Siemens Albatros2 RVS46, Albatros2 AVS37, Albatros2 AVS75, Albatros2 QAA75, Albatros2 QAA78 User Manual

...Page 1

Edition 1.0

Controller series A

CE1U2353en

22. November 2006

Building Technologies

HVAC Products

@

Albatros

2

Zone controler

User Manual

RVS46..

AVS75..

AVS37..

QAA75..

QAA78..

QAA55..

Page 2

2/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products 22. November 2006

Page 3

3/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Table of contents 22. November 2006

Table of contents

1 Overview......................................................................................................... 8

1.1 Type summary.................................................................................................9

2 Safety notes ................................................................................................. 10

2.1 Product liability ..............................................................................................10

3 Mounting and installation ...........................................................................11

3.1 Regulations.................................................................................................... 11

3.2 Basic units RVS… ......................................................................................... 11

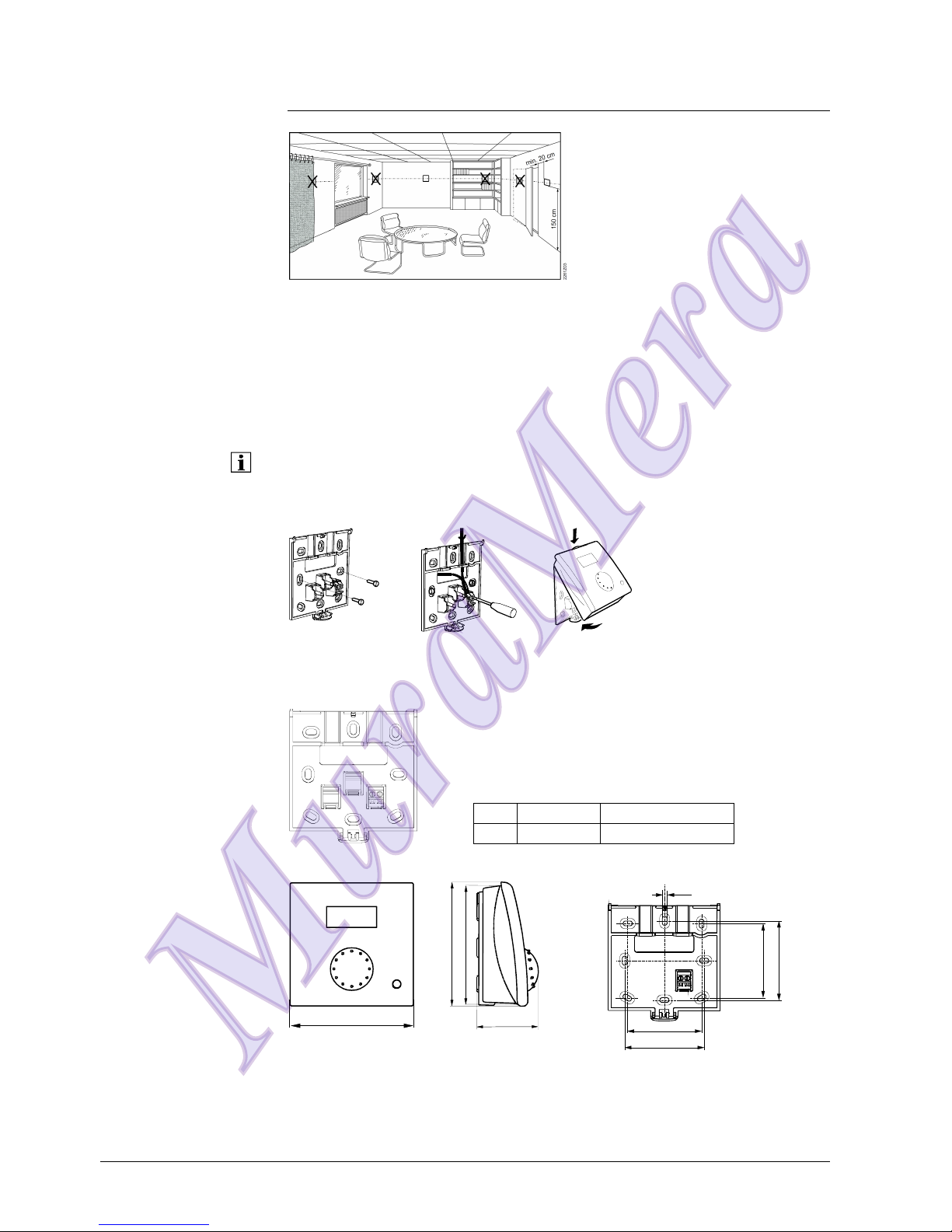

Planning......................................................................................................... 11

Mounting method...........................................................................................12

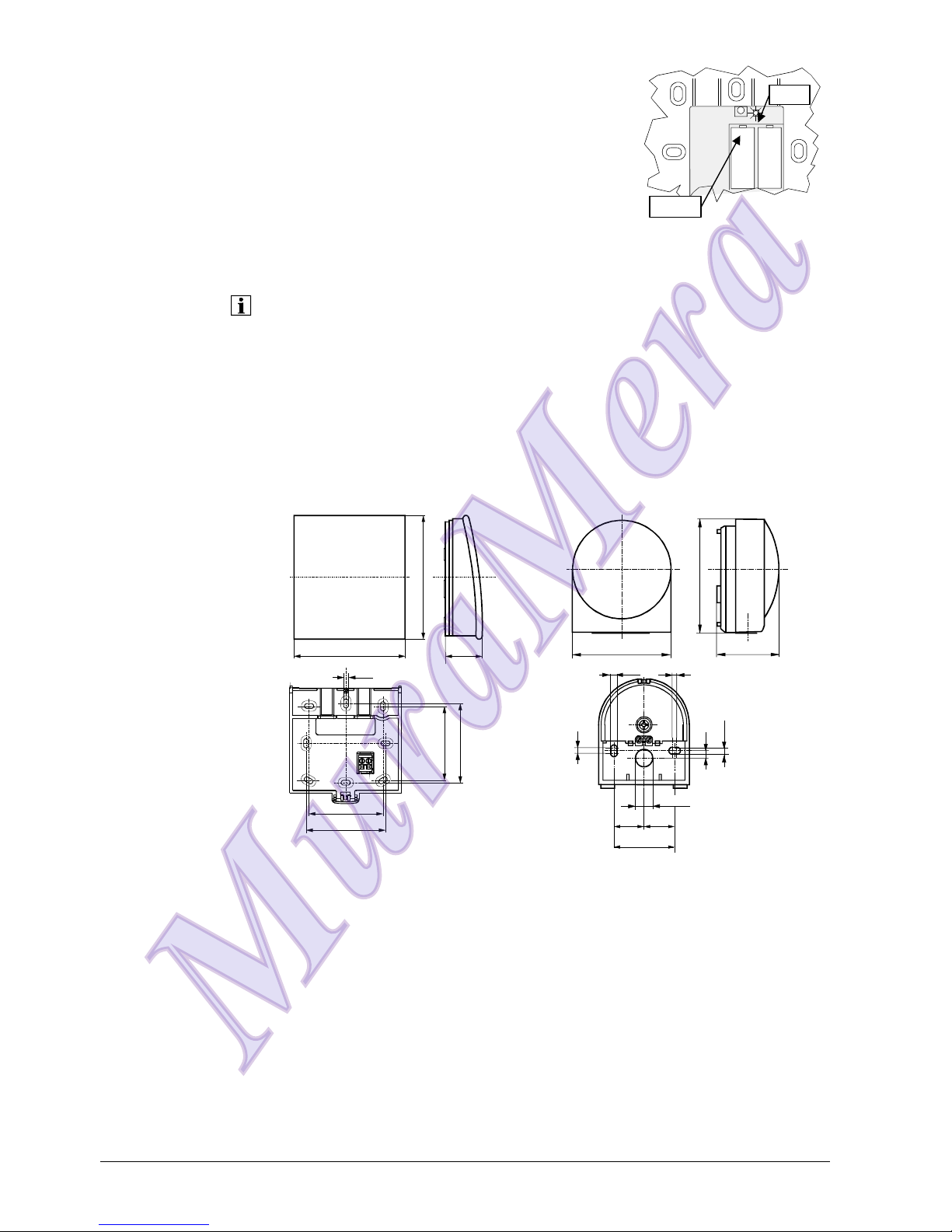

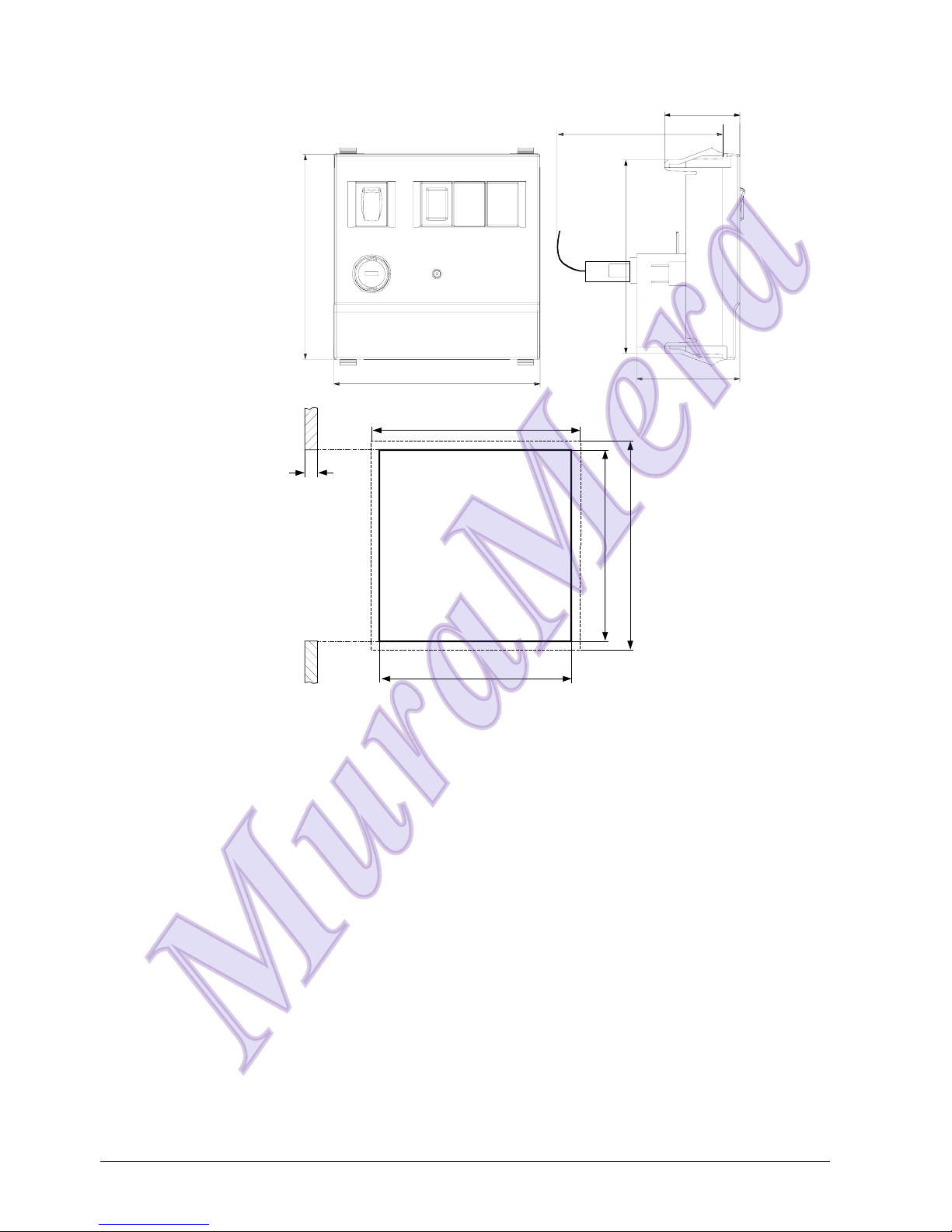

Dimensions and drilling plan.......................................................................... 12

3.2.1 Connection terminals of RVS46.543 .............................................................13

Terminal markings .........................................................................................14

3.3 Extension module AVS75.390.......................................................................15

Dimensions and drilling plan.......................................................................... 15

3.3.1 Connection terminals of AVS75.390.............................................................. 15

Terminal markings .........................................................................................16

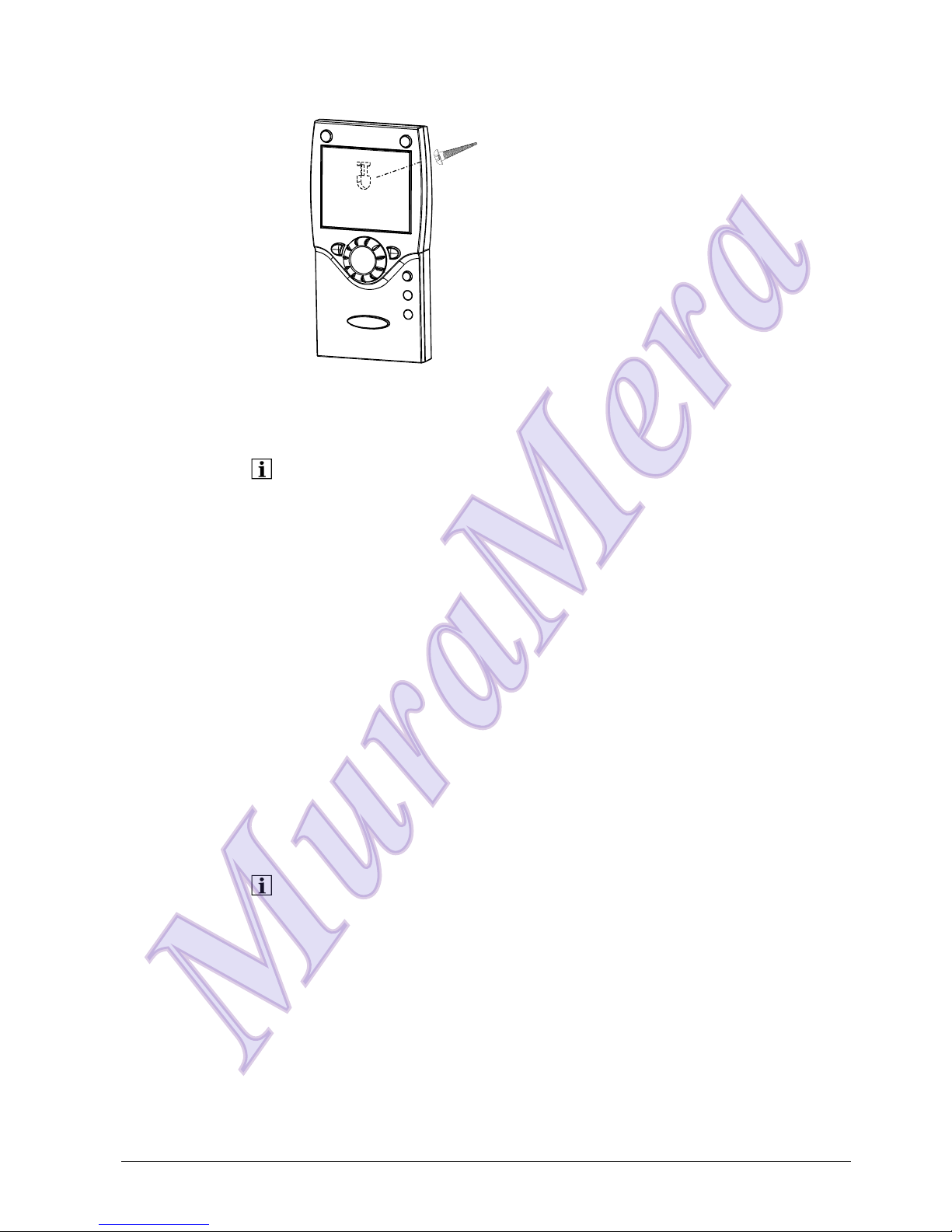

3.4 Operator unit AVS37.294 ..............................................................................16

Mounting method...........................................................................................16

