Siemens 6SE7011-5EP60, 6SE7018-0EP60, 6SE7021-0EP60, 6SE7021-4EP60, 6SE7022-1EP60 Operating Instructions Manual

...Page 1

SIMOVERT MASTERDRIVES

Vector Control

Betriebsanleitung

Operating Instructions

Frequenzumrichter (AC-AC) Bauform Kompakt PLUS

Frequency Converter (AC-AC) Compact PLUS Type

Ausgabe / Edition: AB Bestell-Nr. / Order No.: 6S E7087-6JP60

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 2

Weitergabe sowie Vervielf äl tigung dieser Unterlage, Verwertung

und Mitteilung ihres Inhalts ni cht gestattet, soweit nicht ausdrücklich zugestanden. Zuwiderhandlungen verpflichten zu Schadenersatz. Alle Rechte vorbehalten, insbesondere für den Fall der

Patenterteilung oder GM-Eintragung.

Wir haben den Inhalt der Druckschrift auf Übereinstimmung mit der

beschriebenen Hard- und Software überprüft. Dennoch können

Abweichungen nicht ausgeschlossen werden, so daß wir für die

vollständige Übereinstimmung keine Garantie übernehmen. Di e

Angaben in dieser Druckschrift werden jedoch regelmäßig überprüft

und notwendige Korrekturen sind in den nachfolgenden Auflagen

enthalten. Für Verbesserungsvors chläge sind wir dankbar

SIMOVERT ist ein Warenzeichen von Siemens

The reproduction, transmission or use of this document or its contents is not permitted without express written authority. Off enders

will be liable for damages. All rights, including rights created by

patent grant or registration of a utility model or design, are

reserved.

We have checked the contents of this document to ensure that they

coincide with the described hardware and soft ware. However,

differences cannot be completely excluded, so that we do not

accept any guarantee for complete conformance. However, the

information in this document is regularly check ed and necessary

corrections will be included in subsequent editions. We are grateful

for any recommendations for improvement.

SIMOVERT Registered Trade Mark

Siemens AG 2001 All rights reserved

Diese Betriebsanleitung gilt für den Gerätesoftwarestand ab V3.32.

Änderungen von Funktionen, technischen Daten, Normen, Zeichnungen und Parametern vorbehalten.

These Operating Instructions are valid for software release from V3.32.

We reserve the right to make changes to functions, technical data, standards, drawings and parameters.

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 3

05.2003 Contents

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 1

Contents

1 DEFINITIONS AND WARNINGS .....................................................................1-1

2 DESCRIPTION..................................................................................................2-1

3 FIRST START-UP.............................................................................................3-1

4 TRANSPORT, STORAGE, UNPACKING........................................................4-1

5 INSTALLATION................................................................................................5-1

5.1 Installing the units .............................................................................................5-1

5.2 Installing the optional boards ............................................................................5-4

5.2.1 Installing optional boards on units with a width up to 90 mm ...........................5-4

5.2.2 Installing optional boards on units with a width of 135 mm and 180 mm .........5-7

6 INSTALLATION IN CONFORMANCE WITH EMC REGULATIONS ..............6-1

7 CONNECTING-UP............................................................................................7-1

7.1 Power connections............................................................................................7-5

7.1.1 Power connections for units with a width up to 90 mm.....................................7-5

7.1.2 Power connections for units with a width of 135 mm........................................7-8

7.1.3 Power connections for units with a width of 180 mm......................................7-10

7.2 Control connections ........................................................................................7-12

7.3 Conductor cross-sections, fuses, reactors......................................................7-22

7.4 Combinations of units......................................................................................7-23

8 PARAMETERIZATION.....................................................................................8-1

8.1 Parameter menus..............................................................................................8-1

8.2 Changeability of parameters.............................................................................8-5

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 4

Contents 05.2003

6SE7087-6JP60 Siemens AG

2 Operating Instructions SIMOVERT MASTERDRIVES

8.3 Parameter input with DriveMonitor....................................................................8-6

8.3.1 Installation and connection ...............................................................................8-6

8.3.1.1 Installation.........................................................................................................8-6

8.3.1.2 Connection........................................................................................................8-6

8.3.2 Drive configuration DriveMonitor.......................................................................8-7

8.3.2.1 Setting the interface ..........................................................................................8-9

8.3.2.2 Drive settings ..................................................................................................8-10

8.3.3 Parameterization.............................................................................................8-15

8.3.3.1 Structure of the parameter lists, parameterization with DriveMonitor.............8-15

8.3.3.2 Diagnostic menu .............................................................................................8-16

8.4 Parameter input via the PMU..........................................................................8-17

8.5 Parameter input via the OP1S ........................................................................8-21

8.5.1 General............................................................................................................8-21

8.5.2 Connecting, run-up..........................................................................................8-23

8.5.2.1 Connecting......................................................................................................8-23

8.5.2.2 Run-up.............................................................................................................8-24

9 PARAMETERIZING STEPS.............................................................................9-1

9.1 Parameter reset to factory setting.....................................................................9-2

9.2 Power section definition ....................................................................................9-4

9.2.1 Parameterizing with parameter modules (quick parameterization, P060 = 3)..9-5

10 MAINTENANCE..............................................................................................10-1

10.1 Replacing the fan ............................................................................................10-1

10.1.1 Replacing the fan in units up to 45 mm wide..................................................10-2

10.1.2 Replacing the fan in units up to 90 mm wide..................................................10-2

10.1.3 Replacing the fan in units 135 mm wide.........................................................10-3

10.1.4 Replacing the fan in units up to 180 mm wide................................................10-3

11 FORMING .......................................................................................................11-1

12 TECHNICAL DATA ........................................................................................12-1

13 FAULTS AND ALARMS.................................................................................13-1

13.1 Faults...............................................................................................................13-1

13.2 Alarms...........................................................................................................13-18

13.3 Fatal errors (FF)............................................................................................13-27

14 ENVIRONMENTAL FRIENDLINESS .............................................................14-1

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 5

10.2001 Definitions and Warnings

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 1-1

1 Definitions and Warnings

For the purpose of this documentation and the product warning labels,

a "Qualified person" is someone who is familiar with the installation,

mounting, start-up, operation and maintenance of the product. He or

she must have the following qualifications:

♦ Trained or authorized to energize, de-energize, ground and tag

circuits and equipment in accordance with established safety

procedures.

♦ Trained or authorized in the proper care and use of protective

equipment in accordance with established safety procedures.

♦ Trained in rendering first aid.

indicates an imminently hazardous situation which, if not avoided, will

result in death, serious injury and considerable damage to property.

indicates a potentially hazardous situation which, if not avoided, could

result in death, serious injury and considerable damage to property.

used with the safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in minor or moderate injury.

used without safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in property damage.

NOTICE used without the safety alert symbol indicates a potential

situation which, if not avoided, may result in an undesirable result or

state.

For the purpose of this documentation, "Note" indicates important

information about the product or about the respective part of the

documentation which is essenti al to highl ight.

Qualified personnel

DANGER

WARNING

CAUTION

CAUTION

NOTICE

NOTE

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 6

Definitions and Warnings 10.2001

6SE7087-6JP60 Siemens AG

1-2 Operating Instructions SIMOVERT MASTERDRIVES

Hazardous voltages are present in this elec tric al equ ipment during

operation.

Non-observance of the warnings can thus result in severe personal

injury or property damage.

Only qualified personnel should work on or around the equipment

This personnel must be thoroughly familiar with all warning and

maintenance procedures contained in this documentation.

The successful and safe operation of this equipment is dependent on

correct transport, proper storage and ins ta l lat ion as well as caref ul

operation and maintenance.

This documentation does not purport to cover all details on all types of

the product, nor to provide for every possible contingency to be met in

connection with installation, operation or maintenance.

Should further information be desired or should particular problems

arise which are not covered sufficiently for the purchaser's purposes,

the matter should be referred to the local SIEMENS sales office.

The contents of this documentation shall not become part of or modify

any prior or existing agreement, commitment or relationship. The sales

contract contains the entire obligation of SIEMENS AG. The warranty

contained in the contract between the parties is the sole warranty of

SIEMENS AG. Any statements contained herein do not create new

warranties or modify the existing warranty.

WARNING

NOTE

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 7

10.2001 Definitions and Warnings

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 1-3

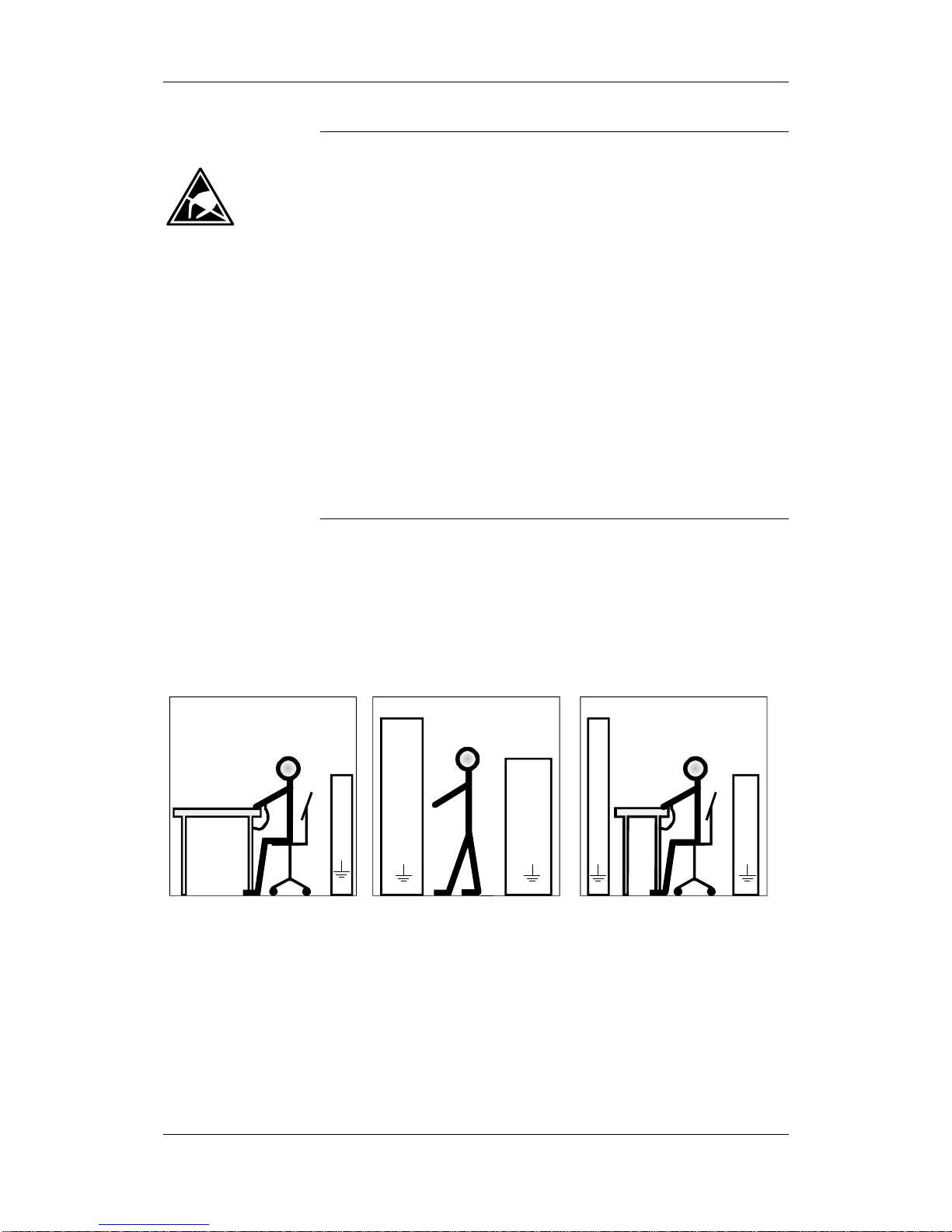

Components which can be destro yed by electros tatic disc har g e (ESD)

The board contains components which can be destroyed by

electrostatic discharge. These components can be easily destroyed if

not carefully handled. If you have to handle elec tr onic boar ds, pl eas e

observe the following:

Electronic boards should only be touched when absolutely necessary.

The human body must be electrically discharged before touching an

electronic board.

Boards must not come into contact with highly insulating materials - e.g.

plastic parts, insulated desktops, articles of clothing manufactured from

man-made fibers.

Boards must only be placed on conductive surfaces.

Boards and components should only be stored and transported in

conductive packaging (e.g. metalized plastic boxes or metal

containers).

If the packing material is not conductive, the boards must be wrapped

with a conductive packaging material, e.g. conductive foam rubber or

household aluminium foil.

The necessary ESD protective measures are clearly shown again in the

following diagram:

♦ a = Conductive floor surface

♦ b = ESD table

♦ c = ESD shoes

♦ d = ESD overall

♦ e = ESD chain

♦ f = Cubicle ground connection

StandingSitting Standin g / Sit ti ng

a

b

e

d

c

d

a

c

d

b

c

a

e

f

f

f f f

Fig. 1-1 ESD protective measures

CAUTION

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 8

Definitions and Warnings 10.2001

6SE7087-6JP60 Siemens AG

1-4 Operating Instructions SIMOVERT MASTERDRIVES

Safety and Operating Instructions

for Drive Converters

(in conformity with the low-voltage directive 73/23/EEC)

1. General

In operation, drive converters, depending on thei r degree

of protection, may have live, uninsulated, and possibly

also moving or rotating parts, as well as hot surfaces.

In case of inadmissible removal of the required covers, of

improper use, wrong installation or maloperation, t here is

the danger of serious personal injury and damage to

property.

For further information, see documentation.

All operations serving transport, installation and

commissioning as well as maintenance are to be carried

out by skilled technical personnel (observe IEC 364 or

CENELEC HD 384 or DIN VDE 0100 and IEC Report

664 or DIN VDE 0110 and national accident prevention

rules).

For the purposes of these basic safety instructions,

"skilled technical personnel" means persons who are

familiar with the installation, mounting, commissioning

and operation of the product and have the qualifications

needed for the performance of their functions.

