_UNITS, PV.DEVICE_VARI‐

ABLE.DIGITAL_VALUE

PV.RANGING.PER‐

CENT_RANGE

PV.DEVICE_VARIABLE.DIGI‐

TAL_UNITS,

SV.DEVICE_VARIABLE.DIGI‐

TAL_UNITS, SV.DEVICE_VARI‐

ABLE.DIGITAL_VALUE, TV.DE‐

VICE_VARIABLE.DIGI‐

TAL_UNITS, TV.DEVICE_VARIA‐

BLE.DIGITAL_VALUE, QV.DE‐

VICE_VARIABLE.DIGI‐

TAL_UNITS, QV.DEVICE_VARI‐

ABLE.DIGITAL_VALUE

rent_mode

rent_mode

FICATION, SV.DEVICE_VARIA‐

BLE.CLASSIFICATION, TV.DE‐

VICE_VARIABLE.CLASSIFICA‐

TION, QV.DEVICE_VARIA‐

BLE.CLASSIFICATION

Read /

Write /

Command

Read

Read

Read

Read

Write

Read

Read

FCT030 HART (From firmware 4.0)

34 Function Manual, 06/2018, A5E39931617-AB

Page 35

HART commands

4.2 Universal commands

Com‐

mand

num‐

ber

11 Read Unique Identifier Associated With Tag 254, device_type, request_pream‐

12 Read Message message

13 Read Tag, Descriptor, Date tag, descriptor, date

14 Read Primary Variable Transducer Informa‐

15 Read Device Information PV.DAQ.ALARM_CODE,

16 Read Final Assembly Number final_assembly_number

17 Write Message message Write

18 Write Tag, Descriptor, Date tag, descriptor, date

19 Write Final Assembly Number final_assembly_number

20 Read Long Tag longTag Read

Function Parameters

bles, universal_revision, transmit‐

ter_revision, software_revision,

hardware_revision <0xf8>, physi‐

cal_signaling_code <0x07>, de‐

vice_flags, device_id, re‐

sponse_preambles,

max_num_device_variables, con‐

fig_change_counter, exten‐

ded_fld_device_status, manufac‐

turer_id, private_label_distributor,

device_profile

PV.DEVICE_VARIABLE.SEN‐

tion

SOR_SERIAL_NUMBER, PV.DE‐

VICE_VARIABLE.DIGI‐

TAL_UNITS, PV.DEVICE_VARI‐

ABLE.UPPER_SENSOR_LIMIT,

PV.DEVICE_VARIABLE.LOW‐

ER_SENSOR_LIMIT, PV.DE‐

VICE_VARIABLE.MINI‐

MUM_SPAN

PV.RANGING.TRANS‐

FER_FUNCTION, PV.RANG‐

ING.RANGE_UNITS, PV.RANG‐

ING.UPPER_RANGE_VALUE,

PV.RANGING.LOW‐

ER_RANGE_VALUE, PV.DE‐

VICE_VARIABLE.DAMP‐

ING_VALUE, write_protect, 250,

PV.DAQ.ANALOG_CHAN‐

NEL_FLAGS

Read /

Write /

Command

Read

Read

Write

Write

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 35

Page 36

HART commands

4.3 Common practice commands

Com‐

mand

num‐

ber

21 Read Unique Identifier Associated With

22 Write Long Tag longTag Write

38 Reset Configuration Changed Flag Command

48 Read Additional Device Status device_specific_status_0, de‐

Function Parameters

254, device_type, request_pream‐

Long Tag

bles, universal_revision, transmit‐

ter_revision, software_revision,

hardware_revision <0xf8>, physi‐

cal_signaling_code <0x07>, de‐

vice_flags, device_id, re‐

sponse_preambles,

max_num_device_variables, con‐

fig_change_counter, exten‐

ded_fld_device_status, manufac‐

turer_id, private_label_distributor,

device_profile

vice_specific_status_1, de‐

vice_specific_status_2, de‐

vice_specific_status_3, de‐

vice_specific_status_4, de‐

vice_specific_status_5,

extended_fld_device_status,

0x00

Read /

Write /

Command

Read

Read

Note

Command #15: Read Device Information / Write Protect Code

The device does not support Write Protection. Therefore the response to command #15

contains the Write Protect Code 251 (as specified in the HART specification).

