Page 1

599 Series

Technical Instructions

2- Way Ball Valves

Document No. 155-703P25

VF 599-9

February 4, 2016

Description

Features

Application

The 599 Series 2-way Ball Valves are coupled with OpenAir™ actuat ors to provide

equal percentage flow control. The ball valves are 1/4-turn rotary control valves and

are available in 1/2-inch to 2-inch line sizes.

· ANSI 250 valve body rating.

· 200 psi close-off with ANSI Cl ass IV leakage for all line sizes and actuators.

· Available with chrome-pl ated brass ball and brass stem or

stainless steel ball and stem.

· Blow-out proof stem withstands high pressure.

· Universal mounting plate.

· Actuator and plate can be rotated (90 degree increments).

· Standoffs provide a thermal barrier between the act uator and the m ounting

plate.

· Operating handle for manual operation.

Ball valves can control hot or chilled water and up t o 50% water-glycol solution i n

air handling units, convectors, fan coil units, unit conditioners, radiators, and reheat

coils.

WARNING:

Personal injury or loss of life may occur if you do not

perform a procedure as specified.

Product Numbers

Accessories/Kits

CAUTION:

See Error! Reference source not found. through Table 12.

599-10078 Ball Valve Bracket Kit

(includes bracket, mounting screws, shaft and handle)

599-10080 Ball Valve Weather Shield

(provides NEMA 3R protection)

Equipment dam age may occur if you do not perform a

procedure as specified.

Page 2

Technical Instructions 599 Series 2-Way Ball Valves

Docume nt Numbe r 155-703P25

February 4, 20 16

Specifications

Material

Body Brass: ASTM B283, C37700

Ball Chrome-plated brass or stainl ess steel

Ball seals Glass filled PTFE with EPDM O-rings

Flow characterizer Glass filled PTFE

End connections Female NPT

St em Brass or stainl ess steel

Stem seals EPDM O-rings

Operating

Valve body rati ng ANSI 250/600 WOG

Media temperature 35°F to 250°F (2°C to 121°C)

Controlled medium Water, water-glycol solutions to 50%

Angle of rotation 0° to 90°

Close-off rati ng 200 psi (ANSI Class IV)

Miscellaneous

Canadian Registrat ion Number OC8213.5ADD4

Mounting location NEMA 1 (interior only)

Dimensions, service envelope, weight See Figure 6 and Table 14.

Ordering a

Valve/Actuator

To order a com plete valve plus actuator assembl y from the factory, combine an

actuator prefix code (see Table 1) with the suffix of the valve assembly product number.

Assembly

Table 1. Actuator Prefix Codes.

Actuator Prefix Code OpenAir Actuator * Control

171A GDE131.1P Floating, fail-in-place

171B GLB131.1P Floating, fail-in-place

171C GDE161.1P 0 to 10 Vdc, fail-in-place

171D GLB161.1P 0 to 10 Vdc, fail-in-place

171E GMA121.1P 2-position, fail-safe, normally open

171F GMA131.1P Floating, fail-safe, normally open

171G GMA161.1P 0 to 10 Vdc, fail-safe, normally open

171H GQD121.1P 2-position, fail-safe, normally open

171J GQD131.1P Floati ng, fail-safe, normally open

171K GQD151.1P 2 to 10 Vdc fail-safe, normally open

171L GQD221.1U 120V, 2-position, fail-safe, normally open

171M GMA221.1U 120V, 2-position, fail-safe, normally open

171N GQD126.1P 2-position, fail-safe, normally open, dual auxiliary switches

171P GMA126.1P 2-position, fail-safe, normally open, dual auxiliary switches

172E GMA121.1P 2-position, fail-safe, normally closed

172F GMA131.1P Floating, fail-safe, normally closed

172G GMA161.1P 0 to 10 Vdc, fail-safe, normally closed

172H GQD121.1P 2-position, fail-safe, normally closed

172J GQD131.1P Floati ng, fail-safe, normally closed

172K GQD151.1P 2 to 10 Vdc fail-safe, normally closed

172L GQD221.1U 120V, 2-position, fail-safe, normally closed

172M GMA221.1U 120V, 2-position, fail-safe, normally closed

172N GQD126.1P 2-position, fail-safe, normally closed, dual auxiliary switches

NEMA 3R (with weathershield)

Page 2 Siemens Industry, Inc.

Page 3

599 Series 2-Way Ball Valves Technical Instructions

Actuator Prefix Code OpenAir Actuator * Control

172P GMA126.1P 2-position, fail-safe, normally closed, dual auxiliary switches

173A GDE131.1Q** Floating, fail-in-place

173B GLB131.1Q** Floating, fail-in-place

173C GDE161.1Q** 0 to 10 Vdc, fail-in-place

173D GLB161.1Q** 0 to 10 Vdc, fail-in-place

*When ordered as an assembly, the actuator is provided with 3-foot (.9 m) wires.

**When ordered as an assembly, the actuator is provided with conduit adapter and 6-foot (1.8 m) wires.

Docume nt Numbe r 155-703P25

February 4, 20 16

See TB253 599 Ser ies Ball Valve and Actuator Assemblies Selection Technical

Bulletin (155-704P25) for complete selection procedures and ordering numbers

for both two-way and three-way ball valve assemblies.