2. Intended use

Drive converters are components designed for inclusion

in electrical installations or machinery.

In case of installation in machinery, commissioning of the

drive converter (i.e. the starting of normal operation) is

prohibited until the machinery has been proved to

conform to the provisions of the EC directive 89/392/EEC

(Machinery Safety Directive - MSD). Account is to be

taken of EN 60204.

Commissioning (i.e. the start of normal operation) is

admissible only where conformity with the EMC directive

(89/336/EEC) has been established.

The drive converters meet the requirements of the lowvoltage directive 73/23/EEC. They are subject to the

harmonized standards of the series prEN 50178/DIN

VDE 0160 in conjunction with EN 60439-1/DIN VDE

0660 Part 500 and EN 60146/DIN VDE 0558.

The technical data as well as information concerning t he

supply conditions shall be taken from the rating plate and

from the documentation and shall be strictly observed.

3. Transport, storage

The instructions for transport, storage and proper use

shall be complied with.

The climatic conditions shall be in conformity with prEN

50178.

4. Installation

The installation and cooling of the appliances shall be in

accordance with the specifications in the pertinent

documentation.

The drive converters shall be protected against

excessive strains. In particular, no components must be

bent and/or isolating distances altered in the course of

transportation or handling. No contact shall be made with

electronic components and contacts.

Drive converters contain electrostatic sensitive

components which are liable to damage through

improper use. Electronic components must not be

mechanically damaged or destroyed (potential health

risks).

5. Electrical connection

When working on live drive converters, the applicable

national accident prevention rules (e.g. VBG 4) must be

complied with.

The electrical installation shall be carried out in

accordance with the relevant requirements (e.g. crosssectional areas of conductors, fusing, PE connection).

For further information, see documentation.

Instructions for the installation in accordance with EMC

requirements, such as screening, grounding, location of

filters and wiring, are contained in the drive converter

documentation. They must always be complied with, also

for drive converters bearing a CE marking. Observance

of the limit values required by the EMC law is the

responsibility of the manufacturer of the installation or

machine.

6. Operation

Installations which include drive converters shall be

equipped with additional monitoring and protective

devices in accordance with the relevant applicable s afet y

requirements, e.g. Act respecting technical equipment,

accident prevention rules, etc. Changes to the drive

converters by means of the operating software are

permissible.

After disconnection of the drive converters from the

voltage supply, live appliance parts and power terminals

must not be touched immediately because of possibly

energized capacitors. In this regard, the corresponding

signs and markings on the drive converter must be

respected.

During operation, all covers and doors shall be kept

closed.

7. Maintenance and servicing

The manufacturer's documentation shall be followed.

Keep these safety instructions in a safe place!

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 9

05.2003 Description

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 2-1

2 Description

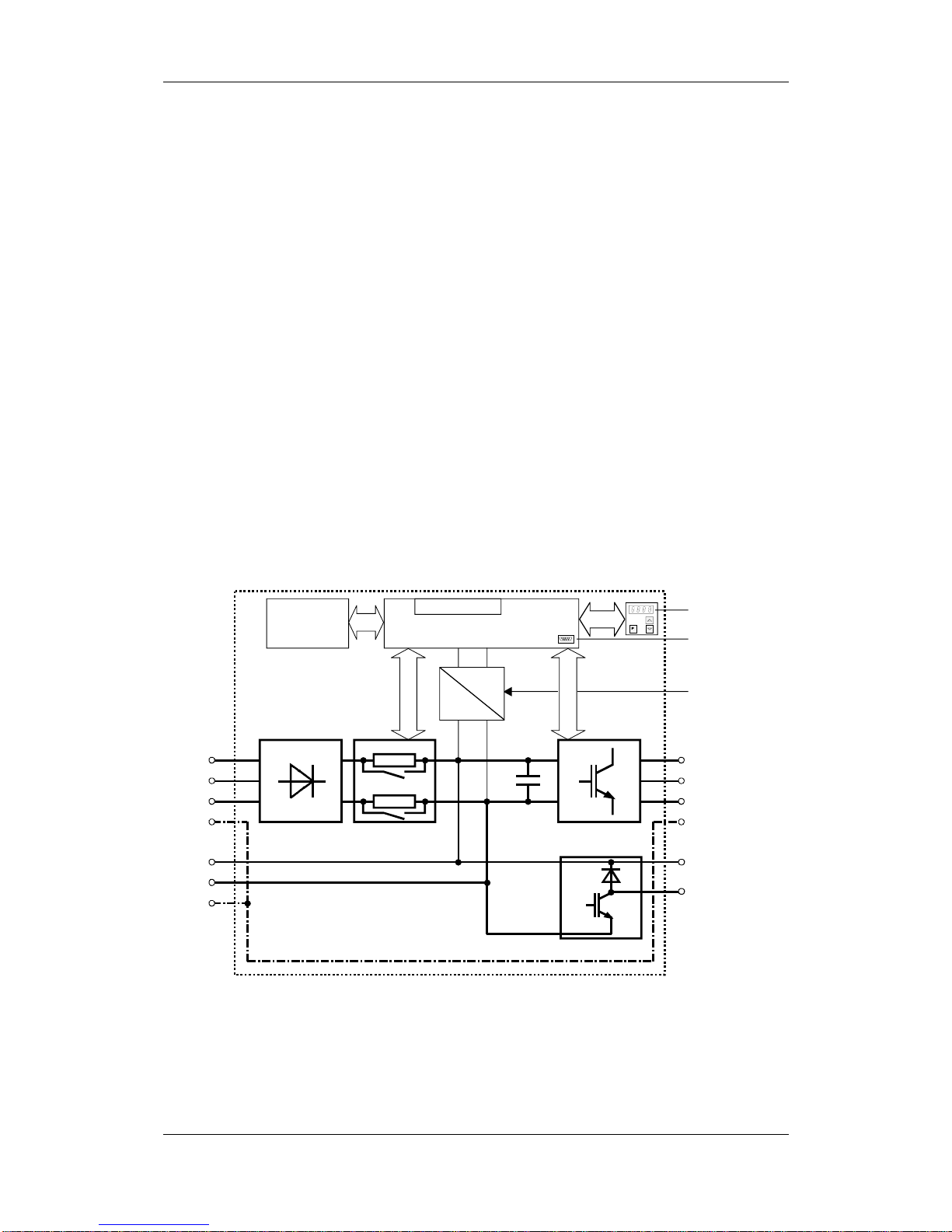

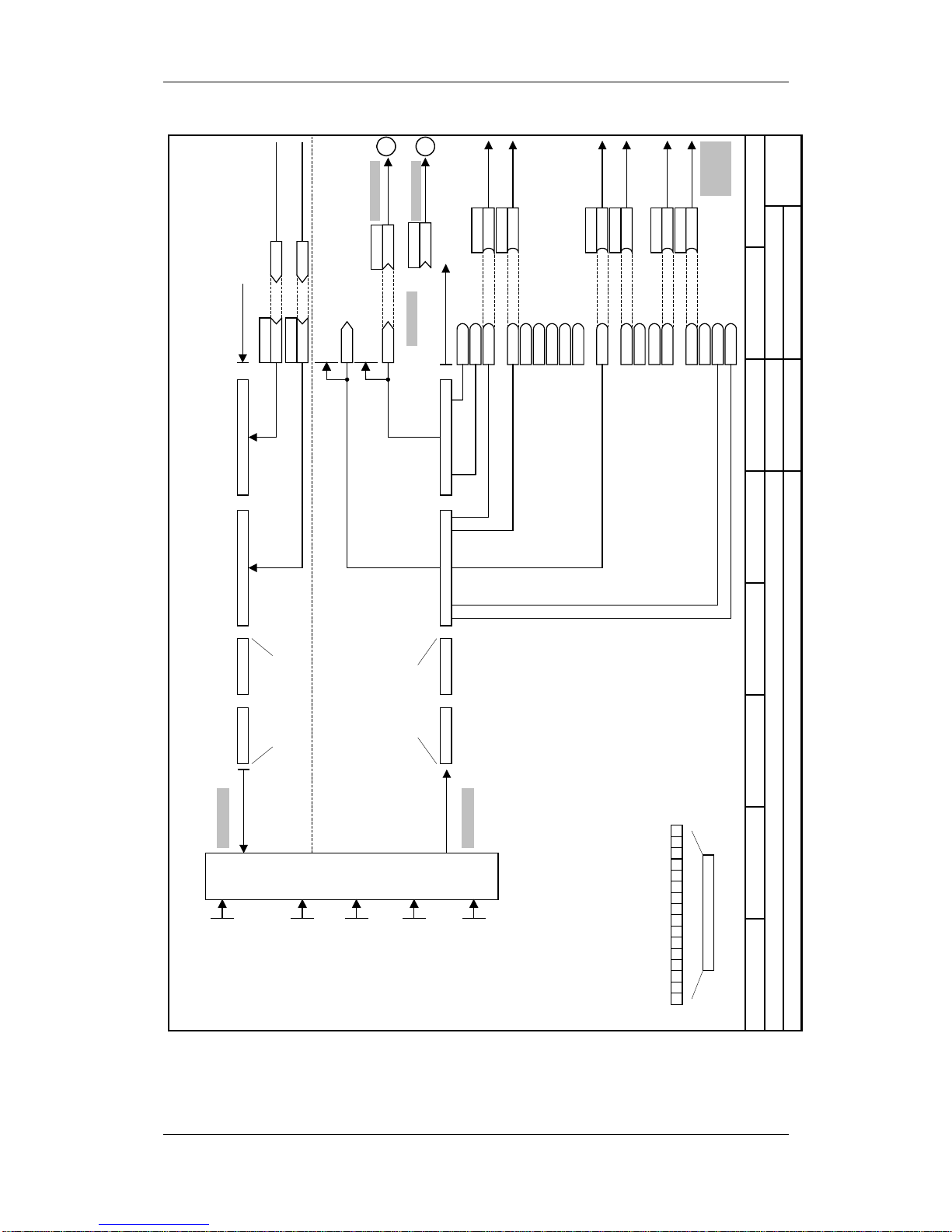

The converters are power electronics components for feeding threephase motors.

They can be operated from a three-phase system with a voltage

between 380 V and 480 V and a frequency of 50/60 Hz.

The line voltage from the system is rectified and fed into the DC link.

The power section enables a three-phase system with a variable output

frequency between 0 Hz and 500 Hz maximum to be generated from

the DC link direct voltage with the pulse width modulation method

(PWM).

The internal DC 24 V voltage is supplied through an integral power

supply unit.

The unit is controlled by the internal control electronics which consists

of a microprocessor system. The functions are provided by the unit

software.

Operator control is effected via the PMU operator control panel, the

user-friendly OP1S operator control panel, the terminal strip or via a

bus system. For this purpose, the unit has a number of interfaces and

two slots for the use of optional boards.

Pulse encoders can be used as motor-specific encoders.

