Siemens 599-03198, 599-03144, 599-03146, 599-03200, 599-03201 Technical Instructions

...

Flowrite™ 599 Seri es

Technical Instructions

Three-Way Valves

• Direct-coupled universal bonnet

1/2 to 2-inch Bronze Body

Document No. 155-185P25

VF 599-4

June 10, 2014

Description

Features

Application

Product Numbers

Ordering a Valve

Plus Actuator

Assembly

The Flowrite VF 599 Series ANSI Class 250 three-way valves are designed to work with

either a pneumatic or electronic actuator with a 3/4-inch (20 mm) stroke.

• ANSI Leakage Class IV (0.01% of Cv)

• Cartridge type packing

• Choice of brass or stainless steel trim

A typical application for the Flowrite three-way valve is the mixing of two different

temperatures of water supplies.

The valve can also be used for throttling or bypass coil control applications. A pump is

recommended on the coil circuit to improve the heat transfer characteristics of the coil

and for freeze protection.

See Table 1.

To order a complete valve plus actuator assembly from the factory, combine the

actuator prefix code with the suffix of the valve assembly product number. See Flowrite

Technical Bulletins 155-772 and 155-776 for complete selection procedure and ordering

codes.

Valve assemblies can be ordered using the valve part numbers in Table 1 and the

actuator prefix codes in Table 7.

Siemens Industry, Inc.

Technical Instructions Flowrite 599 Series Three-Way Valves

Controlled medium 50% water-glycol solutions

Canadian Registration Numbers 0H7645.5ADD2

Document Number 155-185P25

June 10, 2014

Specifications

Material

Operating

Line size 1/2 to 2 inches (15 to 50 mm)

Capacity See Table 2, Table 3 and Figure 3.

Body style Globe style

Seat style Metal-to-metal

Action Three-way mixing

Valve body rating ANSI Class 250. See Table 4.

Stem travel (Stroke) 3/4-inch (20 mm)

Body UNS CA 844 bronze

Body trim See Table 1.

Stem Stainless steel ASTM A582 Type 303

Packing EPDM O-rings

Medium temperature range 20°F to 250°F (-7°C to 120°C)

Maximum inlet pressure See Table 4.

Maximum recommended differential pressure for modulating service

Bronze trim 25 psi (173 kPa)

Stainless Steel trim 50 psi (345) kPa)

Rangeability > 100:1

Close-off pressures See Table 5, Table 6, and Figure 4.

Close-off ratings According to ANSI/FCI 70-2

Leakage rate Class IV (0.01% of Cv)

Flow characteristics Equal percentage for NC

Linear for NO

Mounting location NEMA 1 (interior only)

Miscellaneous

0C0838.9

Dimensions See Table 7, Table 8, and Figure 6.

Valve Weight See Table 8.