Individual two-way ball valves can be ordered using the product numbers i n

through Table 6 for valves with a chrome-plated ball and brass stem or Error!

Not a valid result for table. through Table 11 for valves with stainless steel ball

and stem.

Figure 1.

Page 3 Siemens Industry, Inc.

Page 4

Technical Instructions 599 Series 2-Way Ball Valves

Conduit Adapter

Conduit Adapter

Docume nt Numbe r 155-703P25

February 4, 20 16

Table 2 . Fail-In Place Assemblies: Chrome-Plated Ball with Brass Stem (1/2-Inch and 3/4-Inch).

Fail-in-Place

Valve

Body

Product

Num ber *

599-10300

599-10301 0.63 (0.54) 171A-10301 173A-10301 171C-10301 173C-10301

599-10302 1.0 (0.9) 171A-10302 173A-10302 171C- 1030 2 173C-1030 2

599-10303 1.6 (1.4) 171A-10303 173A-10303 171C-10303 173C-10303

599-10304 2.5 (2.2) 171A-10304 173A-10304 171C-10304 173C-10304

599-10305 4.0 (3.4) 171A-10305 173A-10305 171C-10305 173C-10305

599-10306 6.3 (5.4) 171A-10306 173A-10306 171C-10306 173C-10306

599-10307* 10 (8.6) 171A-10307* 173A-10307* 171C-10307* 173C-10307*

599-10308

599-10309 10 (8.6) 171A-10309 173A-10309 171C-10309 173C-10309

599-10310 16 (14) 171A-10310 173A-10310 171C-10310 173C-10310

599-10311* 25 (22) 171A-10311* 173A-10311* 171C-10311* 173C-10311*

Valve

Size

Inches

(mm)

1/2

(15)

3/4

(20)

Flow Rate

Cv

(Kvs)

3 foot (.9m)

Close-Off ∆P in psi (kPa)

0.4 (0.34)

6.3 (5.4) 171A-10308 173A-10308 171C-10308 173C-10308

171A-10300 173A-10300 171C-10300 173C-10300

200 (1379)

Floating 0 to 10 Vdc

GDE

131.1P

Wires

171A 173A 171C 173C

*Denotes a full-port valve without flow characterizers insert.

Table 3. Fail-In-Place Assemblies: Chrome-Plated Ball with Brass Stem (1-Inch to 2-Inch)

GDE

131.1Q

Conduit Adapter

&

6-foot (1.8m)

Wires

Actuator Prefix Code

Fail-in-Place

GDE

161.1P

3 foot (.9m)

Wires

GDE

161.1Q

Conduit Adapter

&

6-foot (1.8m)

Wires

Valve

Body

Product

Num ber *

599-10312

599-10313 16 (14) 171A-10313 173A-10313 171C-10313 173C-10313

599-10314 25 (22) 171A-10314 173A-10314 171C-10314 173C-10314

599-10315 40 (34) 171A-10315 173A-10315 171C-10315 173C-10315

599-10316* 63 (54) 171A-10316* 173A-10316* 171C-10316* 173C-10316*

599-10317

599-10318 25 (22) 171A-10318 173A-10318 171C-10318 173C-10318

599-10319 40 (34) 171A-10319 173A-10319 171C-10319 173C-10319

599-10320 63 (54) 171A-10320 173A-10320 171C-10320 173C-10320

599-10321* 100 (90) 171A-10321* 173A-10321* 171C-10321* 173C-10321*

599-10322

599-10323 40 (34) 171B-10323 173B-10323 171D-10323 173D-10323

599-10324* 63 (54) 171B-10324* 173B-10324* 171D-10324* 173D-10324*

599-10325 100 (90) 171B-10325 173B-10325 171D-10325 173D-10325

599-10326* 160 (140) 171B-10326* 173B-10326* 171D-10326* 173D-10326*

599-10327

599-10328 63 (54) 171B-10328 173B-10328 171D-10328 173D-10328

599-10329* 100 (90) 171B-10329* 173B-10329* 171D-10329* 173D-10329*

599-10330* 160 (140) 171B-10330* 173B-10330* 171D-10330* 173D-10330*

Valve

Size

Inches

(mm)

1 (25)

1 1/4

(32)

1 1/2

(40)

2 (50)

Flow Rate

Cv

(Kvs)

GDE

131.1P

3 foot (.9m)

Close-Off ∆P in psi (kPa)

171A 171B 173A 173B 171C 171D 173C 173D

10 (9.0)

16 (14) 171A-10317 173A-10317 171C-10317 173C-10317

25 (22) 171B-10322 173B-10322 171D-10322 173D-10322

40 (34) 171B-10327 173B-10327 171D-10327 173D-10327

171A-10312 173A-10312 171C-10312 173C-10312

200 (1379)

Floating 0 to 10 Vdc

GLB

131.1P

Wires

GDE

131.1Q

&

6-foot (1.8m)

Wires

GLB

131.1Q

Actuator Prefix Code

GDE

161.1P

3 foot (.9m)

Wires

GLB

161.1P

GDE

161.1Q

&

6-foot (1.8m)

Wires

GLB

161.1Q

*Denotes a full-port valve without flow characterizers insert.

Page 4 Siemens Industry, Inc.