4.3 Common practice commands

The device supports the following common practice commands:

Table 4-3 Common practice commands

Command number Function

33 Read Device Variables

34 Write Primary Variable Damping Value

35 Write Primary Variable Range Values

36 Set Primary Variable Upper Range Value

37 Set Primary Variable Lower Range Value

40 Enter/Exit Fixed Current Mode

42 Perform Device Reset

44 Write Primary Variable Units

FCT030 HART (From firmware 4.0)

36 Function Manual, 06/2018, A5E39931617-AB

Page 37

Command number Function

45 Trim Loop Current Zero

46 Trim Loop Current Gain

50 Read Dynamic Variable Assignments

51 Write Dynamic Variable Assignments

53 Write Device Variables Units

54 Read Device Variables Information

59 Write Number Of Response Preambles

60 Read Analog Channel And Percent Of Range

63 Read Analog Channel Information

70 Read Analog Channel Endpoint Values

95 Read Device Communications Statistics

4.4 Burst Mode

This device does not support Burst-Mode.

HART commands

4.5 Device-specific commands

4.4.1 Catch Device Variable

This device does not support Catch Device Variable.

4.5 Device-specific commands

4.5.1 Command #130: Read. User Login

Operation: READ

The access level of the HART fieldbus interface can be changed with this command.

By writing a wrong PIN or by timeout the HART-Access-Level falls back to the default access

level.

The HART Access-Level is falling back to RUP after 10 minutes. Timeout is restarted with

every Write-Access over HART.

Byte Format Description

None

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 37

Page 38

HART commands

4.5 Device-specific commands

Byte Format Description

0...1

2

Code Class Description Explanation

0 Success No Command-Specific Errors

5 Error Too few Data Bytes Received Not enough data for User PIN

6 Error Device Specific Command Error

Quintessence

The device supports the following device-specific commands:

Unsigned-16

Enrum

Written User PIN

Resulting Access-Level

16 (RUP)

32 (EUP)

64 (SUP)

Command

number

130 User Login

131 Read Current HART Access Level

140 Read Parameter(s)

141 Write Parameter(s)

142 Read Unit Related Parameter(s)

143 Write Unit Related Parameter(s)

144 Read Device Variable Information

145 Read Unit Related Parameter(s)

146 Write Unit Related Parameter(s)

Description

4.5.2 Command #131: Read, Current HART Access Level

Operation: READ

This command reads the currently set HART Access Level from the device.

Byte Format Description

None

Byte Format Description

0 Enum Current Access Level

16 (RUP)

32 (EUP)

64 (SUP)

FCT030 HART (From firmware 4.0)

38 Function Manual, 06/2018, A5E39931617-AB

Page 39

Code Class Description Explanation

0 Success No Command-Specific Errors

6 Error Device Specific Command Error

4.5.3 Command # 140: Read Parameter(s)

Operation: READ

This command is a general read access command, used to read one or more parameters from

the device. The parameters to read are specified by MODBUS registers that are provided in

the request data.

The value returned when reading a parameter is in its base unit e.g. m³/s, kg/s, kg, m³, °C

(depending on the parameter definition).

For unit related readings of parameters see command #142.

Table 4-4 Request Data Bytes

HART commands

4.5 Device-specific commands

Byte Format Description

0…1 Unsigned-16 MODBUS register of parameter 1

2...3 Unsigned-16 MODBUS register of parameter 2

…

2*n-2…

Unsigned-16 MODBUS register of parameter n

2*n-1

Table 4-5 Response Data Bytes

Byte Format Description

0…? <parameter-specific> Value of parameter 1

<parameter-specific> Value of parameter 2

…

<parameter-specific> Value of parameter n

Code Class Description Explanation

0 Success No Command-Specific Errors

2 Error Invalid Selection Register does not exist

5 Error Too Few Data Bytes Received Not enough data for a Mod‐

bus register

6 Error Device Specific Command Error

16 Error Access Restricted Modbus register is not read‐

able

30 Error Command Response Truncated Response would be too large

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 39

Page 40

HART commands

4.5 Device-specific commands

4.5.4 Command # 141: Write Parameter(s)

Operation: WRITE

This command is a general write access command, used to write one or more parameters to

the device. The parameters to write are specified by MODBUS registers that are provided in

the request data.

When writing floating-point values that are related to a unit (e.g. process value limits) the written

value must be related to its base unit e.g. m³/s, kg/s, kg, m³, °C.

For unit related writings of parameters see command #143.

