Page 1

SiPass integrated

AFI5100

Installation manual

Fire Safety & Security Products

Siemens Building Technologies

Page 2

Liefermöglichkeiten und technische Änderungen vorbehalten.

Data and design subject to change without notice. Supply subject to availability.

© 2005 Copyright by

Siemens Building Technologies AG

Wir behalten uns alle Rechte an diesem Dokument und an dem in ihm dargestellten Gegenstand vor. Der Empfänger anerkennt diese

Rechte und wird dieses Dokument nicht ohne unsere vorgängige schriftliche Ermächtigung ganz oder teilweise Dritten zugänglich machen

oder außerhalb des Zweckes verwenden, zu dem es ihm übergeben worden ist.

We reserve all rights in this document and in the subject thereof. By acceptance of the document the recipient acknowledges these rights

and undertakes not to publish the document nor the subject thereof in full or in part, nor to make them available to any third party without our

prior express written authorization, nor to use it for any purpose other than for which it was delivered to him.

Page 3

Contents

1 Input Point Module (AFI5100) ................................................................5

1.1 Product Description................................................................................... 5

1.2 Product Numbers ......................................................................................5

1.3 Prerequisites .............................................................................................5

1.4 Expected Installation Time........................................................................6

1.5 Mounting Instructions................................................................................6

1.6 Wiring ........................................................................................................6

1.7 Links and Jumpers....................................................................................9

1.8 LEDs .......................................................................................................10

1.9 Recommended Cable Specifications......................................................11

1.10 Programming and Firmware Download ..................................................11

Siemens Building Technologies

Fire Safety & Security Products 02.2005

3

Page 4

4

Siemens Building Technologies

Fire & Security Products 02.2005

Page 5

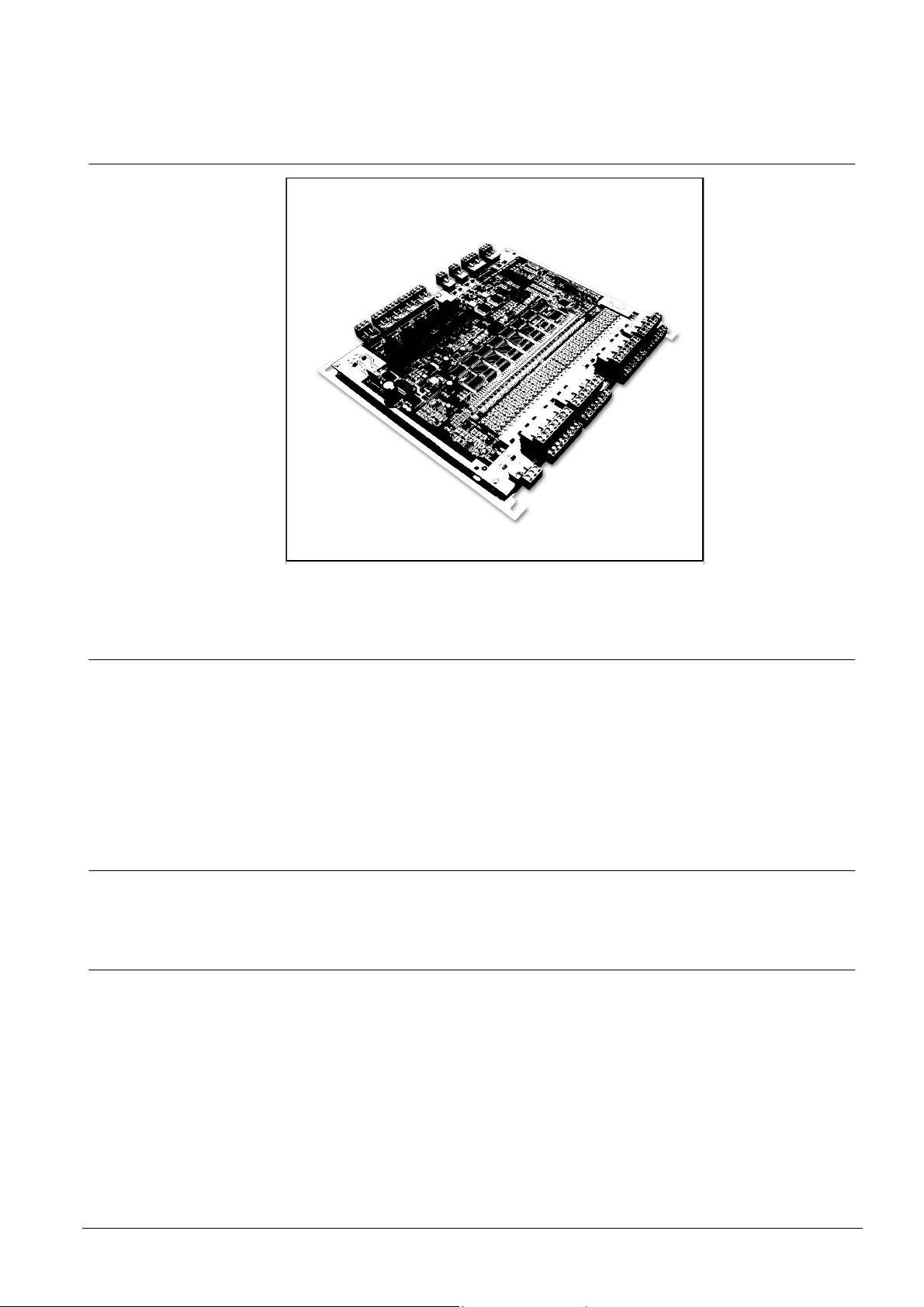

1 Input Point Module (AFI5100)

Input Point Module (AFI5100)

Fig. 1 Input Point Module

1.1 Product Description

The AFI5100 is an Input Point Module used as part of a Siemens integrated access

control and security solution. It provides an interface between an Advanced Access

Controller (ACC) and up to 32 input devices used to monitor a secure facility.

The AFI5100 continuously monitors the status of all input devices connected; for

example, Passive Infrared Detectors (PIRs). Any changes in state are instantly

communicated to the ACC and then on to the Host system if necessary.