Page 5

599 Series 2-Way Ball Valves Technical Instructions

Fail-Safe

GQD121.1P

GQD131.1P

GQD151.1P

N.O.

N.C.

N.O.

N.C.

N.O.

N.C.

Actuator Prefix Code

171H

172H

171J

172J

171K

172K

Docume nt Numbe r 155-703P25

February 4, 20 16

Table 4. Fail-Safe Assemblies: Chrome-Plated Ball with Brass Stem (1/2-Inch and 3/4-Inch).

Valve

Body

Product

Number*

Valve

Size

Inches

(mm)

Flow Rate

Cv

(Kvs)

2-Position Floating 2 to 10 Vdc

Close-off ∆P in psi (kPa)

599-10300

599-10301 0.63 (0.54) 171H-10301 172H-10301 171J-10301 172J-10301 171K-10301 172K-10301

599-10302 1.0 (0.9) 171H-10302 172H-10302 171J-10302 172J-10302 171K-10302 172K-10302

599-10303 1.6 (1.4) 171H-10303 172H-10303 171J-10303 172J-10303 171K-10303 172K-10303

599-10304 2.5 (2.2) 171H-10304 172H-10304 171J-10304 172J-10304 171K-10304 172K-10304

599-10305 4.0 (3.4) 171H-10305 172H-10305 171J-10305 172J-10305 171K-10305 172K-10305

599-10306 6.3 (5.4) 171H-10306 172H-10306 171J-10306 172J-10306 171K-10306 172K-10306

599-10307* 10 (8.6) 171H-10307* 172H-10307* 171J-10307* 172J-10307* 171K-10307* 172K-10307*

599-10308

599-10309 10 (8.6) 171H-10309 172H-10309 171J-10309 172J-10309 171K-10309 172K-10309

599-10310 16 (14) 171H-10310 172H-10310 171J-10310 172J-10310 171K-10310 172K-10310

599-10311* 25 (22) 171H-10311* 172H-10311* 171J-10311* 172J-10311* 171K-10311* 172K-10311*

1/2 (15)

3/4 (20)

0.4 (0.34)

6.3 (5.4) 171H-10308 172H-10308 171J-10308 172J-10308 171K-10308 172K-10308

171H-10300 172H-10300 171J-10300 172J-10300 171K-10300 172K-10300

200 (1379)

*Denotes a full-port valve without flow characterizer insert.

Table 5. Fail-Safe Assemblies: Chrome-Plated Ball with Brass Stem (1-Inch to 2-Inch).

Fail-Safe

Valve

Body

Product

Num ber *

599-10312

599-10313 16 (14) 171E-10313 172E-10313 171F-10313 172F-10313 171G-10313 172G-10313

599-10314 25 (22) 171E-10314 172E-10314 171F-10314 172F-10314 171G-10314 172G-10314

599-10315 40 (34) 171E-10315 172E-10315 171F-10315 172F-10315 171G-10315 172G-10315

599-10316* 63 (54) 171E-10316* 172E-10316* 171F-10316* 172F-10316* 171G-10316* 172G-10316*

599-10317

599-10318 25 (22) 171E-10318 172E-10318 171F-10318 172F-10318 171G-10318 172G-10318

599-10319 40 (34) 171E-10319 172E-10319 171F-10319 172F-10319 171G-10319 172G-10319

599-10320 63 (54) 171E-10320 172E-10320 171F-10320 172F-10320 171G-10320 172G-10320

599-10321* 100 (90) 171E-10321* 172E-10321* 171F-10321* 172F-10321* 171G-10321* 172G-10321*

599-10322

599-10323 40 (34) 171E-10323 172E-10323 171F-10323 172F-10323 171G-10323 172G-10323

599-10324* 63 (54) 171E-10324* 172E-10324* 171F-10324* 172F-10324* 171G-10324* 172G-10324*

599-10325 100 (90) 171E-10325 172E-10325 171F-10325 172F-10325 171G-10325 172G-10325

599-10326* 160 (140) 171E-10326* 172E-10326* 171F-10326* 172F-10326* 171G-10326* 172G-10326*

599-10327

599-10328 63 (54) 171E-10328 172E-10328 171F-10328 172F-10328 171G-10328 172G-10328

599-10329* 100 (90) 171E-10329* 172E-10329* 171F-10329* 172F-10329* 171G-10329* 172G-10329*

599-10330* 160 (140) 171E-10330* 172E-10330* 171F-10330* 172F-10330* 171G-10330* 172G-10330*

Valve

Size

Inches

(mm)

1

(25)

1-1/4

(32)

1-1/2

(40)

2

(50)

Flow

Rate

Cv

(Kvs)

Close-off ∆ P in psi (kPa)

10 (9.0)

16 (14) 171E-10317 172E-10317 171F-10317 172F-10317 171G-10317 172G-10317

25 (22) 171E-10322 172E-10322 171F-10322 172F-10322 171G-10322 172G-10322

40 (34) 171E-10327 172E-10327 171F-10327 172F-10327 171G-10327 172G-10327

200 (1379)

2-Position Floating 0 to 10 Vdc

GMA121.1P GMA131.1P GMA161.1P

N.O. N.C. N.O. N.C. N.O. N.C.

Actuator Prefix Code

171E 172E 171F 172F 171G 172G

171E-10312 172E-10312 171F-10312 172F-10312 171G-10312 172G-10312

* Denotes a full-port valve without flow characterizer insert.