Table 4-6 Request Data Bytes

Byte Format Description

0…1 Unsigned-16 MODBUS register of parameter 1

2…? <parameter-specific> value of parameter 1 to be written

Unsigned-16 MODBUS register of parameter 2

<parameter-specific> value of parameter 2 to be written

…

Unsigned-16 MODBUS register of parameter n

<parameter-specific> value of parameter n to be written

Table 4-7 Response Data Bytes

Byte Format Description

0…1 Unsigned-16 MODBUS register of parameter 1

2…? <parameter-specific> value of parameter 1 as stored

Unsigned-16 MODBUS register of parameter 2

<parameter-specific> value of parameter 2 as stored

…

Unsigned-16 MODBUS register of parameter n

Table 4-8 Command-Specific Response Codes

Code Class Description Explanation

0 Success No Command-Specific Errors

2 Error Invalid Selection Register does not exist

3 Error Parameter too large Value is too large

4 Error Parameter too small Value is too small

5 Error Too Few Data Bytes Received not enough data for a Mod‐

bus register with data

6 Error Device Specific Command Error Invalid value

7 Error Write Protected Device is in write-protect-

mode

FCT030 HART (From firmware 4.0)

40 Function Manual, 06/2018, A5E39931617-AB

Page 41

Code Class Description Explanation

8 Warning Set to Nearest Possible Value Value was adapted

16 Error Access Restricted Modbus register is not write‐

4.5.5 Command # 142: Write Parameter(s)

Operation: READ

This command is a general read access command, used to read one ore more parameters

from the device in a specified unit (only for float-types, has no effect on other parameter types).

The parameters to read are specified by MODBUS registers that are provided in the request

data.

Table 4-9 Request Data Bytes

Byte Format Description

0..1 Unsigned-16 MODBUS register of parameter 1

2 Unsigned-8 Unit Classification to read parameter 1

3 Unsigned-8 Unit Code to read parameter 1

4…5 Unsigned-16 MODBUS register of parameter 2

6 Unsigned-8 Unit Classification to read parameter 2

7 Unsigned-8 Unit Code to read parameter 2

…

4*n-4… 4*n-3 Unsigned-16 MODBUS register of parameter n

4*n-2 Unsigned-8 Unit Classification to read parameter n

4*n-1 Unsigned-8 Unit Code to read parameter n

HART commands

4.5 Device-specific commands

able

Table 4-10 Response Data Bytes

Byte Format Description

0…? <parameter-specific> Value of parameter 1

<parameter-specific>

Value of parameter 2

…

Table 4-11 Command-Specific Response Codes

Code Class Description Explanation

0 Success No Command-Specific Errors

2 Error Invalid Selection

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 41

<parameter-specific>

Value of parameter n

● Register does not exist

● Register is not readable

● invalid unit classification/

unit code combination

Page 42

HART commands

4.5 Device-specific commands

Code Class Description Explanation

5 Error Too Few Data Bytes Received Not enough data for a Mod‐

6 Error Device Specific Command Error

30 Error Command Response Truncated Response would be too large

The product ignores the Unit Classification request bytes. They are kept for compatibility

reasons.

The supported unit codes are listed in chapter 11 Supported Engineering Units.

4.5.6 Command # 143: Write Parameter(s)

Operation: WRITE

This command is a general write access command, used to write one or more parameters in

to the device in a specified unit (only for float-types, has no effect on other parameter types).

The parameters to write are specified by MODBUS registers that are provided in the request

data.

bus register

Table 4-12 Request Data Bytes

Byte Format Description

0...1 Unsigned-16 MODBUS register of parameter 1

2 Unsigned-8 Unit Classification to write parameter 1

3 Unsigned-8 Unit Code to write parameter 1

4…x <parameter-specific> value of parameter 1 to be written

Unsigned-16 MODBUS register of parameter 2

Unsigned-8 Unit Classification to write parameter 2

Unsigned-8 Unit Code to write parameter 2

<parameter-specific>

value of parameter 2 to be written

…

Unsigned-16 MODBUS register of parameter n

Unsigned-8 Unit Classification to write parameter n

Unsigned-8 Unit Code to write parameter n

Table 4-13 Response Data Bytes

Byte Format Description

0...1 Unsigned-16 MODBUS register of parameter 1

2 Unsigned-8 Unit Classification of written parameter 1

3 Unsigned-8 Unit Code of written parameter 1

4…x <parameter-specific> value of parameter 1 as stored

<parameter-specific>

value of parameter n to be written

Unsigned-16 MODBUS register of parameter 2

Unsigned-8 Unit Classification of written parameter 2

FCT030 HART (From firmware 4.0)