Motor

connection

U2/T1

V2/T2

W2/T3

PE2

Cont rol electronics

Serial

interface

Terminal strip

Optional

boards

DC link

U1/L1

V1/L2

W1/L3

PE1

PMU

InverterPrechargingRectifier

Internal

power

supply

G

H

Braking

resistor

24 V

==

==

Brake choppe r

C / L+

D / L PE3

-X9

external DC 24 V

supply

Fig. 2-1 Circuit principle of the frequency converter

Range of application

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 10

10.2001 First Start-up

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 3-1

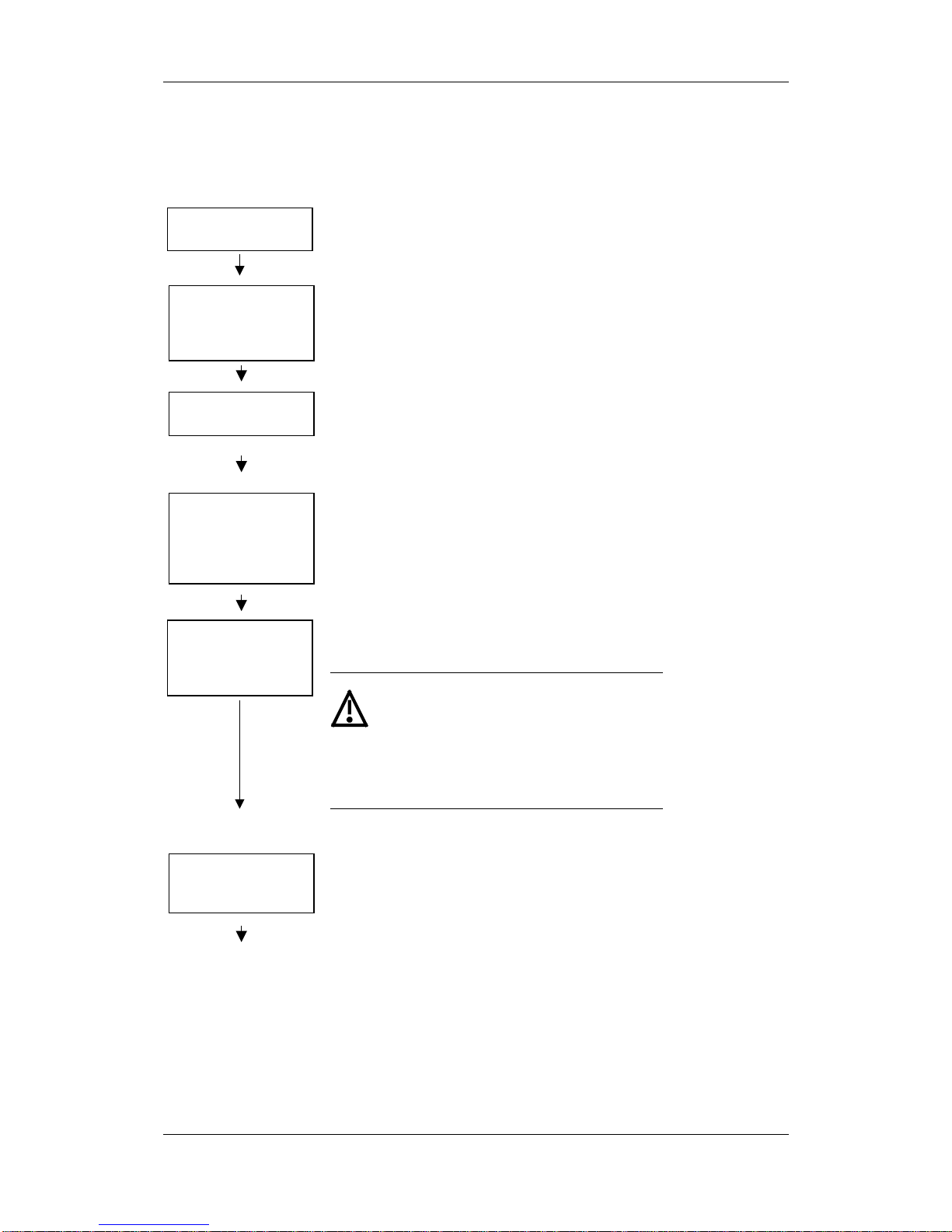

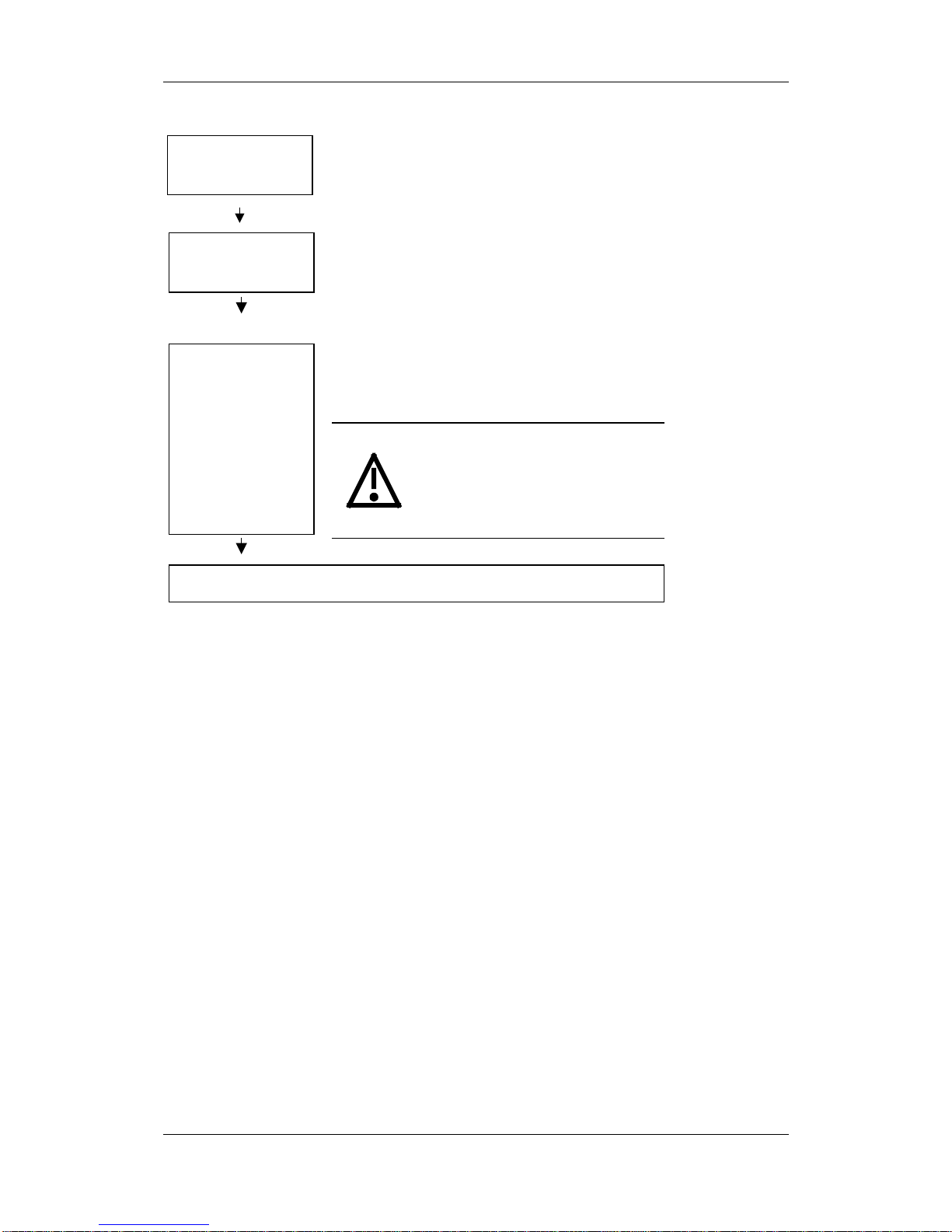

3 First Start-up

After removing the packaging, check that the unit is

intact and undamaged. Only intact units may be started

up. Please also check that the unit is complete and that

the correct optional boards are fitted.

Unpack and check the

units

See section

"Transport,

Storage,

Unpacking"

Retrofit any optional boards which have not yet been

installed, if necessary. Then install the units taking into

account the requirements at the point of installation and

the EMC instructions.

Mount the unit and

install optional boards

which have not yet

been fitted

See section

"Installation"

and "Installation

in Conformance

with EMC

Regulations"

If the DC link of the unit was de-energized for more than

one year, you have to newly form the DC link capacitors

Form the DC link

capacitors, if necessary

See section

"Forming"

Please connect, starting with the protective conductor,

the power cables or DC link buses and, if present, the

external 24 V supply. Pay attention to EMC instructions

when laying the cables. Please do not at this stage

connect any control, communication, encoder and motor

cables (exception: cable for connecting up an OP1S, if

parameterization is to be effected via the OP1S).

Connect the protective

conductor, the power

cables or buses and, if

present, the ext. 24 V

supply

See section

"Connecting-up"

and

"Installation in

Conformance

with EMC

Regulations"

Please connect the remaining control, communication,

encoder and motor cables. Pay attention to the EMC

instructions when laying the cables.

Connect the control

cables, communication

cables, encoder cables

and motor cables

See section

"Connecting-up"

and "Installation

in Conformance

with EMC

Regulations"

WARNING

The device must be

disconnected

from

its voltage supplies (24 V DC electronics

supply

and

DC link / mains voltage)

before the control and encoder leads are

connected or disconnected!

Failure to observe this advice can result in

encoder defects, which may in turn cause

uncontrolled axis movements.

After checking that the cabling has been correctly

connected and that it sits properly, power up the

external 24 V supply or the line voltage. After the

electronics power supply has been started, the unit

initializes itself. The action can take several seconds.

The drive status is subsequently shown on the PMU.

Power up the external

24 V supply or the line

voltage

111

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 11

First Start-up 10.2001

6SE7087-6JP60 Siemens AG

3-2 Operating Instructions SIMOVERT MASTERDRIVES

If the PMU does not show status °009 after completion

of the unit initialization, or if the unit has already been

parameterized before, you should carry out a parameter

reset to factory setting.

If necessary, carry out

parameter reset to

factory setting

See section

"Parameterization"

AAA

Parameterizing by

download or with

parameter modules

See section

"Parameterization"

After checking the unit and the cabling once more,

power up the line voltage or DC bus voltage, if you have

not already done so, and perform a function test

according to your parameterization.

Function test

siehe

"Anschließen"

und "EMV-

gerechter

Aufbau"

It must be ensured that no danger for

persons and equipment can occur by

energizing the power and the unit. It is

recommended not to couple the driven

machine until the function test has

been successfully completed.

WARNING

Further start-up and parameterization according to

your specific requirements

siehe "Ans

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 12

10.2001 Transport, Storage, Unpacking

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 4-1

4 T ran sport, Storage, Unp acking

The units and components are packed in the manufacturing plant

corresponding to that specified when ordered. A packing label is

located on the outside of the packaging. Please observe the

instructions on the packaging for transport, storage and professional

handling.

Vibrations and jolts must be avoided during transport. If the unit is

damaged, you must inform your shipping company immediately.

The units and components must be stored in clean, dry rooms.

Temperatures between -25 °C (-13 °F) and +70 °C (158 °F) are

permissible. Temperature fluctuations must not be more than 30 K per

hour.

If the storage period of one year is exceeded, the unit must be newly

formed. See Section ”Forming".

The packaging comprises board and corrugated paper. It can be

disposed of corresponding to the appropriate local regulations for the

disposal of board products. The units and components can be installed

and commissioned after they have been unpacked and checked to

ensure that everything is complete and that they are not damaged.

Transport

Storage

CAUTION

Unpacking

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 13

05.2003 Installation

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 5-1

5 Installation

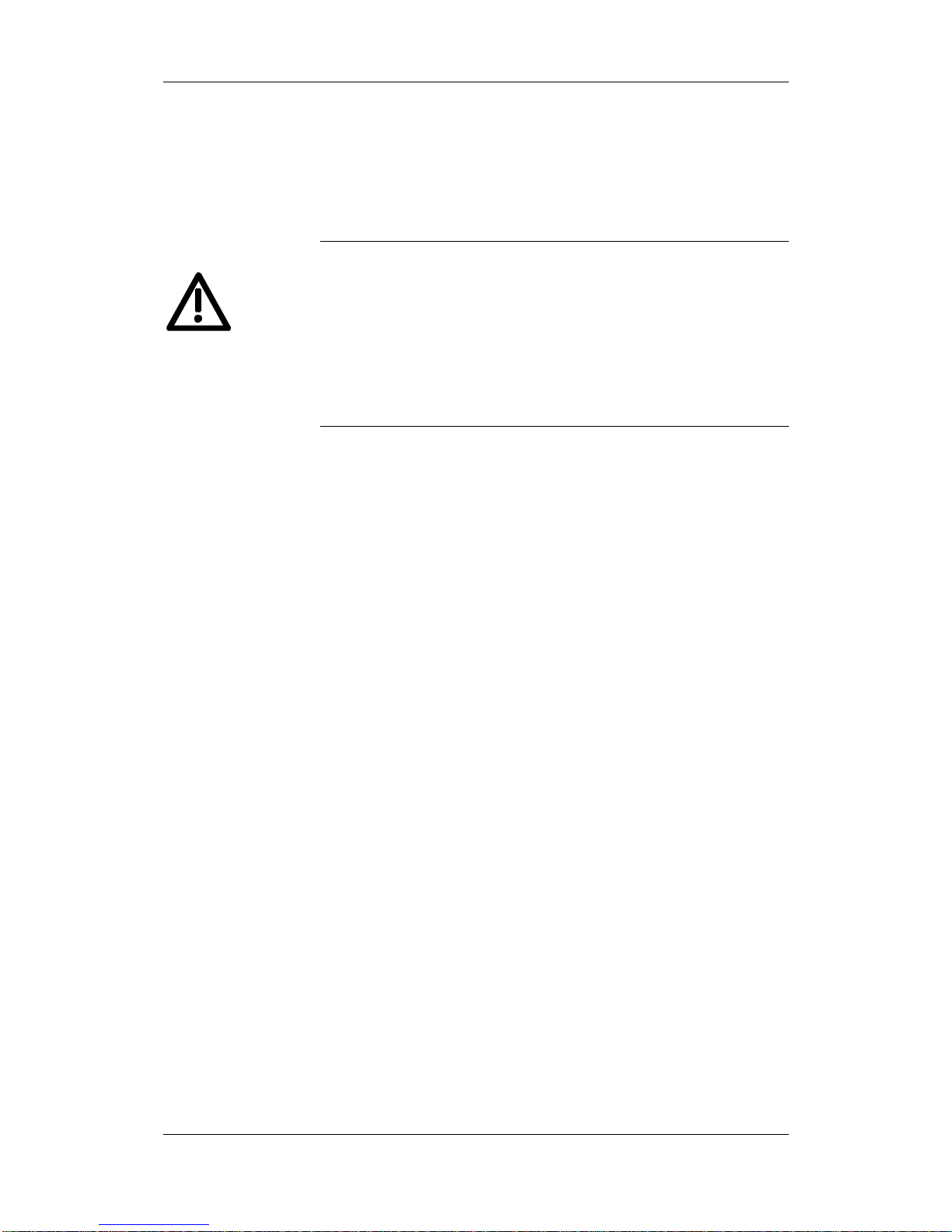

5.1 Installing the units

Safe converter operation requires that the equipment is mounted and

commissioned by qualified personnel taking into account the warning

information provided in these Operating Instructions.

The general and domestic installation and safety regulations for work

on electrical power equipment (e.g. VDE) must be observed as well as

the professional handling of tools and the use of personal protective

equipment.

Death, severe bodily injury or significant material damage could result if

these instructions are not followed.

When installing the units, make sure that the mains connection is

located at the top section and the motor connection at the lower section

of the unit.

The units can be mounted flush with each other.

In order to ensure an adequate supply of cooling air, a clearance of

100 mm must be left at the top of the unit and at the bottom of the unit

respectively to components which may considerably affect the flow of

cooling air.

When mounting in cabinets, the cabinet cooling must be designed

according to the power loss. Please refer to the Technical Data in this

regard.

♦ Foreign particles

The units must be protected against the ingress of foreign particles

as otherwise their function and operational safety cannot be

ensured.

♦ Dust, gases, vapors

Equipment rooms must be dry and dust-free. Ambient and cooling

air must not contain any electrically conductive gases, vapors and

dust which could diminish the functionality. If necessary, filters

should be used or other corrective measures taken.

♦ Cooling air

The units must only be operated in an ambient climate in

accordance with DIN IEC 721-3-3 Class 3K3. For cooling air

temperatures of more than 45 °C (113 °F) and installation altitudes

higher than 1000 m, derating is required.