Page 5 Siemens Industry, Inc.

Page 6

Technical Instructions 599 Series 2-Way Ball Valves

GQD221.1U

GMA221.1U

N.O.

N.C.

N.O.

N.C.

Actuator Prefix Code

171L

172L

171M

172M

Docume nt Numbe r 155-703P25

February 4, 20 16

Table 6. Fail-Safe Assemblies: Full-Port, Chrome-Plated Ball and Brass Stem, 120V.

Fail-Saf e, 120V

Valve

Body

Product

Number*

Valve

Size

Inches

(mm)

Flow Rate

Cv

(Kvs)

2-Positi on

Close-off ∆P in psi (kPa)

599-10307* 1/2 (15) 10 (9)

599-10311* 3/4 (20) 25 (22) 171L-10311* 172L-10311* — —

599-10316* 1 (25) 63 (54) — — 171M-10316* 172M-10316*

599-10321* 1-1/4 (32) 100 (90) — — 171M-10321* 172M-10321*

599-10326* 1-1/2 (40)

599-10330* 2 (50) — — 171M-10330* 172M-10330*

160 (140)

171L-10307* 172L-10307* — —

200 (1379)

— — 171M-10326* 172M-10326*

* Denotes a full-port valve without flow characterizers insert.

Table 7. Fail-In-Place Assemblies: Stainless Steel Ball and Stem (1/2-Inch and 3/4-Inch).

Fail-in-Place

Valve

Body

Product

Num ber *

Valve Size

Inches

(mm)

Flow Rate

Cv

(Kvs)

3 foot (.9m)

Close-Off ∆P in psi (kPa)

599-10300S

599-10301S 0.63 (0.54) 171A-10301S 173A-10301S 171C-10301S 173C-10301S

599-10302S 1.0 (0.9) 171A-10302S 173A-10302S 171C-10302S 173C-10302S

599-10303S 1.6 (1.4) 171A-10303S 173A-10303S 171C-10303S 173C-10303S

599-10304S 2.5 (2.2) 171A-10304S 173A-10304S 171C-10304S 173C-10304S

599-10305S 4.0 (3.4) 171A-10305S 173A-10305S 171C-10305S 173C-10305S

599-10306S 6.3 (5.4) 171A-10306S 173A-10306S 171C-10306S 173C-10306S

599-10307S* 10 (8.6) 171A-10307S* 173A-10307S* 171C-10307S* 173C-10307S*

599-10308S

599-10309S 10 (8.6) 171A-10309S 173A-10309S 171C-10309S 173C-10309S

599-10310S 16 (14) 171A-10310S 173A-10310S 171C-10310S 173C-10310S

599-10311S* 25 (22) 171A-10311S* 173A-10311S* 171C-10311S* 173C-10311S*

1/2

(15)

3/4

(20)

0.4 (0.34)

6.3 (5.4) 171A-10308S 173A-10308S 171C-10308S 173C-10308S

171A-10300S 173A-10300S 171C-10300S 173C-10300S

200 (1379)

*Denot es a full-p ort valve w ithout flow characteriz er insert.

Floating 0 to 10 Vdc

GDE

131.1P

Wires

171A 173A 171C 173C

GDE

131.1Q

Conduit Adapter

&

6-foot (1.8m)

Wires

Actuator Prefix Code

GDE

161.1P

3 foot (.9m)

Wires

GDE

161.1Q

Conduit Adapter

6-foot (1.8m)

Wires

&

Page 6 Siemens Industry, Inc.

Page 7

599 Series 2-Way Ball Valves Technical Instructions

Fail-Safe

GQD121.1P

GQD131.1P

GQD151.1P

N.O.

N.C.

N.O.

N.C.

N.O.

N.C.

Actuator Prefix Code

171H

172H

171J

172J

171K

172K

Docume nt Numbe r 155-703P25

February 4, 20 16

Table 8. Fail-In-Place Assemblies: Stainless Steel Ball and Stem (1-Inch to 2-Inch).

Fail-in-Place

Valve

Body

Product

Num ber *

599-10312S

599-10313S 16 (14) 171A-10313S 173A-10313S 171C-10313S 173C-10313S

599-10314S 25 (22) 171A-10314S 173A-10314S 171C-10314S 173C-10314S

599-10315S 40 (34) 171A-10315S 173A-10315S 171C-10315S 173C-10315S

599-10316S* 63 (54) 171A-10316S* 173A-10316S* 171C-10316S* 173C-10316S*

599-10317S

599-10318S 25 (22) 171A-10318S 173A-10318S 171C-10318S 173C-10318S

599-10319S 40 (34) 171A-10319S 173A-10319S 171C-10319S 173C-10319S

599-10320S 63 (54) 171A-10320S 173A-10320S 171C-10320S 173C-10320S

599-10321S* 100 (90) 171A-10321S* 173A-10321S* 171C-10321S* 173C-10321S*

599-10322S

599-10323S 40 (34) 171B-10323S 173B-10323S 171D-10323S 173D-10323S

599-10324S* 63 (54) 171B-10324S* 173B-10324S* 171D-10324S* 173D-10324S*

599-10325S 100 (90) 171B-10325S 173B-10325S 171D-10325S 173D-10325S

599-10326S* 160 (140) 171B-10326S* 173B-10326S* 171D-10326S* 173D-10326S*

599-10327S

599-10328S 63 (54) 171B-10328S 173B-10328S 171D-10328S 173D-10328S

599-10329S* 100 (90) 171B-10329S* 173B-10329S* 171D-10329S* 173D-10329S*

599-10330S* 160 (140) 171B-10330S* 173B-10330S* 171D-10330S* 173D-10330S*

Valve Size

Inches

(mm)