42 Function Manual, 06/2018, A5E39931617-AB

Page 43

HART commands

4.5 Device-specific commands

Byte Format Description

Unsigned-8 Unit Code of written parameter 2

…

Unsigned-16 MODBUS register of parameter n

Unsigned-8 Unit Classification of written parameter n

Unsigned-8 Unit Code of written parameter n

Table 4-14 Command-Specific Response Codes

Code Class Description Explanation

0 Success No Command-Specific Errors

2 Error Invalid Selection

3 Error Parameter too large provided TRN parameter val‐

4 Error Parameter too small provided TRN parameter val‐

5 Error Too Few Data Bytes Received not enough data for a Mod‐

6 Error Device Specific Command Error Invalid value of SEN param‐

7 Error Write Protected Device is in write-protect-

8 Warning Set to Nearest Possible Value Value was adapted

16 Error Access Restricted Modbus register is not write‐

<parameter-specific>

<parameter-specific>

value of parameter 2 as stored

value of parameter n as stored

● Register does not exist or

● invalid unit classification/

unit code combination

ue is too large

ue is too small

bus register with data

eter

mode

able

The product ignores the Unit Classification request bytes. They are kept for compatibility

reasons.

The supported unit codes are listed in chapter 11 Supported Engineering Units.

The unit code is only evaluated if the specified parameter is an floating-point parameter. If a

unit code unequal to 0 is used for another data type the request is responded with an error.

4.5.7 Command # 144: Read Device Variable Information

Operation: READ

The request is analog to HART Universal Command 9: For each requested PV send one byte

defining the PV of interest, incl. the dynamic variables (see Common Table 34).

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 43

Page 44

HART commands

4.5 Device-specific commands

This command can be used to get the required information to use Commands 142+143

properly.

Table 4-15 Request Data Bytes

Byte Format Description

0 Unsigned-8 Device Variable Number for Slot 1

1 Unsigned-8 Device Variable Number for Slot 2

…

n

-1 Unsigned-8 Device Variable Number for Slot n

Table 4-16 Response Data Bytes

Byte Format Description

0…1 Unsigned-16 MODBUS register of process value

2…3 Unsigned-16 MODBUS register of process value unit

4…5 Unsigned-16 MODBUS register of process value status

6 Unsigned-8 Unit Classification

7 Unsigned-8 Unit Code

8…11 Float Process value related to the unit code

12 Unsigned-8 Process value status

13…16 Float Lower process value limit related to the unit code

17…20 Float Upper process value limit related to the unit code

21..41 <See 0…20> Slot 2

...

(n-1)*21

…(n*21)-1

<See 0…20> Slot n

Table 4-17 Command-Specific Response Codes

Code Class Description Explanation

0 Success No Command-Specific Errors

2 Error Invalid Selection Device Variable does not ex‐

ist

5 Error Too Few Data Bytes Received At least one variable must be

requested

6 Error Device Specific Command Error

30 Error Command Response Truncated Response would be too large

FCT030 HART (From firmware 4.0)

44 Function Manual, 06/2018, A5E39931617-AB

Page 45

4.5.8 Command # 145: Read Unit Related Parameter(s)

This command is a general read access command, used to read one or more parameters from

the device. Each unit related parameter has a reference to a unit parameter that is valid for

the HART interface. The currently set unit is used to convert the returned parameter value

(only for float-types, has no effect on other parameter types). The parameters to read are

specified by HART registers that are provided in the request data.

Table 4-18 Request Data Bytes

Byte Format Description

0..1 Unsigned-16 HART register of parameter 1

2…3 Unsigned-16 HART register of parameter 2

…

2*n-2… 2*n-1 Unsigned-16 HART register of parameter n

Table 4-19 Response Data Bytes

Byte Format Description

0…? <parameter-specific> Value of parameter 1

…

<parameter-specific>

<parameter-specific>

Value of parameter 2

Value of parameter n

HART commands

4.5 Device-specific commands

Table 4-20 Command-Specific Response Codes

Code Class Description Explanation

0 Success No Command-Specific Errors

2 Error Invalid Selection Register does not exist

5 Error Too Few Data Bytes Received Not enough data for a HART

register

6 Error Device Specific Command Error

16 Error Access Restricted HART register is not readable

30 Error Command Response Truncated Response would be too large

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 45

Page 46

HART commands

4.5 Device-specific commands

4.5.9 Command # 146: Write Unit Related Parameter(s)

This command is a general read access command, used to read one or more parameters from

the device. Each unit related parameter has a reference to a unit parameter that is valid for

the HART interface. The currently set unit is used to convert the returned parameter value

(only for float-types, has no effect on other parameter types). The parameters to read are

specified by HART registers that are provided in the request data.