1.2 Product Numbers

6FL7820-8CB10 AFI5100 – Input Point Module and base-plate

1.3 Prerequisites

Input Devices to be connected to the IPM

Cabling (RS-485)

Required Tools & Materials

Medium-duty drill and associated drill-bits (if required)

4 mounting screws or standoffs (approx. 4mm)

Flat-blade terminal screwdriver

Wire cutters

Cable strippers

Siemens Building Technologies

Fire Safety & Security Products 02.2005

5

Page 6

Input Point Module (AFI5100)

1.4 Expected Installation Time

30 minutes

1.5 Mounting Instructions

1. Remove the AFI5100 from its carton and discard the packaging material.

2. Place the AFI5100 (base-plate) against the surface to which it is to be affixed

and mark the location of the mounting holes.

3. If being mounted within a cabinet, simply align the AFI5100 base-plate with

the holes located on the cabinet backplane and proceed to step 3.

4. It is recommended that you affix the AFI5100 in all four of the mounting locations.

WARNING Do not apply power to the IPM or associated components at this stage.

5. Select the appropriate drill bit according to the mounting surface / hole size

and drill the holes in the locations marked (if required).

6. Fasten the AFI5100 base-plate to the surface using the correct type of screws

or standoffs for the surface.

7. Connect the cabling to the AFI5100 PCB (as described in the next section titled ‘Wiring’).

8. Apply power to the AFI5100 and test its operation.

9. This step may require installation and programming of the access control host

software and download of the firmware instruction set.

Alternatively, the firmware and configuration may be carried out using the FLN

Field Service Tool.

1.6 Wiring

It is recommended that you wear a grounding strap while carrying out this procedure.

1. Connect all input devices to the INPUT ports.

Listed end-of-line resistors must be connected to the wiring for each input device if they are to be

supervised. If supervised, cable must

Ohms. Cable shielding must be unconnected at the device end, and connected to the board earth at

the IPM end.

be shielded and total cable run resistance must not exceed 100

2. Connect any devices to the OUTPUT ports.

3. Connect appropriate wiring to the FIRE OVERRIDE INPUT port if required.

Listed end-of-line resistors must be connected to the Fire Over-ride Input wires if you are implement-

ing Enhanced Fire Over-ride. Enhanced mode requires the connection of 22Kohm supervision resistor

circuits. Cable must be shielded and total cable run resistance must not exceed 100 Ohms.

6

Siemens Building Technologies

Fire Safety & Security Products 02.2005

Page 7

9mm

(0.35")

Input Point Module (AFI5100)

4. Connect the next device in the Fire Override sequence to the FIRE OVERRIDE OUTPUT port if required.

5. Connect the FLN wires (from the ACC) to the RS485 BUS port.

6. If the FLN cable is long or subject to high noise, ensure that the jumper across

link LK10 (EOL) has been made. This only applies to units located on the

ends of bus lines.