1

(25)

1-1/4

(32)

1-1/2

(40)

2

(50)

Flow Rate

Cv

(Kvs)

10 (9.0)

16 (14) 171A-10317S 173A-10317S 171C-10317S 173C-10317S

25 (22) 171B-10322S 173B-10322S 171D-10322S 173D-10322S

40 (34) 171B-10327S 173B-10327S 171D-10327S 173D-10327S

GDE

131.1P

3 foot (.9m)

Close-Off ∆P in psi (kPa)

171A 171B 173A 173B 171C 171D 173C 173D

171A-10312S 173A-10312S 171C-10312S 173C-10312S

200 (1379)

Floating 0 to 10 Vdc

GLB

131.1P

Wires

GDE

131.1Q

Conduit Adapter

6-foot (1.8m)

GLB

131.1Q

&

Wires

Actuator Prefix Code

GDE

161.1P

3 foot (.9m)

Wires

GLB

161.1P

GDE

161.1Q

Conduit Adapter

GLB

161.1Q

&

6-foot (1.8m)

Wires

*Denot es a full-p ort valve w ithout flow characteriz er insert.

Table 9. Fail-Safe Assemblies: Stainless Steel Ball and Stem (1/2-inch and 3/4-inch).

Valve

Body

Product

Number*

599-10300S 0.4 (0.34)

599-10301S 0.63 (0.54) 171H-10301S 172H-10301S 171J-10301S 172J-10301S 171K-10301S 172K-10301S

599-10302S 1.0 (0.9) 171H- 1030 2S 172H-10302S 171J-10302S 172J-10302S 171K-10302S 172K-10302S

599-10303S 1.6 (1.4) 171H-10303S 172H-10303S 171J-10303S 172J-10303S 171K-10303S 172K-10303S

599-10304S 2.5 (2.2) 171H-10304S 172H-10304S 171J-10304S 172J-10304S 171K-10304S 172K-10304S

599-10305S 4.0 (3.4) 171H-10305S 172H-10305S 171J-10305S 172J-10305S 171K-10305S 172K-10305S

599-10306S 6.3 (5.4) 171H-10306S 172H-10306S 171J-10306S 172J-10306S 171K-10306S 172K-10306S

599-10307S* 10 (8.6) 171H-10307S* 172H-10307S* 171J-10307S* 172J-10307S* 171K-10307S* 172K-10307S*

599-10308S 6.3 (5.4)

599-10309S 10 (8.6) 171H-10309S 172H-10309S 171J-10309S 172J-10309S 171K-10309S 172K-10309S

599-10310S 16 (14) 171H-10310S 172H-10310S 171J-10310S 172J-10310S 171K-10310S 172K-10310S

599-10311S* 25 (22) 171H-10311S* 172H-10311S* 171J-10311S* 172J-10311S* 171K-10311S* 172K-10311S*

Flow Rate

Cv

(Kvs)

1/2

(15)

3/4

(20)

Valve Size

Inches (mm)

2-Position Floating 2 to 10 Vdc

Close-off ∆P in psi (kPa)

171H-10300S 172H-10300S 171J-10300S 172J-10300S 171K-10300S 172K-10300S

200 (1379)

171H-10308S 172H-10308S 171J-10308S 172J-10308S 171K-10308S 172K-10308S

*Denotes a full-port valve without flow characterizer insert.

Page 7 Siemens Industry, Inc.

Page 8

Technical Instructions 599 Series 2-Way Ball Valves

Fail-Safe, 120V

GQD221.1

UGMA221.1U

N.O.

N.C.

N.O.

N.C.

Actuator Prefix Code

171L

172L

171M

172M

Docume nt Numbe r 155-703P25

February 4, 20 16

Table 10. Fail-Safe Assemblies: Stainless Steel Ball and Stem (1-inch to 2-inch).