Table 4-21 Request Data Bytes

Byte Format Description

0...1 Unsigned-16 HART register of parameter 1

2…x <parameter-specific> value of parameter 1 to be written

Unsigned-16 HART register of parameter 2

…

Unsigned-16 HART register of parameter n

<parameter-specific>

<parameter-specific>

value of parameter 2 to be written

value of parameter n to be written

Table 4-22 Response Data Bytes

Byte Format Description

0...1 Unsigned-16 HART register of parameter 1

2…x <parameter-specific> value of parameter 1 as stored

Unsigned-16 HART register of parameter 2

<parameter-specific>

value of parameter 2 as stored

…

Unsigned-16 HART register of parameter n

Table 4-23 Command-Specific Response Codes

Code Class Description Explanation

0 Success No Command-Specific Errors

2 Error Invalid Selection Register does not exist

3 Error Parameter too large provided value is too large

4 Error Parameter too small provided value is too small

5 Error Too Few Data Bytes Received not enough data for a HART

6 Error Device Specific Command Error

7 Error Write Protected Device is in write-protect-

8 Warning Set to Nearest Possible Value Value was adapted

16 Error Access Restricted Parameter is not writeable

<parameter-specific>

value of parameter n as stored

register with data

mode

FCT030 HART (From firmware 4.0)

46 Function Manual, 06/2018, A5E39931617-AB

Page 47

4.6 Supported Engineering Units

The following table lists all engineering units supported by this device.

Table 4-24 Request Data Bytes

Byte Format Description

15 Volumetric Flow cubic feet per minute

16 Volumetric Flow US gallons per minute

17 Volumetric Flow liters per minute

18 Volumetric Flow imperial gallons per minute

19 Volumetric Flow cubic meters per hour

22 Volumetric Flow US gallons per second

23 Volumetric Flow million US gallons per day

24 Volumetric Flow liters per second

25 Volumetric Flow million liters per day

26 Volumetric Flow cubic feet per second

27 Volumetric Flow cubic feet per day

28 Volumetric Flow cubic meters per second

29 Volumetric Flow cubic meters per day

30 Volumetric Flow imperial gallons per hour

31 Volumetric Flow imperial gallons per day

32 Temperature Degrees Celsius

33 Temperature Degrees Fahrenheit

34 Temperature Degrees Rankine

35 Temperature Kelvin

36 Voltage millivolts

38 Frequency Hertz

39 Current milliamperes

40 Volume US gallons

41 Volume liters

42 Volume imperial gallons

43 Volume cubic meters

46 Volume barrels (= 42 US gallons)

51 Time seconds

57 Ratio percent

60 Mass grams

61 Mass kilograms

62 Mass metric tons

63 Mass pounds

64 Mass short tons

65 Mass long tons

70 Mass Flow grams per second

71 Mass Flow grams per minute

HART commands

4.6 Supported Engineering Units

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 47

Page 48

HART commands

4.6 Supported Engineering Units

Byte Format Description

72 Mass Flow grams per hour

73 Mass Flow kilograms per second

74 Mass Flow kilograms per minute

75 Mass Flow kilograms per hour

76 Mass Flow kilograms per day

77 Mass Flow metric tons per minute

78 Mass Flow metric tons per hour

79 Mass Flow metric tons per day

80 Mass Flow pounds per second

81 Mass Flow pounds per minute

82 Mass Flow pounds per hour

83 Mass Flow pounds per day

84 Mass Flow short tons per minute

85 Mass Flow short tons per hour

86 Mass Flow short tons per day

87 Mass Flow long tons per hour

88 Mass Flow long tons per day

91 Density grams per cubic centimeter

92 Density kilograms per cubic meter

93 Density pounds per US gallon

94 Density pounds per cubic foot

95 Density grams per milliliter

96 Density kilograms per liter

97 Density grams per liter

98 Density pounds per cubic inch

99 Density short tons per cubic yard

110 Volume bushel

111 Volume cubic yards

112 Volume cubic feet

113 Volume cubic inches

121 Standard Volumetric Flow normal cubic meter per hour

122 Standard Volumetric Flow normal liter per hour

123 Standard Volumetric Flow standard cubic feet per minute

124 Volume liquid barrels (= 31.5 US gallons)

125 Mass ounces

130 Volumetric Flow cubic feet per hour

131 Volumetric Flow cubic meters per minute

132 Volumetric Flow barrels (= 42 US gallons) per second

133 Volumetric Flow barrels (= 42 US gallons) per minute

134 Volumetric Flow barrels (= 42 US gallons) per hour

135 Volumetric Flow barrels (= 42 US gallons) per day

136 Volumetric Flow US gallons per hour

137 Volumetric Flow imperial gallons per second

FCT030 HART (From firmware 4.0)