Connections................................................................................................... 16

Ground........................................................................................................... 17

3.5 Room unit QAA55… ......................................................................................18

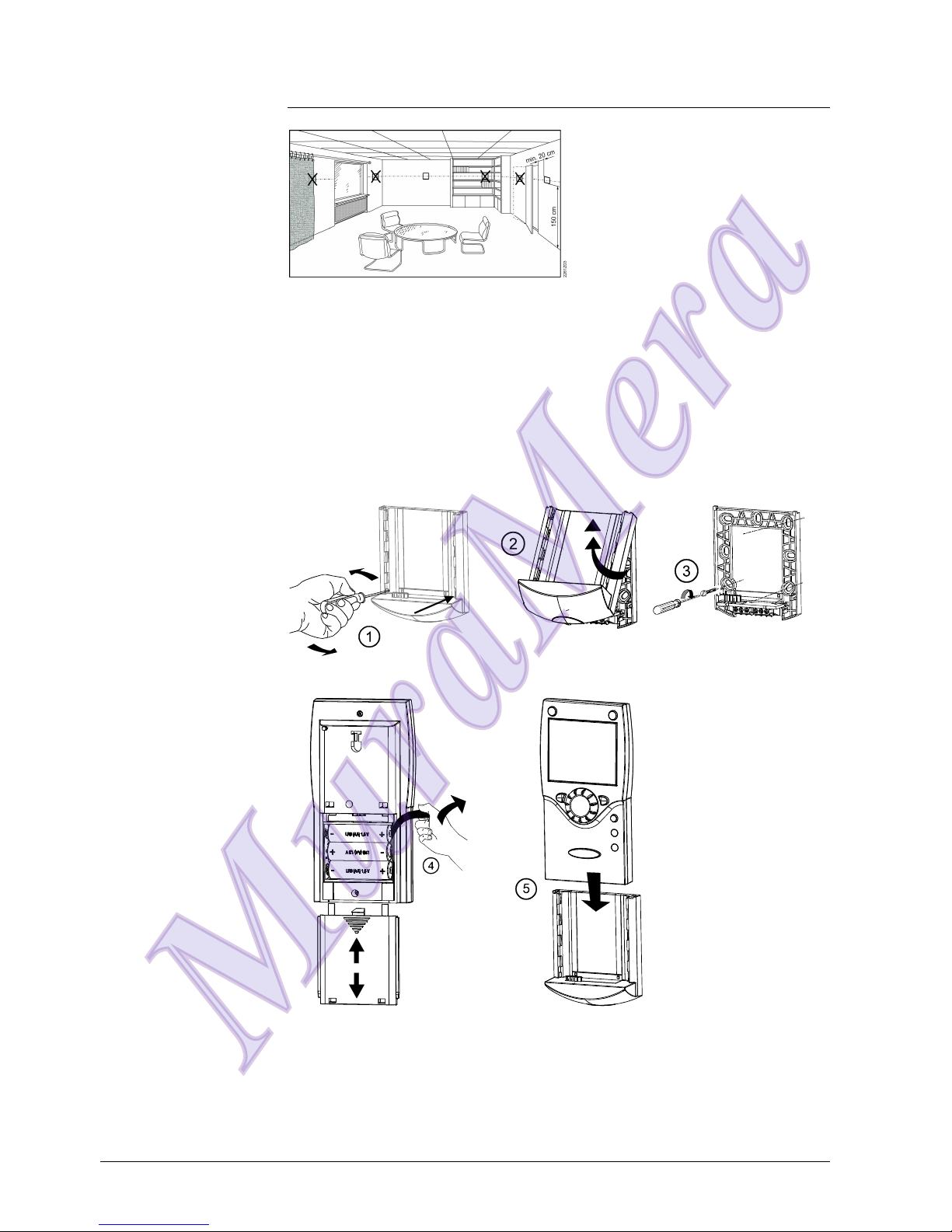

Planning......................................................................................................... 18

Mounting method...........................................................................................18

Connections................................................................................................... 18

Dimensions and drilling plan.......................................................................... 18

3.6 Room unit QAA75… ......................................................................................19

Planning......................................................................................................... 19

Mounting method...........................................................................................19

Connections................................................................................................... 19

Dimensions and drilling plan.......................................................................... 20

3.7 Wireless components .................................................................................... 21

3.7.1 Radio module AVS71…................................................................................. 21

Planning......................................................................................................... 21

Mounting method...........................................................................................21

Connection ....................................................................................................21

Radio link.......................................................................................................21

Dimensions and drilling plan.......................................................................... 21

3.7.2 Room unit QAA78… ......................................................................................22

Planning......................................................................................................... 22

Mounting with base....................................................................................... 22

Mounting without base.................................................................................. 23

Connection / power supply ............................................................................ 23

Radio link.......................................................................................................23

Dimensions and drilling plan.......................................................................... 24

3.7.3 Wireless outside sensor AVS13.399 ............................................................. 25

Page 4

4/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Table of contents 22. November 2006

Mounting method ...........................................................................................25

Connections ...................................................................................................25

Radio link .......................................................................................................25

Dimensions and drilling plan ..........................................................................26

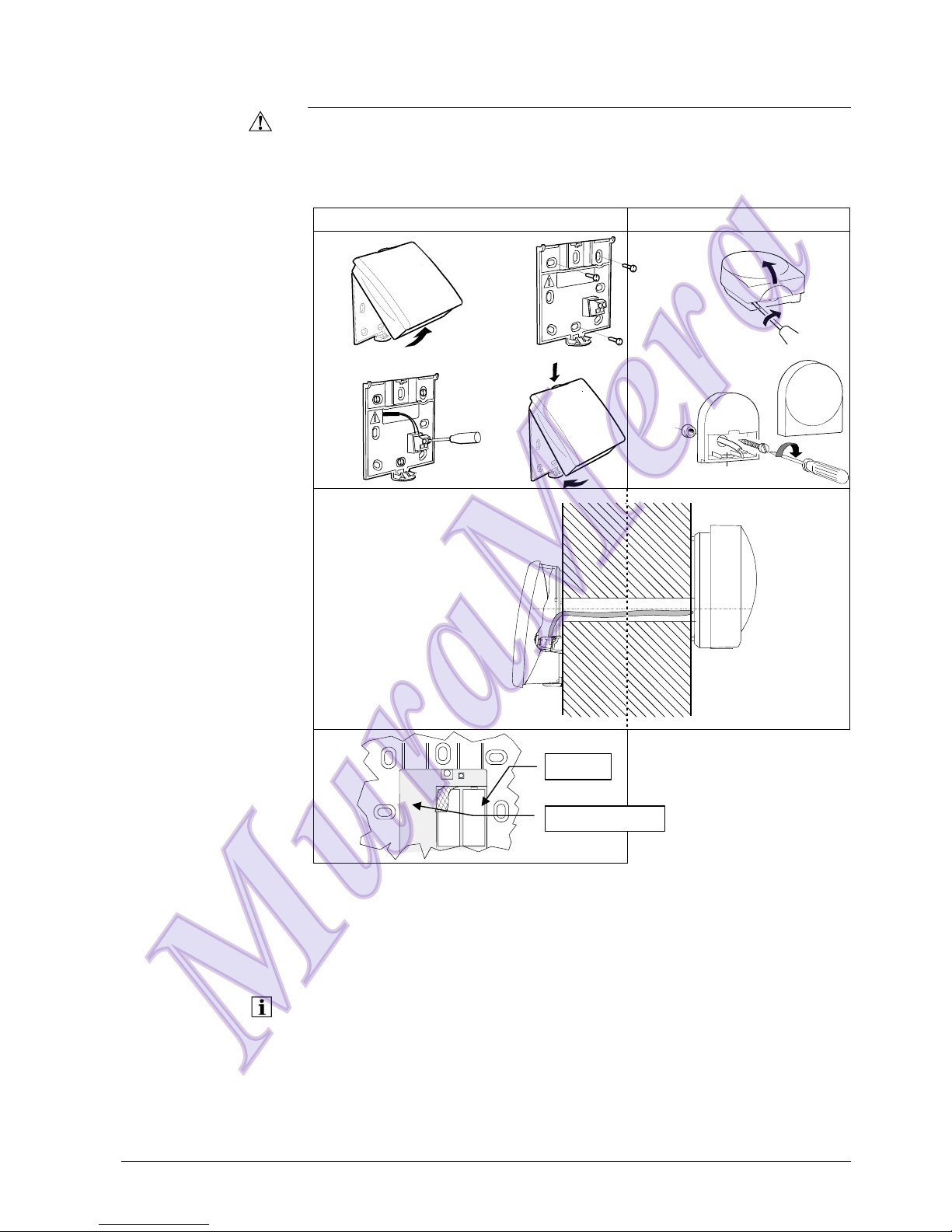

3.7.4 Radio repeater AVS14.390 ............................................................................27

Mounting method ...........................................................................................27

Connections ...................................................................................................27

Radio link .......................................................................................................27

Dimensions and drilling plan ..........................................................................27

3.7.5 Checking the wireless components ...............................................................28

3.8 Power supply AVS16.290 ..............................................................................28

Mounting notes ..............................................................................................28

Connections ...................................................................................................29

Ground ...........................................................................................................30

4 Commissioning ............................................................................................31

4.1 Basic units......................................................................................................31

5 Handling........................................................................................................32

5.1 QAA75... / QAA78... / AVS37… .....................................................................32

5.1.1 operation ........................................................................................................32

Operating elements........................................................................................32

Display choices ..............................................................................................33

Selection of space heating mode...................................................................33

Selecting DHW heating..................................................................................34

Adjusting the room temperature setpoint .......................................................34

Presence button.............................................................................................34

Displaying information....................................................................................34

5.1.2 Programming .................................................................................................37

Setting principle .............................................................................................37

Example “Setting the time of day“..................................................................37

5.1.3 User levels .....................................................................................................38

Setting structure for “Enduser“.......................................................................39

Setting structure for ”Heating engineer“.........................................................39

5.1.4 Overview of settings.......................................................................................40

5.2 QAA55... ........................................................................................................51

5.2.1 operation ........................................................................................................51

Operating elements........................................................................................51

Display choices ..............................................................................................51

5.2.2 Programming .................................................................................................51

6 The settings in detail ...................................................................................52

6.1 Time of day and date .....................................................................................52

6.2 Operator section ............................................................................................52

Operation and display ....................................................................................52

Heating circuit assignment.............................................................................53

Room sensor..................................................................................................54

Device data ....................................................................................................54

6.3 wireless ..........................................................................................................54

Binding ...........................................................................................................54

Page 5

5/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Table of contents 22. November 2006

Device list wireless ........................................................................................54

6.4 Time programs ..............................................................................................55

Switching points............................................................................................. 55

Standard program.......................................................................................... 55

6.5 Holidays.........................................................................................................55

6.6 Heating circuits ..............................................................................................56

Operating mode.............................................................................................56

Setpoints........................................................................................................ 56

Heating curve ................................................................................................57

ECO functions ...............................................................................................58

Flow temperature setpoint limitations ............................................................59

Room influence.............................................................................................. 59

Room temp limitation.....................................................................................60

Boost heating................................................................................................. 60

Quick setback ................................................................................................61

Optimum start / stop control ..........................................................................62

Increase of Reduced setpoint........................................................................ 62

Overtemp prot pump heating circuit ..............................................................63

Mixing valve control .......................................................................................63

floor curing function ....................................................................................... 64

Excess heat draw .......................................................................................... 65

Buffer storage tank / primary controller .........................................................65

Remote ..........................................................................................................65

6.7 Domestic hot water........................................................................................65

Setpoints........................................................................................................ 65

Priority ...........................................................................................................65

Legionella function......................................................................................... 66

Circulating pump............................................................................................ 66

6.8 Pump H1/H2 ..................................................................................................67

Pump H1/2..................................................................................................... 67

6.9 Solar .............................................................................................................. 67

Charging controller (dT)................................................................................. 67

Start function .................................................................................................68

Frost protection for the collector ....................................................................68

Overtemperature protection for the collector .................................................68

Evaporation temperature of medium ............................................................. 69

6.10 DHW storage tank ......................................................................................... 69

Charging control ............................................................................................ 69

Overtemperature protection........................................................................... 69

Recooling....................................................................................................... 70

Electric immersion heater .............................................................................. 70

Excess heat draw .......................................................................................... 71

Plant hydraulics ............................................................................................. 71

6.11 Configuration ................................................................................................. 72

Heating circuits 1 and 2 .................................................................................72

DHW sensor B3.............................................................................................72

DHW controlling element Q3 ......................................................................... 72

Output relay QX.............................................................................................72

Input sensor BX1,2 ........................................................................................74

Input H1 / H2 .................................................................................................74

Mixing valve groups basic unit....................................................................... 76

Extension module ..........................................................................................76

Types of sensors/readjustments.................................................................... 76

Page 6

6/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Table of contents 22. November 2006

Building and room model ...............................................................................77

Frost protection plant .....................................................................................77

Sensor state...................................................................................................77

Parameter reset .............................................................................................77

Plant diagrams ...............................................................................................77

Device data ....................................................................................................78

6.12 LPB ................................................................................................................79

Device address and segment address...........................................................79

Bus power supply...........................................................................................79

Bus power supply state..................................................................................79

Summer changeover......................................................................................79

DHW assignment ...........................................................................................79

Clock mode ....................................................................................................80

Outside temperature source ..........................................................................80

6.13 Faults .............................................................................................................80

6.14 Maintenance / service ....................................................................................81

Manual control ...............................................................................................81

Simulations ....................................................................................................81

Telephone customer service..........................................................................81

6.15 Input / output test ...........................................................................................82

6.16 Status:............................................................................................................82

Messages.......................................................................................................82

6.17 Diagnostics heat source.................................................................................83

6.18 Diagnostics consumers..................................................................................84

6.19 List of displays ...............................................................................................84

6.19.1 Error code ......................................................................................................84

6.19.2 Maintenance code..........................................................................................85

7 Plant diagrams .............................................................................................86

7.1 Basic diagram RVS46.543.............................................................................86

7.2 Extra functions in general ..............................................................................86

Circulating pump ............................................................................................86

Electric immersion heater ..............................................................................87

Collector pump and collector sensor..............................................................87

Pump H1/H2 ..................................................................................................87

Heating circuit pump HCP..............................................................................88

2. DHW sensor...............................................................................................88

7.3 Extra functions with AVS75.390.....................................................................89

Legend ...........................................................................................................90

8 Technical data ..............................................................................................91

8.1 Basic units RVS…..........................................................................................91

8.2 Extension module AVS75.390 .......................................................................92

8.3 Operator unit and room units AVS37... / QAA7x… / QAA55.. .......................93

8.4 Power supply AVS16.290 ..............................................................................94

8.5 Wireless outside sensor AVS13.399..............................................................94

8.6 Radio repeater AVS14.390 ............................................................................95

8.7 sensor characteristics ....................................................................................96

Page 7

7/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Table of contents 22. November 2006

8.7.1 NTC 1 k .........................................................................................................96

8.7.2 NTC 10 k .......................................................................................................97

8.7.3 PT1000 ..........................................................................................................97

Page 8

8/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Overview 22. November 2006

1 Overview

The present User Manual describes the products listed below and covers handling and

configuration of the units for readers ranging from endusers to heating engineers.