Fail-Safe

Valve

Body

Product

Num ber *

599-10312S

599-10313S 16 (14) 171E-10313S 172E-10313S 171F-10313S 172F-10313S 171G-10313S 172G-10313S

599-10314S 25 (22) 171E-10314S 172E-10314S 171F-10314S 172F-10314S 171G-10314S 172G-10314S

599-10315S 40 (34) 171E-10315S 172E-10315S 171F-10315S 172F-10315S 171G-10315S 172G-10315S

599-10316S* 63 (54) 171E-10316S* 172E-10316S* 171F-10316S* 172F-10316S* 171G-10316S* 172G-10316S*

599-10317S

599-10318S 25 (22) 171E-10318S 172E-10318S 171F-10318S 172F-10318S 171G-10318S 172G-10318S

599-10319S 40 (34) 171E-10319S 172E-10319S 171F-10319S 172F-10319S 171G-10319S 172G-10319S

599-10320S 63 (54) 171E-10320S 172E-10320S 171F-10320S 172F-10320S 171G-10320S 172G-10320S

599-10321S* 100 (90) 171E-10321S* 172E-10321S* 171F-10321S* 172F-10321S* 171G-10321S* 172G-10321S*

599-10322S

599-10323S 40 (34) 171E-10323S 172E-10323S 171F-10323S 172F-10323S 171G-10323S 172G-10323S

599-10324S* 63 (54) 171E-10324S* 172E-10324S* 171F-10324S* 172F-10324S* 171G-10324S* 172G-10324S*

599-10325S 100 (90) 171E-10325S 172E-10325S 171F-10325S 172F-10325S 171G-10325S 172G-10325S

599-10326S* 160 (140) 171E-10326S* 172E-10326S* 171F-10326S* 172F-10326S* 171G-10326S* 172G-10326S*

599-10327S

599-10328S 63 (54) 171E-10328S 172E-10328S 171F-10328S 172F-10328S 171G-10328S 172G-10328S

599-10329S* 100 (90) 171E-10329S* 172E-10329S* 171F-10329S* 172F-10329S* 171G-10329S* 172G-10329S*

599-10330S* 160 (140) 171E-10330S* 172E-10330S* 171F-10330S* 172F-10330S* 171G-10330S* 172G-10330S*

Valve

Size

Inches

(mm)

1

(25)

1-1/4

(32)

1-1/2

(40)

2

(50)

Flow Rate

Cv

(Kvs)

Close-off ∆ P in psi (kPa)

10 (9.0)

16 (14) 171E-10317S 172E-10317S 171F-10317S 172F-10317S 171G-10317S 172G-10317S

25 (22) 171E-10322S 172E-10322S 171F-10322S 172F-10322S 171G-10322S 172G-10322S

40 (34) 171E-10327S 172E-10327S 171F-10327S 172F-10327S 171G-10327S 172G-10327S

200 (1379)

2-Position Floating 0 to 10 Vdc

GMA121.1P GMA131.1P GMA161.1P

N.O. N.C. N.O. N.C. N.O. N.C.

Actuator Prefix Code

171E 172E 171F 172F 171G 172G

171E-10312S 172E-10312S 171F-10312S 172F-10312S 171G-10312S 172G-10312S

* Denotes a full-port valve without flow characterizer insert.

Table 11. Fail-Safe Assemblies: Full-Port, Stainless Steel Ball and Stem, 120V.

Valve

Body

Product

Number*

Valve

Size

Inches

(mm)

Flow Rate

Cv

(Kvs)

2-Position

Close-off ∆P in psi (kPa)

599-10307S* 1/2 (15) 10 (9)

599-10311S* 3/4 (20) 25 (22) 171L-10311S* 172L-10311S* — —

599-10316S* 1 (25) 63 (54) — — 171M-10316S* 172M-10316S*

599-10321S* 1-1/4 (32) 100 (90) — — 171M-10321S* 172M-10321S*

599-10326S* 1-1/2 (40) 160 (140) — — 171M-10326S* 172M-10326S*

599-10330S* 2 (50) — — 171M-10330S* 172M-10330S*

171L-10307S* 172L-10307S* — —

200 (1379)

* Denotes a full-port valve without flow characterizers insert.

Page 8 Siemens Industry, Inc.

Page 9

599 Series 2-Way Ball Valves Technical Instructions

Fail-Safe, 24V

171N

172N

171P

172P

10.00

6.94

6.19

25.00

18.66

15.35

63.00

39.78

33.56

100.00

69.19

51.45

63.00

55.34

51.00

160.00

93.80

76.34

100.00

94.30

86.12

Docume nt Numbe r 155-703P25

February 4, 20 16

Table 12. Fail-Safe Assemblies: Full-Port, Stainless Steel Ball and Stem, 24V with Dual Auxiliary Switches.

Valve

Body

Product

Number*

599-10307S* 1/2 (15) 10 (9)

599-10311S* 3/4 (20) 25 (22) 171N-10311S* 172N-10311S* — —

599-10316S* 1 (25) 63 (54) — — 171P-10316S* 172P-10316S*

599-10321S* 1-1/4 (32) 100 (90) — — 171P-10321S* 172P-10321S*

599-10326S* 1-1/2 (40)

599-10330S* 2 (50) — — 171P-10330S* 172P-10330S*

Valve

Size

Inches

(mm)

Flow Rate

Cv

(Kvs)

160 (140)

GQD126.1P GMA126.1P

N.O. N.C. N.O. N.C.

Close-off ∆P in psi (kPa)

171N-10307S* 172N-10307S* — —

200 (1379)

— — 171P-10326S* 172P-10326S*

2-Position

Actuator Prefix Code

* Denotes a full-port valve without flow characterizer insert.

NOTE: Use Table 13 to determine the effective Cv when using a full-port ball valve where the ball size and the

line sizes differ.

Table 13. Full-Port (No Flow Characterizer) Ball Valve Product Numbers and Flow Coefficients.