48 Function Manual, 06/2018, A5E39931617-AB

Page 49

4.6 Supported Engineering Units

Byte Format Description

138 Volumetric Flow liters per hour

146 Density micrograms per liter

147 Density micrograms per cubic meter

166 Standard Volume normal cubic meters

167 Standard Volume normal liters

168 Standard Volume standard cubic feet

170 Density milligrams per liter

Volume beer barrel

Volumetric Flow beer barrel per second

171 Standard Volume standard liter

Volumetric Flow beer barrel per minute

172 Standard Volume standard cubic meter

Volumetric Flow beer barrel per hour

173 Volumetric Flow beer barrel per day

174 Standard Volumetric Flow normal liter per day

175 Standard Volumetric Flow normal liter per minute

176 Standard Volumetric Flow normal liter per second

177 Standard Volumetric Flow standard liter per day

178 Standard Volumetric Flow standard liter per hour

179 Standard Volumetric Flow standard liter per minute

180 Standard Volumetric Flow standard liter per second

181 Standard Volumetric Flow normal cubic meter per day

182 Standard Volumetric Flow normal cubic meter per minute

183 Standard Volumetric Flow normal cubic meter per second

184 Standard Volumetric Flow standard cubic feet per day

185 Standard Volumetric Flow standard cubic feet per hour

186 Standard Volumetric Flow standard cubic feet per second

187 Standard Volumetric Flow standard cubic meter per day

188 Standard Volumetric Flow standard cubic meter per hour

189 Standard Volumetric Flow standard cubic meter per minute

190 Corrected Volumetric Flow standard cubic meter per second

235 Volumetric Flow US gallons per day

236 Volume hectoliters

253 Volume Special (custom unit)

Volumetric Flow Special (custom unit)

Standard Volumetric Flow Special (custom unit)

Mass Special (custom unit)

Mass Flow Special (custom unit)

HART commands

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 49

Page 50

HART commands

4.7 HART specific information table

4.7 HART specific information table

In the following table available Modbus device parameters of the SITRANS FCT030 are

described.

Table 4-25 Operating conditions

Modbus

Register

2100 Unsigned / 1Flow

2130 Unsigned / 1Process

Data type

Size [bytes]

Parameter Description Default

Direction

Noise

Damping

Define positive and negative

flow direction.

Default positive flow direction

is indicated by the arrow

on the sensor.

Possible selections:

● 0: Negative:

The flow is measured '+' in

default

negative direction and '-'

in default positive direction.

● 1: Positive:

The flow is measured '+' in

default

positive direction and '-'

in default negative direction

Select process noise

damping level:

0: 55 ms filtering

(Centrifugal Pump)

1: 110 ms filtering

(Triplex Pump)

2: 220 ms filtering

(Duplex Pump)

3: 400 ms filtering

(Simplex Pump)

4: 800 ms filtering

(Cam Pump)

Value

value

1 0 to 1 Read /

2 0 Low to 4

range

High

Access

level

Write

Read /

Write

FCT030 HART (From firmware 4.0)

50 Function Manual, 06/2018, A5E39931617-AB

Page 51

HART commands

4.7 HART specific information table

Modbus

Register

2125 Float / 4 Low Mass‐

2426 Float / 4 Massflow

Table 4-26 Volume flow

Modbus

Register

2170 Float / 4 Low Volu‐

Data type

Size [bytes]

Data type

Size [bytes]

Parameter Description Default

flow CutOff

Correction

Factor

Parameter Description Default

meflow

Cut Off

Set massflow limit for low

flow cut-off.

Below this limit massflow

output is forced to zero.

If Low Flow Cut-Off is set to

0, the cut-off functionality is

disabled.

Notice:

It is recommended to set a

lower value for gas applica‐

tions.

Specify correction factor for

use in the massflow calcula‐

tion

Define the numerical volume‐

flow value below which the

volume flow output is forced

to zero.

Value

value

Sen‐

sor

size

Specif‐

ic

1 -1.999 to

value

Sen‐

sor

size

specif‐

ic

range

0 to 1023 Read /

+1.999

Value

range

0 to 0.177 Read /

Access

level

Write

Read /

Write

Access

level

Write

Table 4-27 Density

Data type

Modbus

Register

2127 Float / 4 Empty

2129 Unsigned / 1Empty

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 51

Size [bytes]

Parameter Description Default

value

Tube Limit

Tube

Detection

Define threshold value of

empty tube

Set automatic detection of

Empty Tube On/Off

0 = off (Empty tube is off).

1 = on

(a density value below Empty

Tube Limit triggers an alarm.

All flow rate values are forced

to zero %).