Accessories

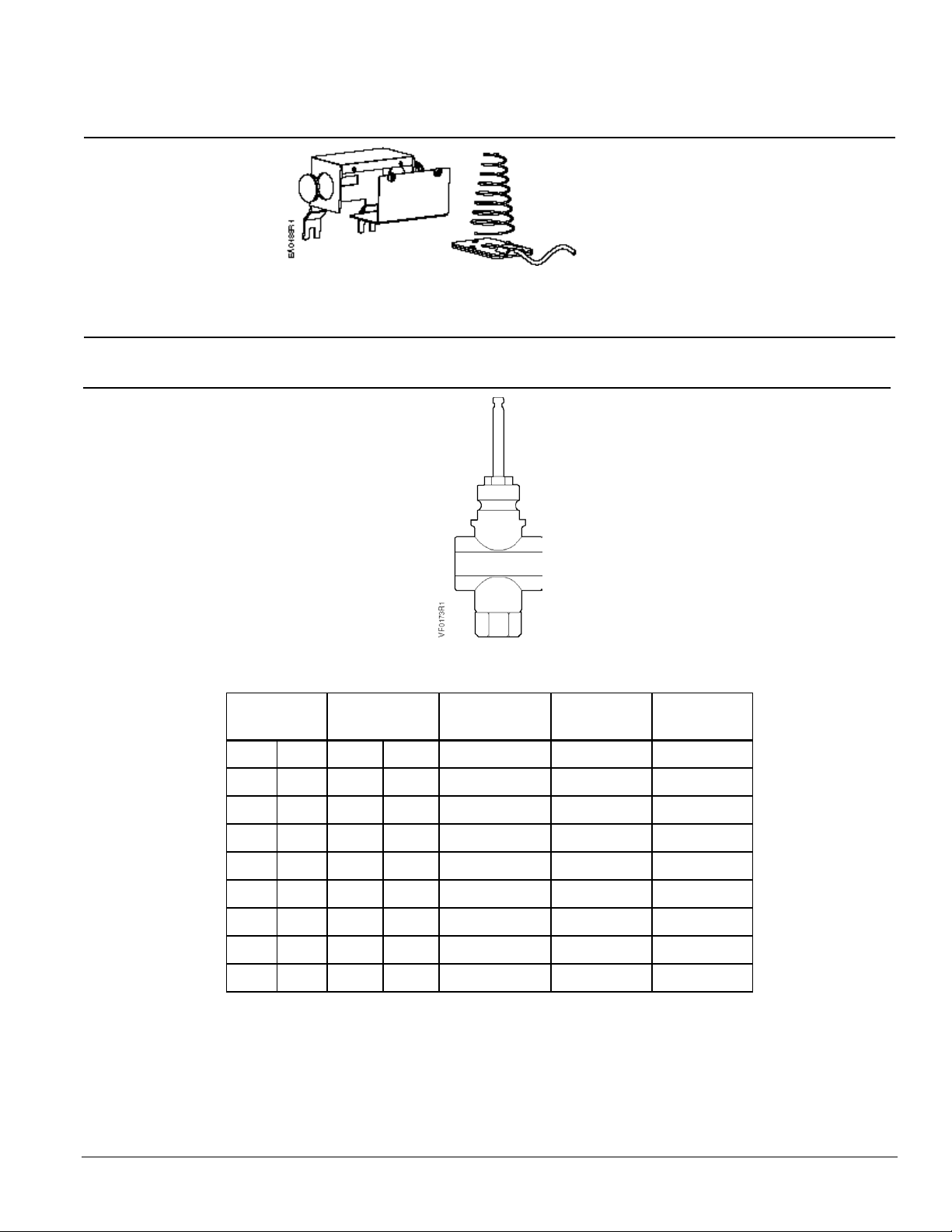

Figure 1. Packing Heating Element for

Use With SKD Actuators.

599-00417 Packing heating element.

The heater allows the stem to move freely

in valves that control fluids at temperatures

below 32°F (0°C). It reduces ice crystal

formation on the stem that can damage the

packing.

Operating Voltage 24 Vac

Heating Output 20 W

Page 2 Siemens Industry, Inc.

Flowrite 599 Series Three-Way Valves Technical Instructions

1

(0.85)

1/2

(15)

1.6

(1.37)

1/2

(15)

2.5

(2.15)

1/2

(15)

4

(3.44)

1/2

(15)

6.3

(5.43)

3/4

(20)

10

(8.6) 1 (25)

16

(13.8)

1-1/4

(32)

25

(21.5)

1-1/2

(40)

40

(34.4)

2

(50)

Document Number 155-185P25

June 10, 2014

Accessories,

Continued

Service Kits

599-00418: The packing heating element.

The heater allows the stem to move freely

in valves that control fluids at temperatures

below 32°F (0°C). It prevents ice crystal

formation on the stem that can damage the

packing.

Figure 2. Packing Heating Element for

Use With SKB/C and 8-inch Actuators.