Valve

Line Size

in

Inches

(mm)

1/2 (15)

3/4 (20)

1 (25)

1-1/4 (32)

1-1/2 (40)

2 (50)

Valve

Product

Number

599-10307

599-10307S

599-10311

599-10311S

599-10316

599-10316S

599-10321

599-10321S

599-10324

599-10324S

599-10326

599-10326S

599-10329

599-10329S

Effective (Installed) Cv (Kvs)

Supply Line Size in Inches (mm)

1/2

(13)

(8.62)

—

— —

— — —

3/4

(20)

(5.93)

(21.55)

1

(25)

(5.29)

(15.95)

(54.31)

1-1/4

(32)

— — — — — — — —

(13.12)

(34.00)

(86.21)

— — — —

— — — —

— — — — —

1-1/2

(38)

2

(51)

2-1/2

(63)

3

(76)4(102)5(127)6(152)

— — — — — — —

(28.69)

(59.13)

(54.31)

(137.93)

— — — — — —

(43.98)

(47.30)

(80.17)

(86.21)

— — — — —

(43.59)

(65.25)

(80.60)

— — — —

— — — —

(73.61)

— — —

= Va lve m ay be ov ersized. = Optimal valve size. = Valve may be undersized.

Siemens Industry, Inc. Page 9

Page 10

Technical Instructions 599 Series 2-Way Ball Valves

CAUTION:

Docume nt Numbe r 155-703P25

February 4, 20 16

Operation

Mounting and

Installation

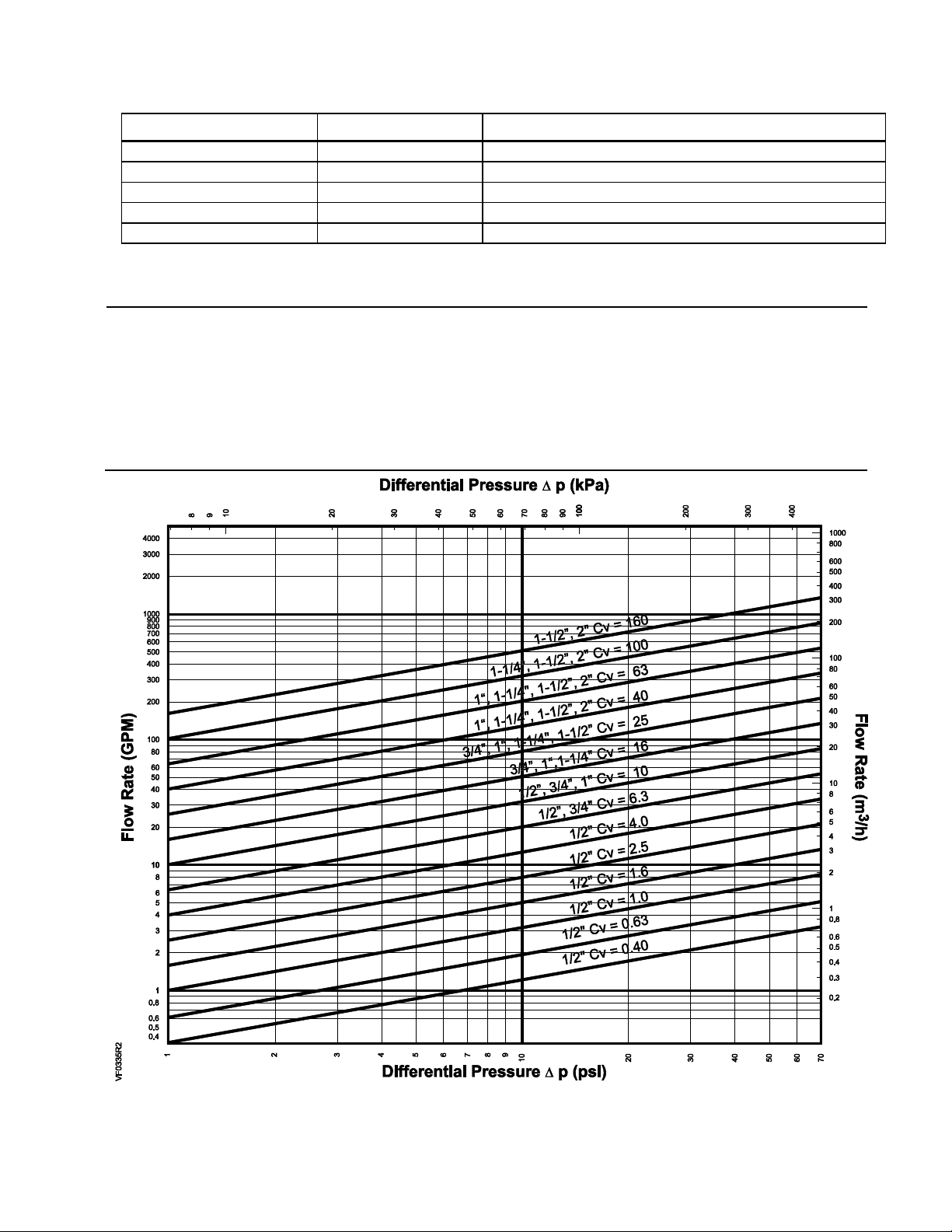

The parabolic shape of the flow characterizer orifice (Figure 2) provides a slowly

opening valve. Equal movements of the valve stem, at any point of the flow range,

change the existing flow an equal percentage regardless of the existing flow. The ball

valve equal percentage flow characteristic (Figure 3) mirrors the flow characteristi c of a

coil, resulting in linear heat transfer.