ASN Title

RVS46.543 Basic unit zone

AVS75.390 Extension module

AVS37.294 Operator unit

QAA75.610 Room unit, wired

QAA75.611 Room unit with backlight, wired

QAA78.610 Room unit, wireless

QAA55.110 Room unit

AVS16.290 Power section

AVS38.291 Dummy cover (96 x 144 mm)

AVS71.390 Radio module

AVS14.390 Radio repeater

AVS13.399 Wireless outside sensor

The following products are described in separate pieces of documentation:

QAC34 Outside sensor

QAD36 Strap-on temperature sensor

QAZ36 Immersion temperature sensor

Page 9

9/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Overview 22. November 2006

1.1 Type summary

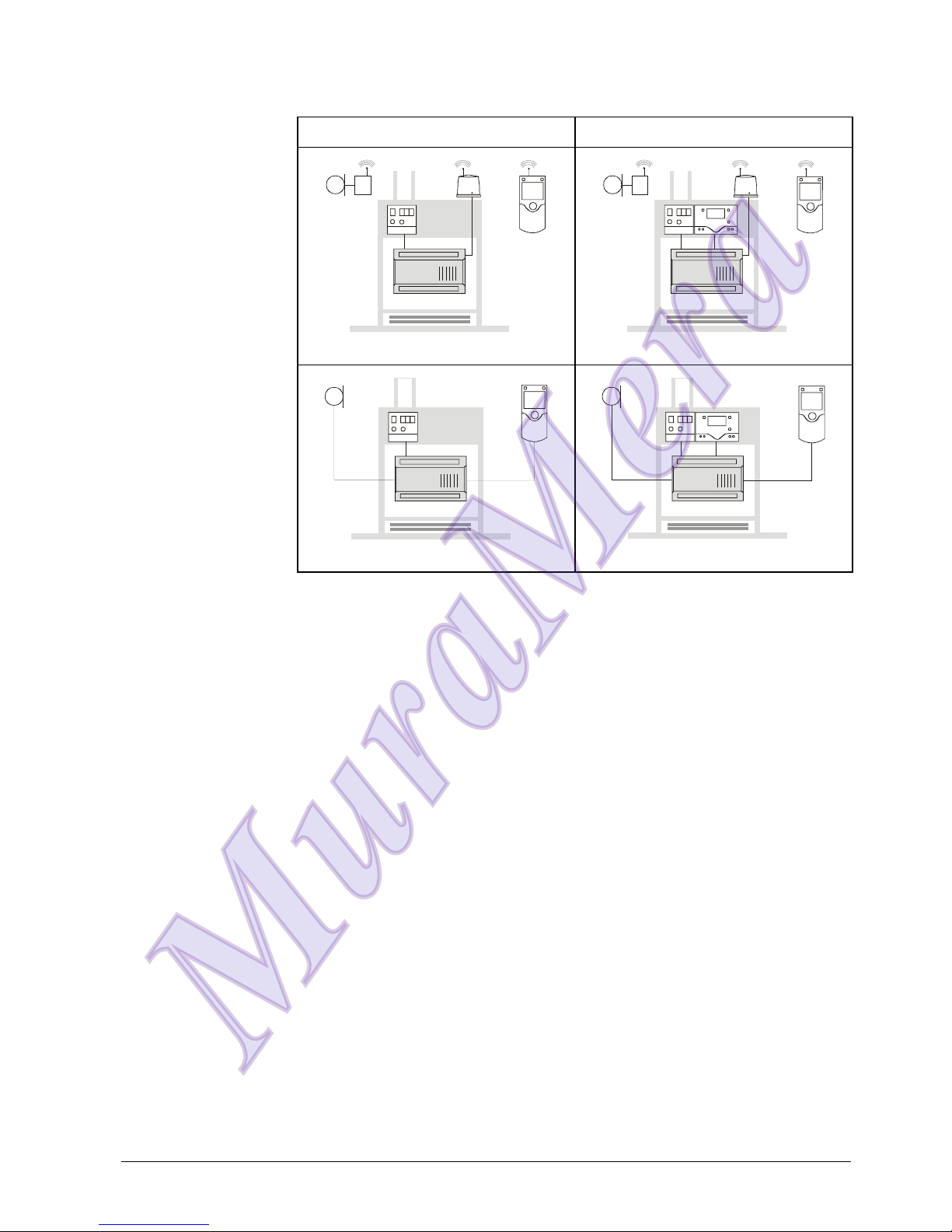

Operation with room unit Operation with operator unit

(optionally together with room unit)

A Basic unit RVS…

B Power section AVS16…

C Room unit QAA55… / QAA75… / QAA78…

D Outside sensor AVS13…

E Operator unit AVS37…

F Radio module AVS71…

wireless

Wire-bound

C

D

B

A

2359Z01

T

C

E

D

B

A

2359Z02

T

C

D

F

B

A

2359Z03

T

C

D

F

B

A

E

2359Z04

T

Page 10

10/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Safety notes 22. November 2006

2 Safety notes

2.1 Product liability

• The products may only be used in building services plant and applications as

described in this document

• When using the products, all requirements specified in chapters "Handling" and

"Technical data" must be satisfied

• Local regulations (for installation, etc.) must be complied with

• Do not open the units. If not observed, warranty by Siemens becomes void

Page 11

11/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

3 Mounting and installation

3.1 Regulations

• Prior to installing the controller, power must be turned off

• The connections for mains and low-voltage are separated

• The wiring must be made in compliance with the requirements of safety class II. This

means that sensor and mains cables must not be run in the same duct

3.2 Basic units RVS…

Planning

• Air circulation around the unit must be ensured, allowing the unit to emit the heat

produced by it.

A clearance of at least 10 mm must be provided for the unit's cooling slots at the top

and bottom of the housing.

That space should not be accessible and no objects should be placed there. If the

controller is enclosed in another (insulating) casing, a clearance of up to 100 mm

must be observed around the cooling slots

• The controller is designed conforming to the directives for safety class II devices

mounted in compliance with these regulations

• Power to the controller may only be supplied when completely fitted. If this is not

observed, there is a risk of electric shock hazard near the terminals and through the

cooling slots

• The controller may not be exposed to dripping water

• Permissible ambient temperature when mounted and when ready to operate:

0...50 °C

• Power cables must be clearly segregated from low-voltage cables (sensors)

observing a distance of at least 100 mm

• Boiler

• Control panel

• Housing for wall mounting

Electrical installation

Mounting location

Page 12

12/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

2359Z10

x

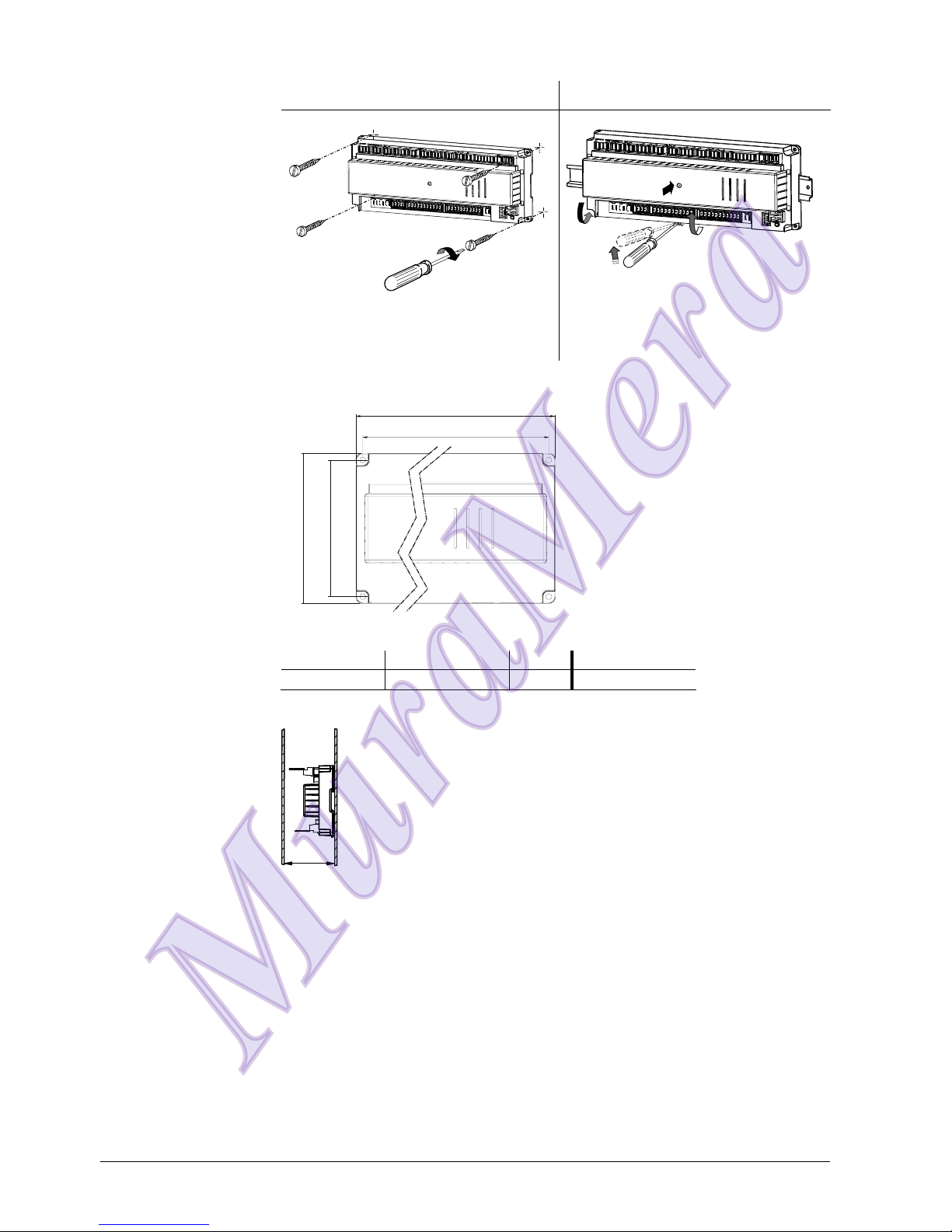

Mounting method

Screwed

On DIN rail

2359Z09

A1

A2

B1

B2

2359Z11

A: Mounting / B: Removal

Note:

To mount the controller on a DIN rail, a mounting clip

is required!

Dimensions and drilling plan

L

BL1B1

2358M01

L B H L1 B1

RVS46.543

180.7 120.7 51.7 170 110

Dimension X:

For connectors with tongues: Minimum 70 mm

For connectors without tongues: Minimum 60 mm

Total height required

Dimensions in mm

Page 13

13/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

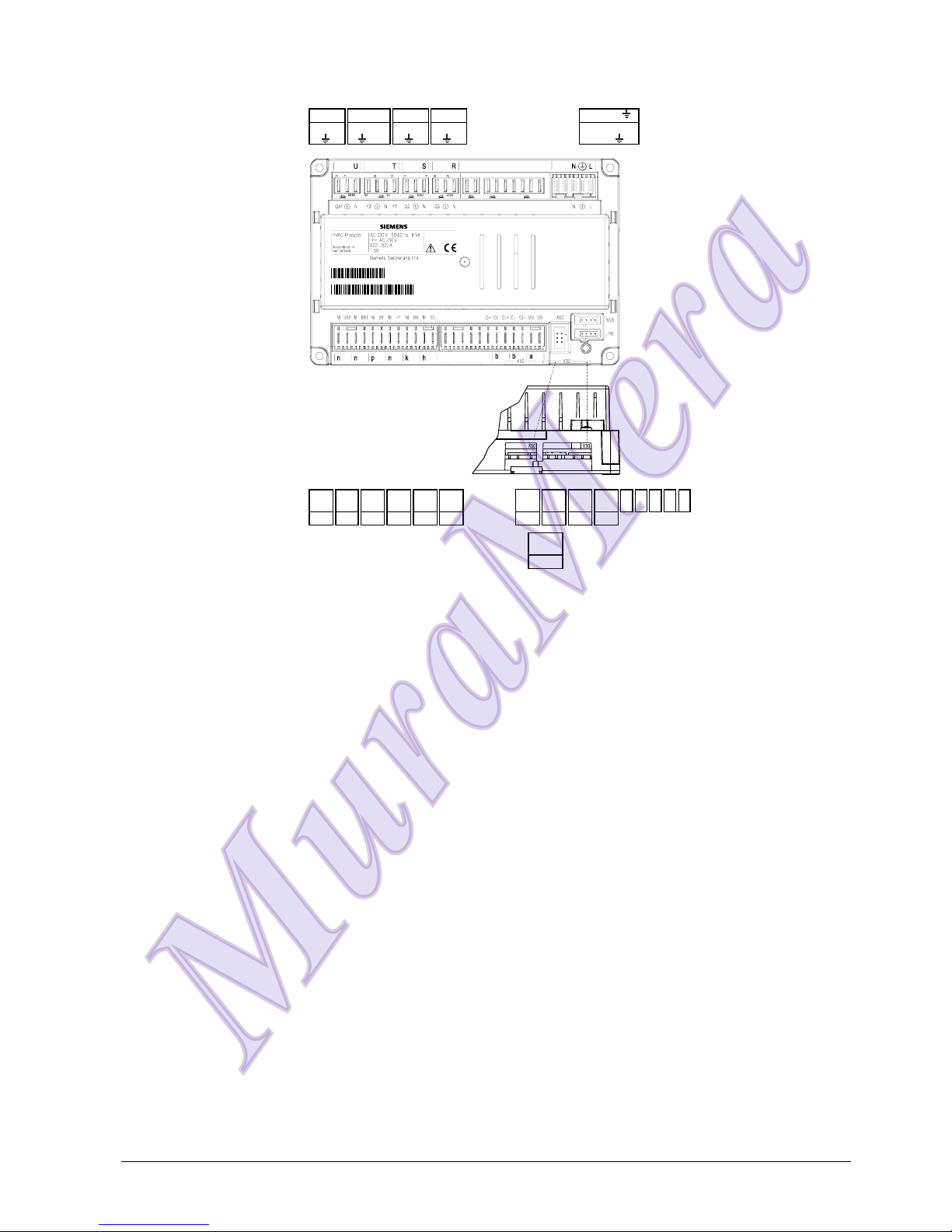

3.2.1 Connection terminals of RVS46.543

U T S R N L

QX1 N

Y2 N

Y1

Q2 N

Q3 N - - - - - - - - - - - N L

2353Z01

060404A

000020RVS46.543/109

1PRVS46.543/10 9

S060404000020

M

BX2 M BX1 M B1 M H1 M B9 M B3 - - - - - G+

CL-

CL+

CL-

CL+

MB

DB

X50

X60

X30

BSB

LPB

n n p n k h b b a

G+

CL-

CL+

b

Page 14

14/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

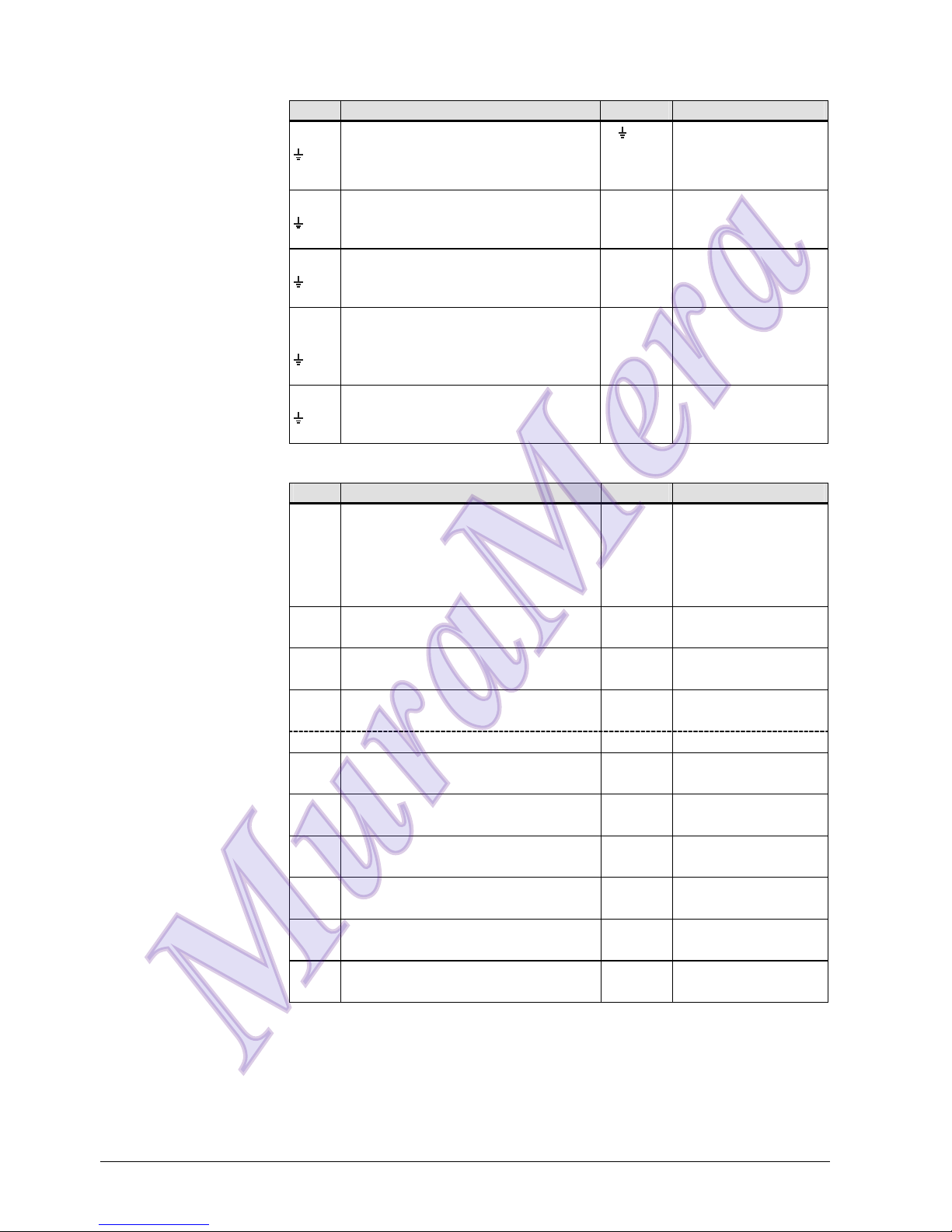

Terminal markings

Use Terminal Type of connector

L Phase AC 230 V basic unit N L AGP4S.05A/109

Protective earth

N Neutral conductor

N Neutral conductor R AGP8S.03A/109

Protective earth

Q3 DHW charging pump / diverting valve

N Neutral conductor S AGP8S.03B/109

Protective earth

Q2 1. Heating circuit pump

Y1 1st heating circuit mixing valve opening T AGP8S.04B/109

N Neutral conductor

Protective earth

Y2 2nd heating circuit mixing valve closing

N Neutral conductor U AGP8S.03C/109

Protective earth

QX1 1st multifunctional output

Use Terminal Type of connector

BSB Service tool OCI700 - LPB Local Process Bus - X60 Radio module AVS71.390 - X50 extension module AVS75.390 - AVS82.490/109

X30 Operator unit / boiler control panel - AVS82.491/109

DB LPB data AGP4S.02H/109

MB LPB ground

CL+ BSB data AGP4S.02A/109

CL- BSB ground b

CL+ Room unit 1 data AGP4S.02A/109

CL- Room unit 1 ground b AGP4S.03D/109

G+ Room unit power supply 12 V

B3 DHW sensor top AGP4S.02C/109

M Ground h

B9 Outside sensor AGP4S.02D/109

M Ground k

H1 Digital / DC 0...10 V input AGP4S.02F/109

M Ground n

B1 Flow temperature sensor HC1 AGP4S.02G/109

M Ground p

BX1 Multifunctional sensor input 1 AGP4S.02F/109

M Ground n

BX2 Multifunctional sensor input 2 AGP4S.02F/109

M Ground n

Mains voltage

Low-voltage

Page 15

15/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

3.3 Extension module AVS75.390

Planning, mounting location and mounting method are in compliance with the basic

modules.

Dimensions and drilling plan

L

BL1B1

2358M01

L B H L1 B1

AVS75.390

108.7 120.9 51.7 98 110

The AVS75.390 extension module must be connected to terminal

X50 of the basic unit

using the AVS83.490/109 connecting cable. The connectors are coded.

3.3.1 Connection terminals of AVS75.390

S T N L

- - -

QX2

3

N

QX2

2

N

QX21

N L

050110A

000020

AVS75.390/109

1PAVS75.390/109

S050110000020

2359Z49

Connections

M

H2 M BX22 M BX21 - - - -

X30

n n n

Dimensions in mm

1

12

= Module 1

2

1

2

= Module 2

Page 16

16/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

Terminal markings

Use Terminal Type of connector

L Phase AC 230 V basic unit N L AGP4S.03E/109

Protective earth

N Neutral conductor

QX21 Assignment according to function t AGP8S.04B/109

N Neutral conductor

Protective earth

QX22 Assignment according to function

N Neutral conductor s AGP8S.03B/109

Protective earth

QX23 Assignment according to function

Use Terminal Type of connector

X30 Operator unit / boiler control panel - AVS82.491/109

BX21 Assignment according to function AGP4S.02F/109

M Ground n

BX22 Assignment according to function AGP4S.02F/109

M Ground n

H2 Digital / DC 0...10 V input

AGP4S.02F/109

M Ground n

When using the 2 parameters

• Function extension module 1 (operating line 6020)

• Function extension module 2 (operating line 6021),

usage of the respective module will be defined.

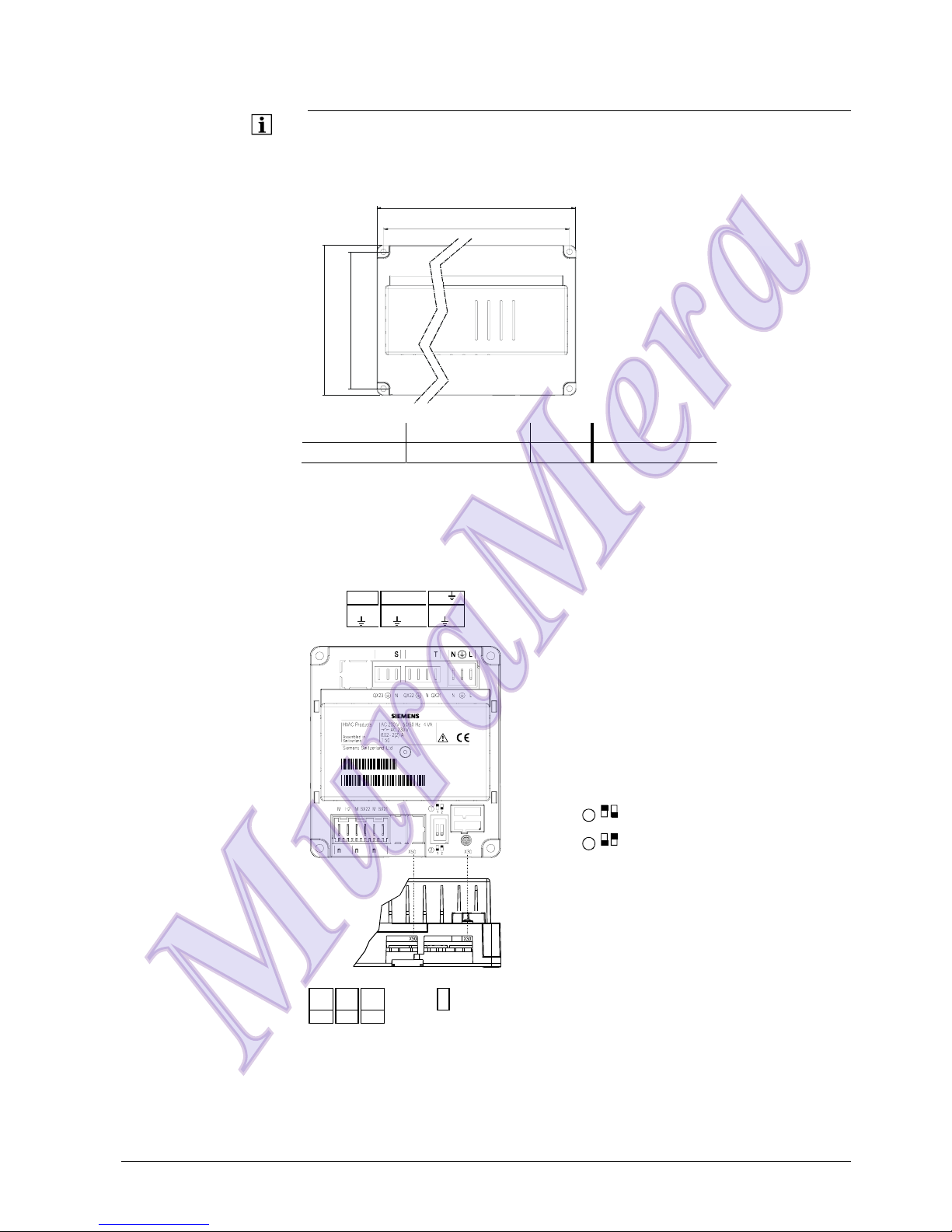

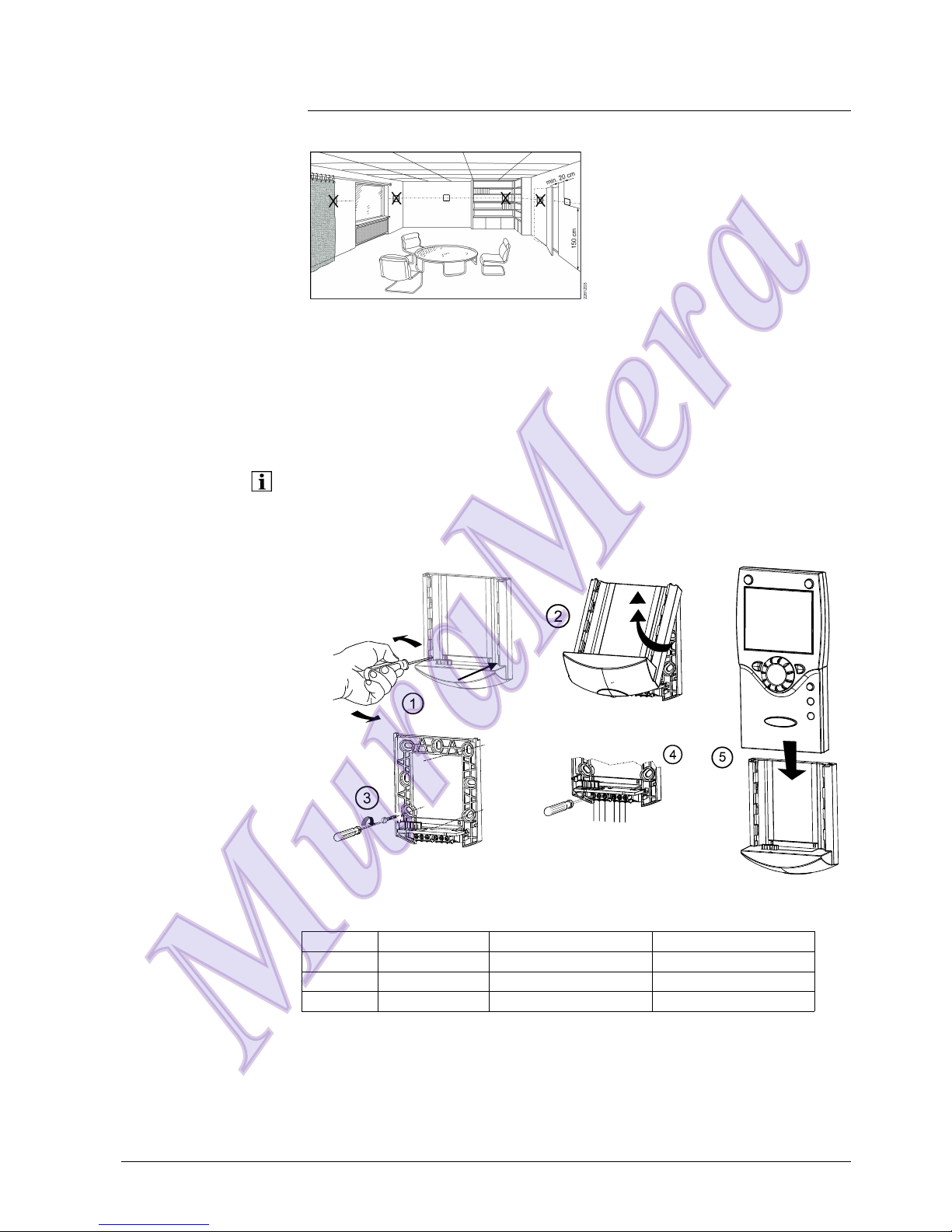

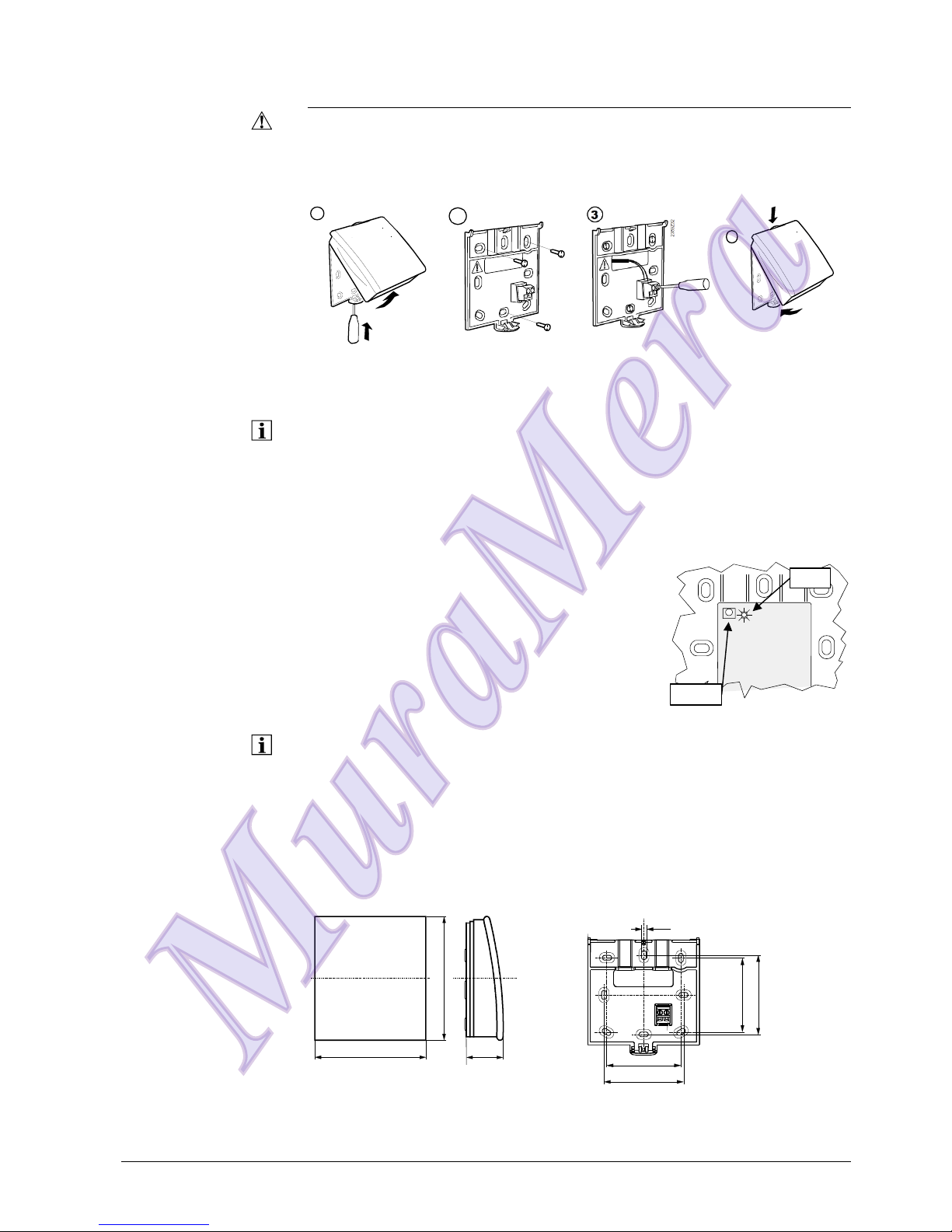

3.4 Operator unit AVS37.294

Mounting method

installation Removal

2358Z30

2358Z31

2358Z32

Connections

The AVS37.294 operator unit must be connected to terminal X30 of the basic unit using

the AVS82.491/109 connecting cable.