Operating Voltage 24 Vac

Heating Output 20 W

Valve packing kit 599-03390

Rebuild/repack kits See Table 10.

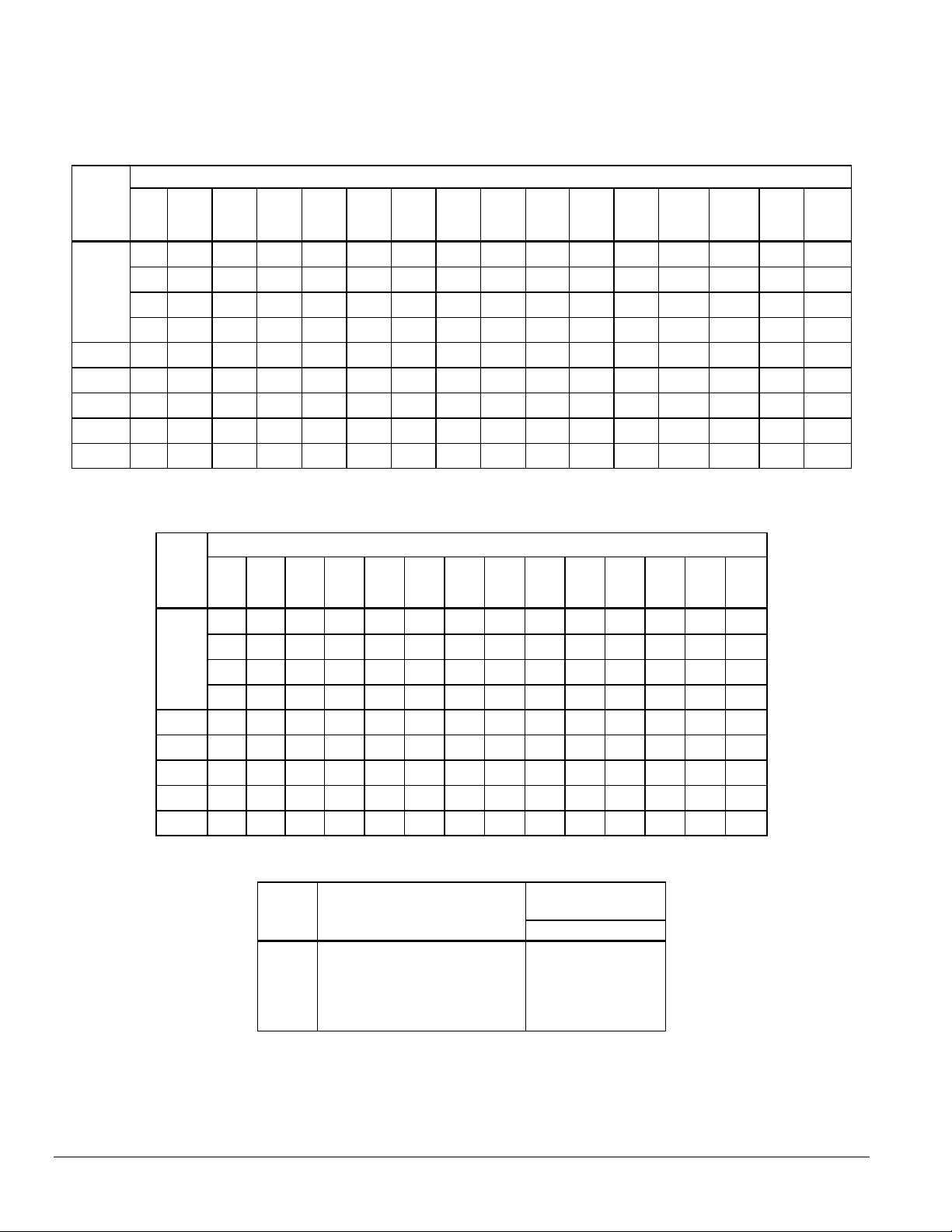

Table 1. Female NPT x Female

NPT (F×F) 3-Way Valves.