Figure 2. Ball Valve Flow

Characterizer.

Figure 3. Ball Valve Equal Percen tage

Flow Control.

Install the valve so that the flow follows the

direction of t he arrow cast on the valve

body.

For added flexibility, the actuator mounting

plate can be installed in any of the four (4)

rotation angles relative to the valve body.

Service

For best performance, install the valve

assembly with the actuator above the

valve body.

The valve and actuator assembly can be

install ed i n a horizontal pipe in any position

between vertical and 90°.

The ball valve also can be installed

vertically.

Do not install the valve assembly

so that the actuator is below

horizontal or upsi de-down.

See Ball Valve Bracket Kit

Installation Instructions 129-496

for complete and proper

installation and mounting

instructions.

Allow sufficient space for servicing the

valve and actuator. See Figure 6 and

Table 14 for valve body dimensions and

service envelope.

Replace the valve or actuator if inoperable.

Figure 4. Mounting Positions.

Page 10 Siemens Industry, Inc.

Page 11

599 Series 2-Way Ball Valves Technical Instructions

Docume nt Numbe r 155-703P25

February 4, 20 16

Dimensions

Figure 5. Two-Way Ball Valve and Low Profile Bracket with Actuator Dimensions in Inches (Millimeters).

C Length

Line Size

Inches

(mm)

1/2 (15) 0.4 to 10 2-7/16 (61)

3/4 (20) 6.3 to 25 2-3/4 (70)

Cv Range

A

Length

B

Height

2-1/4 (57)

2-5/8 67)

171A-D 173A-D 171H, J, K, L, N

5-1/4 (133) 5-3/4 (146) 5-1/4 (133)

5-3/8 (136) 6 (153) 5-3/8 (136) 5-1/4 (133) 1.3 (0.60)

Actuator Codes

GDE

GQD

D

Width

2-3/4 (70)

E

Height

4-13/16 (123) 1 (0.45)

Valve and

Bracket Weight

lbs (kg)

Siemens Industry, Inc. Page 11

Page 12

Technical Instructions 599 Series 2-Way Ball Valves

Docume nt Numbe r 155-703P25

February 4, 20 16

Figure 6. Dimensions with Actuator Mounted on Bracket.

NOTES:

· All dimensions are in inches (mm) and weights are in pounds (kg).

· Dimension D, Depth, is 3.7 inches (94.5mm).

· Dimension E, Handl e, i s 5. 3 inches (135.9 mm ).

Page 12 Siemens Industry, Inc.

Page 13

599 Series 2-Way Ball Valves Technical Instructions

–

–

–

–

–

–

–

–

–

–

Docume nt Numbe r 155-703P25

February 4, 20 16

Dimensions, Continued

Table 14. Dimensions in Inches (Millimeters) and Weights in Pounds (Kg).

Line Size

Inch

(mm)

Cv Range

A

Length

C Length *

Actuator Codes

171A-D,

173A-D

GDE/GLB GQD GMA

C Length *

Actuator

Codes

171H,J,K,L,

N

C Length*

Actuator

Codes

171E,F,G,M,P

172E,F,G,M,P

Fail-Safe

F

Height

Valve and Bracket

Weight

lbs

(kg)

10 3 (77)

1 (25)

1-1/4 (32)

1-1/2 (40)

2 (50)

* D imens i on “C” is ma ximu m leng th, m eas ur ed fr om the act uat or, end f itti ng , or mount in g plat e, whic hev er ext ends t h e furth est.

16, 40, 63 3-1/4 (82)

25 3-7/8 (98) 7 (178)

16 3-3/8(86) 6-11/16 (170)

25 to 100 3-11/16 (94)

25, 63 3-5/8 (92)

40, 100, 160 3-15/16 (100)

40, 100 4 (102)

63

160

4-5/8 (118) 7-1/2 (190)

6-11/16 (170)

6-15/16 (176)

7-1/16 (180)

8 (203) 8 (203) 1.6 (0.73)

8-3/8 (213) 8-5/16 (212)

8-11/16 (221) 8-13/16 (223)

8-7/16 (214) 8-3/8 (213)

8-11/16 (221) 8-13/16 (223)

8-7/16 (214) 8-13/16 (223) 1.8 (0.82)

9-1/4 (235) 3.3 (1.50)

8-3/4 (223)

9-3/8 (238) 3.1 (1.41)

9-1/8 (223) 10-1/16 (255)

1.8 (0.82)

2.0 (0.91)

5.25 (2.38)

2.5 (1.1)

5.3 (2.40)

Information in this publication is based on c urrent specific ations. The company reserves the right to make changes in specifications and models as

design i mprovemen ts are introduced. OpenAir is a tradem ark of Siem ens S chweiz A G. Other pr oduct or c ompany nam es mentioned her ei n may be

the trademarks of their respective owners. © 2016 Siemens Industry, Inc.

Siemens Industry, Inc.

Building Technologies Division

1000 Deerfield Parkway

Buffalo Grove, IL 60 089

USA

+ 1 847-215-1000

Your feedback is important to us. If you have comments about

this docu ment, pl ease send them to

sbt_tec hnical. editor.us.sbt@si emens.com

Document No. 155-703P2 5

Printed in the USA

Page 13

Loading...

Loading...