7. Connect the active (+ve) and neutral (-ve) wires from the Power Supply Unit

(PSU) to the POWER IN port. Ensure the polarity of the connection is made

correctly.

8. Check all connections thoroughly.

9. Power can now be applied to the AFI5100 .The following diagram displays the

layout and dimensions of the AFI5100 with brace attached:

287mm (11.30")

(0.35")

9mm

257mm (10.12")

5mm5mm

(0.20")

I

N

+

I

N

N

-

N+I

N

N

+

IN-

I

8

2

PUT

N

I

I

N

+

-

N

I

3

2

T

NPU

S

/

N

:

LK3

S

B

i

LK5

R

e

D

m

e

-

n

0

LK7

s

0

0

B

0

u

LK8

5

i

l

d

i

n

g

T

e

c

h

n

o

l

o

g

i

LK 9

e

s

I

LK 10

RS-485

LOCAL IN OUT

E - +

IP+ IP- OP+ OP-

-

N

I

2

6

PUT

I

NPU

T 2

7

I

N+I

N

-

I

N

-

0

1

3

NPUT

I

I

I

I

N

N

N

P

P

P

U

U

U

T

T

T

3

3

3

2

1

0

T

X

A

C

C

P

O

T

O

M

I

W

V

M

I

E

T

S

R

Y

2

0

5

2

T

T

NPU

N

I

I

I

N

N

-

+

I

+

N

I

-

N

I

2

4

9

2

UT

N

P

I

INPUT 3

I

I

I

I

N

N

N

N

P

P

P

P

U

U

U

U

T

T

T

T

2

2

2

2

9

8

6

7

R

X

C

O

M

M

S

+

I

I

I

+

I

N

N

-

I

N

N

-

+

I

I

N+I

N

-

N

-

N+I

I

I

N+IN-

1

8

T

NPU

NPU

I

+

N

I

I

N

-

PUT

N

I

23

I

I

N

N

P

P

U

U

T

T

2

2

5

4

I

I

I

N

PUT 1

7

NPUT 19

+

N

I

I

N

+

-

N

I

I

-

N

IN+

2

2

1

I

2

N

PUT

T

NPU

I

INPUT

I

I

I

I

I

N

P

U

T

2

3

I

N

N

N

N

N

P

P

P

P

P

U

U

U

U

U

T

T

T

T

T

2

2

2

1

2

D

C

O

U

T

2

1

0

1

9

8

D

C

O

U

T

1

-

N

I

+

I

+

I

N

N

-

2

1

T 1

1

T

NPU

I

-

+

N

I

-

N

I

1

5

T

I

NPUT 16

I

I

I

I

N

P

U

T

1

7

I

N

N

N

N

P

P

P

P

U

U

U

U

T

T

T

T

1

1

1

1

5

6

4

3

FOR EN

FOR DIS

I

N+I

N

N

-

I

I

N

-

N

+

I

9

T

NPU

NPU

I

I

I

NPU

T 1

0

N

-

N

+

IN+IN

I

I

I

+

N

I

N

-

NPU

I

I

NPUT 13

I

NPUT 14

I

I

I

N

N

N

I

I

P

P

P

N

N

U

U

U

P

P

T

T

T

U

U

1

1

1

T

T

2

1

0

9

8

O

O

O

O

U

U

U

U

T

T

T

T

P

P

P

P

U

U

U

U

T

T

T

T

2

3

4

1

LK12LK11

RLY1

DC OUT

0V V+

DC OUT

0V V+

OUTPUT 4

Nc C No

OUTPUT 3

Nc C No

IN-

N

+

I

I

NPU

T 4

I

N

+

I

-

N

8

PUT

N

I

I

I

N

N

P

P

U

U

T

T

7

6

LK13

OUTPUT 2

Nc C No

N

-

N+I

I

I

N+I

N

N

-

3

N

-

I

I

N

P

U

T

5

I

N

-

+

I

2

T

NPU

I

I

I

NPUT

NPUT

1

I

N

+

I

+

N

N

-

I

N

+

I

I

N

-

NPUT

6

I

I

N

PUT 7

I

NPU

T 5

I

I

I

I

N

N

N

N

P

P

P

P

U

U

U

U

T

T

T

T

2

4

3

1

LK14

RLY5

RLY4RLY3RLY2

FIRE OUT

OUTPUT 1

Nc C No

Nc C No

-

F

I

RE INPU

T

F

O

R

LK1

LK2

N

O

R

M

A

L

F

O

R

E

LK4LK6

N

F

A

O

B

R

L

E

250mm

(9.84")