WARNING

Clearances

Requirements at the

point of installation

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 14

Installation 05.2003

6SE7087-6JP60 Siemens AG

5-2 Operating Instructions SIMOVERT MASTERDRIVES

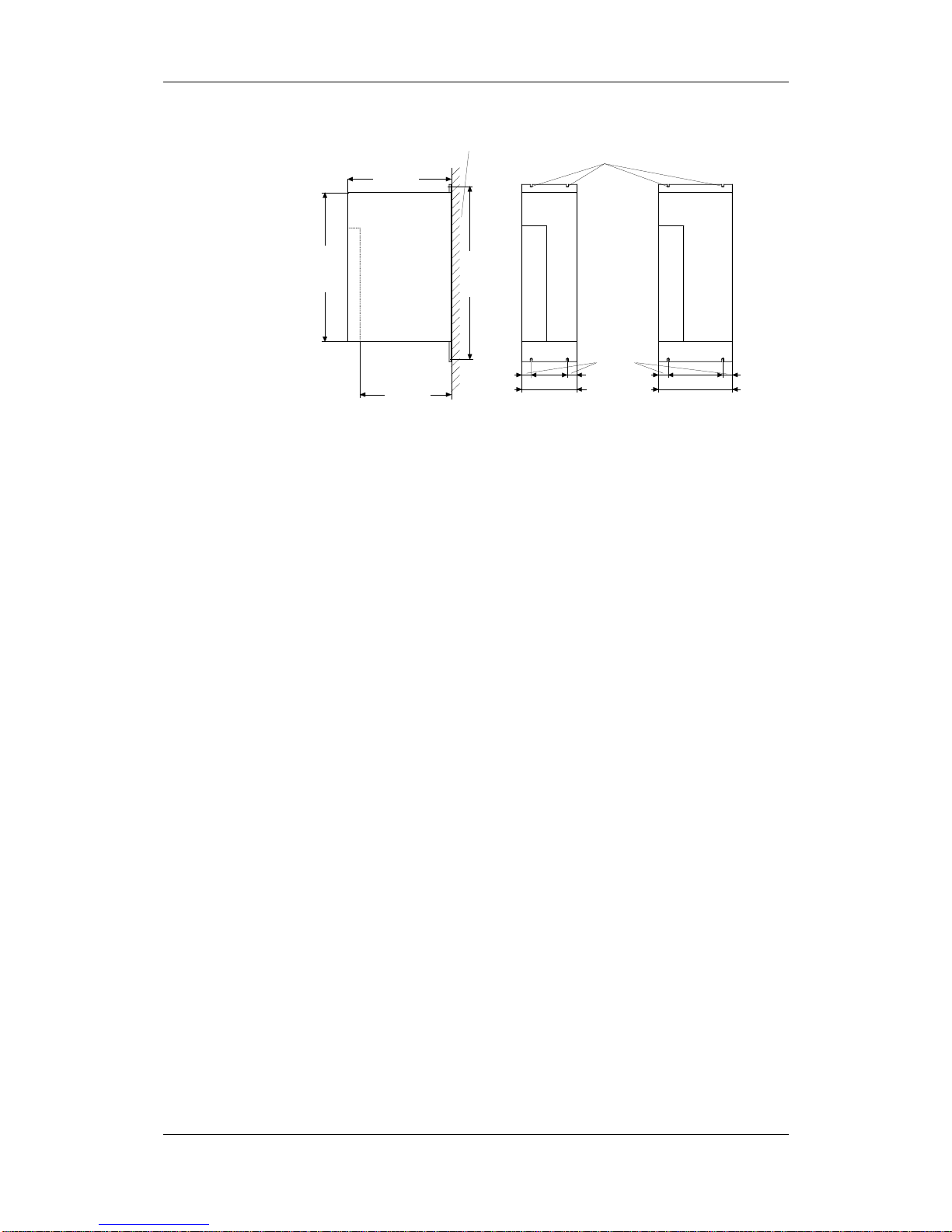

Mounting

surface

100 mm

100 mm

Cooling air

Fig. 5-1 Minimum clearances for cooling

The unit is mounted directly to a mounting surface. Fixing is by means

of two or four M5 screws.

Side view Front view (without front panel)

22.5 mm

220 mm

360 mm

Mounting surface

Cutouts

for M5 screws

414 mm

45 mm

250 mm

33.75 mm

67.5 mm

45 mm

90 mm

0.55 kW 1.1 / 1.5 kW 3.0 / 4.0 kW

Fig. 5-2 Dimension drawings for housings up to 90 mm wide

Installation

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 15

05.2003 Installation

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 5-3

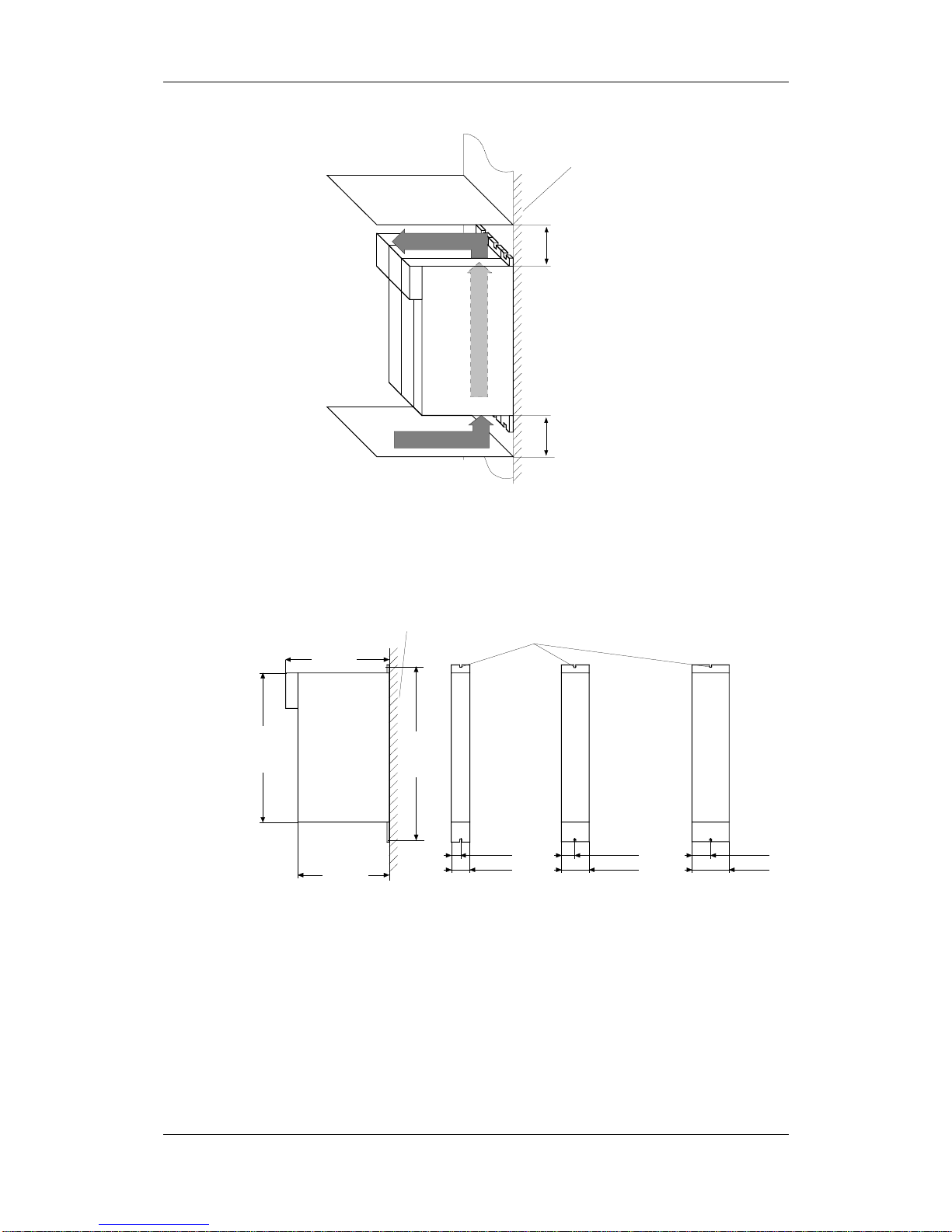

Side view Front view

22.5 mm

220 mm

360 mm

Mounting surface

Cutouts

for M5 screws

414 mm

135 mm

250 mm

5.5 / 7.5 kW

180 mm

11 / 15 kW

Fig. 5-3 Dimension drawings for housings 135 mm and 180 mm wide

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 16

Installation 05.2003

6SE7087-6JP60 Siemens AG

5-4 Operating Instructions SIMOVERT MASTERDRIVES

5.2 Installing the optional boards

The unit has hazardous voltage levels up to 5 minutes after it has been

powered down due to the DC link capacitors. The unit or the DC link

terminals must not be worked on until at least after this delay time.

5.2.1 Installing optional boards on units with a width up to 90 mm

Disconnecting the unit from the supply

Disconnect the unit from the power supply and power down the unit.

Remove the 24 V voltage supply for the electronics. Remove all

connecting cables.

Dismantle the unit as follows:

♦ Open the terminals of the DC link bus module.

♦ Remove the fixing screws by means of which the unit is fixed to the

mounting surface.

♦ Pull the unit down until the DC link bus module is completely

exposed.

♦ Pull the unit out towards you.

♦ Lay the unit on its left side.

If you are using an AC unit as a single drive, there is no DC link bus

module. You can then withdraw the unit directly after removing the

fixing screws.

♦ Unscrew the two fixing screws of the right-hand side wall. The fixing

screws are located at the top of the unit at the rear right-hand

corner, and at the bottom of the unit in the middle of the right-hand

side wall.

♦ You do not have to remove the two fixing screws completely, as the

wall of the unit is provided with a cutout to enable you to swing out

the cover once the screws have been loosened.

♦ Open the right-hand side wall. To open it, swing the right-hand side

wall towards you and pull it upwards out of the guide on the front

edge.

♦ Remove the cover of the selected slot on the front panel.

♦ To do so, you must carefully cut through the four connecting points

of the cover on the front panel with a thin knife.