500

[kg/m3]

0 0 to 1

Value

range

-14 000 to

+14 000

Access

level

Read /

Write

Read /

Write

Page 52

HART commands

4.7 HART specific information table

Data type

Modbus

Register

2442 Float / 4 Density

2444 Float / 4 Density

Table 4-28 Totalizers

Modbus

Register

8303 Unsigned / 1TOT1_SET Control totalizer 1 0 0: TOTALIZE

8403 Unsigned / 1TOT2_SET Control totalizer 2 0 0: TOTALIZE

8503 Unsigned / 1TOT3_SET Control totalizer 3 0 0: TOTALIZE

Size [bytes]

Data type

Size [bytes]

Parameter Description Default

value

Set density compensation

Correction

Factor

Correction

Offset

Parameter Description Default

value (gain) in order to make

a density correction (scale

factor).

To increase the displayed

density value with +0.5 %,

set the density factor to 1.005.

The displayed density value

will now be 0.5 % higher than

before

Set density compensation

value (offset) in order to

make an offset on the meas‐

ured density.

1 -1.999 to

0

[kg/m3]

value

Value

range

+1.999

-1 400 to

+1 400

Value

range

1: RESET

2: PRESET

3: HOLD

1: RESET

2: PRESET

3: HOLD

1: RESET

2: PRESET

3: HOLD

Access

level

Read /

Write

Read /

Write

Access

level

Read /

Write

Read /

Write

Read /

Write

Note

After the command Reset or Preset has been send to the device, the command Totalize must

be send, to continue totalizing

FCT030 HART (From firmware 4.0)

52 Function Manual, 06/2018, A5E39931617-AB

Page 53

Table 4-29 Fraction

HART commands

4.7 HART specific information table

Modbus

Register

7869 Unsigned / 1ACTIVE_

Data type

Size [bytes]

Parameter Description Default

FRAC‐

TION

Selection of the currently

used fraction calibration pa‐

rameter set

Value

value

0 0: no fraction

range

Standard

Fractions:

1: American

Petroleum In‐

stitute (API)

number

2: Balling

3: °Baumé

light

4: °Baumé

heavy

5: °Brix

6: °Oechsle

7: °Plato

8: Specific

Gravity

9: °Twaddell

10: % High

Fructose

Corn Syrup

HFCS42

11: % High

Fructose

Corn Syrup

HFCS55

12: % High

Fructose

Corn Syrup

HFCS90

13: EthanolWater 0% to

20%

14: EthanolWater 15% to

35%

15: EthanolWater 30% to

55%

16: EthanolWater 50% to

100%

17...127: re‐

served

Customized

Fraction:

Access

level

Read /

Write

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 53

Page 54

HART commands

4.8 Example using HART command

Modbus

Register

Data type

Size [bytes]

Parameter Description Default

4.8 Example using HART command

4.8.1 Reset totalizer 1

Use the HART command 141: Write Parameter(s)

Command #141: Operation: WRITE

Table 4-30 Request Data Bytes

Byte Format Description

0…1 Unsigned-16 Modbus register of parameter 1

2…? <parameter-specific> value of parameter 1 to be written

Unsigned-16 Modbus register of parameter 2

<parameter-specific> value of parameter 2 to be written

…

Unsigned-16 Modbus register of parameter n

<parameter-specific> value of parameter n to be written

value

Value

range

128: custom‐

ized fraction

Access

level

Table 4-31 Response Data Bytes

Byte Format Description

0…1 Unsigned-16 Modbus register of parameter 1

2…? <parameter-specific> value of parameter 1 as stored

Table 4-32 Command-Specific Response Codes

Code Class Description Explanation

0 Success No Command-Specific Errors

2 Error InHartvalid Selection Register does not exist

3 Error Parameter too large provided value is too large

4 Error Parameter too small provided value is too small

Unsigned-16 Modbus register of parameter 2

<parameter-specific> value of parameter 2 as stored

…

Unsigned-16 Modbus register of parameter n

<parameter-specific> value of parameter n as stored

FCT030 HART (From firmware 4.0)

54 Function Manual, 06/2018, A5E39931617-AB

Page 55

HART commands

4.8 Example using HART command

Code Class Description Explanation

5 Error Too Few Data Bytes Received not enough data for a HART-

register with data

6 Error Device Specific Command Error

7 Error Write Protected Device is in write-protect-

mode

8 Warning Set to Nearest Possible Value Value was adapted

16 Error Access Restricted HART-register is not writea‐

ble

Request Data Bytes for Reset totalizer 1

Table 4-33 The HART information for Totalizer 1 is (8303 Dec) / (206F Hex)

Byte Format Description

0…1 Unsigned-16 206F

2…? <parameter-specific> 01

Hereafter the Totalizer must be set to totalize, to continue totalizing

Response Data Bytes for Totalize totalizer 1

Table 4-34 The HART information for Totalizer 1 is (8303 Dec) / (206F Hex)