POWER IN

0V V+ E

Siemens Building Technologies

Fire Safety & Security Products 02.2005

7

Page 8

Input Point Module (AFI5100)

The following diagram displays the location of the ports on the AFI5100 :

F

O

R

N

O

R

M

A

L

F

O

R

E

N

A

B

L

E

LK1

LK2

LK4LK6

3

I

N

-

+

N

I

I

N

OR

F

1 2

N

N

N

+

-

N

N

-

N

+IN

-

I

I

I

N

P

27

U

T

28

N

-

I

N

+IN

-

U

T

N

P

32

S

/

N

:

LK3

B

R

D

LK5

S

-

i

0

e

0

m

0

LK7

e

0

n

5

s

LK8

B

u

i

l

d

i

n

g

T

e

c

h

n

o

l

LK 9

o

g

i

e

s

I

P

O

W

E

R

-

+

N

+

N

-

I

I

N

P

U

T

I

N

+

I

U

N

T

31

P

I

N

P

U

T

3

2

I

I

I

I

I

NPUT

I

N

2

5

P

U

T

26

I

N

+

I

I

N

-

N

+

I

N

-

U

NPUT 30

N

T

29

P

I

A

C

T

I

V

I

T

Y

I

I

I

I

I

I

N

N

N

N

P

P

P

P

U

U

U

U

T

T

T

T

3

3

2

2

1

0

8

9

R

T

X

X

C

C

O

O

M

M

M

M

S

S

+

N

N

N

-

I

I

I

I

N

1

9

P

2

0

U

T

I

N

+

I

-

N

-

N

P

U

T

24

3

I

I

I

I

I

N

N

N

N

P

P

P

P

U

U

U

U

T

T

T

T

2

2

2

2

7

6

5

4

N

N

+

I

I

NPUT

IN+IN

N

P

U

T

2

I

N

P

U

T

2

3

N

+

-

N

+IN

-

I

I

I

I

NPUT 17

I

N

P

U

T

1

8

I

I

N

N

+

-

I

N

+IN

-

N

P

U

T

21

N

P

UT 22

I

D

C

O

U

T

2

I

I

I

I

I

I

I

I

N

N

N

N

N

P

P

U

U

T

T

2

2

2

1

D

C

O

U

T

1

N

P

P

P

P

U

U

U

U

T

T

T

T

1

2

1

1

9

0

8

7

-

N

-

+

N

-

N

+

I

I

I

N

P

U

T

12

I

N

+IN

-

U

T

N

P

16

I

I

I

N

N

N

P

P

P

U

U

U

T

T

T

1

1

1

5

6

4

I

T

11

N

-

I

1

5

I

I

N

P

U

T

1

3

FOR EN

FOR DIS

N

+

N

-

I

I

I

I

N

I

N

P

P

U

U

T

1

0

I

N

+

I

N

+IN

-

N

P

U

T

U

T

N

P

14

I

I

I

I

I

N

N

N

P

P

P

U

U

U

T

T

T

1

1

1

2

0

1

O

O

O

U

U

U

T

T

T

P

P

P

U

U

U

T

T

T

2

4

3

N

+

N

-

N

N

+

I

I

I

NPUT

9

IN+IN

-

N

PUT

13

I

I

I

N

N

P

P

U

U

T

T

9

8

O

U

T

P

U

T

1

LK12LK 11

N

+IN

-

I

I

I

I

N

I

NPUT

P

4

U

T

3

I

N+I

I

N

N

+

-

I

N

-

N

N

P

P

U

T

U

T

7

8

I

I

I

I

I

N

N

N

N

P

P

P

P

U

U

U

U

T

T

T

T

4

7

5

6

LK13

N

+

N

+

N

N

-

-

I

I

I

I

I

N

I

N

P

P

U

U

T

T

2

1

I

N

+IN

I

N

-

-

N+I

N

P

N

P

U

U

T

T

6

5

I

I

I

I

I

I

N

N

N

P

P

P

U

U

U

T

T

2

3

F

T

O

1

R

LK14

LK 10

RLY5

RLY1

RLY4RLY3RLY2

RS-485

E - +

9 4

LOCAL IN OUT

IN+ IN- OUT+ OUT-

8

12V OUT 2

0V V+

12V OUT 1

0V V+

7

OUT 4

Nc C No

OUT 3

Nc C No

OUT 2

Nc C No

OUT 1

Nc C No

FOR OUT

Nc C No

56

The following table provides a brief description of each port:

Port Name Brief Description

1 INPUT 17 – INPUT 32

Input Ports 1 - 32

2 INPUT 1 – INPUT 16

Input Ports 1 - 16

3 FOR IN

Fire Over-ride Input Port

4 DC Power IN DC power input

5 FOR OUT

Fire Over-ride Output Port

6 OUT 1 – OUT 4

Output Ports 1 - 4

7 12V OUT 1-12V OUT 2

Auxiliary 12 V DC Power Supply 1-2

8 LOCAL IN OUT

Tamper In/Out Port

9 RS485 BUS RS485 communications port for connection to an

Inputs for connection to monitoring and input

devices

Inputs for connection to monitoring and input

devices

Input for Fire Over-ride wiring

Fire Over-ride for connecting devices in Fire Override sequence

Auxiliary Relay-driven Outputs

12 V DC power source

Local input and output for tamper detection and

alarm

ACC FLN channel

DC POWER IN

0V V+ E

8

Siemens Building Technologies

Fire Safety & Security Products 02.2005

Page 9

1.7 Links and Jumpers

The following table outlines the link settings for the AFI5100 :

Link Description Value

LK1, LK2 Links 1 and 2 are used to configure

LK4, LK6 Links 4 and 6 control whether Fire

LK3, LK5 These auxiliary links have been included for further enhancement of the system.

LK7 LK7 affects the reset action when the

whether Fire Over-ride (FOR) will operate in Enhanced FOR mode or Normal.

Enhanced mode also requires the

connection of a supervision circuit to

the Fire Over-ride Input.

Over-ride (FOR) is enabled.

If the links are set to FOR operation,

activation of the FOR input will cause

the outputs to return to the NO position.

If the links are set to the off position,

FOR input will have no effect on the

state of the output relays.

RESET link (LK9) is set and the power

turned on.

See LK9 below for a description of how

to reset the unit.

Input Point Module (AFI5100)

To enable Normal

Mode:

LK2

LK1

L

A

M

R

O

N

R

O

F

FOR operation

active:

LK6

LK4

E

L

B

A

N

E

R

O

F

LK7

If the jumper on Link 7 is set as shown,

it is set to “Full Reset” mode.

LK7

To enable Enhanced Mode:

LK1

L

A

M

R

O

N

R

O

F

FOR operation

ignored:

LK4

E

L

B

A

N

E

R

O

F

LK2

LK6

If the jumper on Link 7 is taken off, it is

set to “Partial Reset” mode.

LK8 This is a General Purpose links that has been included for further enhancement

of the system.

LK9 Memory Clear and Reset

Setting LK9 and turning the power off and on will reset the IPM. A full or partial

reset can be achieved by setting LK7 on or off.

If LK7 is set, the IPM will fully reset and any firmware loaded into the memory will

be erased. You will need to re-program the IPM with firmware again before it can

operate.

If LK7 has the jumper removed, the microcontroller will be rebooted but the firmware will remain in memory.

LK10 EOL Termination (Bus)

This link allows the RS485 BUS communications channel to be terminated

in noisy or lengthy comms.

Note: Units located at the end of bus

lines only should have this link set.

RS485 BUS port

not terminated.

LK10

EOL

RS485 BUS port

terminated.

LK10

EOL

LK11 – LK14 FOR Activation

These links allow FOR activation to be

enabled or disabled for each individual

relay output.

Enabling Fire Override for a relay

means that when the FOR input is

activated, the relay output switch to the

NO position.

FOR EN

FOR DIS

In the above diagram LK11 (Relay 1) is

set to FOR Enabled and LK12

(Relay 2) is set to FOR Disabled.

LK11

LK12

Siemens Building Technologies

Fire Safety & Security Products 02.2005

9

Page 10

Input Point Module (AFI5100)

1.8 LEDs

The following table describes the operation of the LEDs located on the AFI5100 :

LED Brief Description

POWER The POWER led is illuminated when power has been applied to the device.