DANGER

DANGER

Dismantling the unit

Opening the unit

Removing the slot

cover

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 17

05.2003 Installation

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 5-5

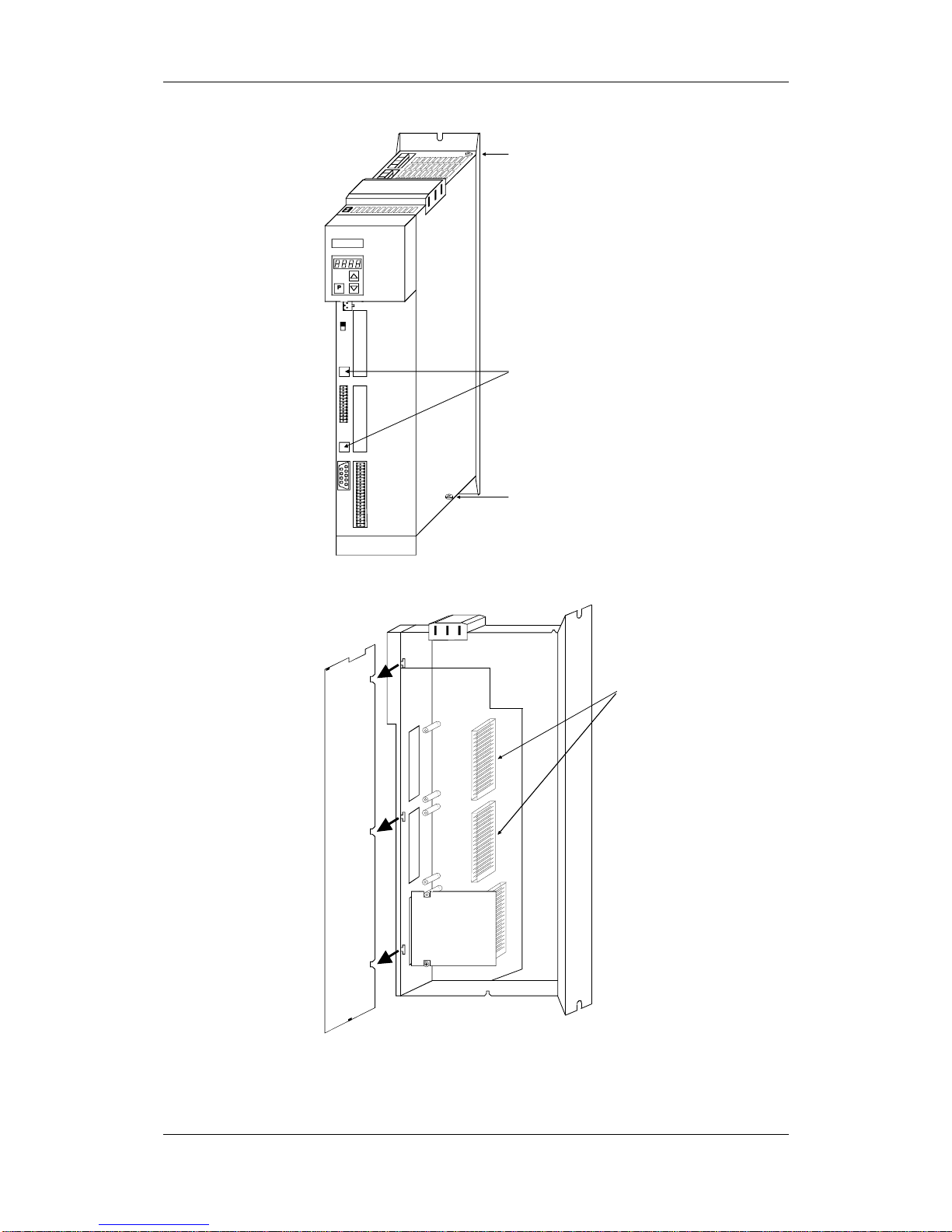

SIEMENS

A

S1

BX101

CX103

Fixing screw for side

cover

Fixing screw for

side cover

Designation plates

for the optional

boards

Fig. 5-4 Position of the fixing screws on the right-hand side wall

Slot A

Slot B

Slot C

Rear wall

Slots for optional

boards

Right-han d side wall open

CU

PBI

Fig. 5-5 Removing the right-hand side wall

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 18

Installation 05.2003

6SE7087-6JP60 Siemens AG

5-6 Operating Instructions SIMOVERT MASTERDRIVES

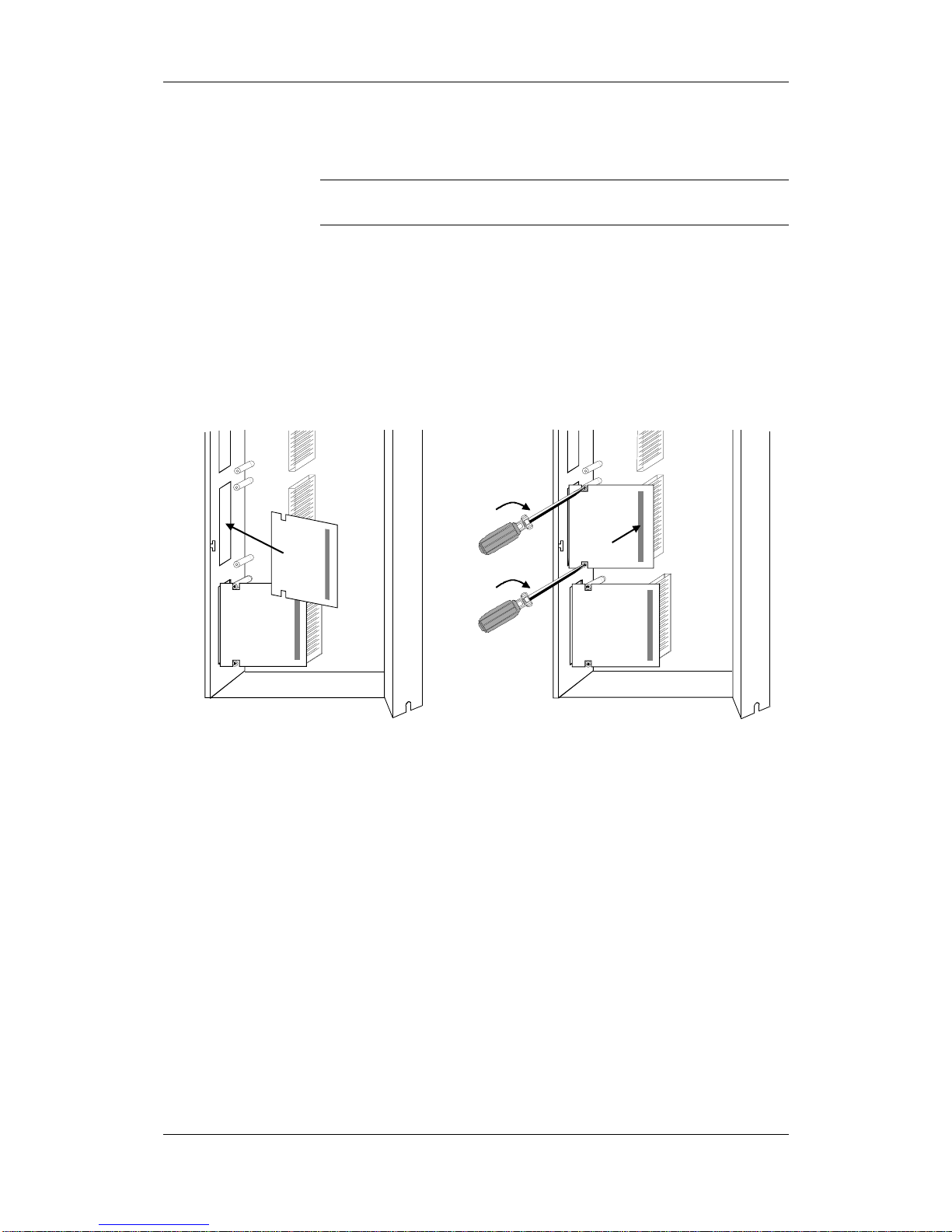

Optional boards can only be inserted in slot A and slot B. Slot C of the

unit is permanently pre-assigned for the terminal module EBV.

Push the optional board from behind into the opening on the front cover

(

) until the position of the 64-pole system connector on the main

board corresponds with the position of the socket.

Insert the optional board from the right onto the 64-pole system

connector on the main board (

). The view shows the installed state.

Screw the optional board tight at the fastening points in the front section

of the optional board (

).

Slot A

Slot B

Slot B

Rear wall

Slot A

Slot C

Slot C

Rear wall

Fig. 5-6 Installing the optional board

Installing the

optional board

NOTICE

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 19

05.2003 Installation

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 5-7

Close the right-hand side wall of the unit as follows

♦ Insert the right-hand side wall from above into the guide on the front

right-hand side.

♦ Swing back the side wall.

♦ Screw the side wall tight again by means of the two fixing screws.

Mount the unit as follows:

♦ Insert the unit into its mounting position from the front underneath

the DC link bus module.

♦ Lift the unit upwards until the DC link bus module is completely in its

original position again.

♦ Screw the unit tight to the mounting surface with the fixing screws.

♦ Interlock the DC bus module.

If you are using an AC unit as a single drive, you can fix the unit directly

to the mounting surface.

♦ Re-connect all previously removed connecting cables.

♦ Check all connecting cables and the shield to make sure they sit

properly and are in the correct position.

♦ To designate the optional board, insert the relevant designation

plate into the envisaged position on the front of the unit.

♦ When the voltage has been switched in, the software of the unit

recognizes which optional bo ar ds have bee n ins tal le d and you can

then commence start-up.

5.2.2 Installing optional boards on units with a width of 135 mm and

180 mm

Disconnecting the unit from the supply

Disconnect the unit from the power supply and power down the unit.

Remove the 24 V voltage supply for the electronics. Remove all

connecting cables.

♦ Loosen the 2 fixing screws on the front of the unit at the top. There

is no need to remove the screws completely, since cutouts are

provided in the housing to permit the front to come away after the

screws have been loosened.

♦ Carefully swing the upper front section forwards (approx. 30 °) away

from the housing.

♦ At the power section, open the locking lever of the ribbon cable that

connects up with the control electronics.

♦ Take off the front of the unit by moving it forwards.

Assembling and

mounting the unit

Designating the

optional board

DANGER

Opening the unit

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 20

Installation 05.2003

6SE7087-6JP60 Siemens AG

5-8 Operating Instructions SIMOVERT MASTERDRIVES

♦ Remove the cover of the selected slot on the front panel.

♦ To do so, you must carefully cut through the four connecting points

of the cover on the front panel with a thin knife.

♦ Undo the two optional board screws by about one turn each.

♦ Loosen the connection between the system connector and the

board so as to prevent any mechanical tension arising when the

screws are fully unscrewed.

♦ Take out the optional board screws and remove the board.

Optional boards can only be inserted in slot A and slot B. Slot C of the

unit is permanently pre-assigned for the terminal module EBV.

♦ Insert the optional board from the behind the broken-out slot conver

(

) until the position of the 64-pole system connector on the

electronic board corresponds with the position of the socket.

♦ Insert the option board into the 64-pole system connector on the

electronic board (

).

♦ Screw the optional board tight at the fastening points in the front

section of the optional board with the two screws (

).

Slot C Slot C

Slot B

Slot B

Slot A

Fig. 5-7 Installing the optional board

Removing the slot

cover

Removing the

optional board

Mounting the

optional board

NOTICE

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 21

05.2003 Installation

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 5-9

♦ Keep the front of the unit tilted about approximately 30 ° forwards

and insert the cutout of the lower guide plate - approaching from

below - into the strip on the power section.

♦ Insert the connection cable plug into the power section socket and

close the locking lever.

♦ Carefully return the front of the unit into the housing. Make sure that

the guide plates on the right-hand side of the front (viewed from the

front) enter the housing cutouts.

♦ Screw the front of the unit securely to the power section with the two

fixing screws.

♦ Re-connect all previously removed connecting cables.

♦ Check all connecting cables and the shield to make sure they sit

properly and are in the correct position.

♦ To designate the optional board, insert the relevant designation

plate into the envisaged position on the front of the unit.

♦ When the voltage has been switched in, the software of the unit

recognizes which optional bo ar ds have bee n ins tal le d and you can

then commence start-up.

Assembling and

mounting the unit

Connecting up the

unit

Designating the

optional board

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 22

05.2003 Installation in Conformance with EMC Regulations

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 6-1

6 Installation in Conformance with EMC

Regulations

The following contains a summary of general information and

guidelines which will make it easier for you to comply with EMC and CE

regulations.

♦ Ensure that there is a conductive connection bet ween the housing of

the converters or inverters and the mounting surface. The use of

mounting surfaces with good conducting properties (e.g. galvanized

steel plate) is recommended. If the mounting surface is insulated

(e.g. by paint), use contact washers or serrated washers.

♦ All of the metal cabinet parts must be connected through the largest

possible surface area and must provide good conductivity.

If necessary, use contact washers or serrated washers.

♦ Connect the cabinet doors to the cabinet frame using grounding

strips which must be kept as short as possible.

♦ For the connection between converter/inverter and motor, use

shielded cables which have to be grounded on both sides over a

large surface area.

If the motor terminal box is of plastic, additional grounding strands

have to be inserted.

♦ The shield of the motor supply cable must be connected to the

shield connection of the converter and to the motor mounting panel

through the largest possible surface area.

♦ The motor cable shield must not be interrupted by output reactors,

fuses or contactors.

♦ All signal cables must be shielded. Separate the signal cables

according to signal groups.

Do not route cables with digital signals unshielded next to cables

with analog signals. If you use a common signal cable for both, the

individual signals must be shielded from each other.

♦ Power cables must be routed separately away from signal cables (at

least 20 cm apart). Provide partitions between signal cables and

power cables. The partitions must be grounded.

♦ Connect the reserve cables/conductors to ground at both ends to

achieve an additional shie ldi ng ef f e ct .

♦ Lay the cables close to grounded plates as this will reduce the

injection of undesired signals.

♦ Eliminate any unnecessary cable lengths because these will

produce additional coupling capacitances and inductances.

♦ Use cables with braided shields. Cables with foil shields have a

shielding effect which is worse by a factor of five.

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 23

Installation in Conformance with EMC Regulations 05.2003

6SE7087-6JP60 Siemens AG

6-2 Operating Instructions SIMOVERT MASTERDRIVES

♦ Use a noise suppression filter in the incoming powerline.

Connect the noise suppression filter to ground and to the converter

through a large surface area.

It is best to directly mount the noise suppression filter on the same

good conductive mounting surface as the converter or inverter.

You must insert a line reactor between the noise suppression filter

and the unit.

♦ Contactor operating coils that are connected to the same supply

network as the converter or that are located in close proximity of the

converter must be connected to overvoltage limiters (e.g. RC

circuits, varistors).

Further information is contained in the chapter 3 "Instructions for

Design of Drives in Conformance with EMC Regulations" of the

Compendium. The Compendium can be found on the attached CD and

can also be ordered as a hard copy (Order No.: 6SE7087-6QX60).

This product has limited availability in accordance with IEC 61800-3.

This product can cause radio interference in residential areas. In such a

case, it may be necessary for the operator to take suitable action.

In line with the EMC product standard for variable-speed drives

EN 61800-3:1996 + A11:2000 Chapter 6.3.2.3 b) drive systems (PDS =

Power Drive Systems) have to compl y with the lim it values (in

accordance with Table 11 and Table 12 of the above-mentioned

standard).

For technical reasons there are a number of applications in which it is

not possible for PDS to comply with these limit values.

Such applications are:

♦ IT networks in complex systems

♦ Applications in which the necessary dynamic operational behavior is

limited on account of filter effects.

This note must be particularly observed for option L20 (operation on

non-grounded network s).

CAUTION

NOTE

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 24

05.2003 Connecting-up

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 7-1

7 Connecting-up

SIMOVERT MASTERDRIVES units are operated at high voltages.

The equipment must be in a no-voltage condition (disconnected from

the supply) before any work is carried out!

Only professionally trained, qualified personnel must work on or with

the units.

Death, severe bodily injury or significant property damage could occur if

these warning instructions are not observ ed.

Hazardous voltages are still present in the unit up to 5 minutes after it

has been powered down due to the DC link capacitors. Thus, the

appropriate delay time must be observed before working on the unit or

on the DC link terminals.

The power terminals and control terminals can still be live even when

the motor is stationary.

If the DC link voltage is supplied centrally, the converters must be

reliably isolated from the DC link voltage!

When working on an opened unit, it should be observed that live

components (at hazardous voltage levels) can be touched (shock

hazard).

The user is responsible that all the units are installed and connected-up

according to recognized regulations in that particular country as well as

other regionally valid regulations. Cable dimensioning, fusing,

grounding, shutdown, isolation and overcurrent protection should be

particularly observed.

Due to their physical characteristics, converters can produce DC

residual currents. If a residual-current protective device (residualcurrent-operated circuit-breaker) is used on the supply side of the

AC/AC converter - or of the rectifier unit in the case of multi-motor

drives - for protective purposes in case of indirect touching, only type B

to IEC 755 is permitted. Due to radio-interference suppression

capacitors and as a result of the parasitic capacity of the motor cable,

leakage currents flow which can lead to undesired responding of the

residual-current protective device.