The connectors are coded.

Mains voltage

Low-voltage

Assignment of terminals

Page 17

17/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

Ground

(144)

0.5...3.0

92

+0.8

0

138

+1

0

2358M05

(96)

Panel cutout

2358M03

144

96

90

27

42.4

17

Page 18

18/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

3.5 Room unit QAA55…

Planning

The room unit should be located in the main living room while giving consideration to

the following points:

• The place of installation should be chosen such that the sensor can capture the room

temperature as accurately as possible without getting adversely affected by direct

solar radiation or other heat or refrigeration sources (about 1.5 meters above the

floor)

• In the case of wall mounting, there must be sufficient clearance above the unit,

enabling it to be fitted and removed

When the unit is removed from its base, power is disconnected so that the unit is out of

operation.

Mounting method

2284Z33a

2284Z34a

• The controller may not be exposed to dripping water

Connections

1

34

562

2284Z40

1 CL+ BSB data

2 CL- BSB ground

Dimensions and drilling plan

2282M02

96

9

6

9

1

4

7

12

2359Z27

4,2

56

60

56

60

Page 19

19/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

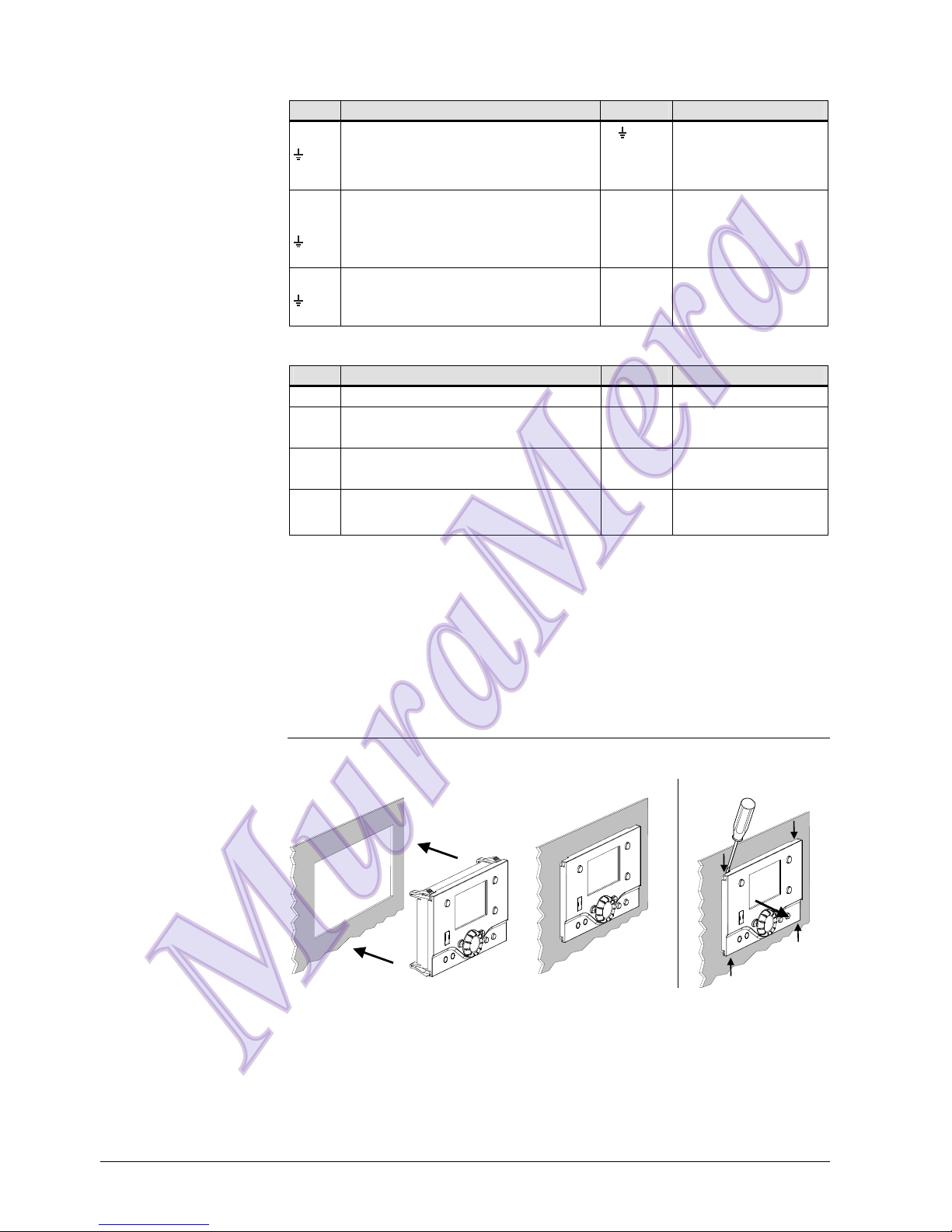

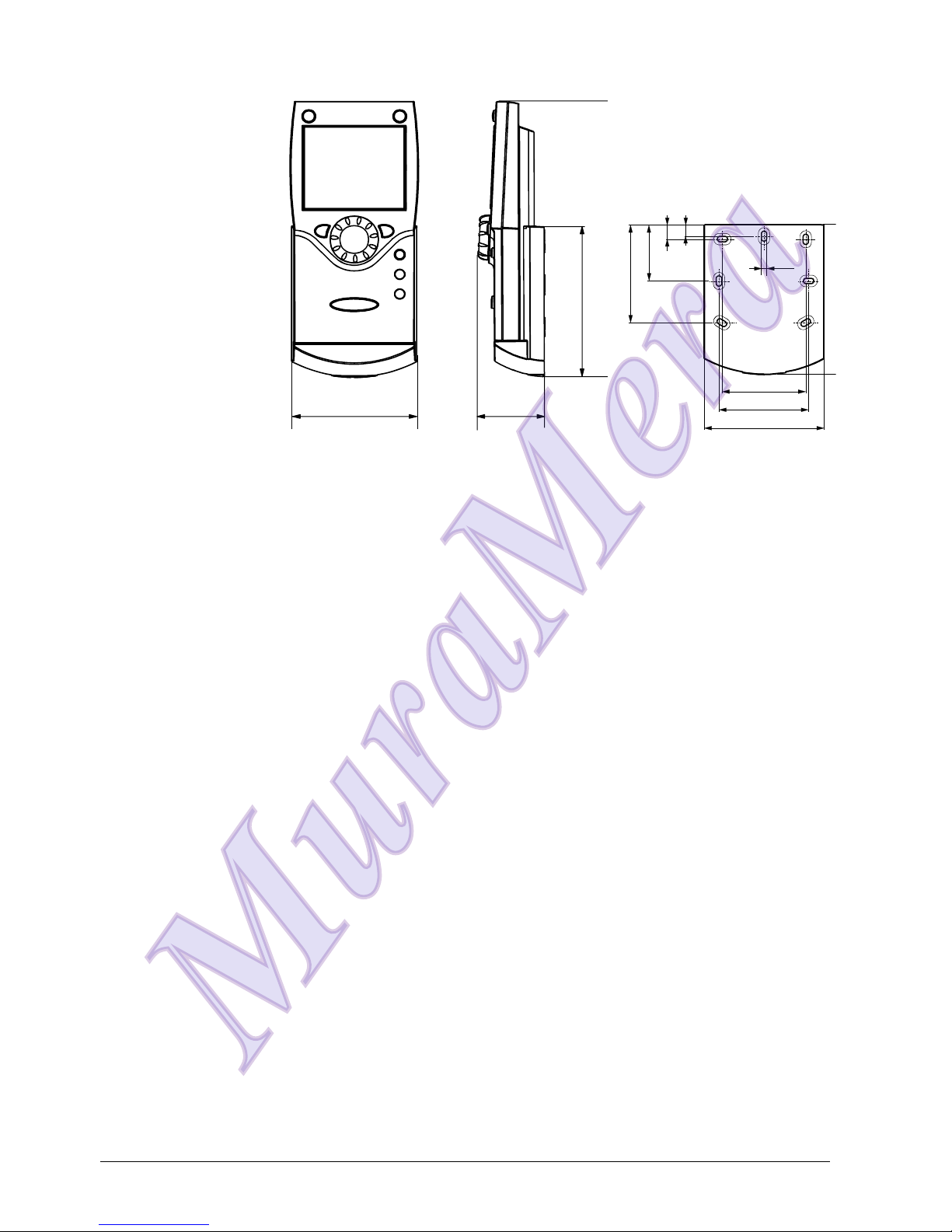

3.6 Room unit QAA75…

Planning

The room unit should be located in the main living room while giving consideration to

the following points:

• The place of installation should be chosen such that the sensor can capture the room

temperature as accurately as possible without getting adversely affected by direct

solar radiation or other heat or refrigeration sources (about 1.5 meters above the

floor)

• In the case of wall mounting, there must be sufficient clearance above the unit,

enabling it to be fitted and removed

When the unit is removed from its base, power is disconnected so that the unit is out of

operation.

Mounting method

Connections

Terminal Designation QAA75.610 QAA75.611

1 CL+ BSB data BSB data

2 CL- BSB ground BSB ground

3 G+ Reserved Power supply DC 12 V

2359Z20

2359Z26

2359Z24

2359Z21

2359Z25

Page 20

20/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

Dimensions and drilling plan

42

185

2359Z12

100

82

2359Z50

4,2

9

56

60

100

80

11

39

67

Page 21

21/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

3.7 Wireless components

The wireless components should be located such that transmission will be as

interferencefree as possible. The following criteria must be observed:

• Not in the vicinity of electrical cables, strong magnetic fields or equipment such as

PCs, TV sets, microwave ovens, etc.

• Not near larger metal structures or constructional elements with fine metal meshes

such as special glass or special concrete

• The distance to the transmitter should not exceed 30 meters or 2 floors

3.7.1 Radio module AVS71…

The radio module extends the product range through the introduction of wireless

communication. With this type of device, system components such as room units

transmit data with no need for using cables.

Planning

Do not install the radio module inside metal casings (e.g. inside the boiler).

Mounting method

2359Z23

Connection

The prefabricated cable must be connected to terminal X60 of the controller.

Prior to connecting the module, the basic unit must be disconnected from power!

Radio link

Establishment of the radio link is described in the following sections which cover the

different radio-controlled units.

Dimensions and drilling plan

43

2354Z11

2359Z57

A

B

LED

Button

Page 22

22/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

3.7.2 Room unit QAA78…

Planning

The room unit should be located in the main living room while giving consideration to

the following points:

• The place of installation should be chosen such that the sensor can capture the room

temperature as accurately as possible without getting adversely affected by direct

solar radiation or other heat or refrigeration sources (about 1.5 meters above the

floor)

• In the case of wall mounting, there must be sufficient clearance above the unit,

enabling it to be fitted and removed

Mounting with

base

2359Z20

2359Z26

2359Z22

2359Z21

2359Z25

Page 23

23/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

Mounting without

base

2359Z61

Connection / power supply

The room unit is powered by three 1.5 V Alkali batteries type AA (LR06).

Radio link

Establish the radio link in the vicinity of the radio module prior to mounting so that all

system components are within easy reach.

Prerequisite for the radio link is that all components receive power, which means that

the radio module must be correctly connected to the basic unit and the batteries must

be correctly installed in the room unit.

1. Press the button on the installed radio module for at least 8 seconds until the LED

on the radio module starts flashing at high frequency.

2. Press the OK button on the room unit to switch to programming.

3. Press the Info button for at least 3 seconds and select operating level

“Commissioning“ with the setting knob. Then, press the OK button.

4. Select operating page “Operator unit“ and press the OK button.

5. Select operating line “Used as“ (operating line 40) and make the appropriate

selection. Then, press the OK button.

6. Select operating page “Wireless“ and press the OK button.

7. Select operating line “Binding“ (line 120). Then, press the OK button.

8. Set the setting knob to “Yes“ and press the OK button. Link establishment is started.

9. The display shows the progress of link establishment in %. This process can take 2

to 120 seconds.

10. The link is established when “Unit ready” appears and the LED on the radio module

extinguishes.

The test is made to check the quality of the radio link.

• The test can be stopped by pressing the ESC button

• While the radio link can be opened on the boiler, the test should be made at the

location where the room unit will be installed

On the room unit, as described above (points 2 to 4), select operating page “Wireless“

and activate the test mode on operating line “Test mode“ (line 121).

Establishing the link

Testing

Page 24

24/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

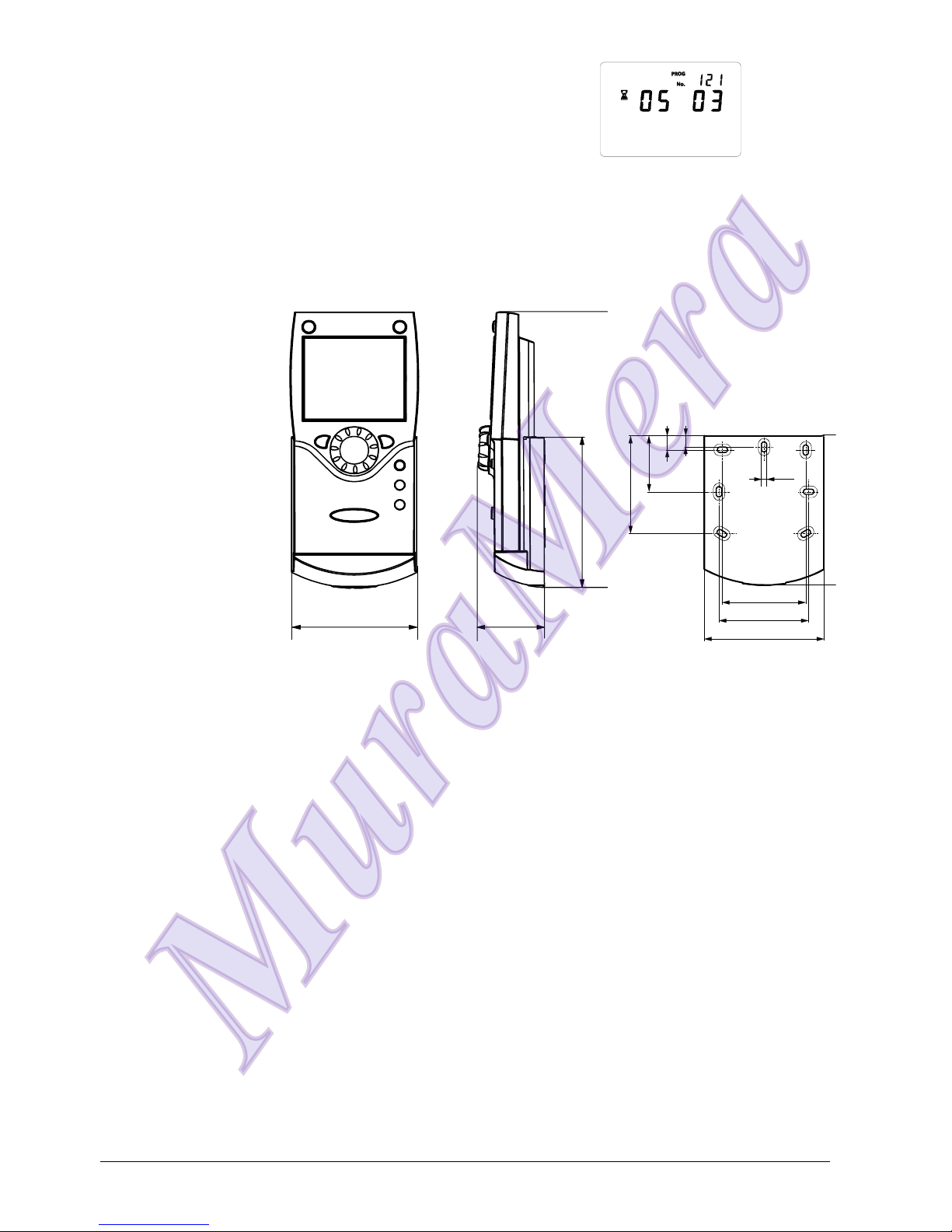

Example of a display during the test:

The digits on the left show telegrams that have

been sent, the digits on the right telegrams that

have been received. The test will be ended

after 24 telegrams. The test will be considered

successful when at least 50 % of the telegrams

sent have been received.