Flow Rate

C

v

(Kvs)

Line Size

Inch (mm)

Connection

Stainless

Steel Trim

Bronze Trim

FxF 599-03144 599-03198

FxF 599-03145 599-03199

FxF 599-03146 599-03200

FxF 599-03147 599-03201

FxF 599-03148 599-03202

FxF 599-03149 599-03203

FxF 599-03150 599-03204

FxF 599-03151 599-03205

FxF 599-03152 599-03206

Siemens Industry, Inc. Page 3

Technical Instructions Flowrite 599 Series Three-Way Valves

Valve

Inches

Pressure Differential - psi

Cv\1 2 3 4 5 6 8

10

15

20

25

30

40

50

60

75

Valve

mm

Pressure Differential - kPa

1

10

20

30

40

50

60

80

Kvs/

150

200

300

400

500

Body

Temperature

Pressure

psig (kPa)

°F °C

ANSI Class 250

Bronze

-20 to +150 (-30 to 66)

+350 (177)

400 (2758)

300 (2068)

Document Number 155-185P25

June 10, 2014

Table 2. Maximum Water Capacity - U.S. Gallons per Minute.

Size

in

1.0 1.4 1.7 2.0 2.2 2.5 2.8 3.2 3.9 4.5 5.0 5.5 6.3 7.1 7.8 8.7

1.6 2.3 2.8 3.2 3.6 3.9 4.5 5.1 6.2 7.2 8.0 8.8 10.1 11.3 12.4 13.9

1/2

2.5 3.5 4.3 5.0 5.6 6.1 7.1 7.9 97 11.2 12.5 13.7 15.8 17.7 19.4 22

4 5.7 7 8.0 8.9 10 11.3 12.6 15.5 17.9 20.0 21.9 25 28 31 35

3/4 6 8.9 10.9 12.6 14.1 15.4 17.8 20 24 28 32 35 40 45 49 55

1 10 14.1 17.3 20 22 24 28 32 39 45 50 55 63 71 77 87

1-1/4 16 23 28 32 36 39 45 51 62 72 80 88 101 113 124 139

1-1/2 25 35 43 50 56 61 71 79 97 112 125 137 158 177 194 217

2 40 57 69 80 89 98 113 126 155 179 200 219 253 283 310 346

3

Table 3. Maximum Water Capacity - Cubic Meters per Hour (m

/hr).

Size

in

100

0.09 0.3 0.4 0.5 0.5 0.6 0.7 0.8 0.9 1.0 1.2 1.5 1.7 1.9

0.14 0.4 0.6 0.8 0.9 1.0 1.1 1.2 1.4 1.7 1.9 2.4 2.7 3.1

15

0.2 0.7 1.0 1.2 1.4 1.5 1.7 1.9 2.2 2.6 3.0 3.7 4.3 4.8

0.3 1.1 1.5 1.9 2.2 2.4 2.7 3.1 3.4 4.2 4.9 6.0 6.9 7.7

20 0.5 1.7 2.4 3.0 3.4 3.8 4.2 4.9 5.4 6.7 7.7 9.4 10.9 12.1

25 0.9 2.7 3.8 4.7 5.4 6.1 6.7 7.7 8.6 10.5 12.2 14.9 17.2 19.2

32 1.4 4.4 6.2 7.6 8.7 9.8 10.7 12.3 13.8 16.9 19.5 23.9 27.6 30.9

40 2.2 6.8 9.6 11.8 13.6 15.2 16.7 19.2 22 26 30 37 43 48

50 3.4 10.9 15.4 18.8 22 24 27 31 34 42 49 60 69 77

Table 4. Body Temperature-Pressure Rating.

Valve

+200 (93)

+250 (121)

+300 (149)

385 (2655)

365 (2586)

335 (2300)

Page 4 Siemens Industry, Inc.

Loading...

Loading...