In general, operation without faults is possible only under the following

conditions:

♦ Rated residual current of the residual-current protective

device ≥ 300 mA

♦ Short motor cables (l < 20 m)

♦ No radio-interference suppression filter built in

♦ Only one converter connected per residual-current protective device

DANGER

NOTICE

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 25

Connecting-up 05.2003

6SE7087-6JP60 Siemens AG

7-2 Operating Instructions SIMOVERT MASTERDRIVES

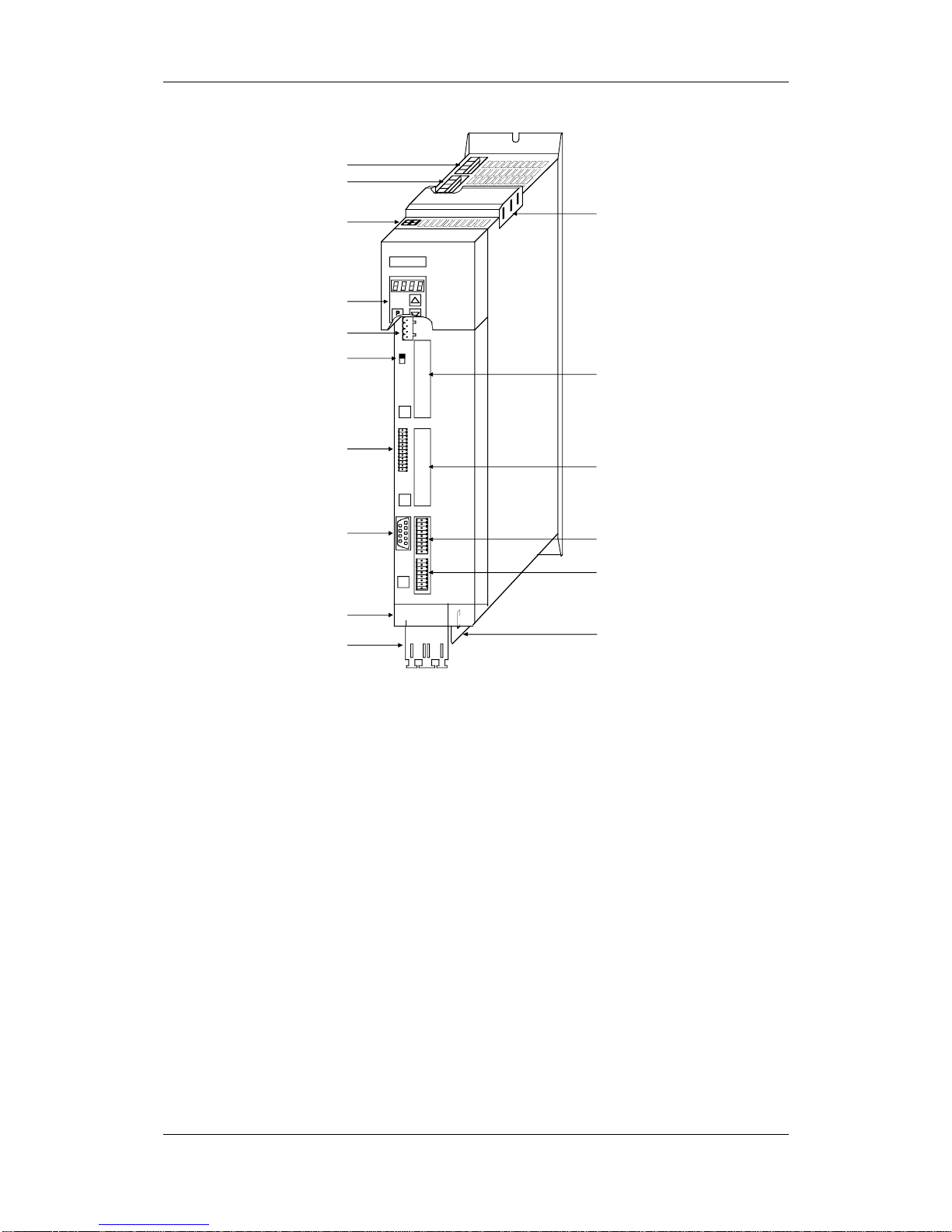

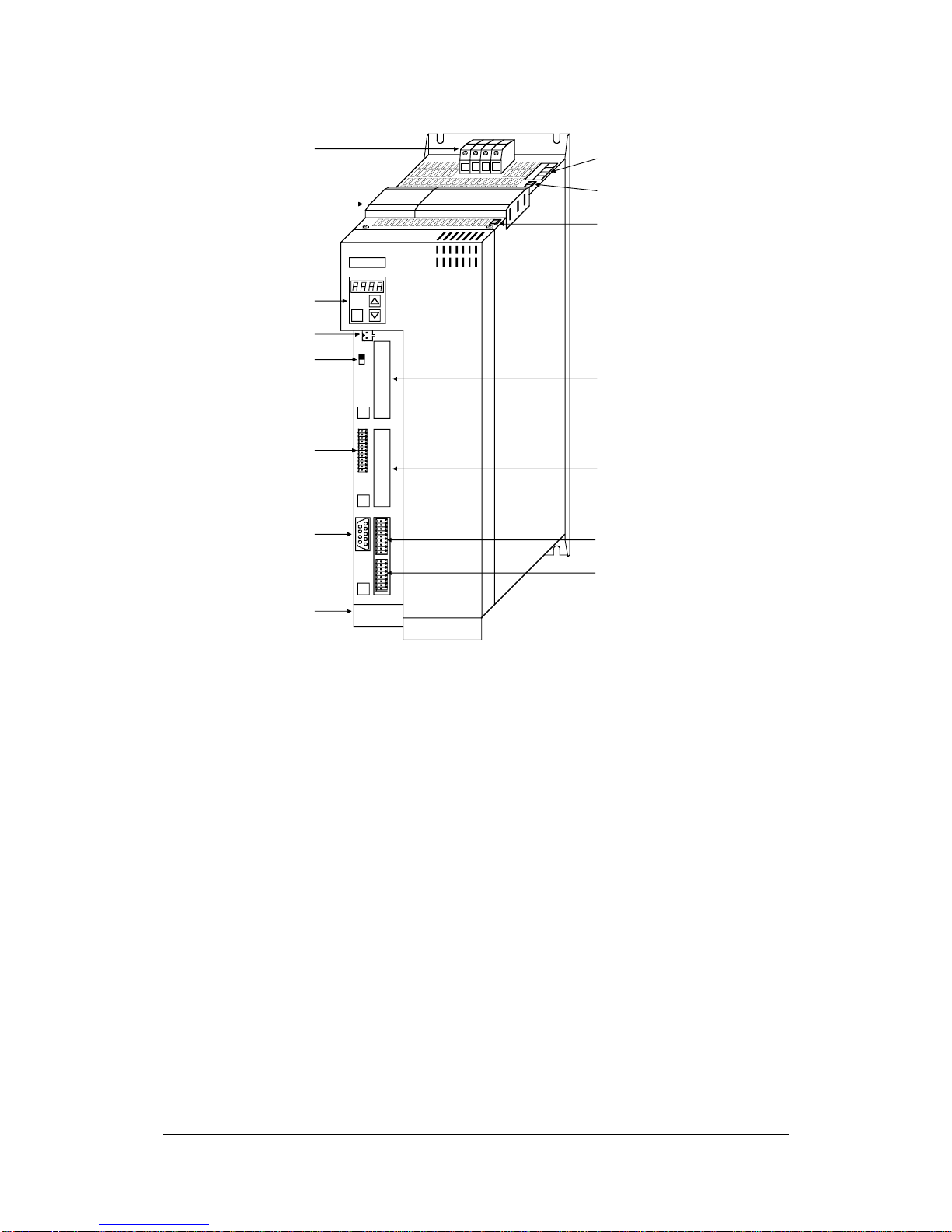

SIEMENS

X100

A

S1

BX101

CX103

PMU

RS232 / RS485 (U SS) X103

Slot A

Slot B

Terminal strip

X102

Motor connecti on X2

PE3

−−−−

++++

Encoder connection

X104

Mains connection X1

Brake r esisto r, X6

Capaci t or module

X3 DC link bus

module

DC24 V output,

RS485 (USS) X100

Bus terminating resistor (USS) S1

Termina l st r ip X1 01

Shield co nn ec t i on

for cont rol cables

Shield co nn ec t i on

for motor cable

External DC24 V supply X9

X533 Safe STOP (option)

Fig. 7-1 Connection overview for units up to 90 mm wide

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 26

05.2003 Connecting-up

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 7-3

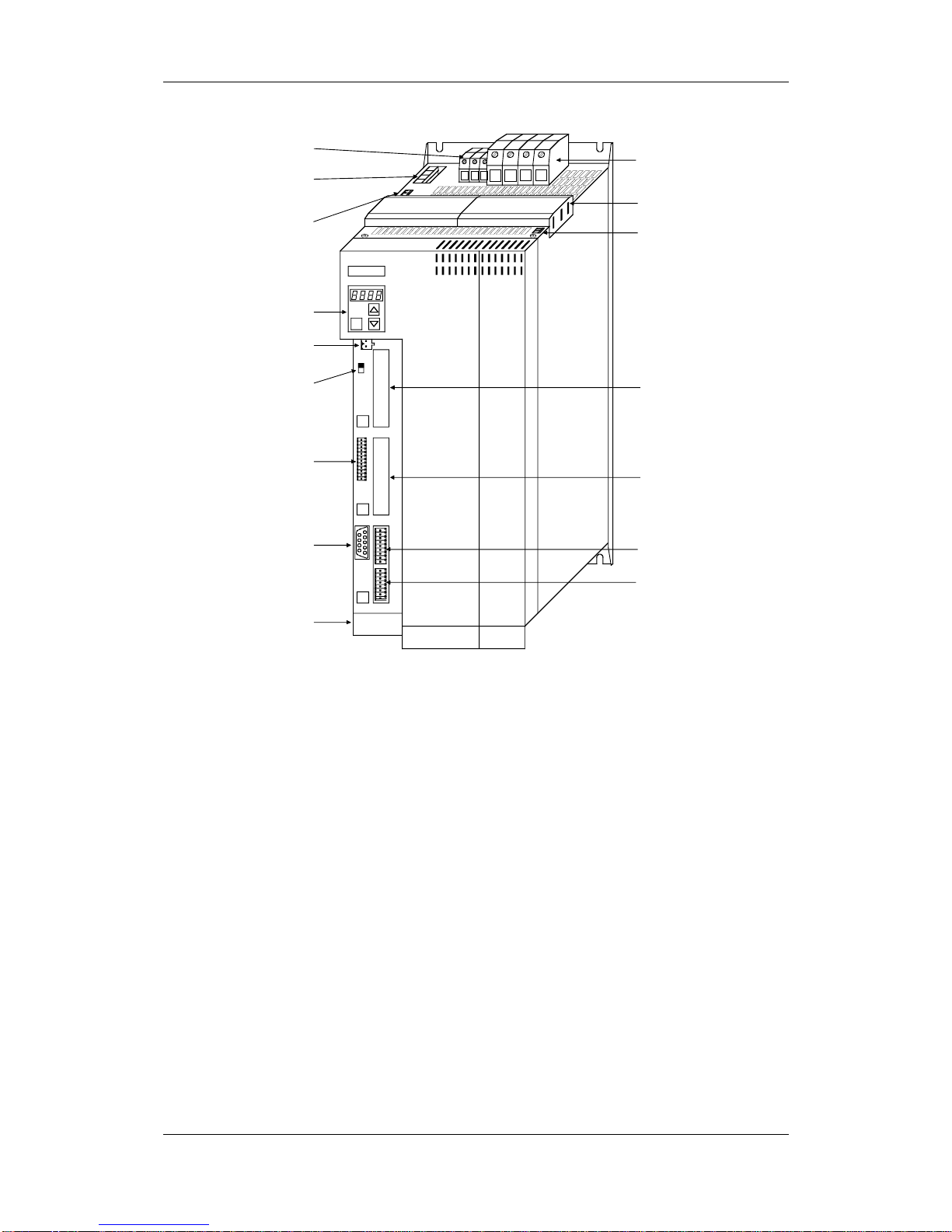

SIEMENS

A

S1

BX101

CX103

P

V1U1PE W1

PMU

RS232/ RS485 (U SS) X103

PE3

−−−−

++++

Slot A

Slot B

X533 Safe stop (option)

Terminal strip

X102

Encoder connection

X104

Mains connection X1

DC link bus module X3

DC24 V output,

RS485 (USS) X100

Bus termin at in g

resistor (USS) S1

X6 Brake resist or,

Capacitor module

X9 External DC24 V supply

Termina l st r ip X1 01

Motor connection X2

Fig. 7-2 Connection overview for units 135 mm wide

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 27

Connecting-up 05.2003

6SE7087-6JP60 Siemens AG

7-4 Operating Instructions SIMOVERT MASTERDRIVES

GHPE

SIEMENS

A

S1

BX101

CX103

P

W1V1U1PE

PMU

RS232/ RS485 (U SS) X103

PE3

−−−−

++++

Slot A

Slot B

X533 Safe stop

(option)

Terminal strip

X102

Encoder connection

X104

Brake r esisto r X6

Precharging

Capacitor module X7

External DC24 V

supply X9

X1 Mains connection

X3 DC link bus

module

DC24 V output,

RS485 (USS) X100

Bus termin at in g

resistor (USS) S1

Termina l st r ip X1 01

Motor connection X2

Fig. 7-3 Connection overview for units 180 mm wide

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 28

05.2003 Connecting-up

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 7-5

7.1 Power connections

Protective conductor

The protective conductor must be connected up both on the mains side

and on the motor side.

On account of leakage current through the interference-suppression

capacitors the following must be observed as per EN 50178

• A minimum cross-section of 10 mm

2

Cu must be used or

• If supply connections with cross-sections less than 10 mm

2

are

used, two protective conductors have to be connected up. The

cross-section of each of the protective conductors corresponds to

the cross-section of an outer conductor.

If the unit is mounted on a grounded mounting surface via a conductive

connection, the protective conductor cross section can be the same as

that of the phase conductor. The function of the second protective

conductor is afforded by the grounded mounting surface.

7.1.1 Power connections for units with a width up to 90 mm

There is an additional ground connection in the form of an M4 threaded

bolt at the upper section of the unit located next to the X1 mains

connection

.

This is used for connecting up the second protective conductor in

accordance with EN 50178.

The mains connection is situated at the top of the unit.

Terminal Meaning Range

PE1 Protective conductor connection

W1 Phase W1 / L3 3 AC 380 V - 480 V

V1 Phase V1 / L2 3 AC 380 V - 480 V

U1 Phase U1 / L1 3 AC 380 V - 480 V

Connectable cross-section: 4 mm² (AWG 10)

Terminal U1 is at the front when installed.