2359Z140

Operator sect ion

Testmode

If the test was not successful, some other mounting location should be chosen or the

AVS14.390 radio repeater should be used.

Dimensions and drilling plan

42

185

2359Z12

100

82

2359Z50

4,2

9

56

60

100

80

11

39

67

Page 25

25/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

2359Z53

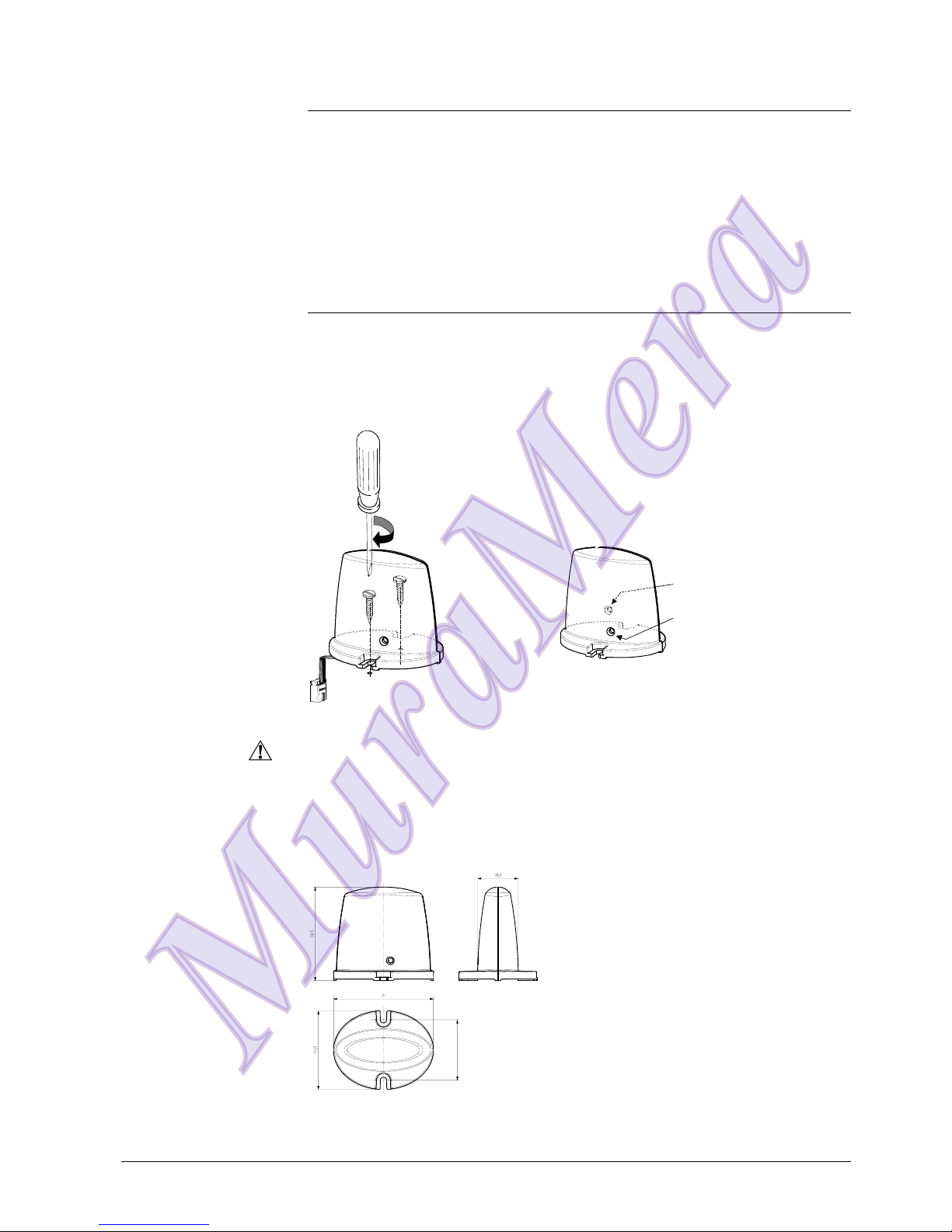

3.7.3 Wireless outside sensor AVS13.399

• The radio transmitter must be installed inside the building

• The radio transmitter’s mounting location should be chosen such that batteries

can be easily changed

Mounting method

Radio transmitter Outside sensor

Connections

The outside sensor is to be connected to the radio transmitter via a 2-core cable; the

connections are interchangeable.

Power is supplied by two 1.5 V Alkali batteries type AAA (LR03).

Radio link

Establish the radio link in the vicinity of the radio module prior to mounting so that all

system components are within easy reach.

Prerequisite for the radio link is that all components receive power, which means that

the radio module must be correctly connected to the basic unit and the batteries must

be correctly installed in the room unit.

2359Z54

2359Z30

2359Z33

2359Z59

2359Z31

2359Z55

AAA

AAA

Battery transit tab

Battery

2359Z32

Page 26

26/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

1. Press the button on the radio module for at least 8

seconds until the LED on the radio module starts

flashing at high frequency.

2. Press the button on the transmitter of the wireless

outside sensor for at least 8 seconds until that LED

also starts flashing at high frequency.

3. The link is established when the LED on the radio

module extinguishes.

4. Press the button on the transmitter of the wireless outside sensor briefly again until

the LED extinguishes.

The test is made to check the quality of the radio link.

• The test can be stopped by pressing the ESC button

• While the radio link can be opened on the boiler, the test should be made at the

location where the room unit will be installed

1. Press button 3 on the transmitter of the wireless outside sensor for a maximum of 8

seconds until the LED starts flashing at low frequency.

2. When radio communication works, the LED on the radio module flashes briefly at

10-second intervals.

3. After the test, press the button on the transmitter of the wireless outside sensor

again briefly until the LED extinguishes.

Dimensions and drilling plan

90

100

32

2359Z16

79,8

91,6

49,7

1811M01

12

2359Z27

4,2

56

60

56

60

3

5,5

Ø 14,1

2524,5

49,5

4

5,5

6

1811M02

Establishing the link

Testing

2359Z58

AAA

AAA

LED

Button

Page 27

27/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

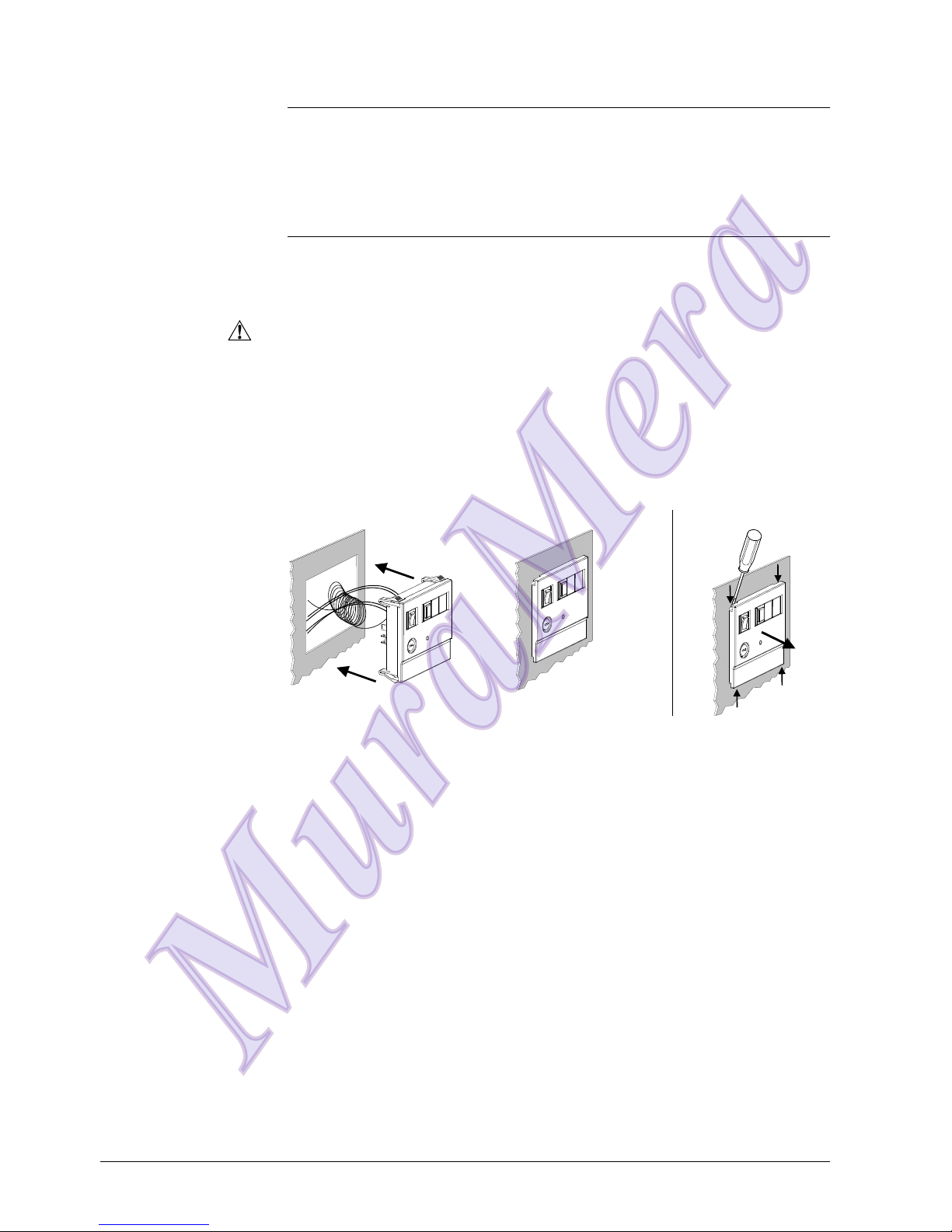

3.7.4 Radio repeater AVS14.390

• To establish the radio link, the device must be temporarily connected to power prior

to mounting, enabling the radio link to be opened and tested

• The radio repeater must be fitted inside the building

Mounting method

1

2359Z30

2

2359Z33

4

2359Z31

Connections

Power is supplied via the enclosed power pack. The wires are interchangeable.

Radio link

Establish the radio link in the vicinity of the radio module prior to mounting so that all

system components are within easy reach.

Prerequisite for the radio link is that all components receive power, which means that

the radio module must be correctly connected to the basic unit and power must be

correctly supplied to the radio repeater.

1. Press the button on the radio module for at least 8

seconds until the LED on the radio module starts

flashing at high frequency.

2. Press the button on the installed radio repeater until

the LED starts flashing at high frequency.

3. The link is established when the LED on the radio

module extinguishes.

The test is made to check the quality of the radio link.

• The test can be stopped by pressing the ESC button

• While the radio link can be opened on the boiler, the test should be made at the

location where the room unit will be installed

1. Press button 3 on the radio repeater for a maximum of 8 seconds until the LED

starts flashing at low frequency.

2. When radio communication works, the LED on the radio module flashes briefly at

10-second intervals.

3. After the test, press the button on the radio repeater again briefly until the LED

extinguishes.

Dimensions and drilling plan

90

100

32

2359Z16

12

2359Z27

4,2

56

60

56

60

Establishing the link

Testing

2359Z56

LED

Button

Page 28

28/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

3.7.5 Checking the wireless components

To check whether the connections to the required system components are operational,

consult operating lines 130 through 135 on operating page “Wireless“ (operating level

“Commissioning“).

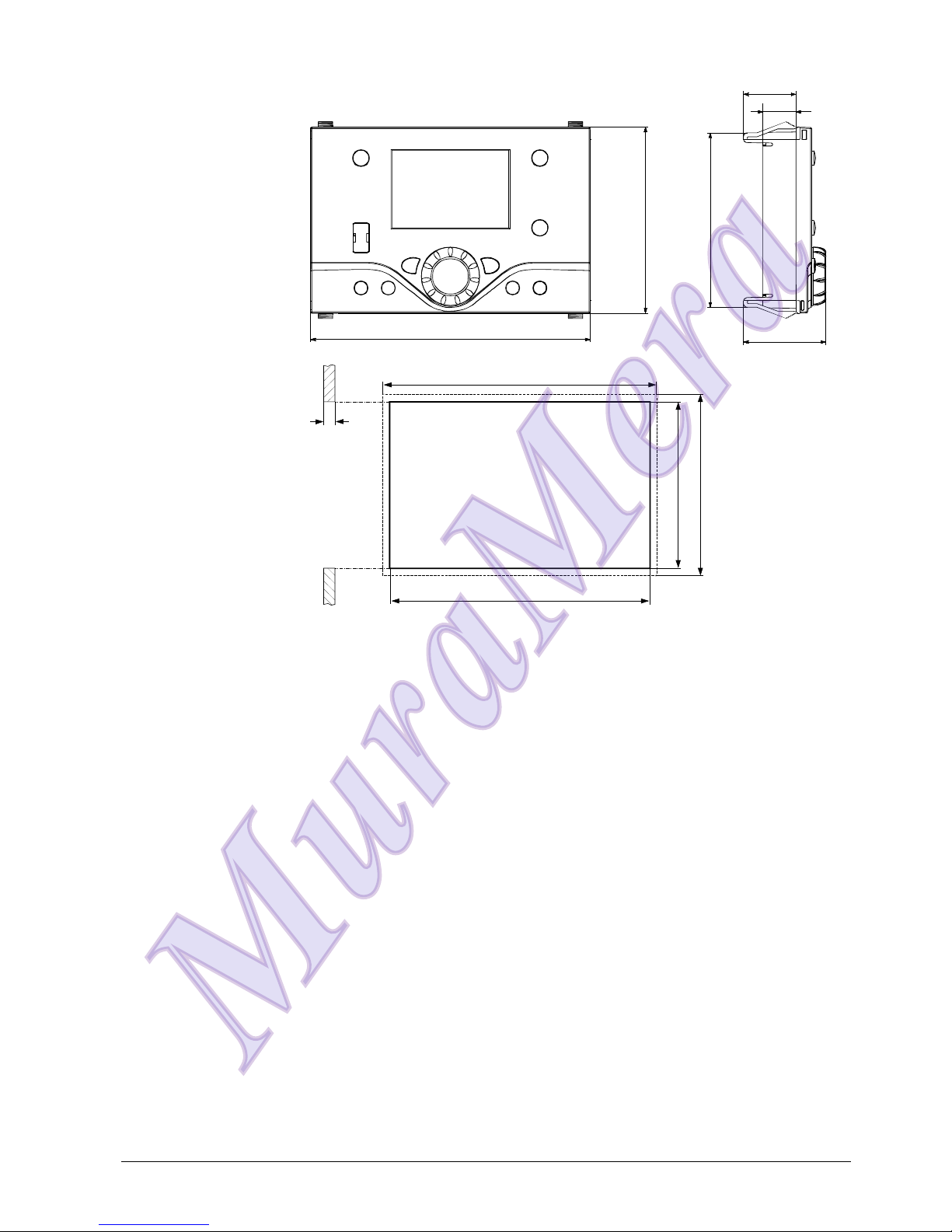

3.8 Power supply AVS16.290

Mounting notes

The boiler control panel is designed for installation in floor-standing or wall-hung oil or

gas boilers and may only be used for that purpose. For installation, the following points

must be observed:

• Power to the control panel may be supplied only after it is completely fitted in the cutout. Extension modules or dummy covers for which cutouts are provided must also

be fitted beforehand

• Dimensions of cutout 92 x 92 mm, sheet metal thickness 0.5 to 3.0 mm

• The boiler control panel must be secured with the 4 clips provided on the panel

• Control panel wiring to the connection terminals does not feature strain relief so that

the cables must be secured inside the boiler

• Local regulations for electrical installation must be complied with

installation Removal

2358Z27

2358Z28

2358Z29

Mounting method

Page 29

29/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

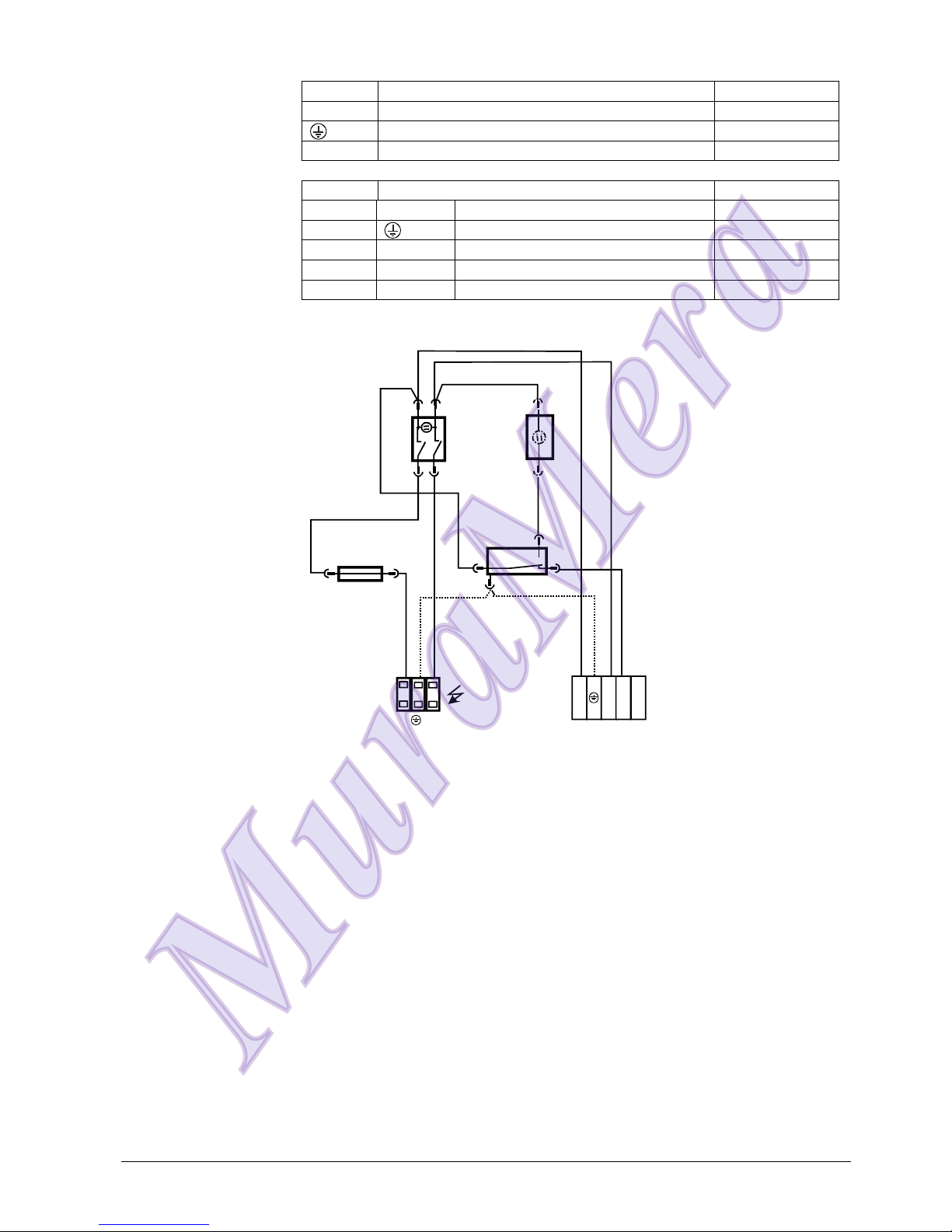

Connections

Terminal Designation Leiterfarben

L Phase AC 230 V Blue

Protective earth Geen + yellow

N Neutral conductor Blue

Terminal Designation Leiterfarben

1 L Phase AC 230 V basic unit Brown

2

Protective earth Geen + yellow

3 N Neutral conductor Blue

4 L1 Phase AC 230 V burner Black

5 S3 Input burner fault -

Mains supply to RVS… basic unit

Si Fuse 6.3AT

S1 Mains switch with green glow lamp

STB Safety limit thermostat (SLT) 110 °C

H1 Signal lamp (SLT tripped)

Mains

Connection to basic unit

S1

Si

1

2

12345

N1L

N

L

3B

4B

1A

2A

C2

1

PE

STB

1A

3B1

H1

L1 S3

2358A16

Page 30

30/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Mounting and installation 22. November 2006

Ground

2358M02

80

96

90

48

35

96

0.5...3.0

92

+0.8

0

2358M04

(96)

92

+0.8

0

(96)

Page 31

31/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Commissioning 22. November 2006

4 Commissioning

To commission the units, the following steps must be carried out:

• Prerequisite is correct mounting and correct electrical installation and, in the case of

wireless systems, correctly working radio links to all the auxiliary units

• Make all plant-specific settings. Special attention must be paid to operating page

”Configuration“. For that purpose, the relevant operating level is to be selected as

follows:

Press the OK button on the room unit to switch to programming.

Press the Info button for at least 3 seconds and select operating level

“Commissioning“ with the setting knob. Then, press the OK button.

• Make the functional check as described below

• Reset the attenuated outside temperature

(operating page “Diagnostics of consumers“, operating line “Outside temp attenuated“

(operating line 8703))

To facilitate commissioning and fault tracing, the controller allows output and input tests

to be made. With these tests, the controller’s inputs and outputs can be checked. To

make the tests, select operating page “Input/output test“ and go through all available

operating lines.

The current operating state can be checked on operating page “State“.

For detailed diagnostics of the plant, check operating pages “Diagnostics heat source“

and “Diagnostics consumer”.

4.1 Basic units

LED off: No power supply

LED on

Ready to operate

LED flashes Local faults

2358Z33

LPB

Prerequisites

functional check

Operating state

Diagnosis

Checking the LED

LED

Page 32

32/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Handling 22. November 2006

5 Handling

5.1 QAA75... / QAA78... / AVS37…

5.1.1 operation

Operating elements

Room unit

Operator unit

Selection of space

heatin

g

mode

Selecting DHW heating

Displaying information

A

djustment of room Comfort

setpoint

Presence button

Quitting the setting verlassen

Confirmation of setting

2359Z06

2359Z62

Selecting DHW heating

Selection of space

Displaying information

Quitting the setting

A

djustment of room Comfort

setpoint

Confirmation of setting

Chimney sweep function

STB test

Manual control

Service connector (BSB)

Page 33

33/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Handling 22. November 2006

Display choices

Heating to the Comfort setpoint

Info level activated

Heating to the Reduced setpoint

Programming activated

Heating to the frost protection setpoint

Heating system temporarily off

ECO function active

Process running – please wait

Holiday function active

Change battery

Reference to heating circuit

Burner in operation (only oil / gas burner)

Maintenance / special mode

Error messages

Display showing all available segments.

Selection of space heating mode

Press the button to switch between the different

operating modes. The choice made is indicated by a bar

which appears below the symbols.

Automatic operation

Automatic operation controls the room temperature according to the time program.

Charactersitics of automatic operation:

− Heating mode according to the time program

− Temperature setpoints according to heating program “Comfort setpoint“ or

“Reduced setpoint“

− Protective functions active

− Automatic summer / winter changeover (ECO functions)

Continuous operation

or

Continuous operation maintains the room temperature at the selected operating level.

Heating to the Comfort setpoint

Heating to the Reduced setpoint

Characteristics of continuous operation:

• Heating mode with no time program

• Protective functions active

• Automatic summer / winter changeover (ECO functions) and 24-hour heating limit

inactive in the case of continuous operation with Comfort setpoint

Protective mode

When using Protection, the heating system is off. But it remains protected against frost

(frost protection temperature), provided there is no power failure.

Characteristics of Protection:

• Heating off

• Temperature according to frost protection

display

2358Z07

Xxxxxxxxxxxxxxxxxxxxxxxxxxx

Xxxxxxxxxxxxxxxxxxxxxxxxxxx

Xxxxxxxxxxxxxxxxxxxxxxxxxxx

Page 34

34/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Handling 22. November 2006

• Protective functions active

• Automatic summer / winter changeover (ECO functions) and automatic 24-hour

heating limit active

Selecting DHW heating

The button is used to switch DHW heating mode on and off. The choice made is

indicated by a bar which appears below the symbols.

DHW heating mode

• On

The DHW is heated according to the selected switching program.

• Off

No DHW heating, but the protective function is active.

DHW push

To do this, keep the DHW operating mode button on the operator or room unit

depressed for at least 3 seconds.

The DHW push can also be started when:

• The operating mode is “Off“

• Operating mode changeover acts via H1 or centrally (LPB)

• All heating circuits have assumed the holiday mode

Adjusting the room temperature setpoint

Turn the setting knob to increase or decrease the Comfort setpoint

.

For the Reduced setpoint

− Press the OK button

− Select operating page “Heating circuit“ and

− Adjust the “Reduced“ setpoint

Each time you make a readjustment, wait at least 2 hours, allowing the room

temperature to adapt.

Presence button

If the rooms are not used for a certain period of time, you can press

the occupancy button to reduce the room temperature, thus saving

heating energy.

When the rooms are occupied again, press again the occupancy

button to resume heating operation.

Heating to the Comfort setpoint

Heating to the Reduced setpoint

• The occupancy button is only active in automatic operation

• The current selection is active until the next switching action according to the heating

program occurs

Displaying information

The Info button is used to display information.

Page 35

35/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Handling 22. November 2006

0

4 8 12 16 20 24

AUTO

2359Z140

Room temperatur e

Depending on the type of unit, configuration and operating state, some of the info lines

listed below may not appear.

Displays:

− Possible error messages from the error code list on page 84

− Possible error messages from the error code list on page 85

− Special mode messages

Other displays:

− Room temperature − State DHW

− Room temperature minimum − State solar

− Room temperature maximum − Date and time of day

− Outside temperature − Telephone customer service

− Outside temp min

− Outside temp max

− DHW temp 1

− State heating circuit 1

− State heating circuit 2

− State heating circuit P

In exceptional cases, the display shows one of the following symbols:

Error messages

If this symbol appears, a plant fault

occurred. In that case, press the Info

button to obtain more information.

Text3 Text4

0

4 8 12 16 20 24

AUTO

2359Z140

30:Flow sensor 1

Error

Maintenance or special mode

If this symbol appears, a maintenance

alarm is delivered or the plant has

changed to special mode. In that case,

press the Info button to obtain more

information.

Text3 Text4

0

4 8 12 16 20 24

AUTO

2359Z140

30:Flow sensor 1

Error

A list of possible displays is given on page 84.

The reset function for meters and the resettable parameters appears on the bottom line

of the display, provided a reset is permitted on the current operating line (enduser /

commissioning / heating engineer).

0

4 8 12 16 20 24

2359Z140

Reset ? yes

After activation with the OK button, the display shows a flashing “Yes“.

0

4 8 12 16 20 24

2359Z140

Reset ?

yes

After confirmation with the OK button, the relevant parameter or meters will be reset.

Possible displays

Exceptional cases

Reset function

Page 36

36/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Handling 22. November 2006

When manual control is active, the relays are no longer energized and deenergized

according to the control state, but are set to a predefined manual operating state

depending on their function.

The burner relay energized in manual control can be deenergized by the electronic

temperature controller (TR).

After manual control has been activated, a change to the basic display must be made.

There, the maintenance/special mode symbol

appears.

Press the Info button to switch to info display “Manual mode“, where the setpoint can

be adjusted.

The chimney sweep function is activated by a short press (maximum 3 seconds) on the

chimney sweep button. It produces the operating state required for making flue gas

measurements.

The SLT test (SLT = safety limit thermostat) is activated by a long press (longer than 3

seconds) on the chimney sweep button. The button must be kept depressed during the

entire test. If released, the test will be aborted. The SLT test is shown on the display.

The test must be made by qualified staff since the boiler temperature will be raised

above the maximum limitations.

Manual control

Setpoint adjustment with

manual control

Chimney sweep function

SLT test

Page 37

37/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Handling 22. November 2006

5.1.2 Programming

Setting principle

Settings that cannot be made directly with the help of operating elements are made

through programming. For this purpose, the individual settings are structured in the

form of operating pages and operating lines, thus forming practical groups of settings.

The following example which shows the setting of the time of day and date shall explain

this.

Example “Setting the time of day“

• When pressing the ESC button, you go back one step; adjusted values will not be

adopted

• If no setting is made for 8 minutes, the unit will automatically return to the basic

display

• Operating lines may be hidden, depending on the type of unit, thev configuration and

user level

Operation Display example Description

1

0

4 8 12 16 20 24

AUTO

2359Z140

Room temperatur e

You see the basic display.

If the basic display is not shown, press

the ESC button to return to it.

Press the OK button.

2

Text3

0

4 8 12 16 20 24

AUTO

2359Z140

Operator sect ion

Time of da y and date

The bottom section of the display

shows a number of operating pages.

Turn the setting knob until operating

page “Time of day and date“ appears.

To confirm, press the OK button.

3

0

4 8 12 16 20 24

AUTO

2359Z140

Time of day and d ate

Hours / minutes

In the bottom section of the display, the

first operating line of operating page

“Time of day and date“ appears.

Turn the setting knob until operating

line “Hours / minutes“ appears.

To confirm, press the OK button.

4

0

4 8 12 16 20 24

AUTO

2359Z140

Time of day and dat e

Hours / minut es

The display shows the hours flashing.

Turn the setting knob until the hours of

the time of day are correct.

To confirm, press the OK button.

Page 38

38/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Handling 22. November 2006

5

0

4 8 12 16 20 24

AUTO

2359Z140

Time of day and dat e

Hours / mi nutes

The display shows the minutes

flashing.

Turn the setting knob until the minutes

of the time of day are correct.

To confirm, press the OK button.

6

Uhrzeit und Datum

0

4 8 12 16 20 24

AUTO

Stunden / Minuten

The settings are saved, the display

stops flashing.

You can continue to make other

settings, or

you press the operating mode button to

return to the basic display.

7

Now, you have returned to the basic

display.

2359Z139

Time of day and date

Operator section

Wireless

Time program heating circuit 1

Time program heating circuit 2

Time program heating circuit P

Holidays heating circuit 1

Diagnostics of consumers

Hours / minutes

Month / day

Year

Start of summer time

End of summer time

Hours 1...24 h

Minutes 0...60 min

5.1.3 User levels

Certain user levels only allow certain user groups to make settings. To reach the

required user level, proceed as follows:

Operation Display example Description

1

0

4 8 12 16 20 24

AUTO

2359Z140

Room temperatur e

You see the basic display.

If the basic display is not shown,

press the ESC button to return to it.

Press the OK button.

2

Text3

0

4 8 12 16 20 24

AUTO

2359Z140

Operator sect ion

Time of day and date

You are on user level “Enduser“.

Press the Info button for 3 seconds.

3

Text3

0

4 8 12 16 20 24

AUTO

2359Z140

Commissioning

Enduser

You are given a choice of user

levels.