Byte Format Description

0…1 Unsigned-16 206F

2…? <parameter-specific> 01

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 55

Page 56

HART commands

4.8 Example using HART command

FCT030 HART (From firmware 4.0)

56 Function Manual, 06/2018, A5E39931617-AB

Page 57

Specification

This device has the following specifications:

Table 5-1 HART communication

Description Specification More information

Manufacturer ID 42 (2A Hex) Manufacturer ID parameter

Device ID 34 (22 Hex) Device type parameter

HART protocol revision 7.5 HART protocol revision parameter

Device revision 5 Device revision parameter

Number of device variables 16 Number of process values, both

Physical layers supported FSK Frequency Shift Keyed

5

measured and derived

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 57

Page 58

Specification

FCT030 HART (From firmware 4.0)

58 Function Manual, 06/2018, A5E39931617-AB

Page 59

Definitions

A

Acyclic Data – data read over the acyclic communication channel, and this data could take

several bus scans to be read. The total amount of time that this process takes is random and

therefore acyclic.

Baud Rate – the speed of the network in bits per second.

Class 1 Master – a type of device on a PROFIBUS network and the traditional master in process

control systems. Refers to a Distributed Control System (DCS) or Programmable Logic

Controller (PLC).

Class 2 Master – a type of device on a PROFIBUS network and the traditional engineering

work station. An example of a class 2 master is SIMATIC PDM.

Cyclic Data – data that is read in every bus scan. It’s the input and output data used for control

and is time sensitive.

Deterministic – the knowledge that something is going to occur with a fixed time period. This

is a requirement of advanced control systems.

EDD – the Electronic Device Description is a collection of text files describing all the acyclic

data in a field device and how to read and write them. EDDs are used by configuration software

such as SIMATIC PDM to configure field instruments.

EDDL – Electronic Device Description Language is the language that EDDs are written in.

EDDL is an international standard defined in IEC 61804-2 and IEC 61804-3.

Ethernet – Ethernet is a type of physical layer defined in the IEEE 802.3 standard used for

communications in a local area network.

FDT – Field Device Tool is standard program interface (software) for configuring field devices.

FDT uses Device Type Managers to program field devices. FDT software is an alternative to

EDD based software such as SIMATIC PDM.

FDI – Field Device Integration is the evolution of FDT and EDD technology. It is for configuration

of field devices and is based on OPC-UA (Object Linking and Embedding for Process Control

– Unified Architecture) and EDD technology.

FF – Foundation Fieldbus is a digital protocol used to configure and troubleshoot field

instruments.

FISCO – Fieldbus Intrinsic Safe Concept. A standard that makes it easy to place FISCO

approved instruments into zone 0 and above environments.

FNICO – Fieldbus Non-Incendive Concept. A similar standard to FISCO. It is makes it easy to

place FISCO approved instruments into zone 2 environments.

Full-duplex – Full-duplex refers to a communication link that is bi-directional allowing for both

devices to talk and listen at the same time.

GSD – General System Data (or Generic Slave Description) is a text file in PROFIBUS and a

XML file in PROFINET defining all the protocol information and cyclic data of a field device. It

is used by the network configuration software to identify the slave and to set up the data

exchanged between the master and the slave during cyclic data exchange. GSD was also

originally the German acronym for Gerätestammdaten.

FCT030 HART (From firmware 4.0)

Function Manual, 06/2018, A5E39931617-AB 59

Page 60

Definitions

Gateway – A gateway is a device that joins two different networks together. For example, to

connect a Modbus device to a PROFIBUS network, a Profibus to Modbus gateway is needed.

HART – Highway Addressable Remote Transducer is an industrial protocol used to configure

and troubleshoot field instruments. It is often considered a transition between the 4–20mA

technology and full digital technology since it uses both.

IEC – International Electrical Congress is an international standards organization committed

to creating and maintaining international and open standards for use in the electrical industries.

I/O-Controller – A type of device on a PROFNET network and the traditional master in process

control systems. Refers to a Distributed Control System (DCS) or Programmable Logic

Controller (PLC).

I/O-Device – A type of device on PROFINET that provides input data or realizes output data

into the real world.

I/O-Supervisor – A type of device on a PROFINET network and the traditional engineering

work station. An example is SIMATIC PDM.

ISA – Instrumentation, Systems, and Automation Society is a world wide organization that

develops standards, certifies industry professionals, provides education and training,

publishes books and technical articles, and hosts conferences and exhibitions.

Interchangeability – The ability to switch from one vendor’s device to another vendor’s similar

device. Interchangeability is a key benefit of PROFIBUS Profile standard.

Intrinsically Safe – An intrinsically safe device keeps the voltage and current low enough so