Table 7-1 Mains connection

The connector has to be screwed firmly to the housing (providing

resistance to vibration and protecting against being inadvertently

withdrawn).

WARNING

NOTE

Ground connection

X1 - Mains

connection

W1PE1 V1 U1

CAUTION

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 29

Connecting-up 05.2003

6SE7087-6JP60 Siemens AG

7-6 Operating Instructions SIMOVERT MASTERDRIVES

The DC link bus module serves as the electrical connection of the

individual units on the DC link side. It is of significance if further

inverters also have to be fed.

Bar Designation Meaning Range

3 PE3 Protective conductor connection

2 D / L- DC link voltage - DC 510 - 650 V

1 C / L+ DC link voltage + DC 510 - 650 V

Connectable cross-section: "Electro-plated copper" 3x10 mm, rounded

off according to DIN 46433 (EN 13601)

Bar 1 is at the front when installed.

Table 7-2 DC link bus module

The motor connection is located at the lower section of the unit.

Terminal Meaning Range

PE2 Protective conductor connection

U2 Phase U2 / T1 3 AC 0 V - 480 V

V2 Phase V2 / T2 3 AC 0 V - 480 V

W2 Phase W2 / T3 3 AC 0 V - 480 V

Connectable cross-section: 4 mm² (AWG 10)

Terminal PE2 is at the front when installed.

Table 7-3 Motor connection

The connector has to be screwed firmly to the housing (providing

resistance to vibration and protecting against being inadvertently

withdrawn).

The motor cables must be dimensioned in accordance with VDE 298,

Part 2.

After installation of the connector, the shield of the motor cable must be

fixed to the shield plate through a large surface area.

X3 - DC link bus

module

X2 – Moto

r

connection

U2PE2 V2 W 2

CAUTION

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 30

05.2003 Connecting-up

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 7-7

The connection for the external braking resistor and the pre-charging of

the capacitor module is provided on the top of the unit.

Terminal Meaning

C´ Pre-charging for capacitor module

G Braking resistor

H Braking resistor

D´ Pre-charging for capacitor module

Connectable cross-section: 4 mm² (AWG 10)

Terminal D’ is at the front when installed.

Table 7-4 Connection of the braking resistor and pre-charging of the capacit or

module

The motor cables must be dimensioned in accordance with VDE 298,

Part 2.

After installation of the connector, the shield of the motor cable must be

fixed to the shield plate through a large surface area.

The connector has to be screwed firmly to the housing (providing

resistance to vibration and protecting against being inadvertently

withdrawn).

♦ During operation, the full DC link voltage is always present at the

terminals for pre-charging the capacitor module.

♦ During pre-charging, the charging current of all connected capacitor

modules flows via the terminals.

♦ For reasons of protection, cables with 4 mm² Cu should be used at

connection X6!

Length of connecting cable between converter and external brake

resistor < 15 m.

X6 – Braking

resistor and precharging of the

capacitor module

GHD'C'

CAUTION

DANGER

CAUTION

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 31

Connecting-up 05.2003

6SE7087-6JP60 Siemens AG

7-8 Operating Instructions SIMOVERT MASTERDRIVES

7.1.2 Power connections for units with a width of 135 mm

The mains connection is to a terminal block on top of the unit.

Terminal Meaning Range

PE Protective conductor connection

U1 / L1 Phase U1 / L1 3AC 380 - 480 V

V1 / L2 Phase V1 / L2 3AC 380 - 480 V

W1 / L3 Phase W1 / L3 3AC 380 - 480 V

Connectable cross-section: 10 mm² (AWG 8), stranded

Viewed from the front, Terminal W1 is at the right.

Table 7-5 Mains connection

The DC link bus module serves as the electrical connection of the

individual units on the DC link side. It is of significance if further

inverters also have to be fed.

Bar Designation Meaning Range

3 PE3 Protective conductor connection

2 D / L- DC link voltage - DC 510 - 650 V

1 C / L+ DC link voltage + DC 510 - 650 V

Connectable cross-section: "Electro-plated copper" 3x10 mm, rounded

off according to DIN 46433 (EN 13601)

Bar 1 is at the front when installed.

Table 7-6 DC link bus module

The motor connection is to a terminal block at the bottom of the unit.

Terminal Meaning Range

PE Protective conductor connection

U2 / T1 Phase U2 / T1 3AC 0 V - 480 V

V2 / T2 Phase V2 / T2 3AC 0 V - 480 V

W2 / T3 Phase W2 / T3 3AC 0 V - 480 V

Connectable cross-section: 10 mm² (AWG 8), stranded

Viewed from the front, Terminal W2 is at the right.

Table 7-7 Motor connection

The motor cables must be dimensioned in accordance with VDE 298,

Part 2.

After installation of the connector, the shield of the motor cable must be

fixed to the shield plate through a large surface area.

X1 Mains connection

PE U1 V1 W1

X3 - DC link bus

module

X2 -

Moto

r

connection

PE U2 V2 W2

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 32

05.2003 Connecting-up

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 7-9

The connection for the external braking resistor and the pre-charging of

the capacitor module is provided on the top of the unit.

Terminal Meaning

D´ Pre-charging for capacitor module

H Braking resistor

G Braking resistor

C´ Pre-charging for capacitor module

Connectable cross-section: 4 mm² (AWG 10)

Terminal C’ is at the front when installed.

Table 7-8 Connection of the braking resistor and pre-charging of the capacit or

module

The connector has to be screwed firmly to the housing (providing

resistance to vibration and protecting against being inadvertently

withdrawn).

♦ During operation, the full DC link voltage is always present at the

terminals for pre-charging the capacitor module.

♦ During pre-charging, the charging current of all connected capacitor

modules flows via the terminals.

♦ For reasons of protection, cables with 4 mm² Cu should be used at

connection X6!

Length of connecting cable between converter and external brake

resistor < 15 m.

X6 - Braking resisto

r

and pre-charging of

the capacitor module

GHD'C'

CAUTION

DANGER

CAUTION

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 33

Connecting-up 05.2003

6SE7087-6JP60 Siemens AG

7-10 Operating Instructions SIMOVERT MASTERDRIVES

7.1.3 Power connections for units with a width of 180 mm

The mains connection is to a terminal block on top of the unit.

Terminal Meaning Range

PE Protective conductor connection

U1 / L1 Phase U1 / L1 3AC 380 - 480 V

V1 / L2 Phase V1 / L2 3AC 380 - 480 V

W1 / L3 Phase W1 / L3 3AC 380 - 480 V

Connectable cross-section: 25 mm² (AWG 4), stranded

Viewed from the front, Terminal W1 is at the right.

Table 7-9 Mains connection

The DC link bus module serves as the electrical connection of the

individual units on the DC link side. It is of significance if further

inverters also have to be fed.

Bar Designation Meaning Range

3 PE3 Protective conductor connection

2 D / L- DC link voltage - DC 510 - 650 V

1 C / L+ DC link voltage + DC 510 - 650 V

Connectable cross-section: "Electro-plated copper" 3x10 mm, rounded

off according to DIN 46433 (EN 13601)

Bar 1 is at the front when installed.

Table 7-10 DC link bus module

The motor connection is to a terminal block at the bottom of the unit.

Terminal Meaning Range

PE Protective conductor connection

U2 / T1 Phase U2 / T1 3AC 0 V - 480 V

V2 / T2 Phase V2 / T2 3AC 0 V - 480 V

W2 / T3 Phase W2 / T3 3AC 0 V - 480 V

Connectable cross-section: 16 mm² (AWG 6), stranded

Viewed from the front, Terminal PE is at the left.

Table 7-11 Motor connection

The motor cables must be dimensioned in accordance with VDE 298,

Part 2.

After installation of the connector, the shield of the motor cable must be

fixed to the shield plate through a large surface area.

X1 Mains connection

PE U1 V1 W1

X3 - DC link bus

module

X2 Motor connection

PE U2 V2 W2

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 34

05.2003 Connecting-up

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 7-11

The connection of the external braking resistor is to a terminal block on

the top of the unit on the left next to the mains connection.

Terminal Meaning

PE Protective conductor connection

H Braking resistor connection

G Braking resistor connection

Connectable cross-section: 10 mm² (AWG 4), stranded

Viewed from the front, Terminal PE is at the left.

Table 7-12 Braking resistor connection

Length of connecting cable between converter and brake resistor

< 15 m.

The connection for pre-charging the capacitor module is on the top of

the unit.

Terminal Meaning

C´ Pre-charging of capacitor module

C´ Pre-charging of capacitor module

D´ Pre-charging of capacitor module

D´ Pre-charging of capacitor module

Connectable cross-section: 4 mm² (AWG 10)

Terminal D’ is at the front when installed.

Table 7-13 Connection of precharging capacitor module

The connector has to be screwed firmly to the housing (providing

resistance to vibration and protecting against being inadvertently

withdrawn).

♦ During operation, the full DC link voltage is always present at the

terminals for pre-charging the capacitor module.

♦ During pre-charging, the charging current of all connected capacitor

modules flows via the terminals.

♦ For reasons of protection, cables with 4 mm

2

Cu should be used at

connection X7!

X6 – Braking

resistor connection

PE H G

CAUTION

X7 – Pre-charging o

f

capacitor module

D'C' C' D'

CAUTION

DANGER

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 35

Connecting-up 05.2003

6SE7087-6JP60 Siemens AG

7-12 Operating Instructions SIMOVERT MASTERDRIVES

7.2 Control connections

In the basic version, the unit has the following control connections:

♦ External 24 V supply

♦ 24 V voltage output, USS bus connection (RS485)

♦ Serial interface for PC or OP1S

♦ Control terminal strip.

Before the control cables and encoder cables are connected or

disconnected, the unit must be disconnected from the supply (24 V

electronic power supply and DC link/line voltag e)!

If this measure is not observed, this can result in defects on the

encoder. A defective encoder can cause uncontrolled axis movements.

The external 24 V infeed and all circuits connected to the control

terminals must meet the requirements for safety separation as

stipulated in EN 50178 (PELV circuit = Protective E

xtra Low Voltage).

Standard

connections

WARNING

WARNING

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 36

05.2003 Connecting-up

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 7-13

Bidirectional

digital inputs

and outputs

I

out

≤ 20 mA

X101

5V

24V

In

Out

Out

In

Out/In

In

Out

In

Out

In

Out

In

Out

In

4 bidirectional digital inputs/outputs

Outputs

Reference voltage

P10 V / N10 V

I ≤ 5 mA

Aux. power

supply

60 mA

5V

24V

In

5V

24V

2

1

3

4

5

6

7

8

19

10

11

12

Micro-

controller

P5V

BOOT

RS232 TxD

Digital inputs

Ri = 3.4 k

Ω

1

23

456789

RS232 RxD

PMU X103

13

14

P10

N10

Slot B

Slot A

BOOT

n.c.

15

16

D

A

D

A

In

5V

24V

1

2

17

18

D

A

S3

45

-10...+10 V

D

A

-10...+10 V

M

M

X102

In

In

A

S

I

C

30

29

28

27

26

25

24

23

Track A

Track B

Tacho M

zero

Control

Tacho P24

Mottemp BS

Mottemp

X104

Pulse

encoder

I≤190 mA

Motor

temperature

sensor

KTY84 or

PTC thermistor

AI 1

AI 2

Analog input 2

(non-floating)

11 bit + sign

U: R

in

= 60 k

Ω

I: R

in

= 250 Ω=(close S3)

10 bit + sign

U: I ≤ 5 mA

AO 2

AO 1

Analog output 2

Analog output 1

RS485P.

9

Inputs

21

20

HS1

HS2

Digital input

Ri = 3.4 kΩ

Analog input 1

(non-floating)

11 bit + sign

R

in

= 60 kΩ

Serial interface 2

(RS485)

24 V output

Serial interface 1

(RS232)

Floating contact switch

30 V / 0.5 A

Out

10 bit + sign

U: I ≤ 5 mA

I: 0...+20 mA

0...+20 mA

3

S4

RS485N.

Exte r nal 24 V

supply

OFF

ON

Bus terminating resistor

P24 AUX

M24

RS485N

RS485P

UART

35

36

P24V

M24

34

33

X9

1

2

+

24 V

ext.

-

int. 24 V-SNT

NTC

X100

Controller

F1

*)

*)

Type of fuse -F1: Miniature circuit-breaker 6 A characteristic C

e. g. Siemens 5SX2 106-7 (see attached sheet)

Fig. 7-4 Overview of the standard connections

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 37

Connecting-up 05.2003

6SE7087-6JP60 Siemens AG

7-14 Operating Instructions SIMOVERT MASTERDRIVES

In order to also enable the unit to be parameterized and monitored with

the DC link discharged (e.g. line interruption), an external 24 V voltage

supply is necessary. The two-pole connection required for this is

situated at the top of the unit.

With the DC link charged, the voltage is supplied by an internal switchmode power supply.