Turn the setting knob until the

required user level is reached.

Press the OK button.

Example of menu

structure

Page 39

39/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Handling 22. November 2006

Text3

0

4 8 12 16 20 24

AUTO

2359Z140

Operator sect ion

Time of day and date

You are now on the required user

level.

To reach the OEM level, enter the relevant code.

Setting structure for “Enduser“

The example given here shows that certain user levels do not allow certain settings to

be made. The example shows them highlighted. On the unit, they are hidden.

2359Z139

OEM

Time of day and date

Operator section

Wireless

Time program heating circuit 1

Time program heating circuit 2

Time program heating circuit P

Holidays heating circuit 1

Diagnostics of consumers

Hours / minutes

Month / day

Year

Start of summer time

End of summer time

Hours 1...24 h

Minutes 0...60 min

Heating engineer

Commissioning

Enduser

Setting structure for ”Heating engineer“

235 9Z139

OEMEnduser

Commissioning

Heating engineer

Time of day and date

Operator section

Wireless

Time program heating circuit 1

Time program heating circuit 2

Time program heating circuit P

Holidays heating circuit 1

Diagnostics of consumers

Hours / minutes

Month / day

Year

Start of summer time

End of summer time

Hours 1...24 h

Minutes 0...60 min

Page 40

40/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Handling 22. November 2006

5.1.4 Overview of settings

The table below shows all available settings up to the heating engineer level. However,

certain operating lines may be hidden, depending on the type of unit.

E = enduser I = commissioning F = heating engineer

BZ = line number

Operating line

User level

Function

Default value

Minimum

Max

Unit

Time of day and date

1 E Hours/minutes - 00:00 23:59 hh:mm

2 E Day/month - 01.01 31.12 tt.MM

3 E Year - 2004 2099 jjjj

5 F Start of summertime 25.03 01.01 31.12 tt.MM

6 F End of summertime 25.10 01.01 31.12 tt.MM

Operator section

20 E Language

German ¦ …

German -

22 F Info

Temporarily ¦ Permanently

Temporarily -

26 F Operation lock

Off ¦ On

Off -

27 F Programming lock

Off ¦ On

Off -

40 I Used as

Room unit 1 ¦ Room unit 2 ¦ Operator unit ¦Service unit

Room unit 1 -

42 I assignment room unit 1

Heating circuit 1 ¦ Heating circuits 1 and 2

Heating circuit 1 -

44 I Operation HC2

Commonly with HC1 ¦ Independently

Commonly with HC1 -

46 I Operation HCP

Commonly with HC1 ¦ Independently

Commonly with HC1 -

48 I Action occupancy button

None ¦ Heating circuit 1 ¦ Heating circuit 2 ¦ Commonly

Heating circuit 1 -

54 F Readjustment room sensor 0.0 -3 3 °C

70 F Software version - 0 99.9 wireless

120 I Binding

No ¦ Yes

No

121 I Test mode

Off ¦ On

Off

130 I Room unit 1

Missing ¦ Ready ¦ No reception ¦ Change batt

- -

131 I Room unit 2

Missing ¦ Ready ¦ No reception ¦ Change batt

- -

132 I Outside sensor

Missing ¦ Ready ¦ No reception ¦ Change batt

- -

133 I Repeater

Missing ¦ Ready ¦ No reception

- -

134 I Operator unit

Missing ¦ Ready ¦ No reception ¦ Change batt

- -

135 I Service unit

Missing ¦ Ready ¦ No reception ¦ Change batt

- -

Legend

Page 41

41/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Handling 22. November 2006

Operating line

User level

Function

Default value

Minimum

Max

Unit

138 I Delete all devices

No ¦ Yes

No -

Time prog heating circuit 1

500 E Preselection

Mo - Su ¦ Mo - Fr ¦ Sa - Su ¦ Mo ¦ Tu ¦ We ¦ Th ¦ Fr ¦ Sa

¦Su

Mo - So -

501 E 1st phase on 6:00 00:00 24:00 hh:mm

502 E 1st phase off 22:00 00:00 24:00 hh:mm

503 E 2st phase on 24:00 00:00 24:00 hh:mm

504 E 2st phase off 24:00 00:00 24:00 hh:mm

505 E 3st phase on 24:00 00:00 24:00 hh:mm

506 E 3st phase off 24:00 00:00 24:00 hh:mm

516 E default values

No ¦ Yes

No -

Time prog heating circuit 2

520 E Preselection

Mo - Su ¦ Mo - Fr ¦ Sa - Su ¦ Mo ¦ Tu ¦ We ¦ Th ¦ Fr ¦ Sa

¦Su

Mo - Su -

521 E 1st phase on 6:00 00:00 24:00 hh:mm

522 E 1st phase off 22:00 00:00 24:00 hh:mm

523 E 2st phase on 24:00 00:00 24:00 hh:mm

524 E 2st phase off 24:00 00:00 24:00 hh:mm

525 E 3st phase on 24:00 00:00 24:00 hh:mm

526 E 3st phase off 24:00 00:00 24:00 hh:mm

536 E default values

No ¦ Yes

No -

Time program 3 / HCP

540 E Preselection

Mo - Su ¦ Mo - Fr ¦ Sa - Su ¦ Mo ¦ Tu ¦ We ¦ Th ¦ Fr ¦ Sa

¦Su

Mo - Su -

541 E 1st phase on 6:00 00:00 24:00 hh:mm

542 E 1st phase off 22:00 00:00 24:00 hh:mm

543 E 2st phase on 24:00 00:00 24:00 hh:mm

544 E 2st phase off 24:00 00:00 24:00 hh:mm

545 E 3st phase on 24:00 00:00 24:00 hh:mm

546 E 3st phase off 24:00 00:00 24:00 hh:mm

556 E default values

No ¦ Yes

No -

Time program 4 / DHW

560 E Preselection

Mo - Su ¦ Mo - Fr ¦ Sa - Su ¦ Mo ¦ Tu ¦ We ¦ Th ¦ Fr ¦ Sa

¦Su

Mo - Su -

561 E 1st phase on 6:00 00:00 24:00 hh:mm

562 E 1st phase off 22:00 00:00 24:00 hh:mm

563 E 2st phase on 24:00 00:00 24:00 hh:mm

564 E 2st phase off 24:00 00:00 24:00 hh:mm

565 E 3st phase on 24:00 00:00 24:00 hh:mm

566 E 3st phase off 24:00 00:00 24:00 hh:mm

576 E default values

No ¦ Yes

No -

Page 42

42/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Handling 22. November 2006

Operating line

User level

Function

Default value

Minimum

Max

Unit

Holidays heating circuit 1

641 E Preselection

Period 1 ¦ Period 2 ¦ Period 3¦ Period 4¦ Period 5¦ Period

6¦ Period 7¦ Period 8

Periode 1 -

642 E Start --.-- 01.01 31.12 tt.MM

643 E End --.-- 01.01 31.12 tt.MM

648 E Operating level

Frost protection ¦ Reduced

frost protection -

Holidays heating circuit 2

651 E Preselection

Period 1 ¦ Period 2 ¦ Period 3¦ Period 4¦ Period 5¦ Period

6¦ Period 7¦ Period 8

Periode 1 -

652 E Start --.-- 01.01 31.12 tt.MM

653 E End --.-- 01.01 31.12 tt.MM

658 E Operating level

Frost protection ¦ Reduced

frost protection -

Holidays heating circuit P

661 E Preselection

Period 1 ¦ Period 2 ¦ Period 3¦ Period 4¦ Period 5¦ Period

6¦ Period 7¦ Period 8

Periode 1 -

662 E Start --.-- 01.01 31.12 tt.MM

663 E End --.-- 01.01 31.12 tt.MM

668 E Operating level

Frost protection ¦ Reduced

frost protection -

Heating circuit 1

710 E Comfort cooling setpoint 20.0 BZ 712 BZ 716 °C

712 E Reduced setpoint 16 BZ 714 BZ 710 °C

714 E Frost protection setpoint 10.0 4 BZ 712 °C

716 F Comfort setpoint max 35.0 BZ 710 35 °C

720 E Heating curve slope 1.50 0.10 4.00 721 F Heating curve displacement 0.0 -4.5 4.5 °C

726 F Heating curve adaption

Off ¦ On

Off -

730 E Summer/winter heating limit 18 − − − / 8 30 °C

732 F 24-hour heating limit -3 − − − / -10 10 °C

740 I Flow temp setpoint min 8 8 BZ 741 °C

741 I Flow temp setpoint max 80 BZ 740 95 °C

750 F Room influence 20 − − − / 0 100 %

760 F Room temp limitation 1 − − − / 0.5 4 °C

770 F Boost heating 5 − − − / 0 20 °C

780 F Quick setback

Off ¦ Down to reduced setpoint ¦ Down to frost prot

setpoint

Down to reduced setpoint -

790 F Optimum start control max 0 0 360 min

791 F Optimum stop control max 0 0 360 min

800 F Reduced setp increase start − − − − − − / -30 10 °C

801 F Reduced setp increase end -15 -30 BZ 800 °C

820 F Overtemp prot pump circuit

Off ¦ On

On -

830 F Mixing valve boost 10 0 50 °C

832 F Actuator:type

2-position ¦ 3-position

3-position -

Page 43

43/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Handling 22. November 2006

Operating line

User level

Function

Default value

Minimum

Max

Unit

833 F Switching differential 2-pos 2 0 20 °C

834 F Actuator: running time 120 30 873 s

850 I Floor curing function

Off ¦ Functional heating ¦ Curing heating ¦

Functional/curing heating¦ Manually

Off -

851 I Floor curing setp manually 25 0 95 °C

861 F Excess heat draw

Off ¦ Heating mode ¦ Always

Always

872 F With prim contr/system pump

No ¦ Yes

Yes

900 I Optg mode changeover

Protection ¦ Recuced

Protection

Heating circuit 2

1010 E Comfort cooling setpoint 20.0 BZ 1012 BZ 1016 °C

1012 E Reduced setpoint 16 BZ 1014 BZ 1010 °C

1014 E Frost protection setpoint 10.0 4 BZ 1012 °C

1016 F Comfort setpoint max 35.0 BZ 1010 35 °C

1020 E Heating curve slope 1.50 0.10 4.00 1021 F Heating curve displacement 0.0 -4.5 4.5 °C

1026 F Heating curve adaption

Off ¦ On

Off -

1030 E Summer/winter heating limit 18 − − − / 8 30 °C

1032 F 24-hour heating limit -3 − − − / -10 10 °C

1040 I Flow temp setpoint min 8 8 BZ 1041 °C

1041 I Flow temp setpoint max 80 BZ 1040 95 °C

1050 F Room influence 20 − − − / 0 100 %

1060 F Room temp limitation 1 − − − / 0.5 4 °C

1070 F Boost heating 5 − − − / 0 20 °C

1080 F Quick setback

Off ¦ Down to reduced setpoint ¦ Down to frost prot

setpoint

Down to reduced setpoint -

1090 F Optimum start control max 0 0 360 min

1091 F Optimum stop control max 0 0 360 min

1100 F Reduced setp increase start − − − − − − / -30 10 °C

1101 F Reduced setp increase end -15 -30 BZ 1100 °C

1120 F Overtemp prot pump circuit

Off ¦ On

On -

1130 F Mixing valve boost 10 0 50 °C

1132 F Actuator:type

2-position ¦ 3-position

3-position -

1133 F Switching differential 2-pos 2 0 20 °C

1134 F Actuator: running time 120 30 873 s

1150 F Floor curing function

Off ¦ Functional heating ¦ Curing heating ¦

Functional/curing heating¦ Manually

Off -

1151 F Floor curing setp manually 25 0 95 °C

1161 F Excess heat draw

Off ¦ Heating mode ¦ Always

Always

1172 F With prim contr/system pump

No ¦ Yes

Yes

1200 I Optg mode changeover

Protection ¦ Recuced

Protection

Page 44

44/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Handling 22. November 2006

Operating line

User level

Function

Default value

Minimum

Max

Unit

Heating circuit P

1300 E Operating mode

Protection ¦ Automatic ¦ Reduced ¦ Comfort

Automatic -

1310 E Comfort cooling setpoint 20.0 BZ 1012 BZ 1016 °C

1312 E Reduced setpoint 16 BZ 1014 BZ 1010 °C

1314 E Frost protection setpoint 10.0 4 BZ 1012 °C

1316 F Comfort setpoint max 35.0 BZ 1010 35 °C

1320 E Heating curve slope 1.50 0.10 4.00 1321 F Heating curve displacement 0.0 -4.5 4.5 °C

1326 F Heating curve adaption

Off ¦ On

Off -

1330 E Summer/winter heating limit 18 − − − / 8 30 °C

1332 F 24-hour heating limit -3 − − − / -10 10 °C

1340 F Flow temp setpoint min 8 8 BZ 1041 °C

1341 F Flow temp setpoint max 80 BZ 1040 95 °C

1350 F Room influence 20 − − − / 0 100 %

1360 F Room temp limitation 1 − − − / 0.5 4 °C

1370 F Boost heating 5 − − − / 0 20 °C

1380 F Quick setback

Off ¦ Down to reduced setpoint ¦ Down to frost prot

setpoint

Down to reduced setpoint -

1390 F Optimum start control max 0 0 360 min

1391 F Optimum stop control max 0 0 360 min

1400 F Reduced setp increase start − − − − − − / -30 10 °C

1401 F Reduced setp increase end -15 -30 BZ 1100 °C

1420 F Overtemp prot pump circuit

Off ¦ On

On -

1450 I Floor curing function

Off ¦ Functional heating ¦ Curing heating ¦

Functional/curing heating¦ Manually

Off -

1451 I Floor curing setp manually 25 0 95 °C

1455 F Floor curing setp current 0 0 95 °C

1456 F Floor curing day current − − − 0 32 °C

1461 F Excess heat draw

Off ¦ Heating mode ¦ Always

Always

1172 F With prim contr/system pump

No ¦ Yes

Yes

1500 I Optg mode changeover

Protection ¦ Recuced

Protection

Domestic hot water

1610 E Nominal setpoint 55 BZ 1612 BZ 1614 OEM °C

1612 F Reduced setpoint 40 8 BZ 1610 °C

1620 I Release

24h/day ¦ Time programs HCs ¦ Time program 4/DHW

Time programs HCs -

1630 I Charging priority

Absolute ¦ Shifting ¦ None ¦ MC shifting, PC absolute

MC shifting, PC absolute -

1640 F Legionella function

Off ¦ Periodically ¦ Fixed weekday

Fixed weekday -

1641 F Legionella funct periodically 3 1 7 Tage

1642 F Legionella funct weekday

Monday ¦ Tuesday ¦ Wednesday ¦ Thursday ¦ Friday ¦

Saturday ¦ Sunday

Montag

Page 45

45/100

Siemens Schweiz AG User Manual CE1U2353en

HVAC Products Handling 22. November 2006

Operating line

User level

Function

Default value

Minimum

Max

Unit

1644 F Legionella funct time − − − − − − / 00:00 23:50 hh:mm

1645 F Legionella funct setpoint 65 55 95 °C

1646 F Legionella funct duration 30 − − − / 10 360 min

1647 F Legionella funct circ pump

Off ¦ On

On -

1660 F Release of the circulating pump

Time program 3/HCP ¦ DHW release ¦ Time program

4/DHW

DHW release -

1661 F Circulating pump cycling

Off ¦ On

On -

1663 F Circulaton setpoint 45 8 80 °C

Pump H1/H2

2010 F H1 Excess heat draw

Off ¦ On

On

2014 F H1 prim contr/system pump

No ¦ Yes

Yes -

2035 F H2 Excess heat draw

Off ¦ On

On

2039 F H2 prim contr/system pump

No ¦ Yes

Yes -

Solar

3810 F Temp diff on 8 BZ 3811 40 °C

3811 F Temp diff off 4 0 BZ 3812 °C