ACTIVITY The ACTIVITY led indicates that the AFI5100 is accessing information con-

tained in its internal database or performing a routine operation.

This LED also indicates whether the initial instruction set has been downloaded.

If power is applied and the LED blinks quickly, the AFI5100 instruction set (firmware) needs to be downloaded. If the LED is blinking slowly, approximately

once per second, a firmware set has already been downloaded.

Tx COMMS The Transmission COMMS LED flashes when the IPM is sending data to the

ACC to which it has been connected (via an FLN).

Rx COMMS The Transmission COMMS LED flashes when the IPM is receiving data from

the ACC to which it has been connected (via an FLN).

Inputs The tricolor Input Port LEDs indicate the current status of the input port. See the

table below for an explanation of the colors.

Outputs Each Output Relay has a corresponding LED that is illuminated when the relay

is activated.

Fire The Fire LED is illuminated when Fire Over-ride is activated.

Each input LED may be in one of two states as indicated by color.

LED Color Input status Fire Over-ride status

Green Denotes input Normal: Closed Denotes FOR Normal: Closed

Orange Denotes input Normal: Open Denotes FOR Normal: Open (alarm)

10

Siemens Building Technologies

Fire Safety & Security Products 02.2005

Page 11

1.9 Recommended Cable Specifications

The following table outlines the cable recommended for connection of an integrated security system:

Type

RS485

RS232

RS422

Power

(12/24 V DC)

Core Pairs AWG Stranding Wire Type Insulation Shield Jacket

4 2 28 7 x 36 Tinned

6 3 28 7 x 36 Tinned

8 4 28 7 x 36 Tinned

4 2 24 7 x 32 Tinned

6 3 24 7 x 32 Tinned

8 4 24 7 x 32 Tinned

4 2 24 7 x 32 Tinned

6 3 24 7 x 32 Tinned

8 4 24 7 x 32 Tinned

8 4 24 Solid Bare

8 4 24 7 x 32 Tinned

8 4 24 Solid Bare

8 4 24 7 x 32 Tinned

2 1 18 19 x 30 Tinned

The previous table provides a guideline for selecting an appropriate cable type only. Other cable types

are also compatible with the system and can be used to achieve the same results.

Recommended Cable Specifications Communication

Polyethylene Aluminium foil- Polyester tape

Copper

Polyethylene Aluminium foil- Polyester tape

Copper

Polyethylene Aluminium foil- Polyester tape

Copper

Polyethylene Aluminium foil- Polyester tape

Copper

Polyethylene Aluminium foil- Polyester tape

Copper

Polyethylene Aluminium foil- Polyester tape

Copper

Polyethylene Aluminium foil- Polyester tape

Copper

Polyethylene Aluminium foil- Polyester tape

Copper

Polyethylene Aluminium foil- Polyester tape

Copper

Polyethylene Unshielded PVC RJ-45

Copper

Polyethylene Unshielded PVC

Copper

Polyethylene Aluminium foil- Polyester tape

Copper

Polyethylene Aluminium foil- Polyester tape

Copper

Polyethylene Unshielded PVC

Copper

Input Point Module (AFI5100)

PVC

/ braided shield

PVC

/ braided shield

PVC

/ braided shield

PVC

/ no braid

PVC

/ no braid

PVC

/ no braid

PVC

/ no braid

PVC

/ no braid

PVC

/ no braid

PVC RJ-12

/ no braid

PVC

/ no braid

1.10 Programming and Firmware Download

The AFI5100 is programmed using the host software application via the ACC, or

using the FLN Configurator Field Service Tool application. Please refer to the appropriate User’s Guide for more Information.

Information in this document is based on specifications believed correct at the time of publication. The

right is reserved to make changes as design improvements are made.

11

Siemens Building Technologies

Fire Safety & Security Products 02.2005

Page 12

Input Point Module (AFI5100)

12

Siemens Building Technologies A24205-A335-B245.doc

Fire Safety & Security Products 02.2005

Page 13

Page 14

Issued by

Siemens Building Technologies

Fire & Security Products GmbH & Co. oHG

D-76181 Karlsruhe

www.sbt.siemens.com

Document no.

Edition 02.2005

A24205-A335-B245

Siemens Building Technologies AG

© 2005 Copyright by

Data and design subject to change without notice.

Supply subject to availability.

Printed in the Federal Republic of Germany

on environment-friendly chlorine-free paper.

Loading...

Loading...