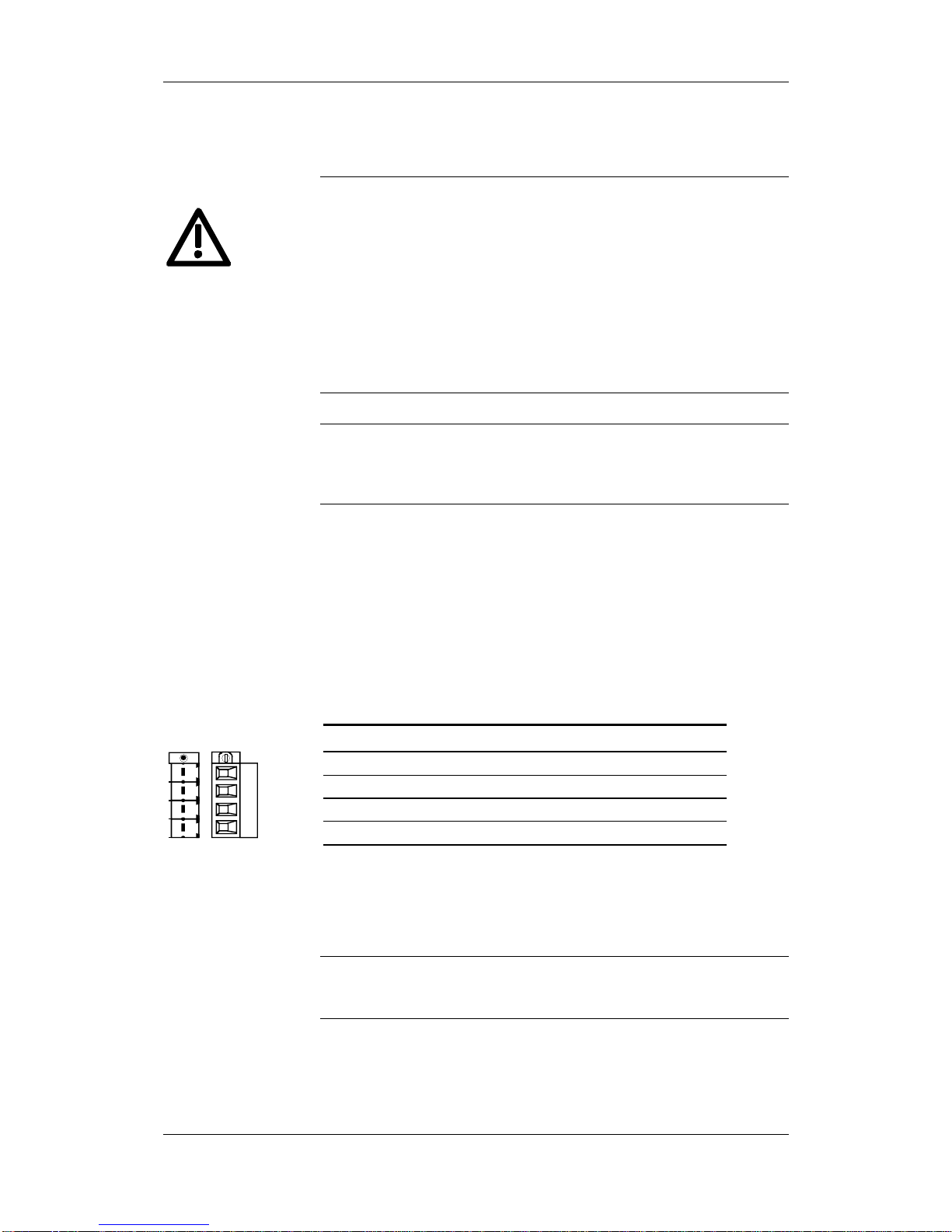

Terminal Designation Meaning Range

2 +24 V External 24 V supply DC 18 V - 30 V

1 0 V Reference potential DC 18 V - 30 V

Connectable cross-section: 2.5 mm² (AWG 12)

Terminal 1 is at the front when installed.

Table 7-14 External 24 V supply

In standby mode, the unit has a current drain of 700 mA. This is

increased if optional cards are inserted.

The unit is provided with a 24 V voltage output to which a maximum of

two further converters can be connected.

One further inverter can be connected to the 24 V voltage output in the

case of a unit with a housing width of 45 mm.

The USS bus connection is linked with the control electronics and the

9-pole SUB D socket of the serial interface.

The bus terminating resistor can, if required, be powered up by means

of the switch S1 located next to the bus connection. In the upper

position, the bus termination is switched in.

Power-up is necessary if the unit is located at one end of the USS bus.

Terminal Designation Meaning Range

33 +24 V (out) 24 V voltage output DC 18 V – 30 V

34 0 V Reference potential 0 V

35 RS485P (USS) USS bus connection RS485

36 RS485N (USS) USS bus connection RS485

Connectable cross-section: 2.5 mm² (AWG 12)

Terminal 33 is at the top when installed.

Table 7-15 24 V voltage output, USS bus

The RS485 interface can be operated either via -X100 or -X103.

X9 - External

24 V supply

1

2

X9 for 135 mm and

180 mm wide units

1

2

X9

X9 for 45 mm,

67.5 mm und 90 mm

wide units

X100 24 V voltage output,

USS bus

33

34

35

36

NOTICE

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 38

05.2003 Connecting-up

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 7-15

The following connections are provided on the control terminal strip:

♦ 4 combined digital inputs and outputs

♦ 2 additional digital inputs

♦ 1 analog input

♦ 1 analog output

♦ 24 V auxiliary voltage supply (max. 60 mA, output only!) for the

inputs.

If the digital inputs are supplied by an external 24 V voltage supply, it

must be referred to ground terminal X101.2. Terminal X101.1 (P24

AUX) must not be connected to the external 24 V supply.

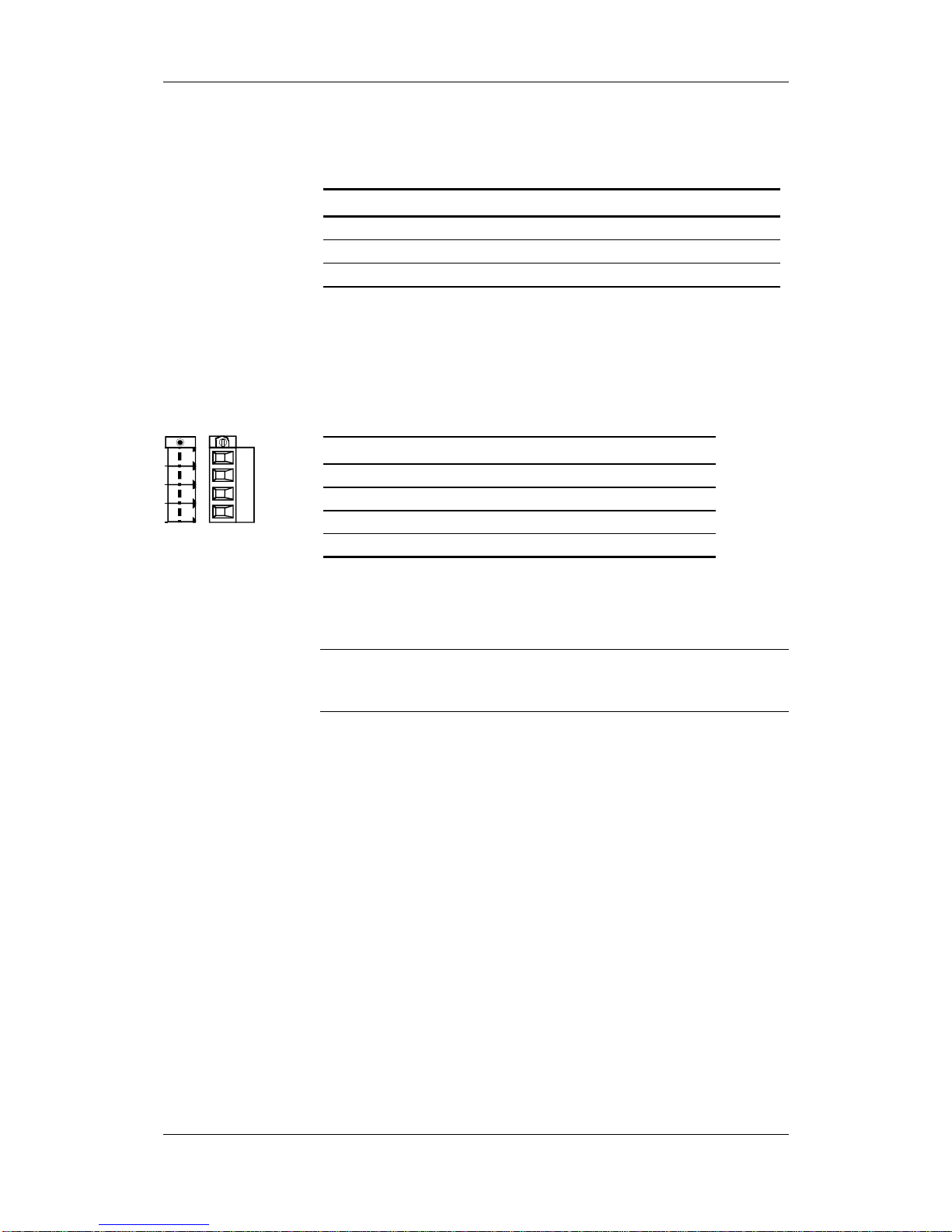

Terminal Designation Meaning Range

1 P24 AUX Aux. voltage supply DC 24 V / 60 mA

2 M24 AUX Reference potential 0 V

3 DIO1 Digital input/output 1 24 V, 10 mA / 20 mA

4 DIO2 Digital input/output 2 24 V, 10 mA / 20 mA

5 DIO3 Digital input/output 3 24 V, 10 mA / 20 mA

6 DIO4 Digital input/output 4 24 V, 10 mA / 20 mA

7 DI5 Digital input 5 24 V, 10 mA

8 DI6 Digital input 6 24 V, 10 mA

9AI++++ Analog input ++++ 11 bit + sign

differential input:

10 AI−−−− Analog input −−−− ± 10 V / Ri = 40 kΩ

11 AO Analog output 10 bit + sign

± 10 V / 5 mA

12 M AO Ground analog output

Connectable cross-section: 0.14 mm² to 1.5 mm² (AWG 16)

Terminal 1 is at the top when installed.

Table 7-16 Control terminal strip

In the case of digital inputs, levels below 3 V are interpreted as low and

levels above 13 V as high.

X101 - Control

terminal strip

WARNING

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 39

Connecting-up 05.2003

6SE7087-6JP60 Siemens AG

7-16 Operating Instructions SIMOVERT MASTERDRIVES

♦ 10 V auxiliary voltage (max. 5 mA) for supplying external

potentiometers

♦ Analog output, suitable for use as current or voltage output

♦ 1 analog input, suitable for use as current or voltage input

♦ 1 additional digital input

♦ 1 floating NO contact

Terminal Designation Meaning Range

13 P10 V + 10 V supply for ext.

potentiometers

+ 10 V ± 1.3 %

I

max

= 5 mA

14 N10 V −−−− 10 V supply for ext.

potentiometers

−

−−

− 10 V ± 1.3 %

I

max

= 5 mA

15 AO2 Analog output 2 10 bit + sign

Voltage:

16 M AO2 Ground for analog output 2 ± 10 V / I

ma

x

= 5 mA

Current:

0...20 mA R ≤ 500 Ω

17 AI2 Analog input 2 11 bit + sign

Voltage:

18 M AI2 Ground for analog input 2

± 10 V / Ri = 60 kΩ

Current:

Rin = 250 Ω

19 DI7 Digital input 7 24 V, 10 mA

20 HS1 NO contact DC 30 V / max. 0.5 A

21 HS2 (floating) Minimum load 7 mA

Connectable cross-section: 0.14 mm2 to 1.5 mm2 (AWG 16)

Table 7-17 Control terminal strip X102

X102 Control terminal

strip

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 40

05.2003 Connecting-up

Siemens AG 6SE7087-6JP60

SIMOVERT MASTERDRIVES Operating Instructions 7-17

It is possible to connect either an OP1S or a PC with RS232 or RS485

serial interface via the 9-pole SUB D socket. There are different

connecting cables for the PC for the various transmission protocols.

The 9-pole SUB D socket is internally coupled with the USS bus, thus

enabling data exchange with other nodes link ed via the USS bus .

This interface is also used for loading software.

Pin Designation Meaning Range

1 NC Not assigned Low active

2 RS232 RxD Receive data via RS232 RS232

3 RS485 P Data via RS485 interface RS485

4 Boot Control signal for software update Low active

5 M5 AUX Reference potential to P5V 0 V

6 P5V 5 V aux. voltage supply +5 V, max. 200 mA

7 RS232 TxD Transmit data via RS232 RS232

8 RS485 N Data via RS485 interface RS485

9 M_RS232/485 Digital ground (choked)

Table 7-18 Serial interface

The RS485 interface can be operated either via -X100 or -X103.

The control terminal strip includes a connection for a pulse generator

(HTL unipolar) and the motor temperature evaluation circuit with KTY or

PTC.

Terminal Designation Meaning Range

23 −−−− V

PP

Ground for power supply

24 Track A Connection track A

25 Track B Connection track B

26 Zero pulse not evaluated

27 CTRL Connection control track

HTL unipolar;

L ≤ 3 V, H ≥ 8 V

28 + V

PP

Pulse generator power

supply

24 V

I

max

= 190 mA

29 −−−− Temp Minus (−−−−) terminal

KTY84/PTC

30 + Temp Plus (++++) terminal

KTY84/PTC

KTY84: 0...200 °C

PTC: R

cold

≤ 1.5 kΩ

Connectable cross-section: 0.14 mm2 to 1.5 mm2 (AWG 16)

Table 7-19 Control terminal strip X104

X103 - Serial

interface

1

5

6

9

NOTICE

X104 –

Control terminal

strip

Aotewell Ltd

www.aotewell.com

Industry Automation

HongKong|UK|China

sales@aotewell.com

+86-755-8660-6182

Page 41

Connecting-up 05.2003

6SE7087-6JP60 Siemens AG

7-18 Operating Instructions SIMOVERT MASTERDRIVES

With the safe stop option, the power supply for the transmission of

pulses into the power section can be interrupted through a safety relay.

This ensures that the unit will definitely not generate a rotating field in

the connected motor.

Even if the control electronics generates trigger commands, the power

section cannot move the motor.

This enables mechanical work to be performed on the drive or on

coupled machine parts with energi zed li ne vo lta ge and with out el ectr ic al

isolation of the motor to the unit.

The "safe stop" function is a "device for the prevention of unexpected

starting" in accordance with EN 60204-1, Section 5.4, and meets the

requirements of Safety Category 3 to EN 954-1 by virtue of appropriate

external protective circuitry.

The safe stop option is not suitable for bringing a rotating motor to a

quick halt as by de-energizing the trigger signals, the motor is only

braked by the connected load.

The motor cannot produce a torque when the "safe stop" function is

activated. Where external forces are applied to the drive axes or with